Water-repellent and oil-repellent fabric finishing agent, as well as preparation method and applications thereof

A water and oil repellent and finishing agent technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of migration and cumulative toxicity, and the difficulty of degradation of perfluorinated compounds, etc., and achieve excellent water and oil repellent finishing effect, Excellent water and oil repellency effect, good water and oil repellency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Synthesis of bis(acryloxypropyl)tetramethyldisiloxane

[0031] In a three-necked flask with a capacity of 500ml, add 67.5g of allyl methacrylate and 150g of toluene, heat to 75°C, add 0.1ml of commercially available Castel catalyst (3000ppm), and blow nitrogen. Slowly add 30 g of tetramethyldisiloxane dropwise for 1.5 to 2 hours, and keep warm for 3 hours after the drop is completed. The reaction was stopped, cooled, and the solvent was removed by rotary evaporation under reduced pressure at 75°C for 80 minutes to obtain a colorless and transparent liquid product which was the addition product bis(acryloyloxypropyl)tetramethyldisiloxane.

[0032] The hydrosilylation reaction of tetramethyldisiloxane and allyl acrylate to prepare bis(acryloyloxypropyl)tetramethyldisiloxane is as follows:

[0033]

[0034]

[0035] 2. Preparation of Tridecafluorooctyl Acrylate Copolymer Emulsion Finishing Agent

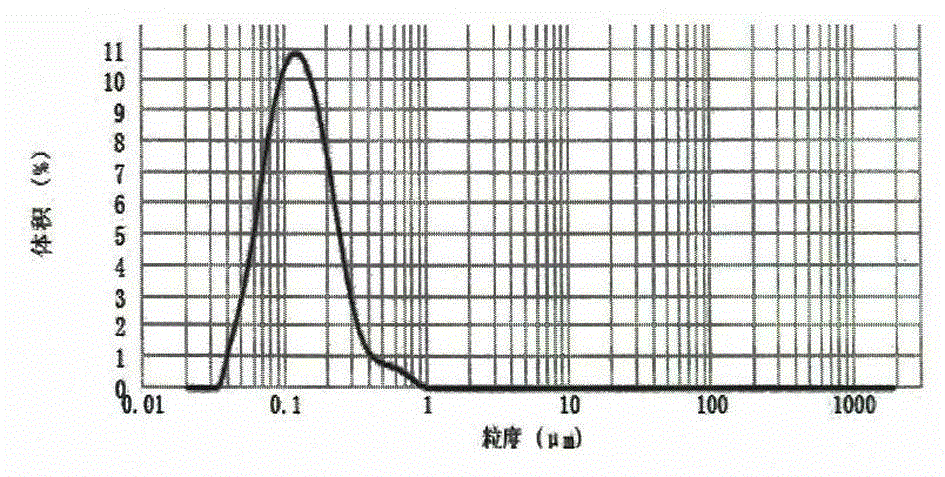

[0036] By weight, add 0.6 g of emulsifier SDS and 0.6 g of emulsifi...

Embodiment 2

[0048] 1. Preparation of Tridecafluorooctyl Acrylate Copolymer Emulsion Finishing Agent

[0049] By weight, add 0.6 g of emulsifier SDS and 0.6 g of emulsifier AEO-9 into 80 g of water, stir in a high-speed shear emulsifier at 8000 rpm for 1 minute, then add tridecafluorooctyl acrylic acid 9.2 grams of esters, 13.0 grams of butyl acrylate, 6.1 grams of methyl methacrylate, 1.0 grams of hydroxyethyl acrylate and 0.45 grams of bis(acryloyloxypropyl) tetramethyldisiloxane, the mixture is at 11000 rpm Stir for 15 minutes at a speed of 10 minutes to obtain a mixed monomer pre-emulsion.

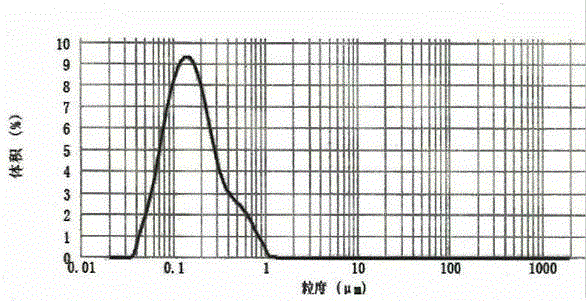

[0050] In a reactor equipped with a thermometer, a constant pressure dropping funnel and a reflux condenser, add the mixed monomer pre-emulsion, stir, and after heating to 75°C, add 10 parts of 20% sodium persulfate aqueous solution. . After heat preservation and reaction at 75-80°C for 4 hours, stop the reaction, cool the reaction solution, and obtain a bluish and translucent silicone-oxygen bon...

Embodiment 3

[0056] 1. Preparation of Tridecafluorooctyl Acrylate Copolymer Emulsion Finishing Agent

[0057] By weight, add 0.6 g of emulsifier SDS and 0.6 g of emulsifier Span-60 into 80 g of water, stir in a high-speed shear emulsifier at 9000 rpm for 1 minute, then add tridecafluorooctyl Acrylate 9.5 grams, butyl acrylate 13.2 grams, methyl methacrylate 6.3 grams and hydroxyethyl acrylate 1.0 grams, the mixture was stirred at 10,000 rpm for 25 minutes to obtain a mixed monomer pre-emulsion.

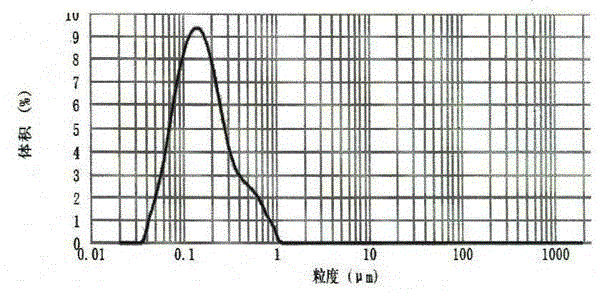

[0058] In a reactor equipped with a thermometer, a constant pressure dropping funnel and a reflux condenser, add the mixed monomer pre-emulsion, stir, and after heating to 75°C, add 8 parts of ammonium persulfate aqueous solution with a mass concentration of 10%, and then add 8 parts of ammonium persulfate aqueous solution at 75 After holding the reaction at ~80°C for 2 hours, stop the reaction, cool the reaction solution, and discharge to obtain a non-crosslinked fluorine-containing copolymer emu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com