Patents

Literature

920 results about "Rock crystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

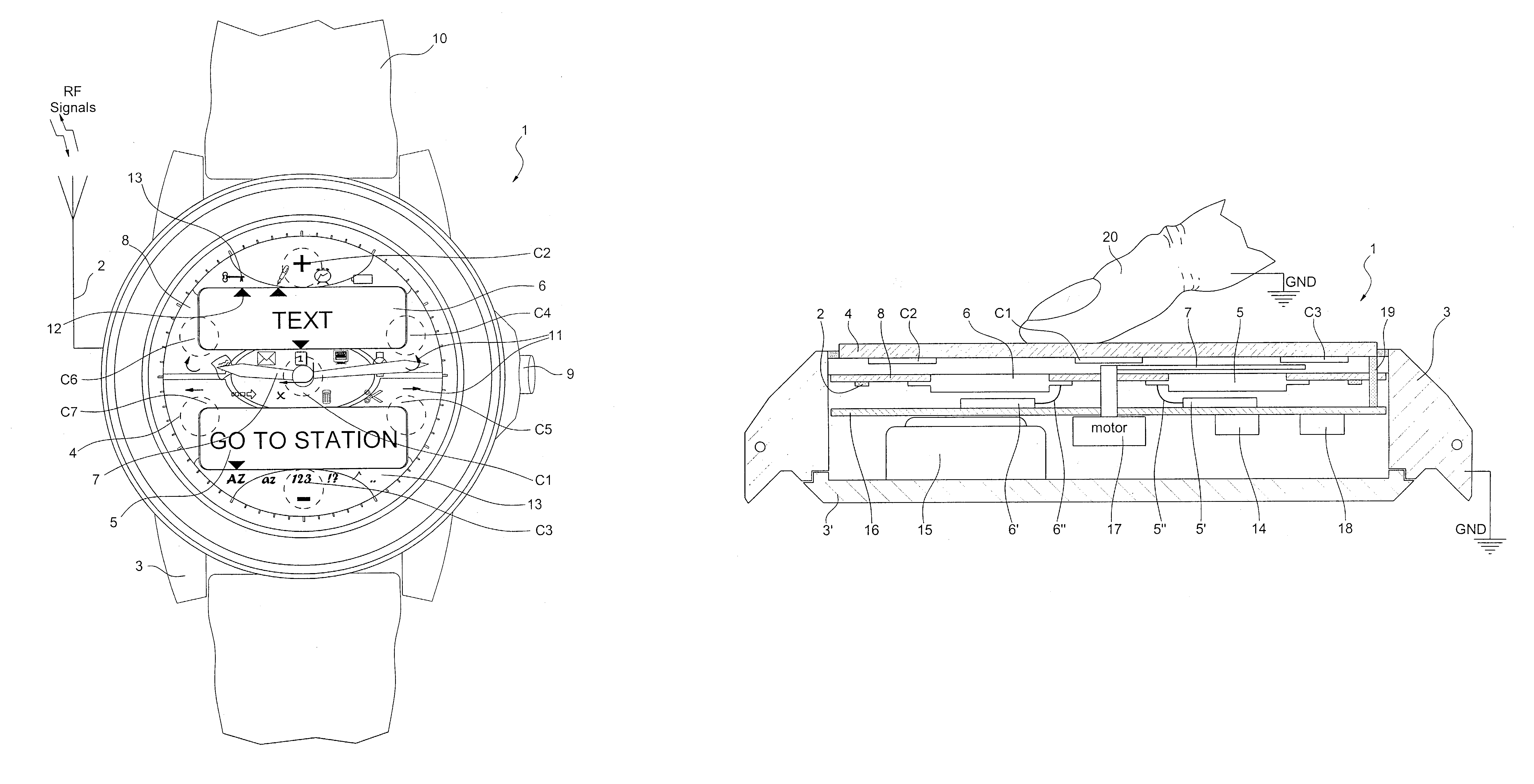

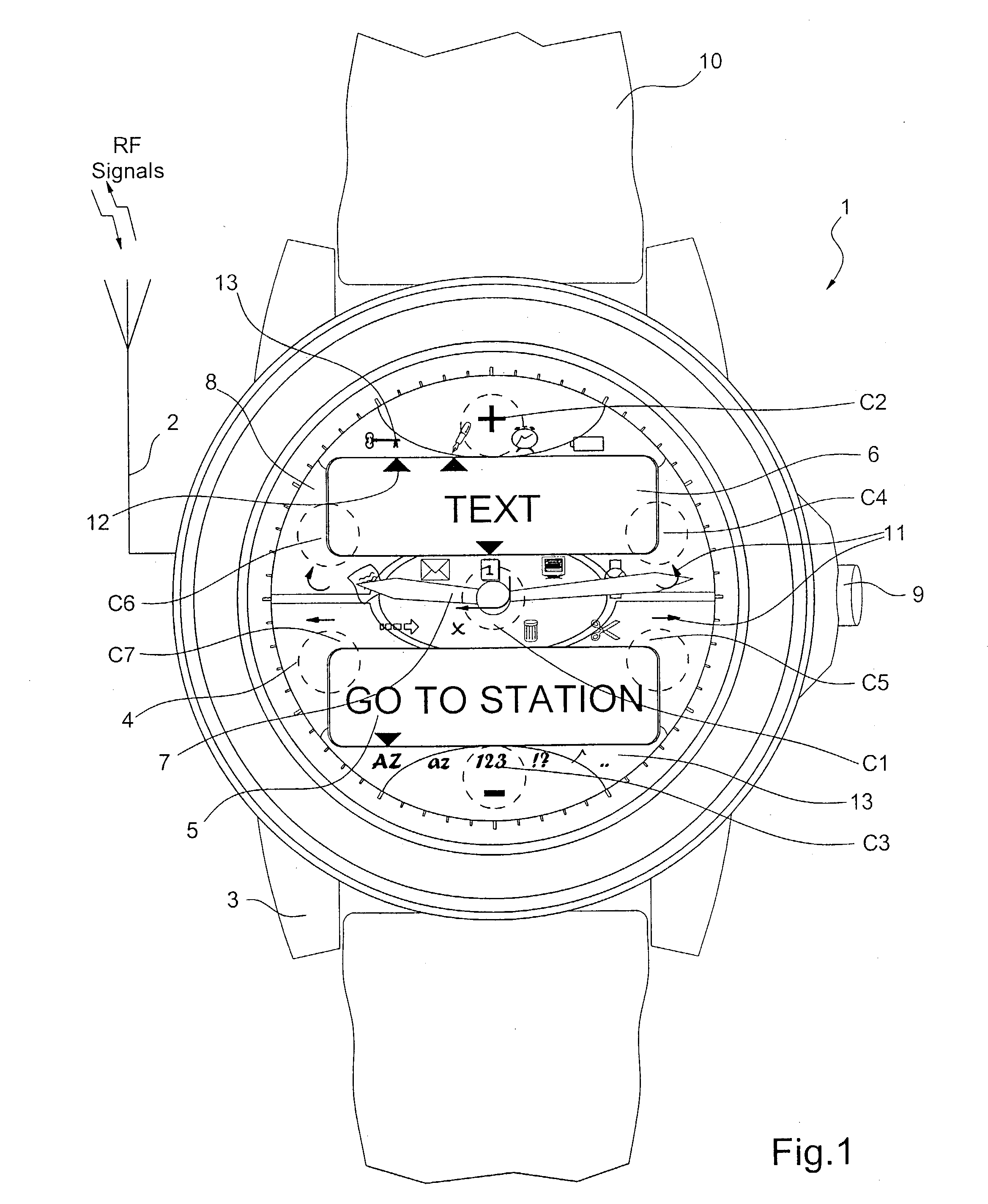

