Patents

Literature

466 results about "Water jet cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

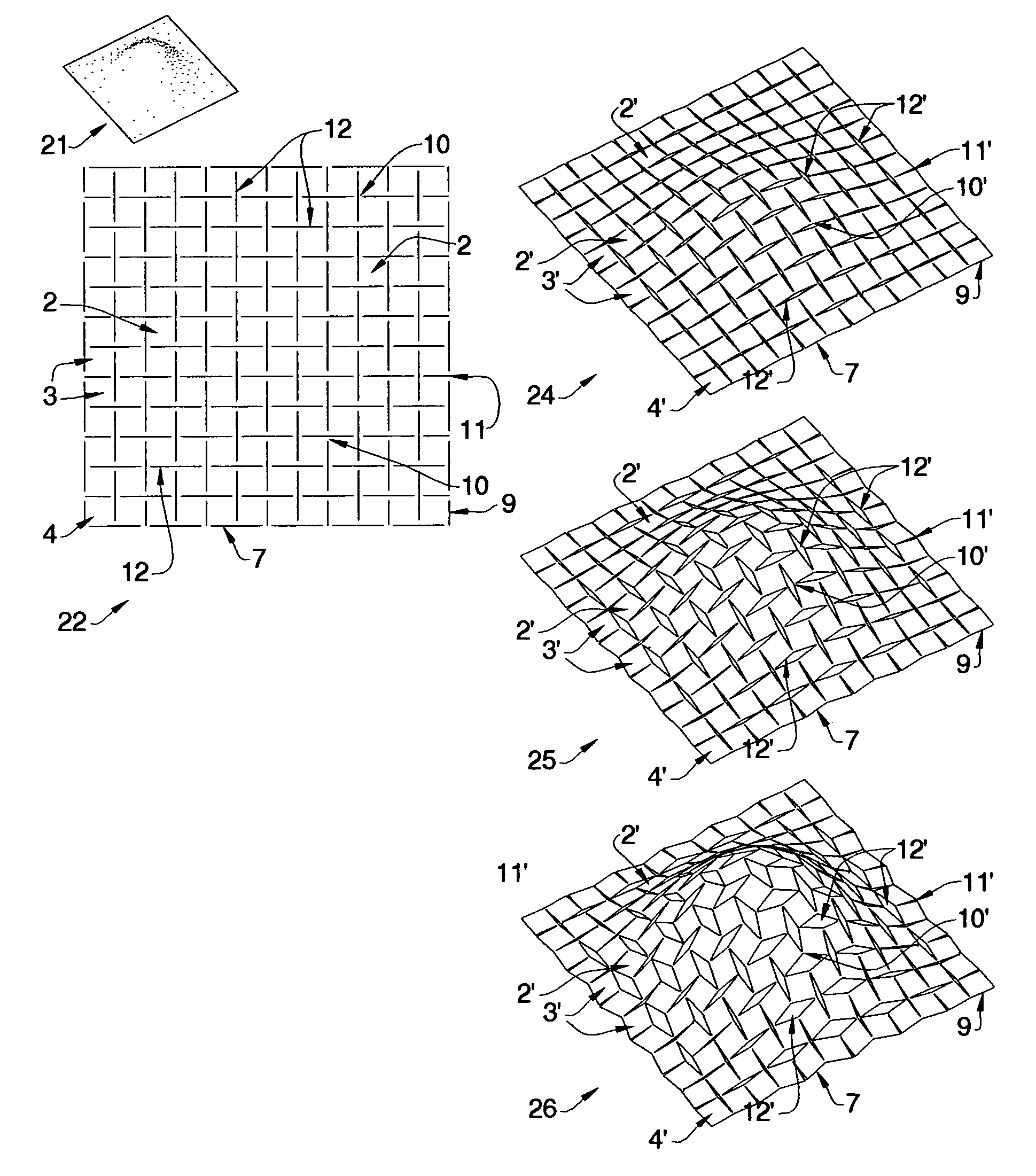

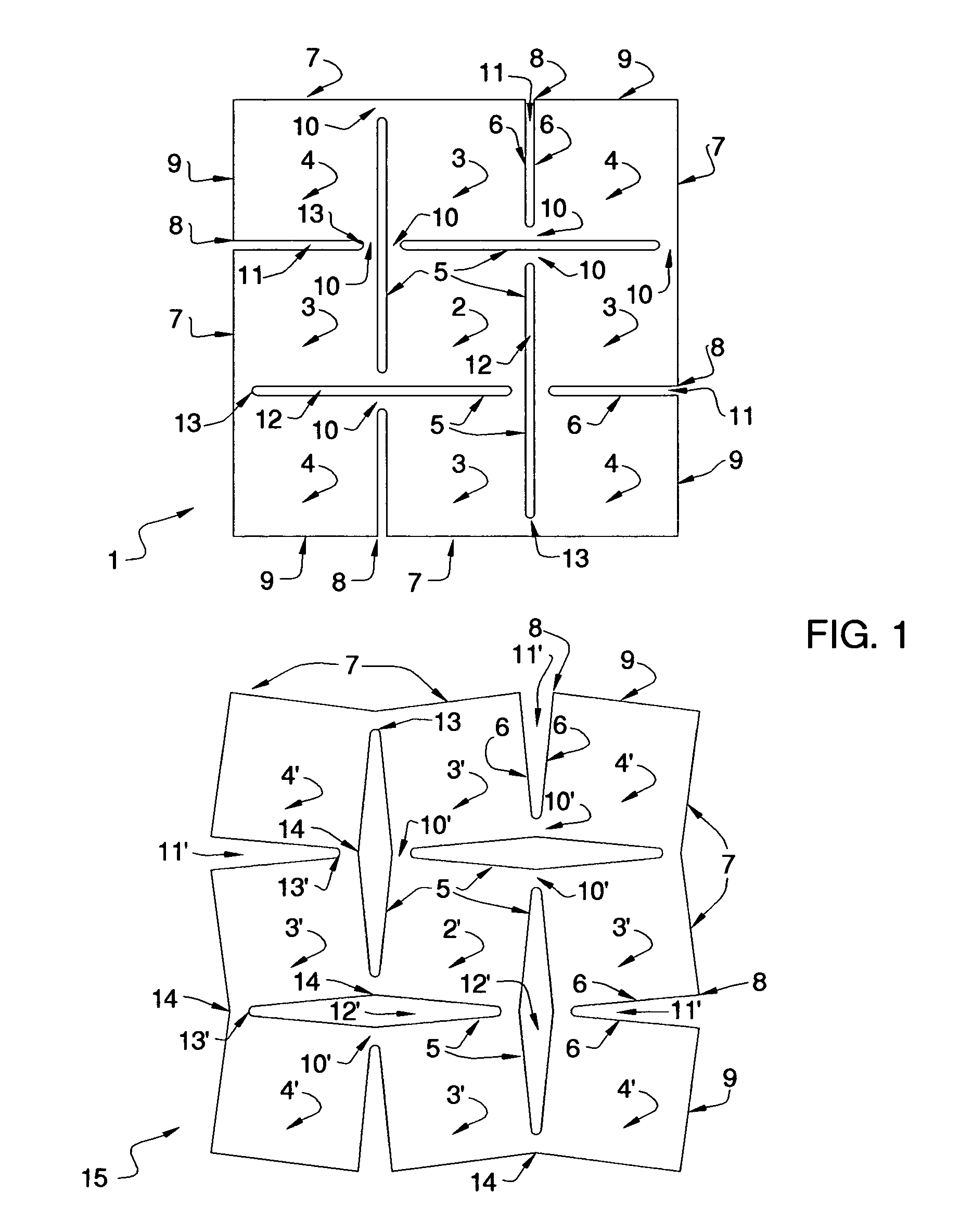

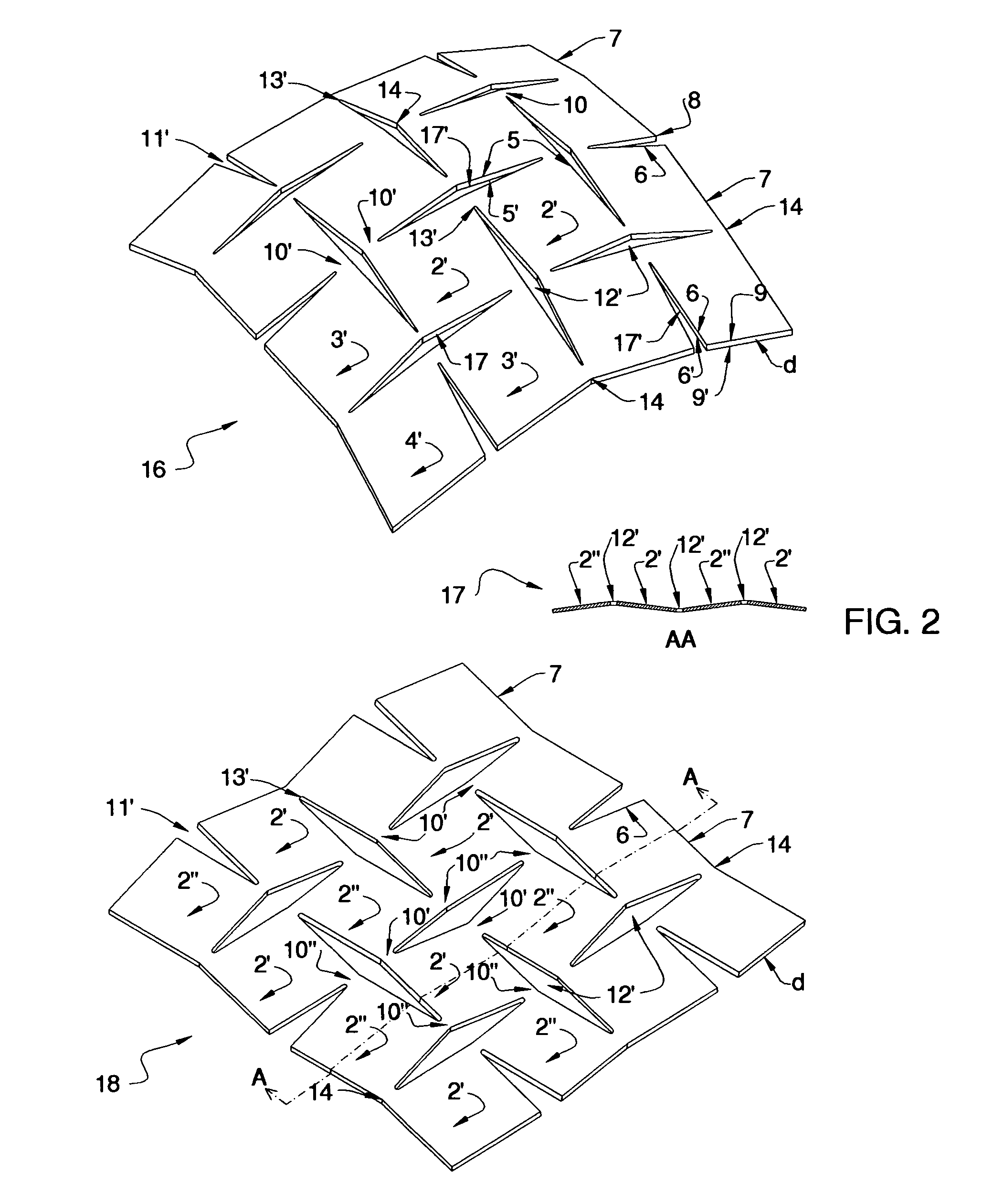

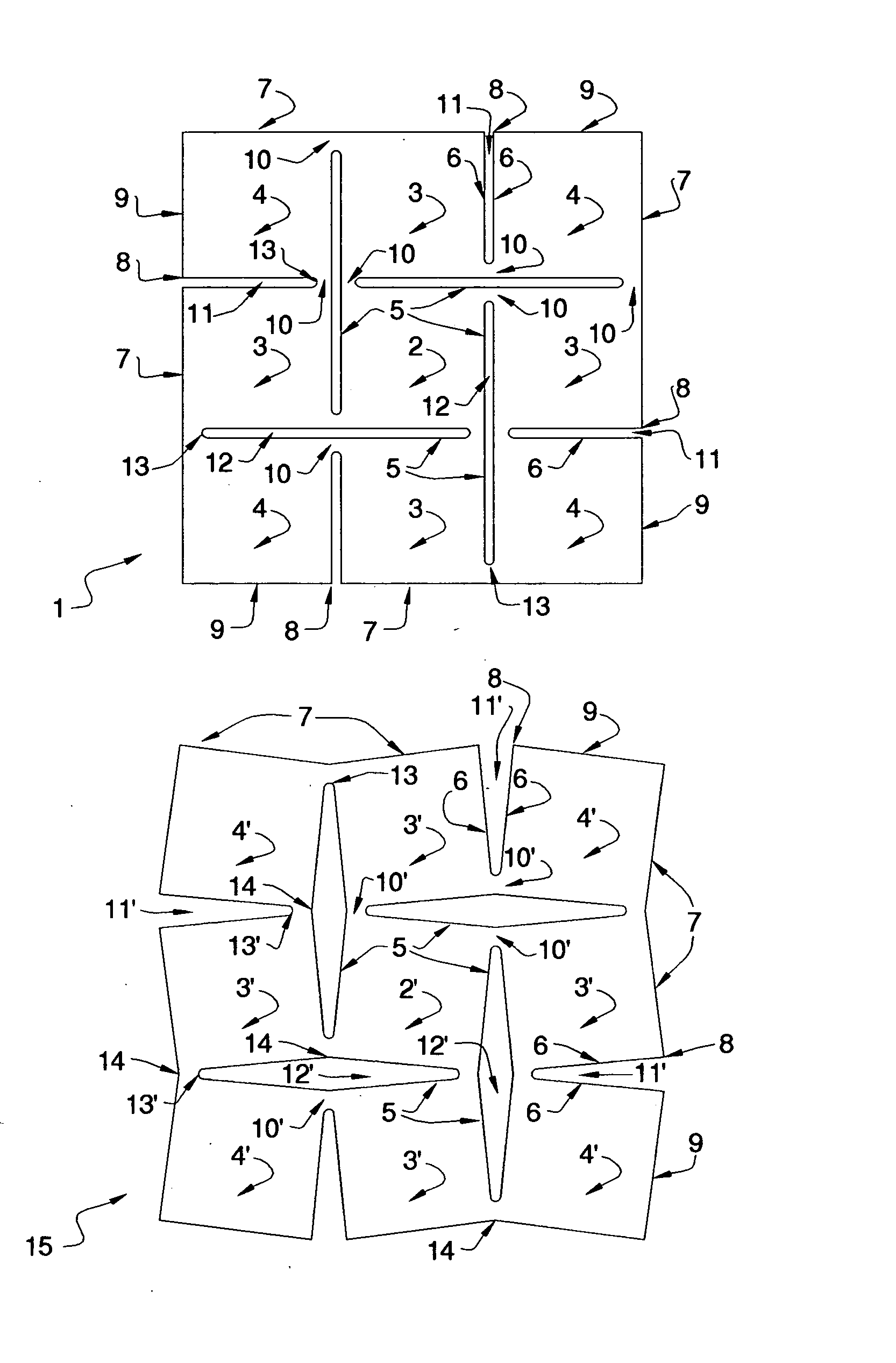

Multi-directional and variably expanded sheet material surfaces

ActiveUS8084117B2Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingMulti directional

Owner:LALVANI HARESH

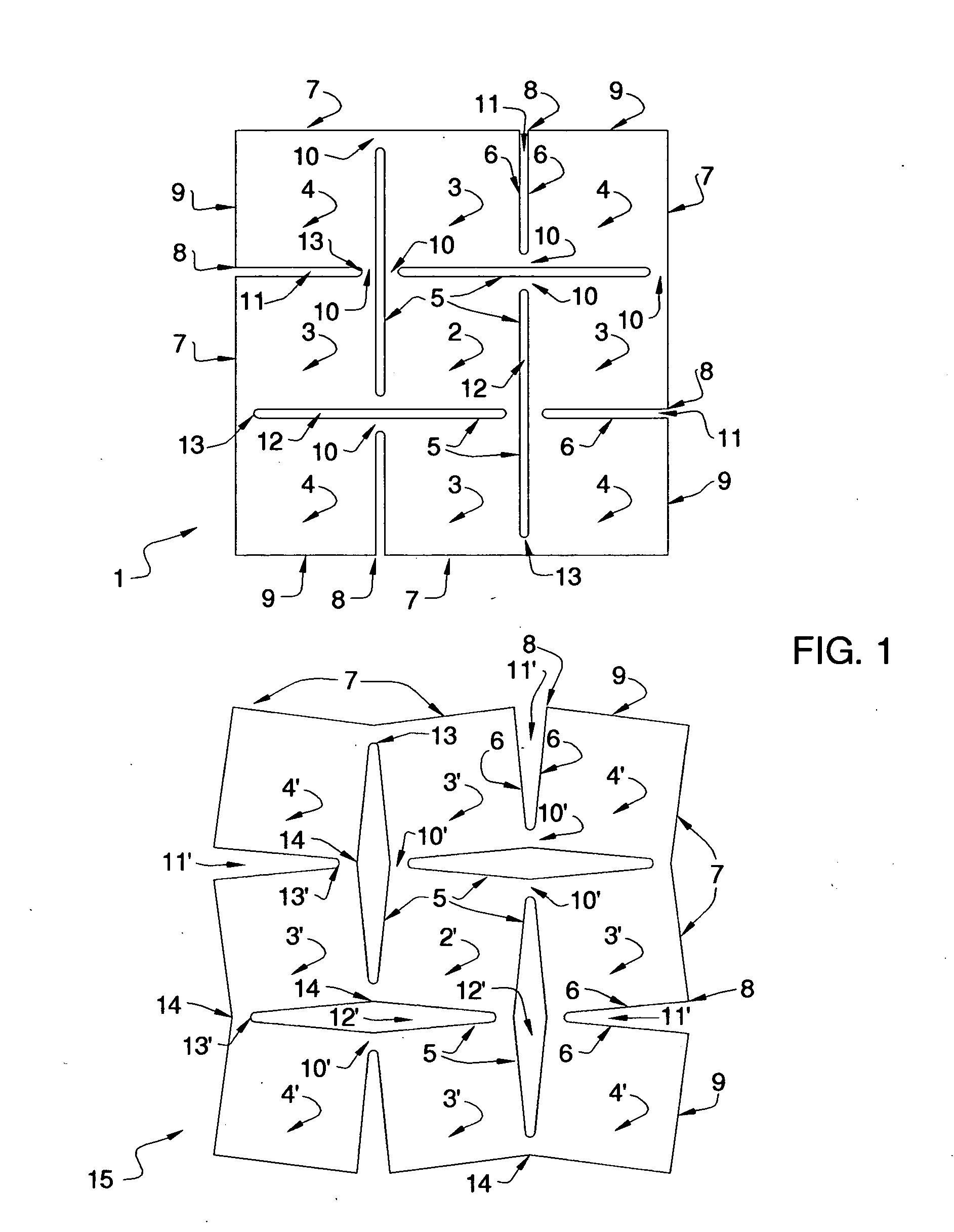

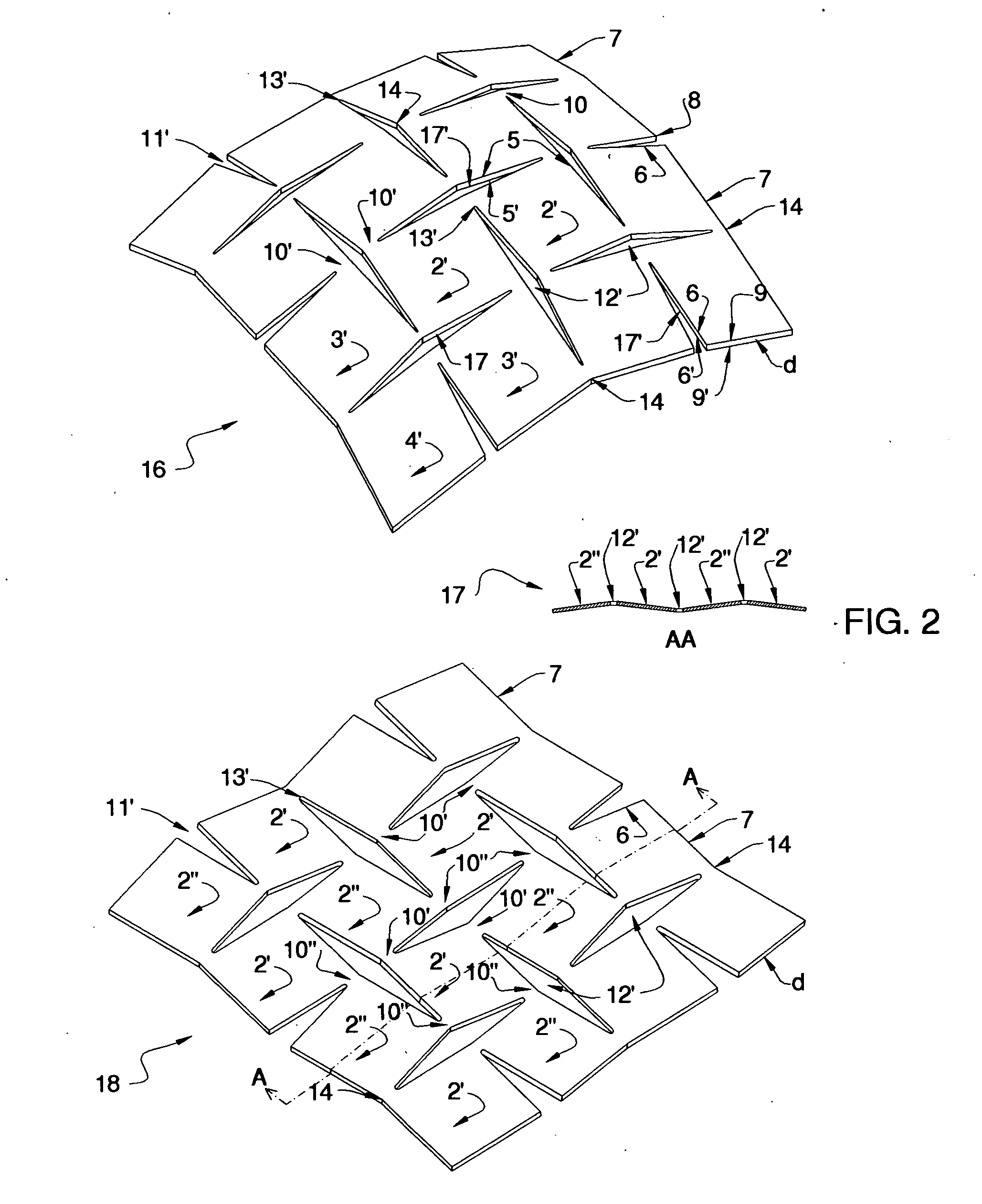

Multi-directional and variably expanded sheet material surfaces

ActiveUS20070122590A1Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingNanoscopic scale

Expandable surfaces made from sheet materials with slits distributed on the surface of sheet material where the surfaces expand by application of force along or / and across the surface of sheet material. The unexpanded surfaces are flat sheets, or closed surfaces like cylinders, spheres, tubes, or custom-designed organic shapes marked with pre-formed or post-formed slit designs. The expanded surfaces can be single units or modules which can be attached to one another through various means. The sheet materials range from hard surfaces like metals, to softer materials like papers and plastics, or pliable materials like fabrics, rubbers, synthetic surfaces or bio-surfaces. The slits are arranged in patterns ranging from periodic, non-periodic to irregular designs. The slits can be straight, bent, curved or irregularly shaped with even or uneven spacing. Slitting can be achieved by digital cutting or punching devices like laser-cutting, water-jet cutting, digital punching, automated dies, etc. or pre-formed when casting the sheet material. Force can be applied manually with tools or through the use of machines and special set-ups. Applications range from architectural surfaces, walls, ceilings, panel systems, structures and sculpture. On a smaller scale, applications include containers, packaging material, fabrics and human wear. On micro- to nano-scale, applications range from expandable surfaces for gauzes, band-aids, stent designs, skin grafts, semi-permeable membranes and micro-filters for various industries including purification of fluids and chemical substances.

Owner:LALVANI HARESH

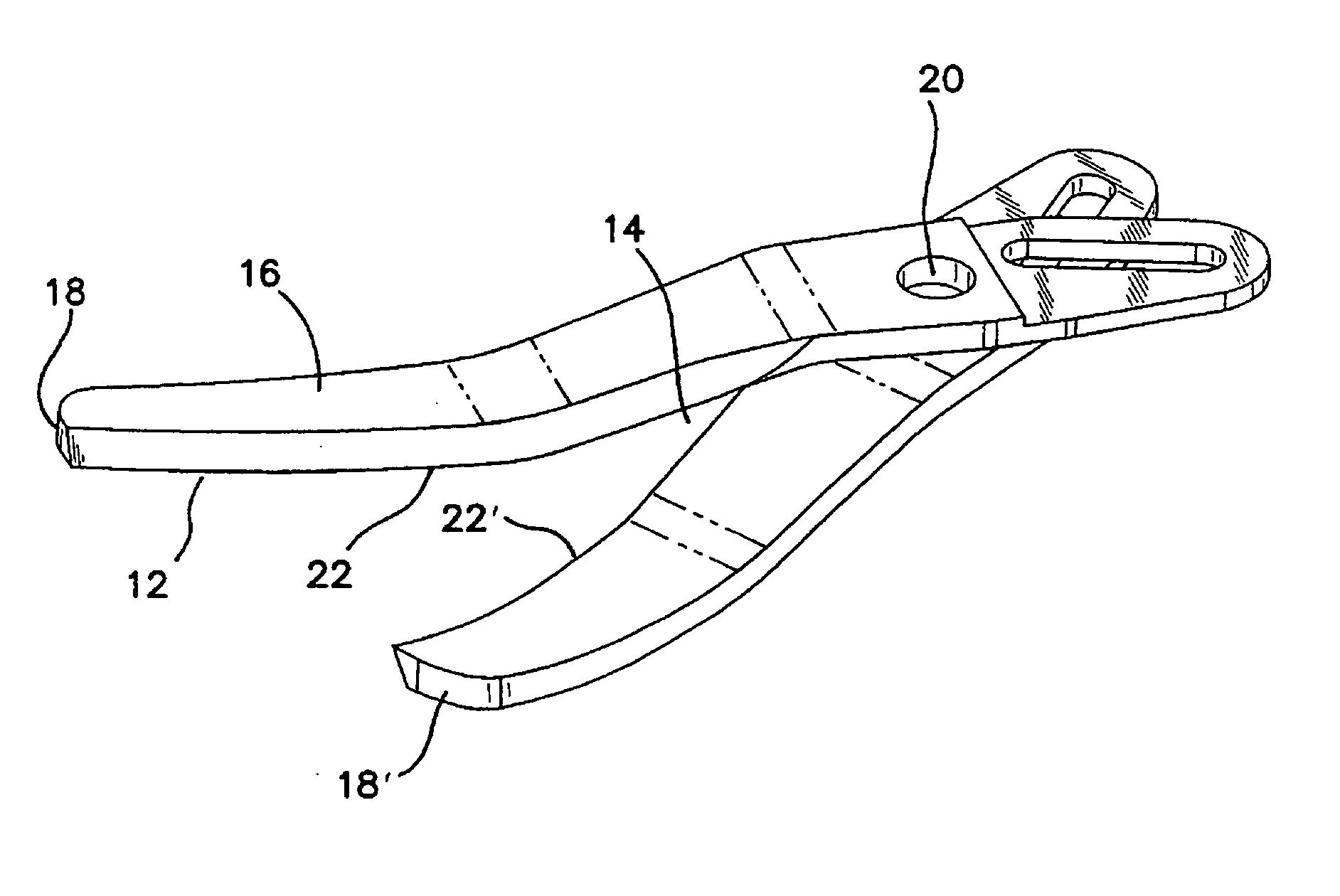

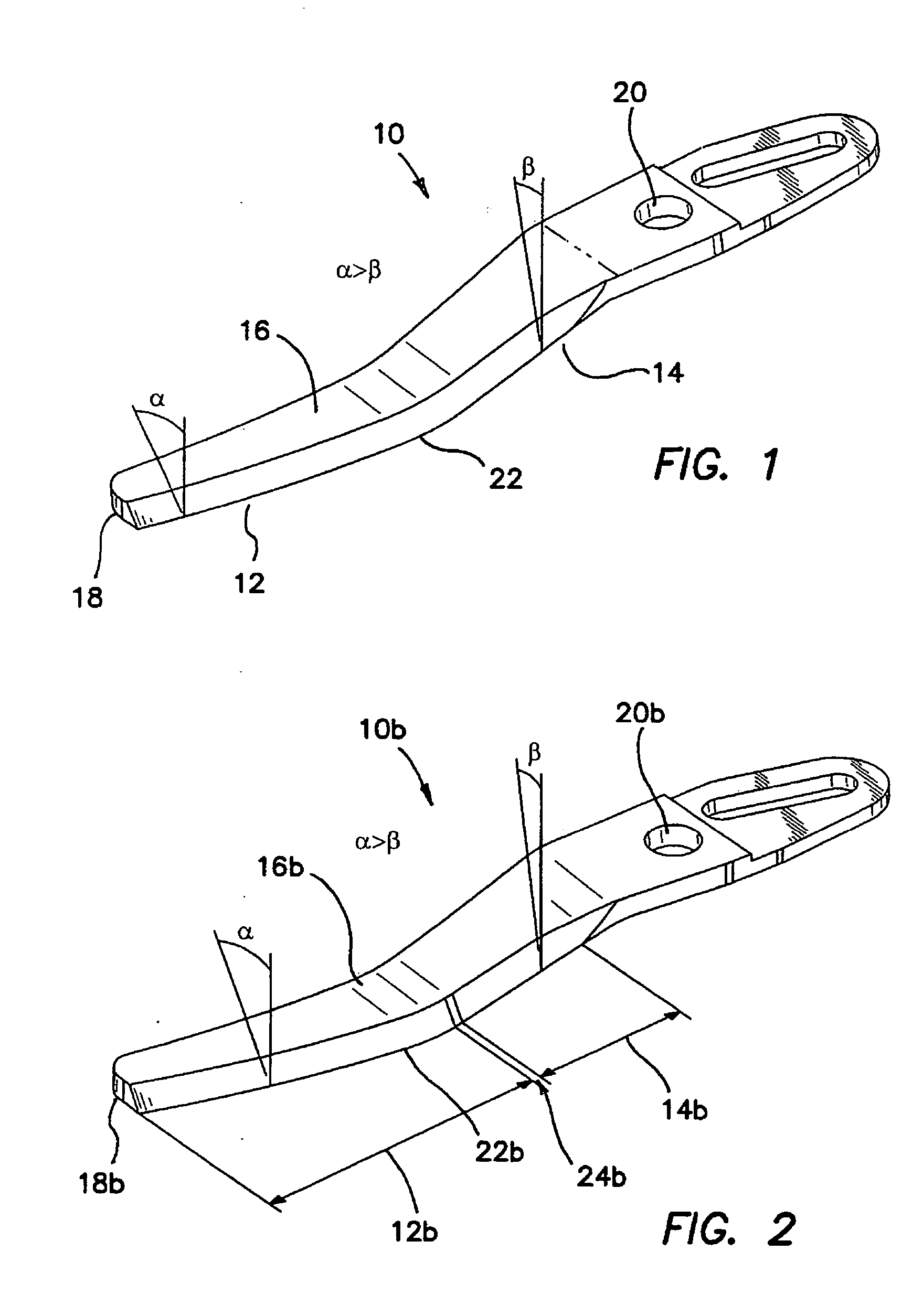

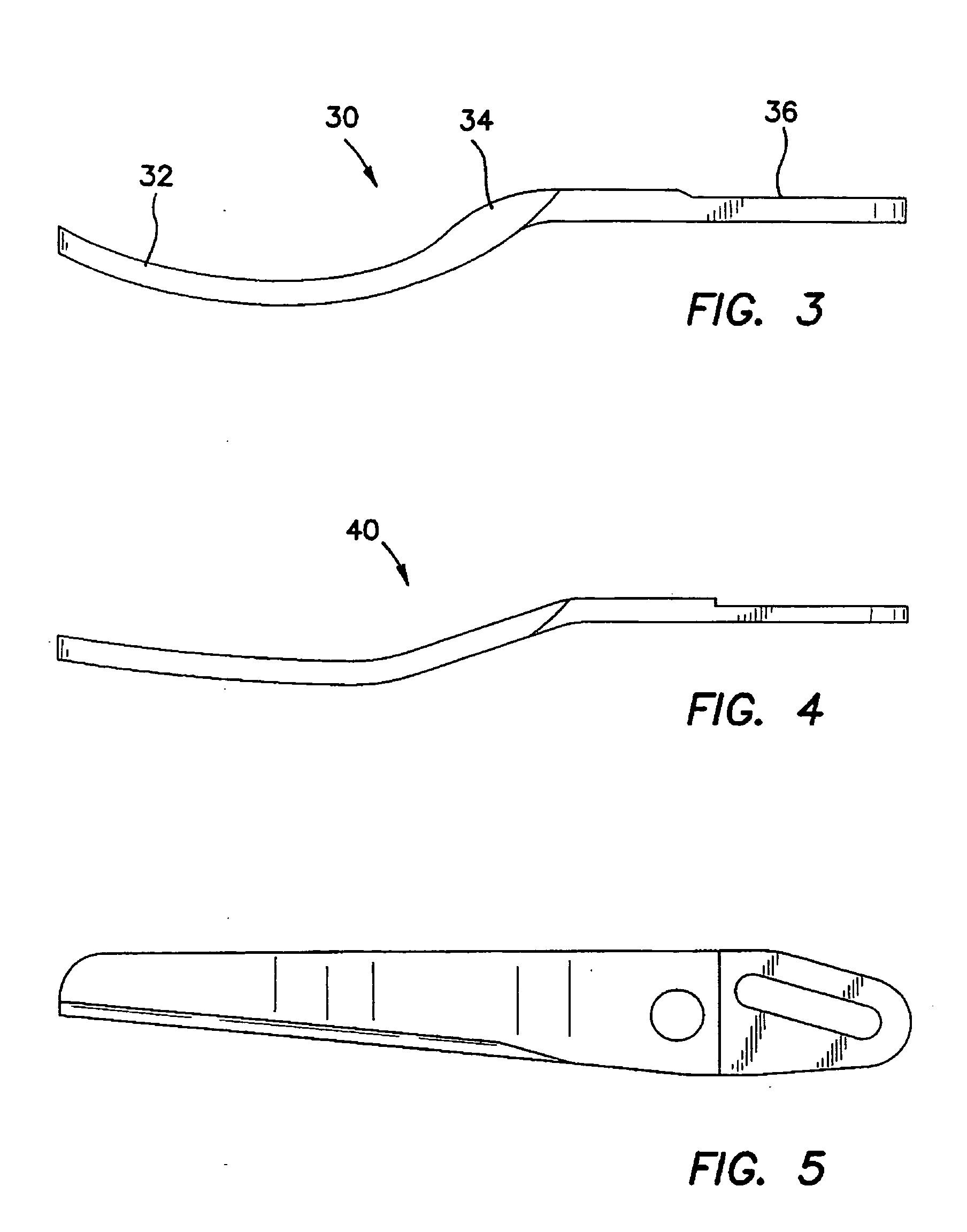

Multiple-angle scissor blade

InactiveUS20050149087A1More strengthReduce tensionSurgical scissorsOther manufacturing equipments/toolsManufacturing technologyLaser cutting

The invention is directed to a pair of laparoscopic scissors, comprising a pair of blades connected at a pivot, each of the blades having a length, a tip portion, a body portion, an outer surface, an inner surface and a cutting edge, the cutting edge forming an angle with the outer surface along the length of the blade such that tension during a cutting operation at the tip portion is about the same as tension at the body portion during the cutting operation. The angle formed may be greater at the tip portion which continuously decreases over the length of the blade. The tip portion may have a first body thickness and the body portion may have a second body thickness different from the first body thickness. During the cutting operation, the blades progressively move over each other to provide a point contact along the cutting edges. The blades may be thickened in a number of locations and combinations including: (1) one blade could be thicker than the other to force the opposing blade to flex; (2) both blades could be thicker at the body portions to give more strength when cutting staples; (3) each blade could be thickened on one side or the other to stiffen certain locations; and (4) the tips of each blade could be thicker than the body portions to provide increased tension at the tips. In another aspect of the invention, a process of manufacturing the pair of scissors of the invention is disclosed, comprising the steps of form grinding the blades into a desired shape from a pre-hardened block of material, and sharpening the cutting edges of the blades. The blades may also be formed through other processes including wire EDM, laser cutting, waterjet cutting, machining, cast or metal injection molding, and other independent profile manufacturing processes. The manufacturing process of the invention is beneficial in that each profile can be accurately controlled, and the parts will be exact every time.

