Production line and method for metal dustpan hand-carry beam

A portable beam and production line technology, applied in the field of dustpan processing, can solve the problems of reduced sales, high labor intensity, uneven product quality, etc., and achieve the effect of reducing the settings of processing molds, reducing processing stations, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

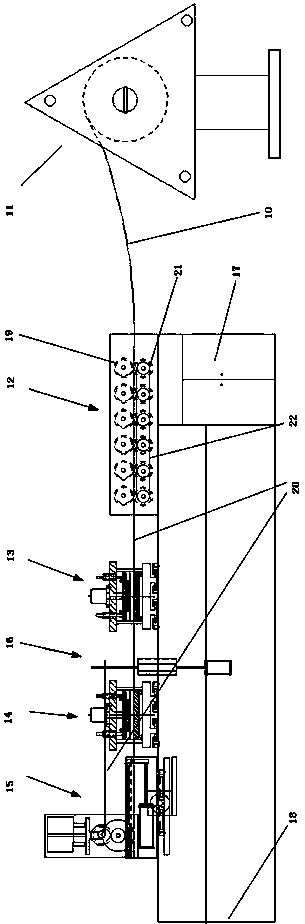

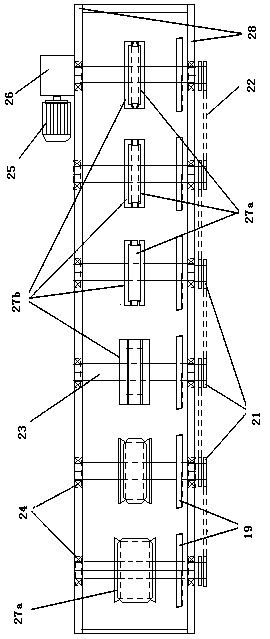

[0065] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings.

[0066] In the following description, the metal strips in the production line in the picture are processed from right to left. The equipment diagram seen from right to left facing the production line is called the front view below, and the one seen from the right side is The end view, the one seen from the left side is the back end view.

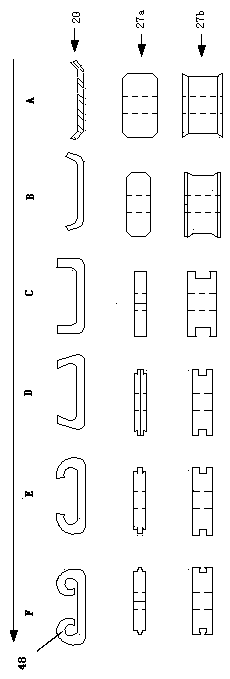

[0067] The technical scheme of the present invention is: a production line of metal dustpan portable beam, figure 1 It is the front view of the portable beam production line. The metal dustpan portable beam includes left and right portable beams 69a and front and rear portable beams 69b. The production line of the metal dustpan portable beam is provided with metal strips. Device 11, metal strip crimping device 12, end processing device 13, portable portion processing device 14, portable portion arc bending device 15, wherein the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com