Control method for executing functions in a diary watch

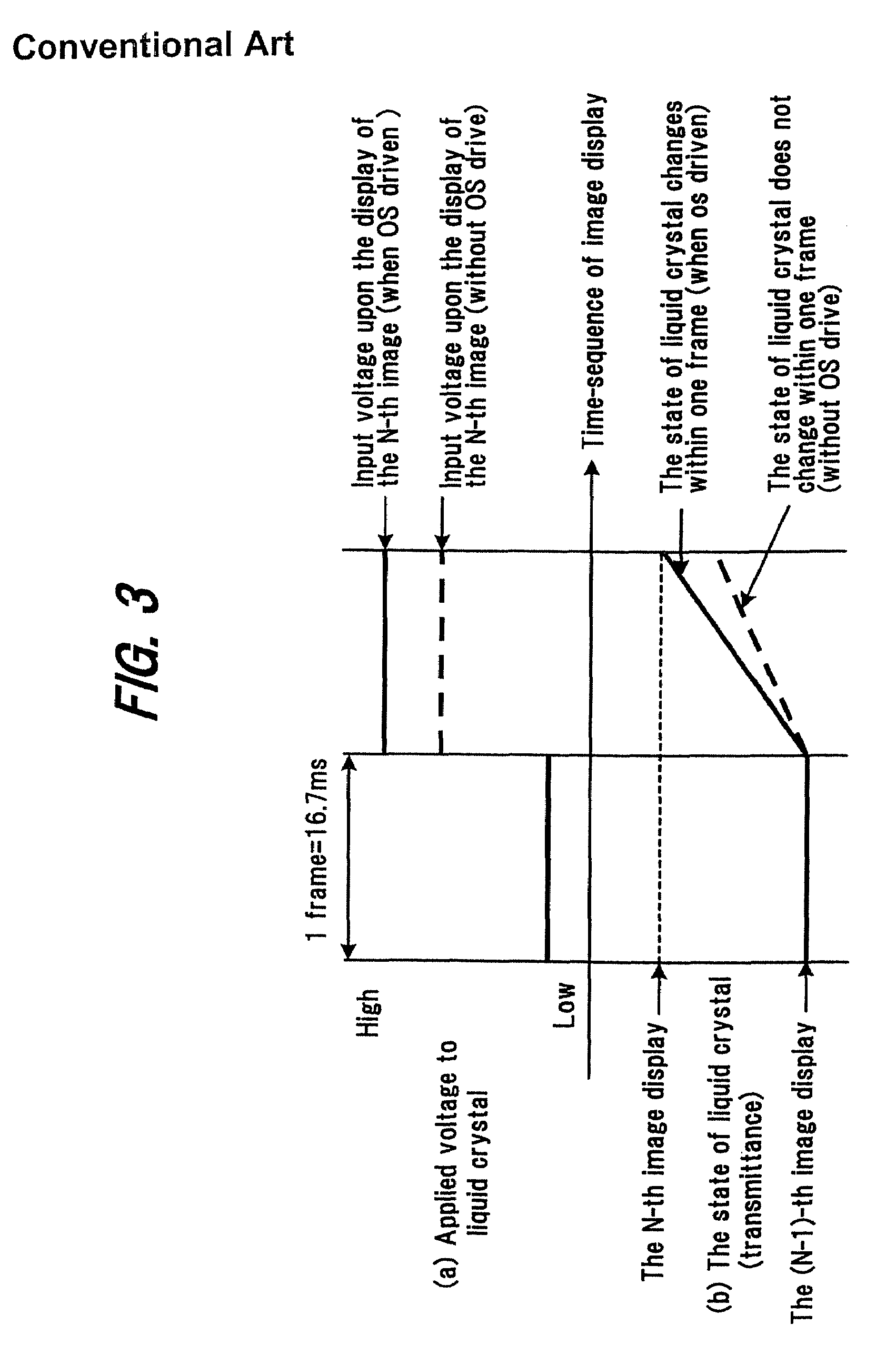

InactiveUS6967903B2Reduce in quantityOvercomes drawbackVisual indicationElectric indicationData controlLiquid-crystal display