Owner:APPL MEDICAL RESOURCES CORP

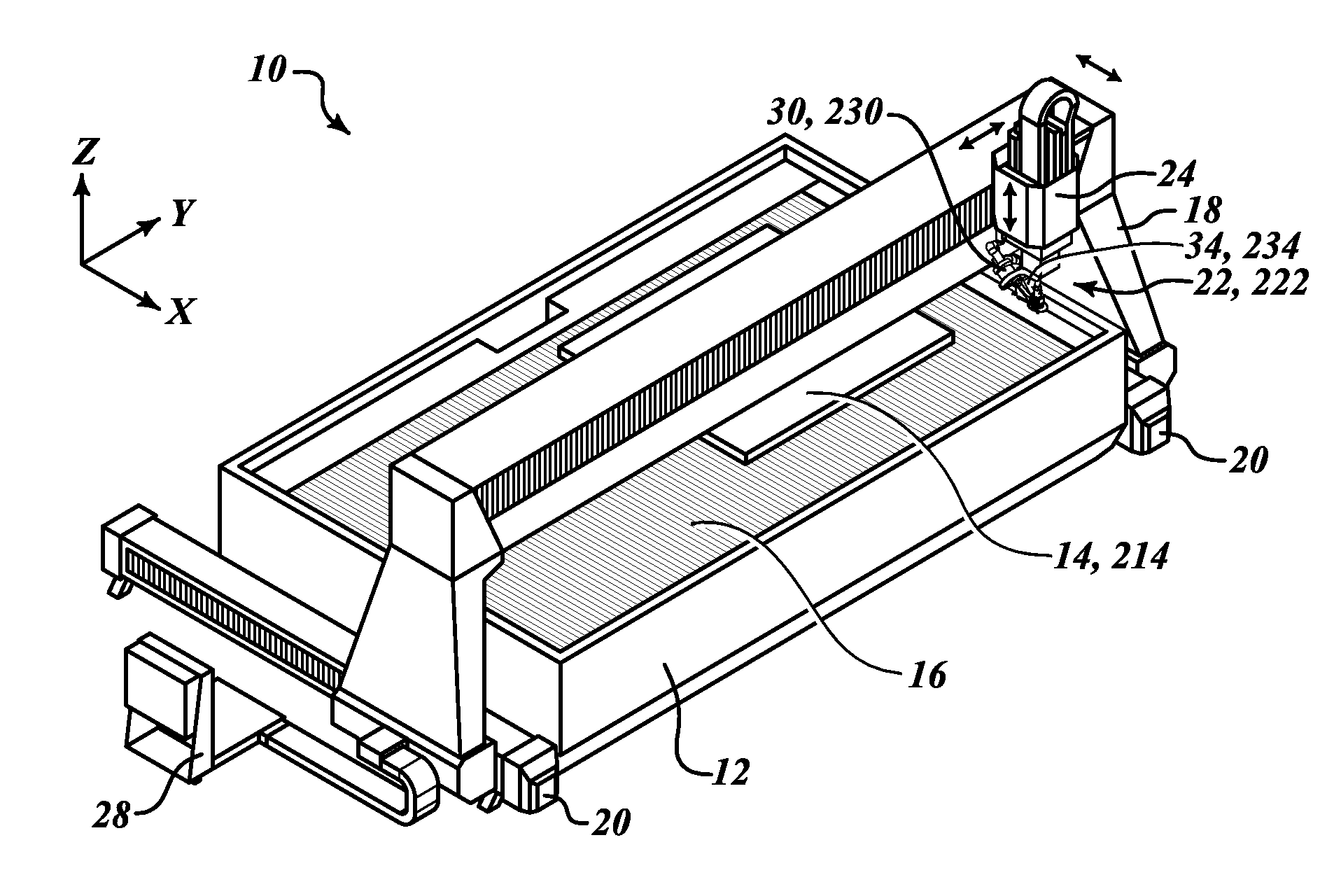

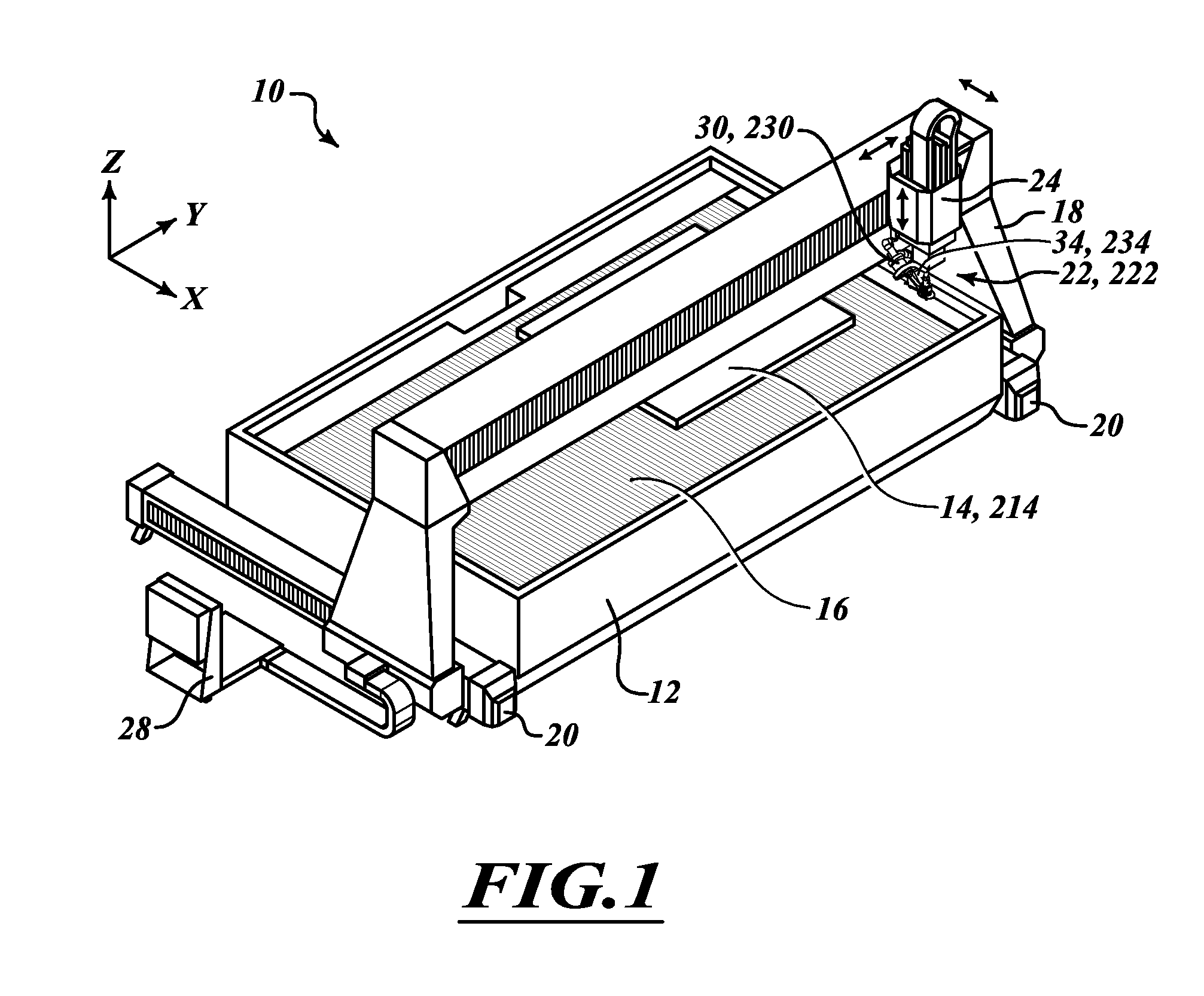

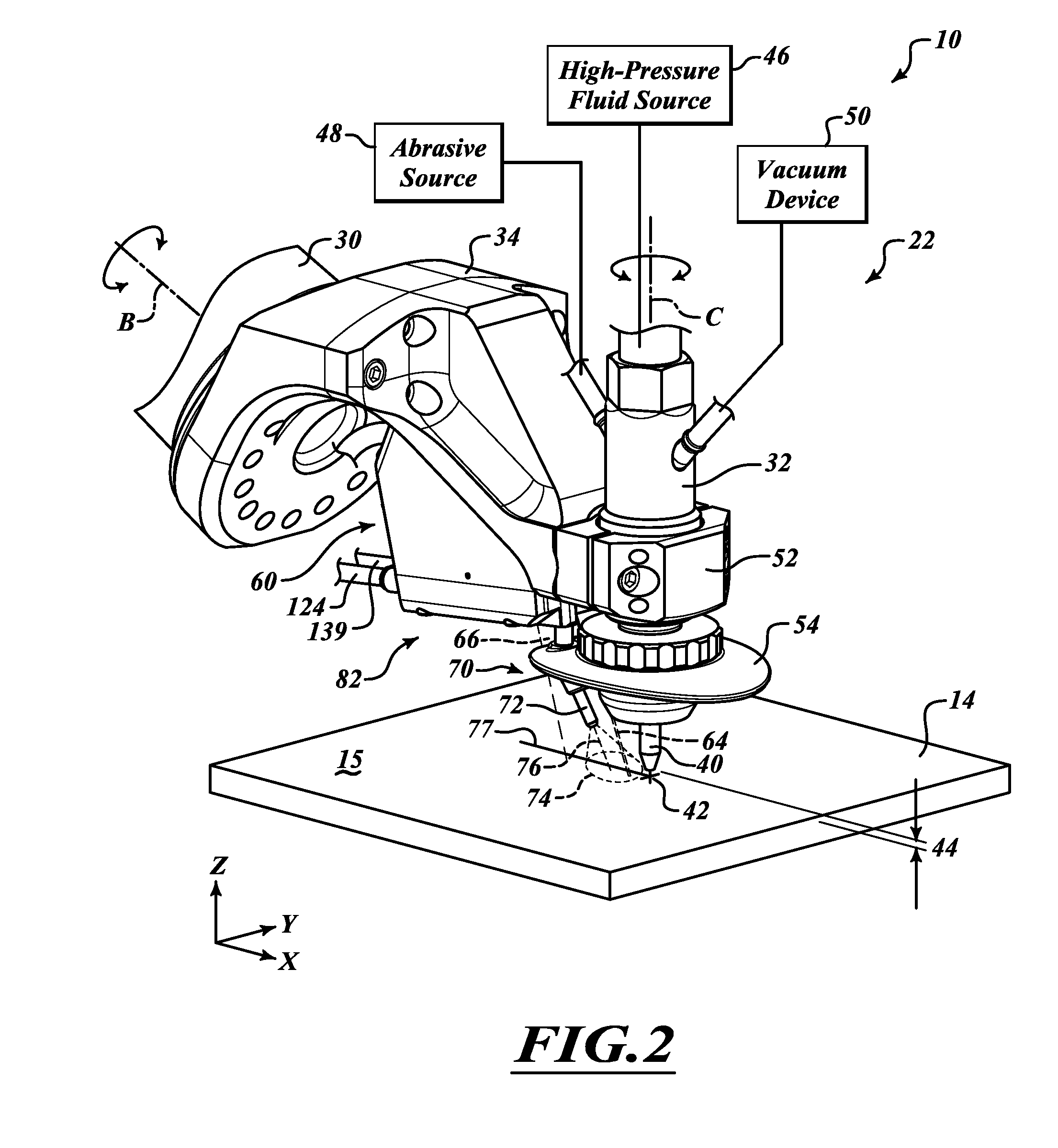

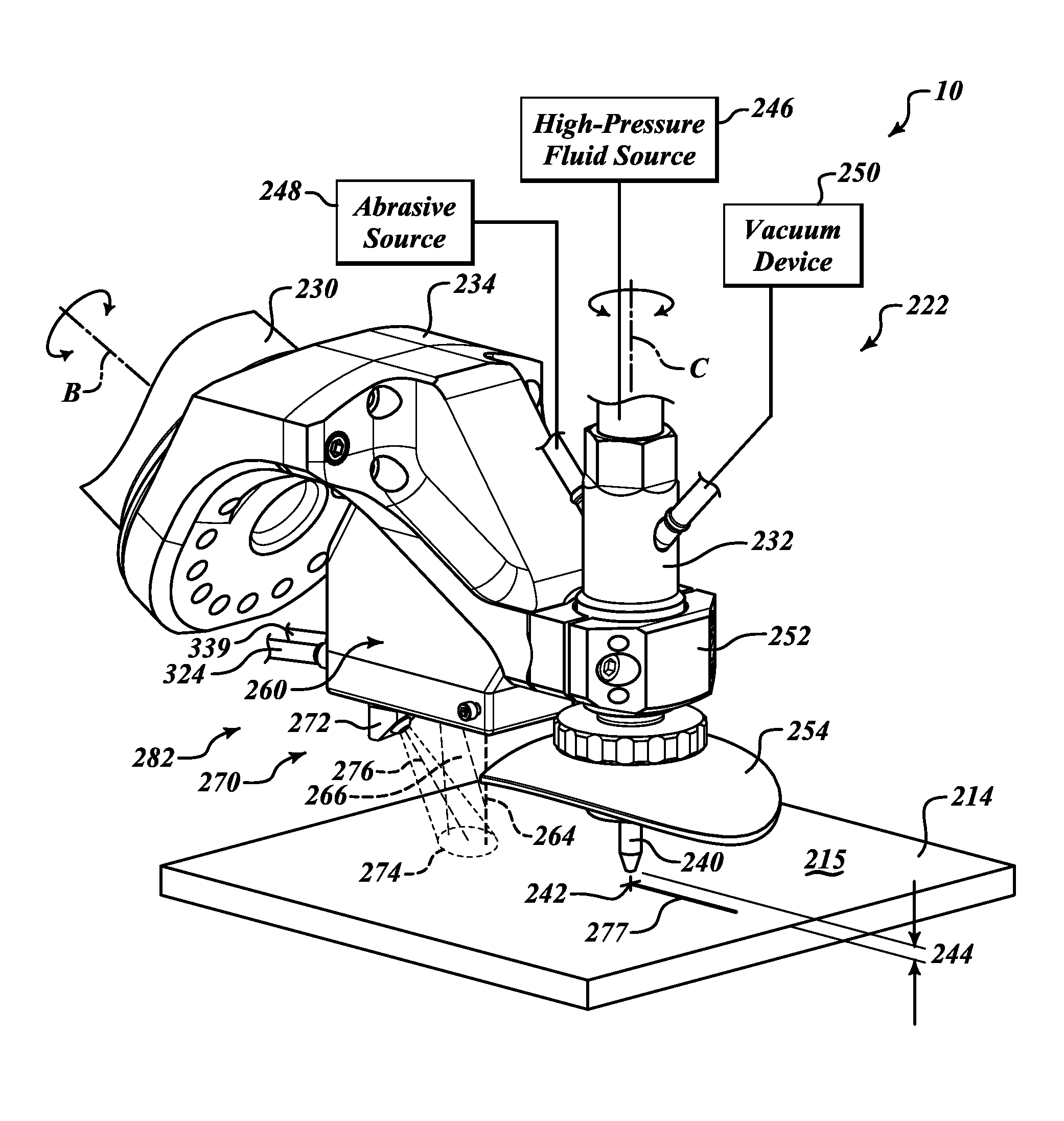

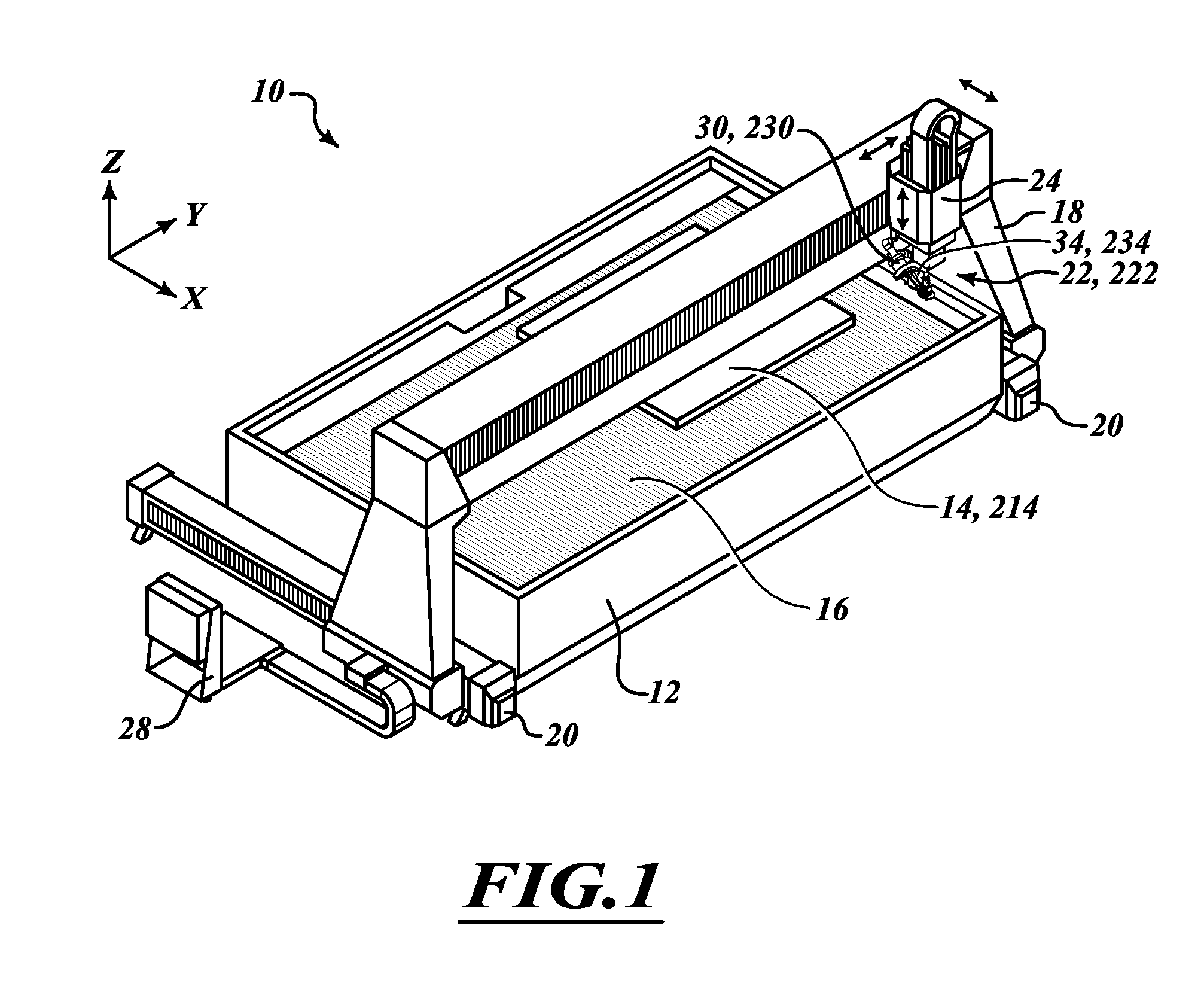

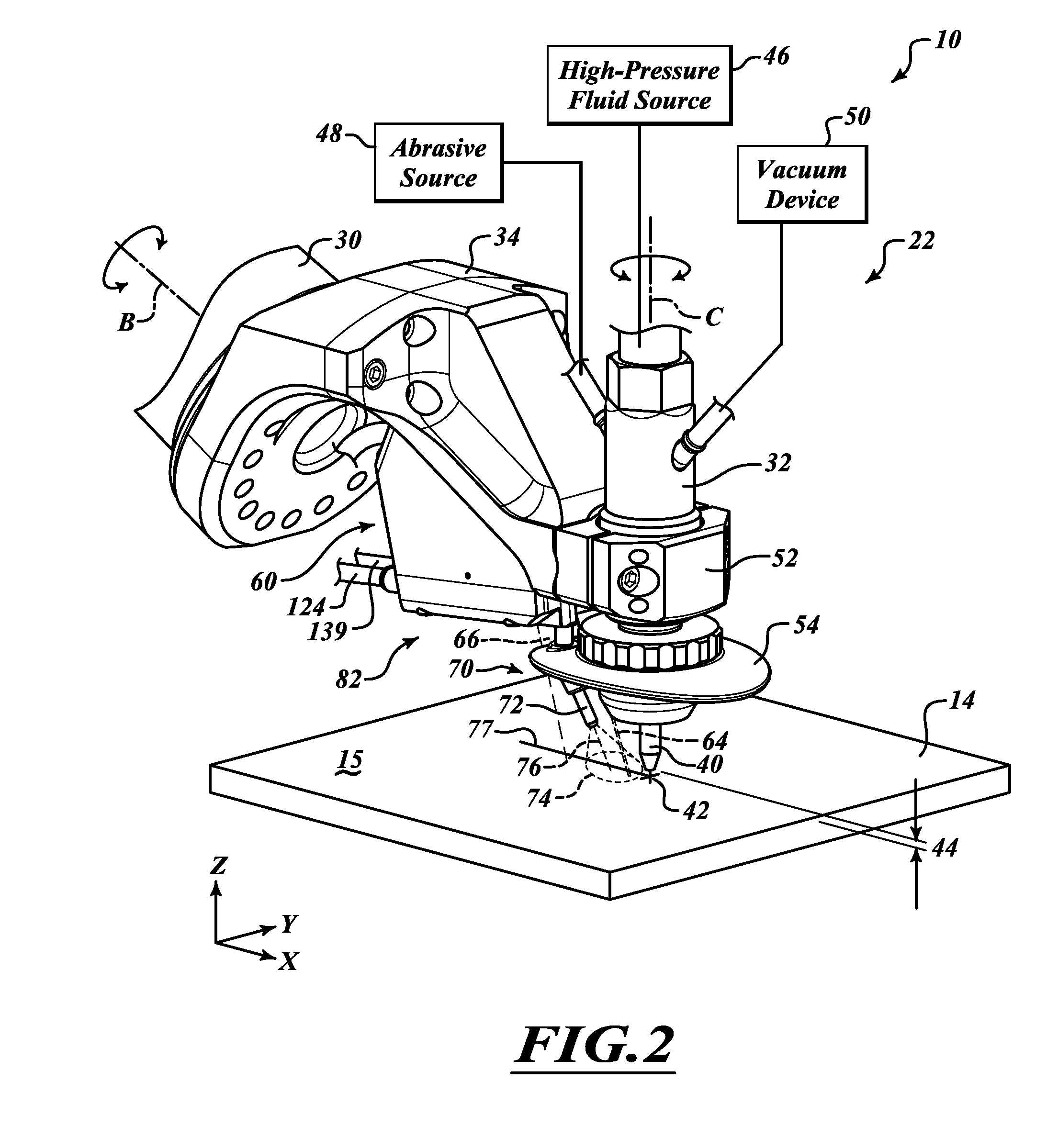

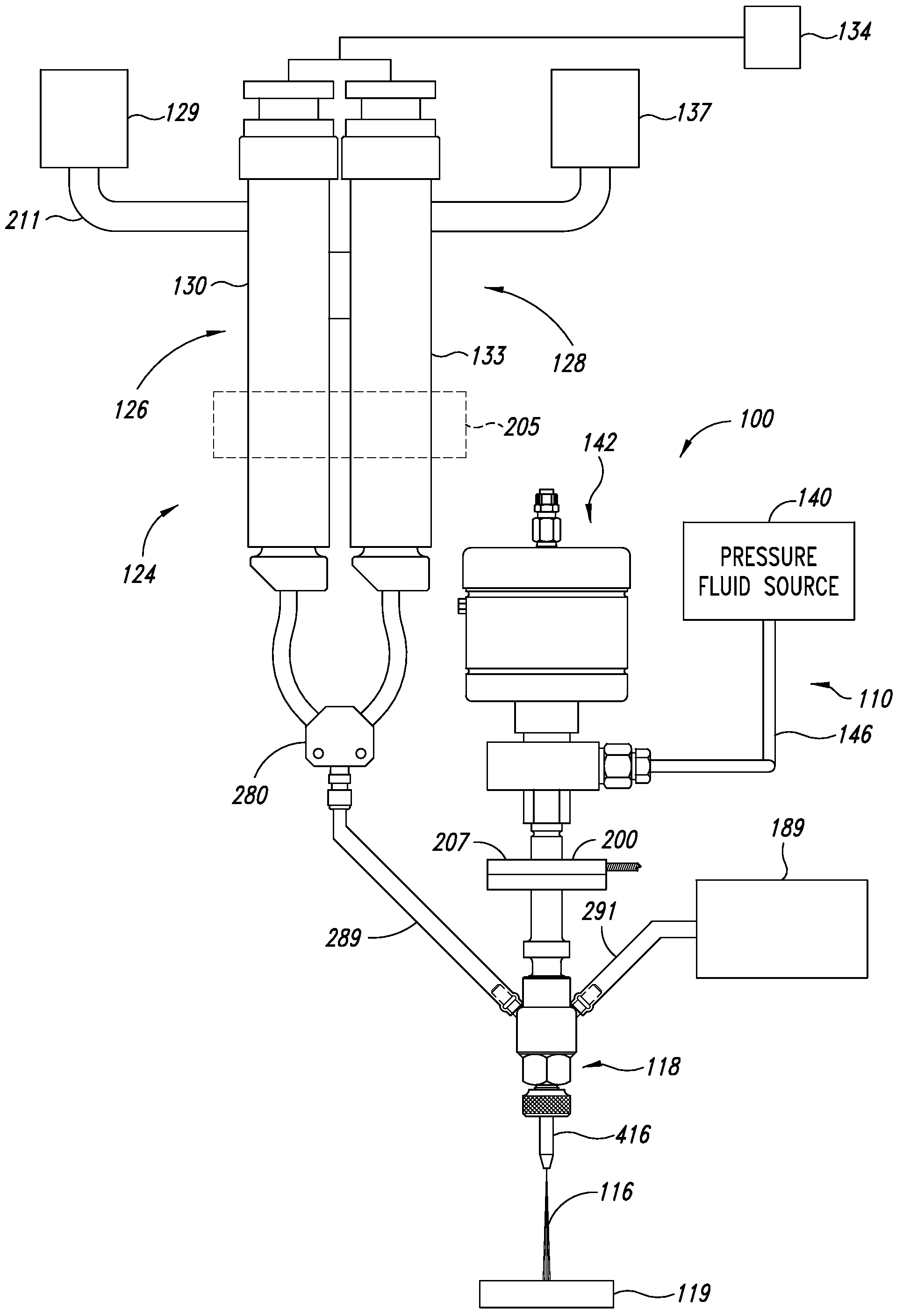

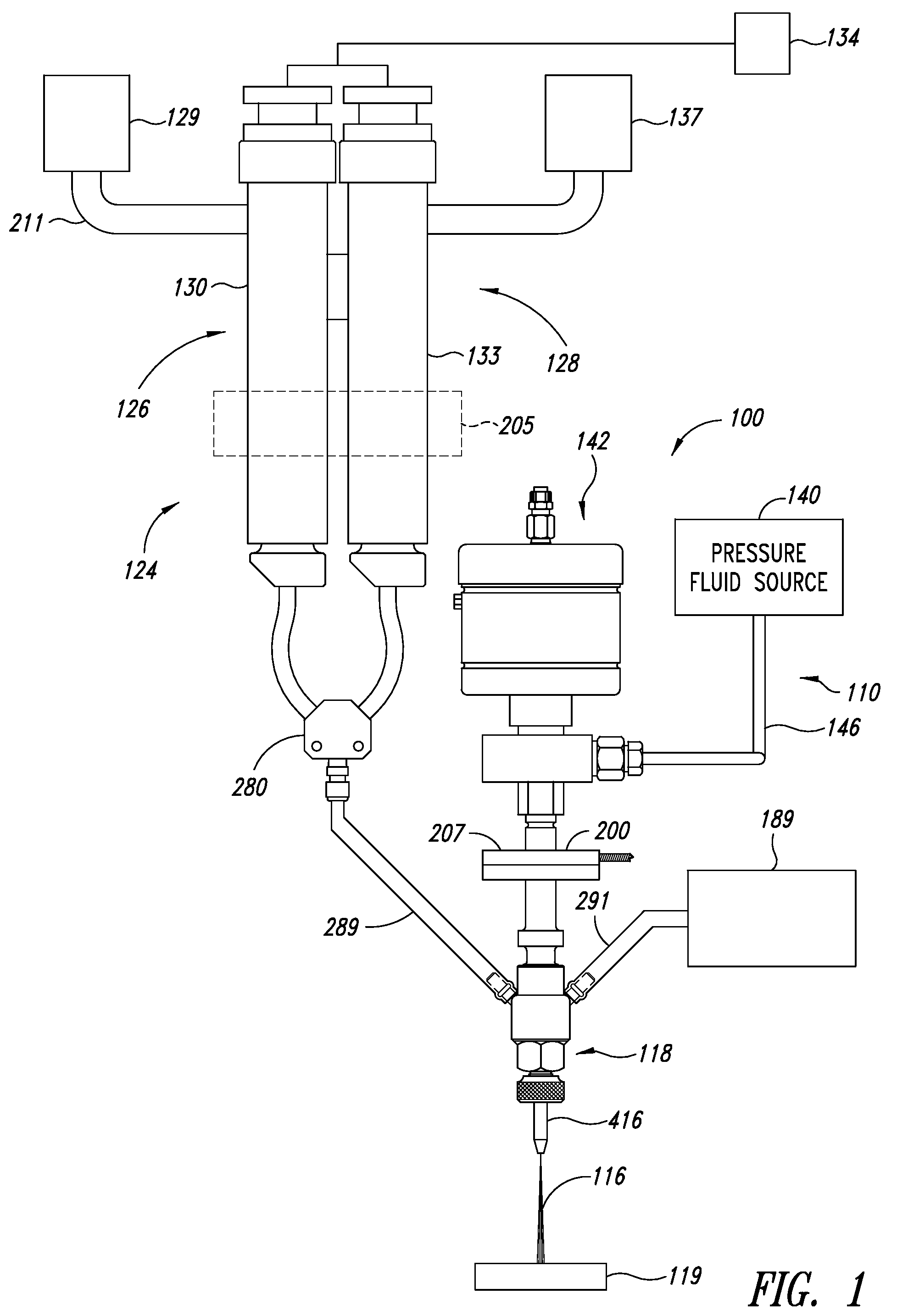

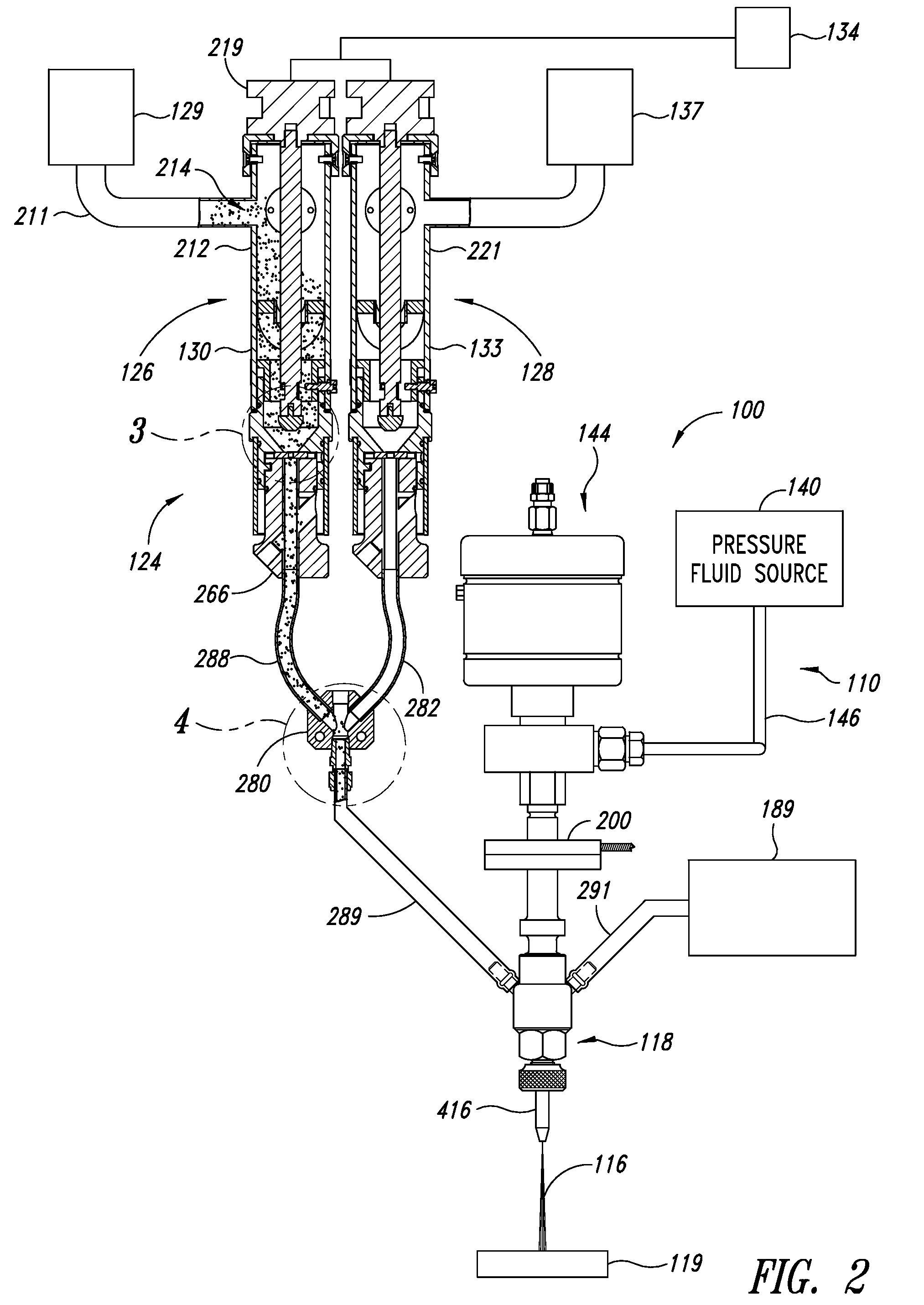

Waterjet cutting system with standoff distance control

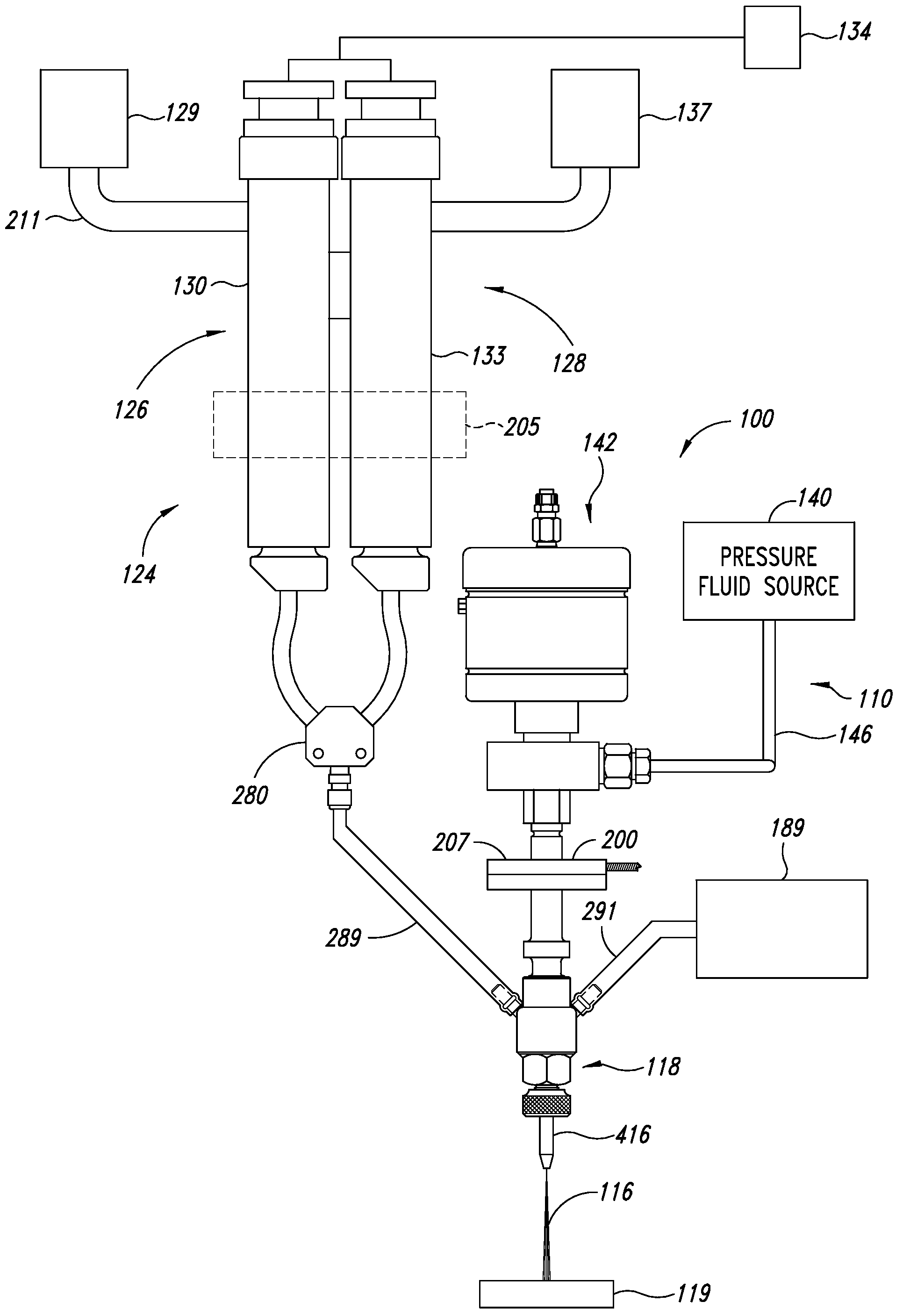

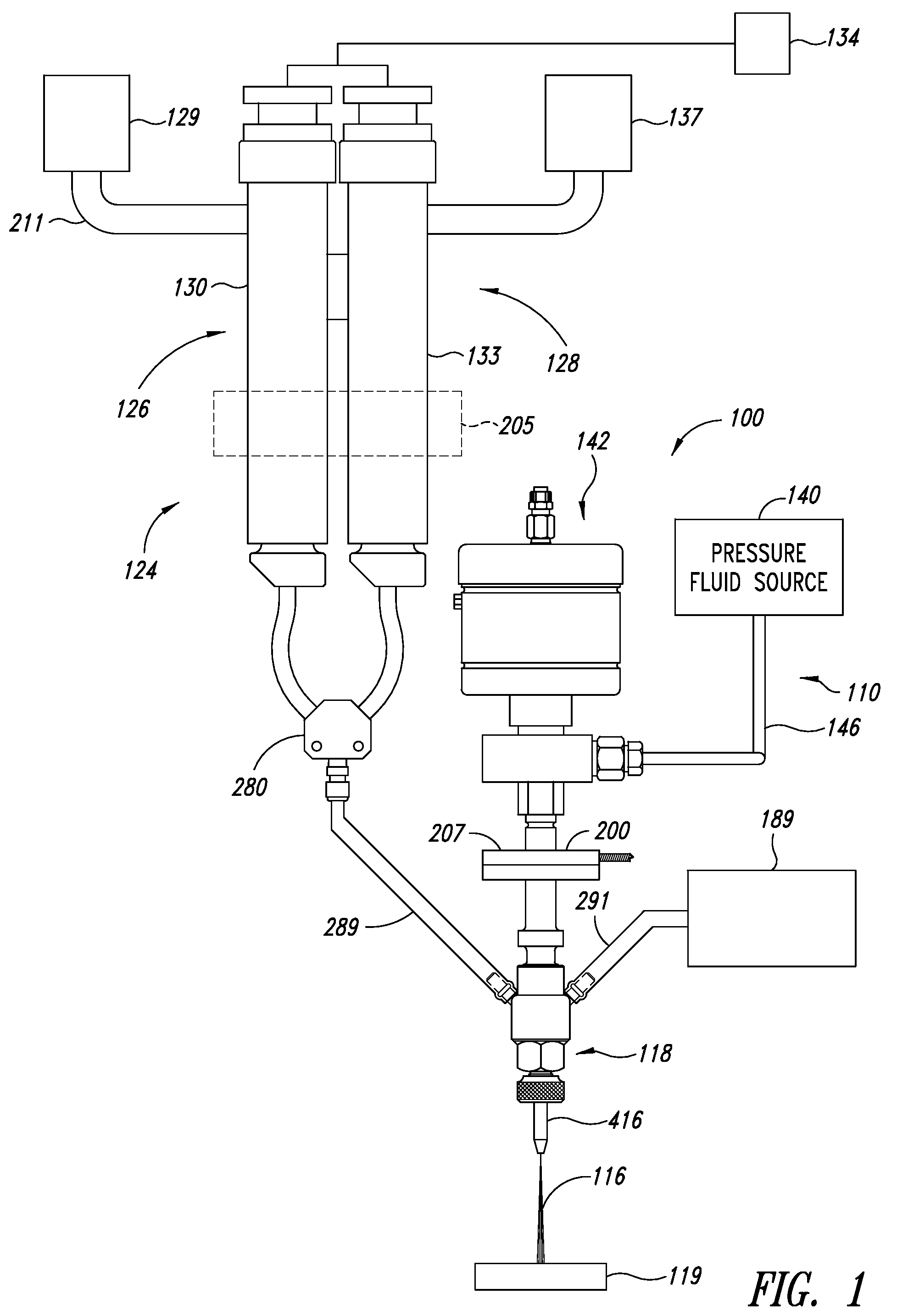

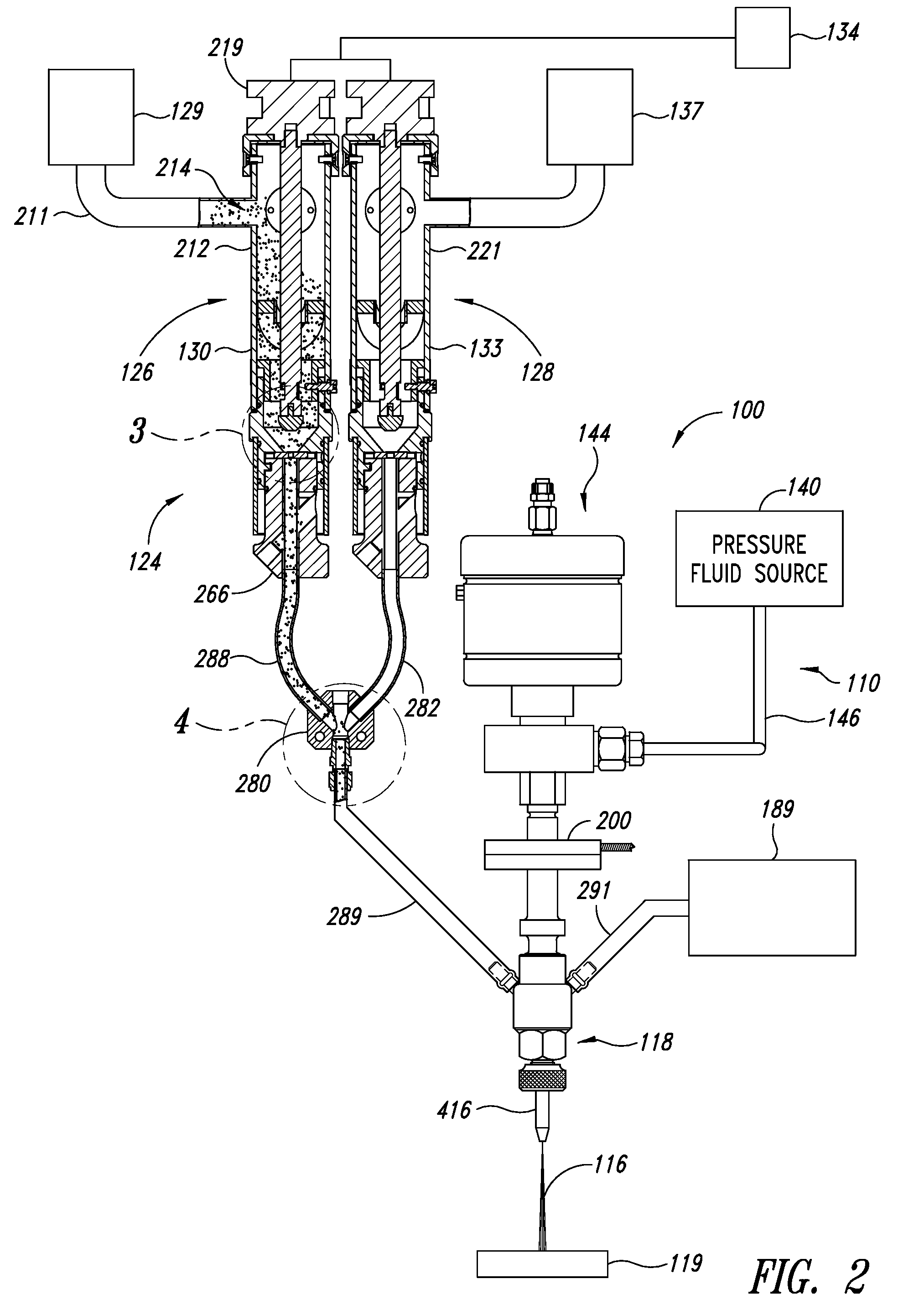

ActiveUS20130025422A1Efficient and accurate mannerBlast gunsAbrasive machine appurtenancesMeasurement deviceControl system

A cutting head of a waterjet cutting system is provided having an environment control device and a measurement device. The environment control device is positioned to act on a surface of a workpiece at least during a measurement operation to establish a measurement area on the surface of the workpiece substantially unobstructed by fluid. The measurement device is positioned to selectively obtain information from within the measurement area indicative of a position of the cutting head relative to the workpiece. A control system is further provided and operable to position the cutting head relative to the workpiece at a standoff distance based at least in part on the information indicative of the position of the cutting head relative to the workpiece obtained by the measurement device. A method of operating a waterjet cutting system is also provided.

Owner:FLOW INT

Underground coal seam hydrofracture crack oriented developing method

InactiveCN103133028AReduce cracking pressureDelayed closureFluid removalGas removalHydraulic fracturingHigh pressure water

The invention discloses an underground coal seam hydrofracture crack oriented developing method which comprises the following steps: (1) drilling into a hydrofracture drill hole and oriented drill holes, wherein the number of the hydrofracture drill hole is one, the oriented drill holes are arranged around the circumference circle at intervals, and respectively conducting water jet cutting to the hydrofracture drill hole and all oriented drill holes, wherein water jet cutting is achieved through a high-pressure water jet cutting device; (2) respectively conducting hole sealing to the hydrofracture drill hole and all oriented drill holes; and (3) conducting hydraulic fracturing to the hydrofracture drill hole. According to the underground coal seam hydrofracture crack oriented