High-gloss and high-viscosity resin binder and preparation technology thereof

A preparation process and high-viscosity technology, which is applied in inks, household utensils, applications, etc., can solve the problems that special inks cannot be widely used, products are prone to high-temperature oxidation and discoloration, and the solubility of aliphatic hydrocarbons is poor, so as to avoid gelling agent failure and color Vivid color, effect of improving oil solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

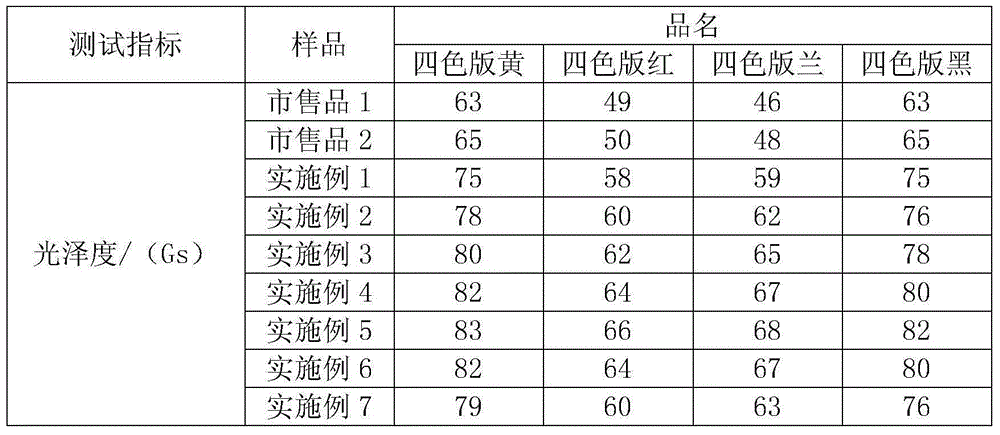

Examples

Embodiment 1

[0031] The specific preparation process of high-gloss, high-viscosity resin binder is as follows:

[0032] (1) Weigh each component according to the number of parts by mass: 20 parts of rosin modified phenolic resin, 20 parts of modified petroleum resin, 20 parts of linseed oil, 30 parts of ink oil, 0.8 part of gelling agent, converted into the weight of each component The actual dosage is: rosin modified phenolic resin 120g, modified petroleum resin 120g, linseed oil 120g, ink oil 180g, gelling agent 4.8g;

[0033] Among them, the rosin-modified phenolic resin is a resin with high viscosity and high n-heptane capacity. The rosin-modified phenolic resin has a n-heptane capacity ≥ 20ml / 2g and a viscosity of 15000-20000mpa.s / 25°C. The modified petroleum resin is High aliphatic hydrocarbon solubility and oil-soluble petroleum resin, modified petroleum resin with n-heptane capacity ≥ 20ml / 2g, viscosity 6000-9000mpa.s / 25℃, color (iron-cobalt) ≤ 8;

[0034] (2) Add 120g of rosin-mo...

Embodiment 2

[0036] The specific preparation process of high-gloss, high-viscosity resin binder is as follows:

[0037] (1) Weigh each component according to the number of parts by mass: 23 parts of rosin modified phenolic resin, 23 parts of modified petroleum resin, 18 parts of linseed oil, 35 parts of ink oil, 1.1 parts of gelling agent, converted into the weight of each component The actual dosage is: rosin modified phenolic resin 138g, modified petroleum resin 138g, linseed oil 108g, ink oil 210g, gelling agent 6.6g;

[0038] Rosin modified phenolic resin, modified petroleum resin kind are with embodiment 1;

[0039] (2) Add 138g of rosin-modified phenolic resin and 108g of linseed oil into a 1000mL three-neck bottle, heat and melt, start stirring to 200°C for 30 minutes, add some ink oil, cool down to 160°C, add 138g of modified petroleum resin, Use the remaining ink oil to adjust the viscosity to 50000mpa.s / 25°C, cool down to 140°C, add 6.6g of gelling agent and raise the temperatur...

Embodiment 3

[0041] The specific preparation process of high-gloss, high-viscosity resin binder is as follows:

[0042] (1) Weigh each component according to the number of parts by mass: 25 parts of rosin modified phenolic resin, 25 parts of modified petroleum resin, 20 parts of linseed oil, 25 parts of ink oil, 1 part of gelling agent, converted into the weight of each component The actual dosage is: rosin modified phenolic resin 150g, modified petroleum resin 150g, linseed oil 120g, ink oil 150g, gelling agent 6g;

[0043] Among them, the rosin-modified phenolic resin is a resin with high viscosity and high n-heptane capacity. The rosin-modified phenolic resin has a n-heptane capacity ≥ 20ml / 2g and a viscosity of 15000-20000mpa.s / 25°C. The modified petroleum resin is High aliphatic hydrocarbon solubility and oil-soluble petroleum resin, modified petroleum resin with n-heptane capacity ≥ 20ml / 2g, viscosity 6000-9000mpa.s / 25℃, color (iron-cobalt) ≤ 8;

[0044] (2) Add 150g of rosin-modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com