Patents

Literature

167results about How to "Prevent overtravel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

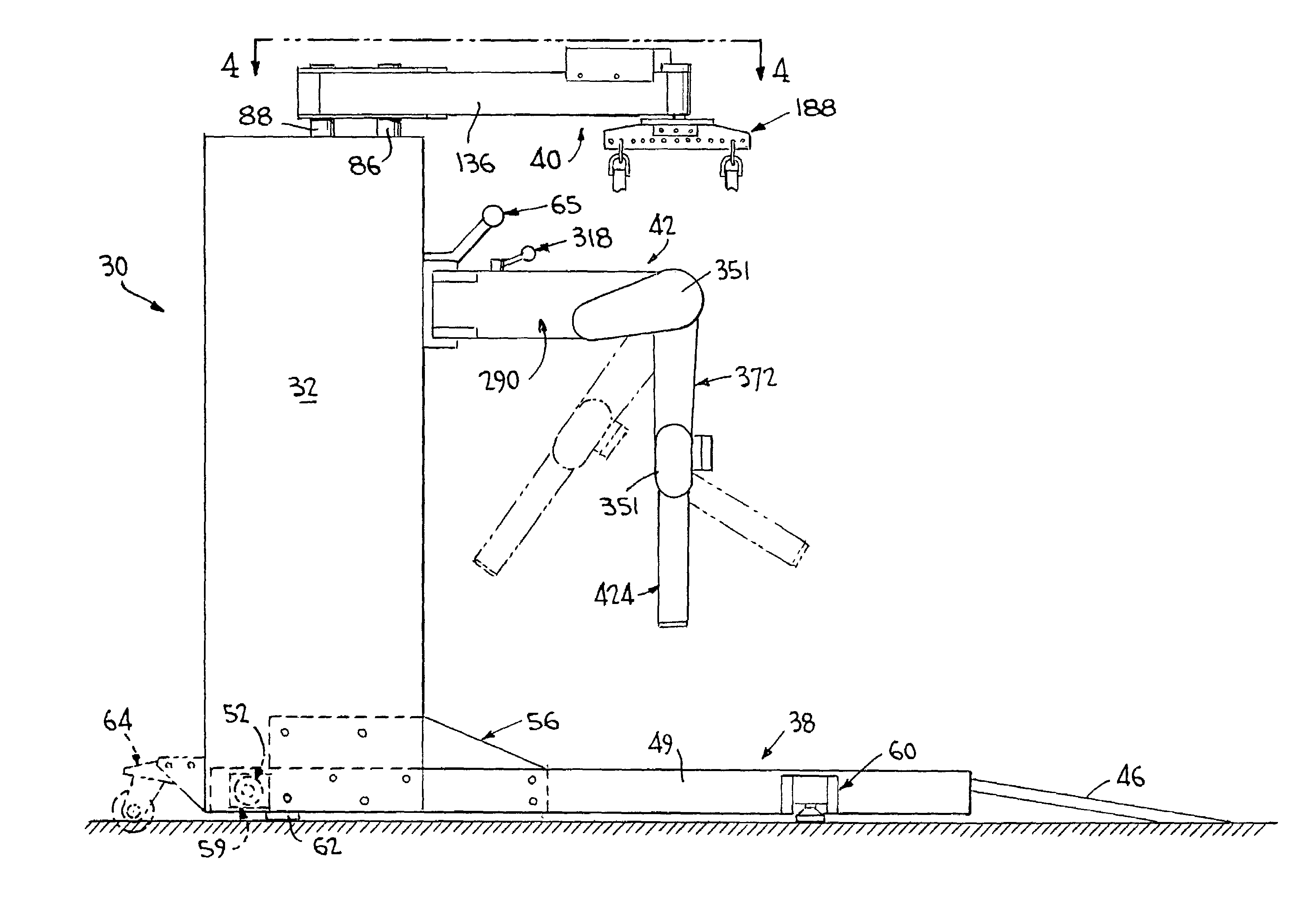

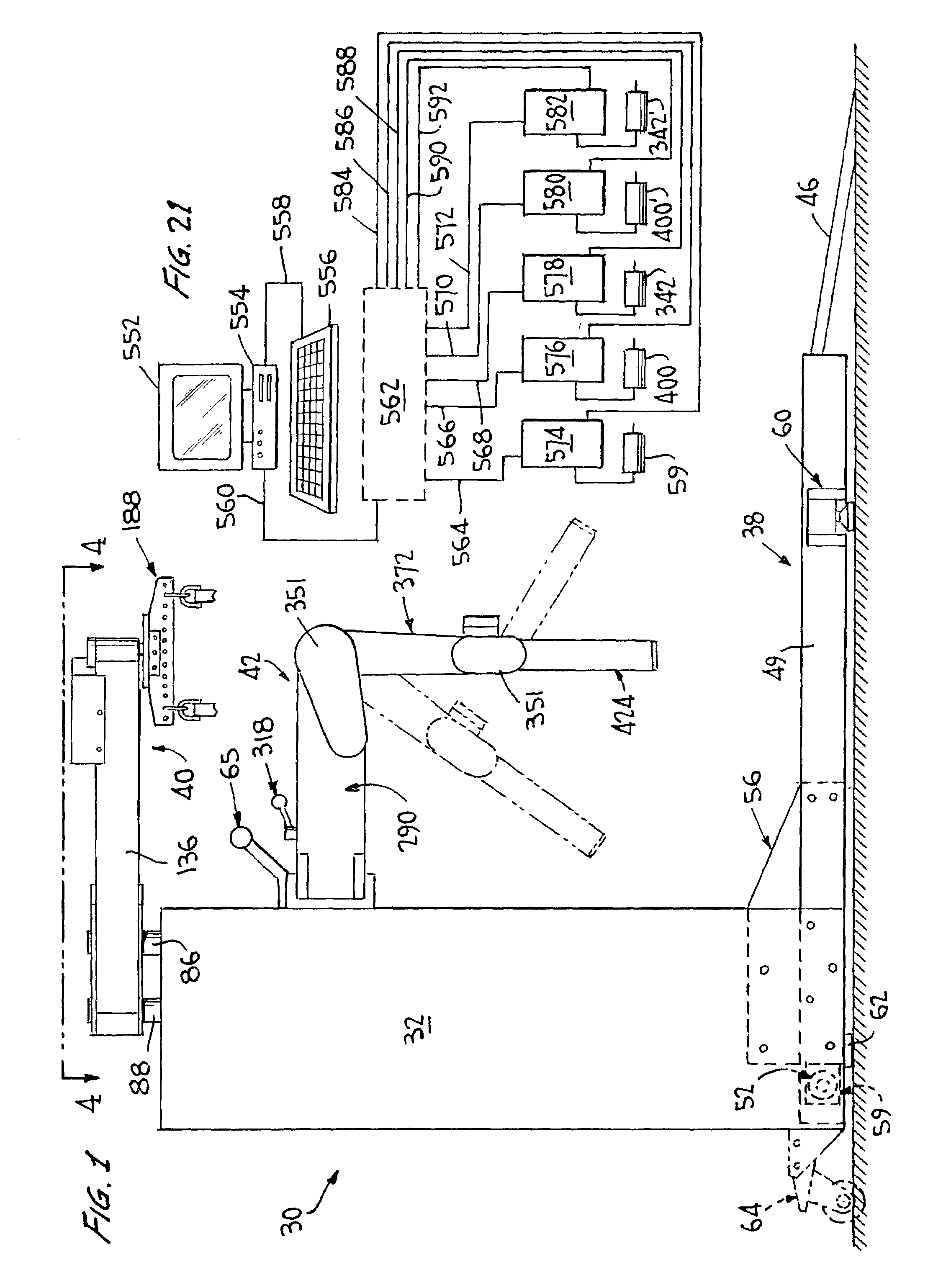

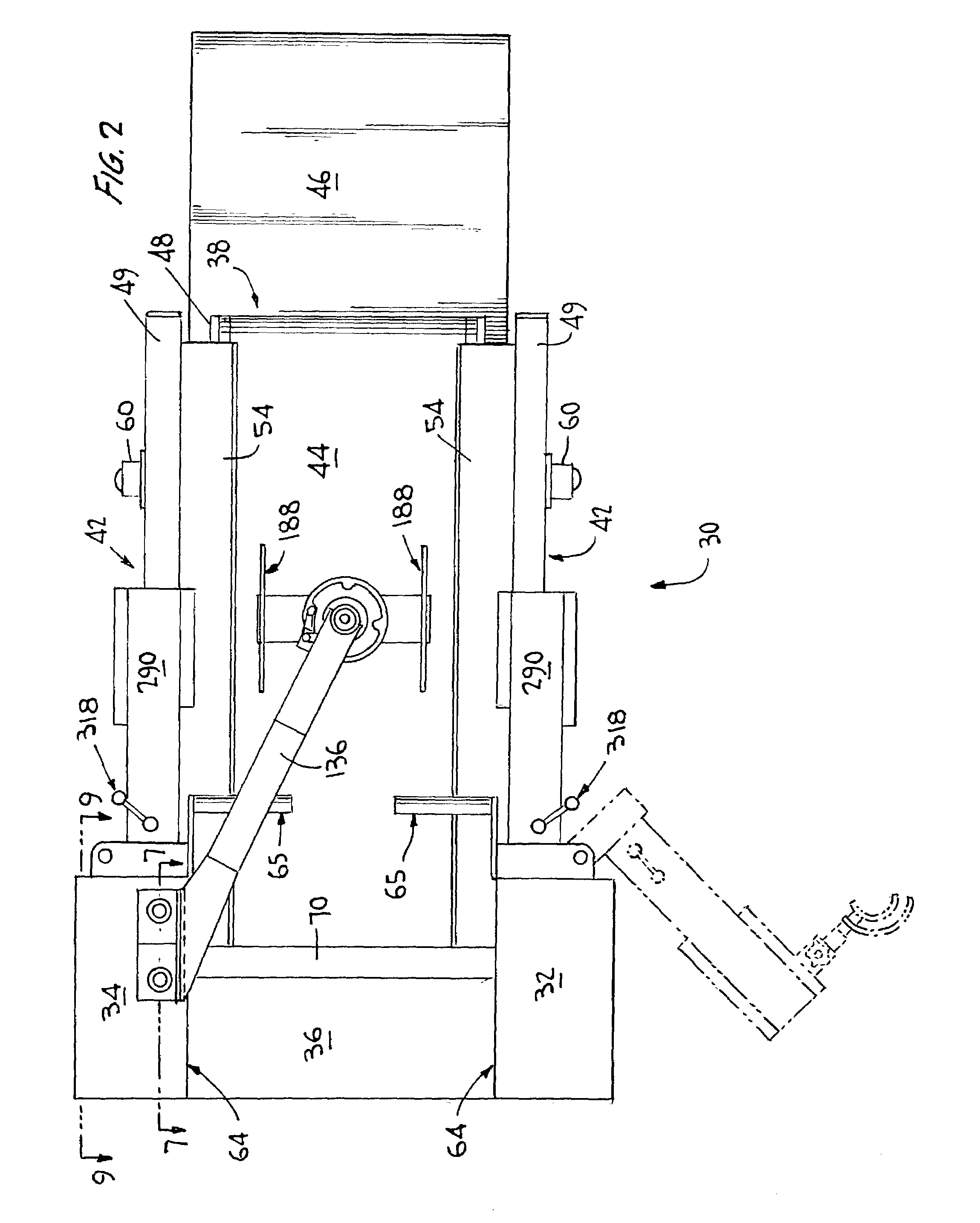

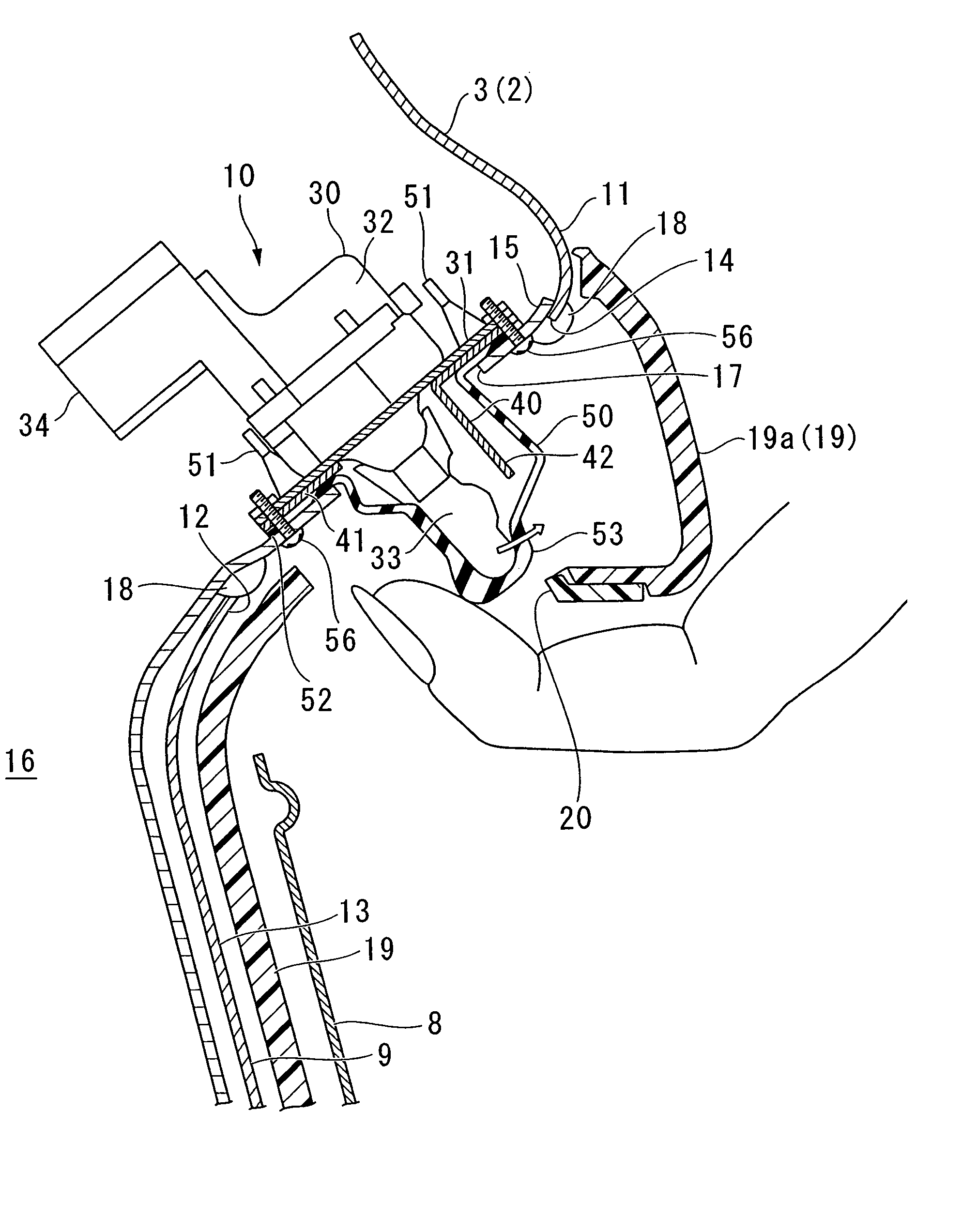

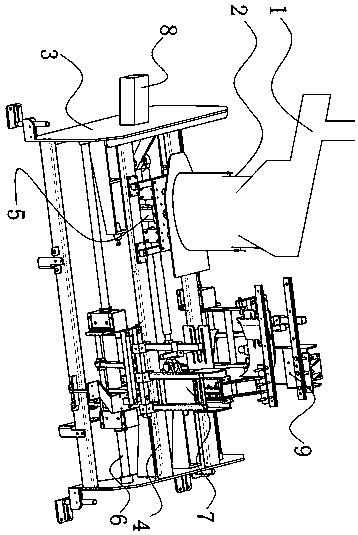

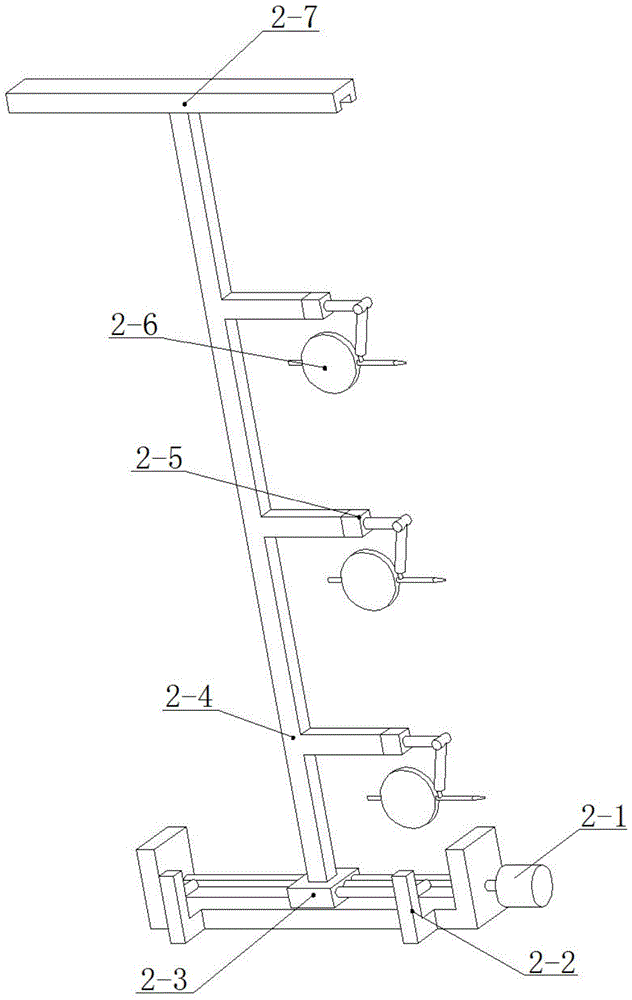

Powered gait orthosis and method of utilizing same

InactiveUS7041069B2Increase powerSimpler and more compactChiropractic devicesWalking aidsThighGait simulation

A powered gait orthosis is provided for exercising the legs of a patient, and includes a treadmill for acting on the feet of the patient and a pair of gait simulation assemblies disposed adjacent to the treadmill. Each gait simulation assembly includes a support arm including pivotally movable first and second depending arms, which further include drive means for movement thereof about first and second horizontal axis. The device further includes first and second attachment means on the first and second depending arms, for attachment to a patient's thigh and ankle, respectively. A lifting means including a drive means is supported in a vertically extending tower, which houses a gait simulation assembly. The lifting means lifts and holds a patient on the treadmill. Control means is provided to operate the depending arms in a controlled manner to cause the legs of the patient to move in a desired gait.

