Novel high-strength glass and preparation method thereof

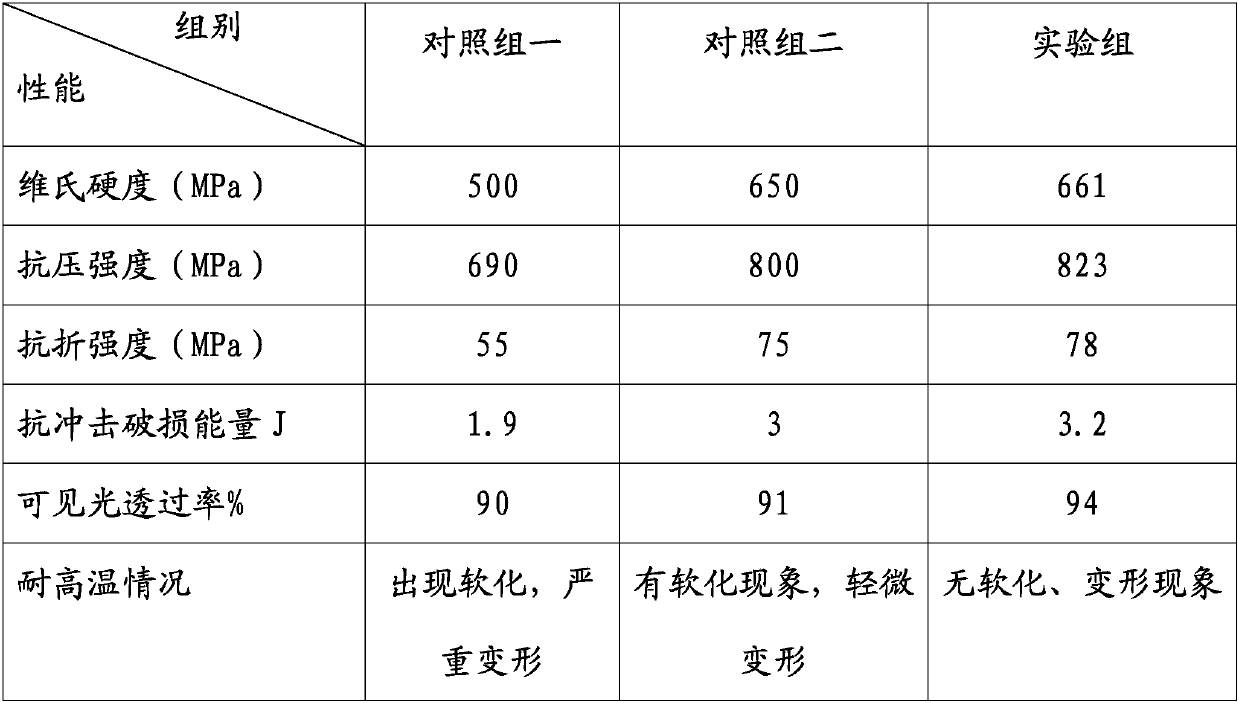

A high-strength glass technology, applied in the field of new high-strength glass and its preparation, can solve problems such as difficult to meet market demand and use requirements, and achieve improved transparency and heat resistance, high mechanical strength, and enhanced transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A new type of high-strength glass, made of the following raw materials in parts by weight: 40 parts of quartz sand, 15 parts of boric acid, 8 parts of polyphenylene sulfide, 3 parts of chitosan, 11 parts of rutile, and 7 parts of sodium silicate , 7 parts of calcium fluoride, 4 parts of barium oxide, 6 parts of borax, 2 parts of dimethylol urea, 3 parts of tungsten-nickel-molybdenum alloy, 2 parts of antimony trioxide, 2 parts of cobalt sulfide, polymethylhydrogen siloxane 2 parts and 6 parts laureth.

[0020] A preparation method of novel high-strength glass, comprising the following steps:

[0021] 1) Put 40 parts of quartz sand and 11 parts of rutile into a ball mill, and ball mill for 20 minutes at a speed of 320r / min to obtain a mixed powder for later use;

[0022] 2) Put the mixed powder obtained in step 1) into a blender, then add 15 parts of boric acid, 8 parts of polyphenylene sulfide, 3 parts of chitosan, 7 parts of sodium silicate, 7 parts of calcium fluorid...

Embodiment 2

[0027] A new type of high-strength glass, made of the following raw materials in parts by weight: 30 parts of quartz sand, 10 parts of boric acid, 6 parts of polyphenylene sulfide, 2 parts of chitosan, 9 parts of rutile, and 5 parts of sodium silicate , 5 parts of calcium fluoride, 2 parts of barium oxide, 5 parts of borax, 1 part of dimethylol urea, 2 parts of tungsten-nickel-molybdenum alloy, 1 part of antimony trioxide, 1 part of cobalt sulfide, polymethylhydrogen siloxane 1 part and 4 parts laureth.

[0028] A preparation method of novel high-strength glass, comprising the following steps:

[0029] 1) Put 30 parts of quartz sand and 9 parts of rutile into a ball mill, and ball mill for 10 minutes at a speed of 280r / min to obtain a mixed powder for later use;

[0030] 2) Put the mixed powder obtained in step 1) into a blender, then add 10 parts of boric acid, 6 parts of polyphenylene sulfide, 2 parts of chitosan, 5 parts of sodium silicate, 5 parts of calcium fluoride, and...

Embodiment 3

[0035] A new type of high-strength glass, made of the following raw materials in parts by weight: 35 parts of quartz sand, 12.5 parts of boric acid, 7 parts of polyphenylene sulfide, 2.5 parts of chitosan, 10 parts of rutile, and 6 parts of sodium silicate , 6 parts of calcium fluoride, 3 parts of barium oxide, 5.5 parts of borax, 1.5 parts of dimethylol urea, 2.5 parts of tungsten-nickel-molybdenum alloy, 1.5 parts of antimony trioxide, 1.5 parts of cobalt sulfide, polymethylhydrogen siloxane 1.5 parts and 5 parts laureth.

[0036] A preparation method of novel high-strength glass, comprising the following steps:

[0037] 1) Put 35 parts of quartz sand and 10 parts of rutile into a ball mill, and ball mill at a speed of 300r / min for 15 minutes to obtain a mixed powder for later use;

[0038] 2) Put the mixed powder obtained in step 1) into a blender, then add 12.5 parts of boric acid, 7 parts of polyphenylene sulfide, 2.5 parts of chitosan, 10 parts of rutile, 6 parts of sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com