The control method allows execution of various functions in an electronic diary watch, which includes, in a case closed by a crystal, a time-keeping circuit and / or a watch movement powered by an energy source, and a dial on which the time is displayed in a digital and / or analogue manner. A determined number of sensors (C1 to C7) are provided with touch sensitive pads arranged on an inner or outer face of the crystal. These sensors are provided for carrying out the various controls of the method when they are individually activated by a user's finger. In order to consult data or parameters, the method includes a first series of steps consisting in displaying different menus (102 to 106) of the diary function on at least one liquid crystal display by activating at least one sensor (C4, C5) of a group of sensors (C4 to C7), and in selecting the menu or record to be consulted (107 to 111) by activating a validation sensor (C1). In order to enter data, the method includes a second series of steps consisting in activating the validation sensor (C1) for a determined period of time or with a determined application of pressure, entering diary data by activating certain sensors (C2 to C7) each controlling execution of a specific determined function, and validating data entered by action on the validation sensor.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

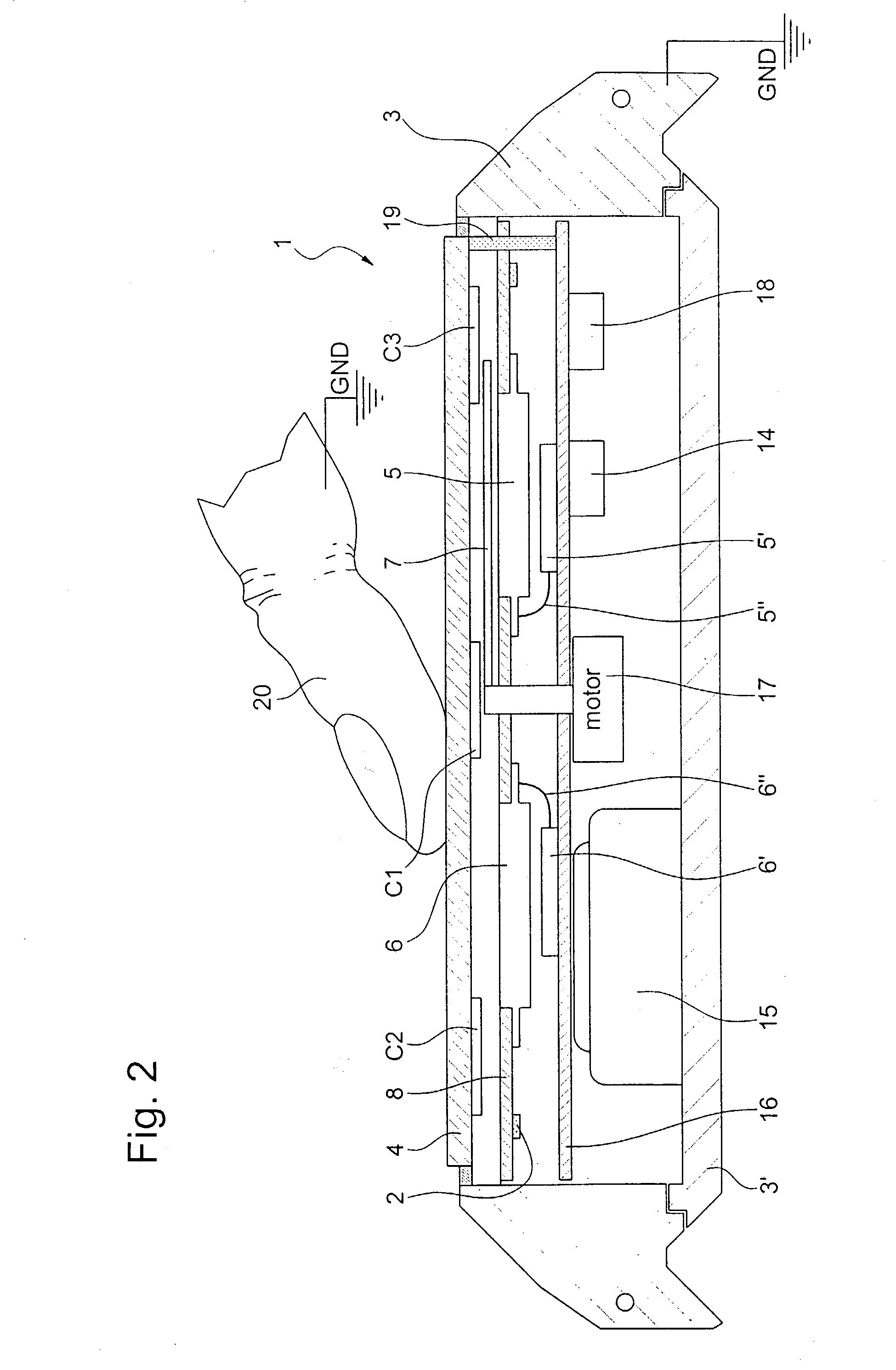

