Stonecutting apparatus and method using saw and water jet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

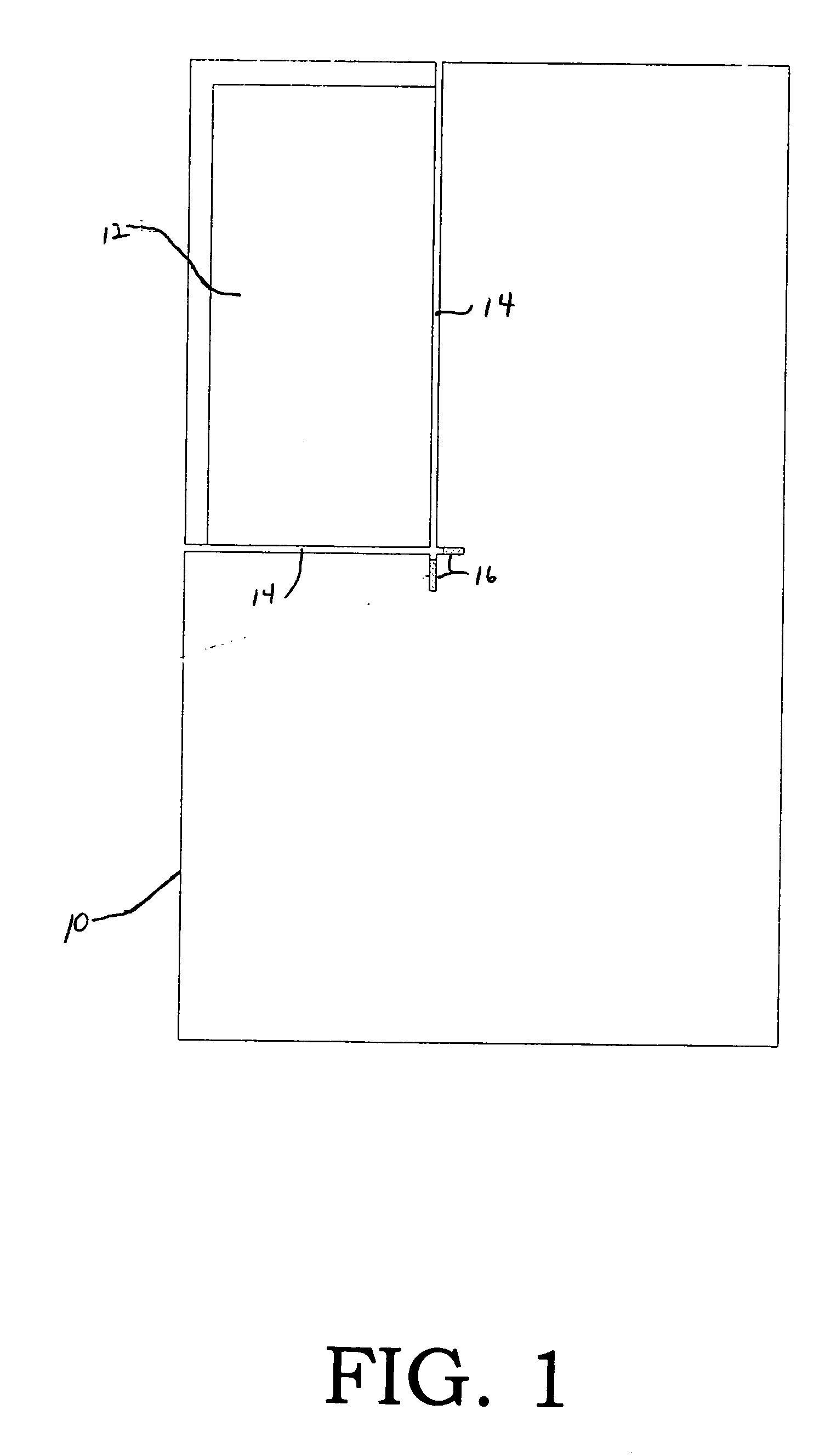

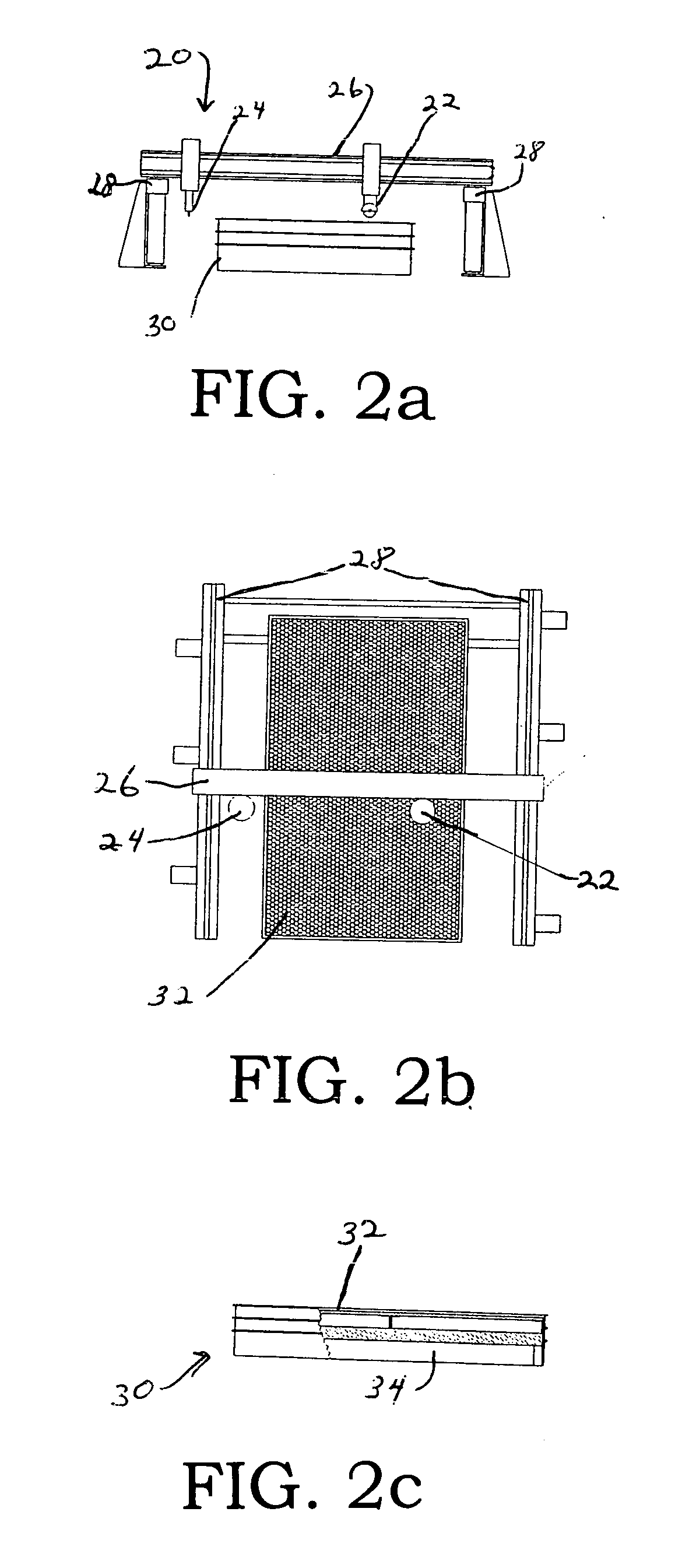

[0024] Referring now to the drawings, wherein like reference characters designate identical or corresponding parts throughout the several views, and more particularly in FIG. 2a, where a front view of the present apparatus 20 is shown. The cutting apparatus includes a saw 22 and a water jet machine 24 both mounted on a traveling gantry 26. The gantry is mounted on tracks 28 which extend along the length of the apparatus. The traveling gantry extends perpendicularly to the tracks and is movable in the longitudinal direction of the tracks.

[0025] A residue tank 30 is placed below the gantry and is used to collect the water and residue from the cutting operations. The top of the tank is a support grating 32 on which the stone slab or other workpiece is placed. The support grating has multiple holes through which the water and other residue can travel. The lower portion 34 of the tank merely acts as a container for receiving and storing the water and residue, which travels through the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Efficiency | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com