A kind of dty silk containing anti-ultraviolet agent and its production process

An anti-ultraviolet agent and production process technology, applied in the manufacture of rayon, conjugated synthetic polymer rayon, melt spinning, etc. Effective anti-ultraviolet ability, high mechanical properties and stability, durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

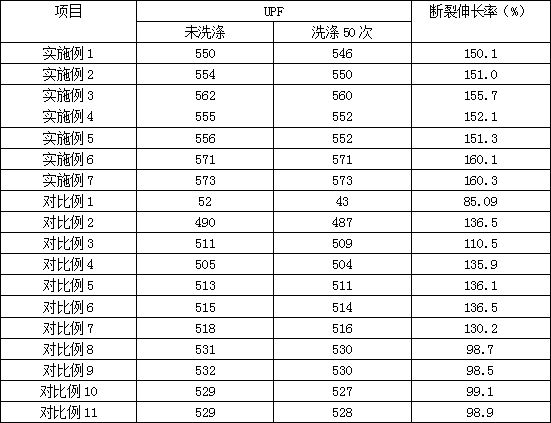

Examples

preparation example 1

[0055] Mix 1.5g ashwain, 2.2g grape seed proanthocyanidin extract, 0.6g artemisia annua extract and 3.7g chitosan cinnamaldehyde Schiff base at a temperature of 45°C, and then dry at a temperature of 75°C. get anti-ultraviolet agent;

[0056] Wherein, the chitosan cinnamaldehyde Schiff base is prepared by the following method:

[0057] Disperse 3g chitosan in 50g methanol, swell at 20°C for 12h, then add 14g cinnamaldehyde and 30g absolute ethanol, ultrasonically disperse at 40°C for 10h, filter, wash, and extract for 12h , dried under vacuum at 50°C to obtain chitosan cinnamaldehyde Schiff base.

preparation example 2

[0059] After mixing 2.5g ashwain, 1.8g grape seed proanthocyanidin extract, 0.8g artemisia annua extract and 3.5g chitosan cinnamaldehyde Schiff base at a temperature of 45°C, it was dried at a temperature of 75°C. get anti-ultraviolet agent;

[0060] Wherein, the chitosan cinnamaldehyde Schiff base is prepared by the following method:

[0061] Disperse 3g chitosan in 50g methanol, swell at 20°C for 12h, then add 14g cinnamaldehyde and 30g absolute ethanol, ultrasonically disperse at 40°C for 10h, filter, wash, and extract for 12h , dried under vacuum at 50°C to obtain chitosan cinnamaldehyde Schiff base.

preparation example 3

[0063] After mixing 2g ashwain, 2g grape seed proanthocyanidin extract, 0.7g artemisia annua extract and 3.6g chitosan cinnamaldehyde Schiff base at a temperature of 47.5 °C, it was dried at a temperature of 80 °C to obtain the antibacterial agent. UV agent;

[0064] Wherein, the chitosan cinnamaldehyde Schiff base is prepared by the following method:

[0065] Disperse 3.1g chitosan in 51g methanol, swell at 22°C for 12.5h, then add 15g cinnamaldehyde and 31g absolute ethanol, disperse by ultrasonic for 10.25h at 45°C, filter, wash, Then extract for 12.5 h, and vacuum dry at 51 °C to obtain chitosan cinnamaldehyde Schiff base.

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com