developing method, secondary disasters of a coal seam top base plate caused by disordered developing of cracks can be avoided, meanwhile, effective stress in the hydrofracture area can be reduced, closing of the cracks is retarded, flow conductivity of the cracks is strengthened, and therefore the purposes of effectively managing gas and efficiently pumping and exploiting the gas can be achieved.

Owner:HENAN POLYTECHNIC UNIV

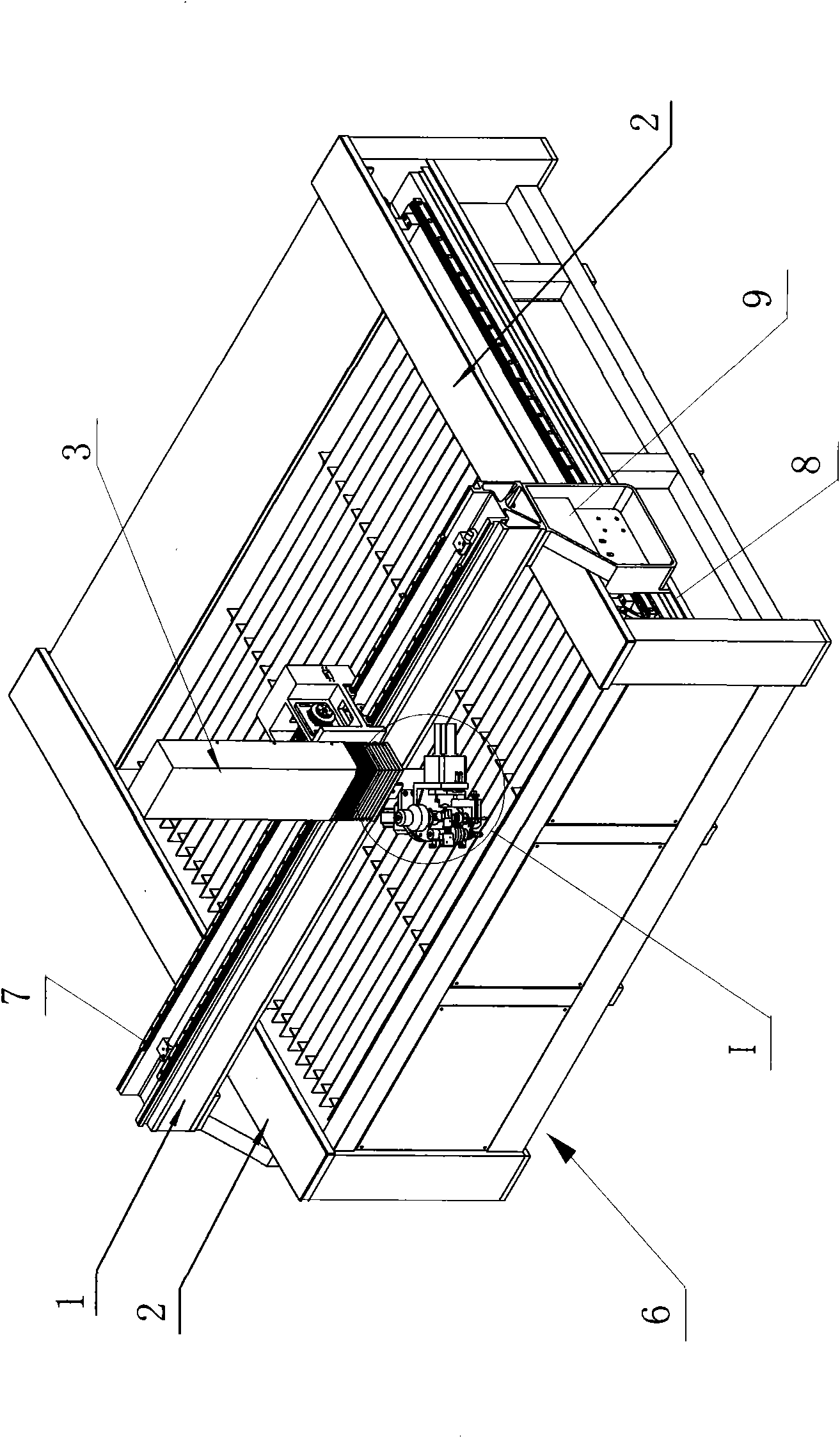

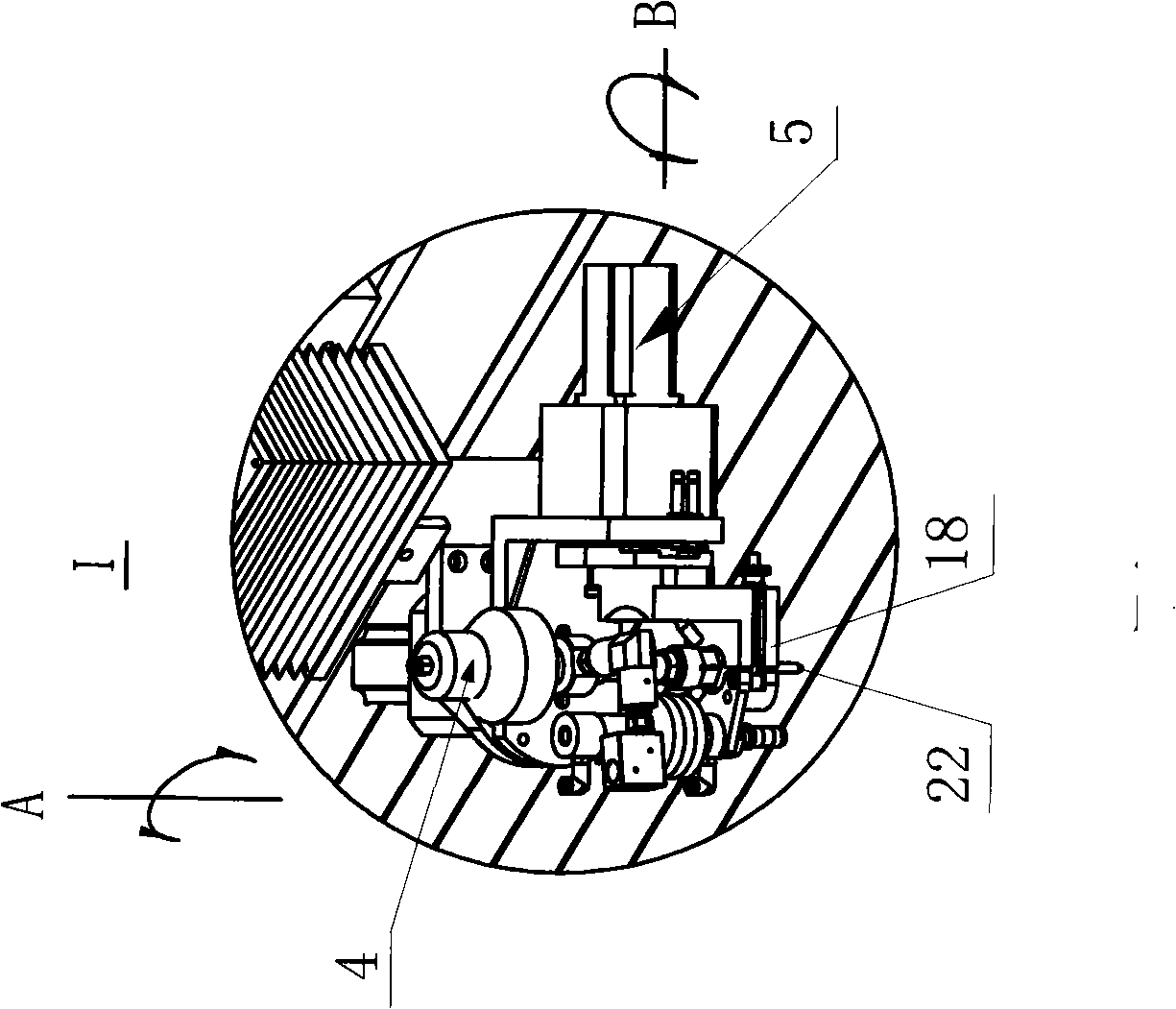

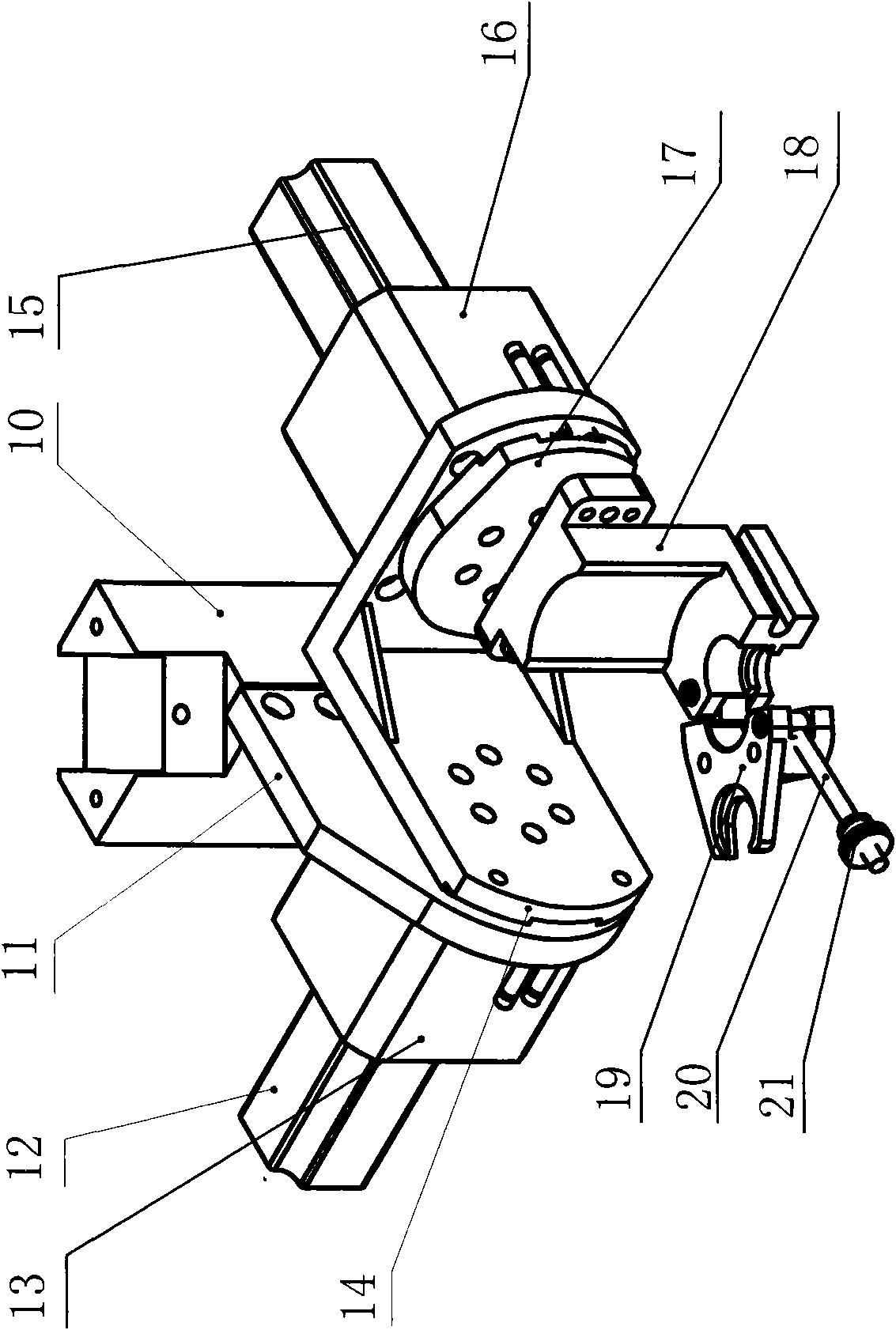

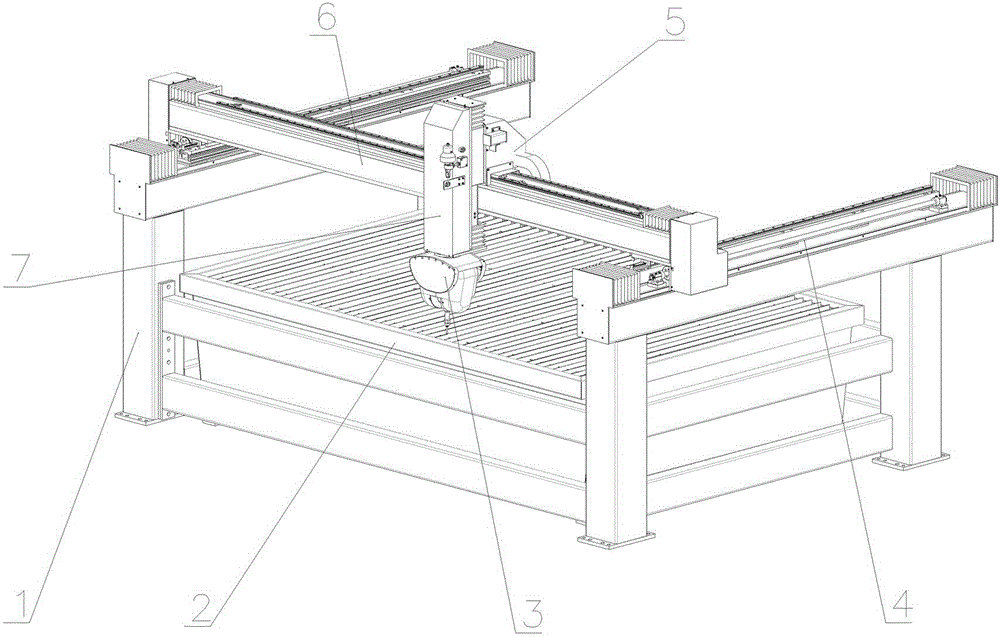

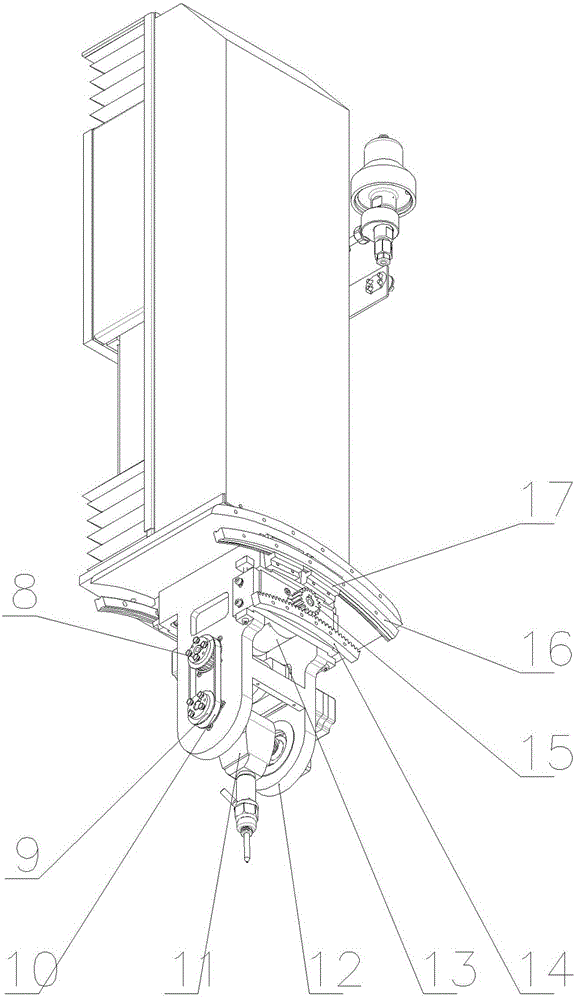

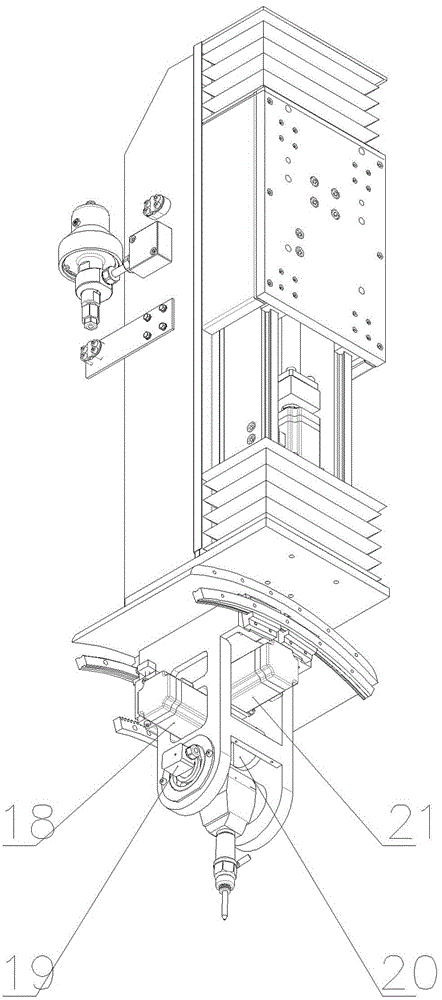

Numerical control five-axle linkage super-high pressure water jet cutting machine

ActiveCN101554738AHigh dimensional accuracyImprove cut qualityShearing machinesMetal working apparatusNumerical controlReducer

The invention relates to a numerical control five-axle linkage super-high pressure water jet cutting machine which comprises a super-high pressure water jet generator, a water jet cutting platform, an X-axle transmission mechanism, a Y-axle transmission mechanism, a Z-axle transmission mechanism and a cutting head connected with the Z-axle transmission mechanism. The numerical control five-axle linkage super-high pressure water jet cutting machine is characterized in that the cutting head has a composite rotating head of axles A and B. The composite rotating head of axles A and B comprises an A axle motor, a B axle motor, a connecting plate of axles A and B and a movable seat, wherein the A axle motor is fixedly connected to a transition plate of the Z-axle transmission mechanism through an A axle speed reducer of the A axle motor, and the output shaft of the A axle speed reducer is connected with the connecting plate of axles A and B; and the B axle motor is fixed on the connecting plate of axles A and B through a B axle speed reducer of the B axle motor, the output shaft of the B axle speed reducer is connected with the movable seat, the cutting head is clipped on the movable seat, the X-axle, the Y-axle, the Z-axle, the A axle and the B axle are interlocked under a main programmable digital controller to control the cutting head to incline in any direction, and the cut bevel edge generated after water jet cutting is filled up. The water jet cutting machine has high automation and cutting efficiency, effectively overcomes the problems of water jet lag and cut bevel edge of the traditional water jet cutting machine and has high cutting precision.

