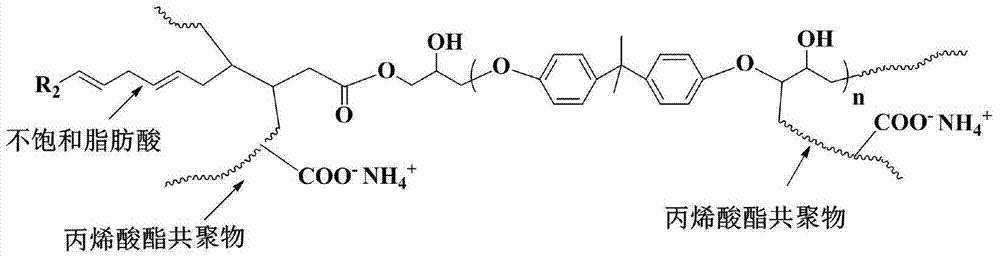

Preparation method for low acid value and low VOC waterborne acrylic acid and fatty acid modified epoxy resin

A fatty acid modification, water-based acrylic technology, used in coatings, anti-corrosion coatings, etc., can solve the problems of poor water resistance, poor storage stability, and poor rust resistance of resins, and achieve good water resistance, low VOC, and good dryness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

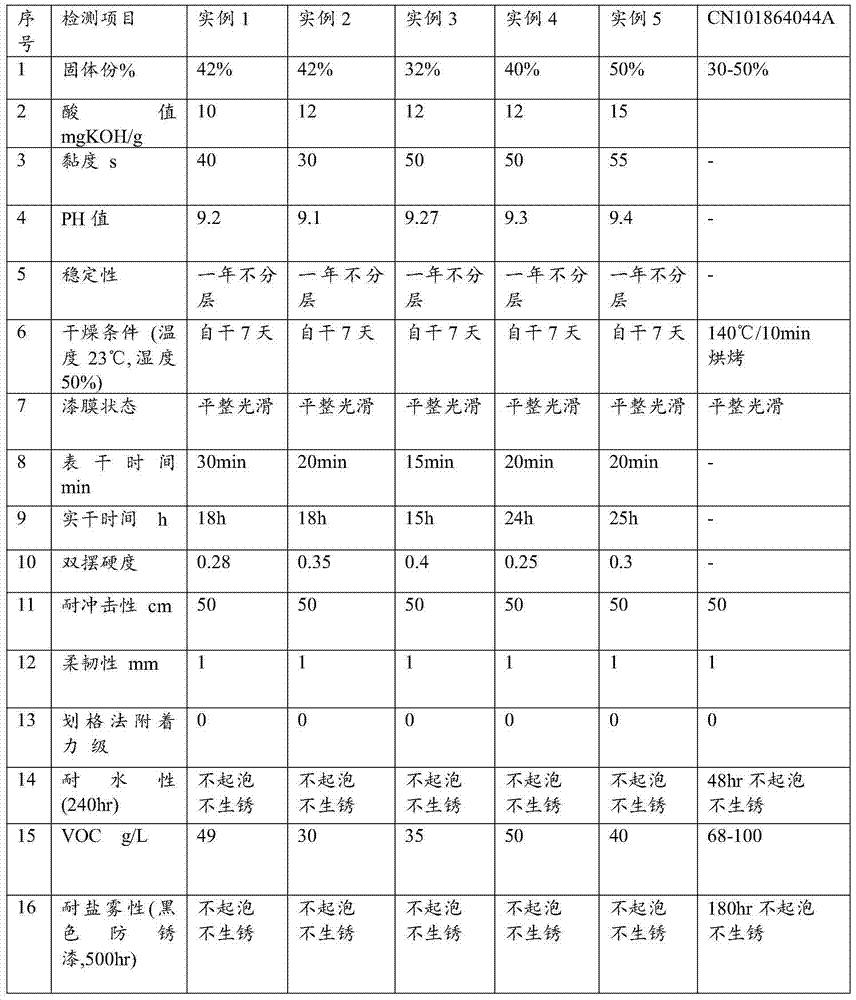

Examples

Embodiment 1

[0036] (1) Add 320g of epoxy resin E20, 30g of dehydrated ricinoleic acid, 220g of linolenic acid, and 0.5g of zinc oxide into the reaction bottle, heat up to 200-220°C, react until the acid value is below 5mgKOH / g, cool down to 160°C and add Ethylene glycol butyl ether 50g. Keep the temperature at 145-150°C to obtain fatty acid modified epoxy resin;

[0037] (2) Mix 20g of acrylic acid, 50g of styrene, and 50g of methyl methacrylate, add 5g of di-tert-butyl peroxide, mix well, and drop them into the above materials for 2-3hrs, and add three times after the addition Add 5g of di-tert-butyl peroxide, and finally keep warm for 3hr to obtain acrylic acid, fatty acid modified epoxy resin;

[0038] (3) Cool the modified resin to 80°C, add 50g of triethylamine, 22g of cobalt and zinc mixed drier, 150g of ethanol, stir evenly, drop 1000g of distilled water at 40°C into the resin, and emulsify;

[0039] (4) Put the emulsified emulsion into a three-necked bottle, install a vacuum dev...

Embodiment 2

[0041] (1) Add 280g of epoxy resin E12, 30g of dehydrated ricinoleic acid, 200g of tall oleic acid, and 0.5g of zinc oxide into the reaction bottle to raise the temperature to 200-220°C, react until the acid value is below 5mgKOH / g, and cool down to 118°C Add 220 g of n-butanol. Keep the temperature at 115°C to obtain fatty acid modified epoxy resin;

[0042] (2) Mix 22g of acrylic acid and 100g of methyl methacrylate, add 5g of tert-butyl peroxybenzoate, mix well and drop it into the above material for 2-3hr, add benzene peroxide three times after the dropwise addition Tert-butyl formate 5g, last insulation 3hr, obtains acrylic acid, the epoxy resin of fatty acid modification;

[0043](3) Cool the modified resin to 80°C, add 55g of triethylamine, 22g of cobalt and zinc mixed drier, stir evenly, drop 1000g of distilled water at 40°C into the resin, and emulsify;

[0044] (4) Put the emulsified emulsion into a vacuum container, install the vacuum device, control the temperatu...

Embodiment 3

[0046] (1) Add 98g of epoxy resin E12, 10g of dehydrated ricinoleic acid, 90g of linolenic acid, and 0.2g of zinc oxide into the reaction bottle and raise the temperature to 200-220°C, react until the acid value is below 5mgKOH / g, cool down to 118°C and add 130 g of n-butanol. Keep the temperature at 115°C to obtain fatty acid modified epoxy resin;

[0047] (2) Mix 15g of acrylic acid and 115g of styrene, add 5g of tert-butyl peroxybenzoate, mix well and drop it into the above material with 3-4hr, add tert-butyl peroxybenzoate three times after the dropwise addition Ester 1g, last insulation 3hr, obtains acrylic acid, the epoxy resin of fatty acid modification;

[0048] (3) Cool down the modified resin to 80°C, add 30g of N,N-dimethylethanolamine, 10g of cobalt and zinc mixed drier, stir evenly, drop 500g of distilled water at 40°C into the resin, and emulsify;

[0049] (4) Put the emulsified emulsion into a three-necked bottle, install a vacuum device, control the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com