A scratch-resistant water-based automotive nanocoating

A nano-coating and anti-scratch technology, which is applied in the direction of polyester coating, polyamide coating, coating, etc., can solve the problems of affecting the use effect, poor adhesion and scratch resistance, etc., and achieves convenient coating and good paint film Plump, low VOC effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

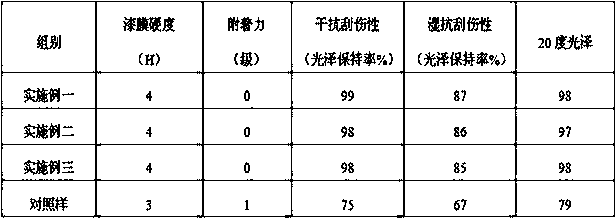

Examples

Embodiment 1

[0014] A scratch-resistant water-based automotive nano coating of the present invention comprises the following raw materials in parts by weight: 30 parts of alkyd resin, 20 parts of light calcium carbonate, 10 parts of ethylene glycol amine, 10 parts of Span-80, chitosan 0.5 parts of sugar, 5 parts of nano-zinc oxide, 5 parts of nano-zirconia, 0.1 part of nano-flaky brass powder, 1 part of dendritic polyamidoamine, 0.5 parts of polycarboxylate, 0.1 part of defoamer, 20 parts of water , where the alkyd resin is polymerized from soybean oleic acid and glycerin.

[0015] Among them, the mesh number of light calcium carbonate is 1000-1200 mesh, the particle size of nano-zinc oxide is 20-30nm, the particle size of nano-zirconia is 30-40nm, and the particle size of nano-flaky brass powder is 10-30nm. 20nm.

Embodiment 2

[0017] A scratch-resistant water-based automotive nano coating of the present invention comprises the following raw materials in parts by weight: 40 parts of alkyd resin, 25 parts of light calcium carbonate, 15 parts of ethylene glycol amine, 15 parts of Span-80, chitosan 1 part of sugar, 6 parts of nano-zinc oxide, 7 parts of nano-zirconia, 0.6 part of nano-flaky brass powder, 6 parts of dendritic polyamidoamine, 1 part of polycarboxylate, 0.5 part of defoamer, 30 parts of water , where the alkyd resin is polymerized from soybean oleic acid and glycerin.

[0018] Among them, the mesh number of light calcium carbonate is 1000-1200 mesh, the particle size of nano-zinc oxide is 20-30nm, the particle size of nano-zirconia is 30-40nm, and the particle size of nano-flaky brass powder is 10-30nm. 20nm.

Embodiment 3

[0020] A scratch-resistant water-based automotive nano coating of the present invention comprises the following raw materials in parts by weight: 50 parts of alkyd resin, 30 parts of light calcium carbonate, 20 parts of ethylene glycol amine, 20 parts of Span-80, chitosan 3 parts of sugar, 10 parts of nano-zinc oxide, 10 parts of nano-zirconia, 1 part of nano-flaky brass powder, 10 parts of dendritic polyamidoamine, 2 parts of polycarboxylate, 1 part of defoamer, 40 parts of water , where the alkyd resin is polymerized from soybean oleic acid and glycerin.

[0021] Among them, the mesh number of light calcium carbonate is 1000-1200 mesh, the particle size of nano-zinc oxide is 20-30nm, the particle size of nano-zirconia is 30-40nm, and the particle size of nano-flaky brass powder is 10-30nm. 20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com