Owner:沈阳奥拓福科技股份有限公司

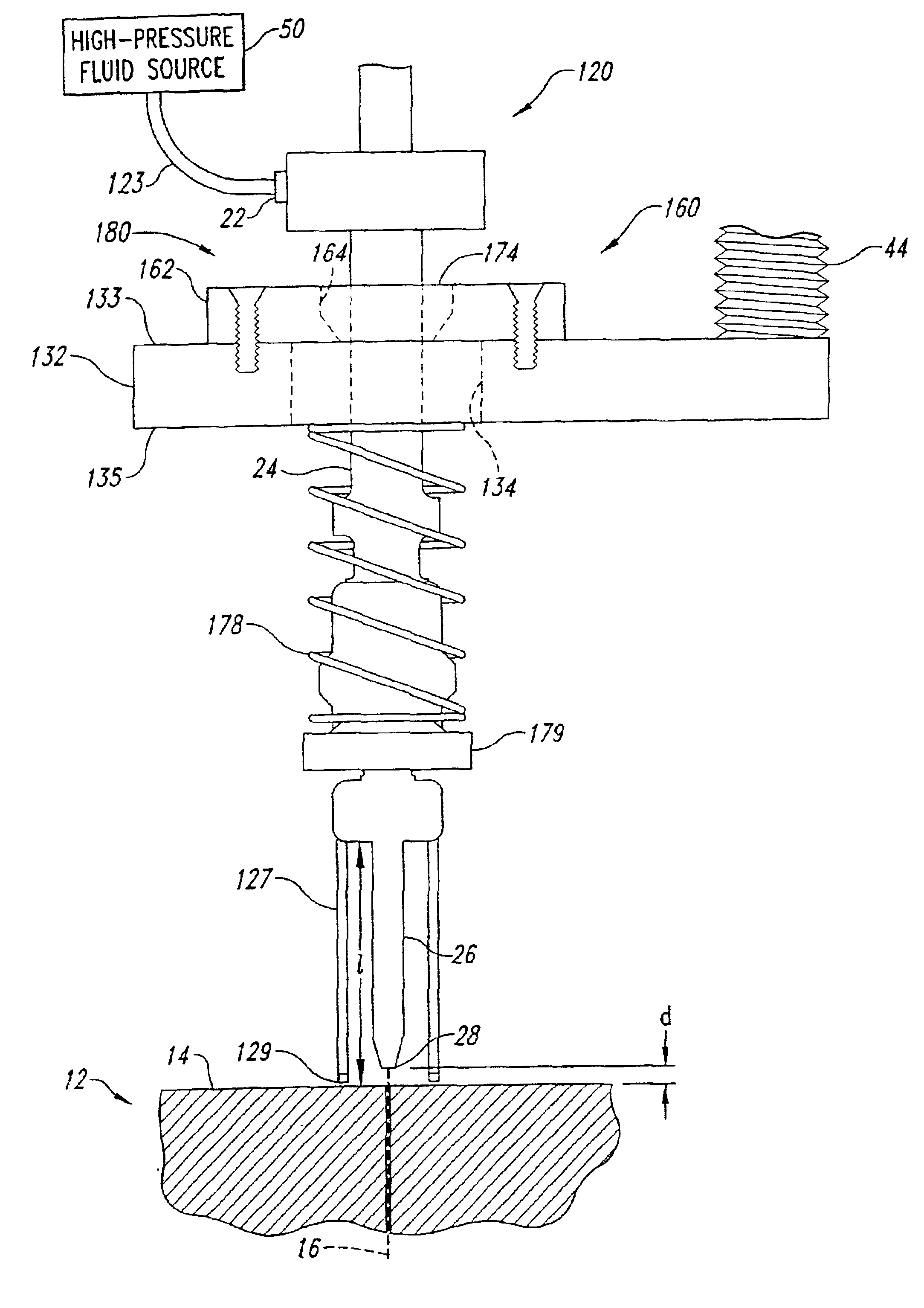

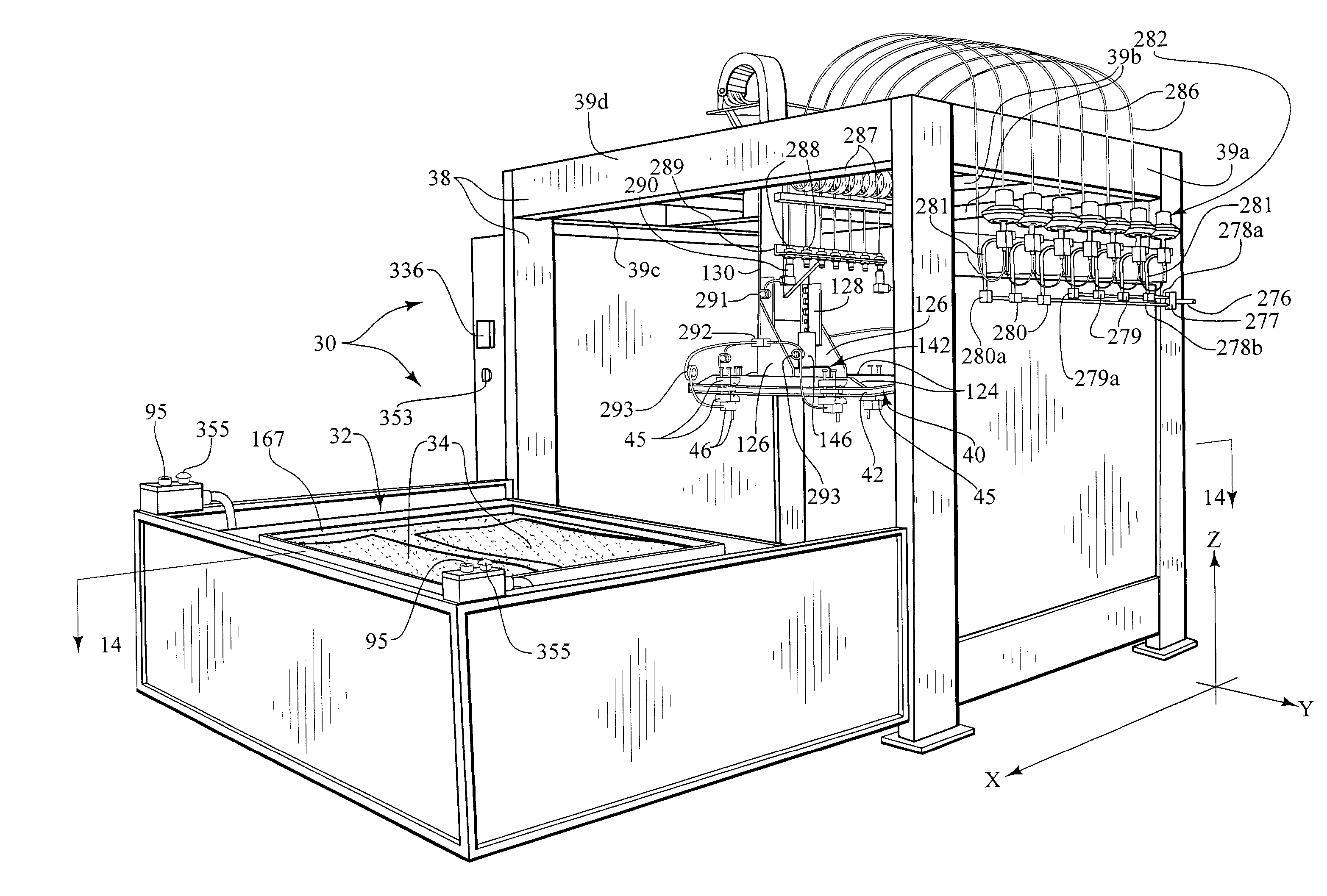

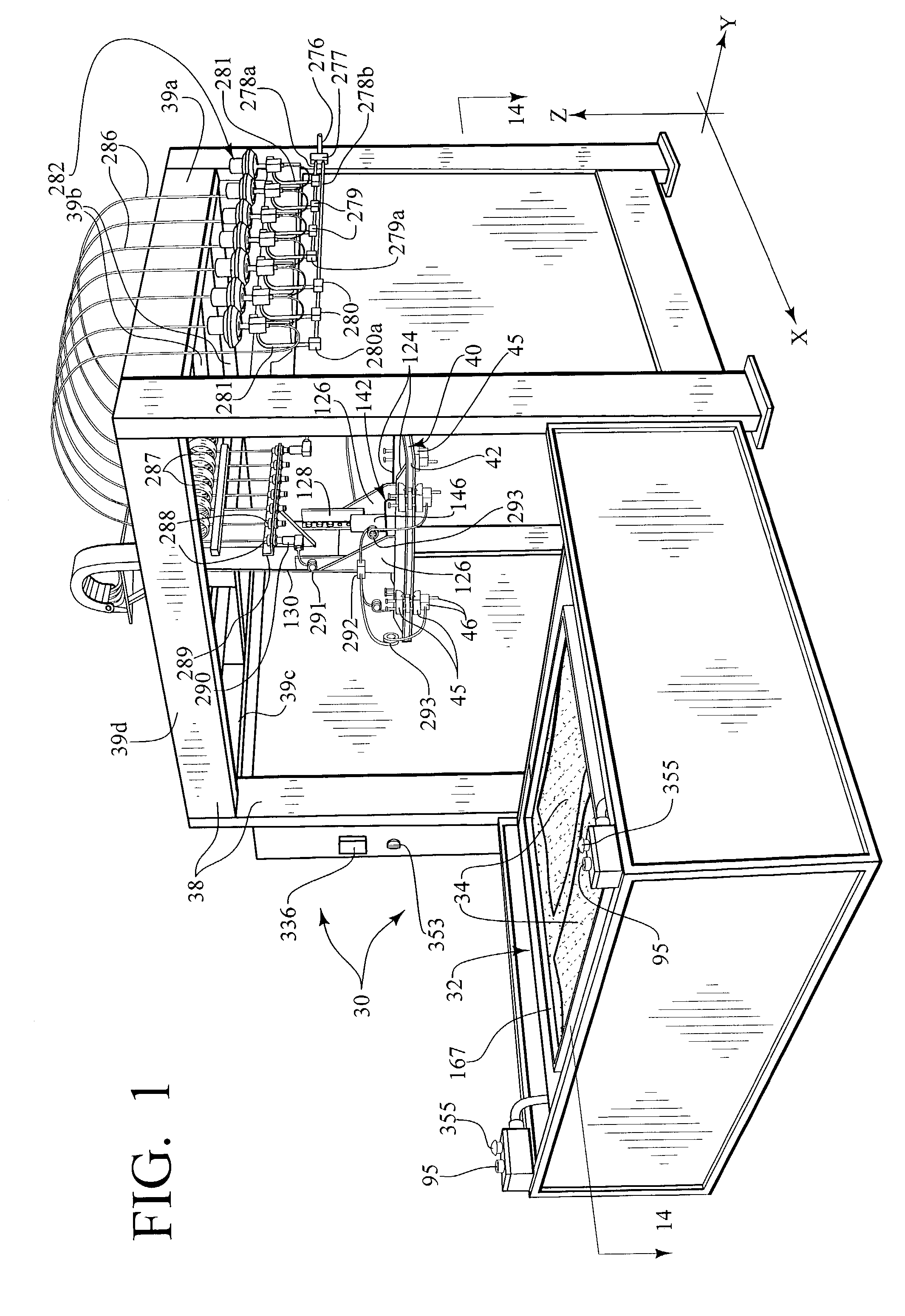

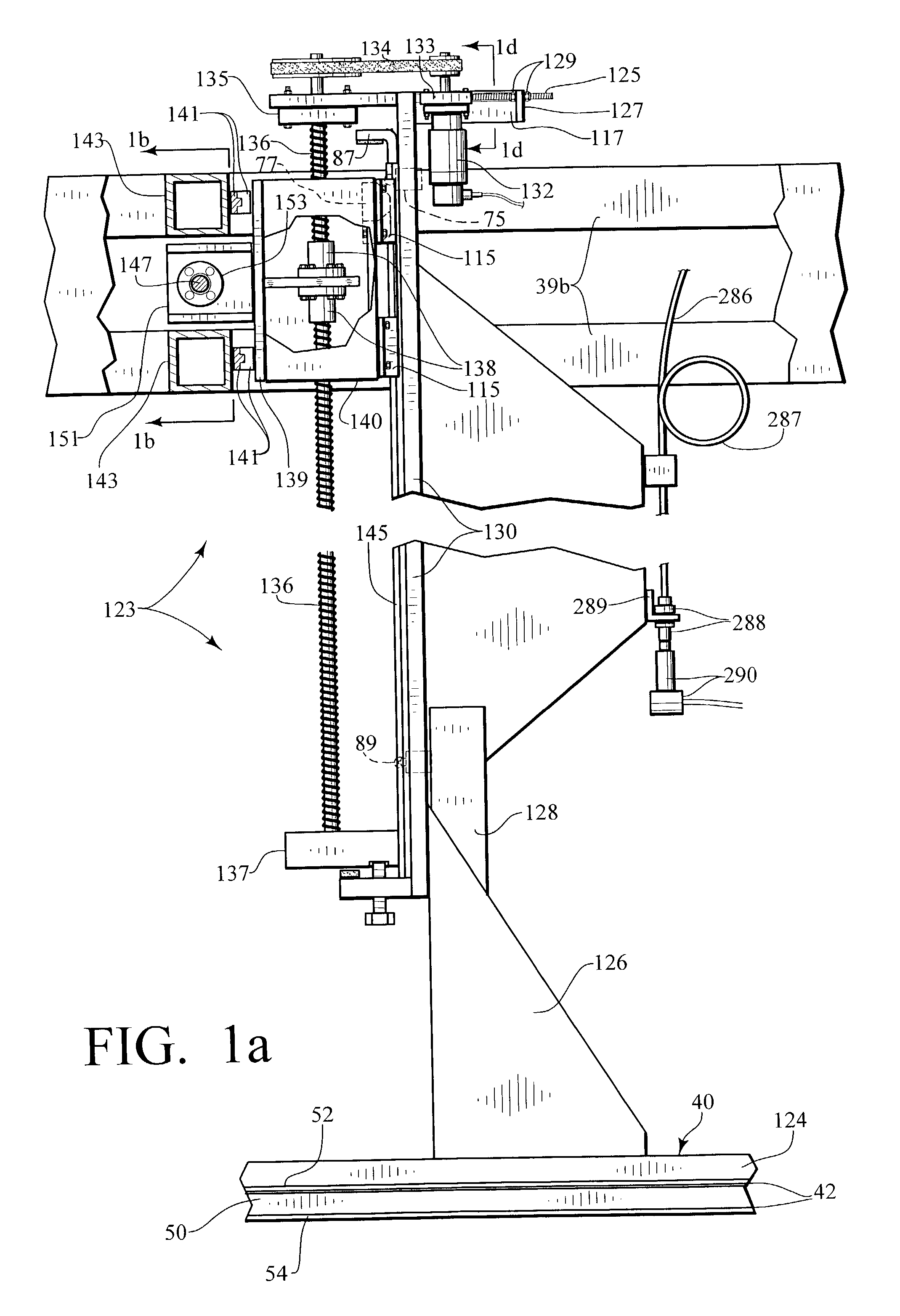

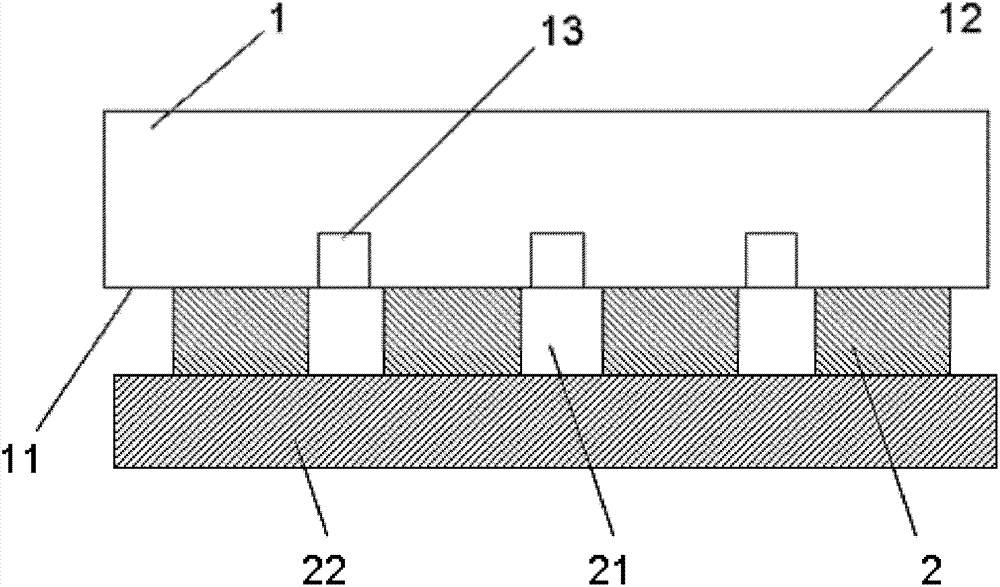

Apparatus and methods for Z-axis control and collision detection and recovery for waterjet cutting systems

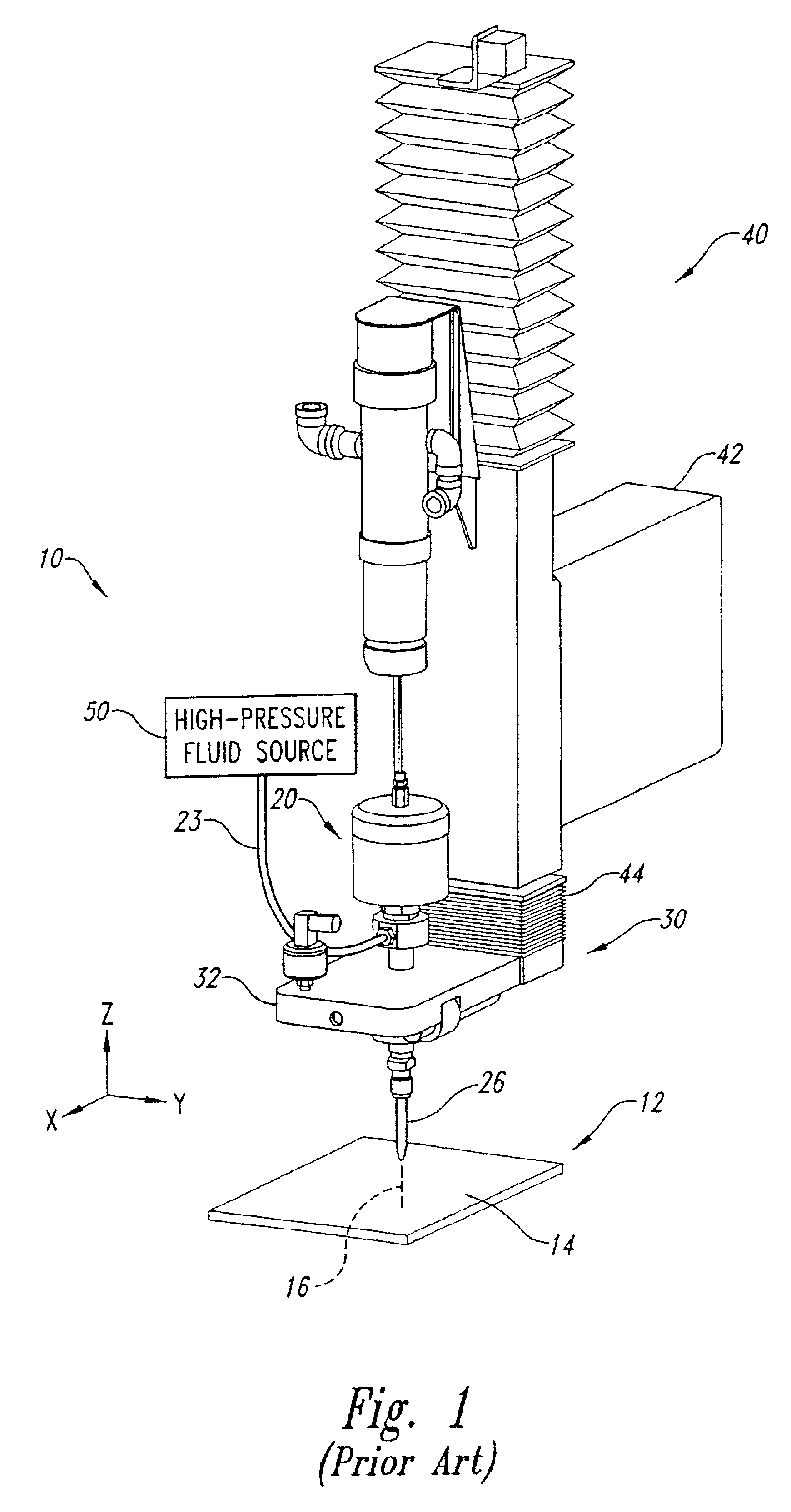

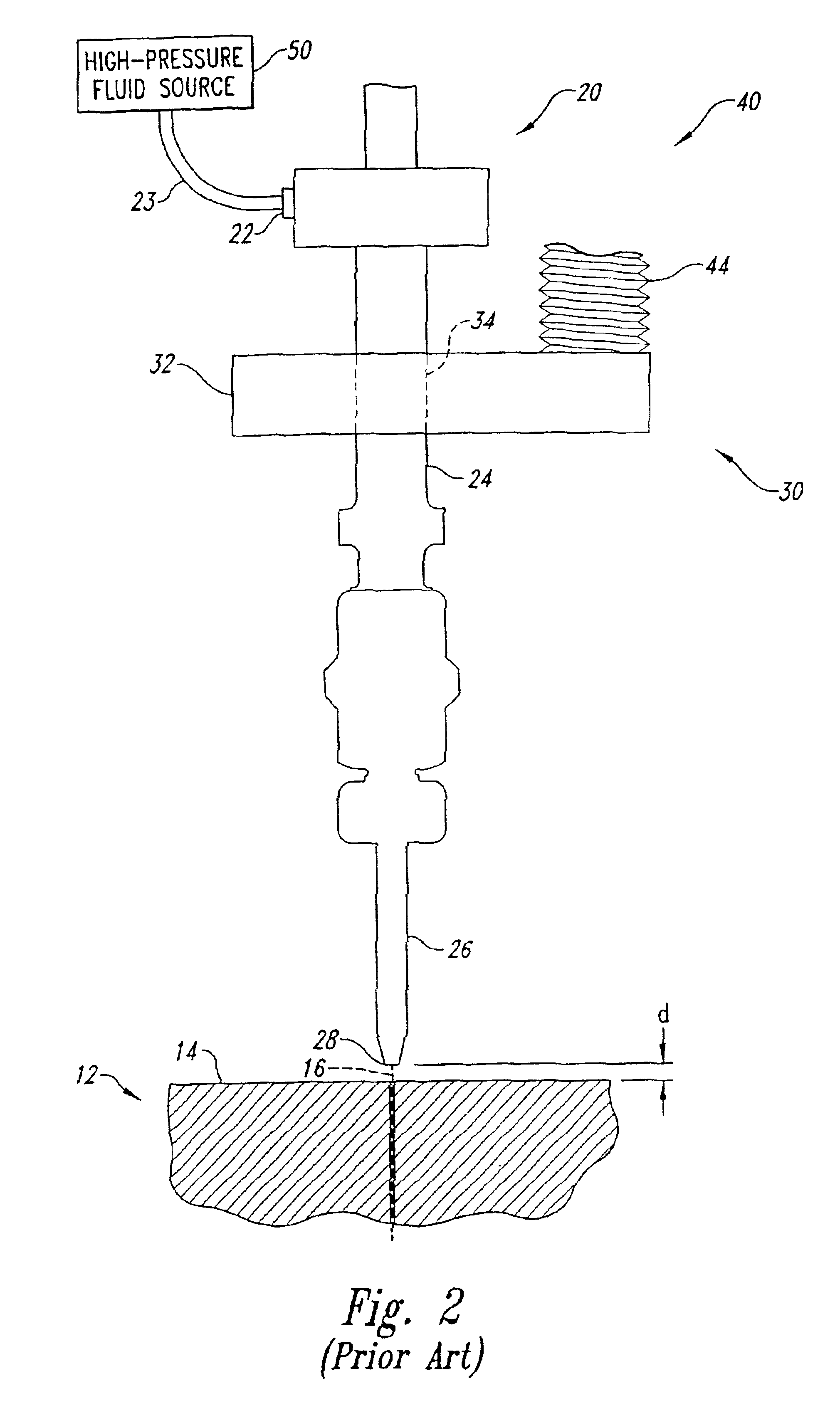

InactiveUS6852002B2Avoid breakingQuickly and easily re-engagedAutomatic control devicesMeasurement/indication equipmentsCollision detectionEngineering

This invention relates to apparatus and methods for z-axis control and collision detection and recovery for waterjet and abrasive-jet cutting systems. In one embodiment, an apparatus includes a linear rail, a slide member coupleable to a cutting head and slideably coupled to the linear rail, at least one actuator having a first end coupled to the slide member and a second end fixed with respect to the linear rail, a position sensor, and a controller. The actuator provides an adjustable support force that supports the weight of the cutting head, allowing the cutting head to be controllably positioned at a desired height above the workpiece. The actuator may include a pneumatic cylinder, or alternately, a linear motor. In another aspect, an apparatus includes a first mount member coupleable to a controllably positionable mounting surface of the waterjet cutting system, a second mount member coupleable to the cutting head and disengageably coupled to the first mount member, and a sensing circuit having a plurality of first conductive elements disposed on the first mount member and a plurality of second conductive elements disposed on the second mount member. In the event of a collision between the cutting head and an obstruction, the second mount member disengages from the first mount member to prevent breakage of the cutting head. Following the collision, the second mount member is quickly and easily re-engaged with the first mount member without time-consuming re-calibration. In one embodiment, re-engagement of the second end first mount members is automatically performed by a biasing member.

Owner:FLOW INT

Processes and apparatuses for enhanced cutting using blends of abrasive materials

ActiveUS20100124872A1Composition is limitedBlast gunsControlling ratio of multiple fluid flowsEngineeringDelivery system

A waterjet system selectively produces fluid jets for water jet cutting or abrasive jets for abrasive-waterjet-cutting. The abrasive materials in the abrasive jet are determined based on the properties of the workpiece. The waterjet system includes an abrasive delivery system that is capable of delivering either a single abrasive or a plurality of abrasives as an abrasive blend, to a cutting head assembly. The cutting head assembly entrains the abrasive into a fluid jet to form an abrasive jet.

Owner:FLOW INT

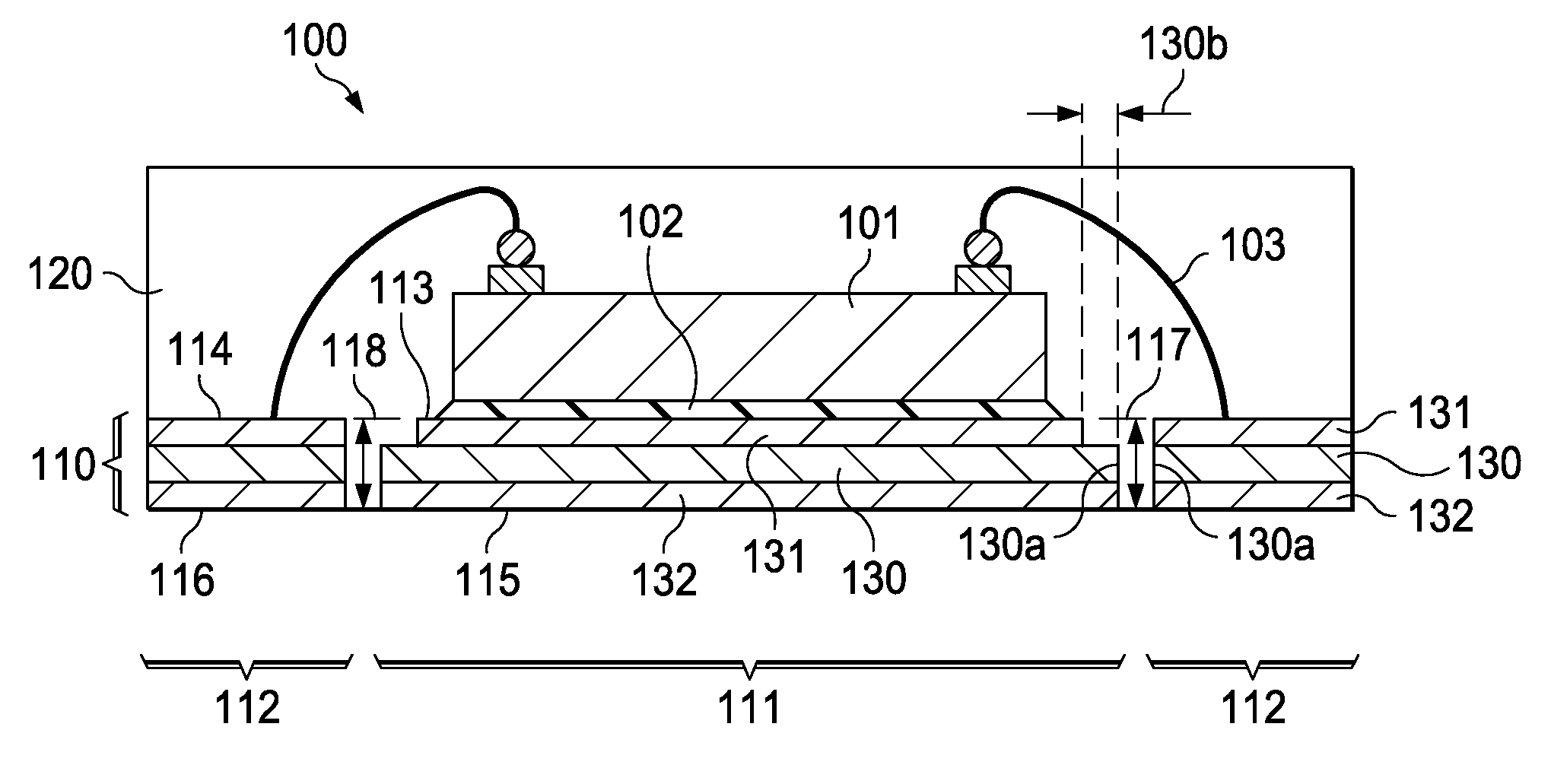

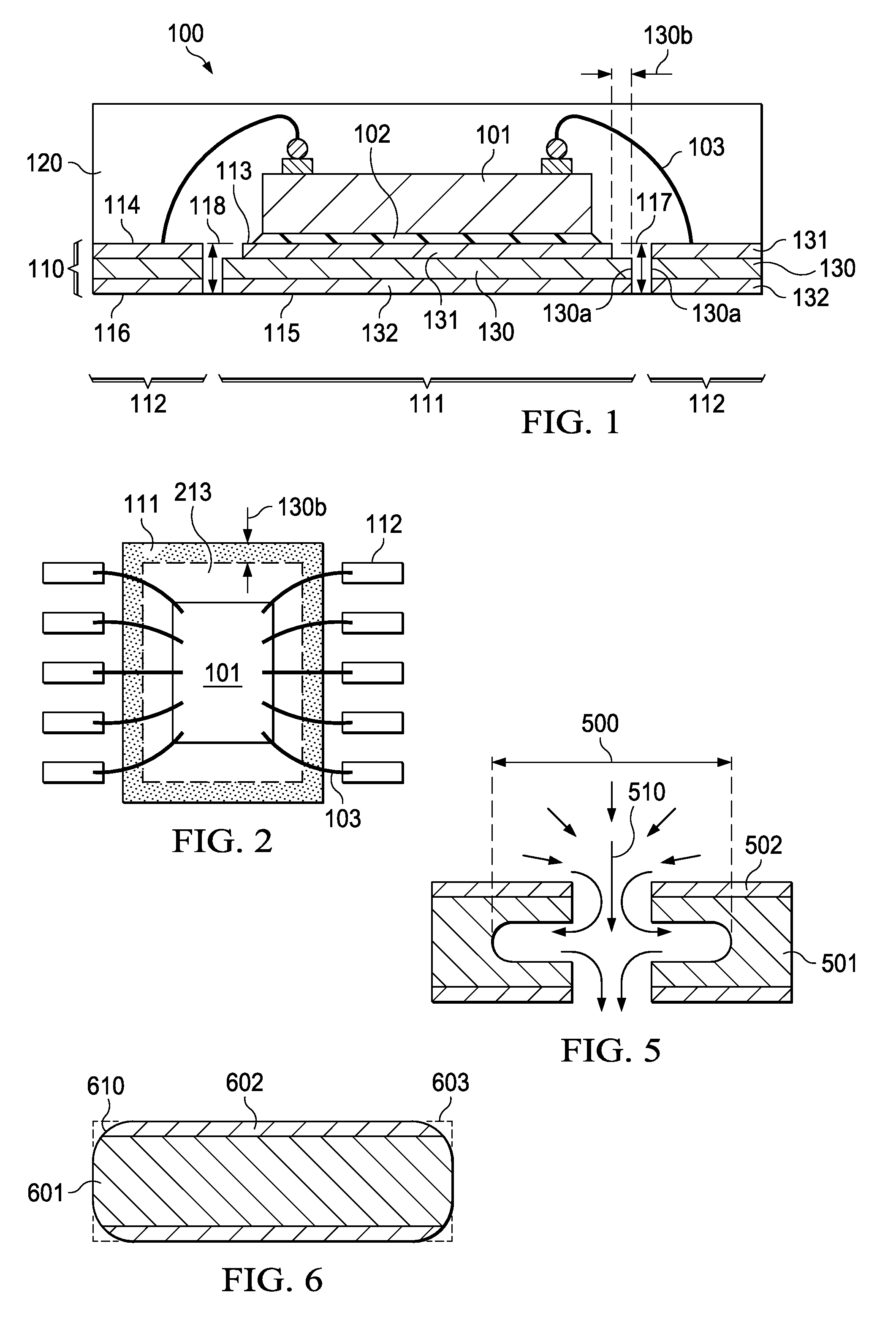

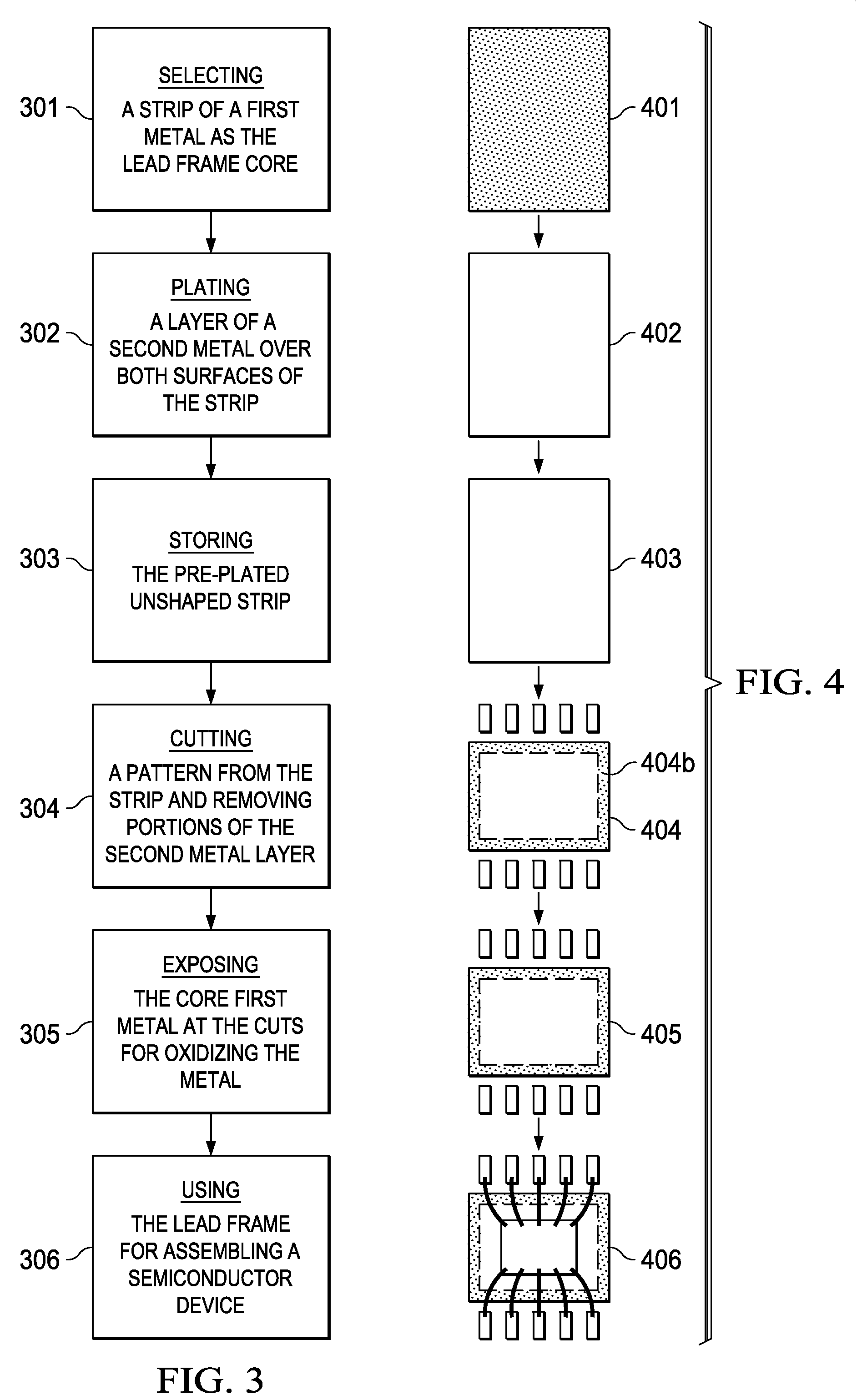

Method for Semiconductor Leadframes in Low Volume and Rapid Turnaround

ActiveUS20100295161A1Simple designImprove functionalitySemiconductor/solid-state device detailsSolid-state devicesNumerical controlLaser cutting

A method for fabricating a leadframe for a QFN / SON semiconductor device by selecting (301) a strip of a first metal as the leadframe core, then plating (302) a layer of a second metal over both surfaces of the strip, then cutting (304) a pattern from the pre-plated strip and further removing (304) portions of the second metal layer over a surface to expose the underlying core first metal. The exposed core first metal oxidized (305) before using (306) the leadframe for assembling the semiconductor device. The steps of cutting and removing are performed programmable machining techniques such as computer numerical controlled tools (CNC), electrical discharge machining (EDM), laser cutting, and water jet cutting.

Owner:TEXAS INSTR INC

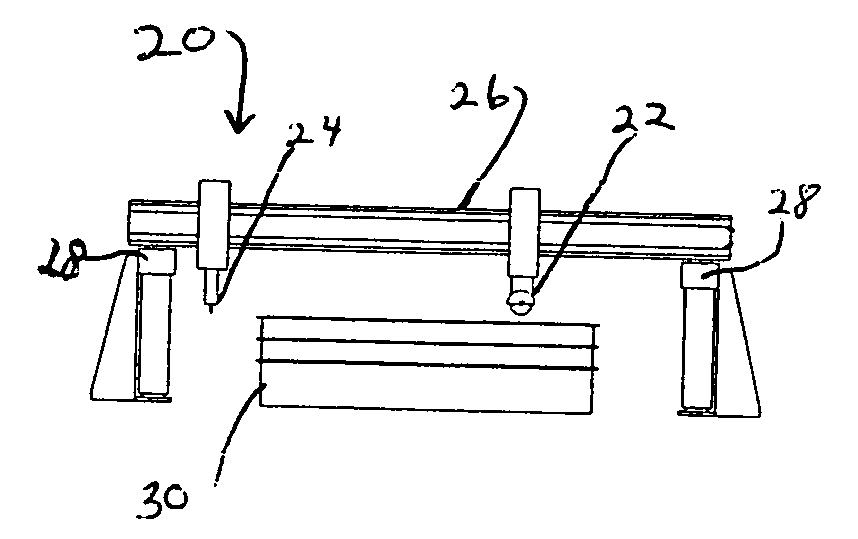

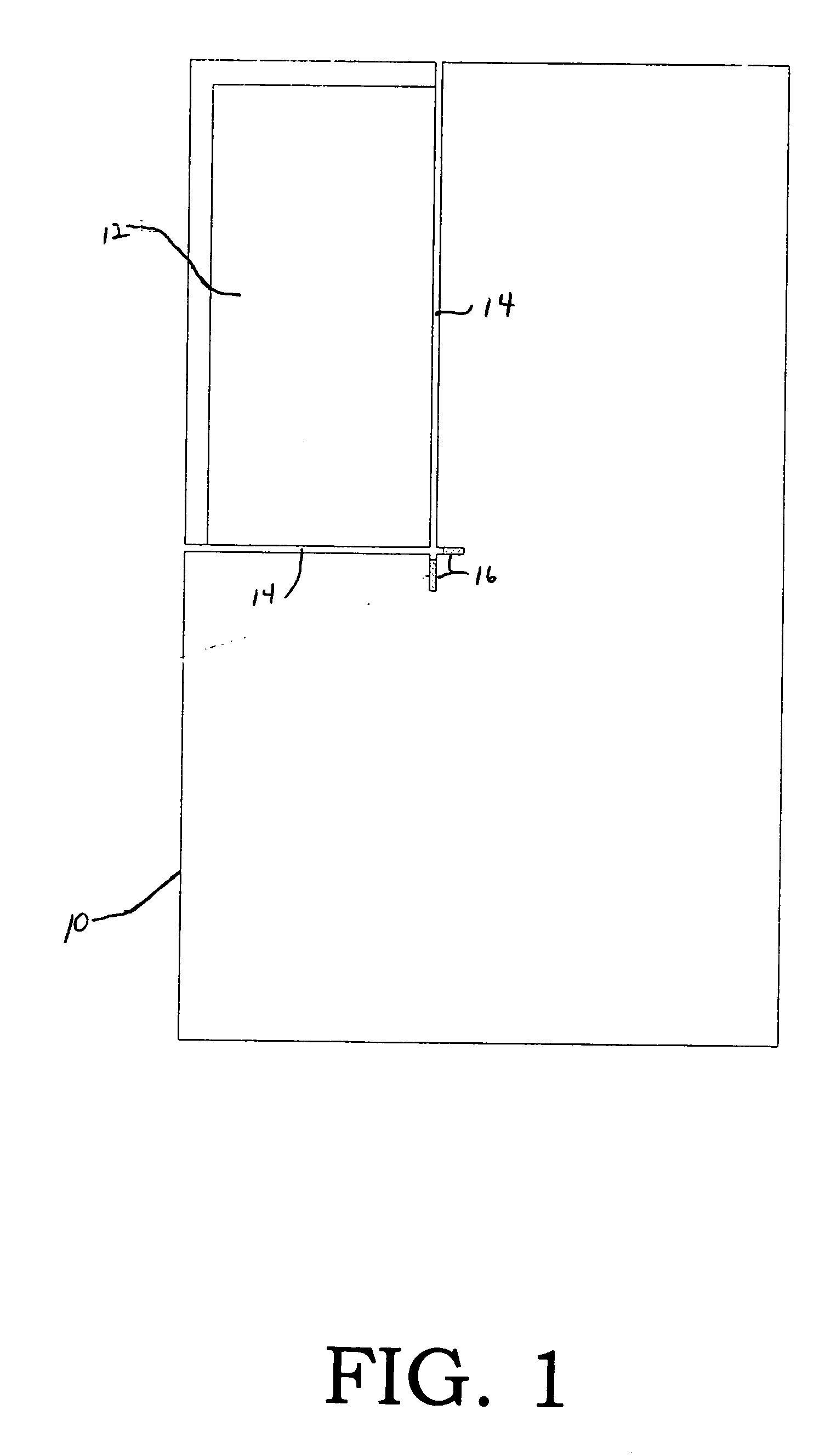

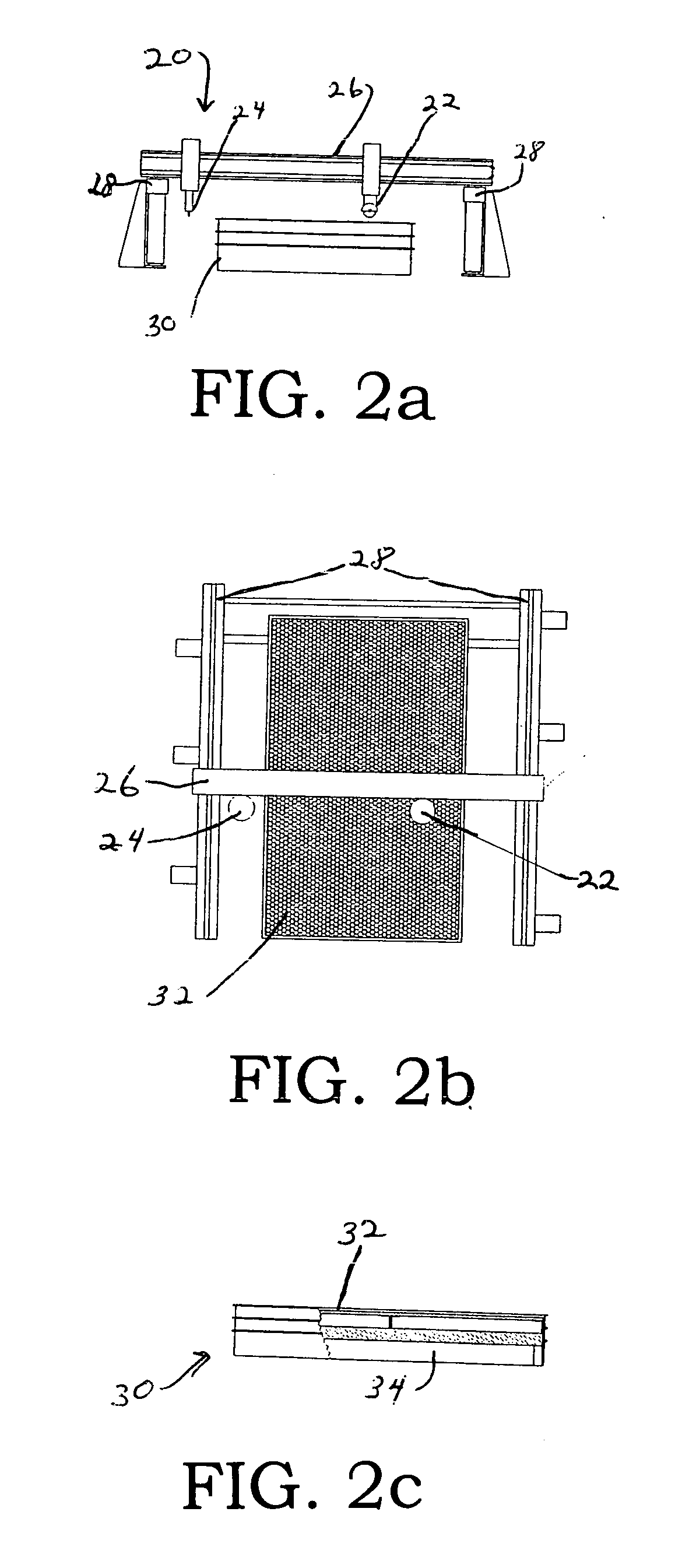

Stonecutting apparatus and method using saw and water jet

InactiveUS20060135041A1Prevent overtravelAvoid problemsGrinding feed controlAutomatic grinding controlEngineeringWater jet cutting

An apparatus for cutting stone which utilizes both a circular saw and a water jet. Both the saw and the water jet are mounted on a gantry, which moves along tracks. All the parts are under the control of the CNC device. The saw is used for straight cuts and curves where possible. The water jet, which is slower and more expensive to operate is only used where the saw cannot be used. The water jet is used to finish a saw cut to avoid any overtravel.

