Cutting method for MEMS wafer

A cutting method, wafer technology, applied in the fields of technology for producing decorative surface effects, decorative arts, gaseous chemical plating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] The cutting method of the MEMS wafer that the present invention relates to, it comprises the following steps:

[0025] The first step, to protect the MEMS structure,

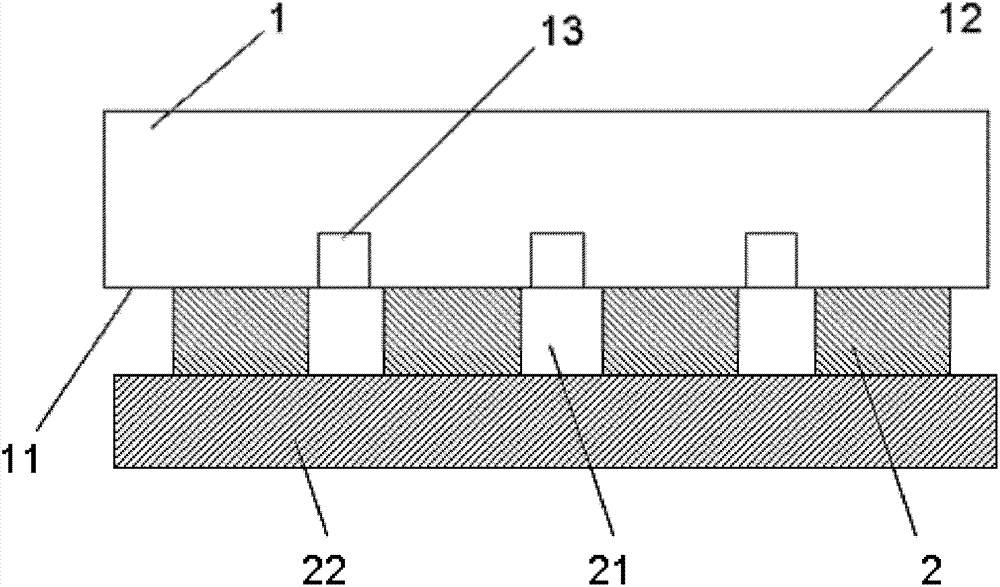

[0026] Such as figure 1 As shown, the front side 11 of the MEMS wafer 1 is provided with MEMS structures 13 . Paste the first film 2 with holes 21 on the front surface of the wafer 11. The holes 21 correspond to the MEMS structures 13 one by one, and the size of the holes 21 is slightly larger than the MEMS structures 13. The MEMS structure corresponds to the middle position of the holes 21. The complete second membrane 22 is pasted on the top of the first membrane 2, thereby forming a closed protection space at the hole 21, and the MEMS structure 13 is effectively protected.

[0027] In the second step, wafer thinning,

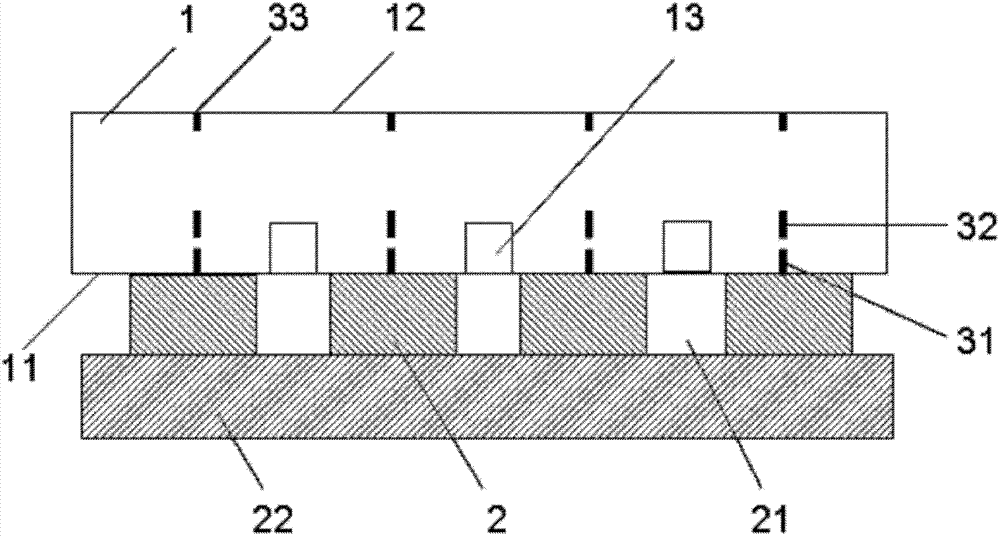

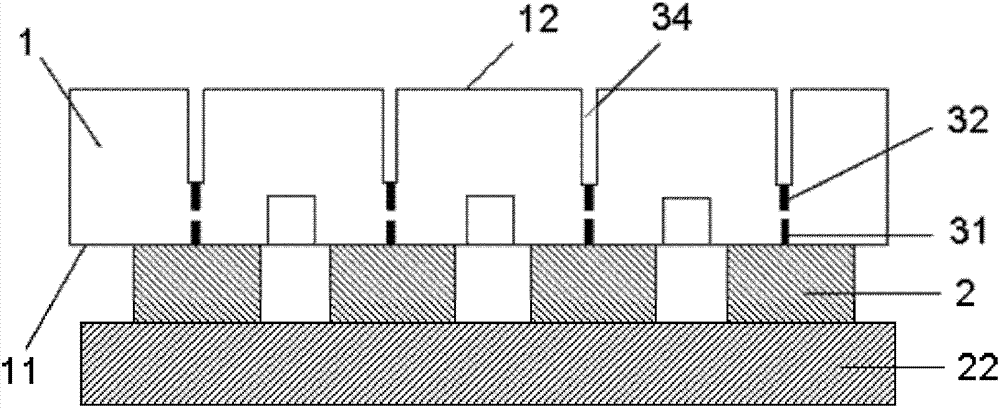

[0028] The backside 12 of the wafer 1 is thinn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com