Adhesive for fiber board and preparation method of adhesive

A technology for adhesives and fiberboards, applied in the direction of adhesives, adhesive types, aldehyde/ketone condensation polymer adhesives, etc., can solve the problems of reduced bonding strength, high water expansion rate, poor sizing performance, etc. Joint density and rigidity, resin molecular weight is small, and the effect of improving the capture ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

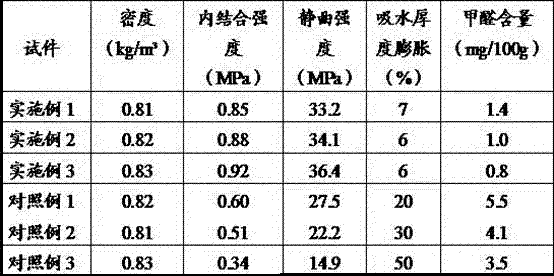

Examples

Embodiment 1

[0020] A kind of adhesive for fiberboard, raw material formula sees the following table 1:

[0021] raw material

[0022] A kind of preparation method of adhesive for fiberboard, according to formaldehyde and urea molar ratio is 1.0 to prepare raw material, and reaction step comprises:

[0023] Put 648.6 parts by weight of 37% industrial formaldehyde into the reactor, add 240.5 parts by weight of the first batch of urea, adjust the pH to 5.0, raise the temperature to 80°C within 20 minutes, keep the pH at 5.0, and keep the temperature for 30 minutes. Control the temperature at 70°C: adjust the pH value to 7.0, add 2.3 parts by weight of crosslinking agent, 0.48 parts by weight of catalyst, and 4.52 parts by weight of oxidant in sequence, react for 30 minutes, add the second batch of urea 102.2 parts by weight, adjust the pH value to 5.0, and react 20min, adjust the pH value to 7.0, add 1.15 parts by weight of crosslinking agent, 0.24 parts by weight of catalyst, 2.26...

Embodiment 2

[0032] Raw material formula:

[0033] raw material

moles

content,%

weight fraction

formaldehyde

8

37

648.6

crosslinking agent

1

11.8

catalyst

0.15

1.8

1.5

17.8

Urea (total)

8.9

99.8

535.1

Urea (first batch)

4

99.8

240.5

Urea (second batch)

1.7

99.8

102.2

Urea (the third batch)

3.2

99.8

192.4

Acid (formic acid)

30

Appropriate amount

30

Appropriate amount

[0034] A kind of preparation method of adhesive for fiberboard, be 0.9 by formaldehyde and urea molar ratio, reaction step comprises:

[0035] Put 648.6 parts by weight of 37% industrial formaldehyde into the reactor, add 240.5 parts by weight of the first batch of urea, adjust the pH to 5.0, raise the temperature to 80°C within 20 minutes, keep the pH at 5.0, and keep the temperature for 30 minutes....

Embodiment 3

[0043] Raw material formula:

[0044] raw material

moles

content,%

weight fraction

formaldehyde

8

37

648.6

crosslinking agent

1.5

18.7

catalyst

0.2

2.5

2

25

Urea (total)

10

99.8

601.2

Urea (first batch)

4

99.8

240.5

Urea (second batch)

1.7

99.8

102.2

Urea (the third batch)

4.3

99.8

258.5

Acid (formic acid)

30

Appropriate amount

30

Appropriate amount

[0045] A kind of preparation method of adhesive for fiberboard, be 0.8 by formaldehyde and urea molar ratio, reaction step comprises:

[0046] Put 648.6 parts by weight of 37% industrial formaldehyde into the reactor, add 240.5 parts by weight of the first batch of urea, adjust the pH to 5.0, raise the temperature to 80°C within 20 minutes, keep the pH at 5.0, and keep the temperature for 30 minutes. Cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com