Oxidized peat fulvic acid composite water retaining agent and preparation method thereof

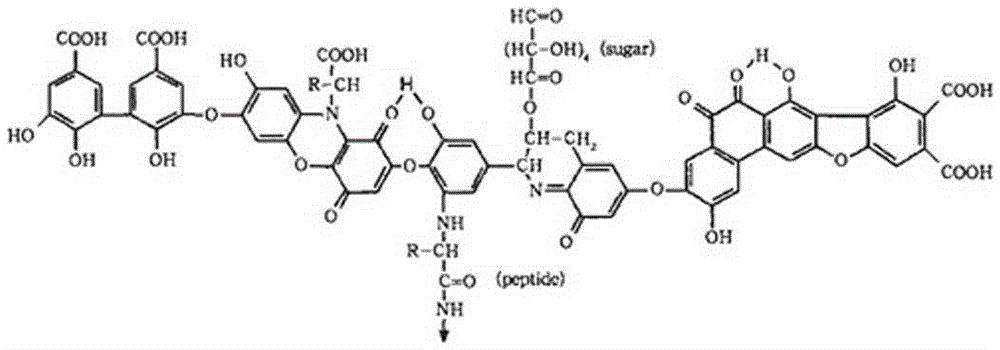

A technology of peat fulvic acid and water-retaining agent, which is applied in chemical instruments and methods, fertilizer mixtures, applications, etc., can solve the problems of short service life, difficulty in plant nutrition preservation, production cost of compacted soil, etc., to reduce costs and improve maintenance Effects of Fertility and Biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

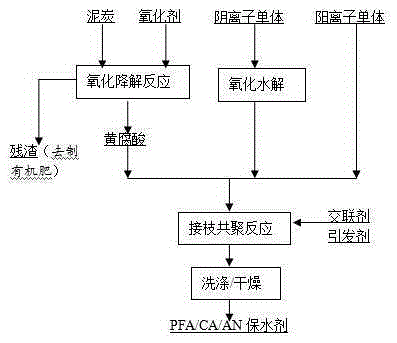

Method used

Image

Examples

Embodiment 1

[0042] Using the method of the present invention to prepare the oxidized peat fulvic acid composite water-retaining agent comprises the following steps:

[0043] (1) Preparation of oxidized peat fulvic acid Weigh 100g of herbal peat samples (dry basis weight), 600ml of industrial pure water, 10g of potassium permanganate in a three-necked bottle, adjust the pH to 6.5 with 10% NaOH solution under stirring, Heat to 85°C with an electric heating mantle, react at this temperature for 2h, then pour out the material, cool to room temperature, centrifuge at 3000r / min for 20min with a sedimentation centrifuge, collect 550ml of clear liquid, and measure the content of fulvic acid in the solution to be 10.6 %, fold 58.3g fulvic acid.

[0044] (2) Preparation of oxidized peat fulvic acid composite water-retaining agent In a 500ml stainless steel pressure-resistant closed reactor, take 200ml of the fulvic acid solution collected in (1) (21.2g of fulvic acid), and add 3-methacrylamide in t...

Embodiment 2

[0046] Using the method of the present invention to prepare the oxidized peat fulvic acid composite water-retaining agent comprises the following steps:

[0047] (1) Preparation of oxidized peat fulvic acid Weigh 100g of herbal peat sample (dry basis weight), 800ml of industrial pure water, and 98% HNO in a three-necked bottle 3 10ml, adjust the pH to 6.5 with 10% NaOH solution under stirring, heat to 60°C with an electric heating mantle, react at this temperature for 2h, then pour out the material, cool to room temperature, and centrifuge at 3000r / min for 20min with a decanter centrifuge , collect clear liquid 488ml, measure the content of fulvic acid in the solution to be 9.7%, convert 47.3g fulvic acid.

[0048] (2) Preparation of hydrolyzed acrylamide Weigh 50g of acrylamide and 300ml of industrial pure water in the reactor, adjust the solution to pH=12 with NaOH, heat to 50°C, slowly add 3%H 2 o 2 After 3 hours, the hydrolysis was completed, and 35 ml of hydrolyzed acry...

Embodiment 3

[0051] Using the method of the present invention to prepare the oxidized peat fulvic acid composite water-retaining agent comprises the following steps:

[0052] (1) Preparation of oxidized peat fulvic acid Weigh 100g of moss peat samples (dry basis weight), 400ml of industrial pure water, 30%H 2 o 2 10ml, potassium permanganate 2g, adjust the pH=9 with 10% NaOH solution under stirring, use a constant temperature water bath to 45°C, react at this temperature for 3 hours, adjust the pH=7 with 10% HCl, pour out the material, and cool to At room temperature, use a sedimentation centrifuge to centrifuge at 3000r / min for 20min, and collect 530ml of supernatant. The content of fulvic acid in the measured solution was 12.4%, equivalent to 65.7g of fulvic acid.

[0053] (2) Synthesize dimethylolurea in a polymerization reactor to process 500ml of pure water, 100g of urea, 244ml of 37% formaldehyde solution, 4g of triethanolamine, adjust the pH to 8 with 10% NaOH, and react at 65°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com