Owner:DAVES CABINET

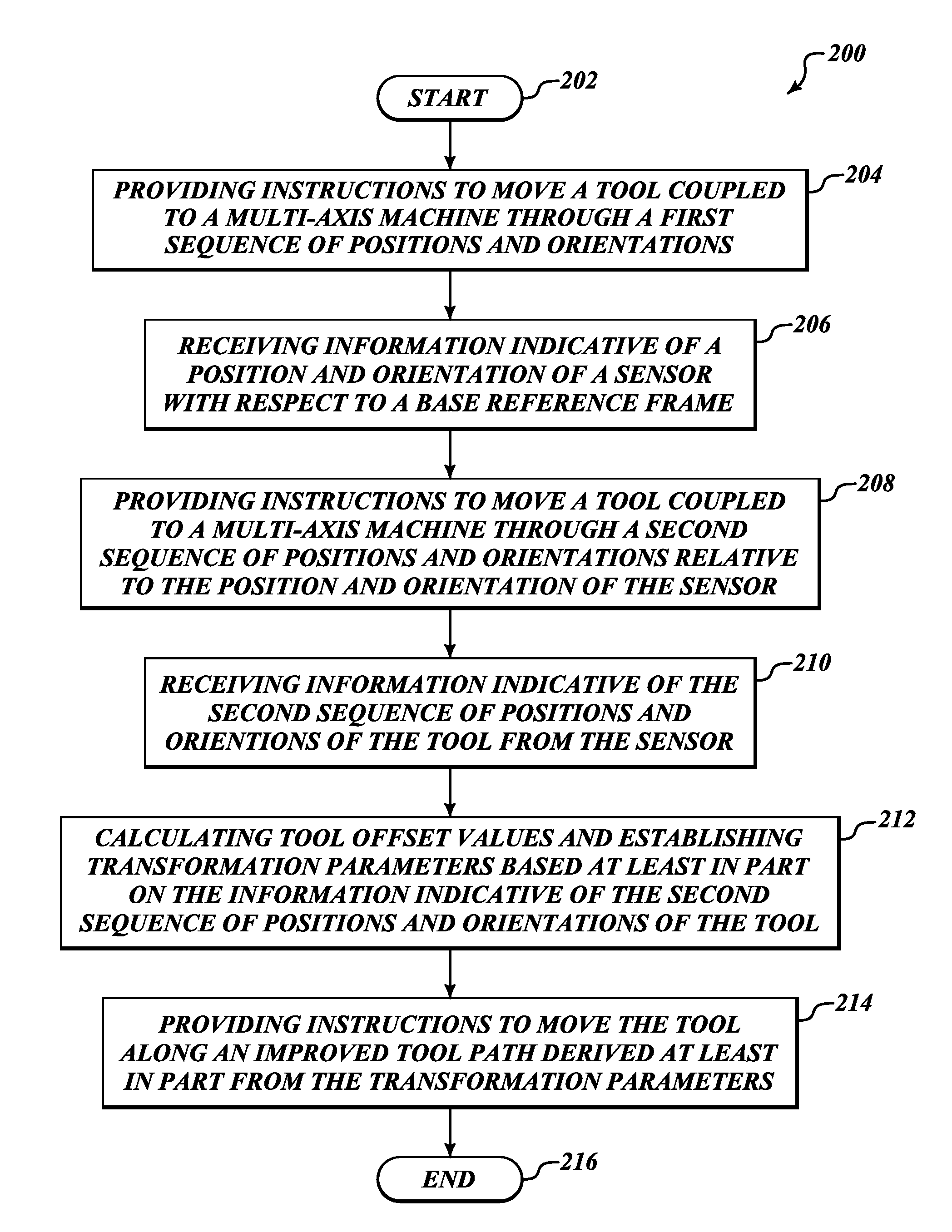

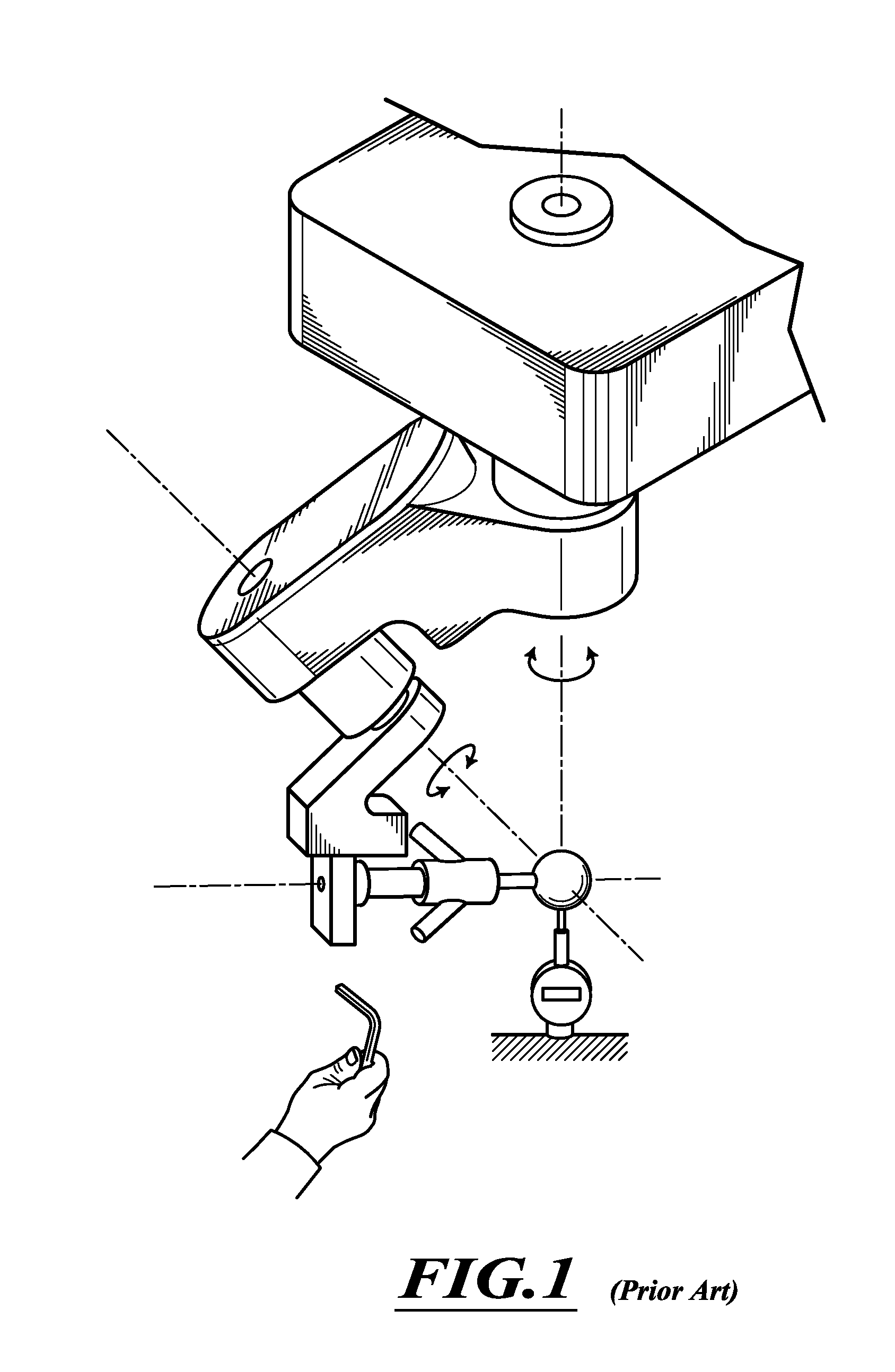

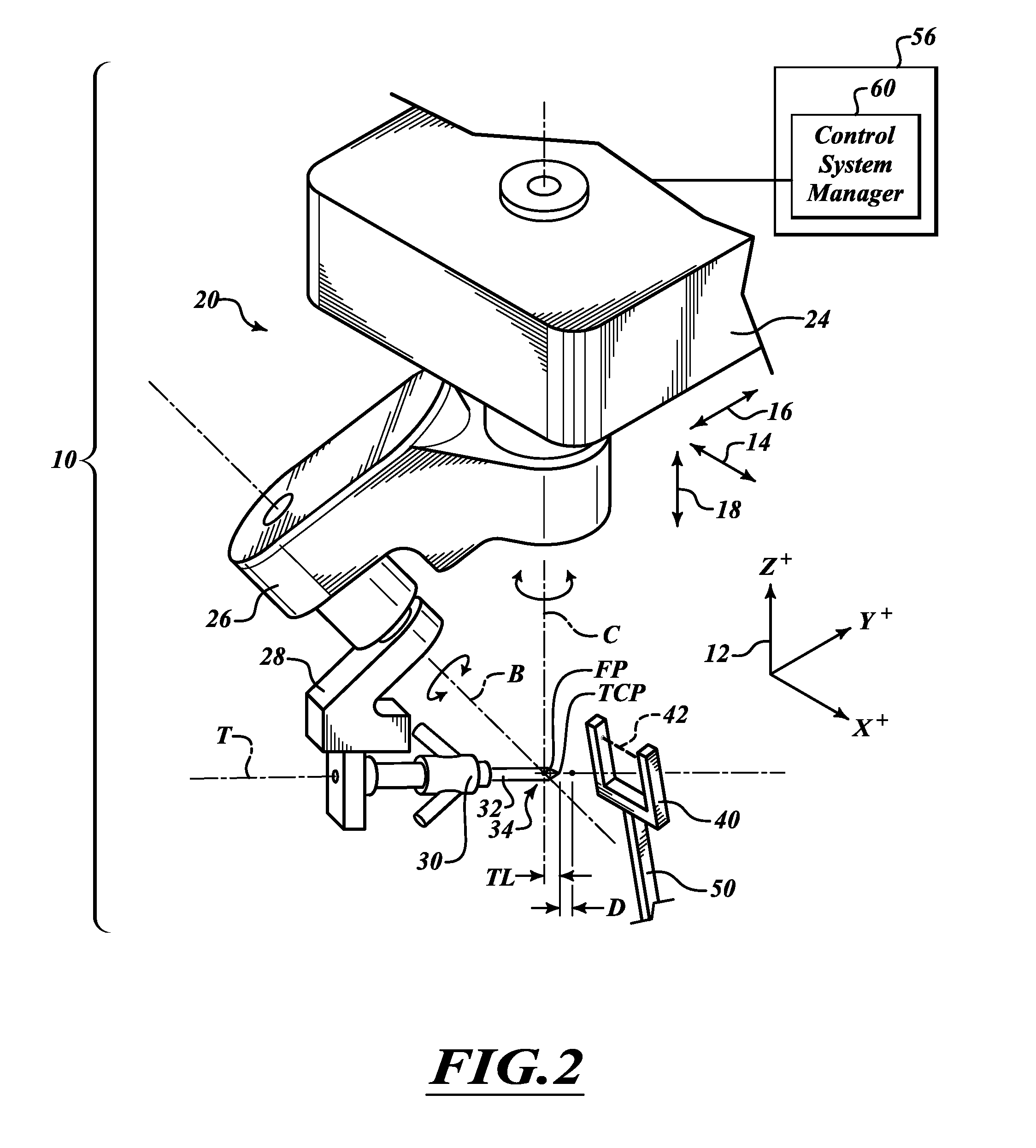

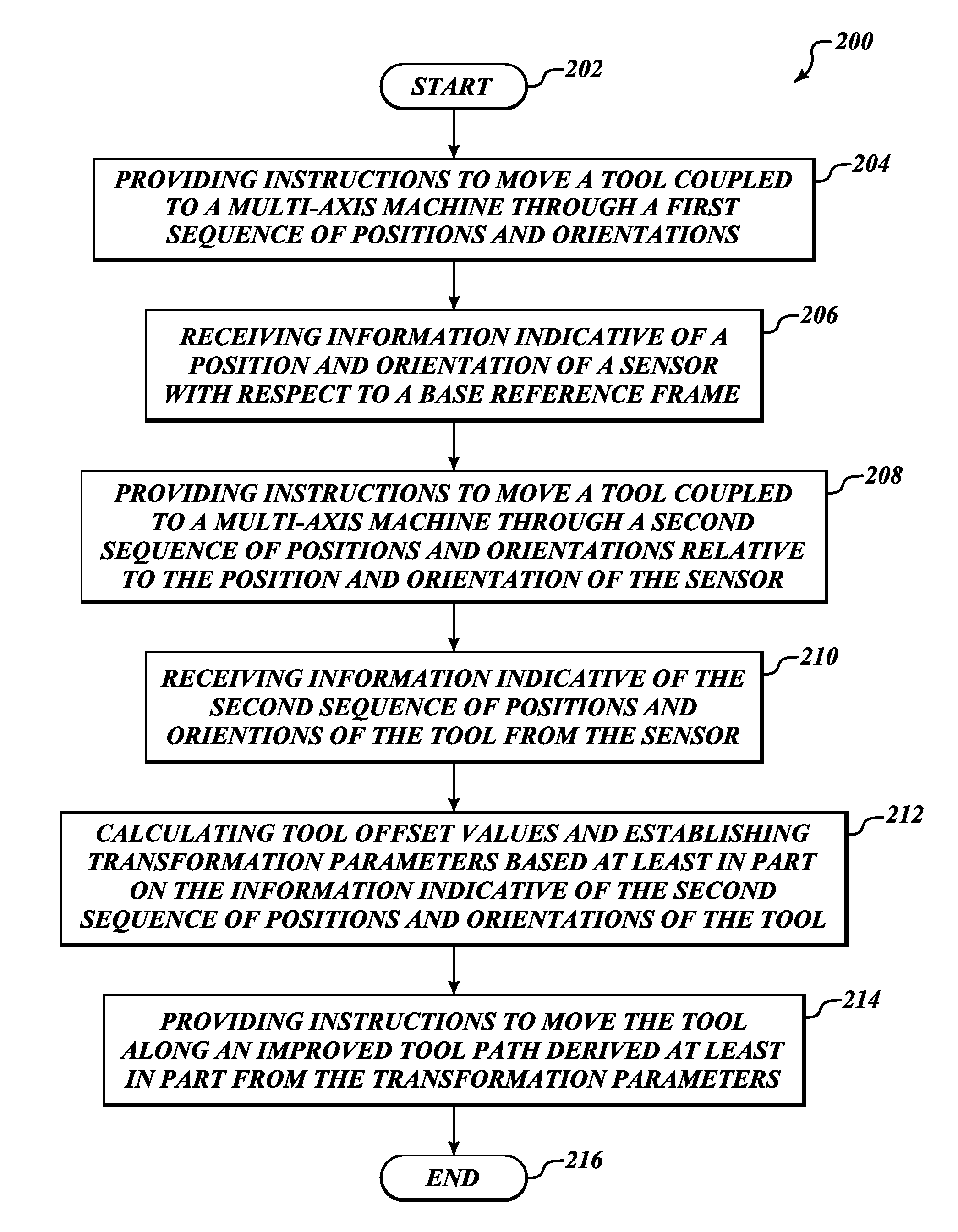

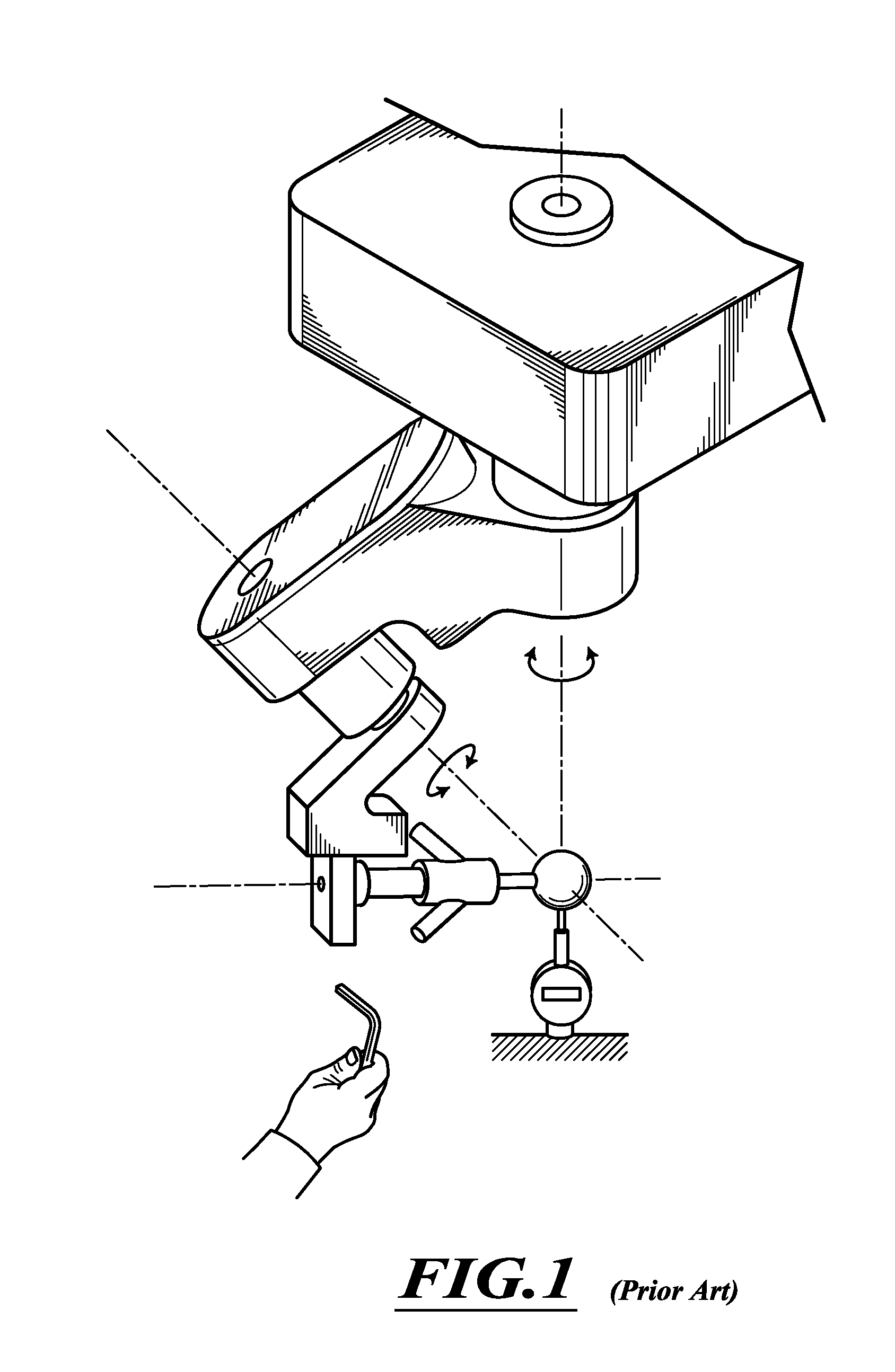

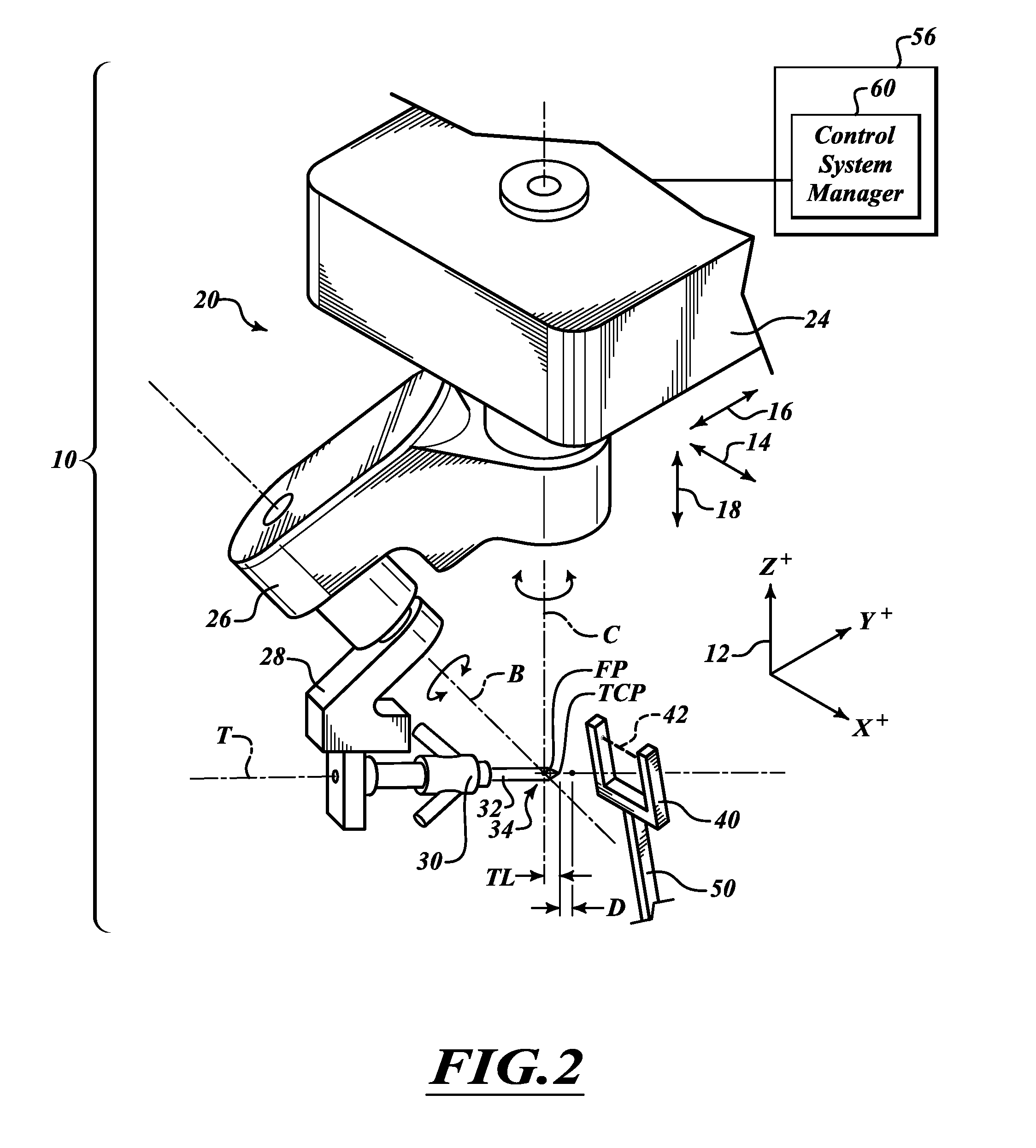

System and method for tool testing and alignment

A system and method for improving a tool tip path of a machine, such as a waterjet cutting machine, by testing and compensating for tool misalignment. The system and method using a sensor positioned to sense a portion of the machine, such as a cutting head assembly, during a sequence of movements thereof and configured to output information indicative of various positions and orientations of a tool of the machine so as to generate an improved tool tip path based on transformation parameters derived from such information.

