Numerical-control six-shaft intelligent water jet cutter

A six-axis, intelligent technology, applied in metal processing and other directions, to achieve the effect of reducing attitude adjustment time, improving cutting accuracy and cutting efficiency, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

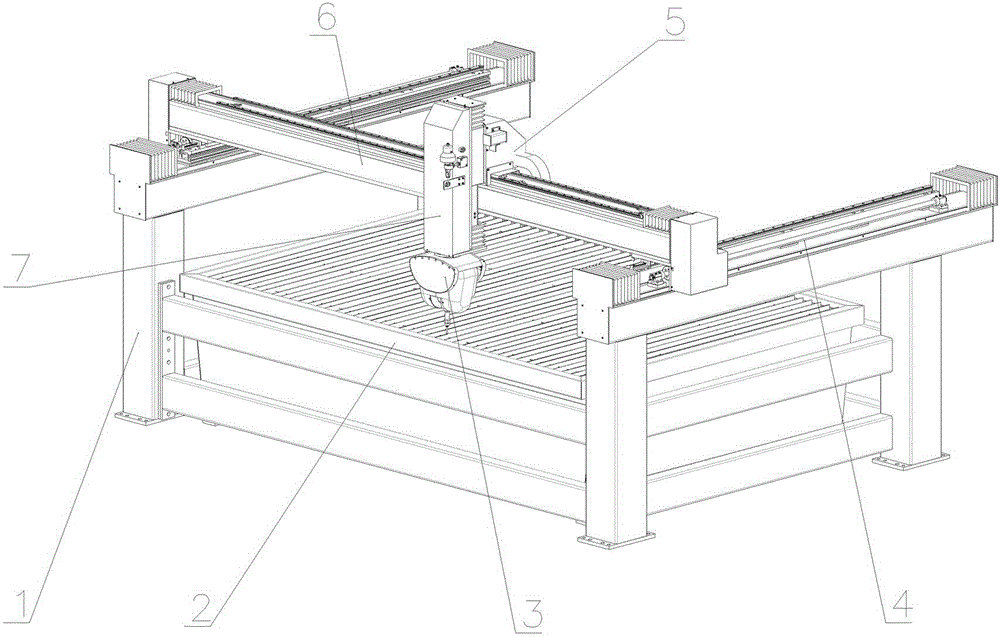

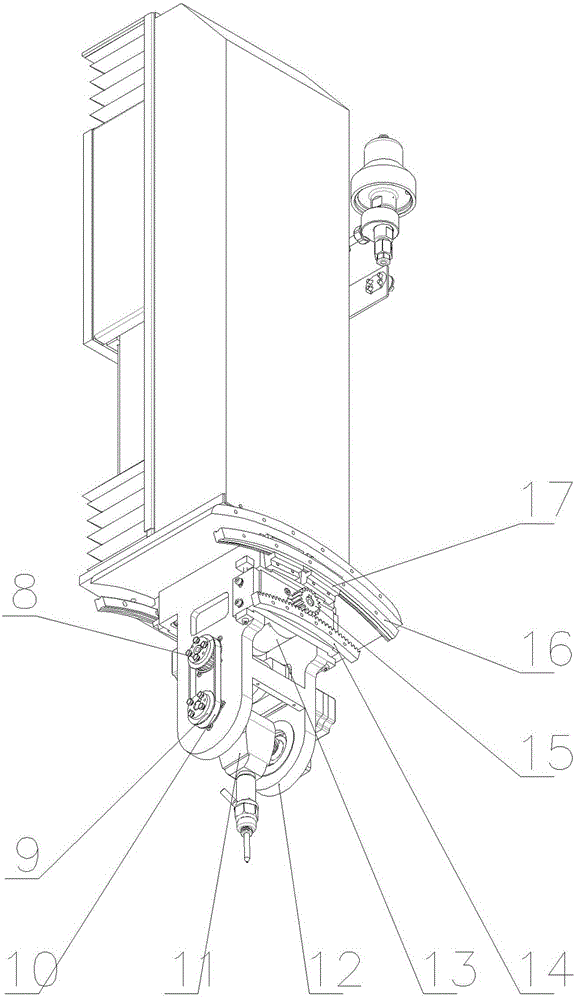

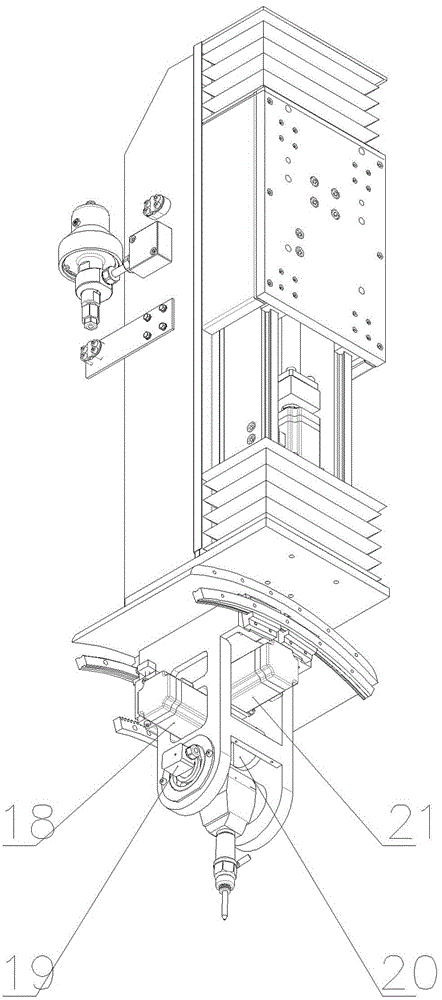

[0015] CNC six-axis intelligent water jet, including ultra-high pressure water jet generator, water jet cutting platform composed of side frame 1, beam 6 and water tank 2, X-axis transmission mechanism 5 and Y-axis transmission mechanism installed on the water jet cutting platform 4. The Z-axis transmission mechanism 7, the numerical control circuit that controls the X-axis, Y-axis, and Z-axis feed motors of the water jet cutting platform, is installed on the cutting head 3 connected with the Z-axis transmission mechanism 7. The cutting head 3 is a cutting head equipped with A, B, and C shafts for compound rotation, and the cutting head 3 for A, B, and C shafts for compound rotation includes an A-axis motor 18, an A-axis reducer 20, and an A-axis drive. Belt 10, A-axis driving pulley 8, A-axis passive pulley 9, B-axis motor 21, B-axis reducer 13, B-axis arc guide rail 16 centered on the water nozzle 11 nozzle, B-axis arc guide rail slider 17. B-axis gear 15, B-axis arc rack 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com