Owner:HEALTHSOUTH

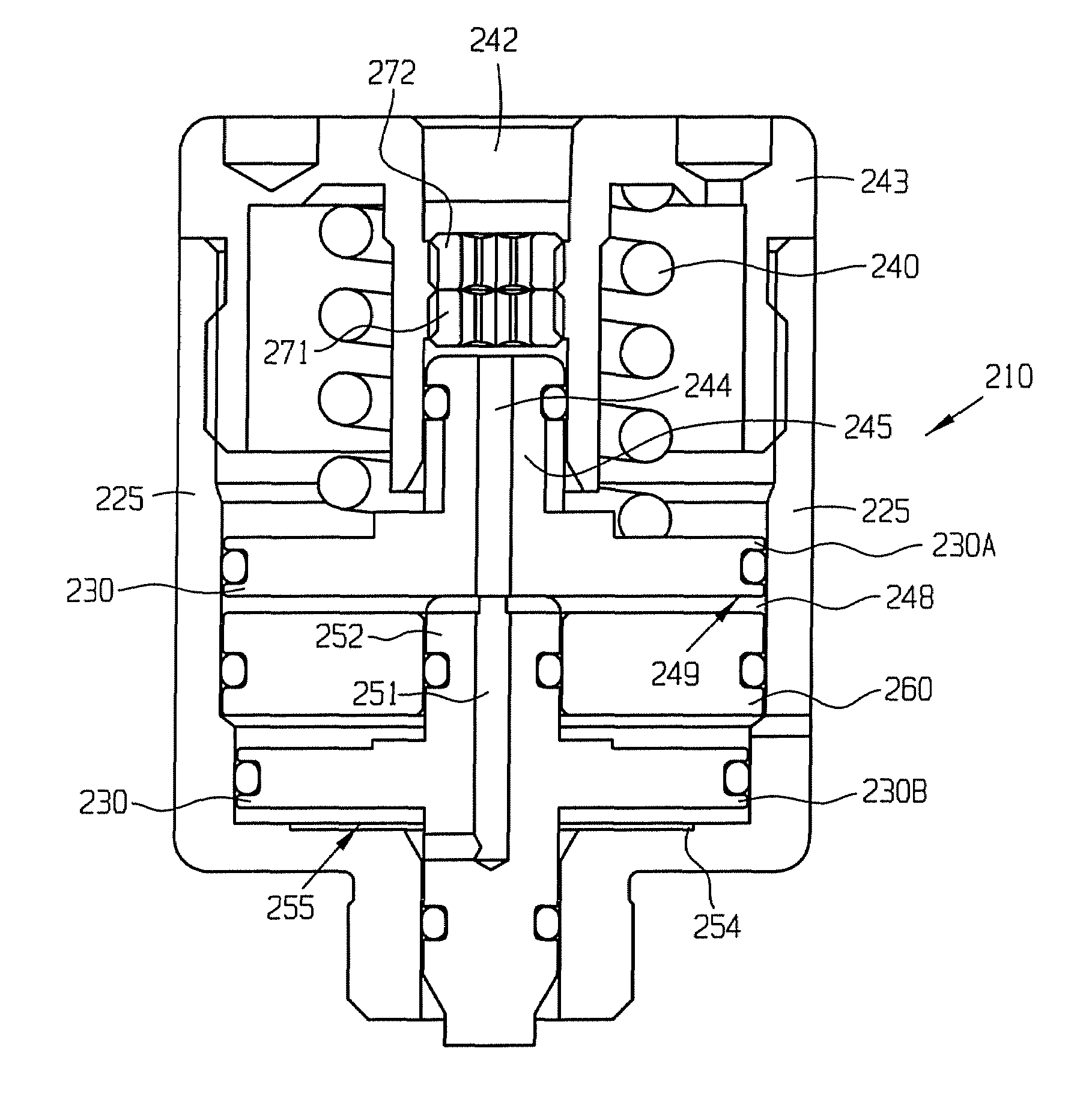

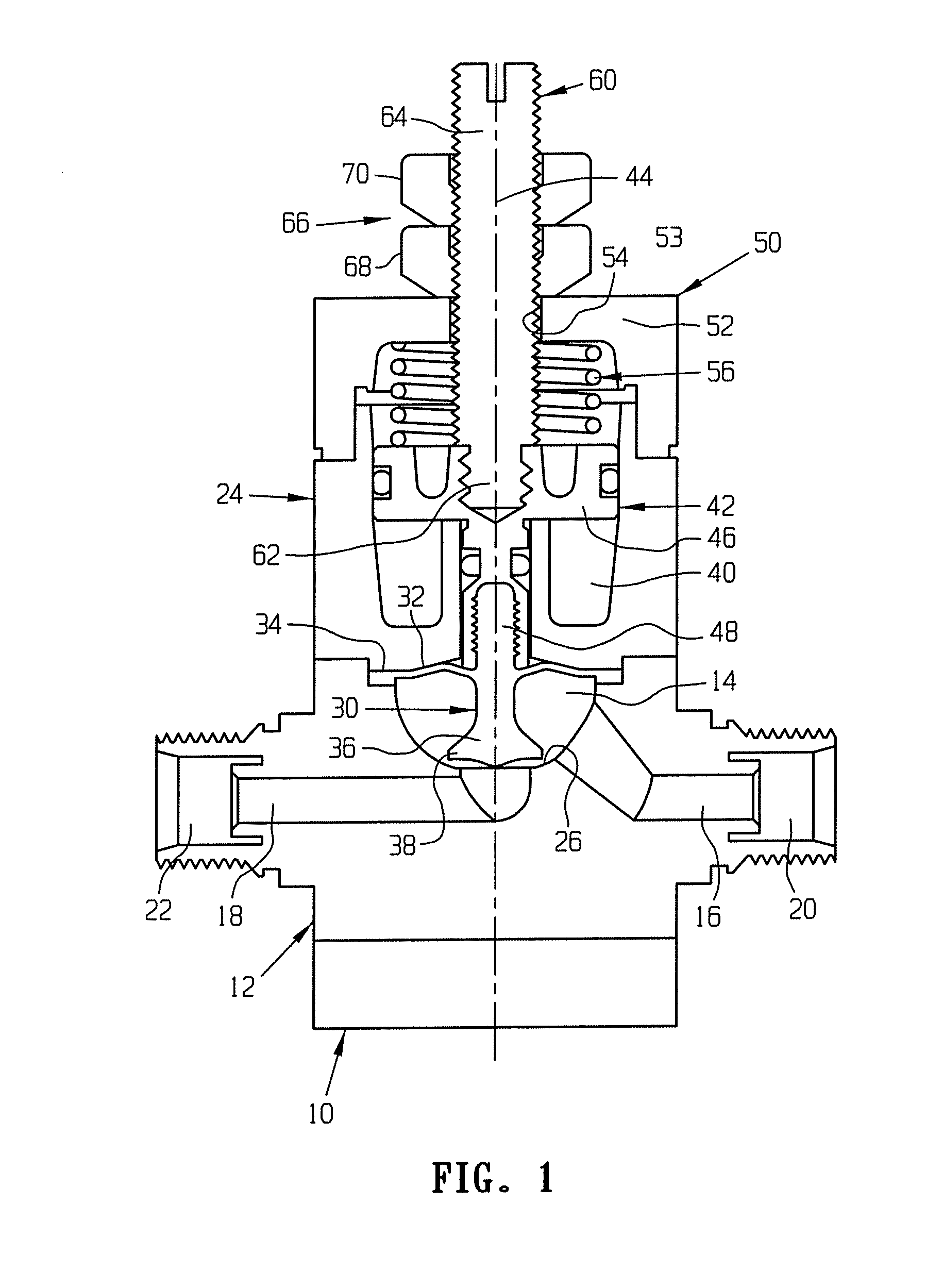

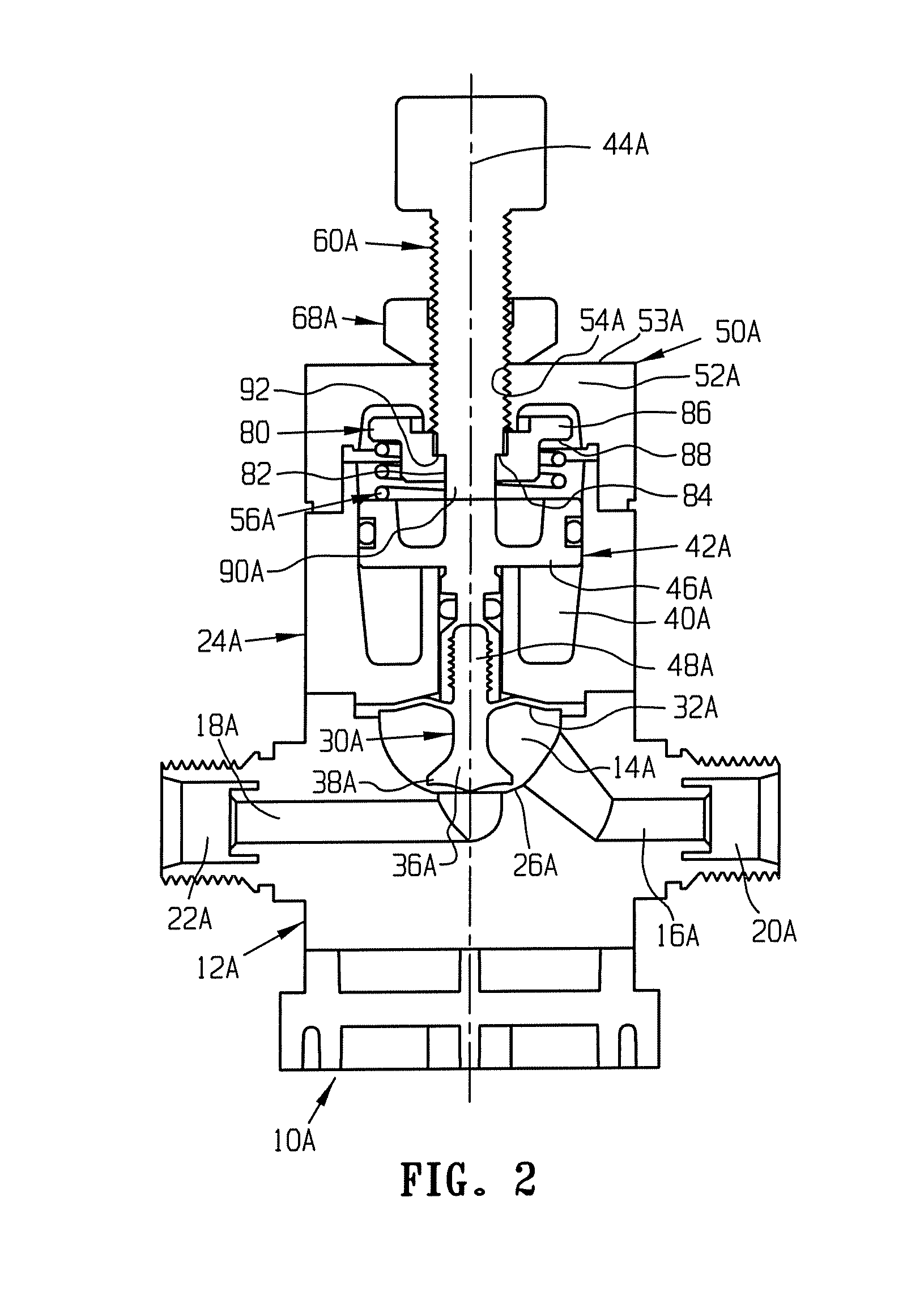

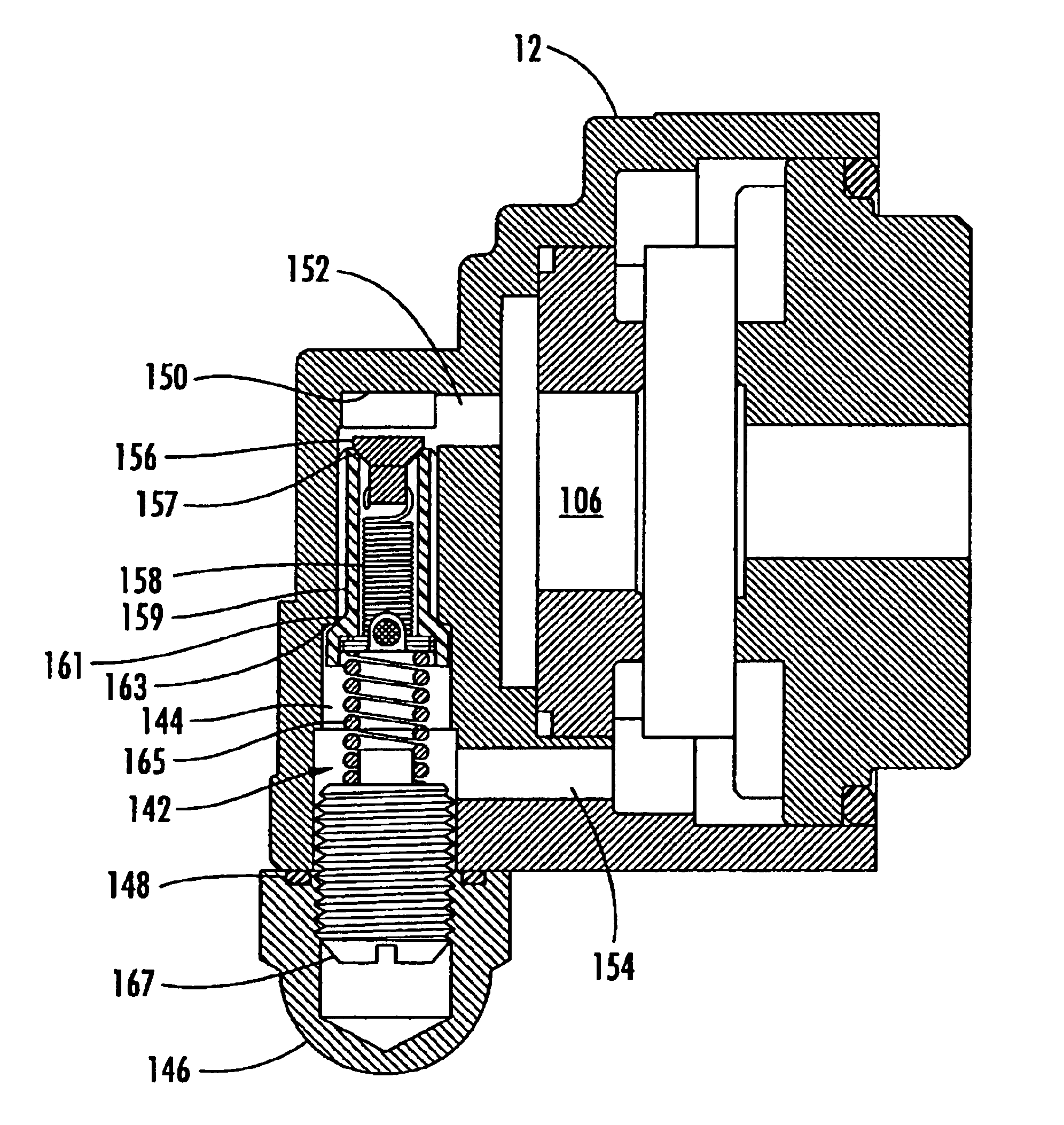

Valve with adjustable stop

InactiveUS7337805B2Prevent overtravelImprove cycle lifeSpindle sealingsDiaphragm valvesAxial displacementEngineering

An adjustable mechanism for a valve or actuator is provided. The adjustable mechanism cooperates with one or more pistons, which in turn cooperates with a valve element to limit the axial displacement of the valve element relative to the valve seat. The adjustable mechanism can be adjusted axially, thereby providing a greater or lesser distance for the piston and diaphragm to travel. Embodiments incorporating the adjustable mechanism include a trickle valve, an on / off valve and a mixing valve. The adjustable mechanism also provides to the adjustment of the piston stroke to match or closely mirror the stroke of the vale element.

Owner:SWAGELOK CO

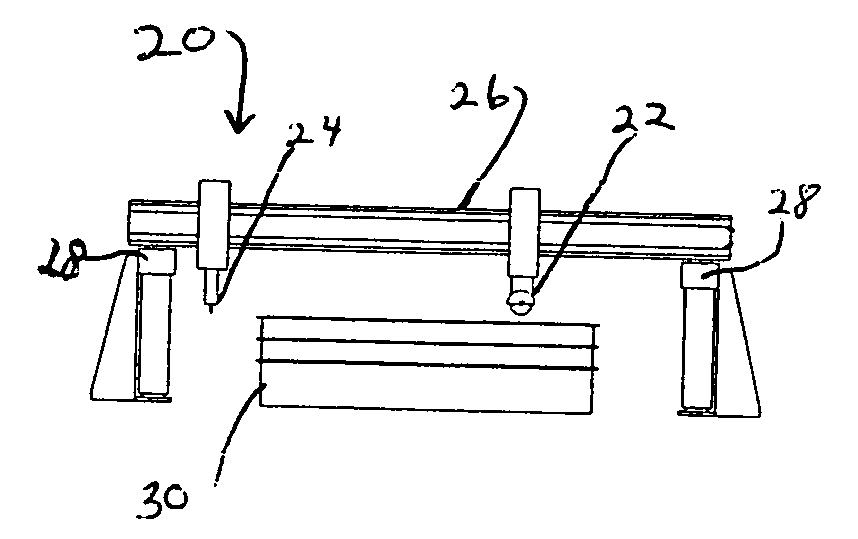

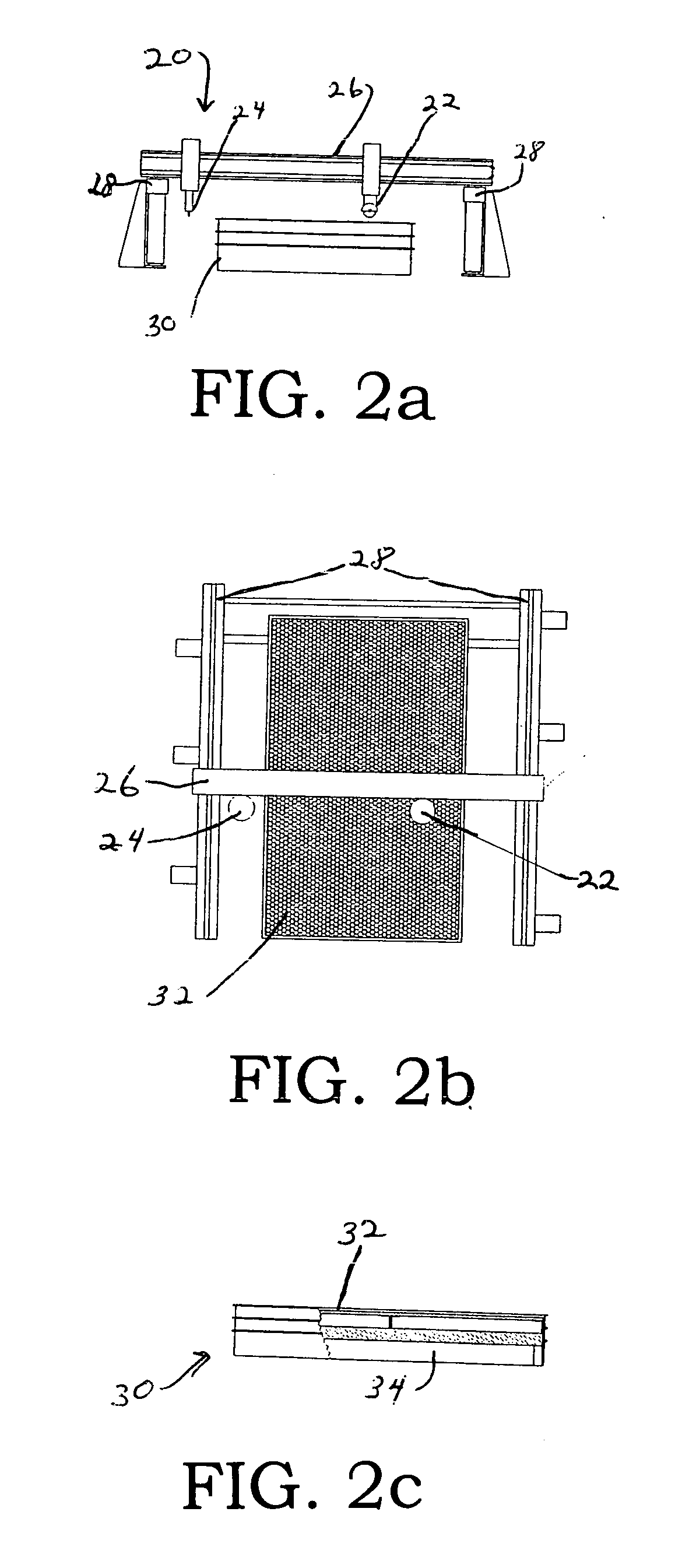

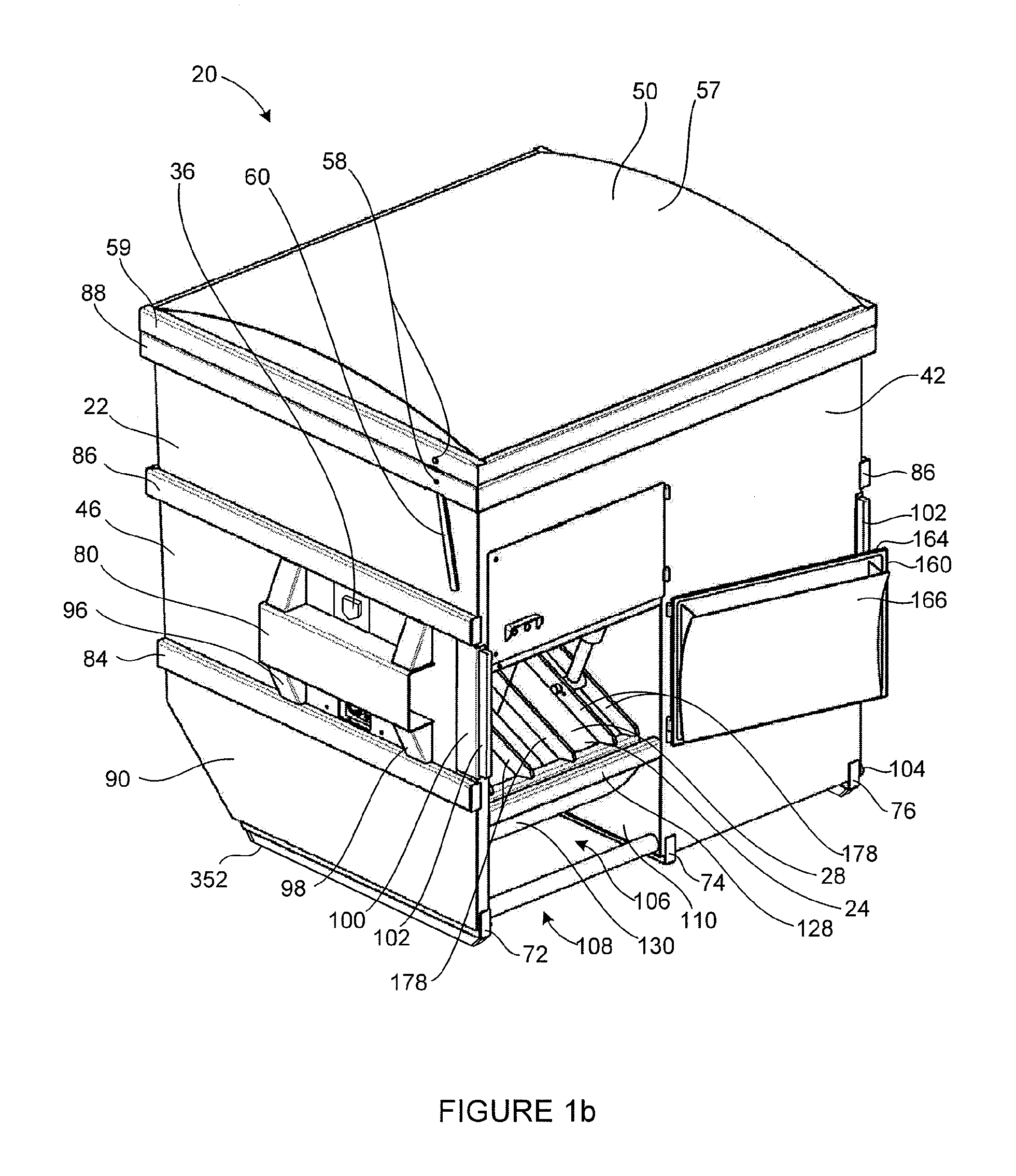

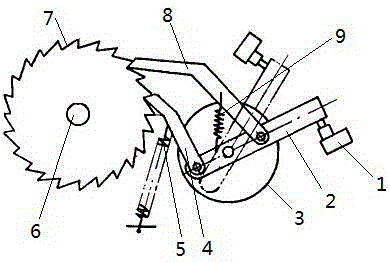

Stonecutting apparatus and method using saw and water jet

InactiveUS20060135041A1Prevent overtravelAvoid problemsGrinding feed controlAutomatic grinding controlEngineeringWater jet cutting

An apparatus for cutting stone which utilizes both a circular saw and a water jet. Both the saw and the water jet are mounted on a gantry, which moves along tracks. All the parts are under the control of the CNC device. The saw is used for straight cuts and curves where possible. The water jet, which is slower and more expensive to operate is only used where the saw cannot be used. The water jet is used to finish a saw cut to avoid any overtravel.

Owner:DAVES CABINET

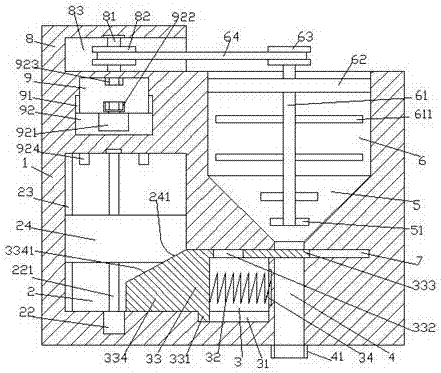

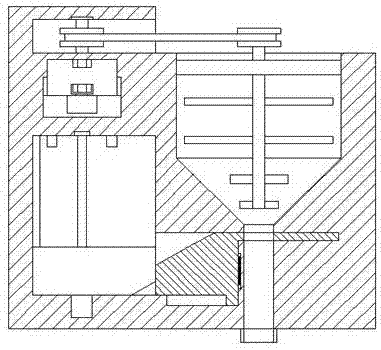

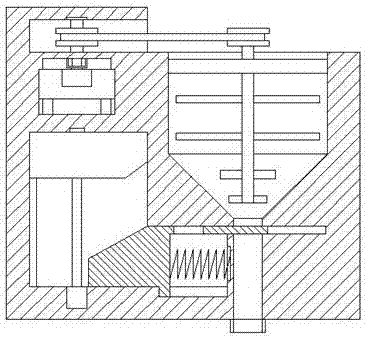

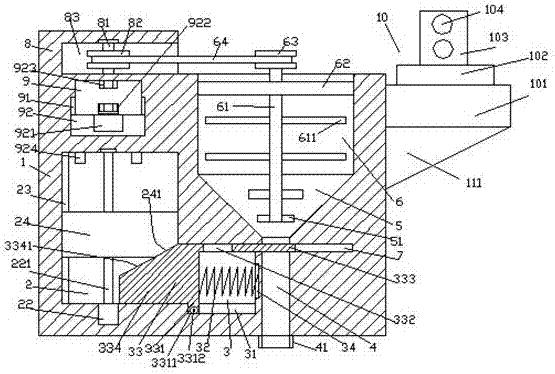

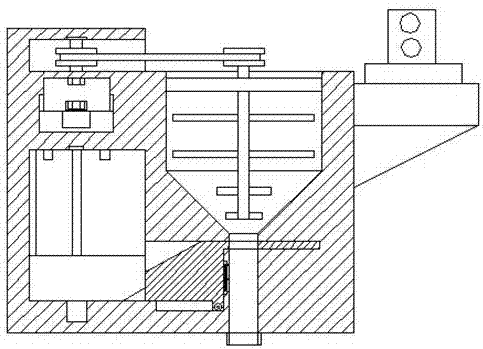

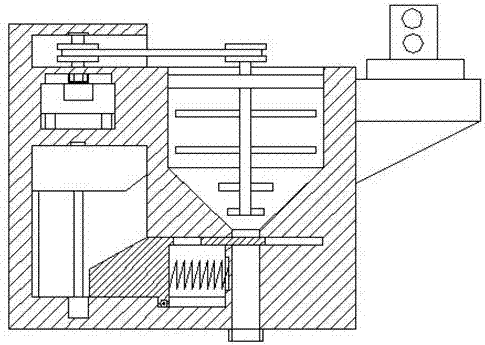

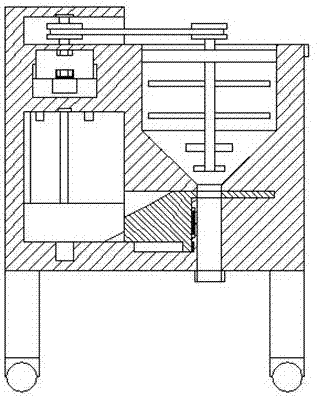

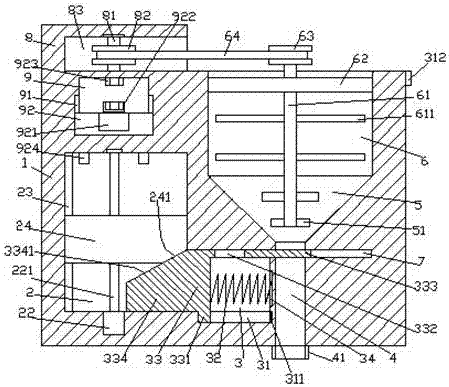

Automatic stirring and feeding equipment for pig farm

InactiveCN106900576AControl to move left and rightRealize automatic reset workAnimal feeding devicesPig farmsAutomatic control

The invention discloses an automatic stirring and feeding equipment for pig farms, which comprises a casing, a first sliding chamber is arranged inside the left side of the casing, a first guide groove is arranged on the left inner wall of the first sliding chamber, a first sliding The casing on the right side of the chamber is provided with a second sliding chamber connected with the first sliding chamber, the casing on the right side of the second sliding chamber is provided with a discharge hole extending up and down, and the top of the second sliding chamber is provided with a horizontal through discharge hole. The material hole and the partition guide groove extending to the right, the top of the discharge hole is provided with a funnel-shaped hopper, the top of the funnel-shaped hopper is provided with a feed hopper, the housing above the first sliding chamber is provided with a third sliding chamber, the third The inner walls of the left and right sides of the sliding cavity are symmetrically provided with a third guide groove, and a screw is provided in the first sliding cavity, the bottom of the screw is connected with the power of the first motor, and the upper screw is threaded and connected with a moving block; the present invention is simple in structure, reasonable in design, and easy to operate It is simple, the manufacturing cost is very low and the maintenance cost is low. It is suitable for small and medium-sized farmers. It can automatically control the feeding work and reduce the labor load of workers.

