Strong washing resistance waterproof coating adhesive finishing agent for textile and preparation method thereof

A waterproof coating and textile technology, applied in the direction of textiles and papermaking, fiber treatment, liquid repellent fibers, etc., can solve the problems of washing resistance, poor cold resistance, limited application, insufficient oil resistance, etc., to achieve good anti-corrosion The effect of water and oil repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

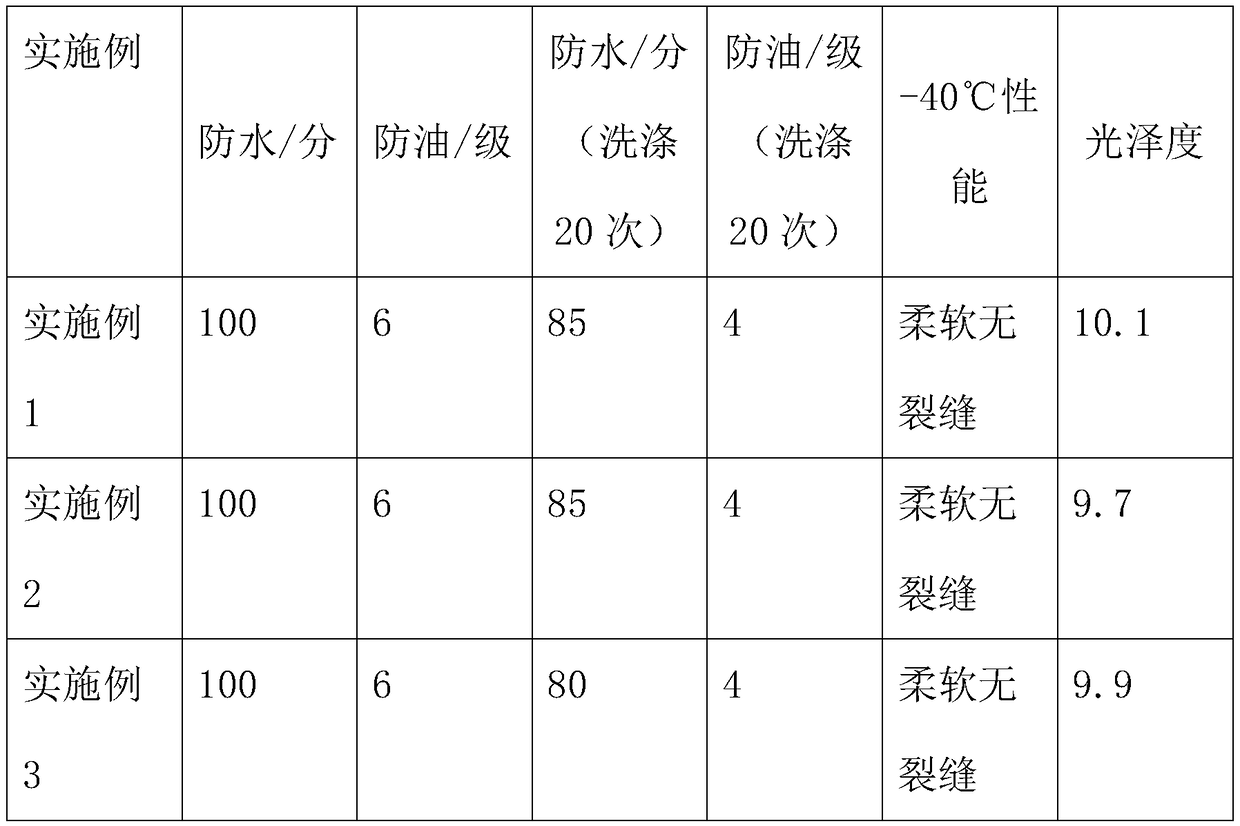

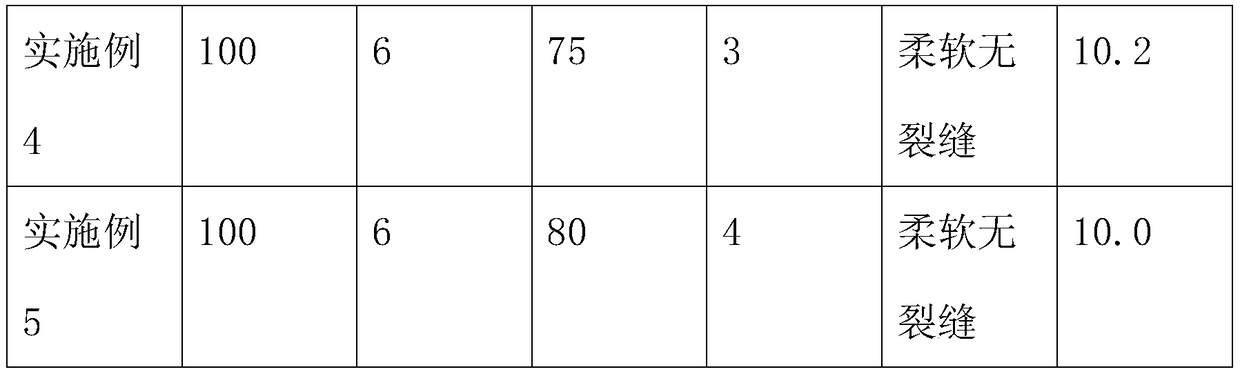

Examples

Embodiment 1

[0016] Embodiment 1: A waterproof coating adhesive finishing agent for textiles resistant to strong washing, which is composed of the following raw materials in parts by weight: 15 parts of perfluorooctyl ethyl acrylate, 25 parts of n-butyl acrylate, 2 parts of fumed titanium dioxide 12 parts of higher fatty alcohol acrylate, 3 parts of sodium dibutylnaphthalene sulfonate, 4 parts of non-ionic hydrophobically modified ethylene oxide polyurethane copolymer, 3 parts of polyether silicone oil, 2 parts of dimethylolurea, six parts 0.7 parts of zinc nitrate hydrate, 0.3 parts of catalyst, and 120 parts of water; the catalyst is n-butyllithium.

[0017] The preparation method of described a kind of strong washing-resistant textile waterproof coating adhesive finishing agent, it comprises the following steps:

[0018] (1) Prepare raw materials according to the parts by weight;

[0019] (2) Put fumed titanium dioxide, zinc nitrate hexahydrate and polyether silicone oil in a container...

Embodiment 2

