Large-diameter crystal wafer chamfering tool and chamfering method thereof

A crystal wafer and large-diameter technology, applied in the field of large-diameter crystal wafer chamfering tooling and chamfering, can solve the problems of difficult quality control, unsatisfactory quality, uneven size of chamfering, etc., to solve the problem of chamfering and edge collapse problem, easy cost control, low manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

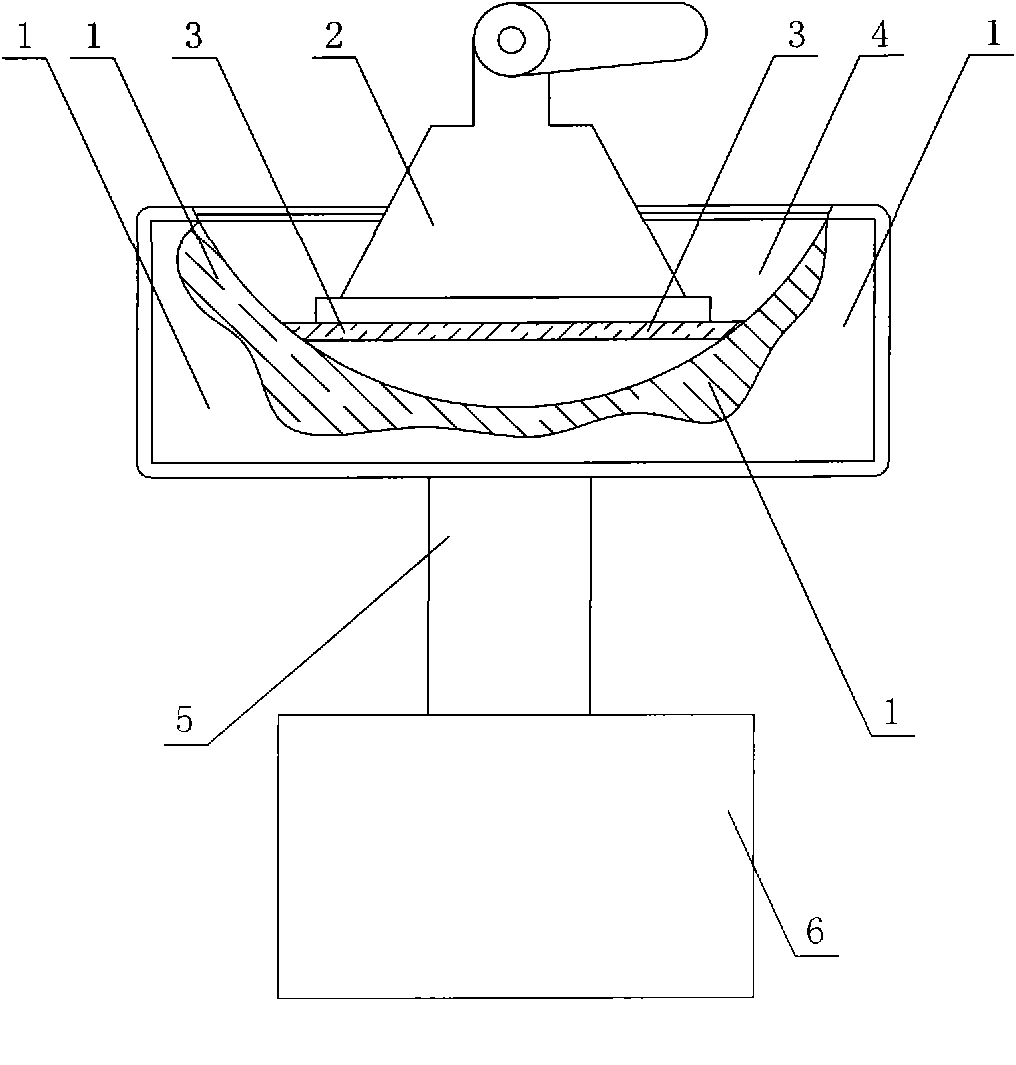

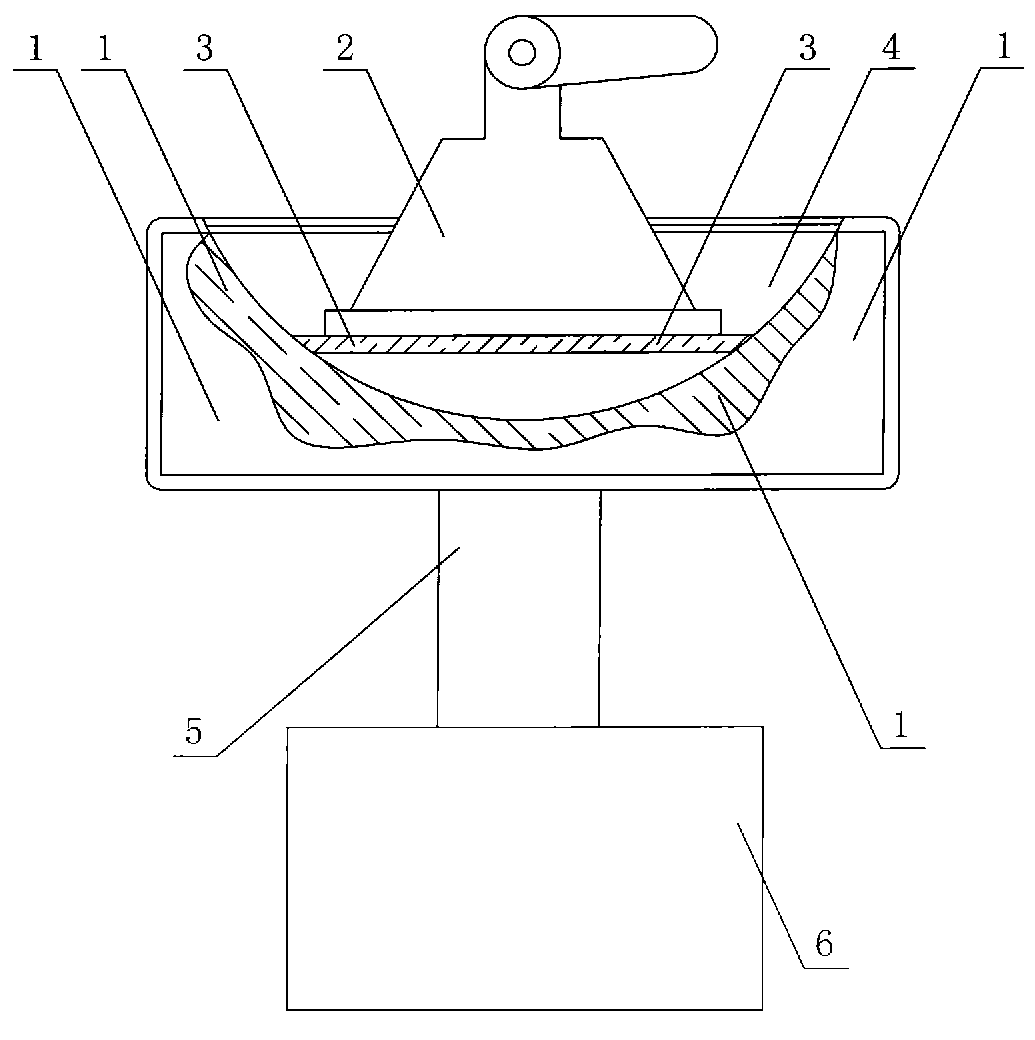

[0016] Such as figure 1 As shown, a large-diameter crystal wafer chamfering tool, which includes a four-axis grinder 6, a bowl-shaped chamfering tool and a crystal wafer vacuum sticky hook 2;

[0017] Wherein, the bowl-shaped chamfering tool includes a bowl 1 with a spherical concave surface 4 and a connecting body 5 arranged at the bottom of the bowl 1. A layer of abrasive sand is provided on the spherical concave surface 4 of the bowl 1. The bowl-shaped The connecting body 5 of the chamfering tool is installed on the transmission shaft of the four-axis grinder 6 , and the center of the crystal wafer vacuum hook 2 is set corresponding to the center of the spherical concave surface 4 .

[0018] Based on the above, the top of the crystal wafer vacuum hook 2 is provided with a handle.

[0019] A chamfering method of a large-diameter cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com