Supersonic vibration assisted fluidifying fine grinding material feeding device

An ultrasonic vibration and feeding device technology, which is applied in the direction of abrasive feeding devices, abrasives, metal processing equipment, etc., can solve problems such as easy blockage and uneven feeding, and achieve the goal of improving processing quality and uneven feeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

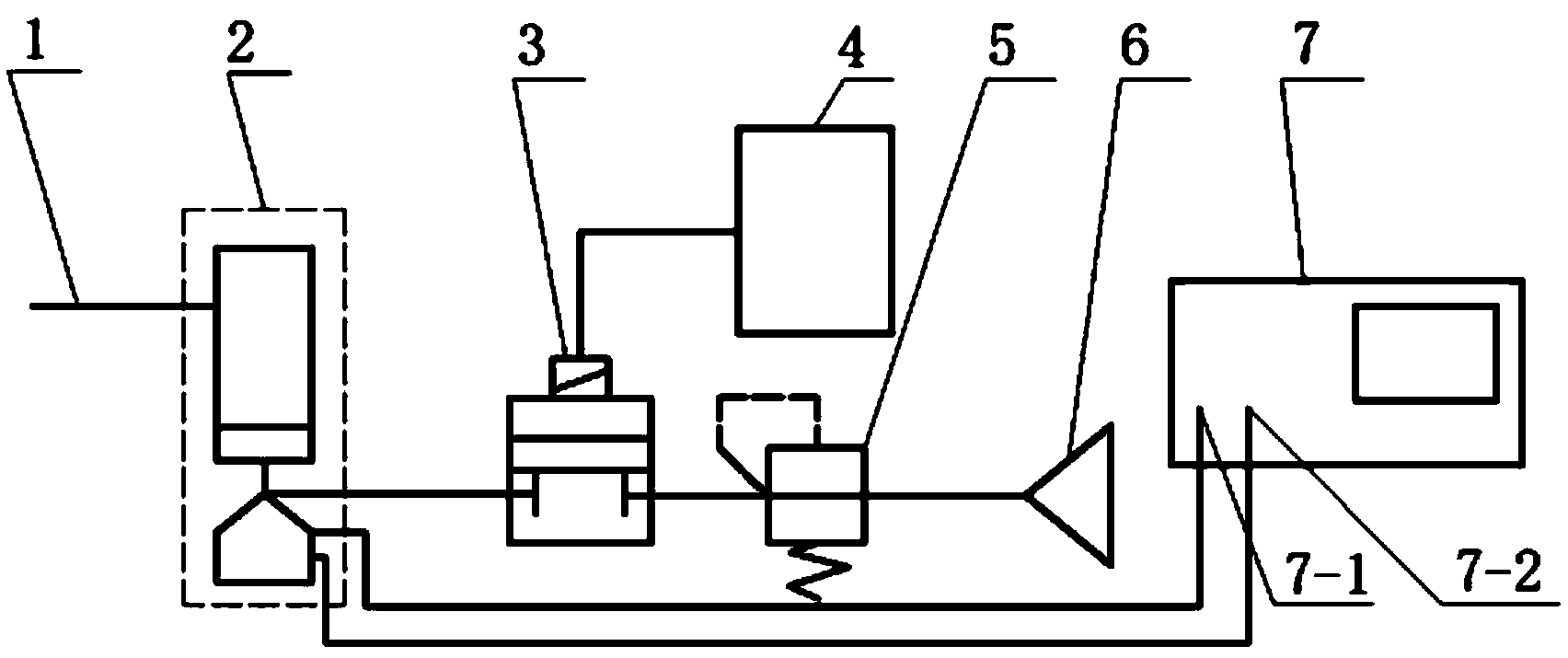

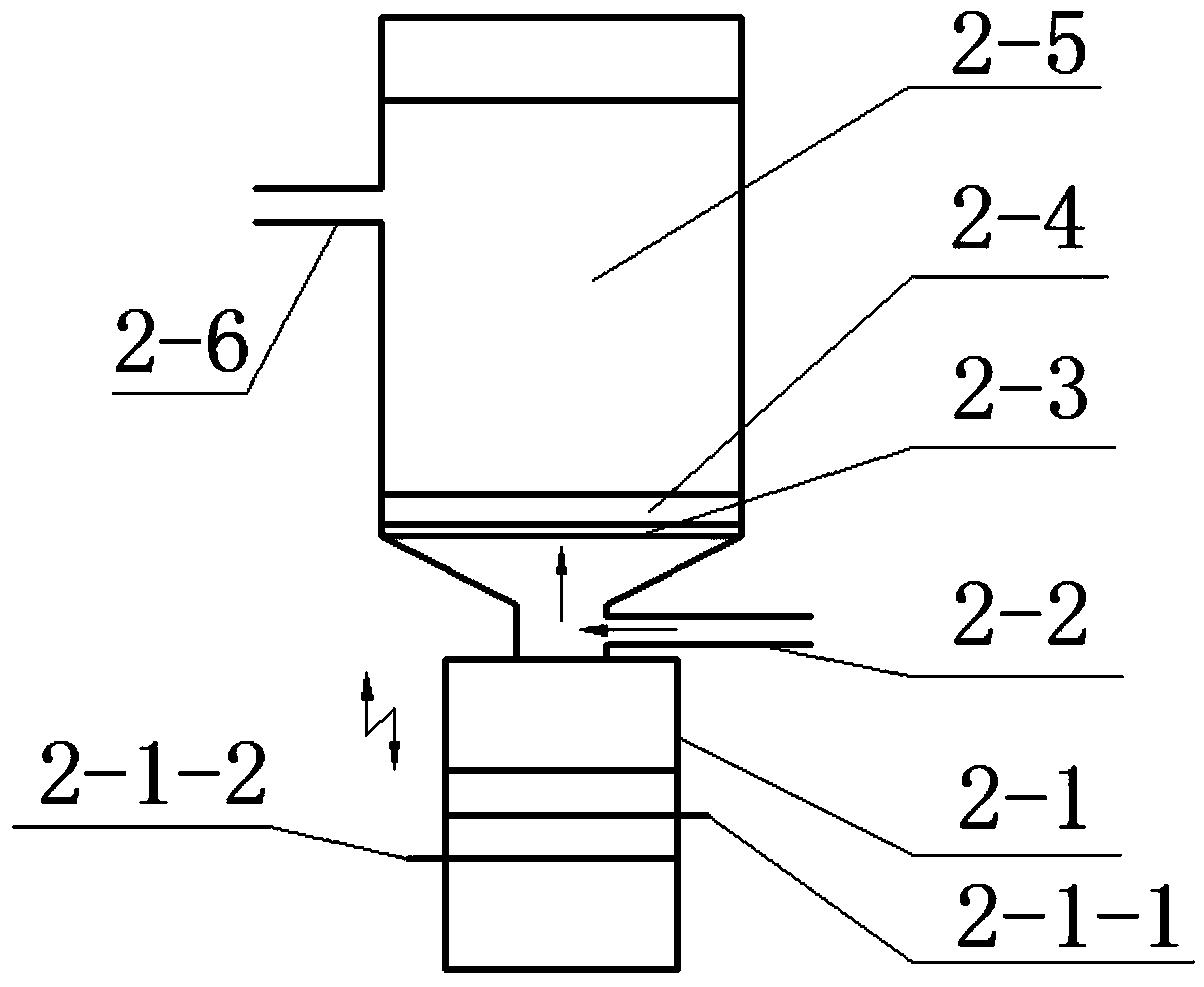

[0016] Describe the implementation process of the present invention in detail in conjunction with accompanying drawing, as figure 1 , figure 2 shown.

[0017] The present invention is connected to the abrasive water jet processing system, and is composed of an air source 6, a pressure regulating valve 5, a frequency conversion control circuit 4, a high-frequency switching valve 3, an ultrasonic generator 7, and a vibrating silo 2; the vibrating silo 2 is provided with a silo The air inlet 2-2 and the bin outlet 2-6, the air source 6 is connected to the pressure regulating valve 5 through the air pipe, the outlet of the pressure regulating valve 5 is connected to the high-frequency switching valve 3 through the air pipe, and the frequency conversion control circuit 4 is connected with the circuit of the high-frequency switching valve 3, the air outlet of the high-frequency switching valve 3 is connected with the air inlet 2-2 of the silo, the vibrating silo 2 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com