[0024] Embodiment 2: A waterproof coating adhesive finishing agent for textiles resistant to strong washing, which consists of the following raw materials in parts by weight: 10 parts of perfluorooctyl ethyl acrylate, 20 parts of n-butyl acrylate, 1 part of fumed titanium dioxide 10 parts of higher fatty alcohol acrylate, 1 part of sodium dibutylnaphthalene sulfonate, 3 parts of non-ionic hydrophobically modified ethylene oxide polyurethane copolymer, 2 parts of polyether silicone oil, 1.5 parts of dimethylolurea, six 0.5 parts of zinc nitrate hydrate, 0.2 parts of catalyst n-butyllithium, and 100 parts of water.

[0025] The preparation method of described a kind of strong washing-resistant textile waterproof coating adhesive finishing agent, it comprises the following steps:

[0026] (1) Prepare raw materials according to the parts by weight;

[0027] (2) Put gas-phase titanium dioxide, zinc nitrate hexahydrate and polyether silicone oil in a container and stir for 1 hour t...

Embodiment 3

[0032] Embodiment 3: A waterproof coating adhesive finishing agent for textiles resistant to strong washing, which consists of the following raw materials in parts by weight: 20 parts of perfluorooctyl ethyl acrylate, 30 parts of n-butyl acrylate, 3 parts of fumed titanium dioxide 15 parts of higher fatty alcohol acrylate, 4 parts of sodium dibutylnaphthalene sulfonate, 6 parts of non-ionic hydrophobically modified ethylene oxide polyurethane copolymer, 4 parts of polyether silicone oil, 3 parts of dimethylolurea, six parts 1 part of zinc nitrate hydrate, 0.5 part of catalyst n-butyllithium, and 140 parts of water.

[0033] The preparation method of described a kind of strong washing-resistant textile waterproof coating adhesive finishing agent, it comprises the following steps:

[0034] (1) Prepare raw materials according to the parts by weight;

[0035] (2) Put gas-phase titanium dioxide, zinc nitrate hexahydrate and polyether silicone oil in a container and stir for 1.5 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com