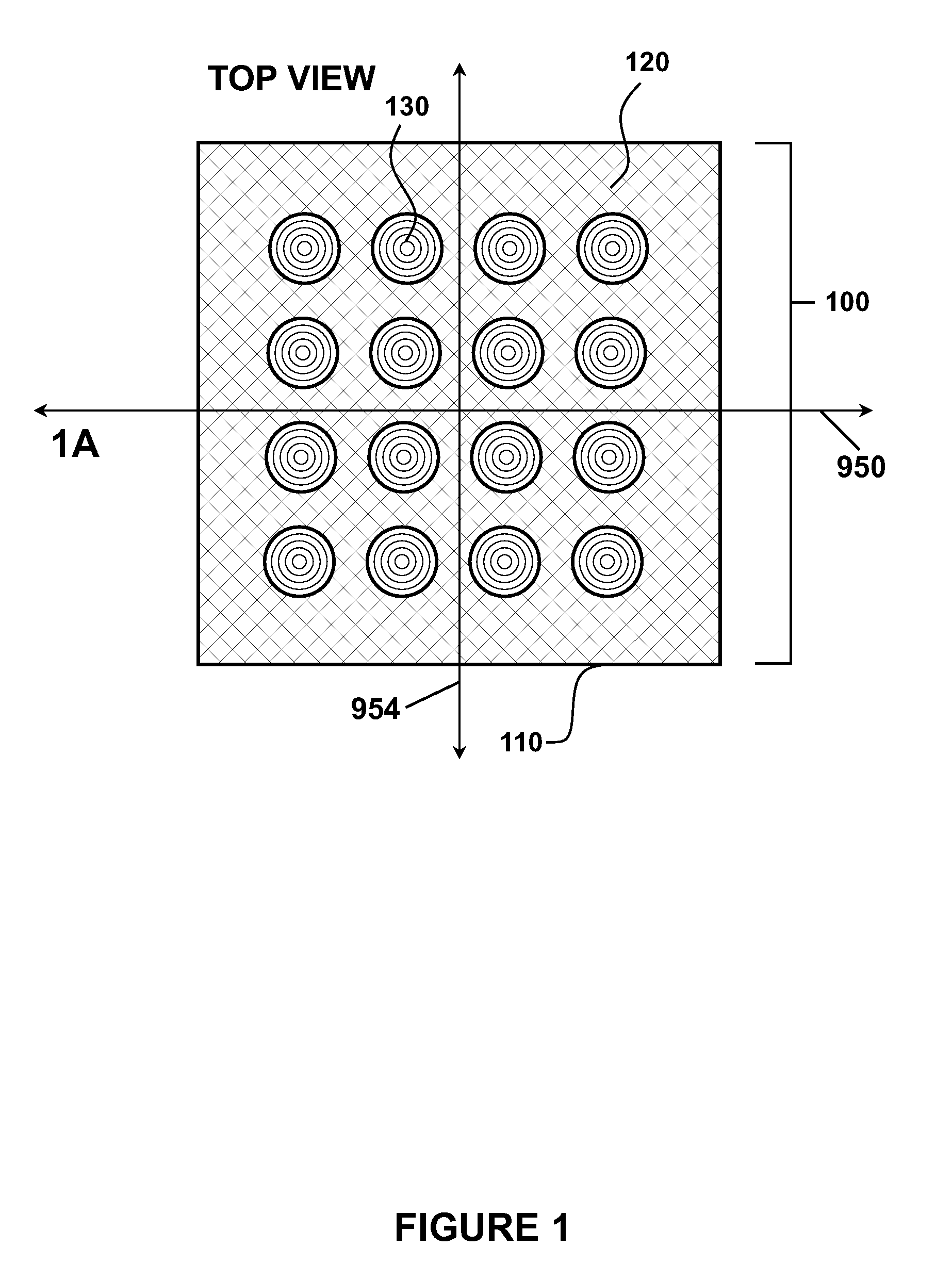

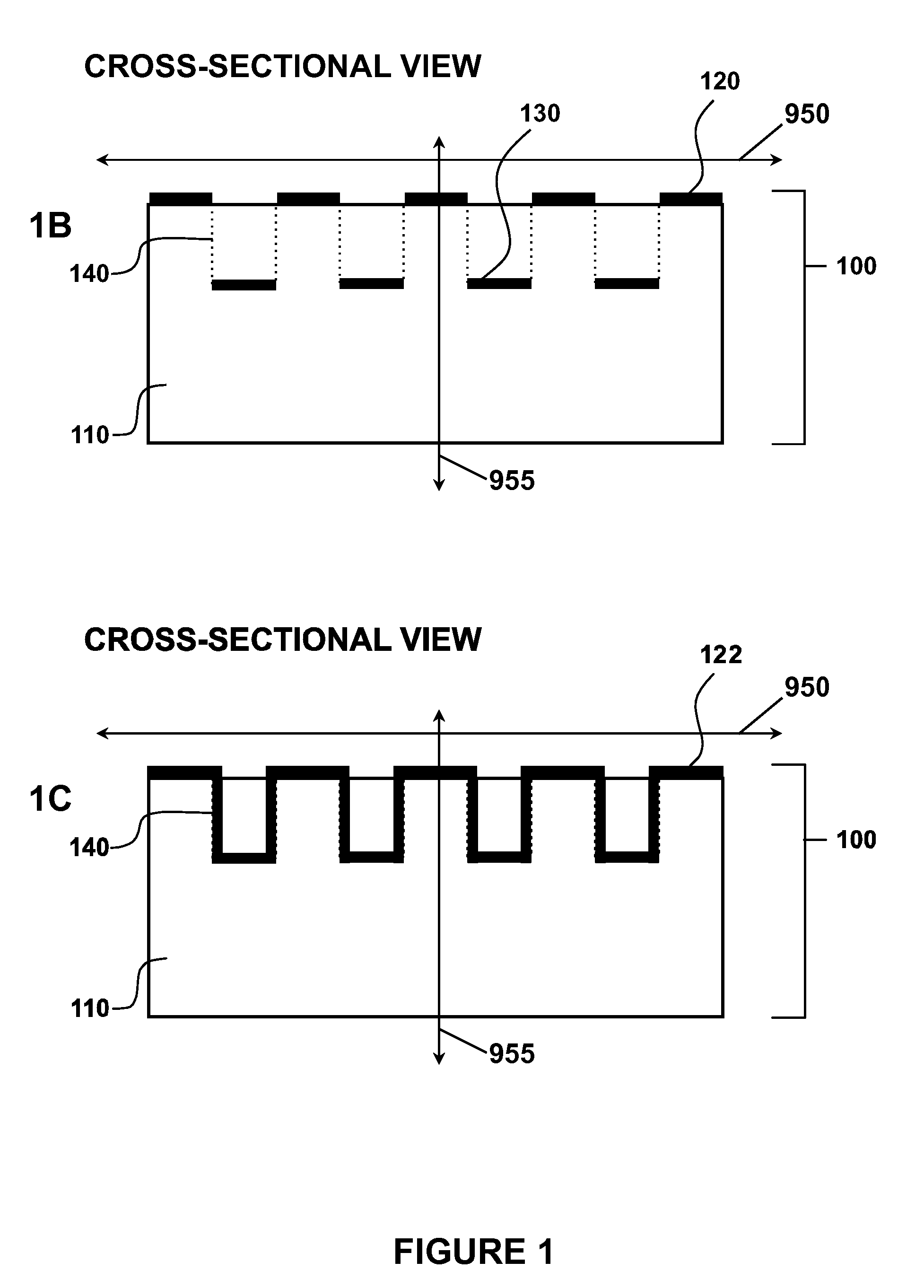

Multispectral plasmonic crystal sensors

InactiveUS7705280B2Improved field distributionImprove performanceSolid-state devicesScattering properties measurementsCouplingCrystal structure

The present invention provides plasmonic crystals comprising three-dimensional and quasi comprising three-dimensional distributions of metallic or semiconducting films, including multi-layered crystal structures comprising nanostructured films and film arrays. Plasmonic crystals of the present invention include precisely registered and deterministically selected nonplanar crystal geometries and spatial distributions providing highly coupled, localized plasmonic responses in thin film elements and / or nanostructures of the crystal. Coupling of plasmonic responses provided by three-dimensional and quasi-three dimensional plasmonic crystal geometries and structures of the present invention generates enhanced local plasmonic field distributions useful for detecting small changes in the composition of an external dielectric environment proximate to a sensing surface of the plasmonic crystal. Plasmonic crystal structures of the present invention are also useful for providing highly localized excitation and / or imaging of fluorophores proximate to the crystal surface.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