Owner:FLOW INT

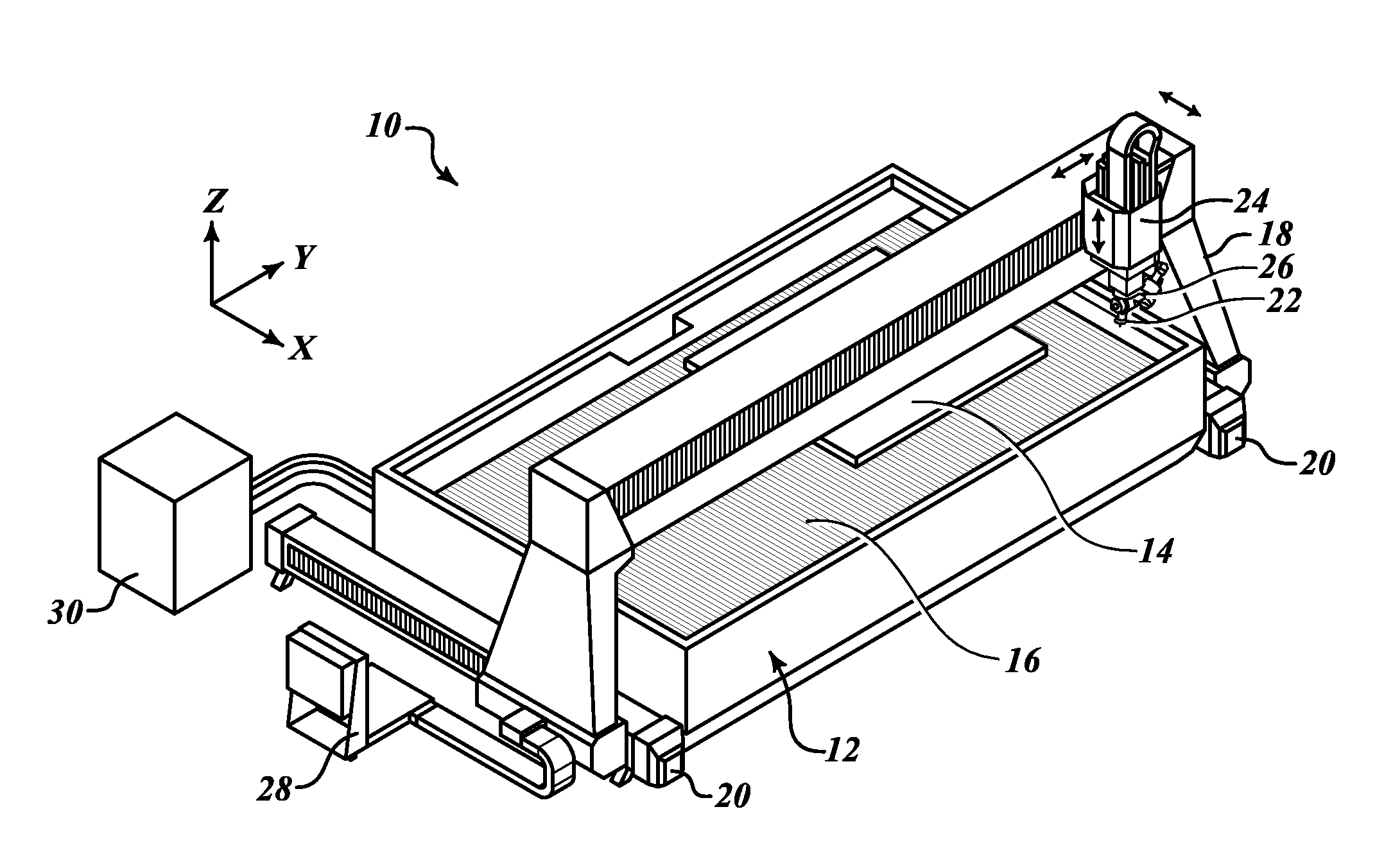

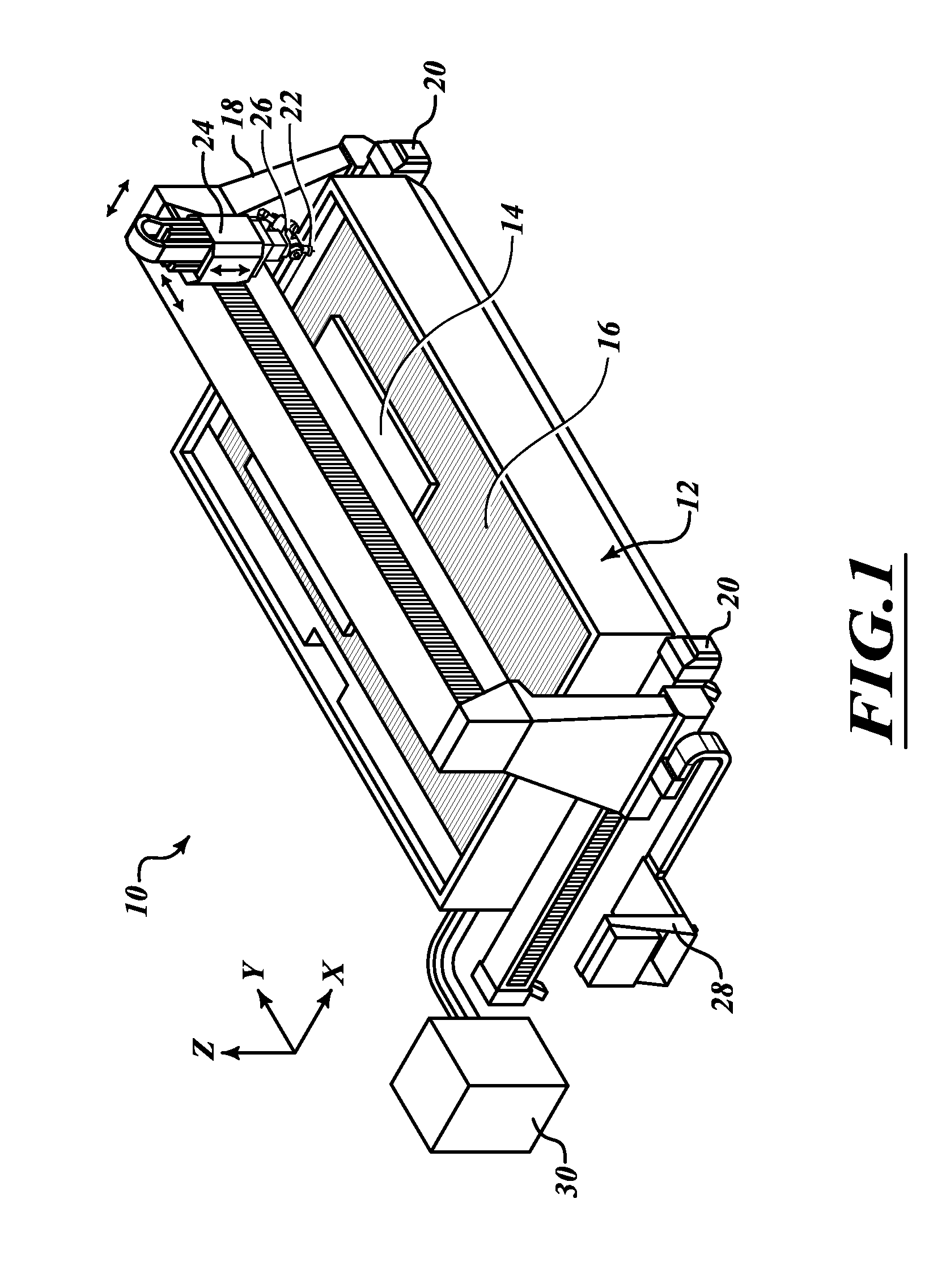

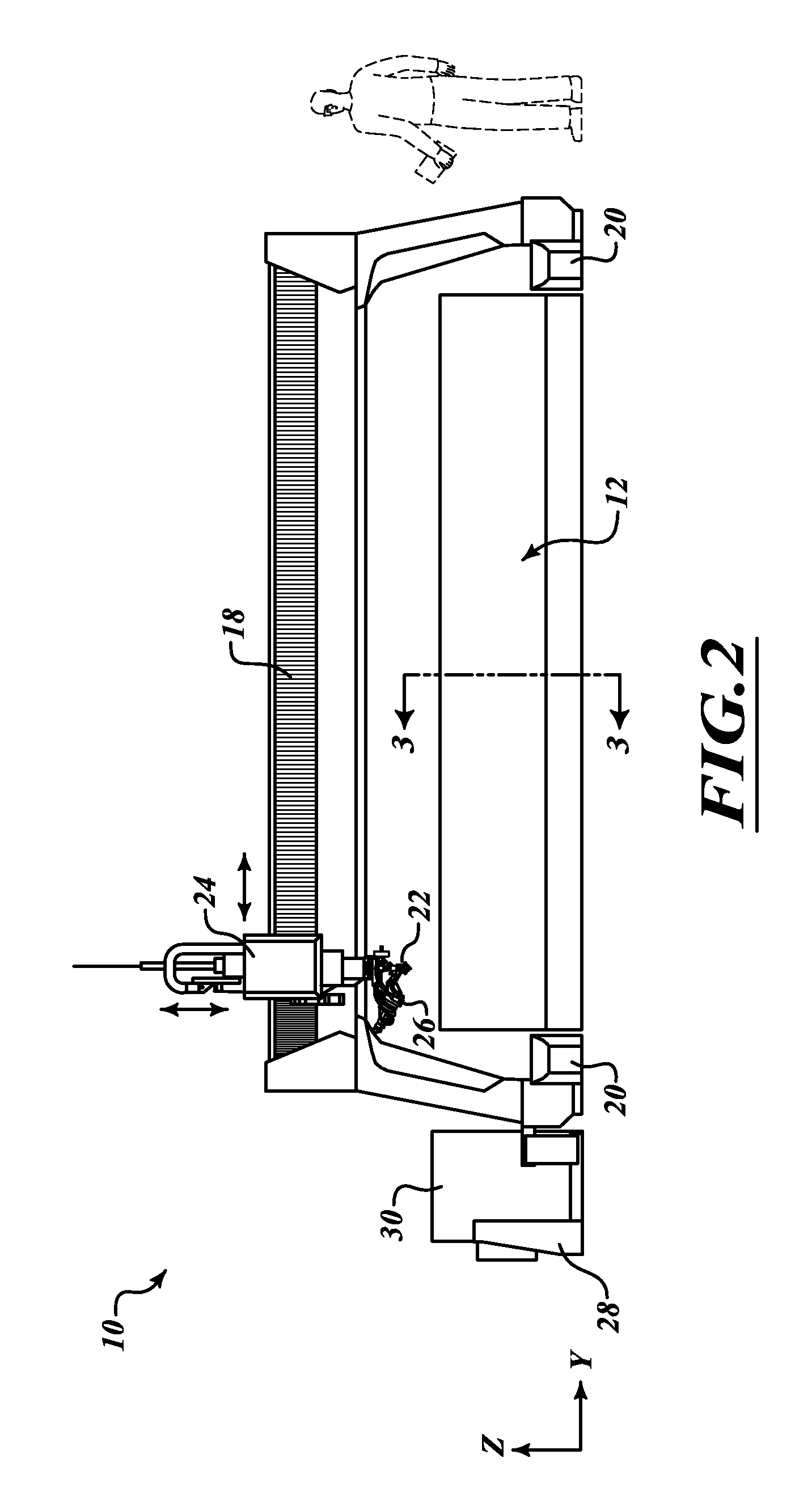

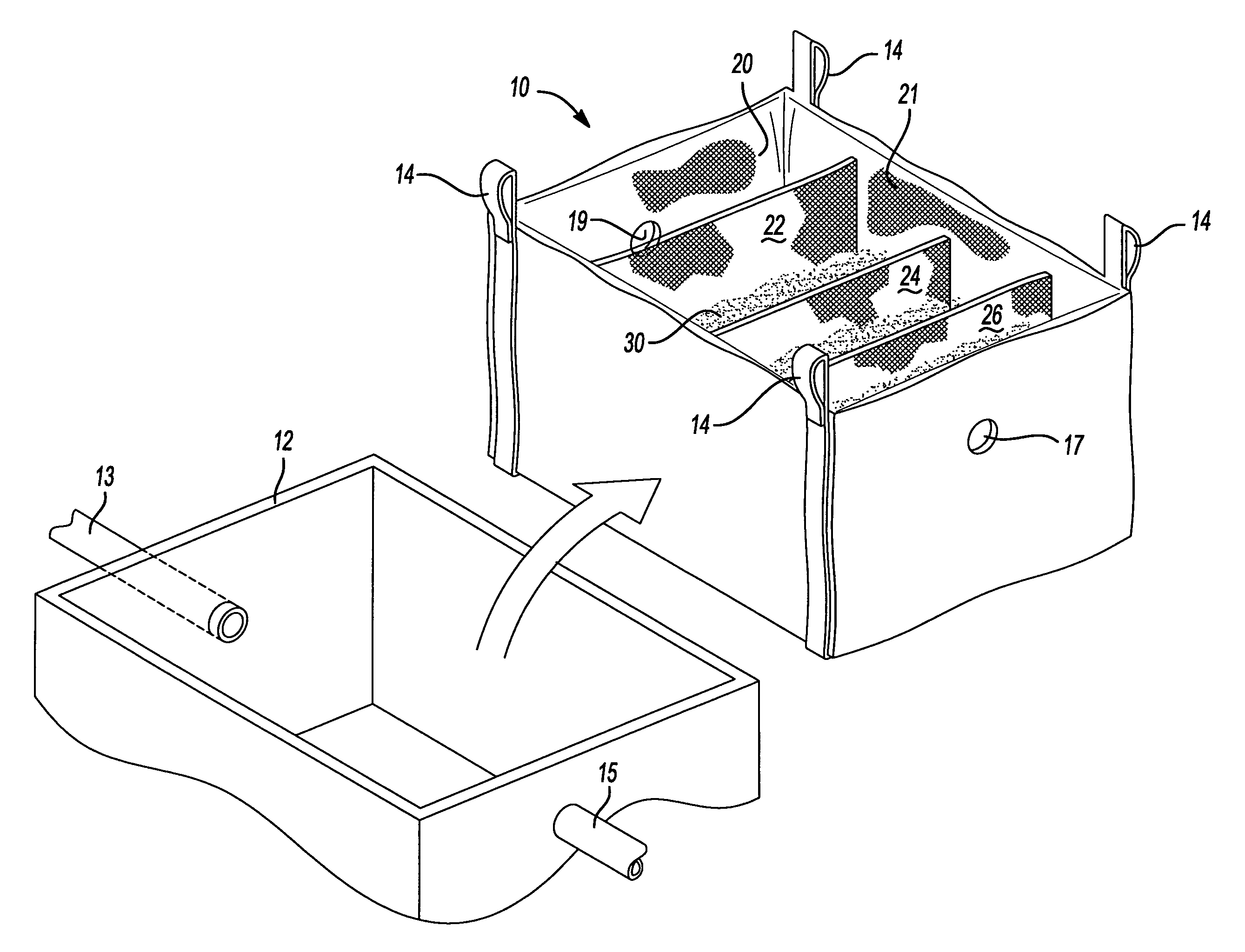

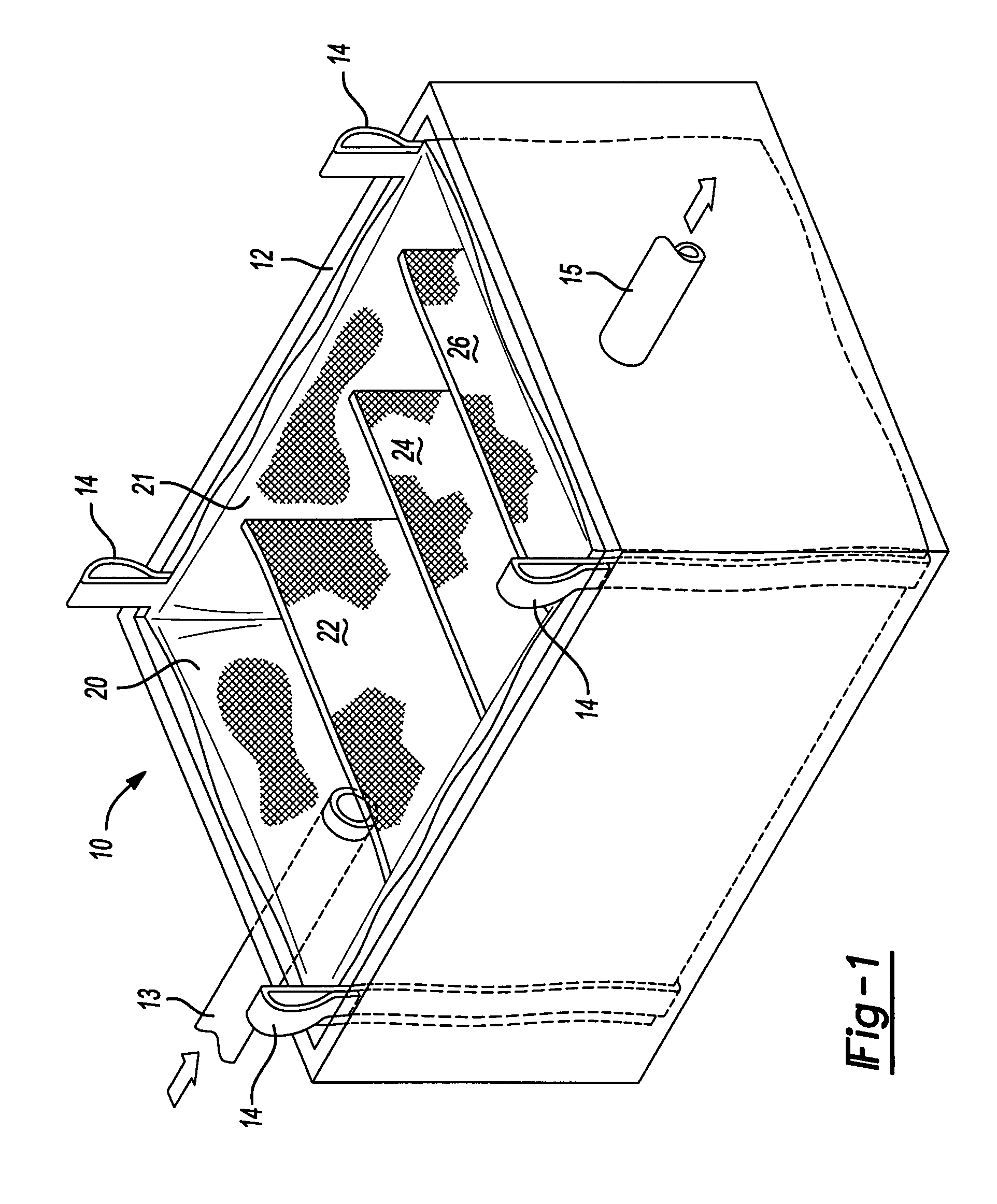

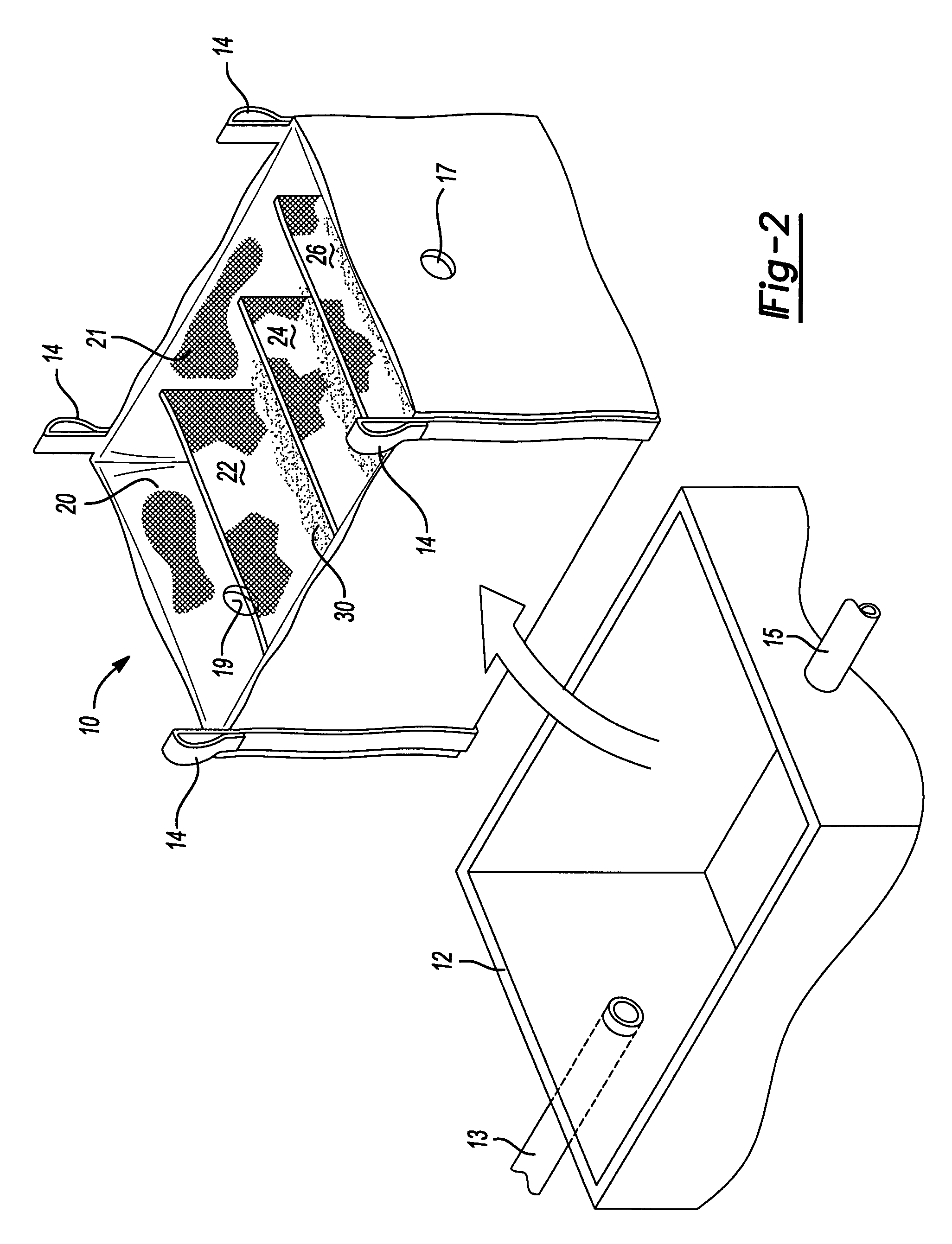

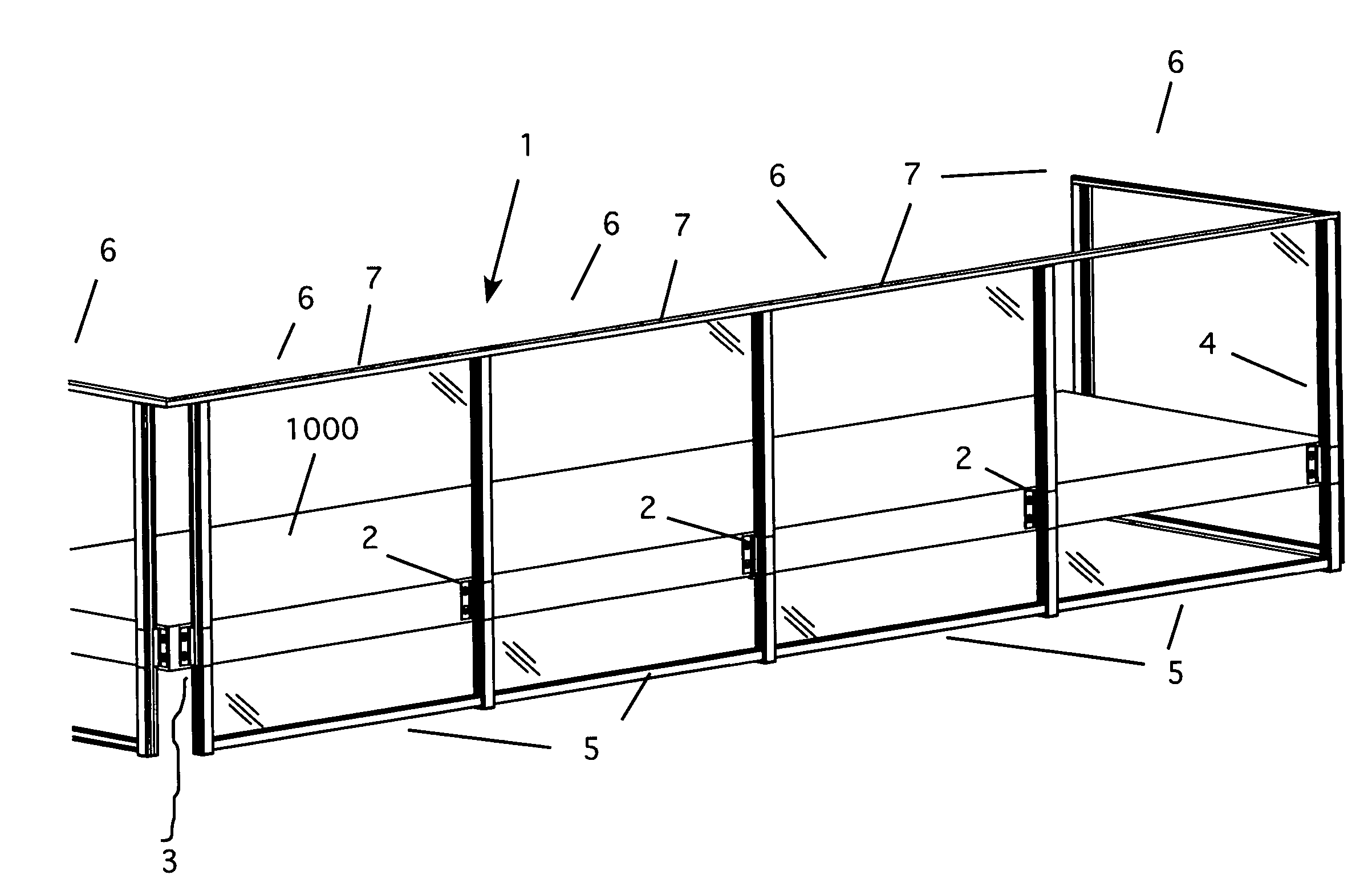

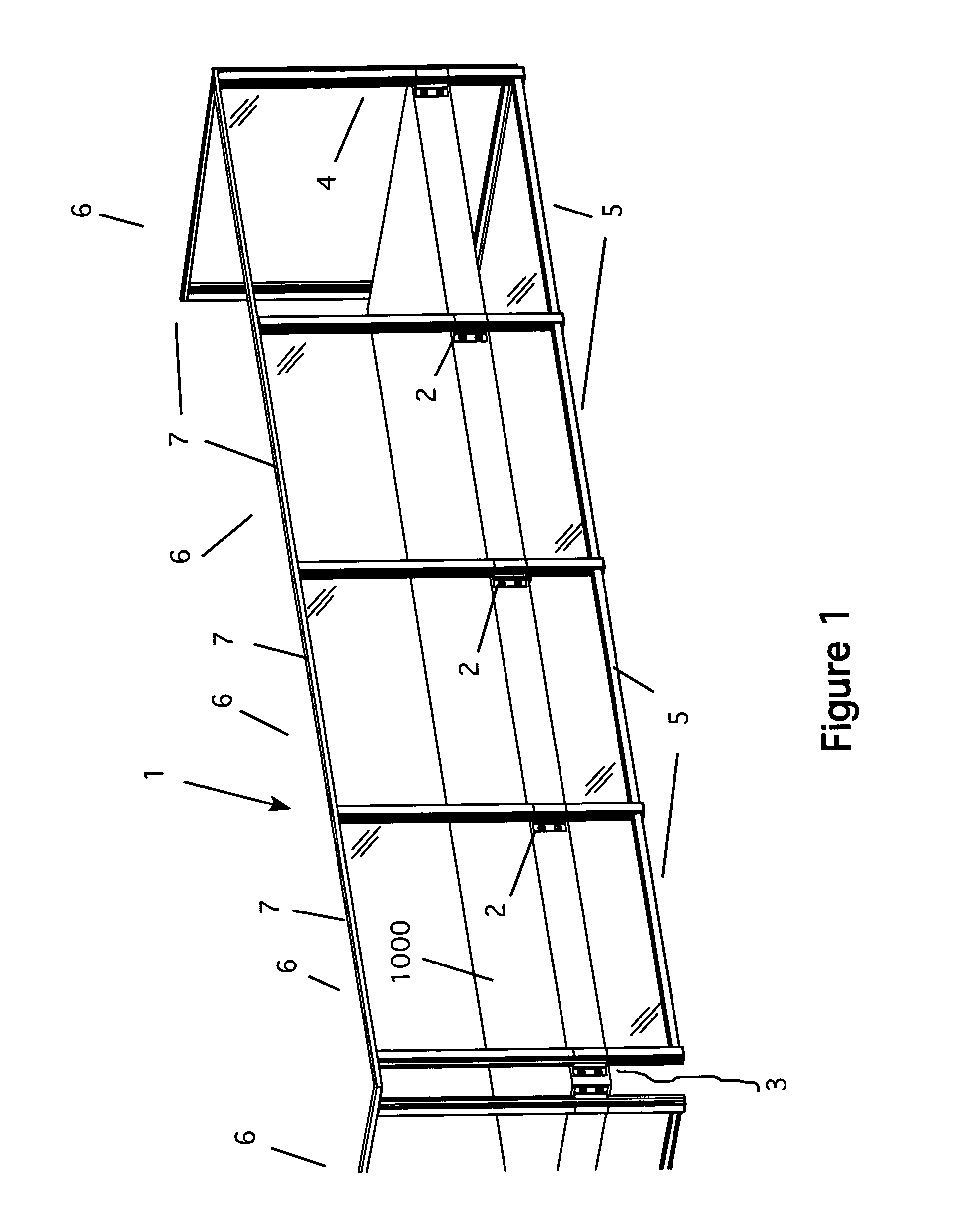

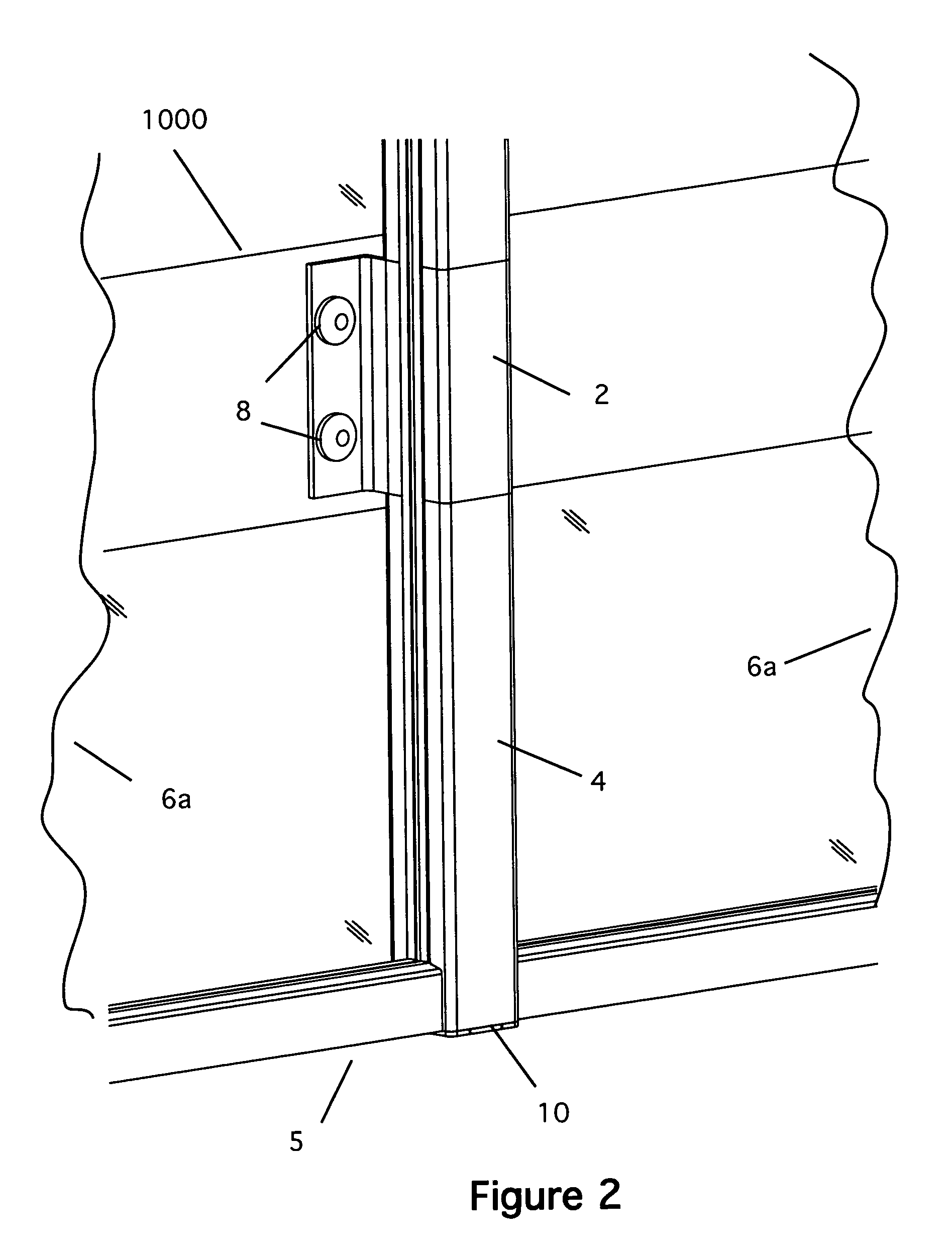

Catcher tank assembly of waterjet cutting system

ActiveUS20130025425A1Versatile form factorConvenient shipmentLarge containersMetal working apparatusSupporting systemEngineering

A catcher tank assembly is provided for a waterjet cutting machine. The catcher tank assembly includes a catcher tank having a plurality of tank sections detachably coupleable together in a side-by-side manner to collectively define a catcher tank having a desired configuration. The catcher tank assembly further includes a workpiece support system detachably coupleable to an interior cavity of the catcher tank. The workpiece support system may include a plurality of workpiece support modules arrangeable in an array to support a workpiece platform of the waterjet cutting machine. The workpiece platform may be formed, for example, by a series of slats supported transversely to parallel rows of the workpiece support modules. Methods and systems which relate to or include the aforementioned catcher tank assembly are also provided.

Owner:FLOW INT

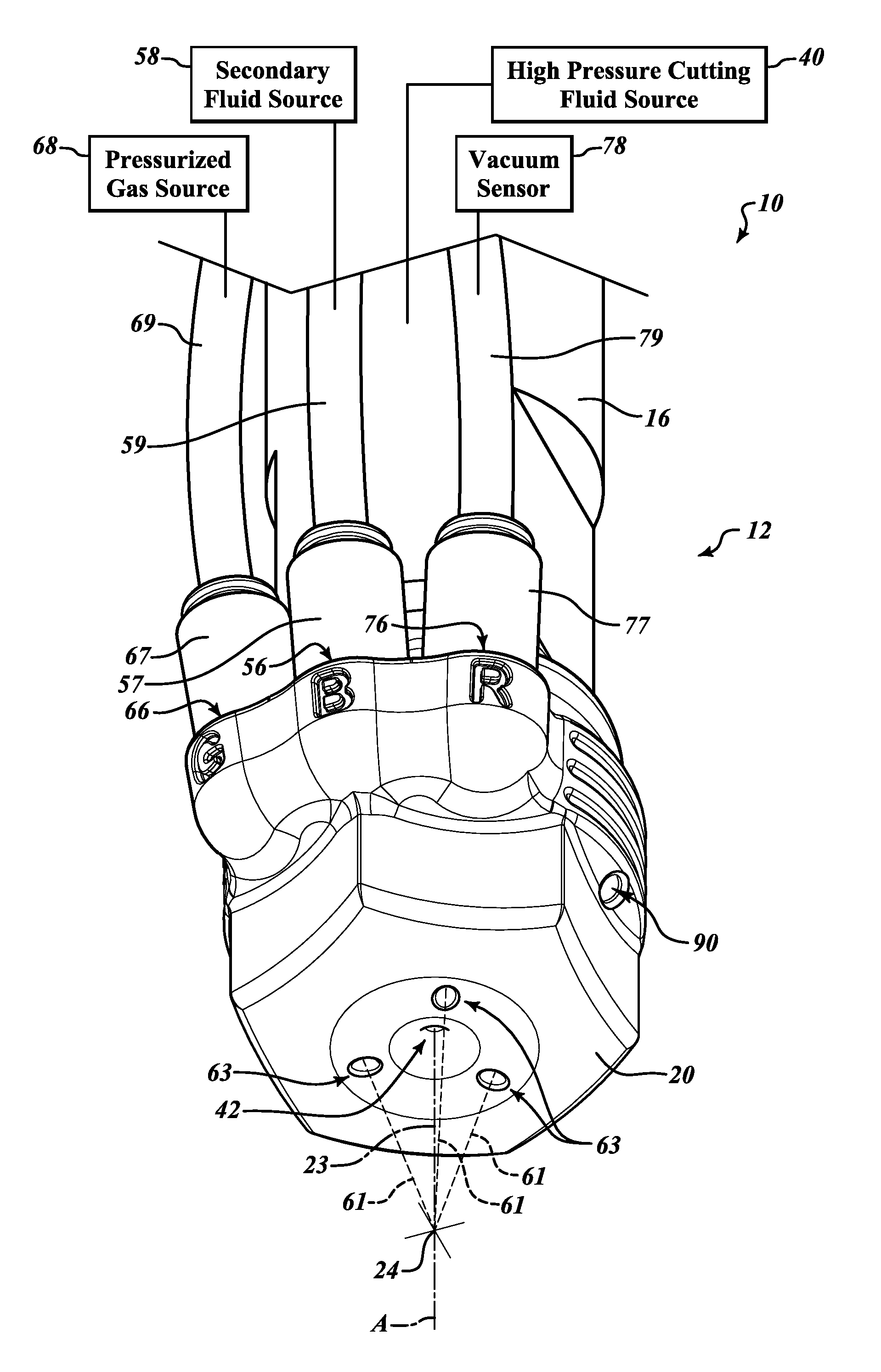

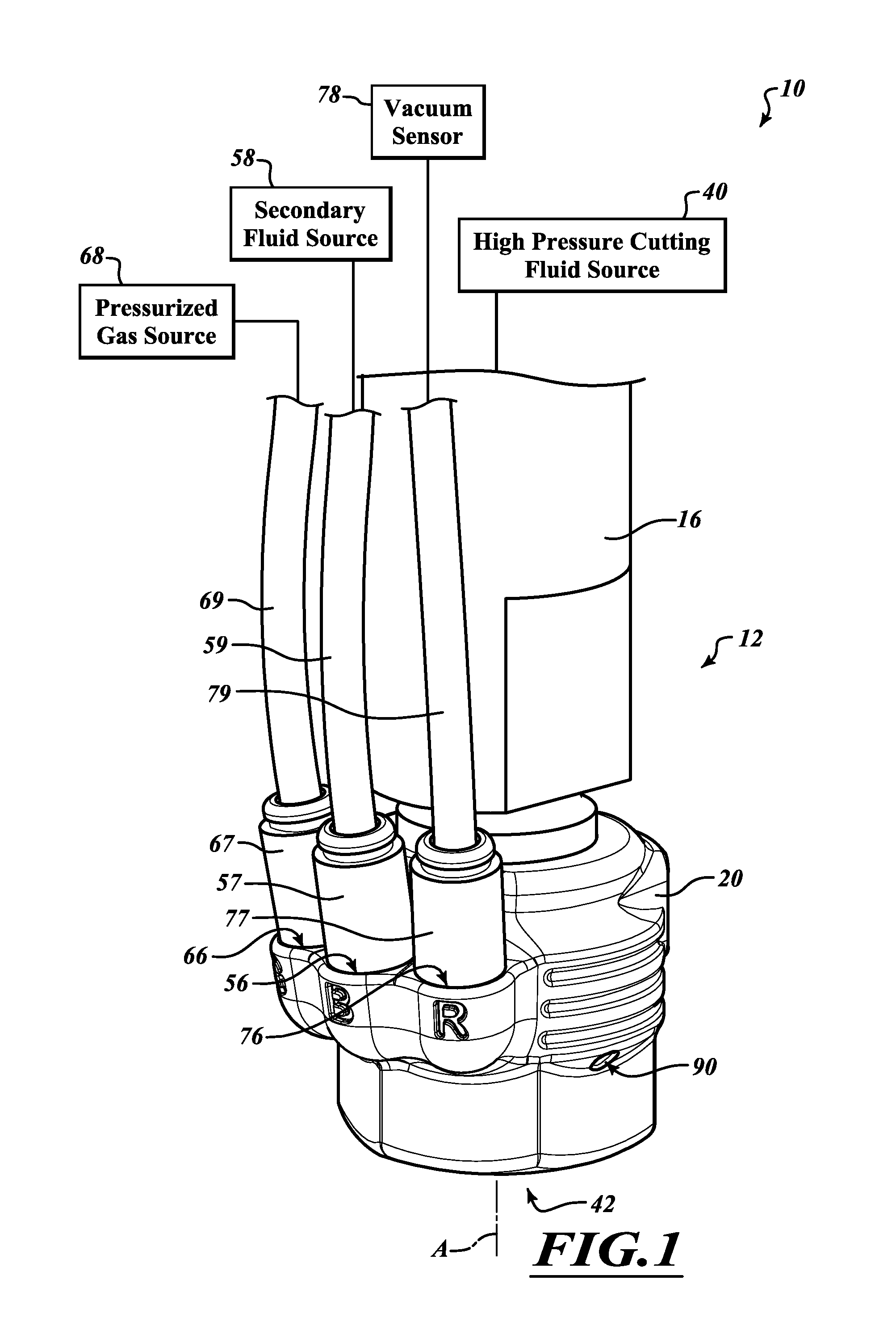

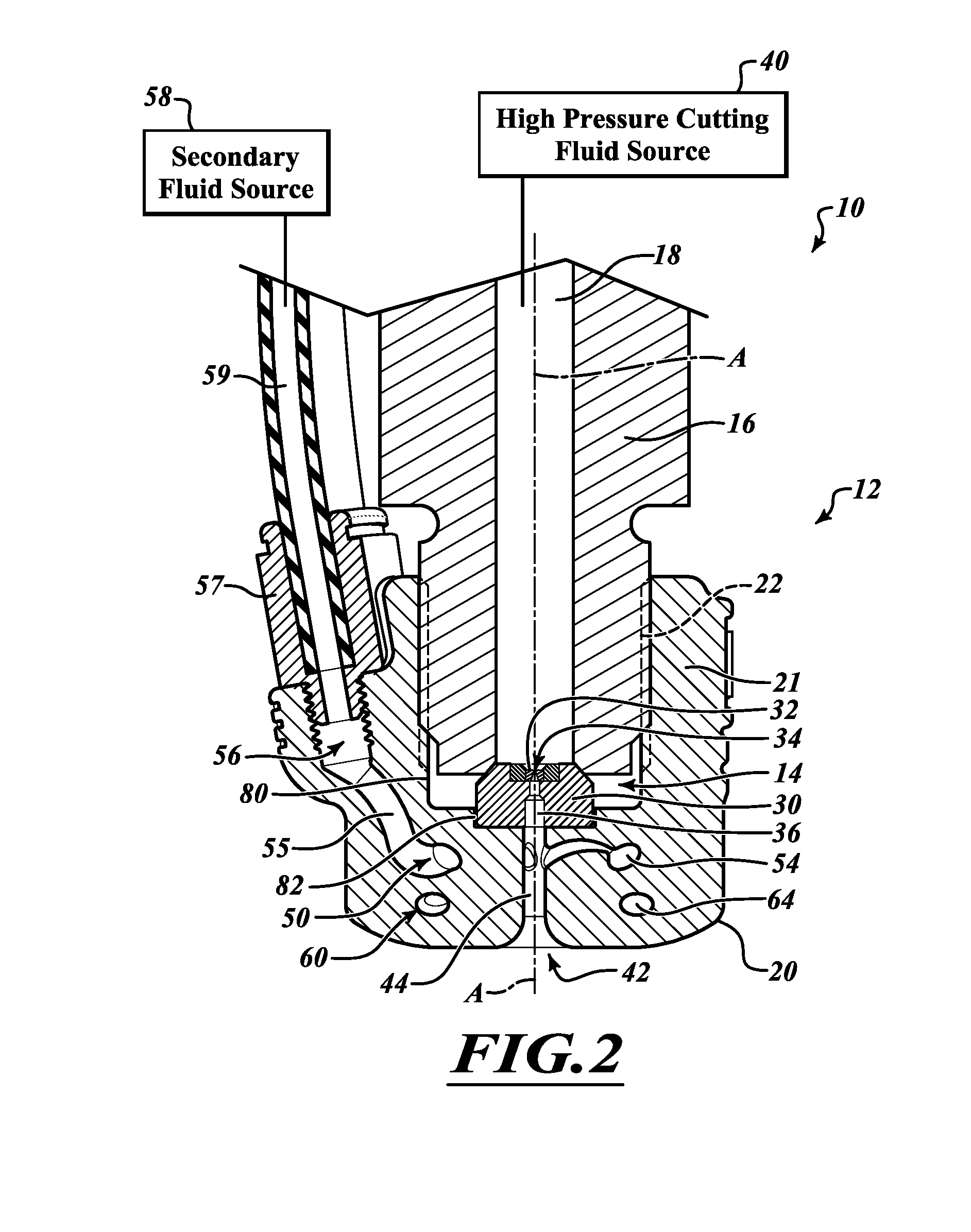

High-pressure waterjet cutting head systems, components and related methods

ActiveUS20150196989A1Reduce generationMaintain its cutting performanceBlast gunsAbrasive feedersSpray nozzleHigh pressure

A waterjet cutting head assembly is provided which includes an orifice unit to generate a high-pressure waterjet, a nozzle body and a nozzle component coupled to the nozzle body with the orifice unit positioned therebetween. The nozzle component may include a waterjet passage, at least one jet alteration passage and at least one environment control passage. The jet alteration passage may intersect with the waterjet passage to enable selective alteration of the waterjet during operation via the introduction of a secondary fluid or application of a vacuum. The environment control passage may include one or more downstream portions aligned relative to the fluid jet passage so that gas passed through the environment control passage during operation is directed to impinge on an exposed surface of a workpiece at or adjacent to a location where the waterjet is cutting the workpiece. Other high-pressure waterjet cutting systems, components and related methods are also provided.

