Strong washing resistant waterproofing agent for textiles and preparation method thereof

A technology for textiles and water repellents, applied in textiles and papermaking, improved hand-feeling fibers, fibers repelling liquids, etc., can solve the problems of poor washing resistance and insufficient oil resistance, and achieve good water and oil resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

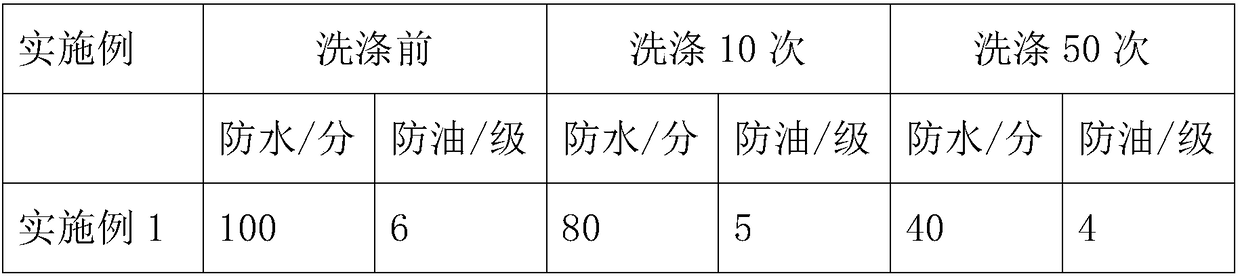

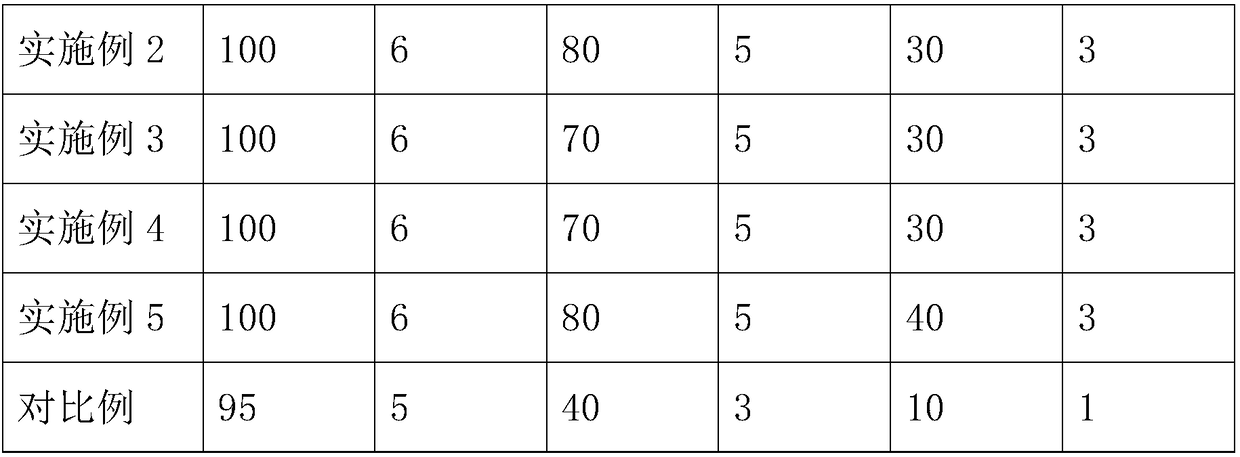

Examples

Embodiment 1

[0015] Embodiment 1: A waterproofing agent for textiles resistant to strong washing, which is composed of the following raw materials in parts by weight: 15 parts of perfluorooctylethyl acrylate, 25 parts of n-butyl acrylate, 2 parts of fumed titanium dioxide, higher fatty alcohol 12 parts of acrylate, 3 parts of sodium dibutylnaphthalene sulfonate, 4 parts of alkyl glyceryl ether sulfonate, 3 parts of polyether silicone oil, 2 parts of dimethylol urea, 0.7 part of zinc nitrate hexahydrate, 0.3 part of catalyst, 120 parts of water; Described catalyst is n-butyllithium.

[0016] The preparation method of described a kind of strong washing resistant textile waterproofing agent, it comprises the following steps:

[0017] (1) Prepare raw materials according to the parts by weight;

[0018] (2) Put fumed titanium dioxide, zinc nitrate hexahydrate and polyether silicone oil in a container and stir for 75 minutes to obtain a homogeneous material;

[0019] (3) Perfluorooctyl ethyl a...

Embodiment 2

[0022] Embodiment 2: A waterproofing agent for textiles resistant to strong washing, which is composed of the following raw materials in parts by weight: 10 parts of perfluorooctylethyl acrylate, 20 parts of n-butyl acrylate, 1 part of fumed titanium dioxide, and higher fatty alcohol 10 parts of acrylate, 1 part of sodium dibutylnaphthalene sulfonate, 2 parts of alkyl glyceryl ether sulfonate, 2 parts of polyether silicone oil, 1.5 parts of dimethylol urea, 0.5 part of zinc nitrate hexahydrate, catalyst n-butyl Lithium 0.2 parts, water 100 parts.

[0023] The preparation method of described a kind of strong washing resistant textile waterproofing agent, it comprises the following steps:

[0024] (1) Prepare raw materials according to the parts by weight;

[0025] (2) Put gas-phase titanium dioxide, zinc nitrate hexahydrate and polyether silicone oil in a container and stir for 1 hour to obtain a homogeneous material;

[0026] (3) Perfluorooctyl ethyl acrylate, n-butyl acryla...

Embodiment 3

[0029] Embodiment 3: A kind of water repellent for textiles resistant to strong washing, which is composed of the following raw materials in parts by weight: 20 parts of perfluorooctylethyl acrylate, 30 parts of n-butyl acrylate, 3 parts of fumed titanium dioxide, higher aliphatic alcohol 15 parts of acrylate, 4 parts of sodium dibutylnaphthalene sulfonate, 5 parts of alkyl glyceryl ether sulfonate, 4 parts of polyether silicone oil, 3 parts of dimethylol urea, 1 part of zinc nitrate hexahydrate, catalyst n-butyl Lithium 0.5 parts, water 140 parts.

[0030] The preparation method of described a kind of strong washing resistant textile waterproofing agent, it comprises the following steps:

[0031] (1) Prepare raw materials according to the parts by weight;

[0032] (2) Put gas-phase titanium dioxide, zinc nitrate hexahydrate and polyether silicone oil in a container and stir for 1.5 hours to obtain a homogeneous material;

[0033] (3) Perfluorooctyl ethyl acrylate, n-butyl a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com