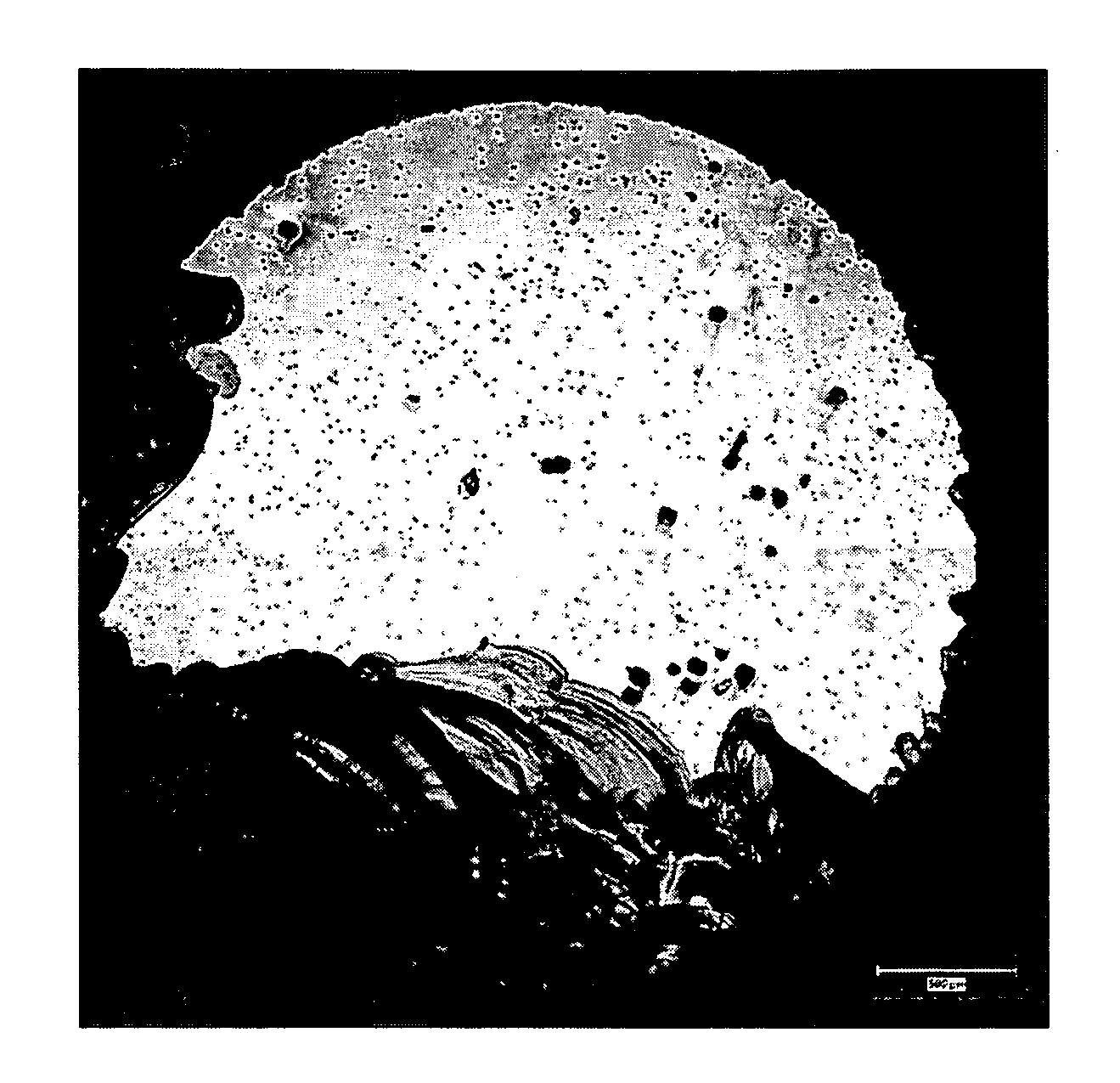

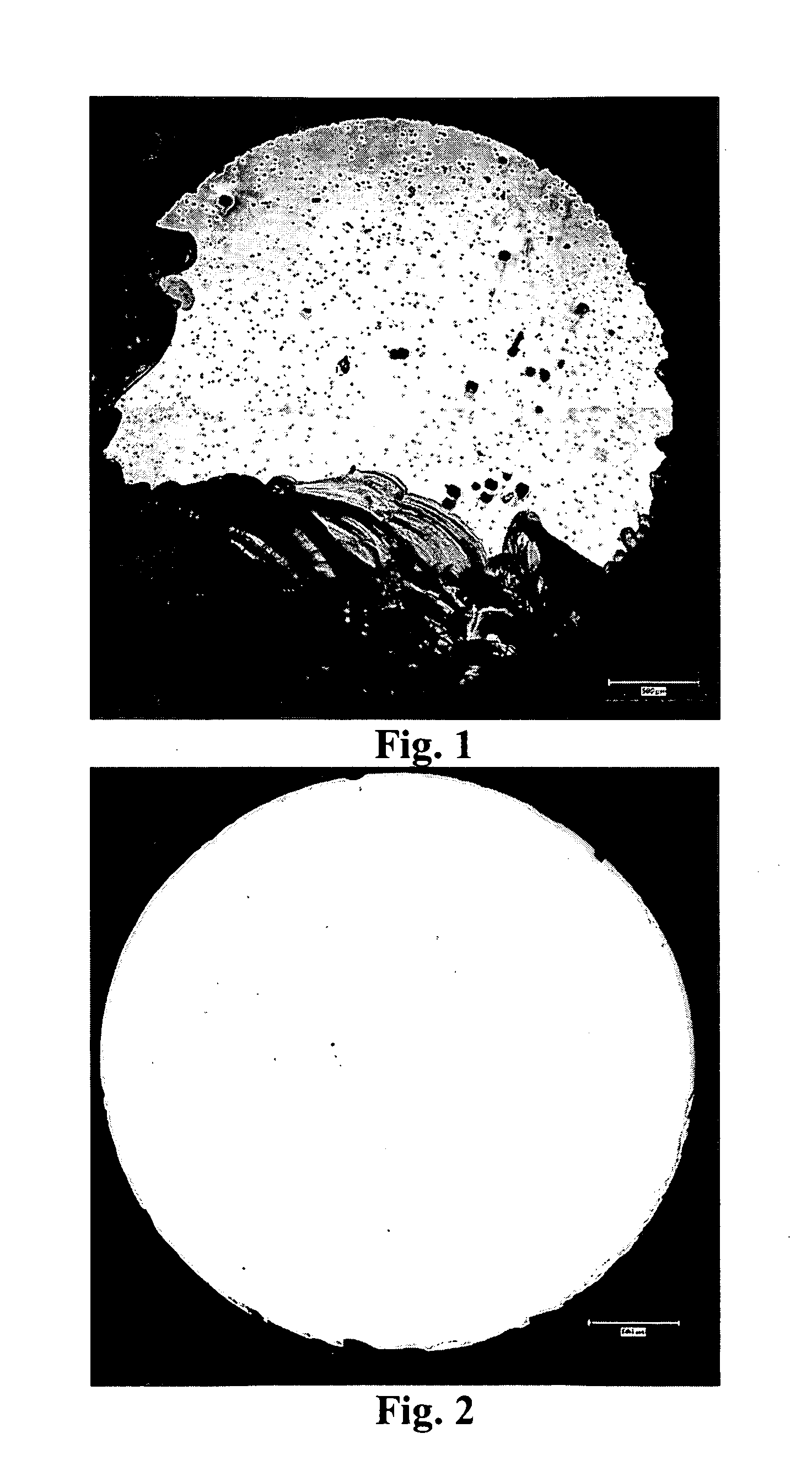

Method for reducing defect concentration in crystals

ActiveUS20060096521A1Reduce defect concentrationRelieve pressureAfter-treatment detailsUltra-high pressure processesDiamond crystalHigh pressure cell

A method for removing defects at high pressure and high temperature (HP / HT) or for relieving strain in a non-diamond crystal commences by providing a crystal, which contains defects, and a pressure medium. The crystal and the pressure medium are disposed in a high pressure cell and placed in a high pressure apparatus, for processing under reaction conditions of sufficiently high pressure and high temperature for a time adequate for one or more of removing defects or relieving strain in the single crystal.