Owner:FLOW INT

Waterjet cutting system with standoff distance control

ActiveUS9003936B2Efficient and accurate mannerBlast gunsAbrasive machine appurtenancesMeasurement deviceControl system

A cutting head of a waterjet cutting system is provided having an environment control device and a measurement device. The environment control device is positioned to act on a surface of a workpiece at least during a measurement operation to establish a measurement area on the surface of the workpiece substantially unobstructed by fluid. The measurement device is positioned to selectively obtain information from within the measurement area indicative of a position of the cutting head relative to the workpiece. A control system is further provided and operable to position the cutting head relative to the workpiece at a standoff distance based at least in part on the information indicative of the position of the cutting head relative to the workpiece obtained by the measurement device. A method of operating a waterjet cutting system is also provided.

Owner:FLOW INT CORP

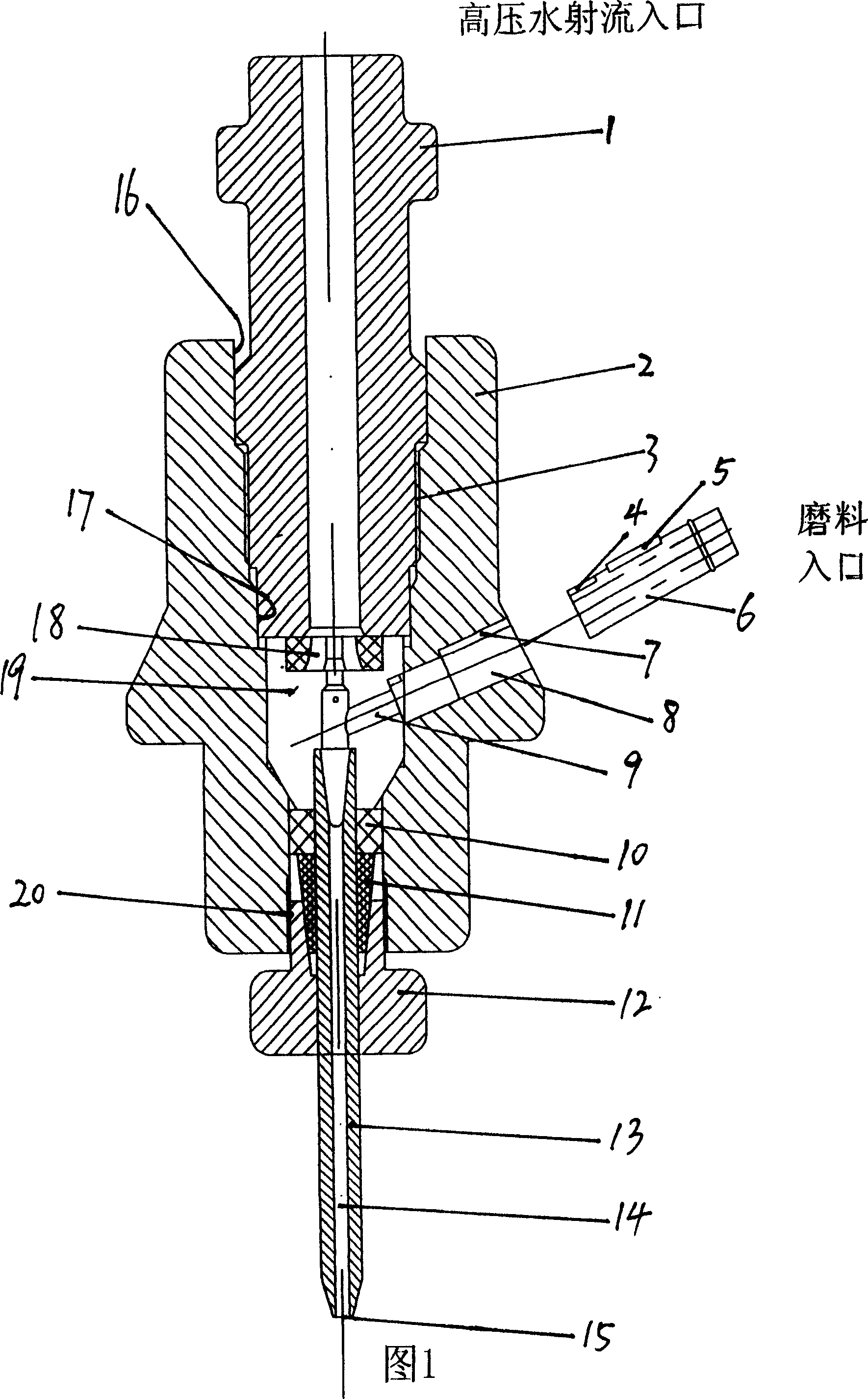

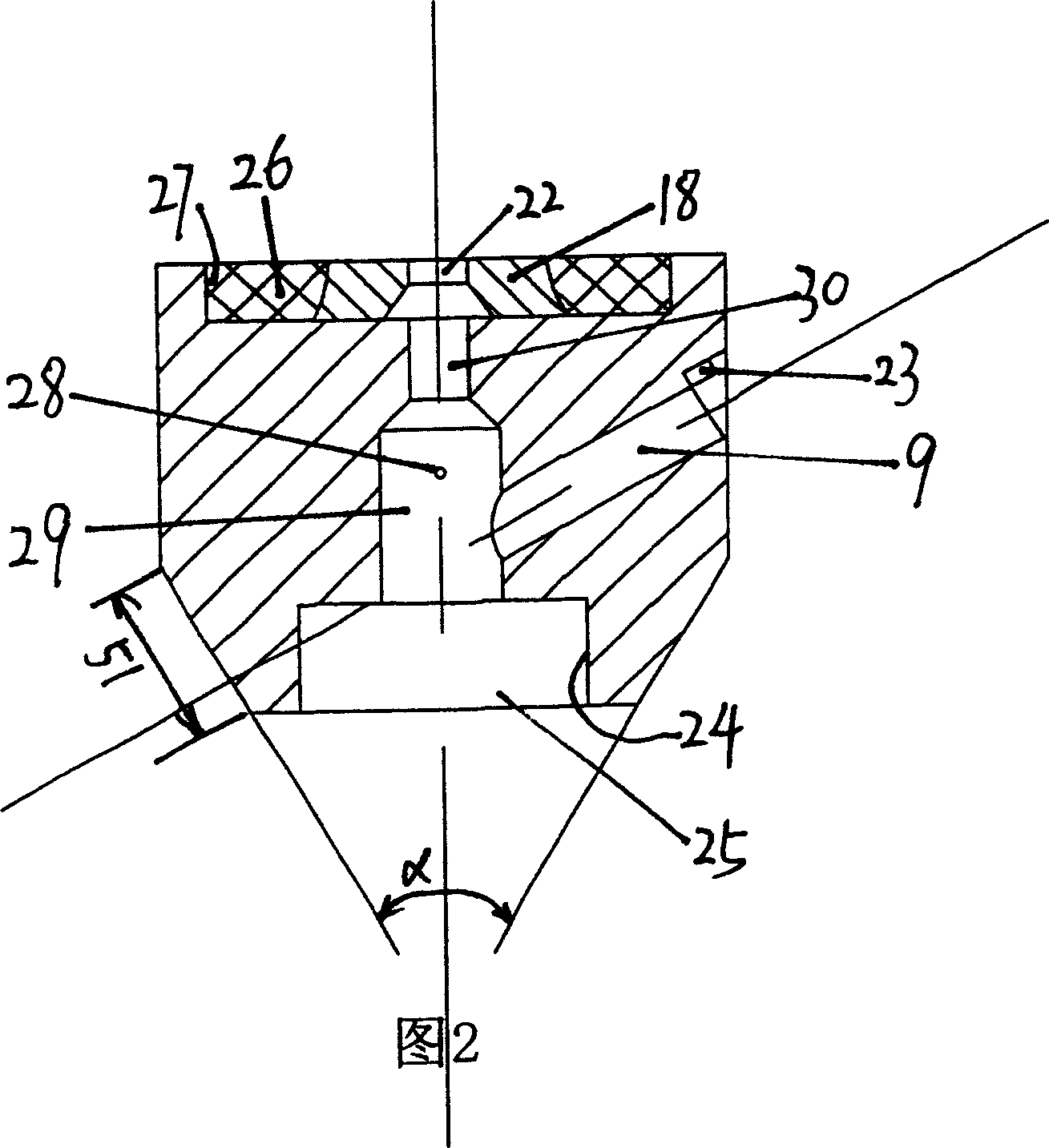

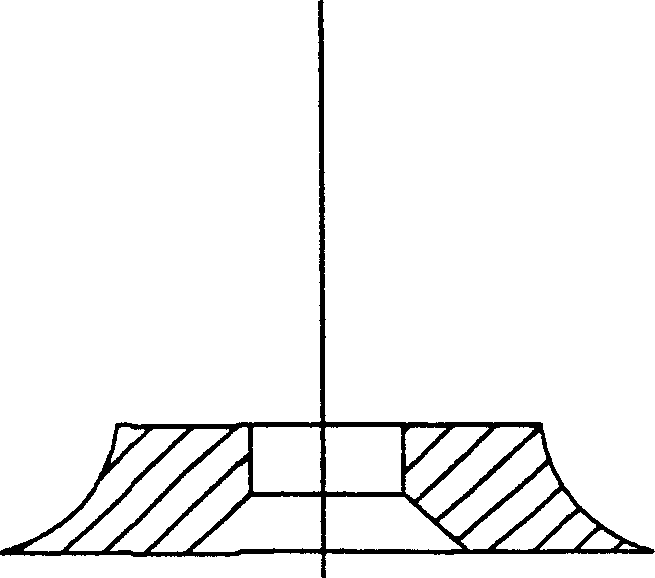

High-pressure abrasive material and water jet cutting head and blending tube

The invention provides a cutting muzzle and a mixing tube based on present abrasive water cutting muzzle. The invention has a mixing chamber inside the base of muzzle head and a conic part on the lower end of muzzle head; two guide surfaces on the cutting head to conform the axiality of muzzle body, muzzle head and base; and a taper locking device on the lower end of mixing tube. The invention can easily adjust the axiality of mixing tube and muzzle head to attain higher axiality. The invention has easy detachment of muzzle and mixing tube, lower cost which can save 10-20% power consumption, higher cutting efficiency, better quality, higher cutting speed, small kerf, and bigger cutting depth.

Owner:JIANGSU UNIV

Numerical-control six-shaft intelligent water jet cutter

InactiveCN104526765AOvercome the defect that the cutting cannot be completed at one timeReduce processing costsMetal working apparatusNumerical controlRotation function

The invention discloses a numerical-control six-shaft intelligent water jet cutter. The numerical-control six-shaft intelligent water jet cutter comprises a water jet cutting platform composed of a side frame, a transverse beam and a water tank, an X-shaft transmission mechanism, a Y-shaft transmission mechanism, a Z-shaft transmission mechanism and a cutting head installed on a Z shaft, wherein the X-shaft transmission mechanism, the Y-shaft transmission mechanism and the Z-shaft transmission mechanism are installed on the water jet cutting platform. The cutting head is a cutting head with the A-shaft, B-shaft and C-shaft transmission combined rotation function, an A-shaft driven belt wheel installed on an A-shaft frame is driven by an A-shaft motor, a water jet nozzle is fixed to the A-shaft driven belt wheel, and the water jet nozzle and the A-shaft driven belt wheel synchronously rotate. A B-shaft motor drives the A-shaft frame through the B-shaft transmission mechanism to perform arc rotation. A C-shaft motor drives a B-shaft frame to rotate, and a C-shaft flange shaft is connected with a C-shaft frame fixed to the Z shaft. Under the control of a master programmable controller, an X shaft, a Y shaft, the Z shaft, an A shaft, a B shaft and a C shaft are linked to control the position and the direction of the water jet nozzle, the defect that a traditional water jet cutting device can not complete cutting at a time under some conditions is overcome, the cutting head posture adjustment time is shortened, the cutting accuracy and the cutting efficiency are improved, and the water jet cutting machining cost is reduced.

Owner:奥拓福水刀有限公司

Water jet cutting machine

A machine for cutting the border of a workpiece using one or more water jet cutting tools separately carried by one or more monorail track mounted carriage assemblies is disclosed. The machine can also include an aperture forming apparatus for forming circular openings and / or elongated slots in the workpiece prior to / or simultaneously with the border trimming operation, all while the workpiece occupies a single work station in the machine. In one embodiment, the aperture forming apparatus features a cutting tool mounted on an elongate arm affixed to and extending from a plate which is fixedly oriented in a horizontal plane. While so oriented, a motor and gear assembly causes the plate to wobble in a circular pattern in the plane to, in turn, cause the tool to make a circular cut in the workpiece. In another embodiment of the apparatus, a motor rotates a cam carried on a free end of a stationary arm, the cam containing an eccentrically mounted cutting tool.

Owner:ADKINS DANIEL +2

Method for manufacturing composite fabric automobile roof

ActiveCN101987599ASolve flame retardancyAddressing Pollution ResistanceSevering textilesHeating/cooling textile fabricsFiberAlcohol

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Method for producing automotive sound-insulating pad

ActiveCN101987511AReduce weightMeet the requirements of lightweight designDomestic articlesFlat articlesThermoplasticEngineering

The invention relates to a method for producing an automotive sound-insulating pad. The method for producing the automotive sound-insulating pad comprises the following steps of: a, laying a raw material, namely laying a thermoplastic felt material on the network chain of an oven; b, baking and softening, namely feeding the thermoplastic felt material into the oven through the network chain of the oven for baking and softening, wherein the temperature of an upper heating zone in the oven is between 230 and 250 DEG C, the temperature of a lower heating zone is between 310 and 330 DEG C, and the baking time is 255 to 285 s; c, performing compression molding, namely performing compression and cooling on the baked and softened thermoplastic felt material to be a semi-finished product, wherein during the compression and cooling molding, the molding pressure is 16 to 17 MPa, the molding time is 90 to 110 s, and the cooling temperature is between 20 and 30 DEG C; d, performing water jet cutting, namely positioning the semi-finished product subjected to the compression cooling, and performing water jet cutting to obtain the required sound-insulating pad, wherein the cutting water pressure is 40,000 to 50,000 psi, and the cutting air pressure is 0.6 to 0.8 MPa; and e, inspecting, namely inspecting the sound-insulating pad, and packing and warehousing. The method for producing the automotive sound-insulating pad is simplified, energy-saving and environment-friendly, the automotive sound-insulating pad has high strength, the production efficiency of the method is high, and the method can reduce labor intensity.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Disposable weir liner

InactiveUS7438803B1Reduce downtimeThe process is convenient and fastSedimentation tanksWater/sewage treatmentParticulatesFiltration

A garnet settling / filtration system for use with a plurality of machine tools such as a water jet cutting machine is described. The garnet settling / filtration system comprises a settling tank, which utilizes a removable, disposable settling weir, which is received therein. The settling weir drops into the settling tank and provides an over-under flow system through which the garnet slurry must travel. As the flow of the slurry travels over and under the incorporated series of baffles, the garnet particulate settles out on the bottom of the liner. Once the liner has reached its maximum holding capacity, a series of incorporated, reinforced removal loops located near the top of the liner allow for the easy and quick removal of the liner and the settled-out particulate from the settling tank. The liner can then be discarded and a new one replaced in a matter of minutes, thereby reducing downtime of the machine.

Owner:EBBSO

Processes and apparatuses for enhanced cutting using blends of abrasive materials

A waterjet system selectively produces fluid jets for water jet cutting or abrasive jets for abrasive-waterjet-cutting. The abrasive materials in the abrasive jet are determined based on the properties of the workpiece. The waterjet system includes an abrasive delivery system that is capable of delivering either a single abrasive or a plurality of abrasives as an abrasive blend, to a cutting head assembly. The cutting head assembly entrains the abrasive into a fluid jet to form an abrasive jet.

Owner:FLOW INT CORP

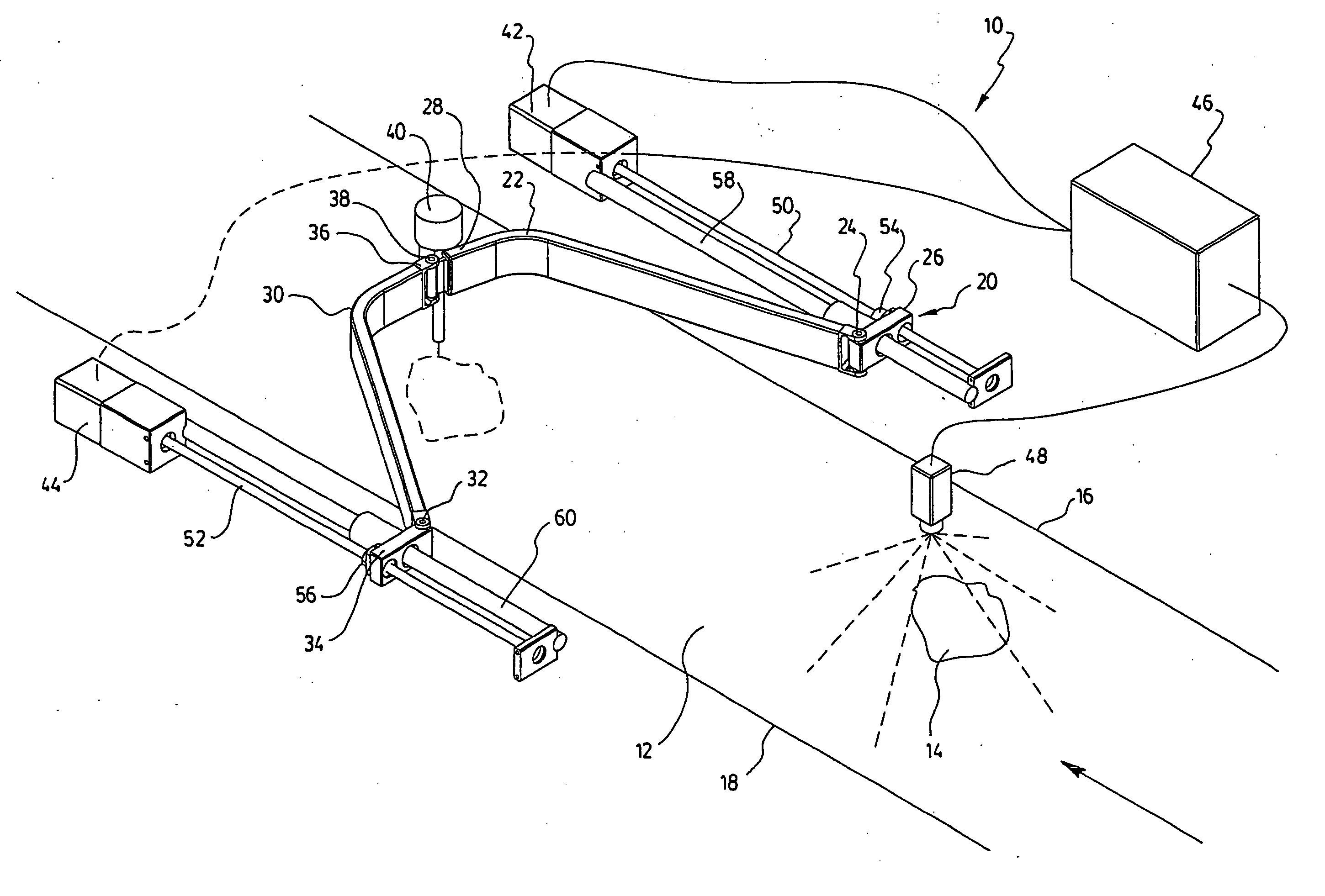

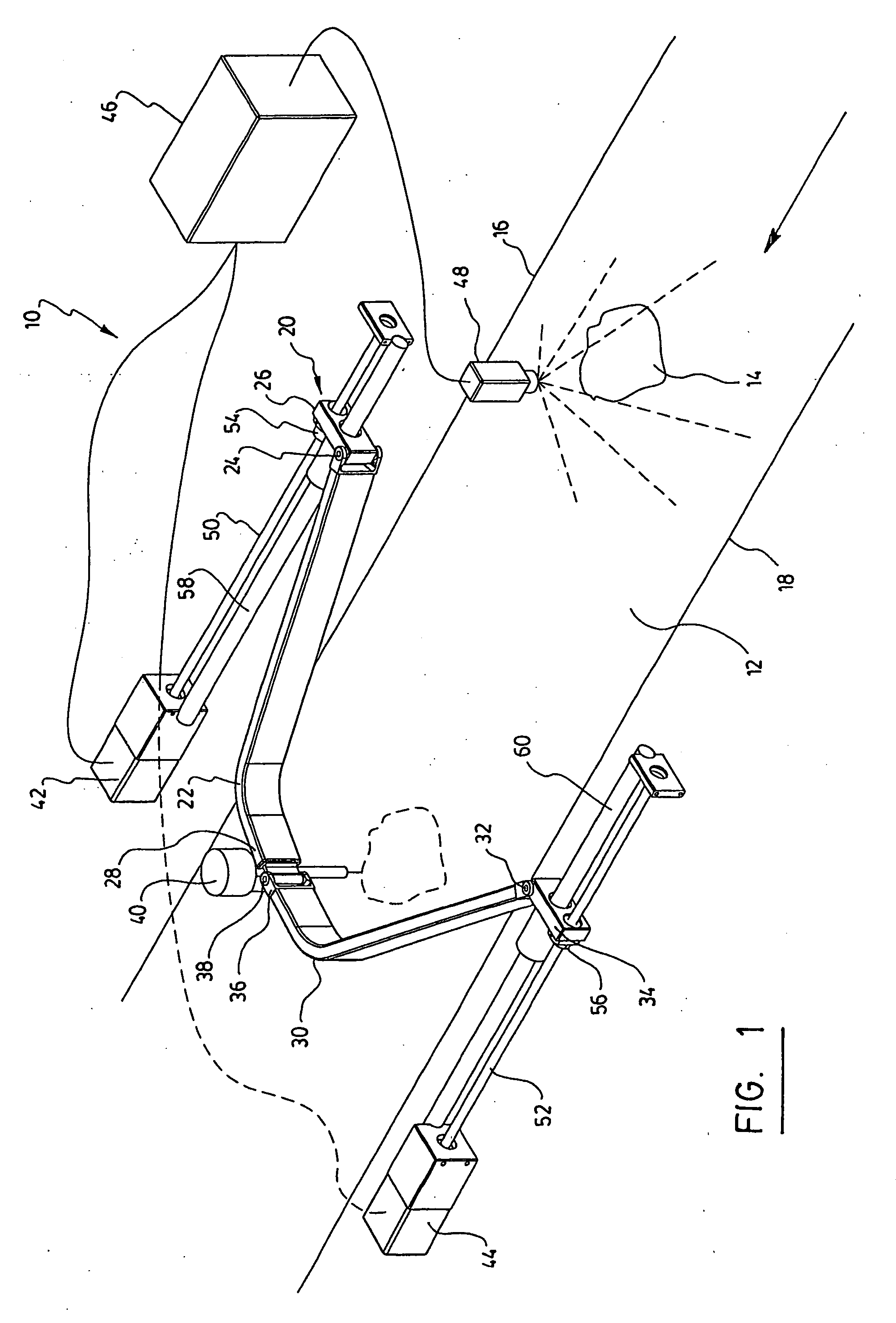

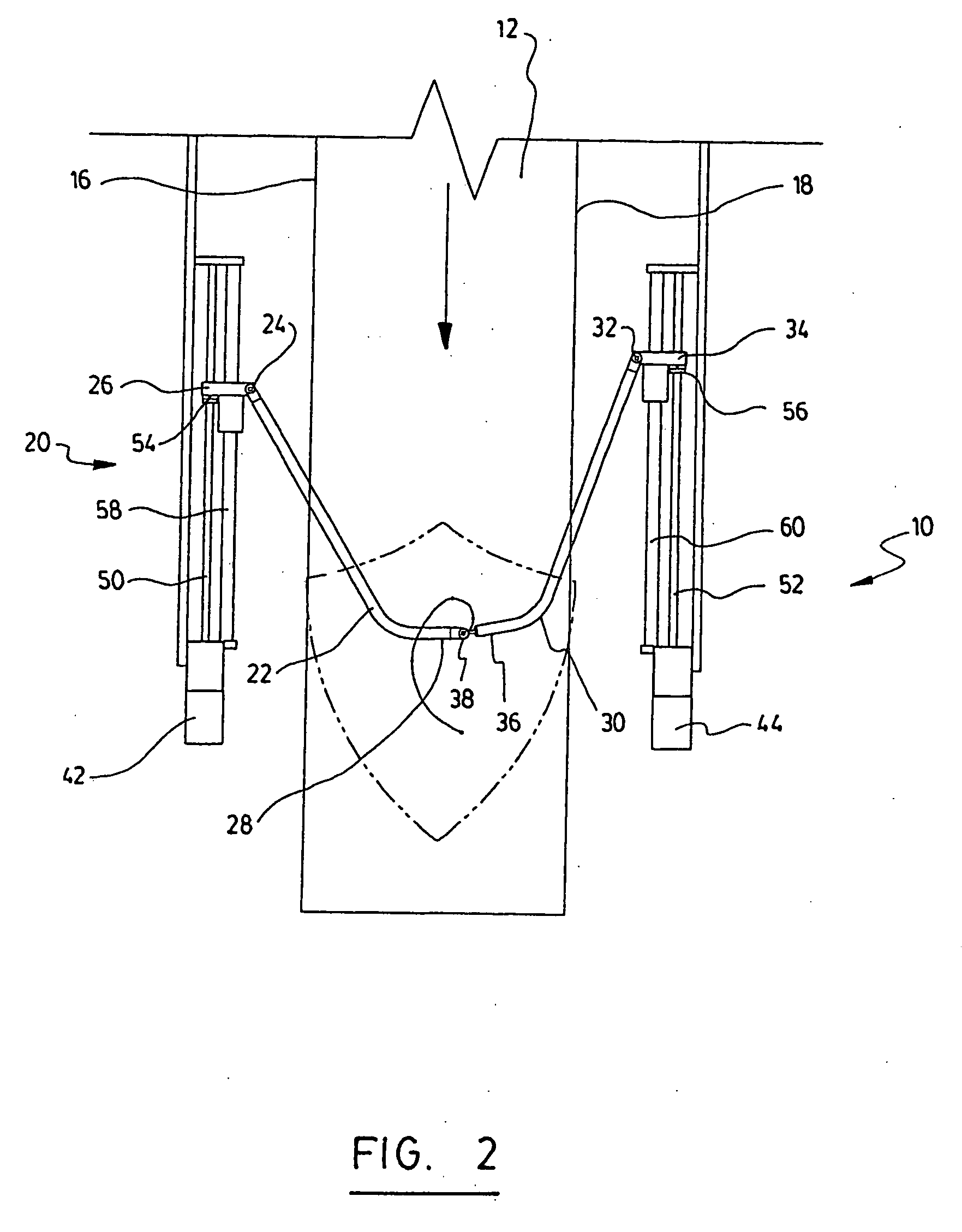

Planar robot with parallel axes and fixed motors for a water jet cutter

ActiveUS20060288833A1Mechanically simpleReduce loadGang saw millsMetal working apparatusWater jet cutterEngineering

A planar robot for cutting products, such as pieces of meat. The product is displaced along a conveyor or positioned onto a working table and is cut by a tool, preferably a water jet. The tool is held by a pair of arms. The arms have first extremities pivotally mounted on mobile bases. The arms also have second extremities pivotally connected to each other. An actuator displaces each of the mobile bases in order to control the position of the cutting tool in a plane above the conveyor or table.

Owner:G E LEBLANC

System and method for tool testing and alignment

A system and method for improving a tool tip path of a machine, such as a waterjet cutting machine, by testing and compensating for tool misalignment. The system and method using a sensor positioned to sense a portion of the machine, such as a cutting head assembly, during a sequence of movements thereof and configured to output information indicative of various positions and orientations of a tool of the machine so as to generate an improved tool tip path based on transformation parameters derived from such information.

Owner:FLOW INT

Fascia-mounted aluminum railing system

An improved railing / wall system for elevated slab balconies. The system uses a number of fascia brackets to secure posts to the outer face of the elevated slab balcony. The posts have a base track secured to them. Infill panels are then placed between the posts to provide the wall structure. A top rail can be used to cover the top of the infill panels. The lower portion of the infill panels also can be tinted to conceal the face of the concrete balcony, if desired. The infill panels can be selected from a group of materials, including tempered glass, pickets, expanded metal, perforated metal, metal cut with water jets or a composite material.

Owner:HANSEN TRACY C +1

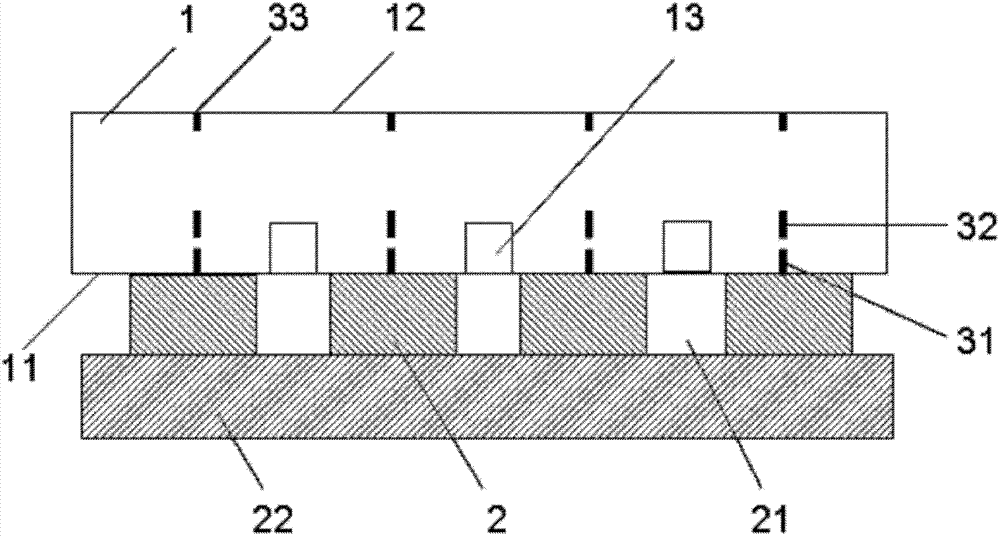

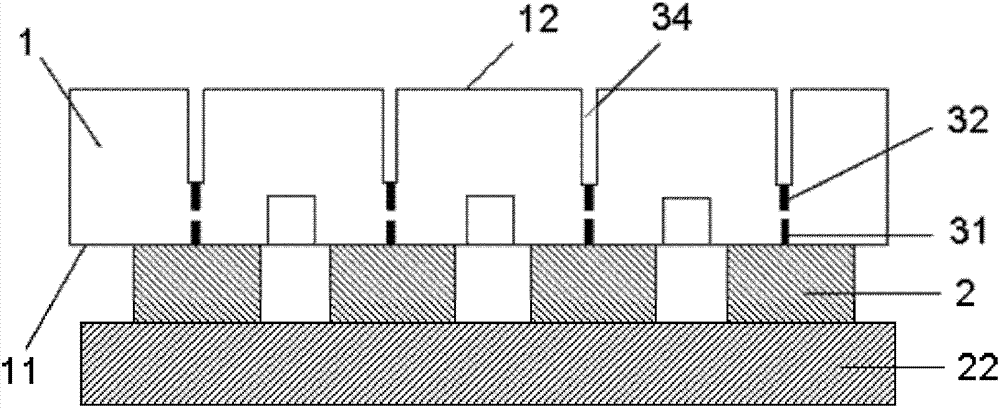

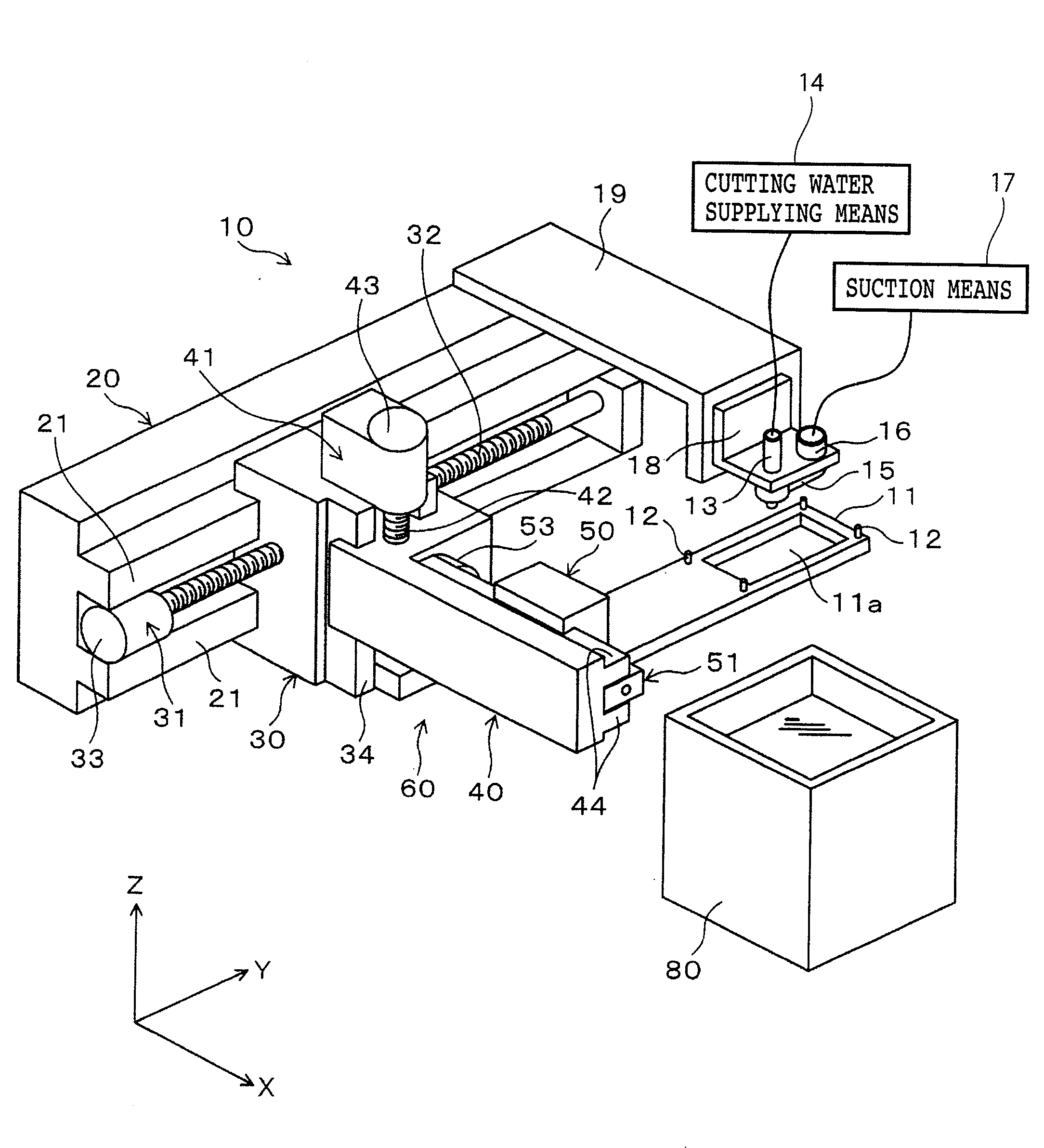

Cutting method for MEMS wafer

ActiveCN102897708ANo chippingReduce chippingDecorative surface effectsChemical vapor deposition coatingEngineeringIrradiation

The invention relates to a method for a MEMS wafer. The cutting method comprises the following steps of pasting a membrane on the front surface of the wafer to protect an MEMS structure; focusing a laser on the inner part of the wafer, irradiating to form a modified layer at a position from the front surface of the wafer to the inner part of the wafer; irradiating the laser to the back surface of the wafer at a position corresponding to that of the modified layer so as to form a mark groove on the back surface of the wafer; performing water jet cutting on the back surface of the wafer along the position of the mark groove but do not reach the bottom so as to form a water jet cutting groove from the back surface of the wafer to the inner part of the wafer, wherein one end far away from the back surface of the wafer of the water jet cutting groove is connected with the modified layer; and extending splits along the modified layer till to all the MEMS structures are separated completely from each other. The method for the MEMS wafer combines the advantages of laser irradiation and water jet cutting, and realizes the edge breakage-free and low-contamination cutting for the MEMS wafer.

