High-pressure abrasive material and water jet cutting head and blending tube

An abrasive water jet and cutting head technology, applied in abrasives, explosion generating devices, metal processing equipment, etc., can solve problems such as large energy loss, low coaxiality, and inconvenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

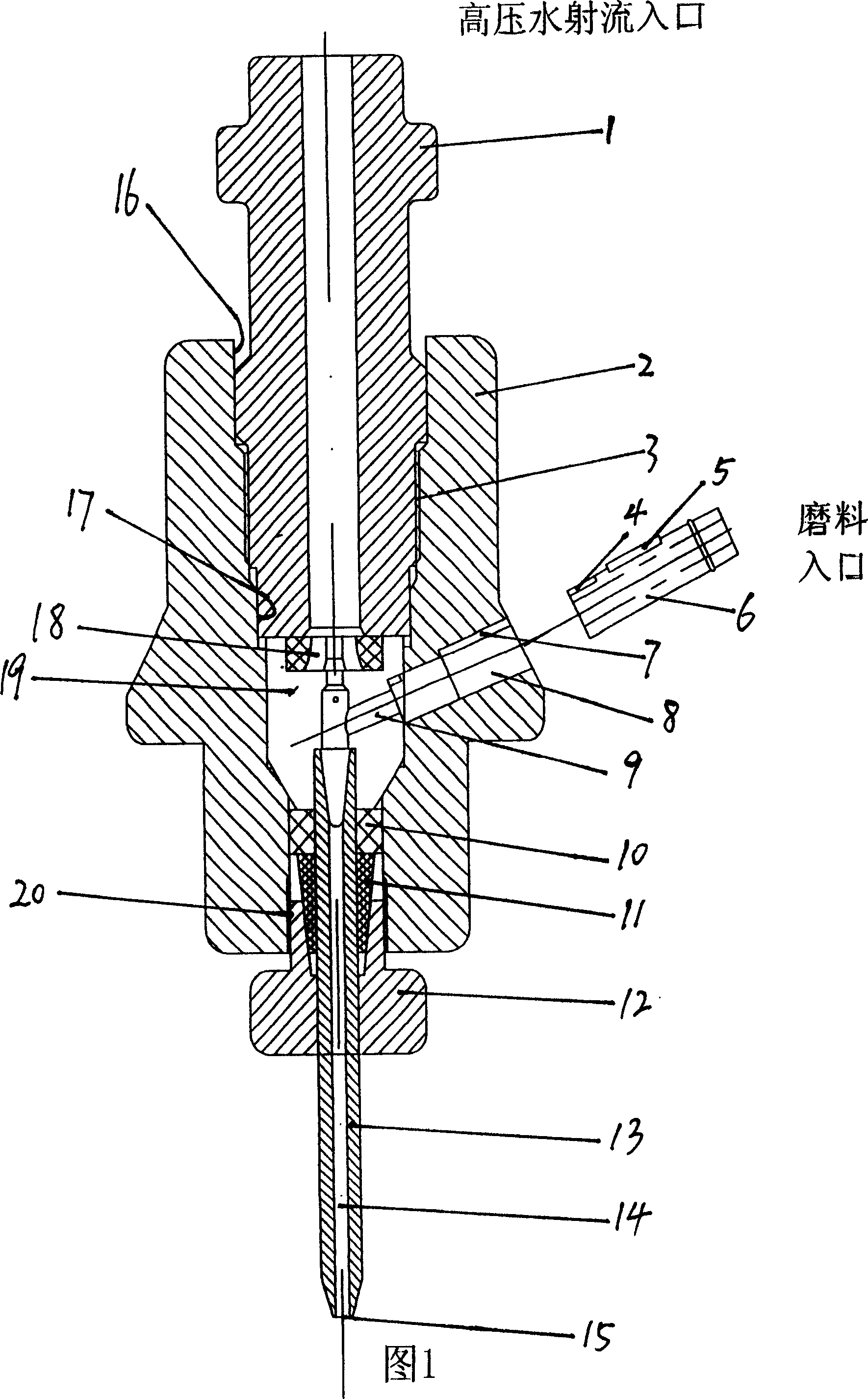

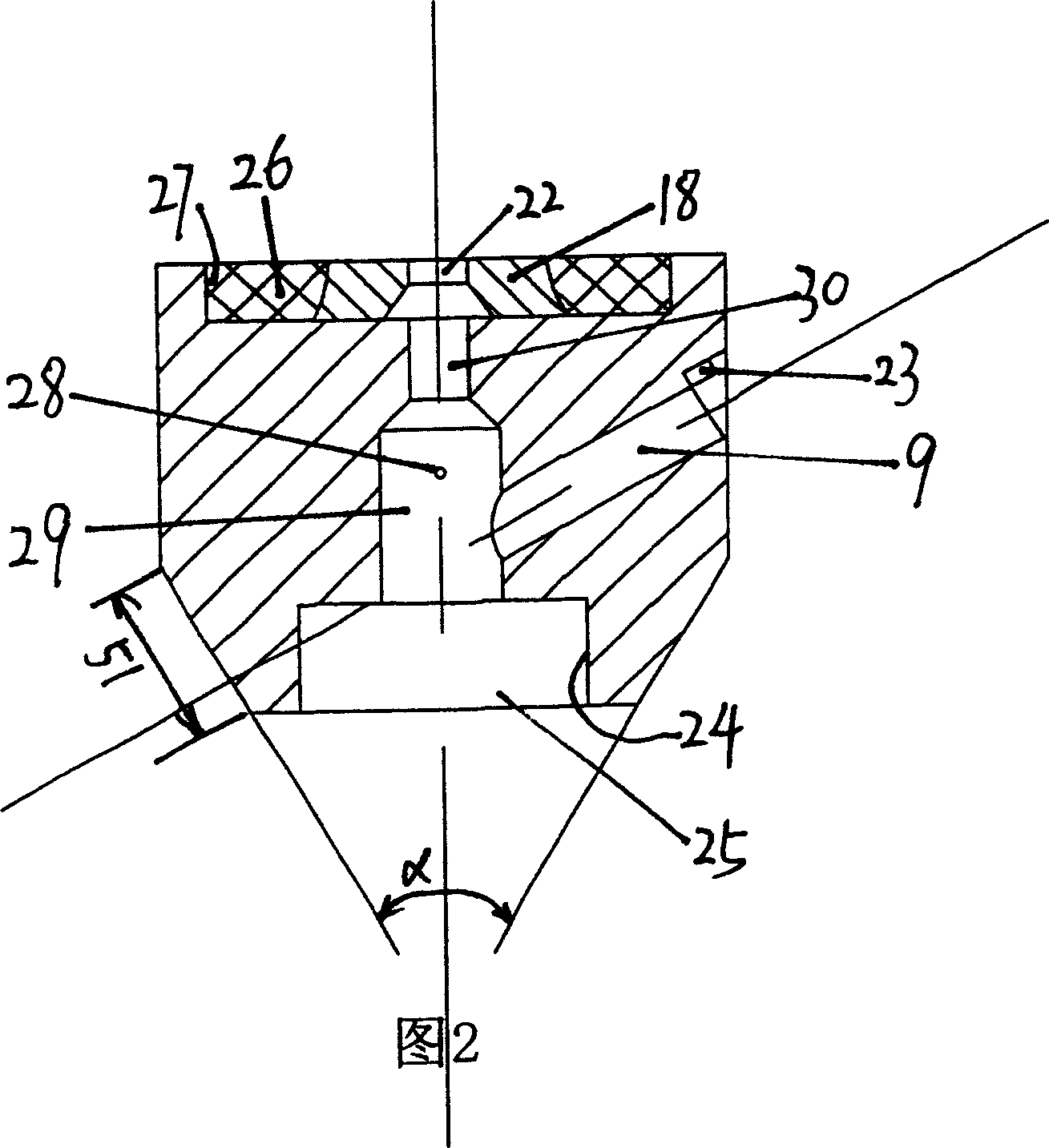

[0018] In the present invention, the nozzle head base (19) is first inserted into the cutting head (2), and the tapered body at the lower end of the base (19) contacts the tapered surface (34) of the cutting head (2), and (51) and ( 52) The ratio of the length is between 0.2 and 0.47, plus the outer peripheral surface of the base (19) cooperates with the inner surface of the cutting head to ensure the fixing effect; the degree of freedom in the circumferential direction is fixed by the keyway (4) and the pin (23), based on Whether the through hole (28) on the seat (19) is facing the through hole (33) on the cutting head determines the positioning effect of the base.

[0019] Insert the nozzle body (1) into the cutting head (2), tighten it by the thread (3), and use two guide surfaces to make the inner tube axis of the nozzle body (1) and the channel upper opening (30) of the nozzle head (18) axes are on the same straight line. And the nozzle body (1) bears against the base (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com