Owner:SLT TECH

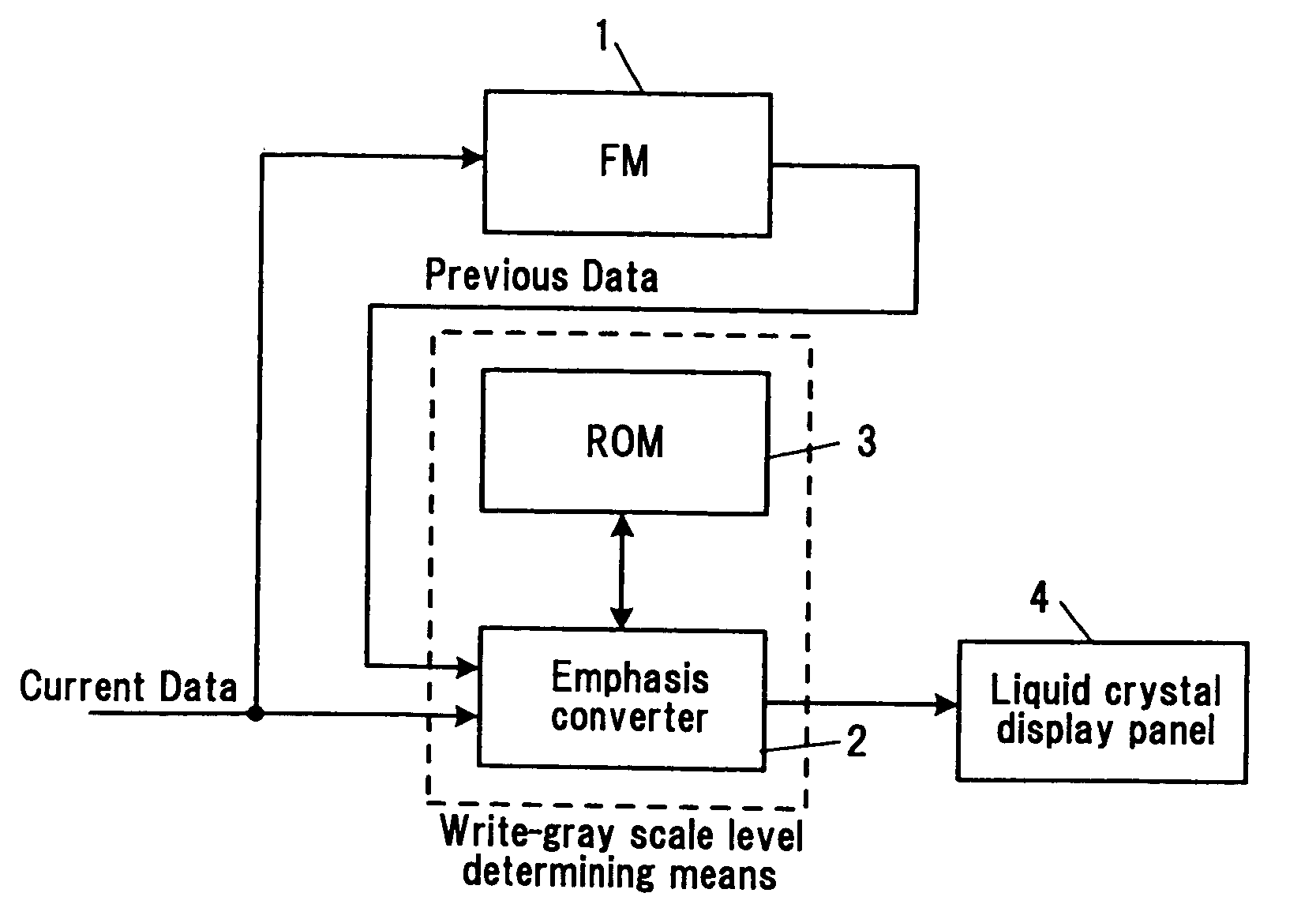