Owner:朱娟红

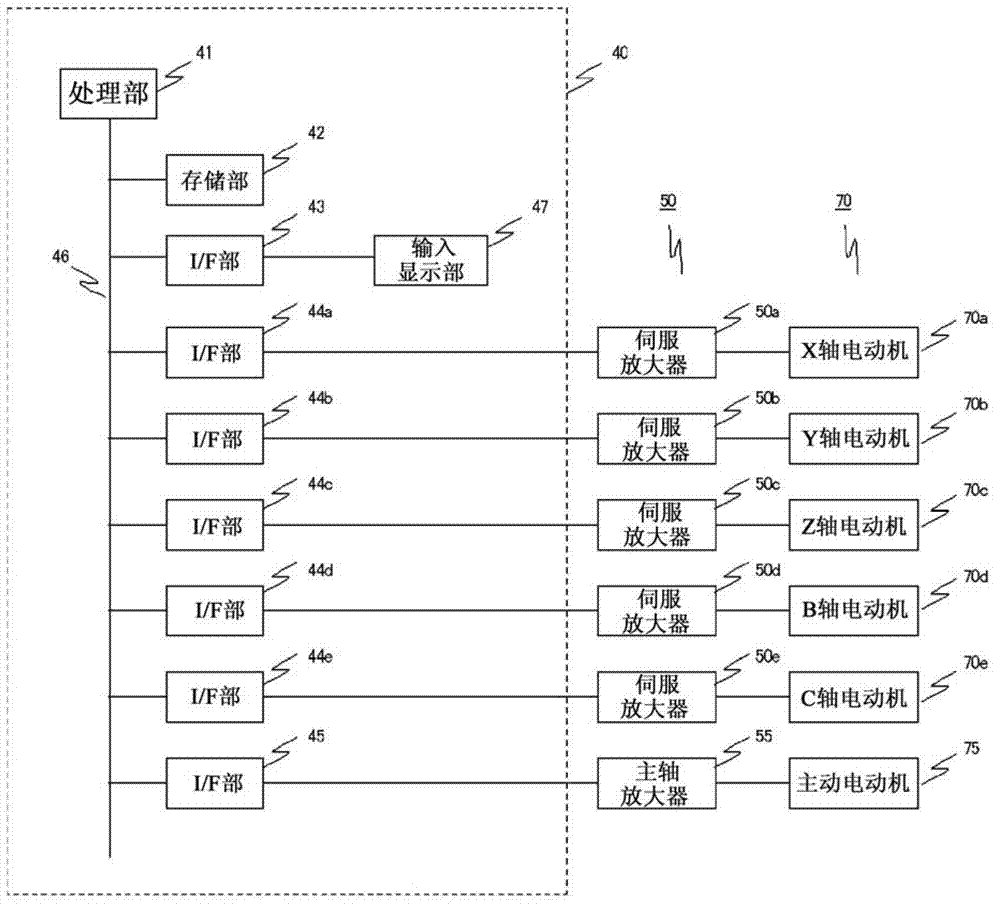

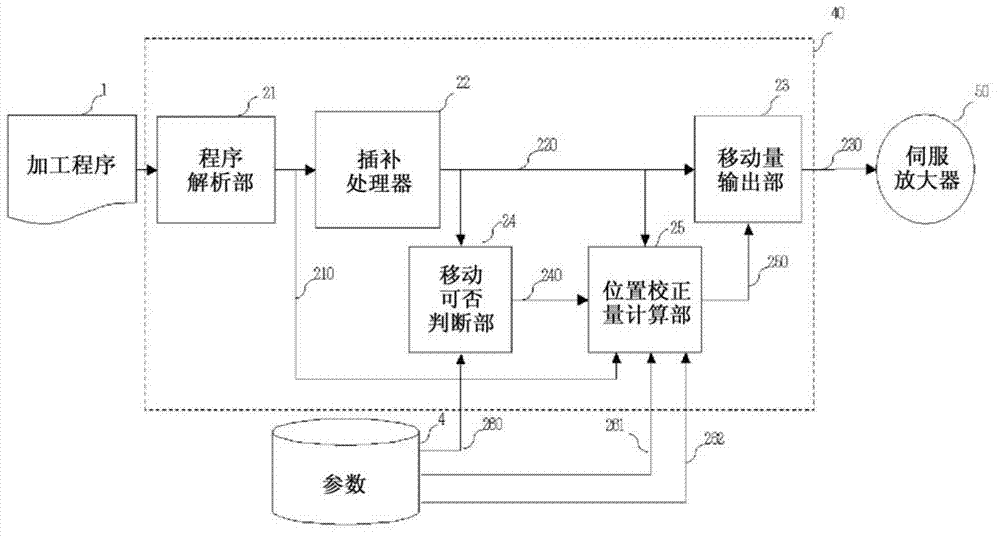

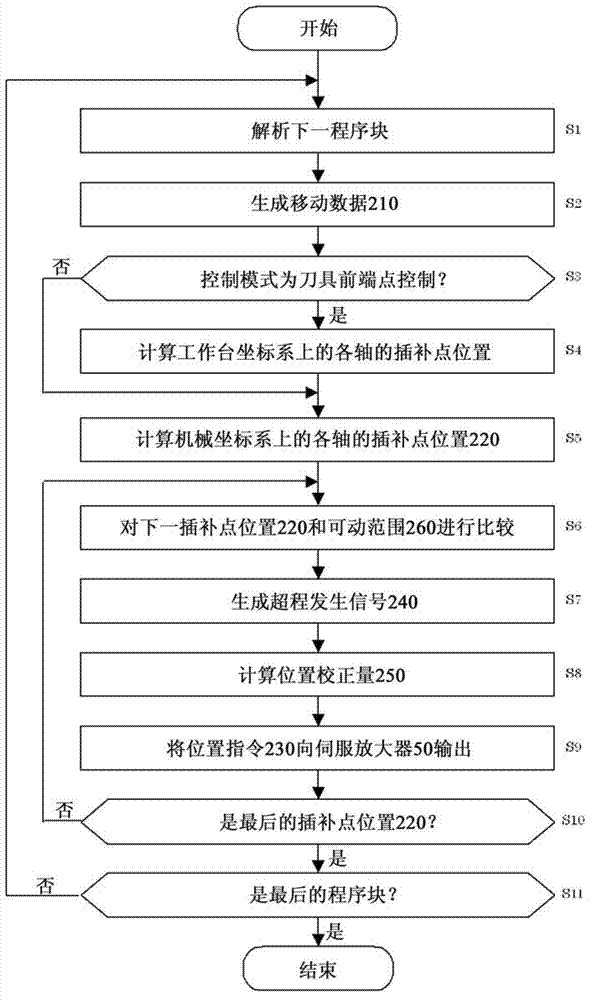

Numerical control device and control method of numerical control device

InactiveCN102792238AAvoid interferencePrevent overtravelComputer controlSimulator controlCompletion timeNumerical control

Disclosed is a numerical control device provided with a retracted direction determination unit for determining a direction different from a linear axial direction upon which a tool deviates from a movable range as a retraction direction of the tool if the tool is determined to deviate from the movable range; and a tool trace correction unit for correcting a trace of the tool so that, on the basis of the retraction direction, the distance between the tool and the rotational center of the table during when the tool is retracted is greater than or equal to the distance between the tool and the rotational center of the table at the rotation starting time or rotation completion time for the table. According to the disclosed numerical control device, if a table rotation instruction which causes stroke-over to occur upon a linear axis is made while executing control with a coordinate system that is different from the coordinates of a mechanical system, it is possible to avoid stroke-over while avoiding interference between the tool and a work.

Owner:MITSUBISHI ELECTRIC CORP

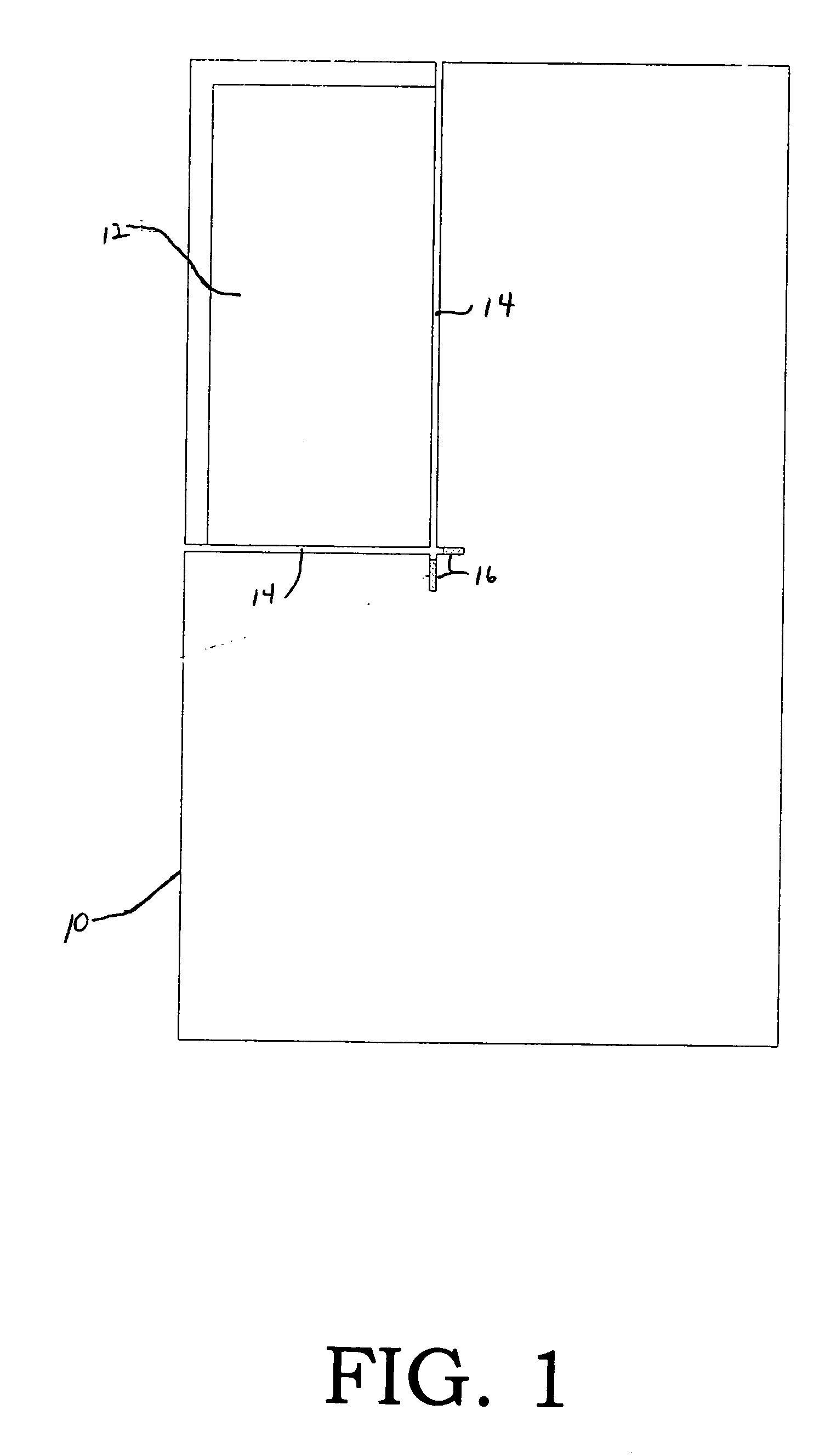

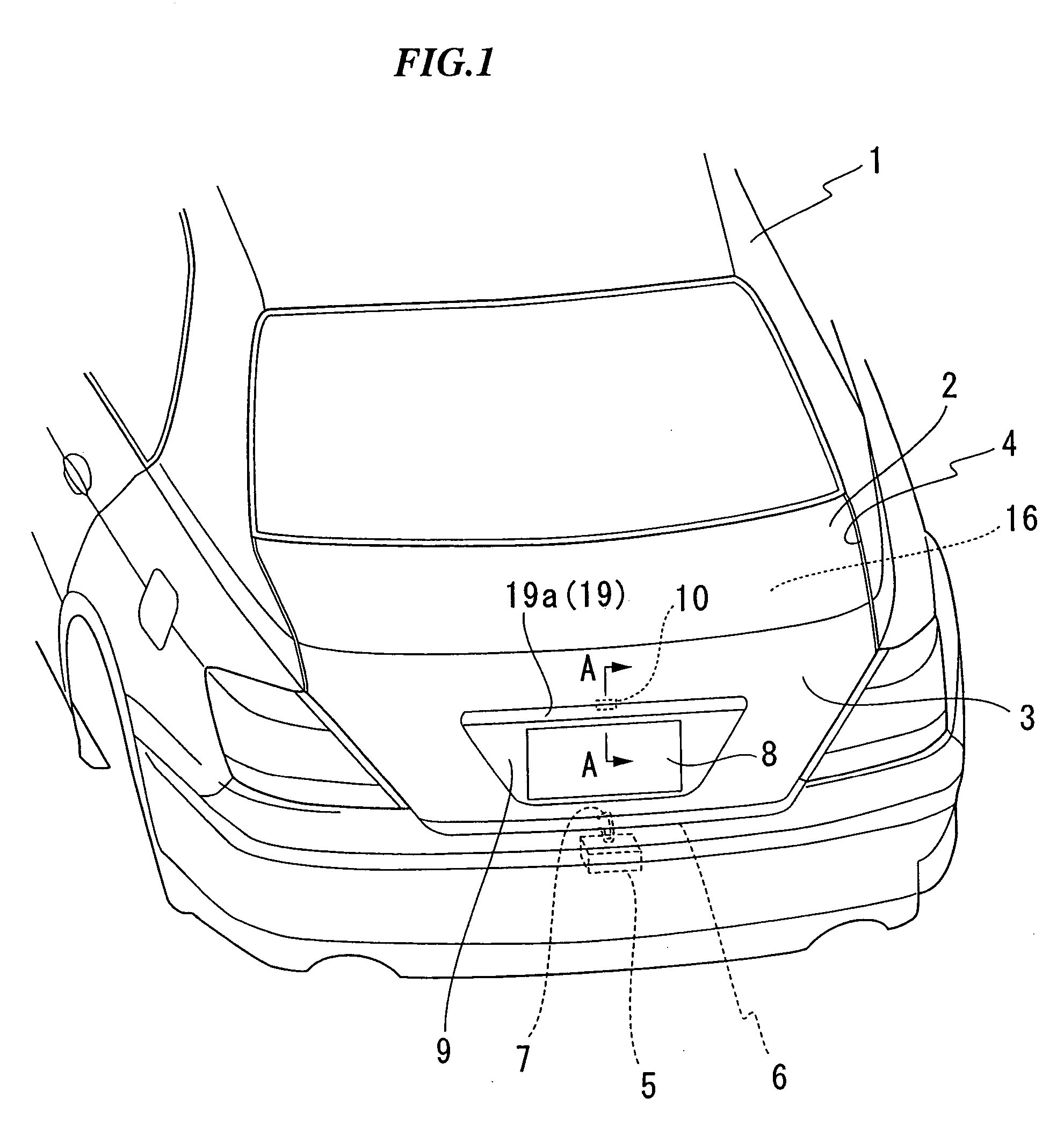

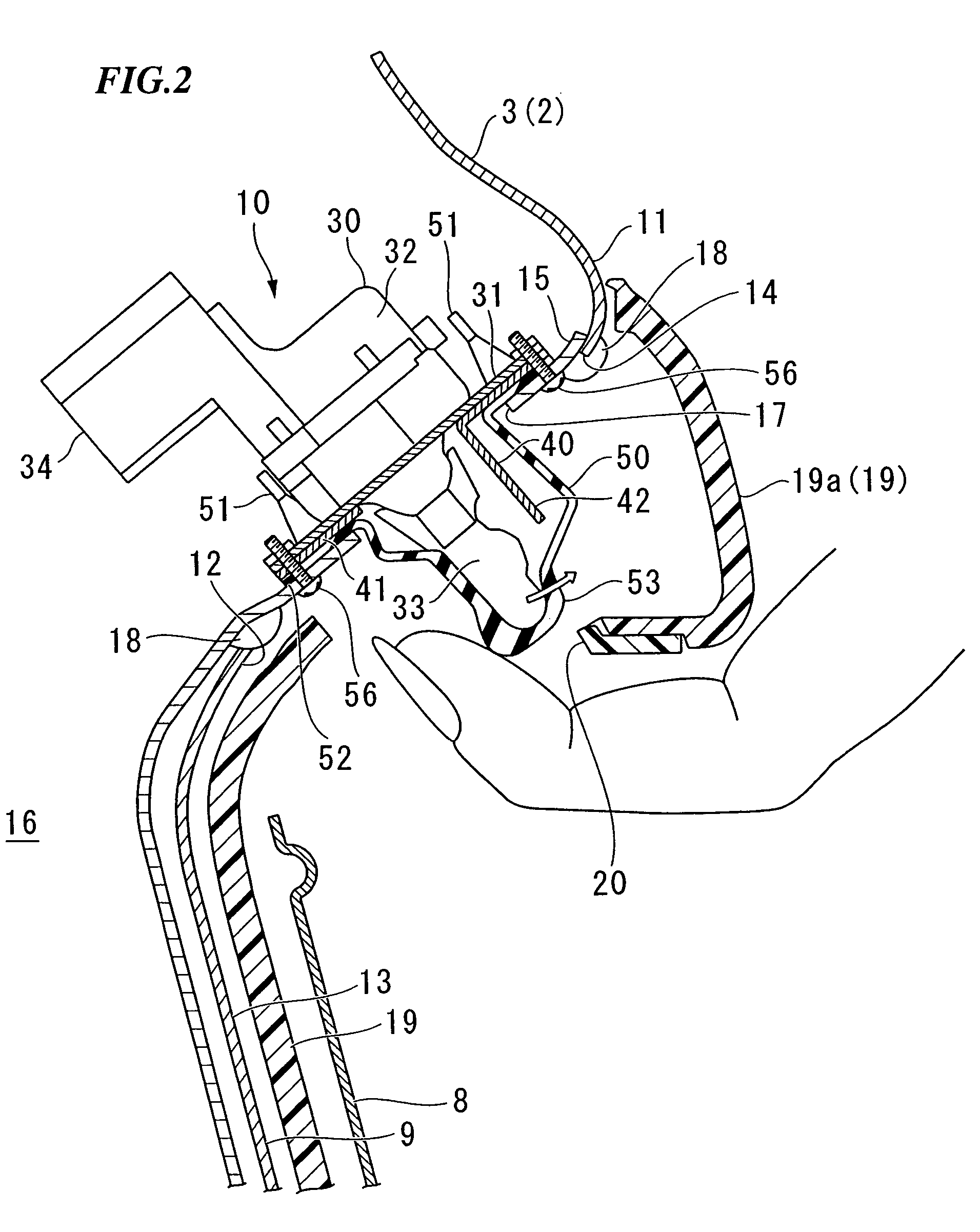

Opening switch for an opening and closing body

ActiveUS7078640B2Easy to operatePrevent overtravelWing handlesContact operating partsEngineeringFlange

An opening switch for an opening and closing body includes a switch base having a first substrate and a second substrate which are put together in a manner such that inner faces of the substrates face each other and outer faces of the substrates are outer faces of the switch base; a main switch body provided on the outer face of the first substrate; a lever portion which is provided on the inner face of the first substrate and passes the second substrate through a through hole; and a flange portion for preventing an over stroke of the lever portion. The flange portion protrudes from the outer face of the second substrate and is positioned away from the lever portion and on a side toward which the lever portion is inclined. A flexible cover member for covering a combined body of the lever portion and the flange portion is provided.

Owner:MITSUI KINZOKU ACT +1

Novel bridge maintaining equipment

ActiveCN107044087ARealize automatic reset workRestricted taxi positionBridge erection/assemblyRoads maintainenceAutomatic controlArchitectural engineering

The invention discloses novel bridge maintaining equipment. The novel bridge maintaining equipment comprises a material box, a first sliding cavity is formed in the left side of the material box, a first guide groove is formed in the inner wall of the left side of the first sliding cavity, and a second sliding cavity communicating with the first sliding cavity is formed in the portion, located at the right side of the first sliding cavity, of the material box; an arrangement groove arranged in a vertical-extending mode is formed in the portion, located at the right side of the second sliding cavity, of the material box, a closed groove penetrating through the arrangement groove and extending rightwards is formed in the top of the second sliding cavity, a cone-shaped cavity is formed in the top of the arrangement groove, and a feeding cavity is formed in the top of the cone-shaped cavity; and a third sliding cavity is formed in the portion, located above the first sliding cavity, of the material box, third guide grooves are symmetrically formed in the inner walls of the left and right sides of the third sliding cavity, a screw rod is arranged in the first sliding cavity, a first driver is connected with the bottom of the screw rod, and a lifting block is connected to the screw rod in a threaded fit mode. According to the novel bridge maintaining equipment, the structure is simple, the design is reasonable, operation is simple, stirring and discharging work can be automatically controlled, the labor capacity of workers are reduced, the construction and maintenance speed is enhanced, meanwhile the lighting function is achieved, the use cost is low, and current requirements are met.

Owner:NANTONG YIXUAN IND DESIGN CO LTD

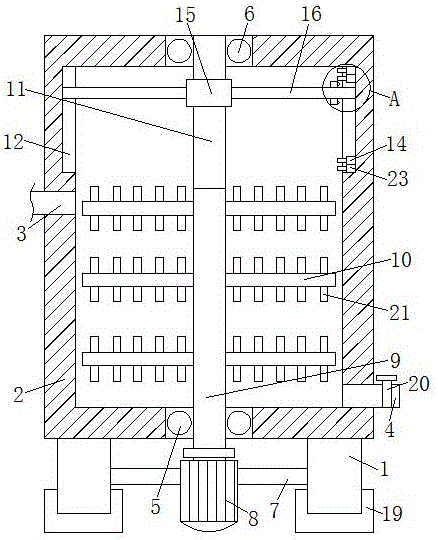

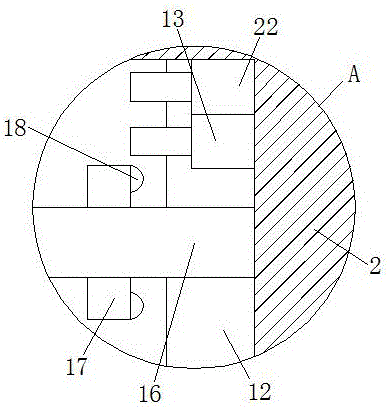

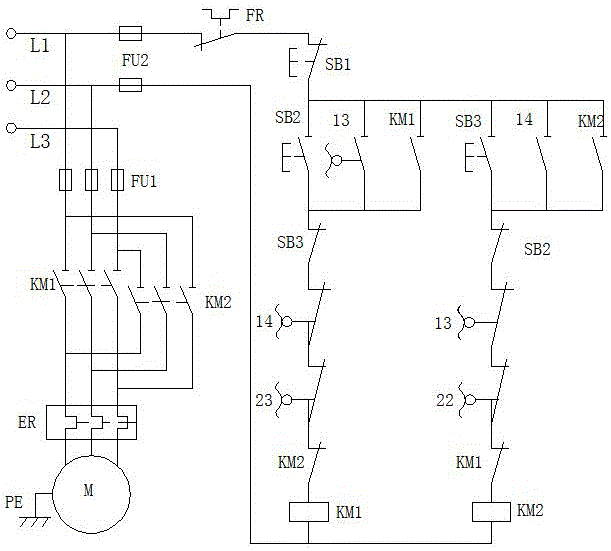

Automatic anti-sedimentation device for textile assistant

InactiveCN106669502AAvoid centrifugationReduce the possibility of stirring dead endsRotary stirring mixersTransportation and packagingEngineeringTextile

The invention discloses an automatic anti-sedimentation device for a textile assistant. The device comprises a support leg and a stirring motor, wherein a stirring box is fixedly connected with the upper surface of the support leg; a feeding hole and a discharging hole are respectively formed in the surface of the stirring box; a first bearing and a second bearing are respectively fixed on the inner bottom wall and the inner top wall of the stirring box; a supporting plate is fixedly connected with the middle part of the support leg; the stirring motor is fixedly arranged in the middle of the supporting plate; an output shaft of the stirring motor is fixedly connected with a rotating shaft through a coupler. The automatic anti-sedimentation device for the textile assistant can achieve the effect of positively and negatively turning the stirring motor, and meanwhile, the effect of the stirring motor capable of automatically positive and negative turning also can be achieved, the effect of positively and negatively stirring the textile assistant in the stirring box can be achieved, the problem of centrifugal separation of the matters in the textile assistant can be effectively avoided, a contact block connected with the surface of a contact rod can ascend and descend, and an upper travel switch, a lower travel switch, an upper limiting switch and a lower limiting switch can be conveniently touched.

Owner:佘峰

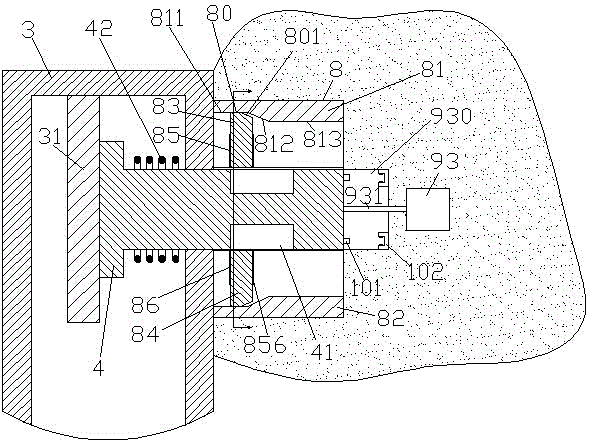

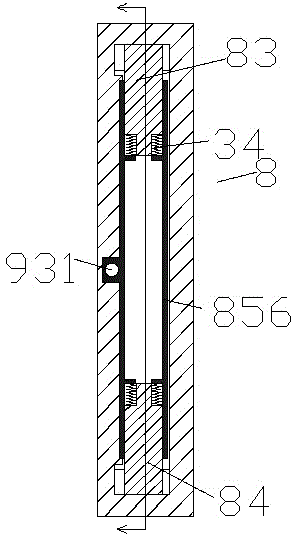

Advertising board installation device with U-shaped infrared sensor

An advertising board installation device with a U-shaped infrared sensor comprises an advertising board bearing frame (3) and a plug hole type fixing module fixedly embedded into a building wall, wherein side plates of the front side of the advertising board bearing frame (3) are used for installing an advertising board, the advertising board bearing frame (3) is provided with a cavity in the inside, a positioning plate (31) is fixedly arranged in the cavity and used for limiting the retraction position of extensible fixing columns (4) in side plates of the back side of the advertising board bearing frame (3), and a pressing spring (42) is arranged in the cavity and used for pressing the extensible fixing columns (4) towards the positioning plate (31) so as to be in a retraction position.