Owner:MEMSIC SEMICON WUXI

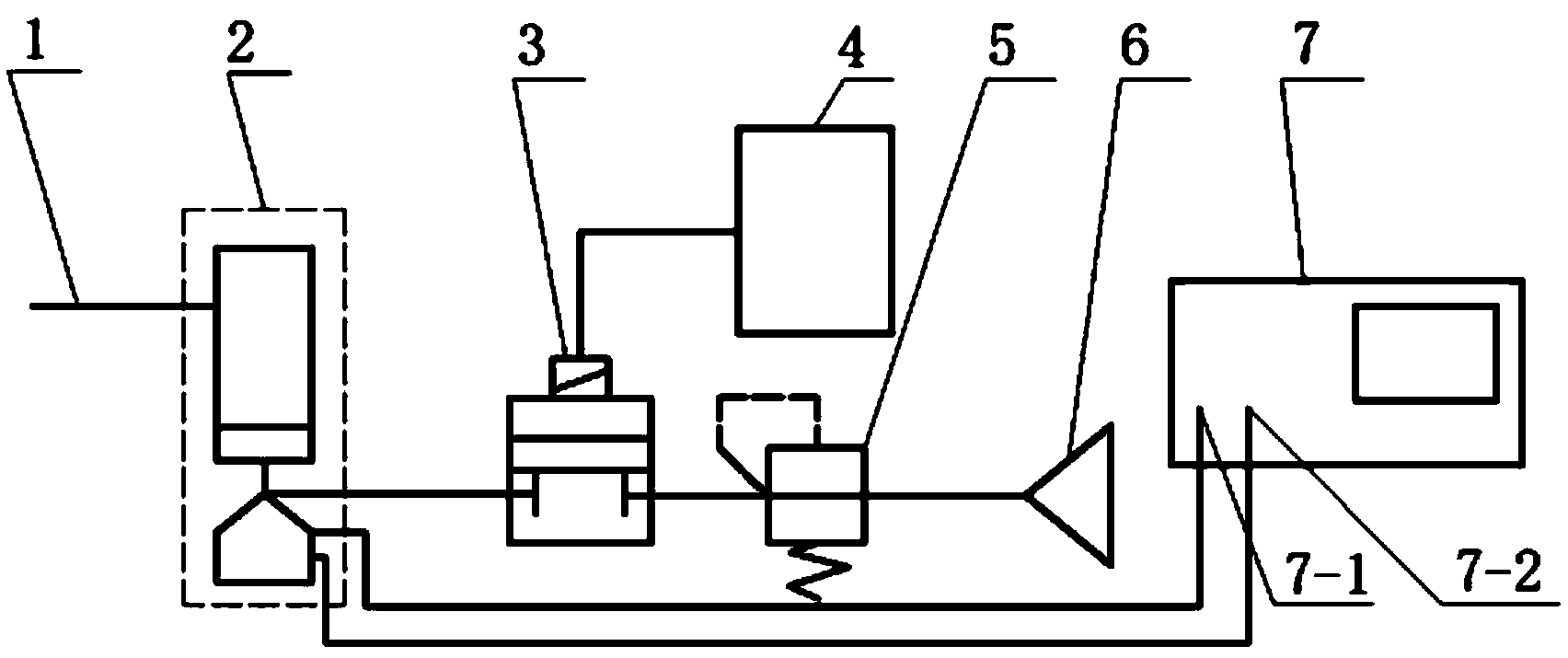

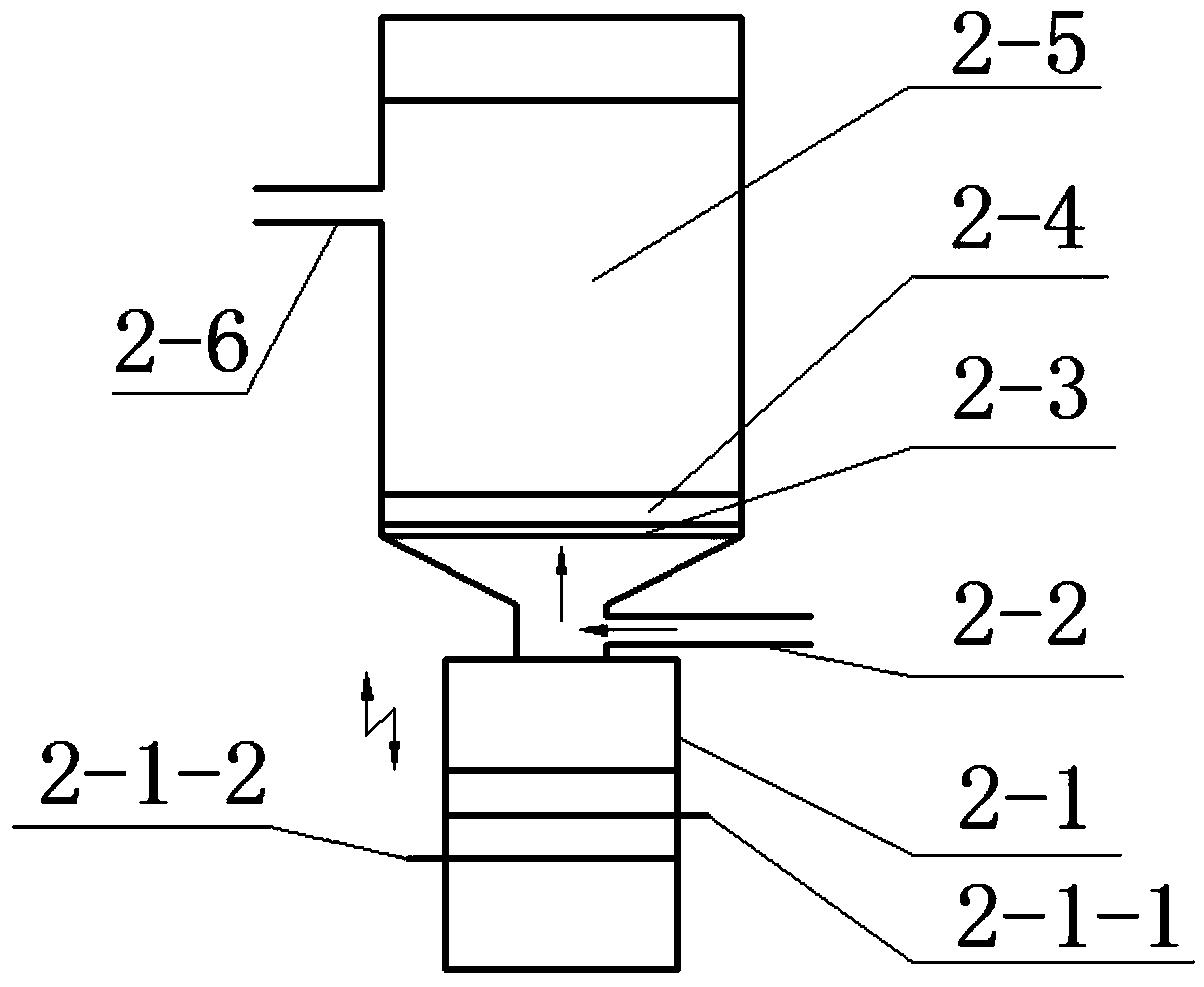

Supersonic vibration assisted fluidifying fine grinding material feeding device

The invention relates to a special processing technology, and discloses a supersonic vibration assisted fluidifying fine grinding material feeding device which is particularly applied in a grinding material water jet processing system. The supersonic vibration assisted fluidifying fine grinding material feeding device is composed of an air source, a pressure regulating valve, a frequency converting control circuit, a high-frequency switch valve, an ultrasonic generator and a vibration material bin, wherein the vibration material bin is provided with a material bin air inlet and a material bin air outlet; the air source is connected with the pressure regulating valve through an air delivering pipe, an outlet of the pressure regulating valve is connected with the high-frequency switch valve through the air delivering pipe, and the frequency converting control circuit is connected with a circuit of the high-frequency switch valve; an air outlet of the high-frequency switch valve is connected with an air inlet of the vibration material bin, the vibration material bin is connected with the ultrasonic generator, and a discharging hole of the vibration material bin is connected with a grinding material water jet cutting head mixing cavity. The supersonic vibration assisted fluidifying fine grinding material feeding device provided by the invention has the advantages that the defects that the material supplying capacity of the existing grinding material feeding device is not uniform and the grinding material feeding device is easy to plug are overcome, meanwhile, the precision regulation of the grinding material flow is also realized, and thus the processing quality of the fine grinding material water jet processing technic is greatly improved, and the supersonic vibration assisted fluidifying fine grinding material feeding device has an important popularization and application value.

Owner:SHANDONG UNIV

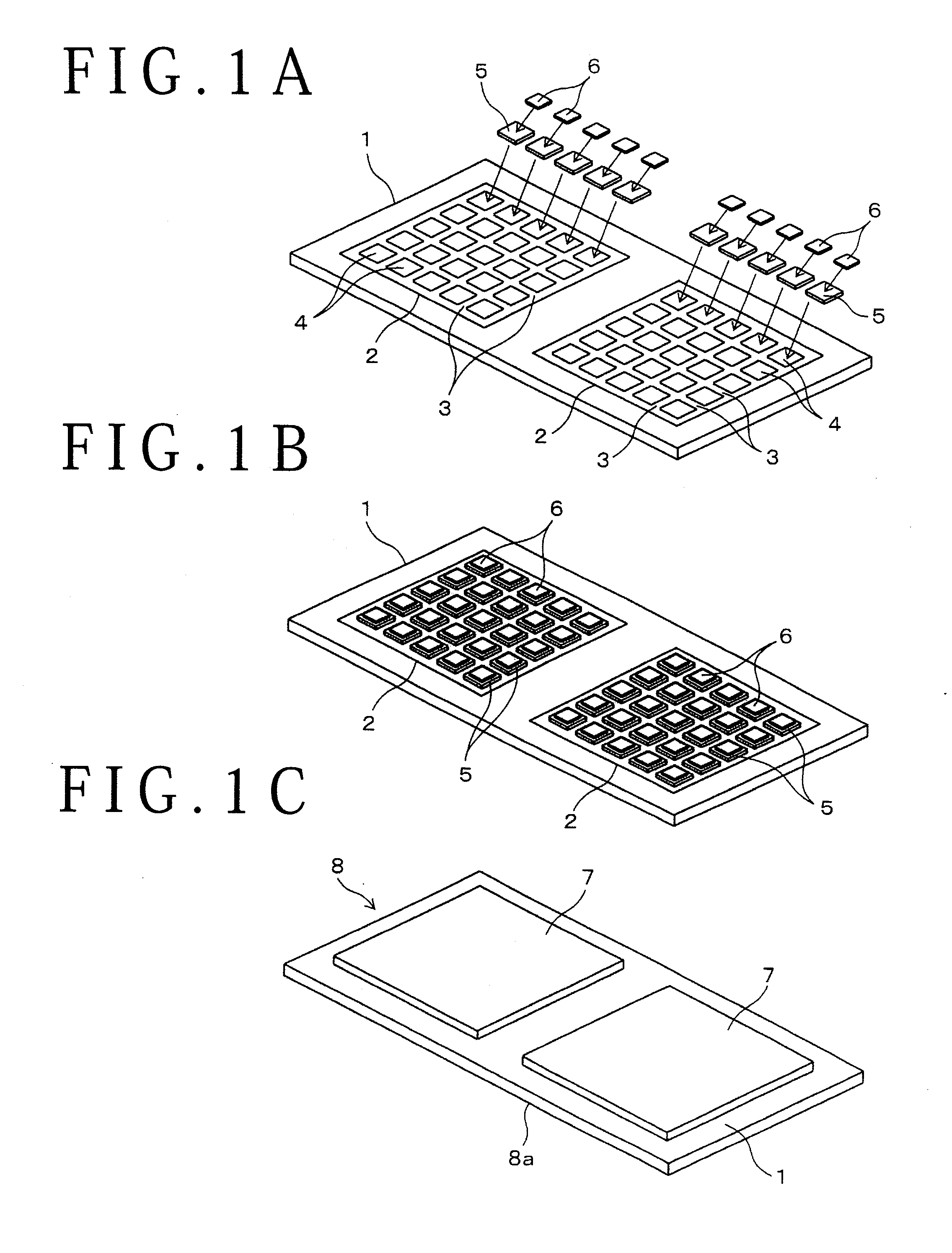

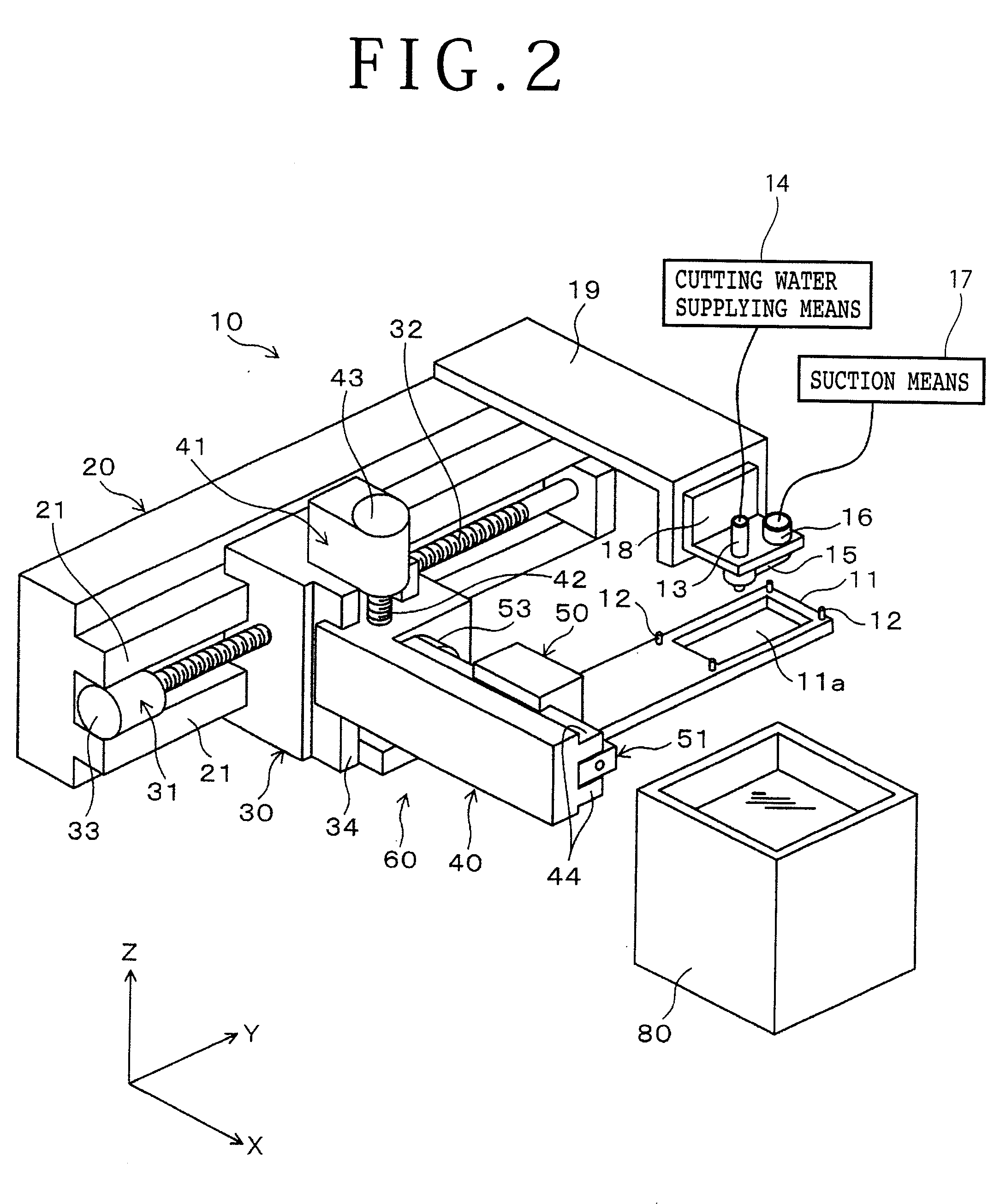

Water jet cutting method

InactiveUS20080282855A1Efficient cuttingDesired accuracySemiconductor/solid-state device manufacturingMetal working apparatusDicing tapeEngineering

A package base is held on a holding table, and an XYZ moving mechanism is next moved to adjust a jet position to a cutting start point of a primary subject line to be first cut. Thereafter, a cutting water supplying unit is operated to direct a water jet onto the package base at this cutting start point. Thereafter, the XYZ moving mechanism is operated to move the package base, thereby cutting the package base along the primary subject line until a cutting stop point. Similarly, this cutting operation is repeated for the other primary subject line to thereby obtain a plurality of primary cut areas having the same shape and size in the condition that each primary cut area is integrally supported at its opposite ends to the package base, thus finishing a primary cutting step. Thereafter, a dicing tape is attached to one side surface of the package base. Thereafter, the package base is cut along a plurality of secondary subject lines as in the primary cutting step, thus finishing a secondary cutting step.

Owner:DISCO CORP

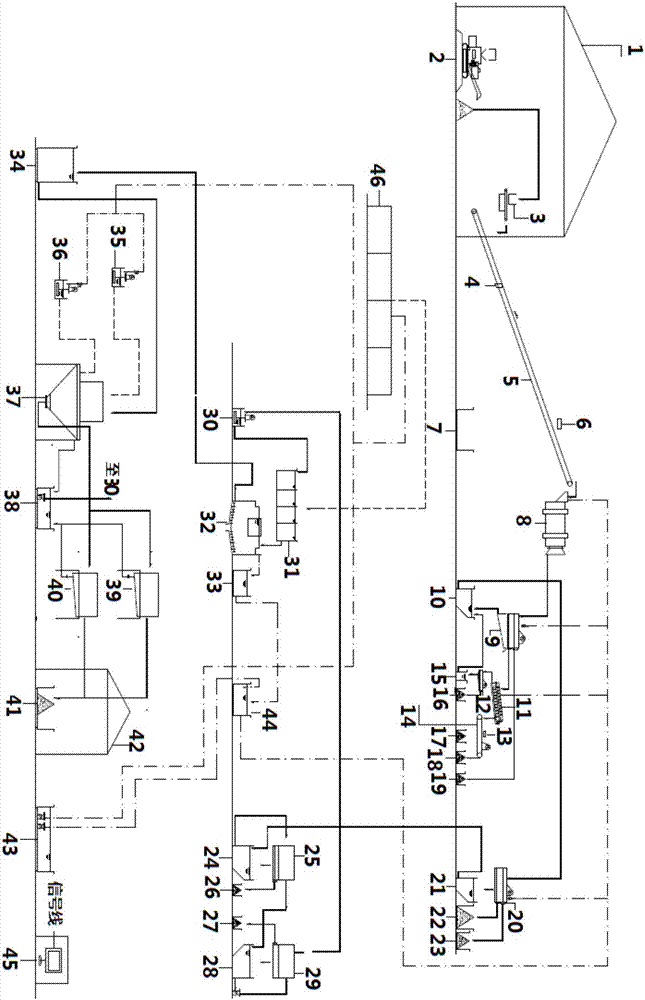

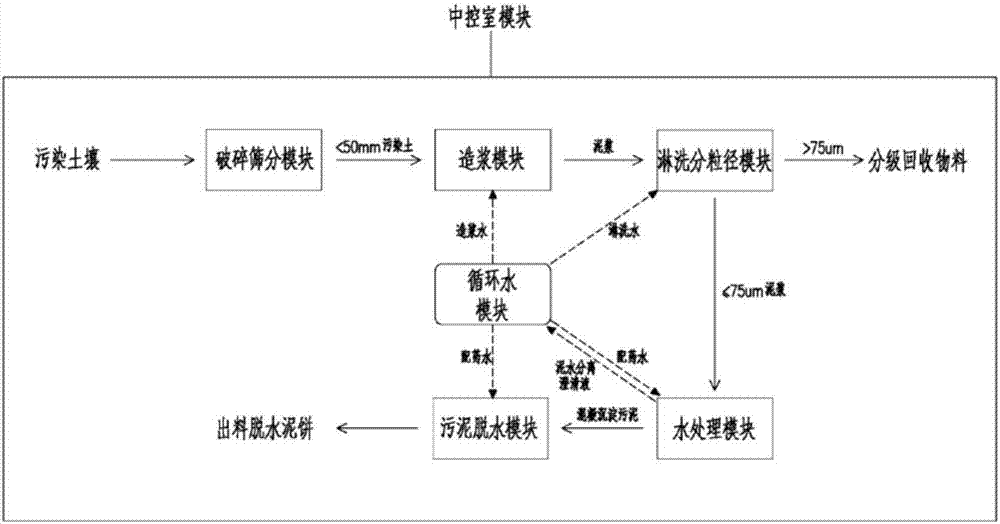

Soil flushing repair system and method

ActiveCN107127210AGuaranteed compatibilityGuaranteed subsequent dryingContaminated soil reclamationEngineeringHigh pressure

The invention discloses a soil flushing repair system and method, and belongs to the technical field of soil repair. The soil flushing repair system sequentially comprises a crushing and screening module, a feeding and mud making module, a flushing and particle size distributing module, a water treatment module, a mud dehydration module, a water supply module and a central control room module. The crushing and screening module including a sieve with the hole diameter of a screen cloth being 30mm-60mm is arranged in front of the operating process of the feeding and mud making module. The flushing and particle size distributing module can achieve level-7 wet sieving and flushing of contaminated soil by means of water jet cutting of a high-pressure spraying system and mechanical vibration of a vibration motor, and discharging cleanliness and recoverability can be guaranteed. The mud dehydration module is provided with a drying workshop and used for preventing rainwater from wetting dehydration mud cakes, guaranteeing subsequent drying of the mud cakes and controlling secondary pollution of pollutants in the mud cakes. By the adoption of the soil flushing repair system and method, the problem that the screen cloth can be blocked easily due to the uneven feeding grain size in the prior art is solved, and the problems of flushing dehydration mud cake storage, subsequent drying and secondary pollution of the pollutants are also solved.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

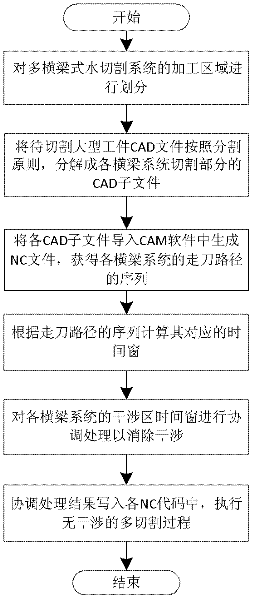

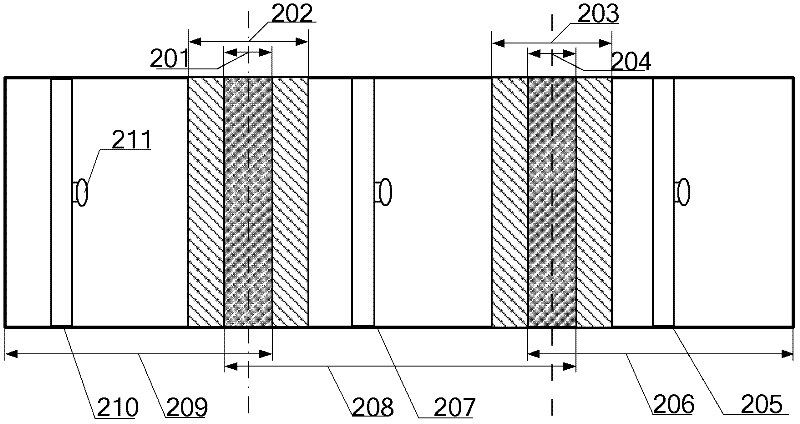

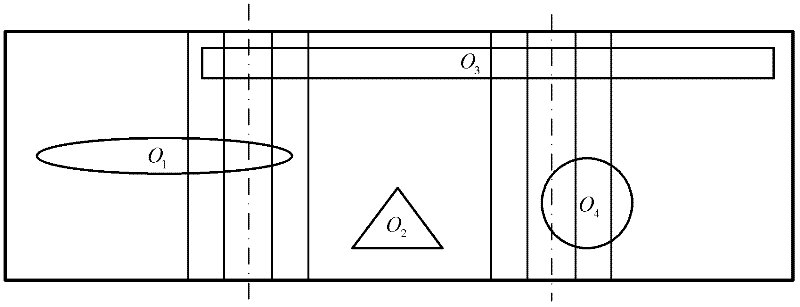

Cutting process offline coordination method of multi-beam type water jet cutting system

InactiveCN102346459ANo need to change KAEliminate interferenceProgramme controlComputer controlNumerical controlComputer-aided

The invention provides a cutting process offline coordination method of multi-beam type water jet cutting system. The method comprises the following steps: dividing a processing area of the multi-beam water cutting system; inputting a CAD (computer-aided design) file of a large workpiece to be cut, and decomposing and allocating the cutting contour accordingly to form the CAD sub-file of the cutting part of each beam system; importing each CAD sub-file into water cutting CAM (computer-aided manufacturing) software to generate an executable NC (numerical control) code file, and reading the NC code file to obtain a sequence of the cutting path of each beam system; calculating a time window executed by each path in each cutting sequence, and coordinating the time windows in an interference area so as to achieve the purpose of avoiding mutual interference between two adjacent beams; and writing the coordination result into the original NC code file, downloading the NC code file to a CNC (computer numerical controller) of each beam system, and executing the multi-beam water cutting process. According to the invention, smooth and non-interference execution of a parallel cutting processes of a water cutting system with more than three beams can be realized.

Owner:SOUTHEAST UNIV

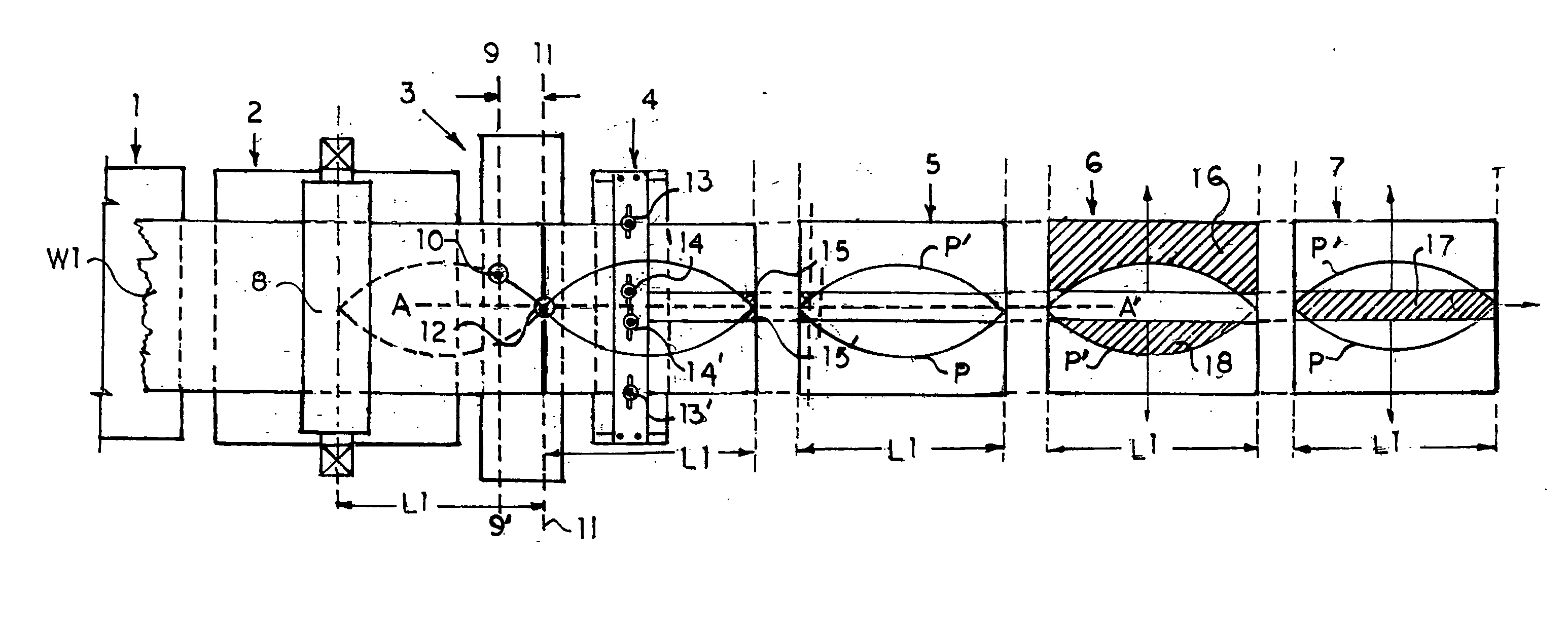

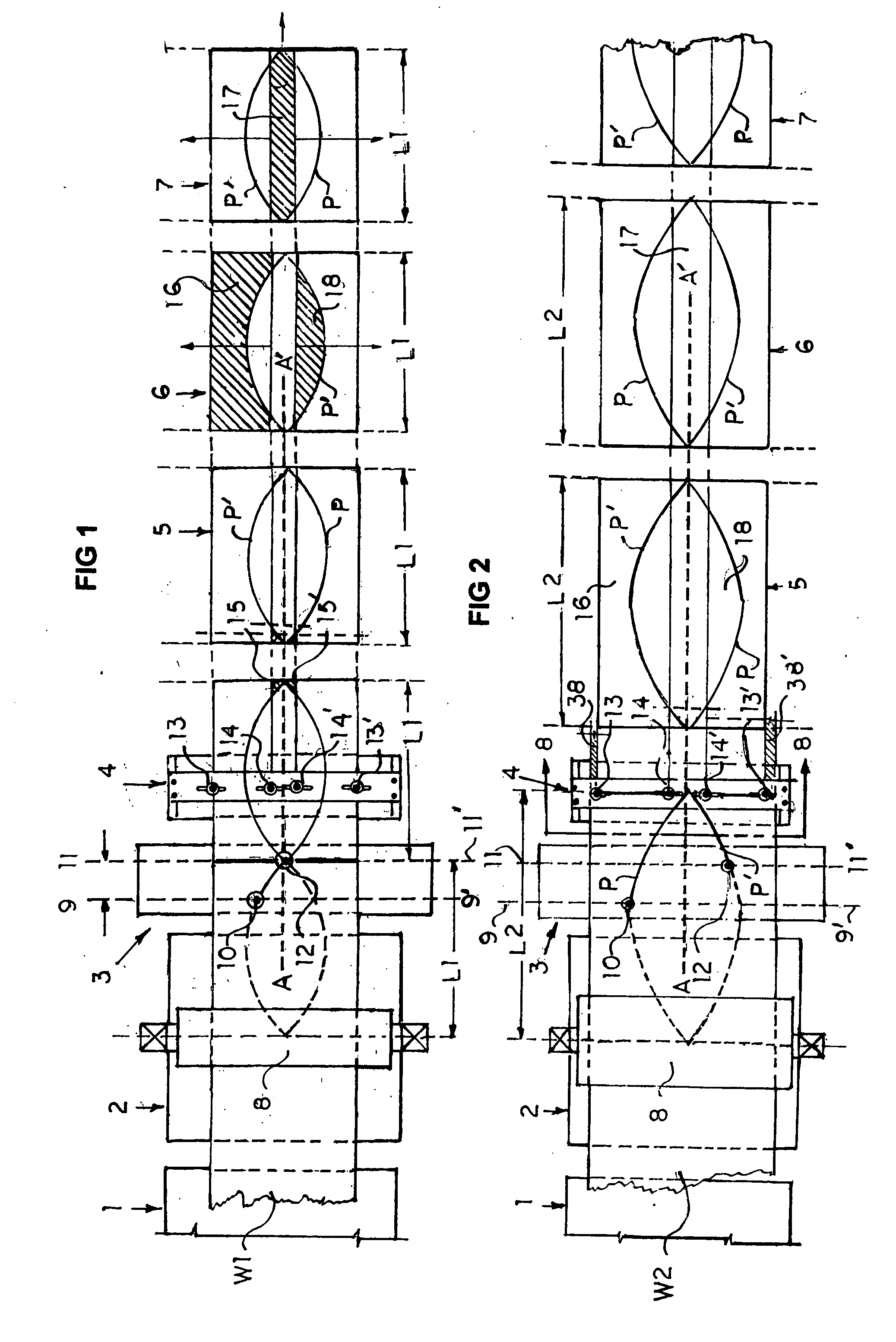

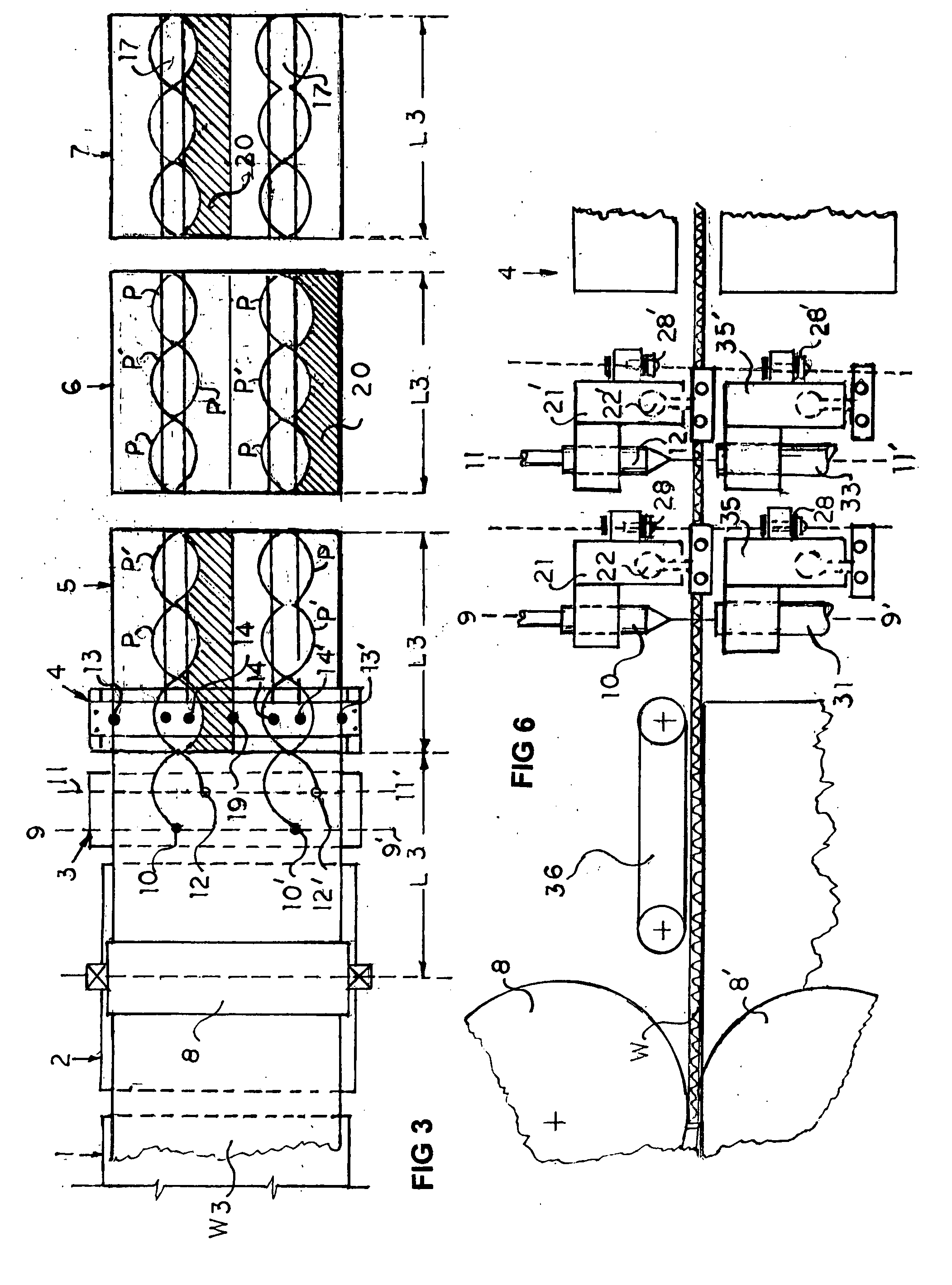

Method and apparatus for cutting parabolic shaped segments on a corrugating machine

Method and apparatus for water jet cutting parabolic shaped segments that support reflective surfaces of a concentrating solar collectors. Apparatus describes corrugating machine cutoff, parabolic curve water jet cutters longitudinal slitters, transfer / diverters, and stackers. Parabolic curve cutting involves at least one cutter on a first transverse path with means for reversing movement over a moving web in cooperation with a cutter on a parallel second path with means for mirror image movement to make a pair of opposite curves which intersect at segment ends. Jet cutter reversing servo motor drive means programmable for different parabolic curves. Includes use of plurality of cutter pairs to make segments with multiple parabolic curves per length. Apparatus includes means to make standard corrugated board or parabolic segments by electronic switching without machine adjustments.

Owner:NIEDERMEYER WILLIAM PAUL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com