Sulfate lignin modified urea resin adhesive and preparation method thereof

A technology of sulfate lignin and urea-formaldehyde resin glue, applied in the direction of adhesive, aldehyde/ketone condensation polymer adhesive, adhesive type, etc., to achieve the effect of ensuring comprehensive performance, low formaldehyde emission and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

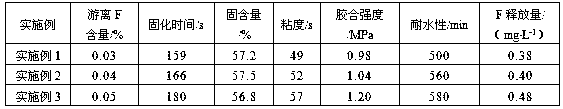

Examples

Embodiment 1

[0033] Add 74.5 grams of formaldehyde solution with a mass percentage concentration of 37% into a 500 mL four-necked flask, stir and heat up to 45 ° C, adjust the pH to 6.17 with a mass percentage concentration of 2% and 5% NaOH solution, and add the first batch of urea 27.5 grams , stir and heat up to 85°C, keep warm for 35min;

[0034] It is 8.55 to adjust pH with the NaOH solution of mass percentage concentration 20%, add the second batch of urea 10 grams, add 5 grams of kraft lignin again, then immediately adjust pH with the NaOH solution of mass percentage concentration 20% to be 8.86, then add poly Vinyl alcohol 0.5g, react for 40min;

[0035] Adjust the pH to 5.36 with a formic acid solution with a concentration of 40% by mass, add a third batch of 8.5 grams of urea, and react for 18 minutes;

[0036] Adjust the pH to 8.65 with a NaOH solution with a concentration of 20% by mass, add the fourth batch of 4 grams of urea and 1 gram of melamine, and react for another 30 m...

Embodiment 2

[0039] Add 76 grams of formaldehyde solution with a mass percentage concentration of 37% into a 500 mL four-neck flask, stir and heat up to 45°C, adjust the pH to 6.26 with a mass percentage concentration of 2% and 5% NaOH solution, and add the first batch of urea 29 grams , stir and heat up to 85°C, keep warm for 40min;

[0040] It is 8.68 to adjust pH with the NaOH solution of mass percentage concentration 20%, add the second batch of urea 9 grams, add 4 grams of kraft lignin again, then immediately adjust pH with the NaOH solution of mass percentage concentration 20% to be 8.78, then add poly Vinyl alcohol 0.6g, react for 38min;

[0041] Adjust the pH to 5.27 with a formic acid solution with a concentration of 40% by mass, add a third batch of 9 grams of urea, and react for 16 minutes;

[0042] Adjust the pH to 8.50 with a NaOH solution with a mass percentage concentration of 20%, add the fourth batch of 3 grams of urea and 1.25 grams of melamine, and react for another 35 ...

Embodiment 3

[0045] Add 77 grams of formaldehyde solution with a mass percentage concentration of 37% into a 500 mL four-neck flask, stir and heat up to 45°C, adjust the pH to 6.34 with a mass percentage concentration of 2% and 5% NaOH solution, and add the first batch of urea 30 grams , stir and heat up to 85°C, keep warm for 38min;

[0046] It is 9.15 to adjust pH with the NaOH solution of mass percentage concentration 20%, add the second batch of urea 7.5 grams, add 6 grams of kraft lignin again, then immediately adjust pH with the NaOH solution of mass percentage concentration 20% to be 8.50, then add poly Vinyl alcohol 0.8g, react for 37min;

[0047] Adjust the pH to 5.15 with a formic acid solution with a mass percentage concentration of 40%, add the third batch of urea 7.5 grams, and react for 14 minutes;

[0048] Adjust the pH to 8.90 with a 20% NaOH solution by mass percentage, add the fourth batch of 5 grams of urea and 1.50 grams of melamine, and react for another 40 minutes; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com