Owner:嘉兴市朗盛机械有限公司

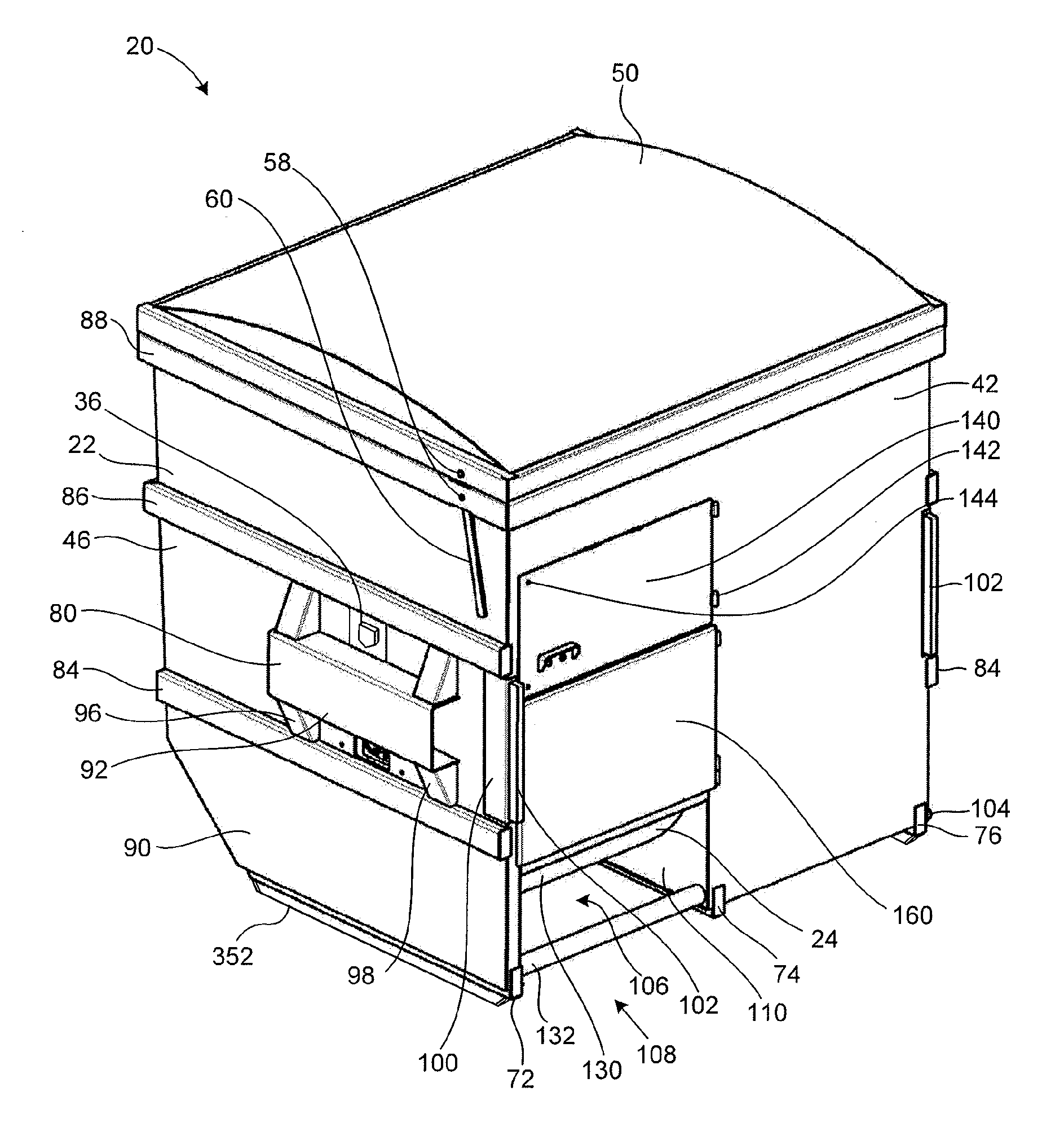

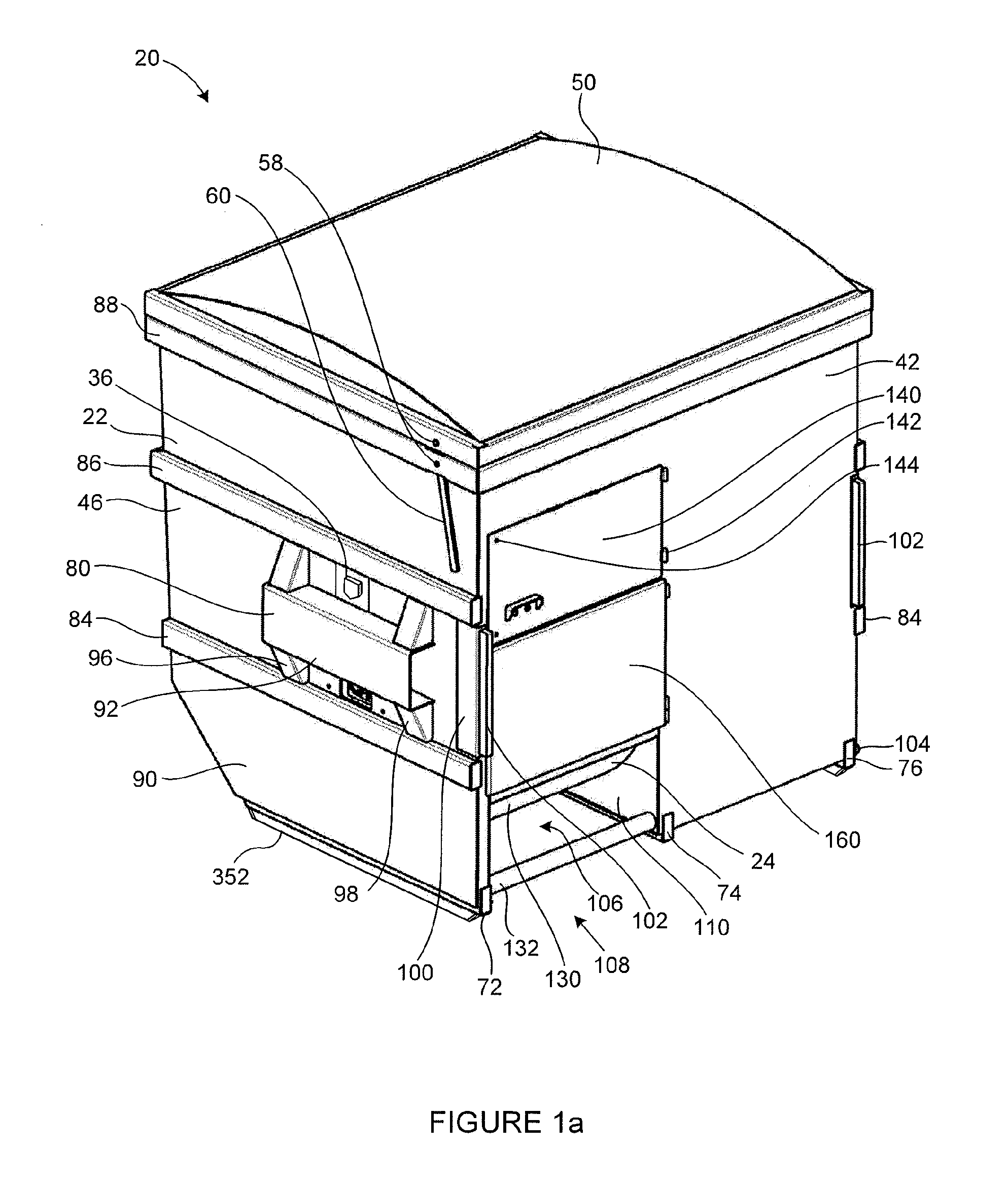

Waste containment apparatus

InactiveUS20160023417A1Prevent overtravelPressesSpecial purpose weighing apparatusElectrical controlWaste management

A waste containment apparatus fits within, the same physical envelope as a typical 6 cubic yard bin. The apparatus has lifting fittings to permit conventional lifting and dumping by a garbage truck. The bin has, internally, a compactor including a motor and a compaction head driven by the motor. The working mechanical assemblies and the electrical control unit are mounted well above the inlet chute. The lifting height of the inlet chute is significantly lower than the top opening level of the bin. The unit has an internal refuse flow accumulation path, and internal members such as deflector plates. The unit may have a liquid drain and collection sump. The sump may have a sump heater. The unit has at least one weighing skid that responds to a weight condition in the event that the bin is loaded to an extent that may make it difficult for a lift truck to raise and tip.

Owner:MODERN WASTE PROD

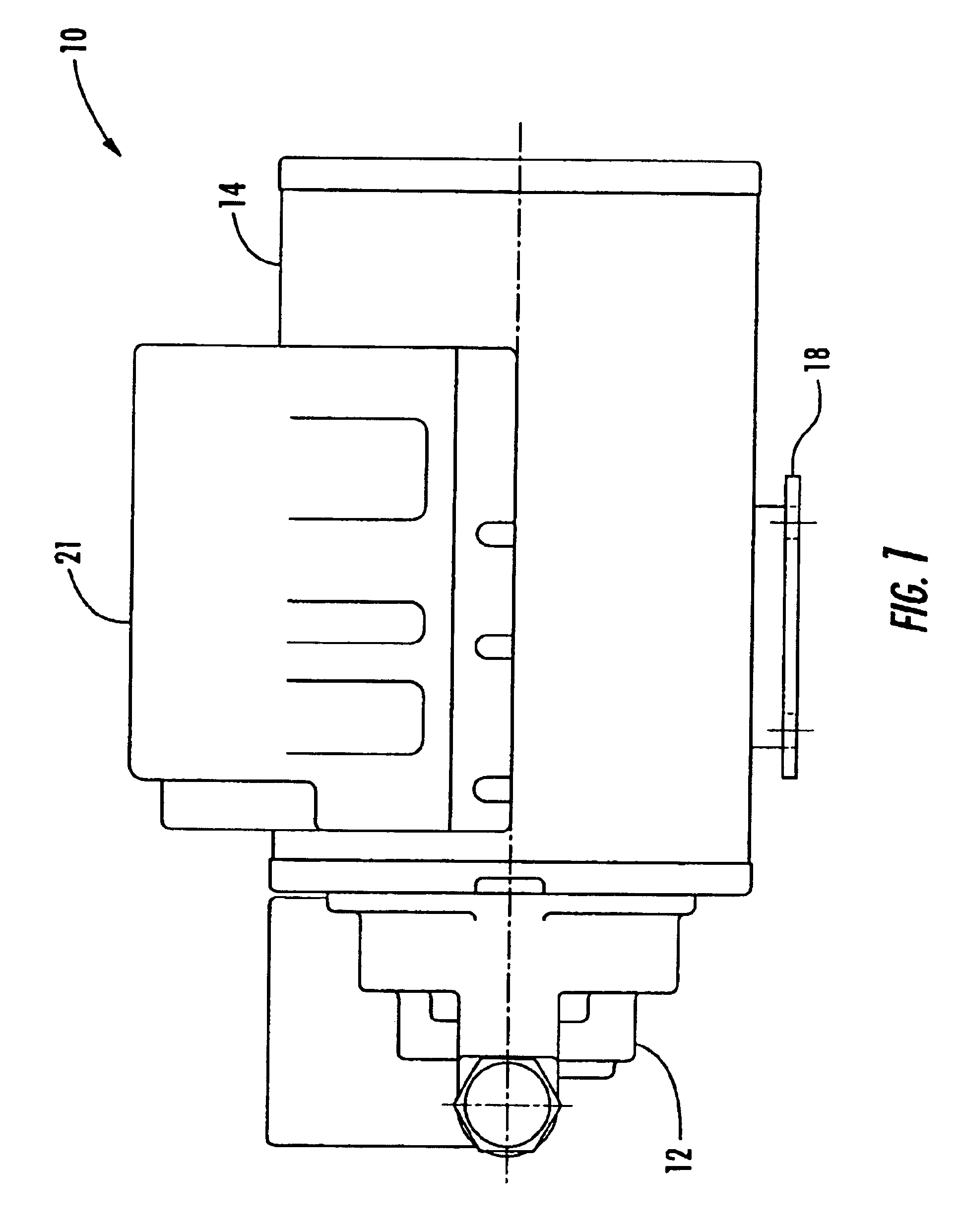

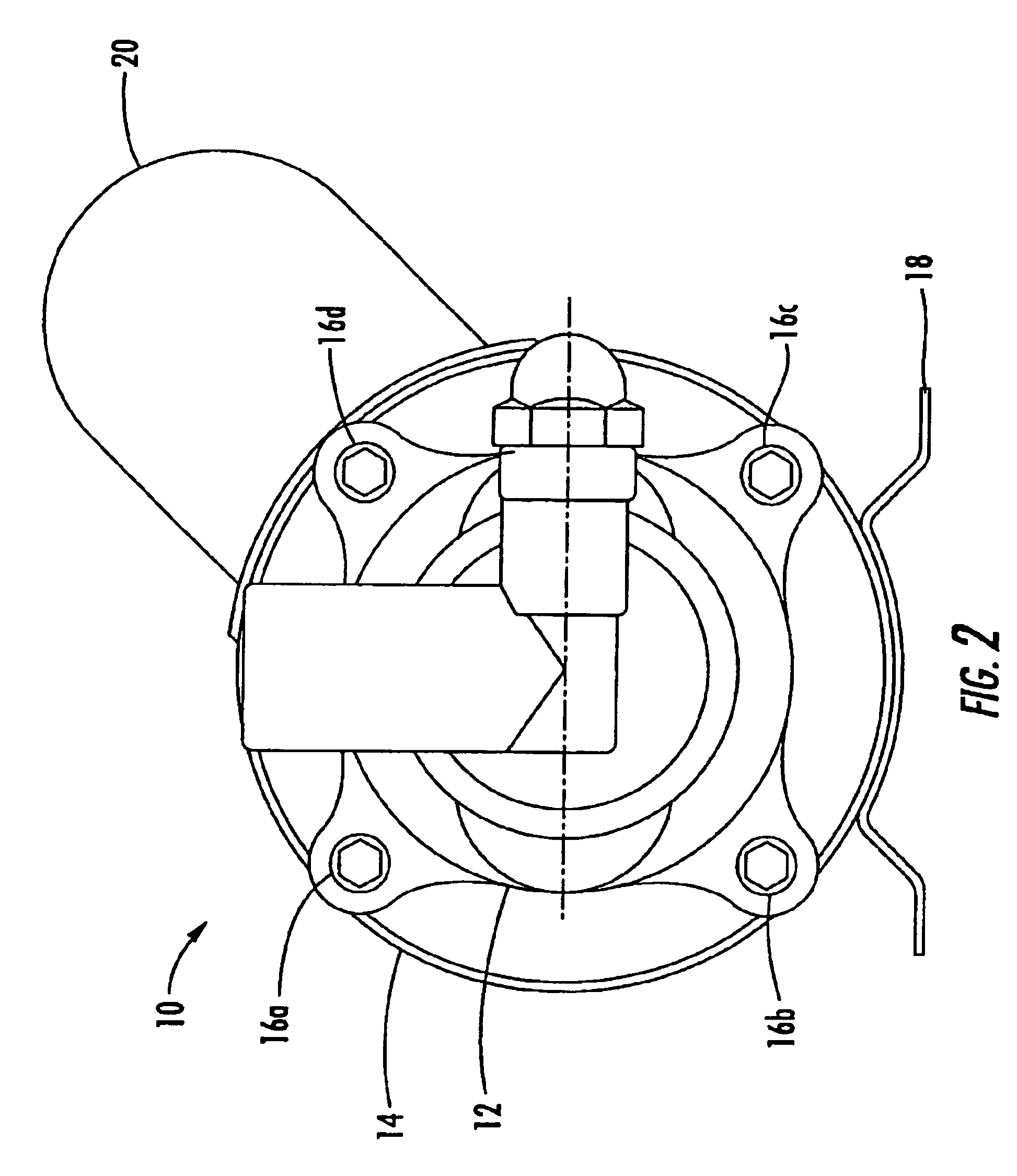

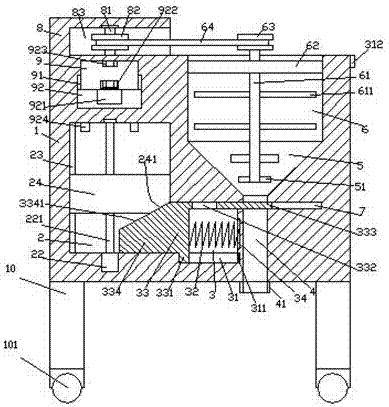

Fluid pump relief valve

A pump head for a fluid pump driven by a motor includes an inlet for receiving fluid at a first pressure and an outlet for outputting fluid at a second pressure greater than the first pressure. A relief valve cavity formed in the pump head housing includes a first portion in fluid communication with the inlet and a second portion in fluid communication with the outlet. A relief valve is disposed in the relief valve cavity with no portion of the relief positioned to block or otherwise impede the normal flow of fluid through the inlet or outlet. The relief valve is bi-directional and configured to operate in two modes including: (1) a low pressure relief mode where fluid flows from the inlet to the outlet when fluid pressure at the inlet exceeds fluid pressure at the outlet by a first threshold amount; and (2) a high pressure relief mode where fluid flows from the outlet to the inlet when fluid pressure at the outlet exceeds fluid pressure at the inlet by a second threshold amount greater than the first threshold amount. The relief valve cavity is specially configured to provide a barrier preventing an element of the relief valve from damaging the pump head in the event the relief valve element fails.

