Fluorocarbon resin high-strength anti-corrosion bridge and preparation method thereof

A fluorocarbon resin and anti-corrosion technology, applied in the direction of electrical components, etc., can solve the problems of insufficient surface corrosion resistance, increased manufacturing costs, poor corrosion resistance, etc., achieve high adhesion strength, prevent fire spread, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

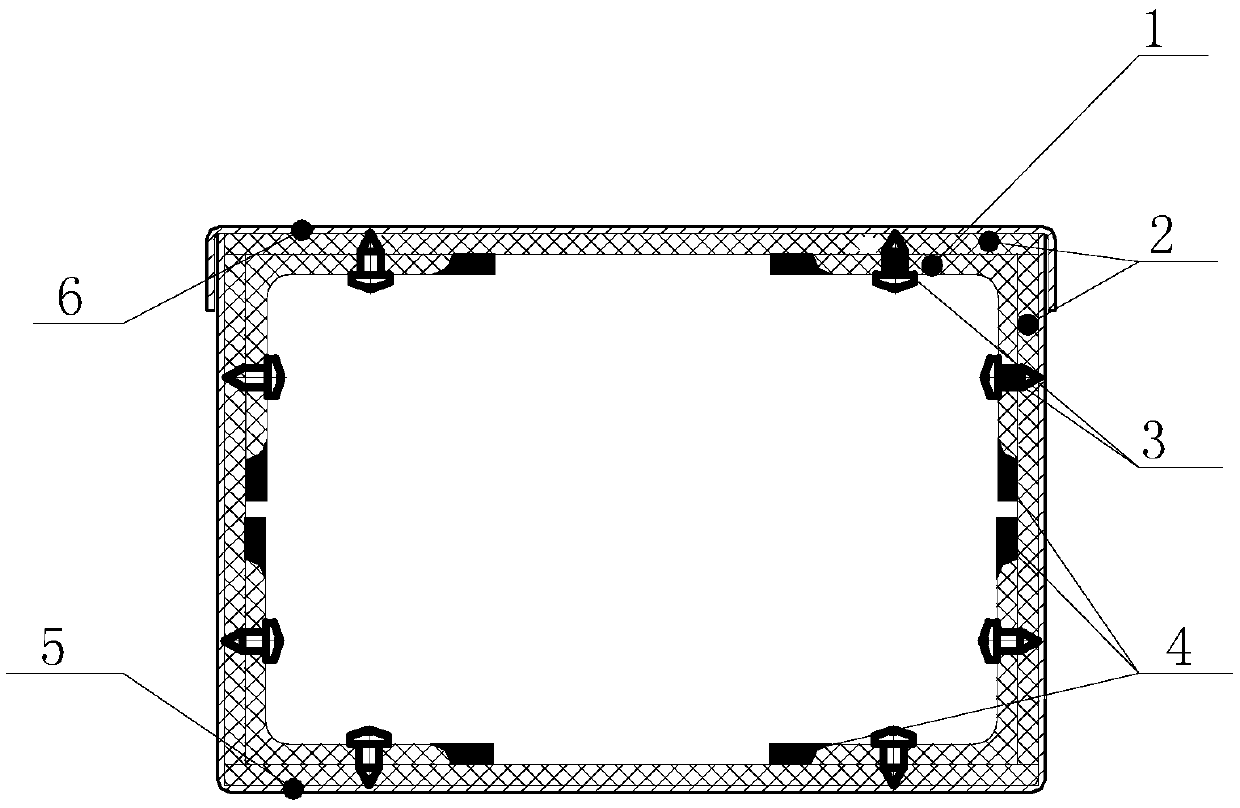

[0019] This embodiment is a fluorocarbon resin high-strength anti-corrosion and fireproof bridge, including a bridge base, the surface of the bridge base is coated with a metal coating, and the metal coating is sprayed with fluorocarbon resin powder by electrostatic powder to form a fluorocarbon with a thickness of 70-80 microns The resin powder layer, the fluorocarbon resin powder layer has a flat surface and the fluorocarbon resin powder below the surface is fused and bonded with the metal coating, wherein the metal coating is galvanized or aluminum coated. The structure of this embodiment is as figure 1 As shown, the base of the bridge frame includes an underframe 5 and a cover plate 6, the underframe 5 is a groove with an opening upward, and the cover plate 6 is covered at the opening of the underframe 5 and is fixedly connected with the underframe 5; the inner wall of the underframe 5 is provided with Fireproof frame, the fireproof frame is spliced by inorganic fireproo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com