Owner:STANDEX INT CORP

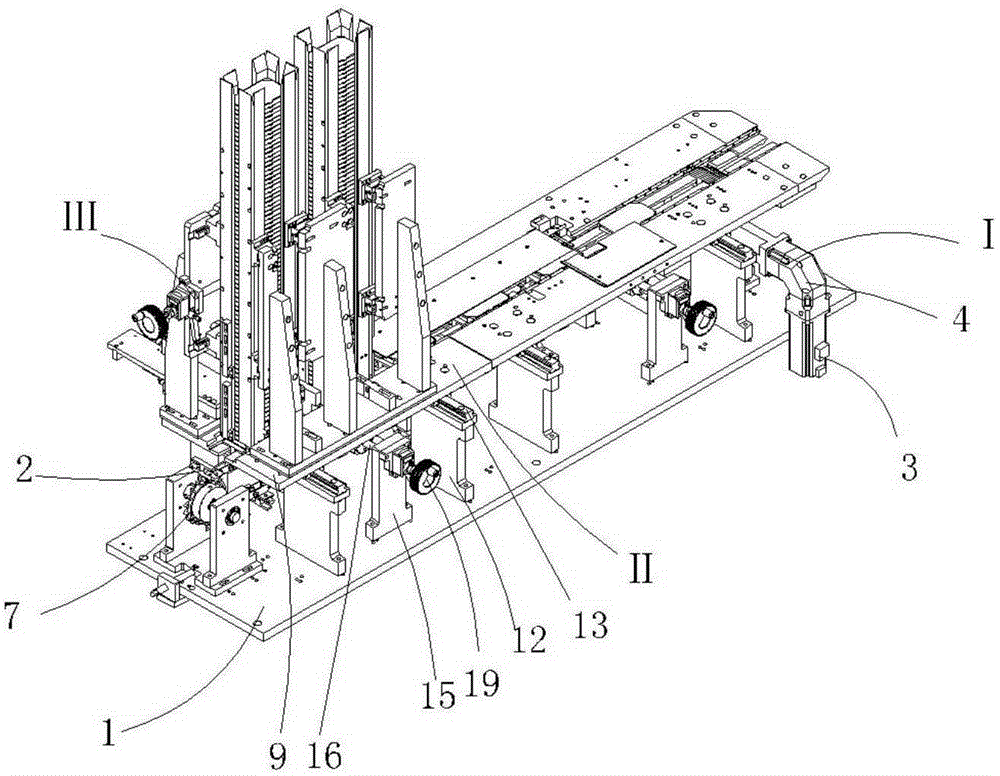

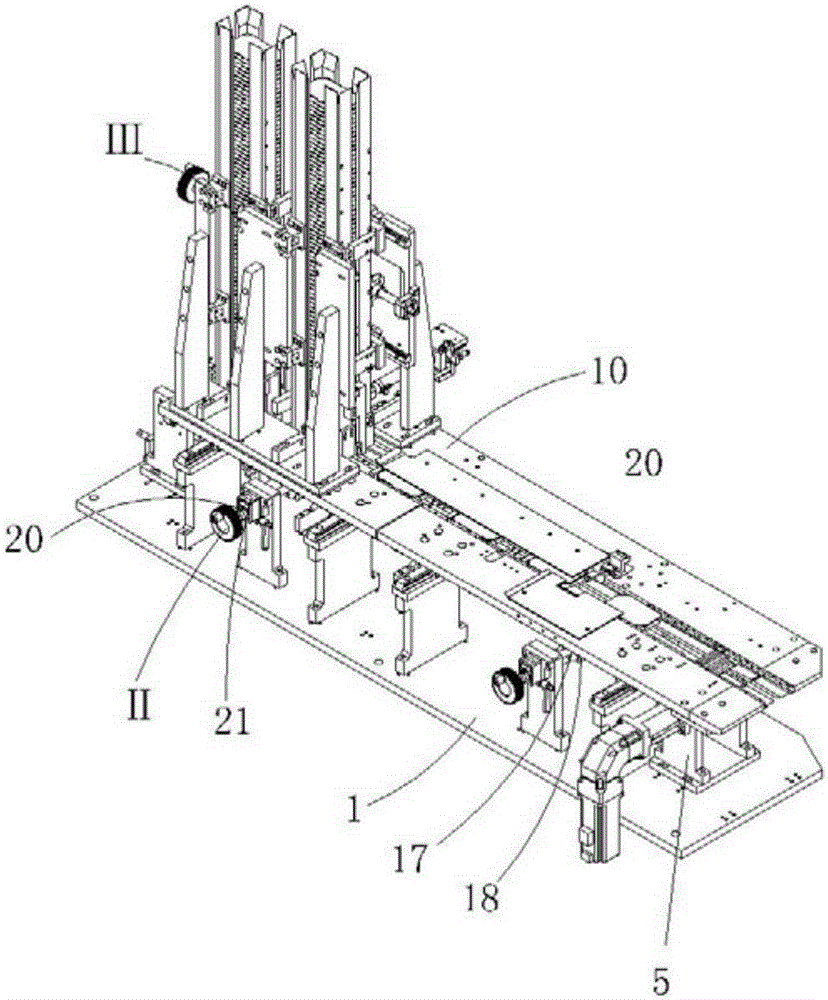

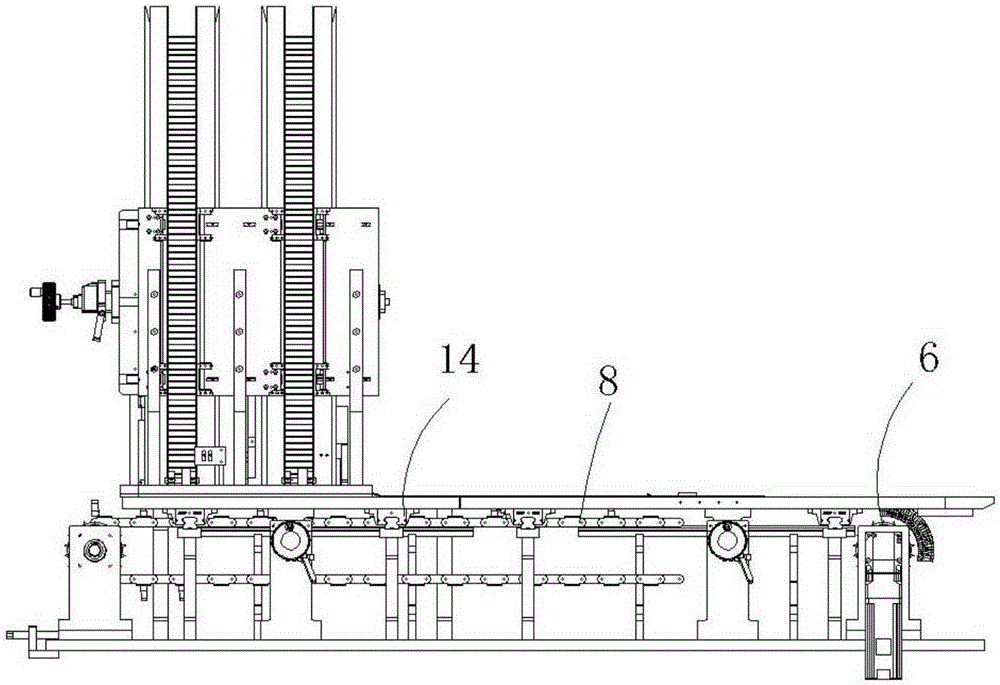

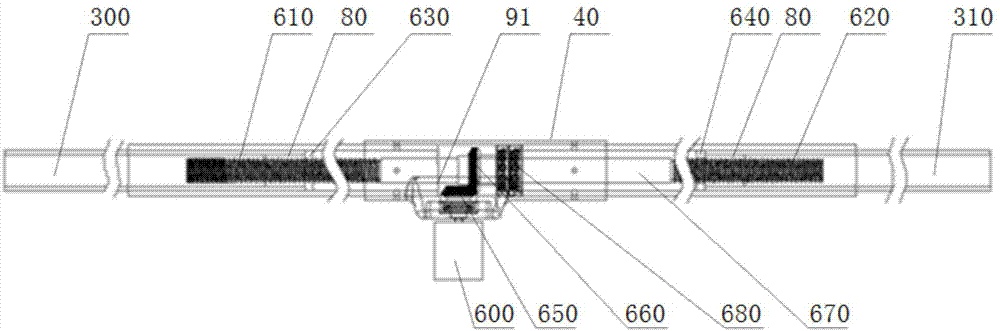

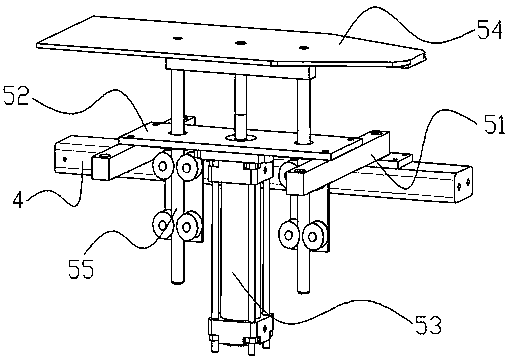

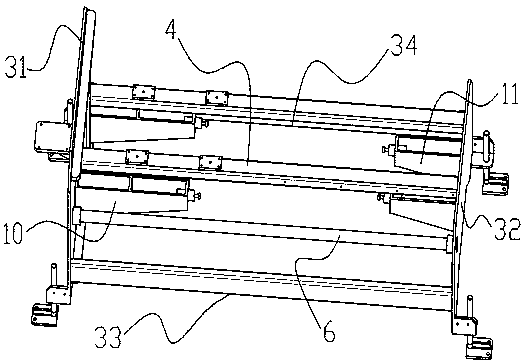

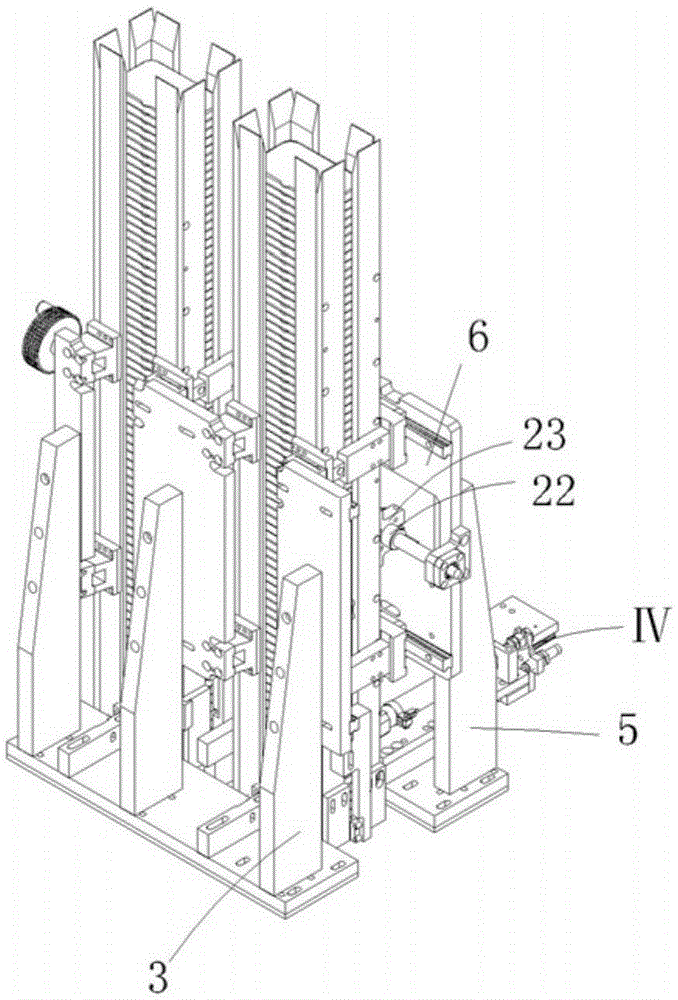

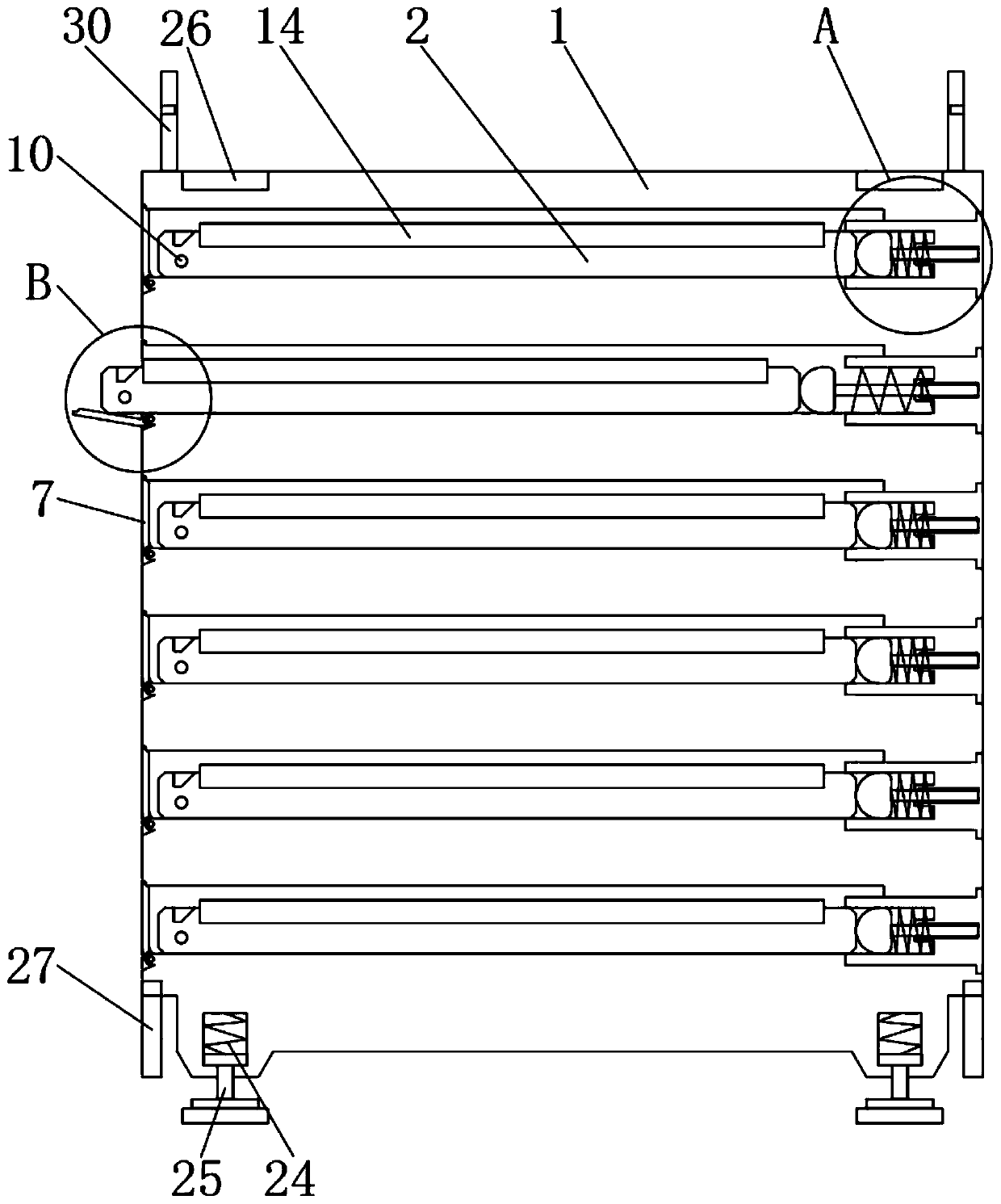

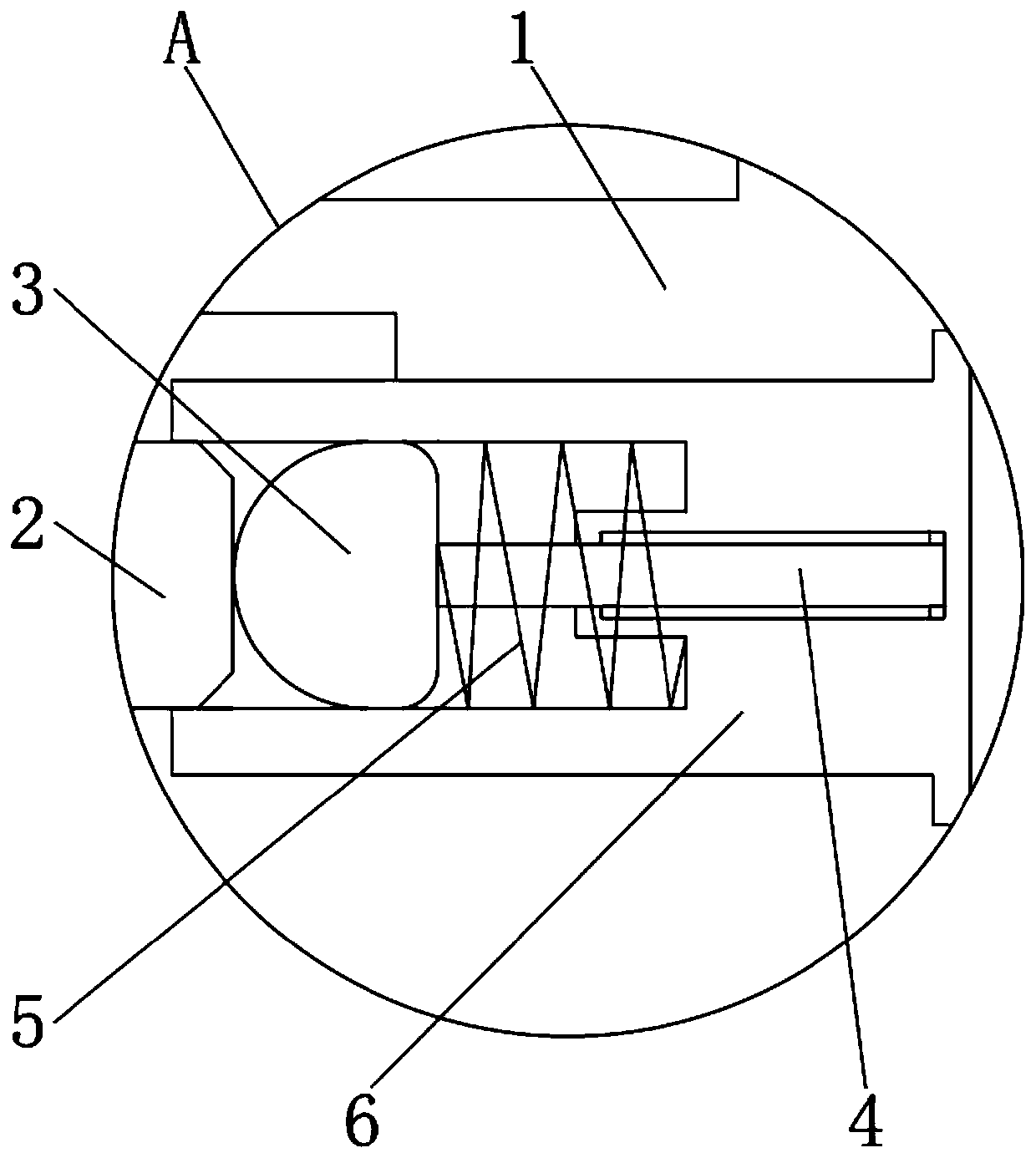

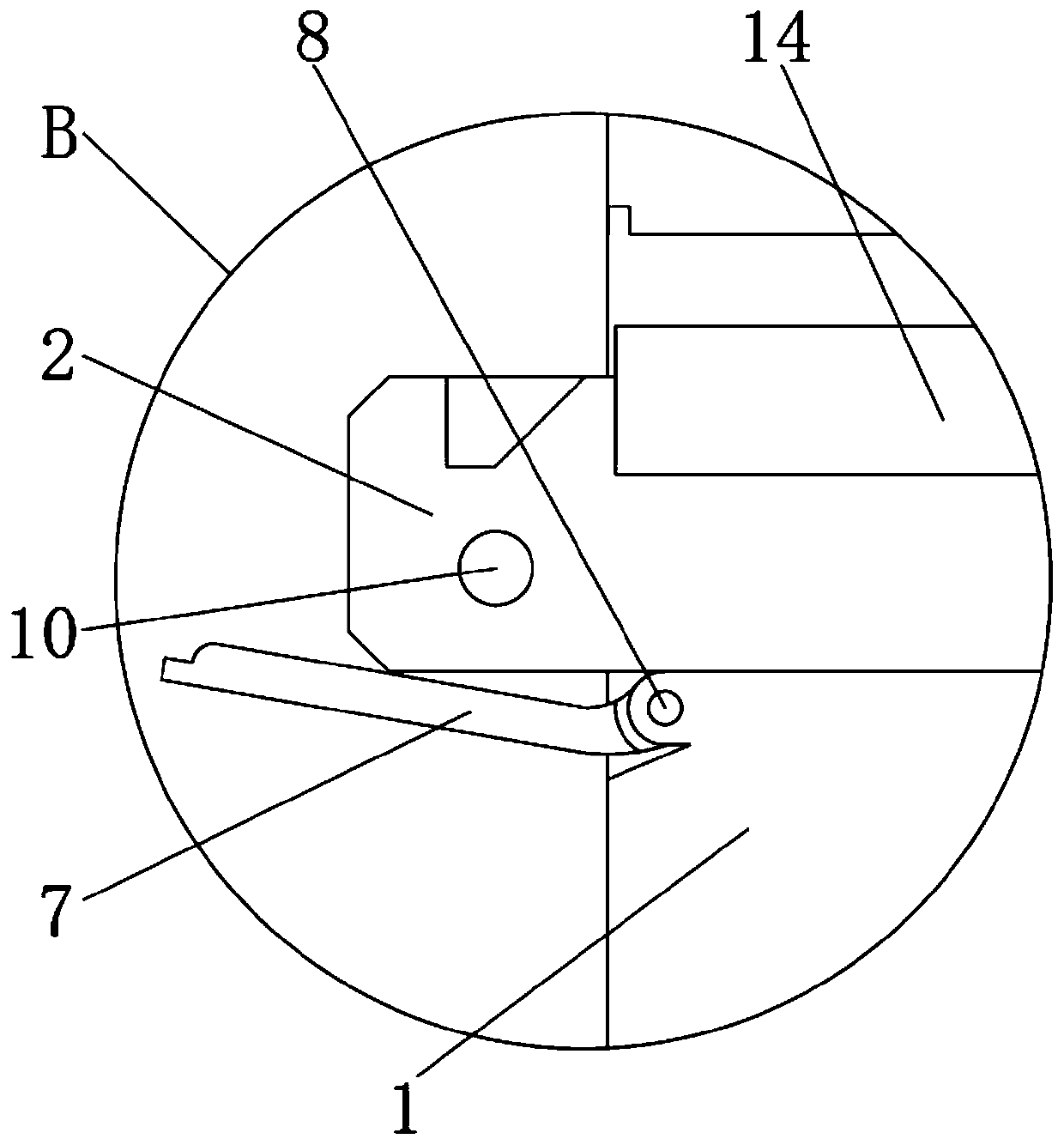

Discharging mechanism

The invention relates to a discharging mechanism. A conveying assembly is installed on a bottom plate, and multiple poking blocks are installed on a conveying belt of the conveying assembly. A front and back adjustment assembly is installed on the bottom plate, and a left and right adjustment assembly is installed on the front and back adjustment assembly. Two discharging carrier tool sets are arranged inside the left and right adjustment assembly. The discharging mechanism further comprises two supporting-carrying assembly sets, each discharging carrier tool set corresponds to one supporting-carrying assembly set, and the supporting-carrying assemblies can support products inside the discharging carrier tools. The front and back adjustment assembly can adjust the width of the discharging carrier tools. The left and right adjustment assembly can adjust the length of the discharging carrier tools. The conveying assembly drives the poking blocks to poke one square product on the bottommost layer inside each discharging carrier tool to move forwards. The discharging mechanism can be adapted to discharging products of different lengths.

Owner:BOZHON PRECISION IND TECH CO LTD

Coating matching device

InactiveCN107149898ARealize automatic reset workLimit sliding positionTransportation and packagingRotary stirring mixersBiochemical engineering

The invention discloses a coating matching device which comprises a matrix. A first slide cavity is arranged inside the left side of the matrix, a first guide groove is formed in the inner wall of the left side of the first slide cavity, a second slide cavity which is communicated with the first slide cavity is arranged in the matrix and is positioned on the right side of the first slide cavity, an output groove is formed in the matrix in an extension manner in the up-down direction and is particularly formed in the right side of the second slide cavity, an enclosed groove which is perforated through the output groove and extends towards the right side is formed in the top of the second slide cavity, a hopper-shaped portion is arranged on the top of the output groove, a stirring portion is arranged on the top of the hopper-shaped portion, a third slide cavity is arranged in the matrix and is positioned above the first slide cavity, third guide grooves are correspondingly formed in the inner walls of the left side and the right side of the third slide cavity, a spiral rod is arranged in the first slide cavity, a first electric rotary machine is connected with the bottom of the spiral rod, and a pushing and lifting block is fittingly connected onto the spiral rod in a threaded manner. The coating matching device has the advantages that the coating matching device is simple in structure, reasonable in design and easy to operate, stirring and discharging work can be automatically controlled, and accordingly the amount of labor can be reduced for workers; the coating matching device is low in service cost, uniform stirring effects can be realized, the stirring efficiency can be improved, and existing requirements can be met.

Owner:蒋雷杰

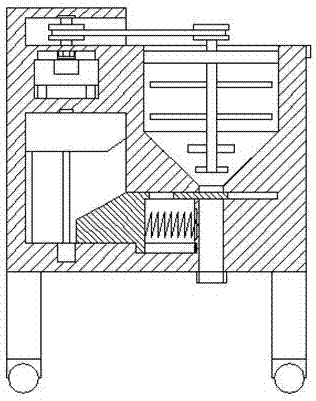

Automatic stirring and feeding equipment used for pig farm

InactiveCN107306813AControl to move left and rightRealize automatic reset workAnimal feeding devicesPig farmsAutomatic control

The invention discloses an automatic stirring and feeding equipment for pig farms, which comprises a casing, a first sliding chamber is arranged inside the left side of the casing, a first guide groove is arranged on the left inner wall of the first sliding chamber, and the first sliding chamber The housing on the right side is provided with a second sliding chamber connected with the first sliding chamber, the housing on the right side of the second sliding chamber is provided with a discharge hole extending up and down, and the top of the second sliding chamber is provided with a horizontal through discharge hole. hole and the partition guide groove extending to the right, a funnel-shaped hopper is provided on the top of the discharge hole, a feed hopper is provided on the top of the funnel-shaped hopper, a third sliding chamber is provided in the housing above the first sliding chamber, and the third sliding chamber The inner walls of the left and right sides of the cavity are symmetrically provided with a third guide groove, and a screw is provided in the first sliding cavity, the bottom of the screw is connected with the power of the first motor, and the upper screw is threaded and connected with a moving block; the invention has simple structure, reasonable design and simple operation , The manufacturing cost is very low and the maintenance cost is low. It is suitable for small and medium-sized farmers. It can automatically control the feeding work and reduce the labor load of workers.

Owner:朱娟红

Temporary cross arm capable of operating in alive state

ActiveCN107069543AAvoid damageEasy to install and adjustApparatus for overhead lines/cablesEngineering

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

Material bag automatic filling and opening sealing integration facility

ActiveCN110803346AEasy to movePrevent overtravelWrapper twisting/gatheringSolid materialPhysicsPower unit

The invention relates to a material bag automatic filling and opening sealing integration facility. The material bag automatic filling and opening sealing integration facility comprises a bag fillingmachine and an opening sealing machine. An automatic bag opening device is arranged in a material outlet of the bag filling machine. The opening sealing machine is located at the bottom of the automatic bag opening device and comprises a fixing frame, a supporting and vibrating compaction device, a material push power unit, a bag holding device and an opening sealing portion. The lower end of a woven bag is located on the upper portion of the supporting and vibrating compaction device. The lower portion of the bag holding device is connected with a lower sliding rail in a sliding mode, and thelower sliding rail is installed on the lower portion of the fixing frame. The working end of the material push power unit is fixedly connected with one side of the bag holding device through a push-and-pull rod assembly so as to drive the bag holding device to slide leftwards and rightwards on the lower sliding rail. According to the material bag automatic filling and opening sealing integrationfacility, the empty woven bag is clamped by the automatic bag opening device, the bag holding device conducts bag holding operation on the material bag, the supporting and vibrating compaction devicecan vibrate materials in the material bag, the opening sealing portion conducts opening sealing operation on a feeding inlet of the material bag, and therefore the material filling, bag holding, vibrating compaction, opening sealing and discharging integration operation can be accomplished, the degree of automation is high, and the facility has the high market application value.

Owner:潘亚军

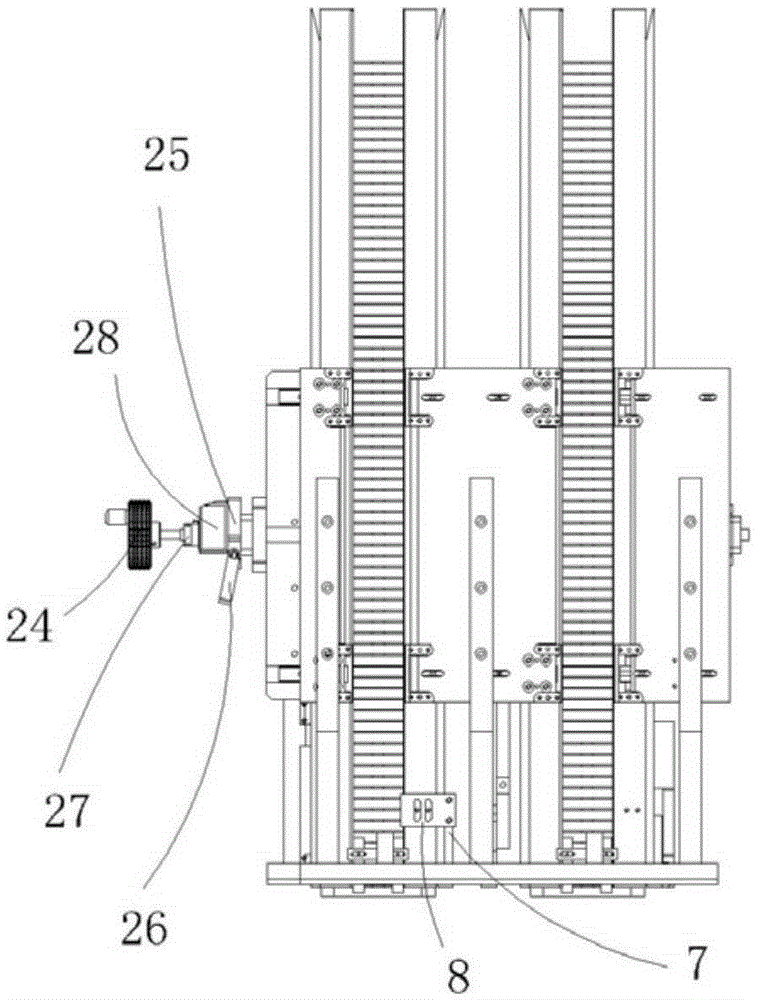

Feeding mechanism adaptive to products in different lengths

The invention relates to a feeding mechanism adaptive to products in different lengths. Front support blocks are installed on a front support block bottom plate, and a front installation plate is installed on the rear side of the front support blocks. Rear support blocks are installed on a rear support block bottom plate, and a rear installation plate is installed on the front side of the rear support blocks. Two sets of feeding carriers are installed between the front installation plate and the rear installation plate in a sliding mode and are the left feeding carrier and the right feeding carrier respectively. Multiple sets of products are stacked in each feeding carrier. A left-right adjustment assembly capable of adjusting the transverse intervals of the feeding carriers is installed on the rear installation plate. The feeding mechanism adaptive to the products in different lengths further comprises two supporting assemblies, each feeding carrier corresponds to one supporting assembly, and the supporting assemblies can support products in the feeding carriers. A discharging height adjustment stop block is installed on the rear side of the front supporting block bottom plate and provided with a discharging height adjustment block in an adjustable mode, and the discharging height adjustment block is used for preventing products on the upper layer from moving downwards along with products on the lower layer due to friction. The feeding mechanism can adapt to feeding of products in different lengths.

Owner:BOZHON PRECISION IND TECH CO LTD

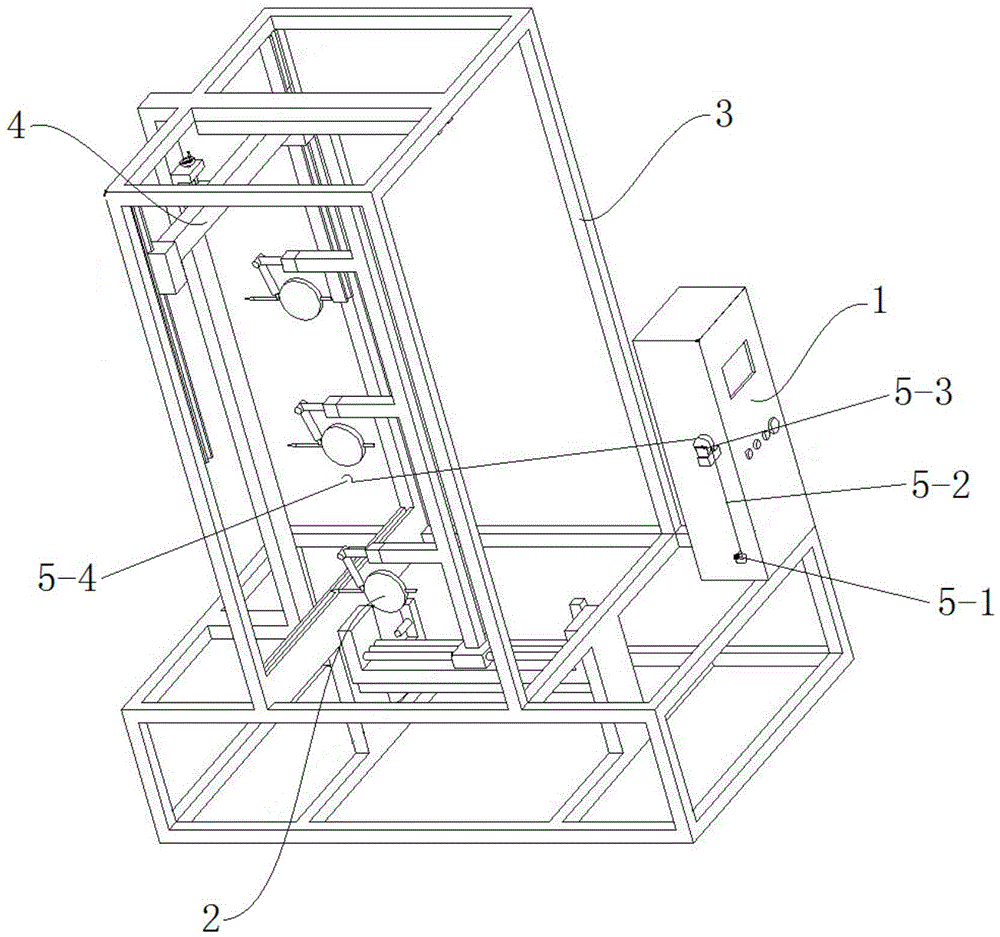

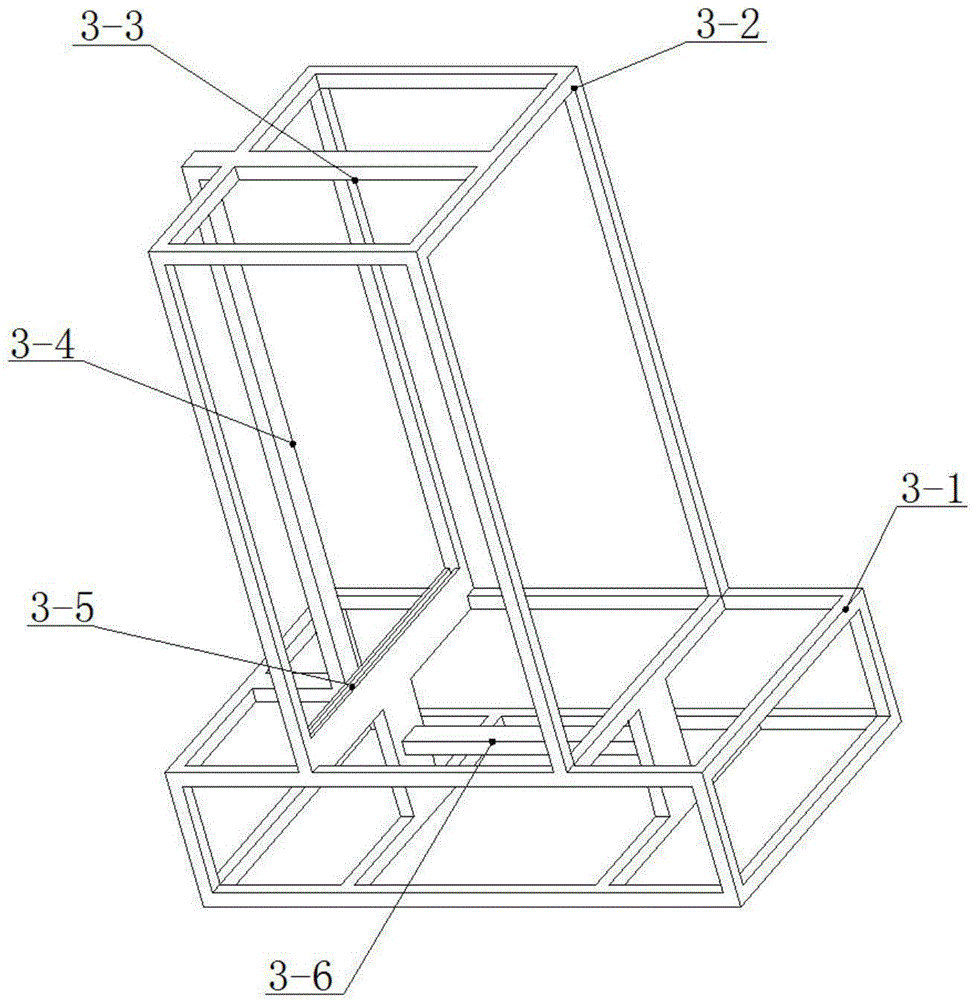

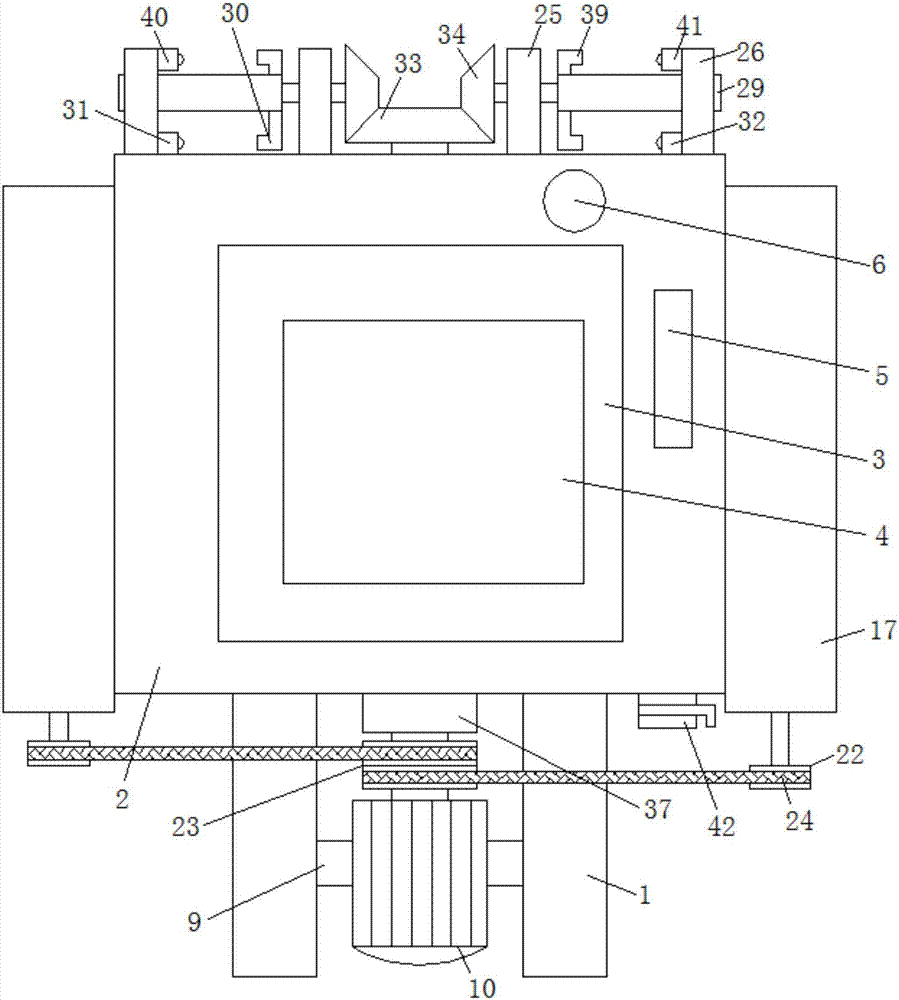

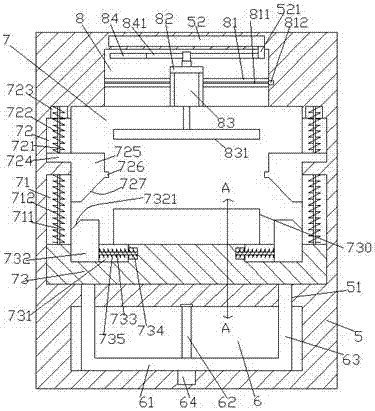

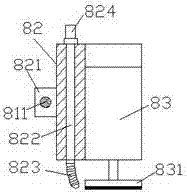

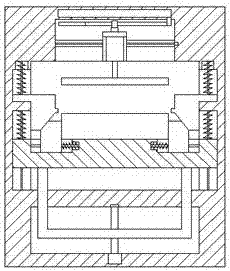

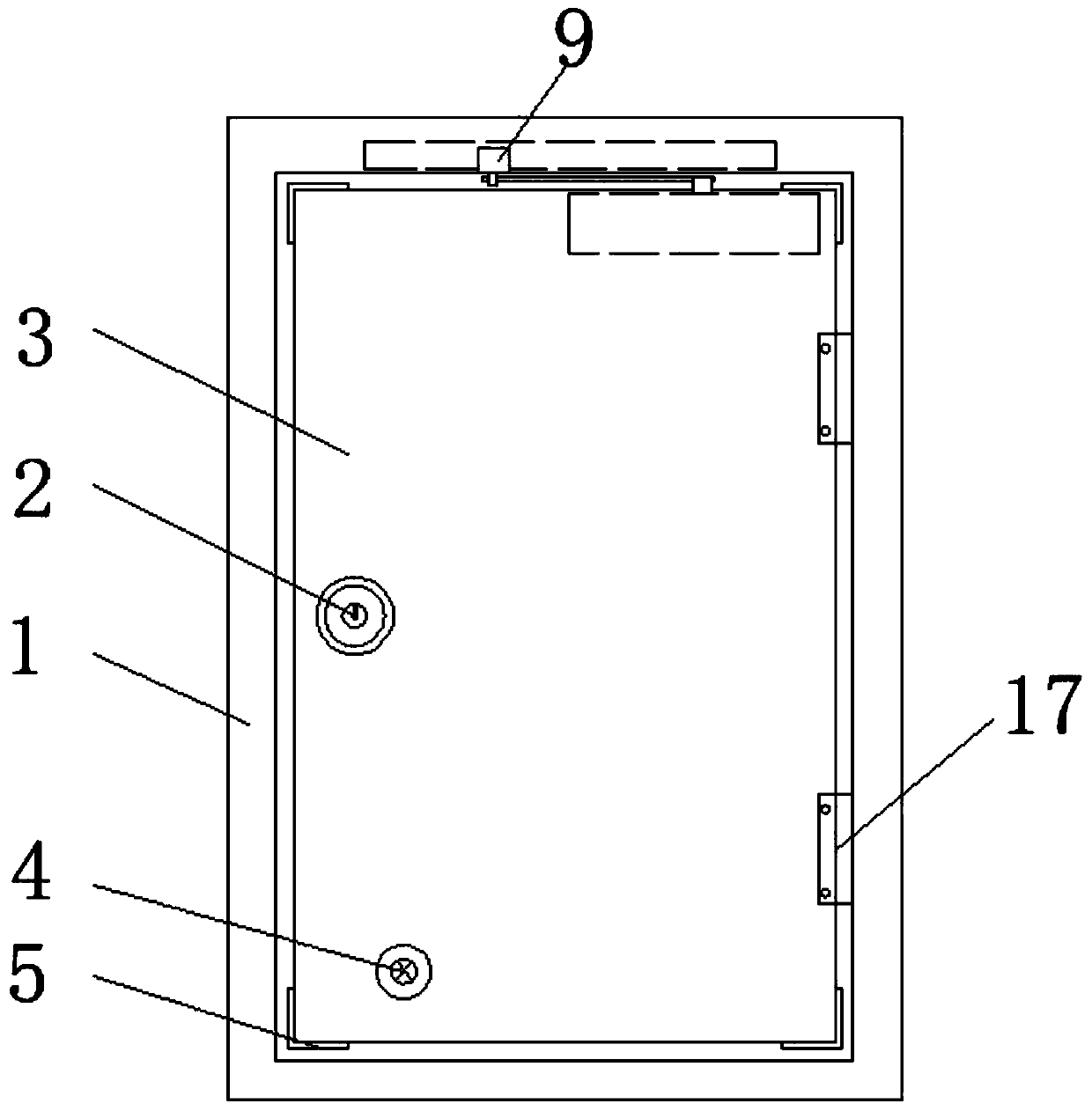

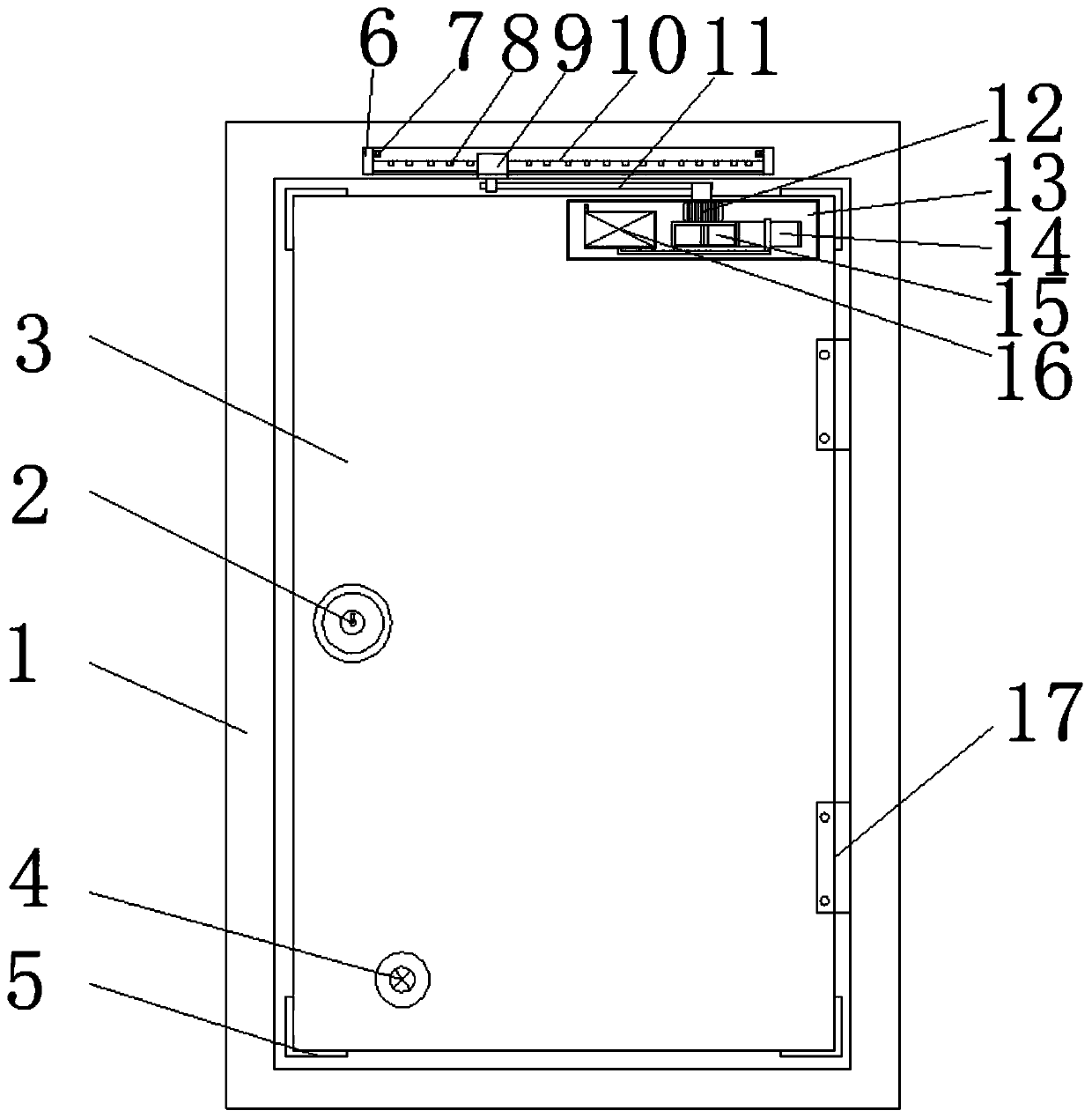

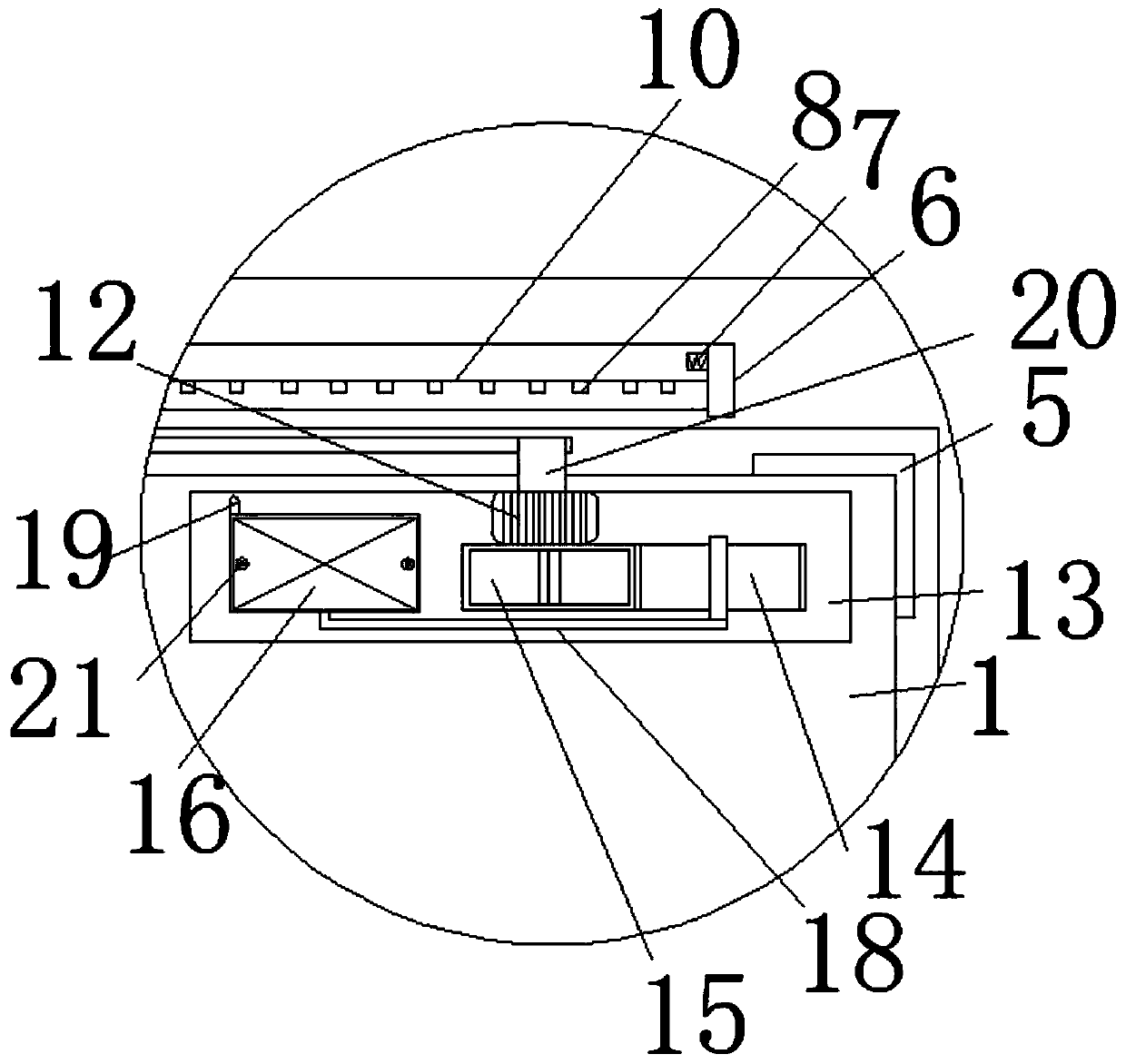

Quality detection device for door/window screen and using method thereof

ActiveCN104655444AEasy to set upThe test results are close to the realStructural/machines measurementDrive motorEngineering

The invention discloses a quality detection device for a door / window screen, belonging to the field of quality detection. The quality detection device disclosed by the invention comprises an overall frame, a screen clamping mechanism, a detection mechanism and a loading mechanism, wherein the screen clamping mechanism adjusts the relative height of a screen fixing rod on the overall frame by utilizing a tensioning mechanism; a screen fixing clamping groove is formed in the overall frame, and the upper and lower sides of a to-be-detected screen are clamped by virtue of the screen fixing clamping groove and the screen fixing rod; the detection mechanism comprises a driving motor, a lead screw sliding table, a support frame, a detection meter bracket, a digital indicator and a sliding rail; the lead screw sliding table is driven by the driving motor and is used for driving the support frame to move along the horizontal direction; a measuring head of the digital indicator faces the to-be-detected screen, and the digital indicator is positioned in the middle of the to-be-detected screen; and the loading mechanism hooks the to-be-detected screen by virtue of a hook so as to realize tension loading of the to-be-detected screen. The special detection device and method are designed according to the screen detection standard, the structure is simple, the detection is convenient, and the intelligent degree is high.

Owner:常州常工院技术转移有限公司

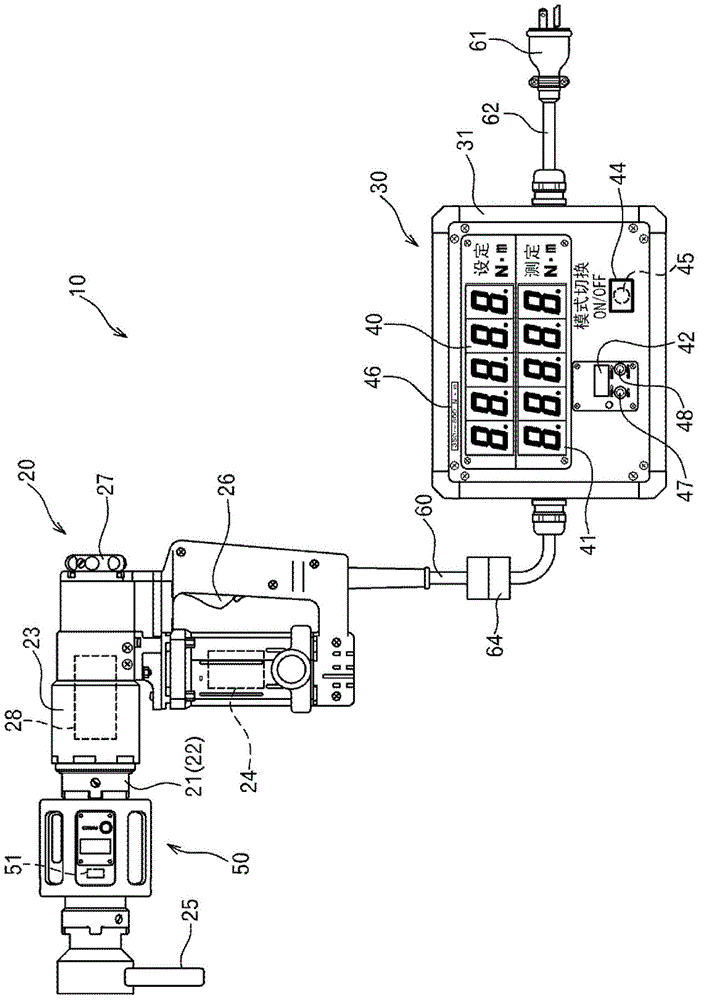

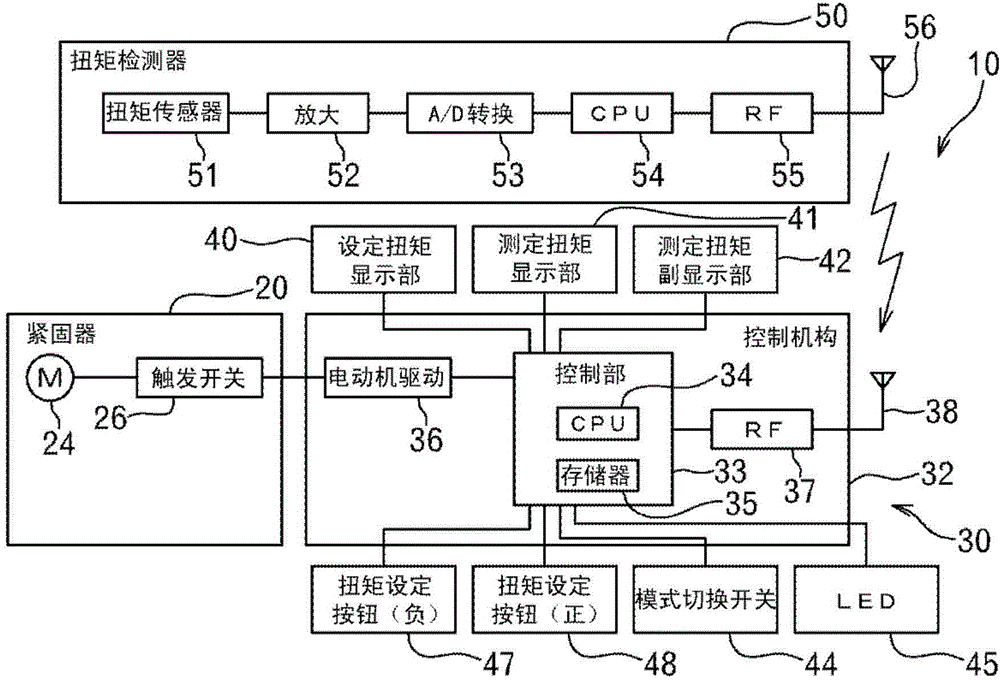

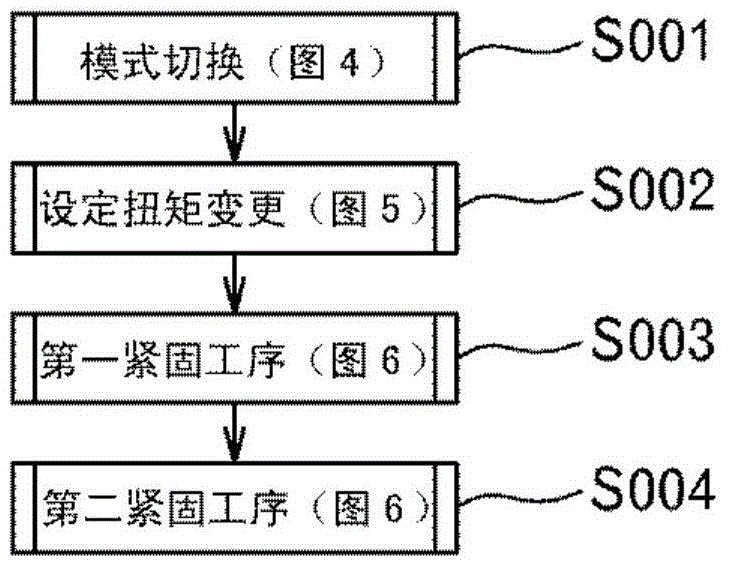

Tightening device

ActiveCN104589260ASmall initial outputAvoid tightnessMeasurement of torque/twisting force while tighteningWheel mounting apparatusPhysicsElectric motor

A tightening device is able to check that a fastening member has been fastened to a desired set torque or greater after being tightened, without loosening the fastening member. The tightening device is provided with a mode switching switch (44) for switching between a first tightening process of adjusting the output of a motor after measured torque that is measured by a torque detector (50) has reached a preset first control start torque, such that the measured torque reaches a preset first set torque in a phased manner through repeated increases and decreases in torque, and blocking power supply to the motor when the measured torque reaches the first set torque, and a second tightening process of driving the motor at an initial output that is less than in the first tightening process, adjusting the output of the motor after the measured torque that is measured by the torque detector has reached a preset second control start torque, such that the measured torque reaches a preset second set torque in a phased manner through repeated increases and decreases in torque, and blocking power supply to the motor when the measured torque reaches the second set torque.

Owner:TONE CO LTD +1

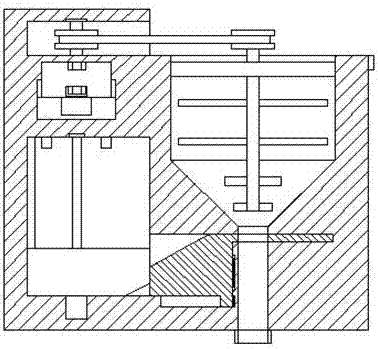

Automatic stirring and feeding equipment for pig raising

InactiveCN107306824AControl to move left and rightRealize automatic reset workTransportation and packagingRotary stirring mixersAutomatic controlEngineering

The invention discloses automatic stirring and feeding equipment for pig raising. The equipment includes a housing, the left side of the housing is internally provided with a first sliding cavity, the inner wall of the left side of the first sliding cavity is provided with a first guide groove, the portion, on the right side of the first sliding cavity, of the housing is internally provided with a second sliding cavity communicated with the first sliding cavity, the portion, on the right side of the second sliding cavity, of the housing is internally provided with a discharge hole extending up and down, the top of the second sliding cavity is provided with a partition plate guide groove which transversely penetrates through the discharge hole and extends to the right side, the top of the discharge hole is provided with a funnel-shaped hopper, the top of the funnel-shaped hopper is provided with a feeding hopper, the portion, above the first sliding cavity, of the housing is internally provided with a third sliding cavity, the inner walls of the left side and the right side of the third sliding cavity are symmetrically provided with third guide grooves, a threaded rod is arranged in the first sliding cavity, the bottom of the threaded rod is in powered connection with a first motor, and the threaded rod is connected with a moving block in a screw-thread fit mode. According to the equipment, the structure is simple, the design is reasonable, the operation is simple, the manufacturing cost and the maintenance cost are very low, the equipment is suitable for small and medium-sized farmers to use, feeding work can be automatically controlled and the labor amount of workers is reduced.

Owner:朱娟红

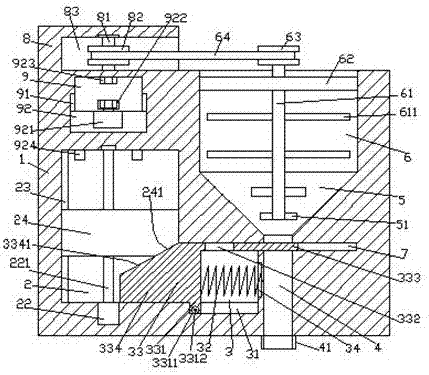

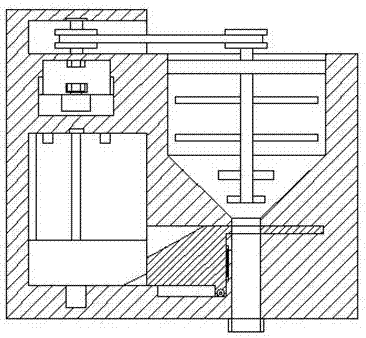

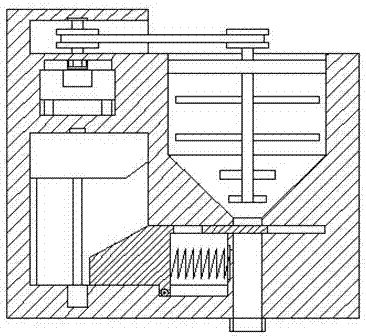

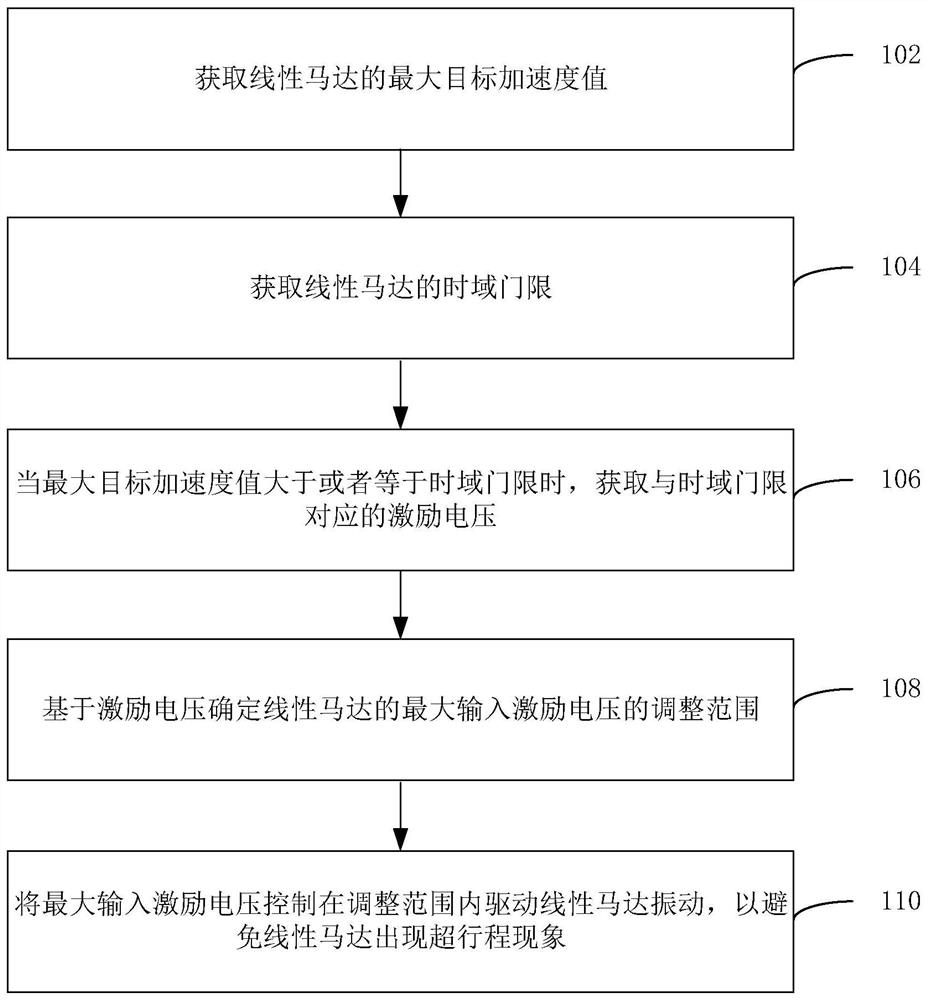

Linear motor overtravel control method and device, computer equipment and storage medium

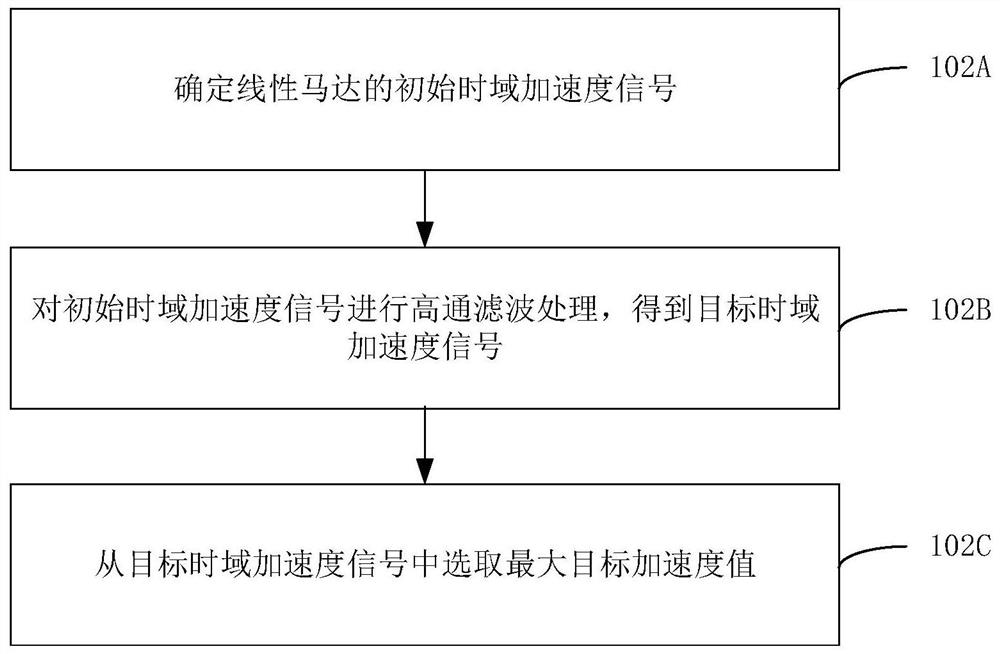

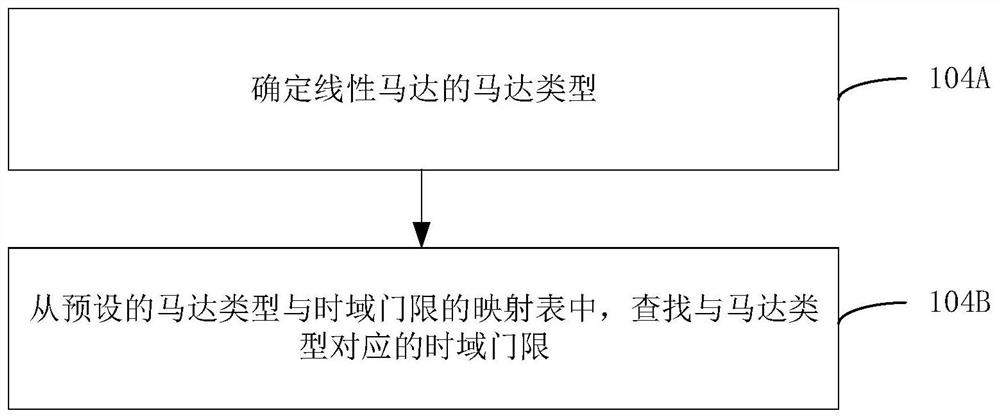

ActiveCN112491323APrevent overtravelSolve the problem of poor haptic effectMotor parameters estimation/adaptationComputer equipmentLinear motor

The embodiment of the invention discloses a linear motor overtravel control method. The method comprises the following steps: acquiring a maximum target acceleration value of the linear motor; obtaining a time domain threshold of the linear motor, wherein the time domain threshold is the maximum acceleration when the linear motor does not have an overtravel phenomenon; when the maximum target acceleration value is greater than or equal to the time domain threshold, acquiring an excitation voltage corresponding to the time domain threshold; determining an adjustment range of a maximum input excitation voltage of the linear motor based on the excitation voltage; and controlling the maximum input excitation voltage to be within the adjustment range to drive the linear motor to vibrate, so that the overtravel phenomenon of the linear motor is avoided, the tactile feedback effect of the linear motor is improved, and the structural design efficiency is improved. In addition, the invention further provides a linear motor overtravel control device, computer equipment and a storage medium.

Owner:RUISHENG NEW ENERGY DEV CHANGZHOU +1

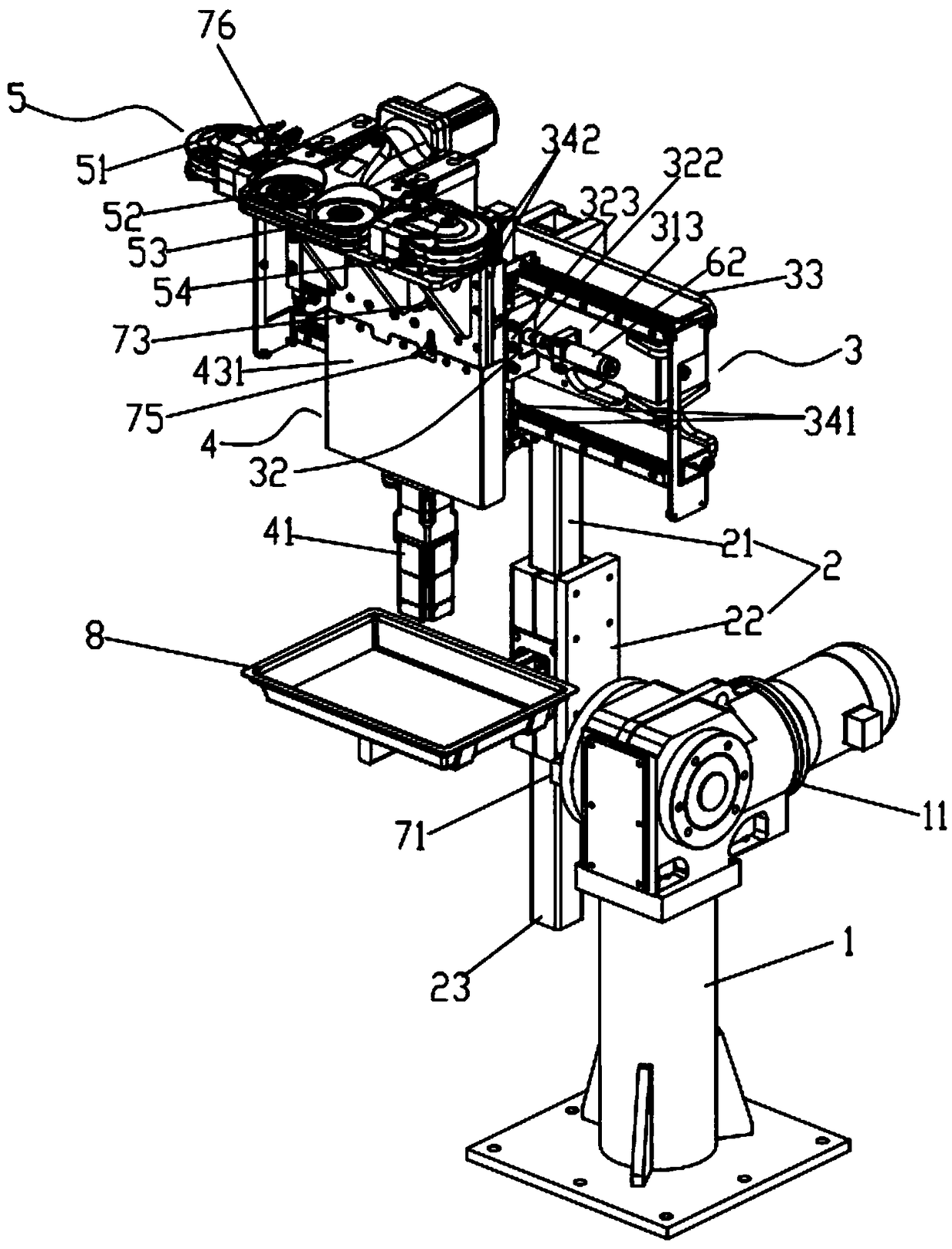

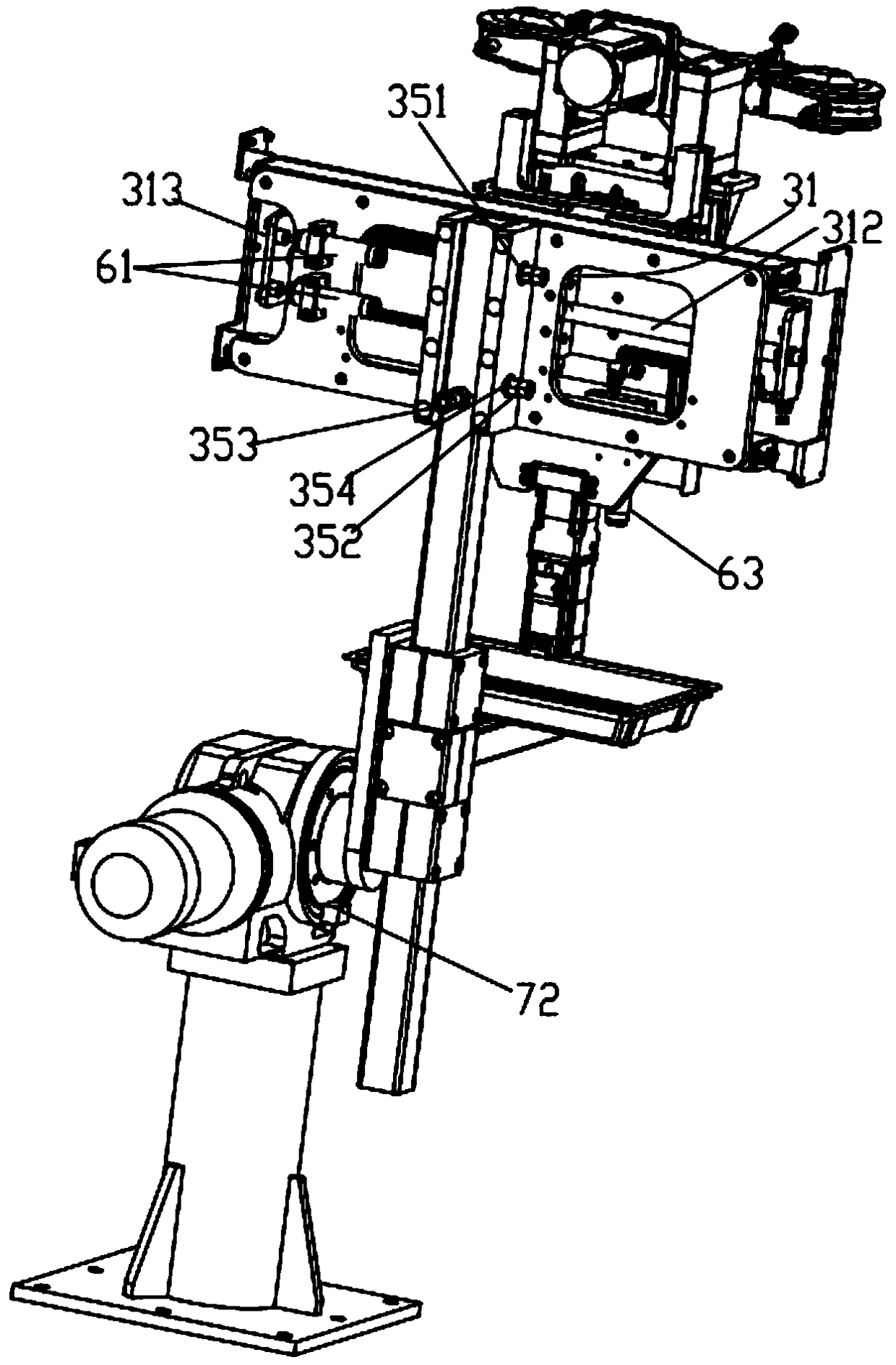

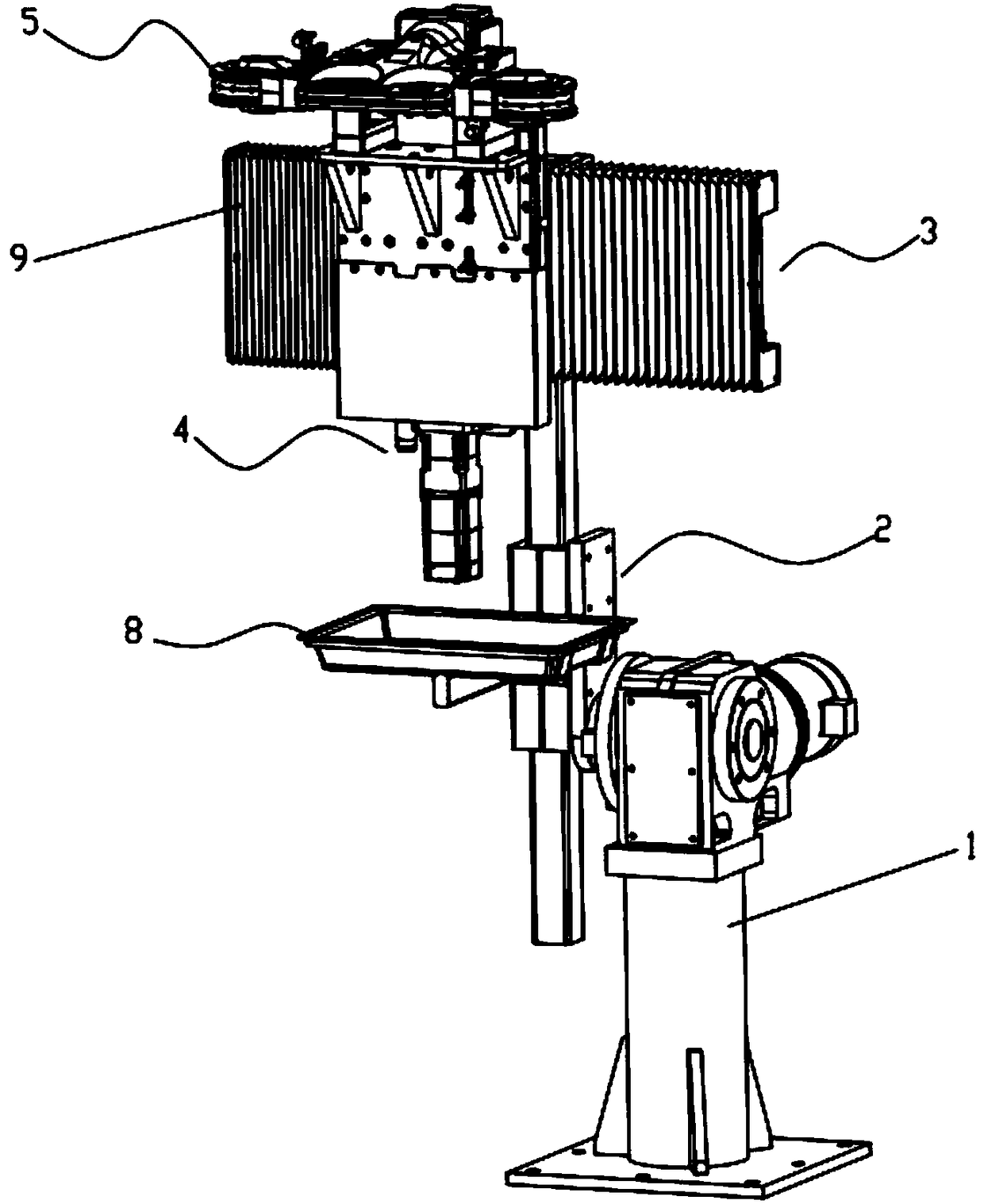

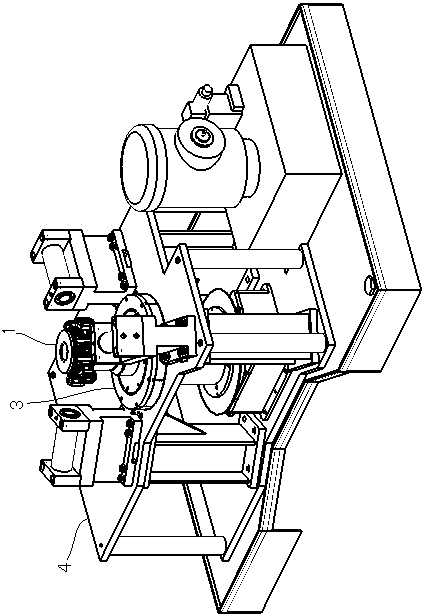

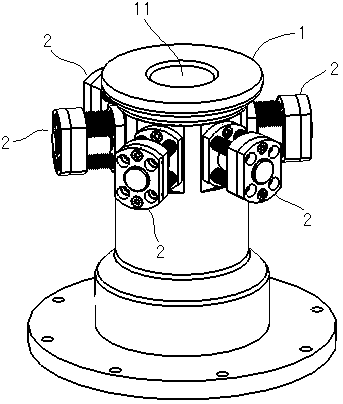

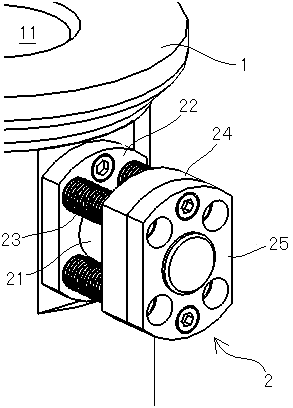

Swing arm all-in-one machine for overhauling electrode cap

ActiveCN108213958APrecise positioningAvoid interferenceOther manufacturing equipments/toolsEngineeringIntegrated devices

The invention relates to the technical field of welding, in particular to a swing arm all-in-one machine for overhauling an electrode cap. The swing arm all-in-one machine comprises a mounting machineframe, a swing arm assembly, an X-axis movement assembly, a Z-axis movement assembly, an electrode cap automatic disassembly and grinding integrated device and a controller. According to the swing arm all-in-one machine, the electrode cap automatic disassembly and grinding integrated device can be positioned automatically, and the electrode cap of a welding machine can be automatically ground, disassembled and replaced, the swing arm all-in-one machine can be applied to a fixed welding machine, and the influence of interference on welding operation of fixed welding is avoided.

Owner:GUANGZHOU KYOKUTOH CHINA

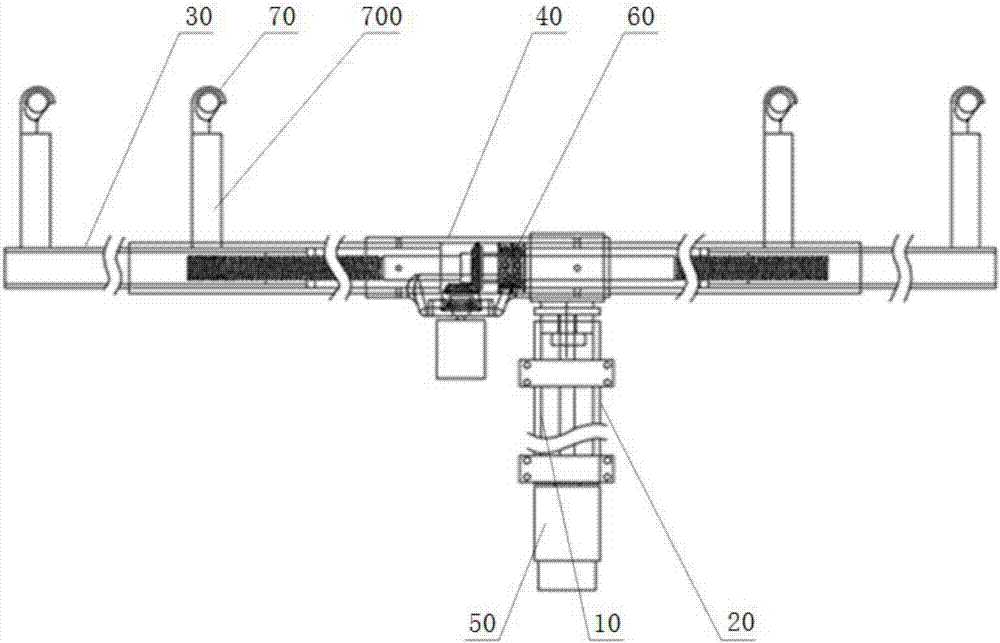

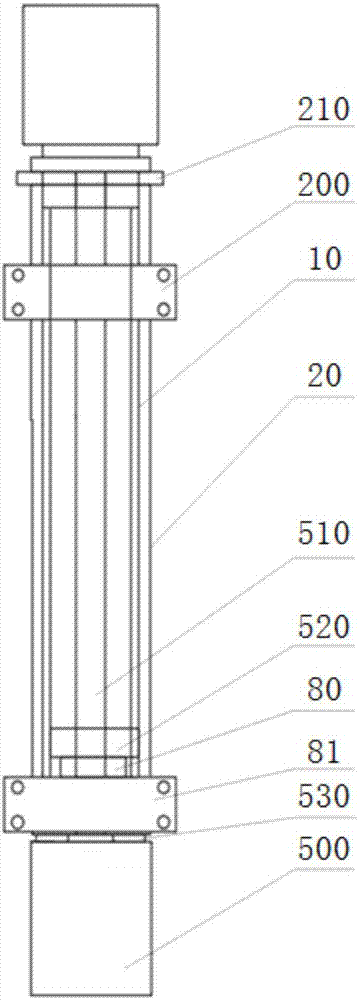

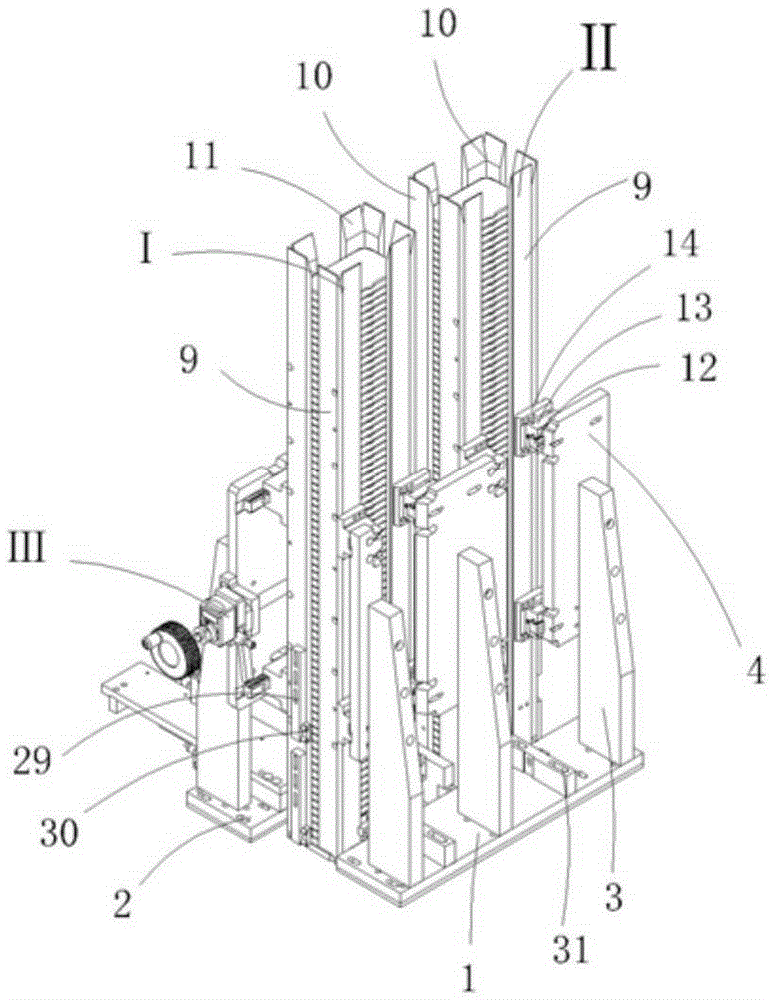

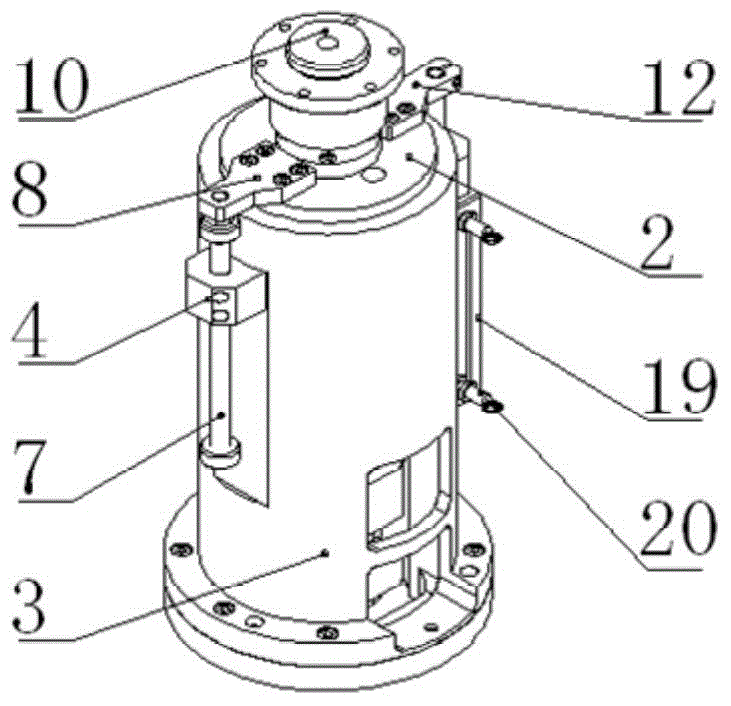

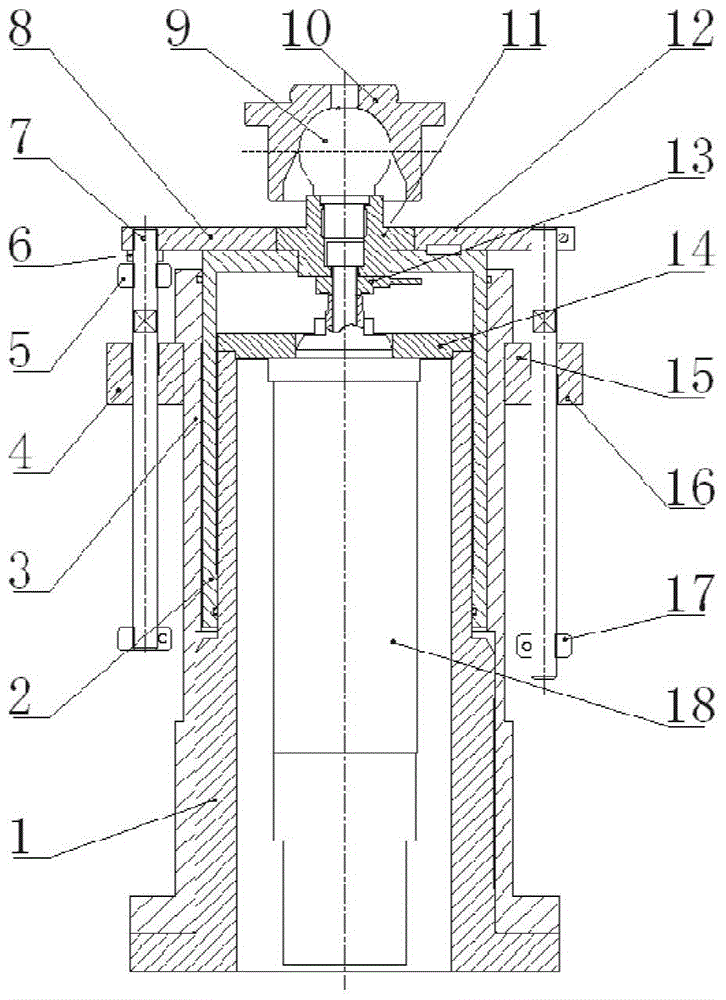

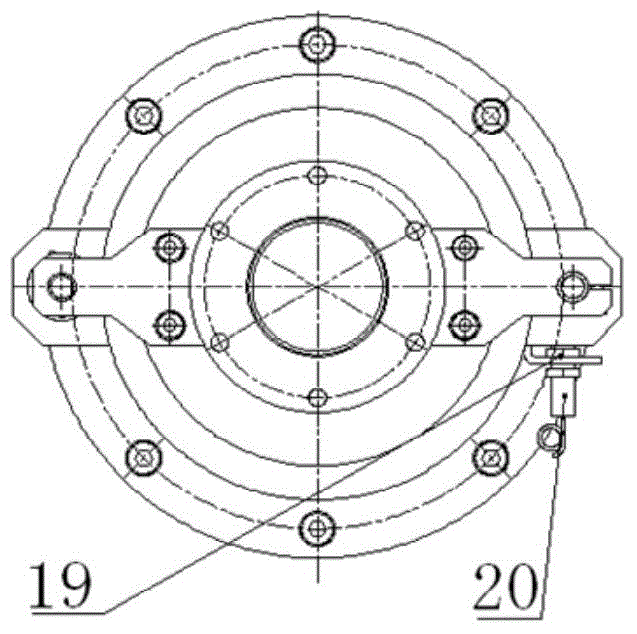

Vertical supporting device

The invention relates to a vertical supporting device which comprises an inner guiding base and an outer guiding sleeve located on the outer layer of the inner guiding base, wherein a guiding pillar which can slide along the axial direction is disposed between the inner guiding base and the outer guiding sleeve, a motor installation base is installed on the end part of the inner guiding base, a servo electric cylinder is placed inside the inner guiding base and fixed with the motor installation base, a connecting base connected with a push rod of the servo electric cylinder is installed on the guiding pillar, a supporting bulb is installed on the connecting base, and the supporting bulb is placed on a ball socket supporting base to form ball joint floating supporting; and an anti-rotation connecting plate is fixed on the guiding pillar, an anti-rotation base is fixed on the side wall of the outer guiding sleeve, an anti-rotation rod is disposed in parallel with the axial direction of the push rod of the servo electric cylinder, one end of the anti-rotation rod is fixed on the anti-rotation base, and the other end passes through a guiding hole in the anti-rotation base. A guiding part and a transmission part coincide at positions and heights, and both the inner guiding and the outer guiding are adopted in the guiding pillar to keep good guiding performance and rigidity. As vertical guiding, the guiding pillar has large rigidity, so that guiding deviation caused by force carrying does not take place.

Owner:WENZHOU UNIVERSITY

Double-pawl intermittent rotating mechanism

InactiveCN105179626ARealize intermittent rotationPrevent overtravelGearingEngineeringMechanical engineering

The invention discloses a double-pawl intermittent rotating mechanism which is high in acting efficiency and long in service life. The double-pawl intermittent rotating mechanism comprises a swing rod, a first pawl, a second pawl and a ratchet wheel. A supporting shaft is hinged to the middle of the swing rod and the swing rod can swing in a reciprocating manner with the supporting shaft as a fulcrum. The lower end of the swing rod is hinged to the V-shaped first pawl. The middle of the first pawl is connected with a first tension spring. The end face of the first pawl is a slope matched with the toothed face of the ratchet wheel in shape. When the swing rod o swings clockwise, the first pawl can push the ratchet wheel to rotate. The side, the same as the first pawl, of the upper end of the swing rod is hinged to the V-shaped second pawl. The middle of the second pawl is connected with a second tension spring. The end face of the second pawl is a slope matched with the toothed face of the ratchet wheel in shape. When the swing rod swings anticlockwise, the second pawl can push the ratchet wheel to rotate.

Owner:CHONGQING YUKUNLONG METALLURGICAL MATERIAL CO LTD

Chip manufacturing based storing device with protective structure

InactiveCN111591551AEasy to stackGood protective structureSealingNon-removalbe lids/coversTorsion springChip fabrication

The invention belongs to the technical field of storing devices and particularly relates to a chip manufacturing based storing device with a protective structure. The chip manufacturing based storingdevice comprises a storing device main body and a clamping buckle; a sliding plate is mounted in the storing device main body; a pushing block is arranged on the outer side of the sliding plate; a limiting rod is mounted on the outer wall of the pushing block; a first spring is arranged on the edge side of the limiting rod; a mounting block is mounted on the edge side of the first spring; an opening-closing door is mounted on the outer wall of the storing device main body; a first rotary shaft penetrates through the opening-closing door; a torsional spring is arranged on the edge side of the first rotary shaft; a slot is formed in the outer wall of the sliding plate; a fixture block is mounted on the inner wall of the storing device main body; and a pull rod is arranged on the outer wall of the fixture block. The chip manufacturing based storing device can be automatically fixed after a chip placing disc is accommodated, has a better protective structure and better vibration reducing effect and can be conveniently placed in a superposed manner.

Owner:申启蕾

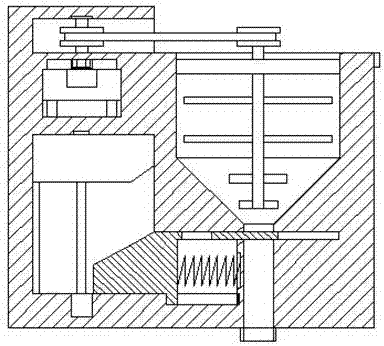

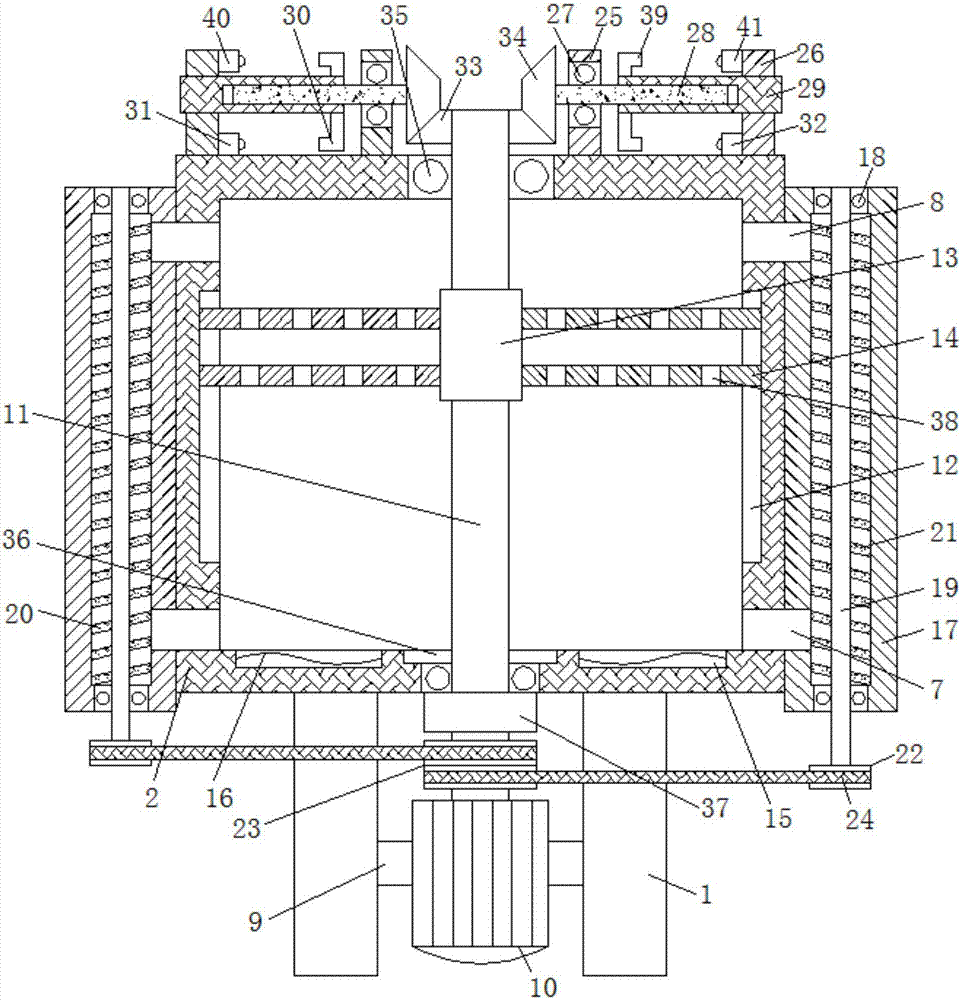

High voltage circuit breaker air cylinder riveting die

ActiveCN103978111ALow costReduce the number of partsShaping toolsElectric switchesPunchingCircuit breaker

The invention discloses a high voltage circuit breaker air cylinder riveting die which is arranged on an air cylinder riveting machine frame. The die comprises a die body and a plurality of groups of punching units radially connected onto the periphery of the die body. A cavity used for containing workpieces is axially arranged in the middle of the die body, and punches of the punching units can be punched into the cavity in the radial direction. The punching units serve as a whole. When some parts are damaged, users can simply replace the corresponding parts. The die is convenient and reduces cost. The punches have functions of guiding and punching, the part number of the punching units is saved, the punching units are simple in structure, and the cost is reduced.

Owner:深圳中清创力智能科技有限公司

Automatic circulating device of printing, dyeing and boiling-off

InactiveCN107338603AAchieve the effect of sliding up and down cycle cookingTo achieve the effect of circular cookingTextile treatment containersTextile treatment machine arrangementsCouplingEngineering

The invention discloses an automatic circulating device of printing, dyeing and boiling-off. The device comprises supporting legs, a boiling-off tank is fixedly connected with the tops of the supporting legs, a water inlet and a water outlet are formed in the top and the bottom of the boiling-off tank respectively, circulation inlets and circulation outlets are formed in the inner bottom wall and the inner top wall of the boiling-off tank respectively, a supporting plate is fixedly connected with the middles of the supporting legs, a stirring motor is fixedly connected with the middle of the supporting plate, a first threaded rod is fixedly connected with the output shaft of the stirring motor through a coupling, and the top of the first threaded rod penetrates the boiling-off tank and extends to the upper surface of the boiling-off tank. According to the automatic circulating device of printing, dyeing and boiling-off, the effect that circulating boiling-off is conducted on material to be boiled off in a vertically sliding mode is achieved, the material to be boiled off is placed in a cavity in the middle portion of a placing rod, a first threaded tube drives the material to be boiled off to slide vertically after being connected with the first threaded rod, and the effect that vertical circulation is conducted on hot water in the boiling-off tank is achieved, so that the problem that the temperature is likely to be uneven is solved.

Owner:范威

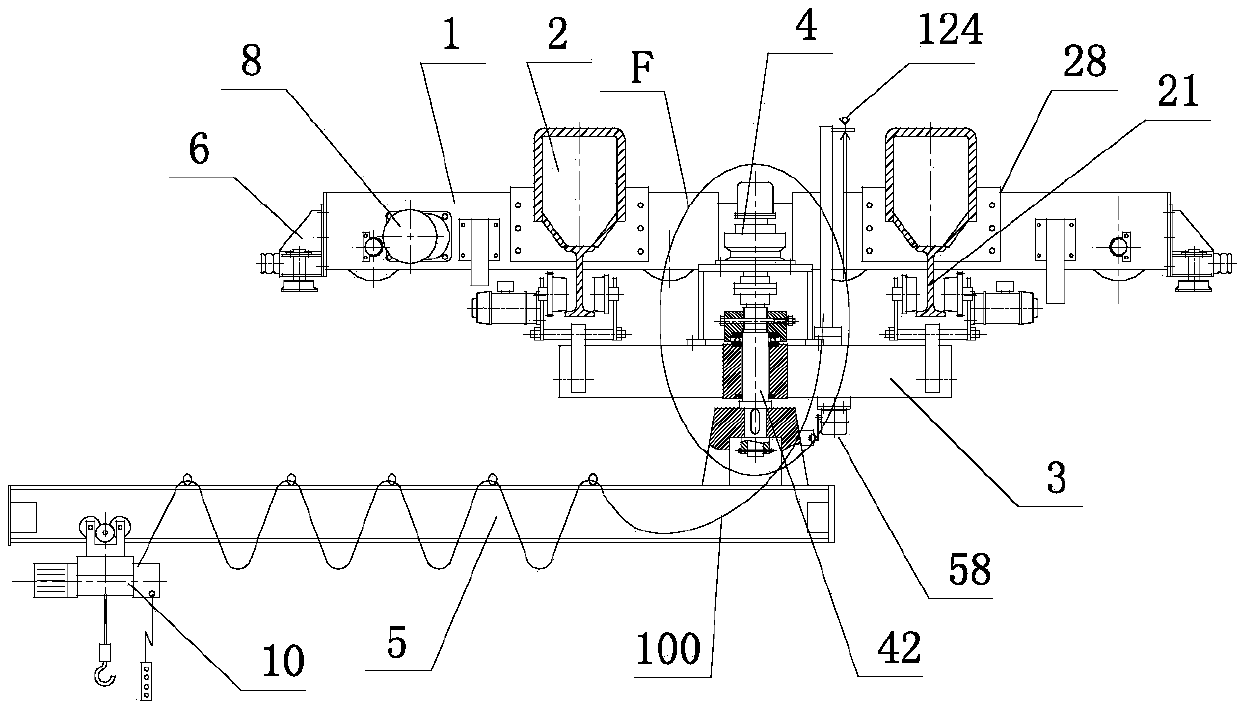

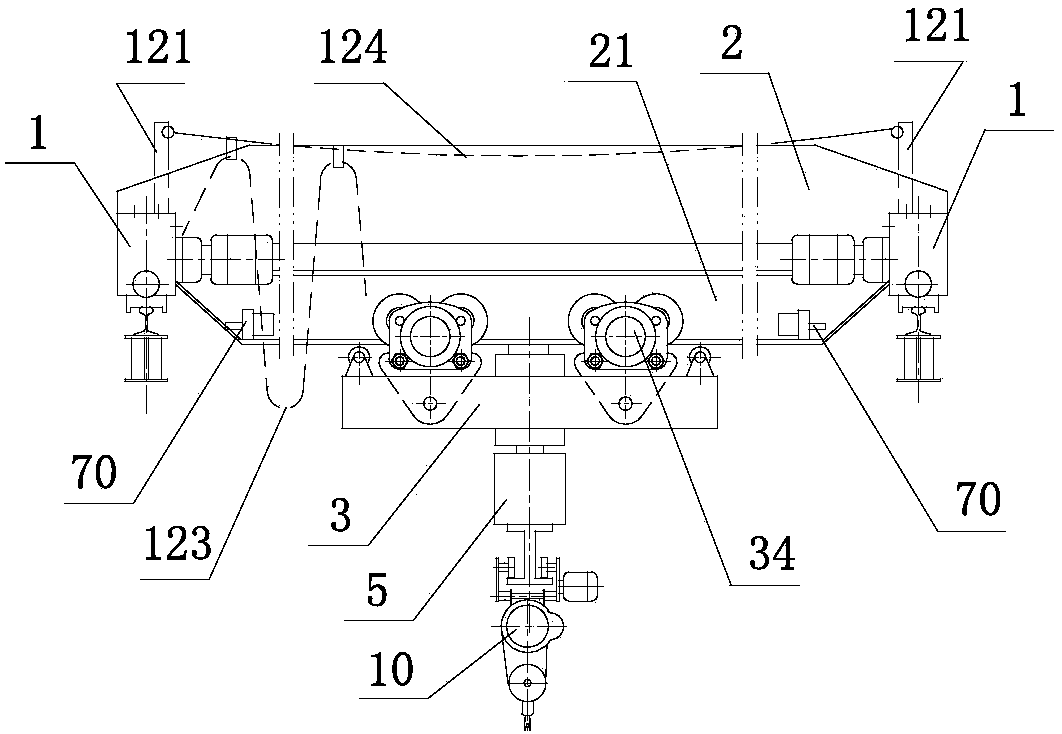

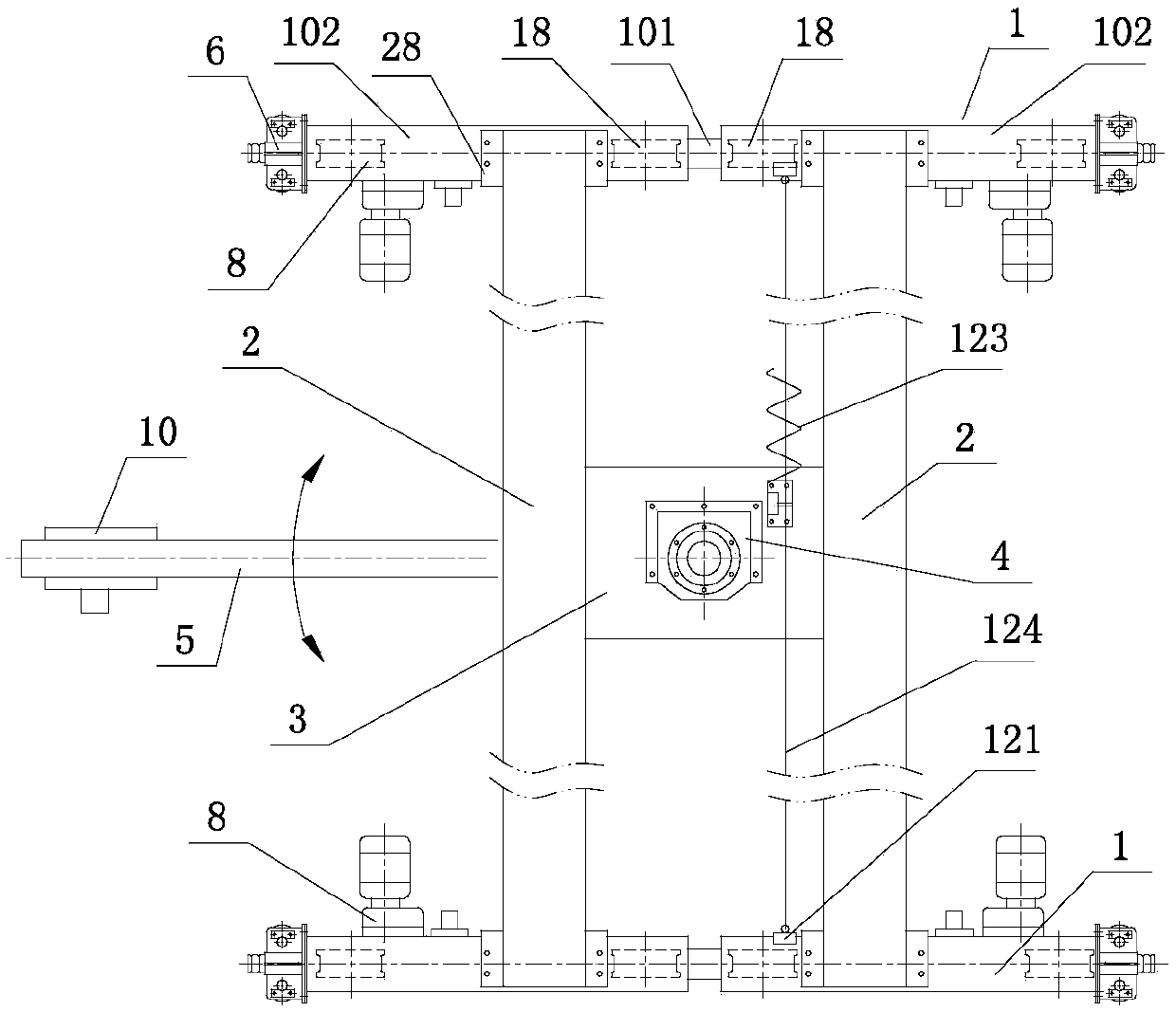

Cantilever crane with suspended car and balance end beams

InactiveCN107777580AImprove efficiencySmall installation spaceTravelling cranesTravelling gearEngineeringCantilever

The invention discloses a cantilever crane with a suspended car and balance end beams. The cantilever crane comprises a double girder bridge which comprises end beams and a main beam; the end beams are formed by connecting the two balance end beams and a connecting rod between the two balance end beams; one ends of the balance end beams are connected with cart driving devices, and the other ends of the balance end beams are connected with driven wheel sets; the two ends of the end beams are each connected with a horizontal wheel device, and rails are arranged below the main beam; a car bumperis arranged on the rails, and the suspended car is connected to the rails and provided with a rotary mechanism; a suspender shaft in the rotary mechanism is connected with a cantilever component whichis provided with a rotary limiting device, and an electric hoist is mounted on the cantilever component and can horizontally move along a cantilever beam which is located below the main beam and canrotate; and two wire suspending frames are arranged on the double girder bridge, and a steel cable rail is connected between the wire suspending frames and connected with a suspended cable.

Owner:谢新华

Waste treatment equipment

ActiveCN106976268ALimit the maximum push slip distanceLimit push slip distanceShaping pressTransverse grooveVolumetric Mass Density

The invention discloses waste treatment equipment which comprises a main body. An extruding cavity is formed in the main body; a regulating cavity is formed in the position, on the lower portion of the extruding cavity, in the main body; a transverse groove is formed in the inner top wall of the extruding cavity in a left and right extending mode; a sliding block is arranged in the transverse groove; an extruding power device is fixedly arranged on the end face of the front side of the sliding block; the bottom of the extruding power device is provided with an extruding head which stretches into the extruding cavity and is rotatably connected with the extruding cavity in a matched mode; first guiding grooves and second guiding grooves formed in the upper portions of the first guiding grooves are formed in the inner side faces of the left side and the right side of the extruding cavity correspondingly; first guiding rods are arranged in the first guiding grooves in an up and down extending mode; and first square grooves are formed in the inner top walls of the second guiding grooves. The waste treatment equipment is simple in structure, waste can be extruded into waste blocks with different sizes and different densities according to different requirements, the size is reduced, the landfill space is saved, the deodorization effect is good, the requirement of extrusion work of the waste in waste boxes with different specifications is met, self fixation can be achieved, and the working efficiency is high.

Owner:天长市天香源粮油食品有限公司

Hidden automatic opener of electric control side-hung door

InactiveCN110499991ARealize automatic controlTorque stabilizationBuilding braking devicesWing fastenersAutomatic controlEngineering

The invention discloses a hidden automatic opener of an electric control side-hung door. The hidden automatic opener comprises a door frame, one side of the door frame is rotationally connected with adoor leaf through a hinge, and one end of the door frame is fixedly connected with a slide rail in an embedded mode. According to the hidden automatic opener, by arranging a PLC driving panel, control commands of upper devices are converted,a direct current motor is driven to rotate,so as to form stable torque, a sliding block moves to support a connection shaft to support openthe door leaf, andclose the door leaf, so as to realize automatic control fordoor opening and closing,the speed is adjusted by a deceleration gear and a torque limiting wheel to obtain stable torque, control of angle opening and closing can be realized by arranging limiting teeth in the slide rail, and over run is effectively avoided bylimit stopping blocks on both sides and anti-collision springs. According to thehidden automatic opener, automation of the side-hung door can be effectively improved, home intelligent can be effectively achieved, the structure is simple, and beauty and integrity are high.

Owner:傅勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com