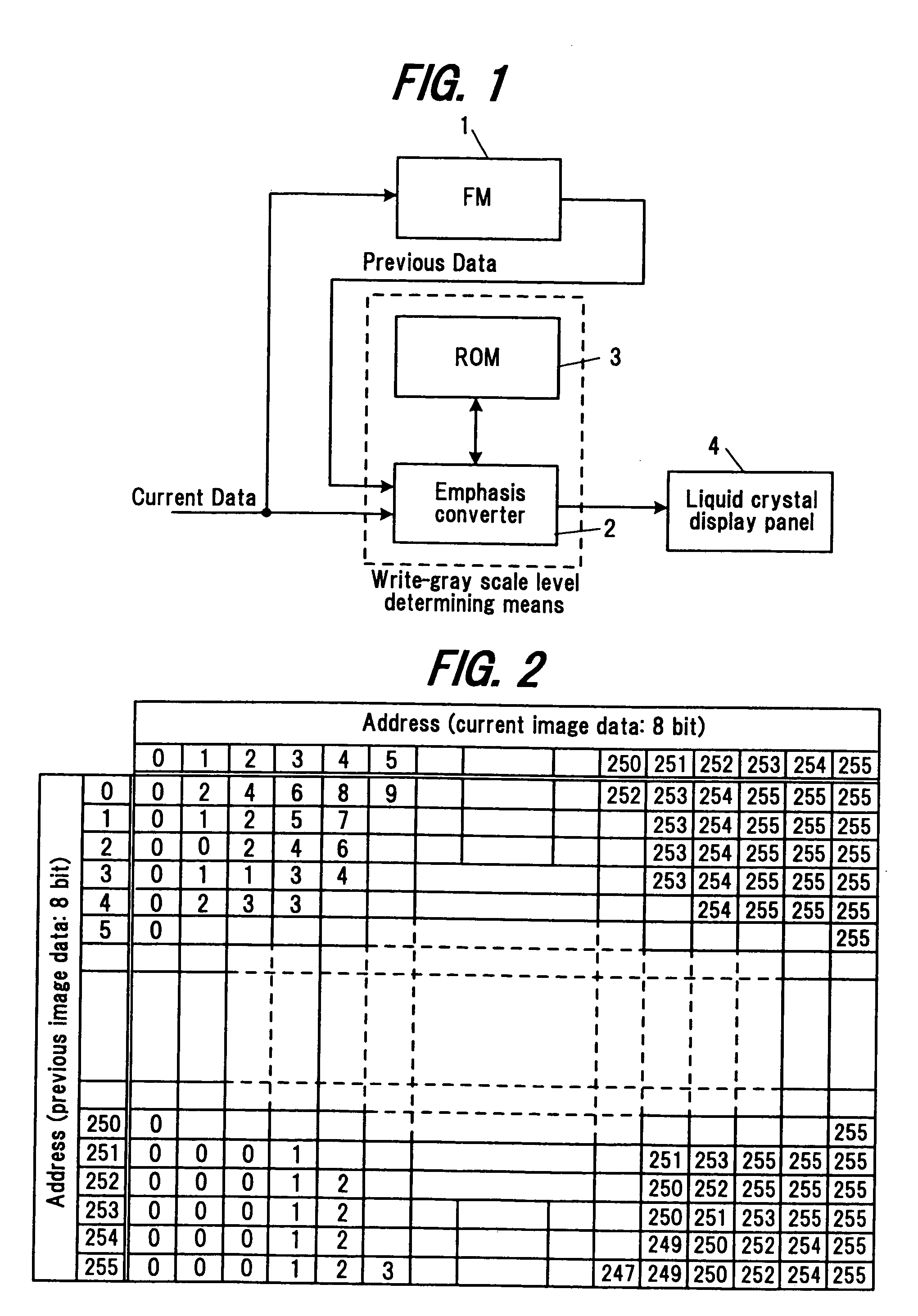

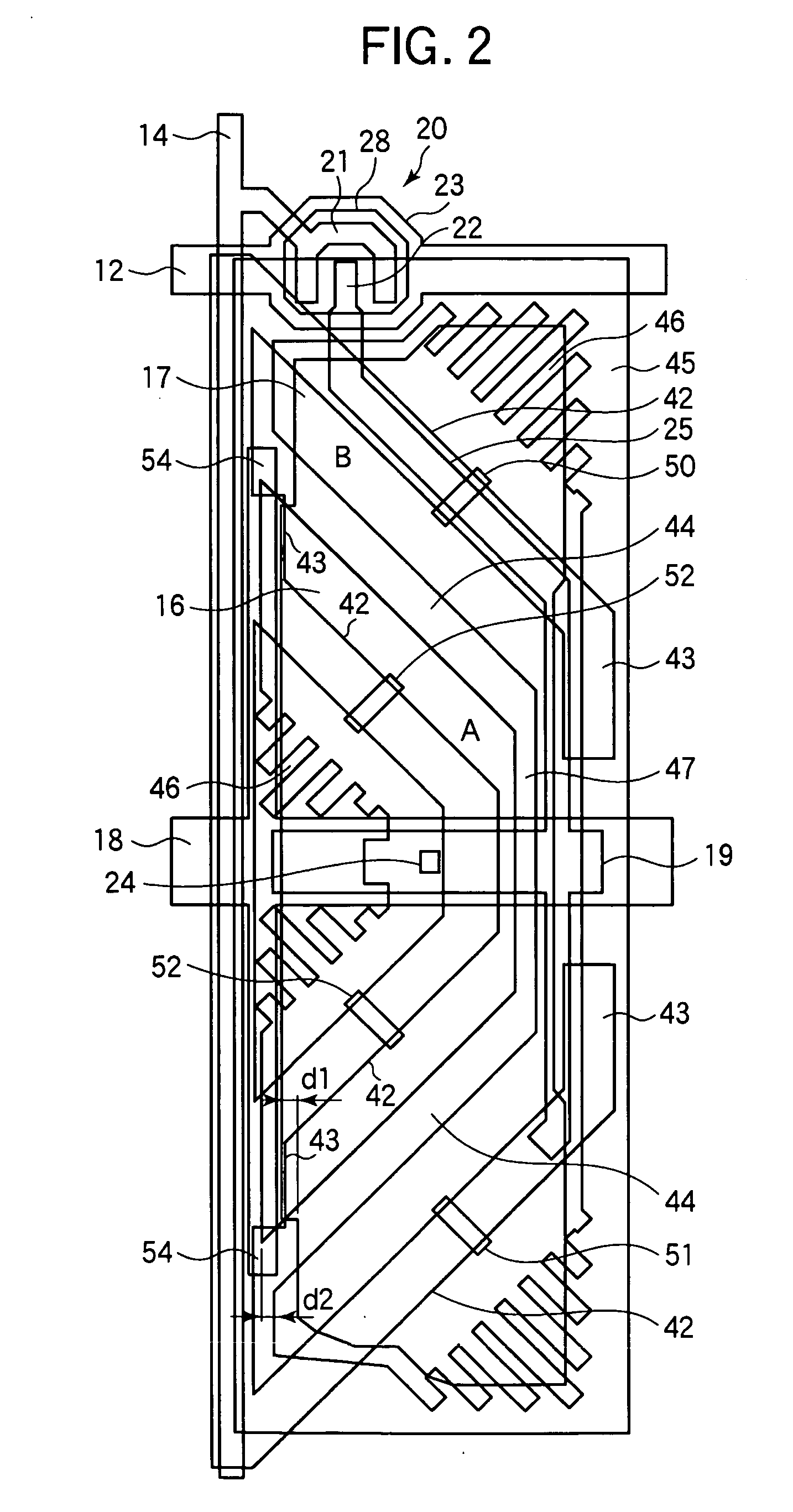

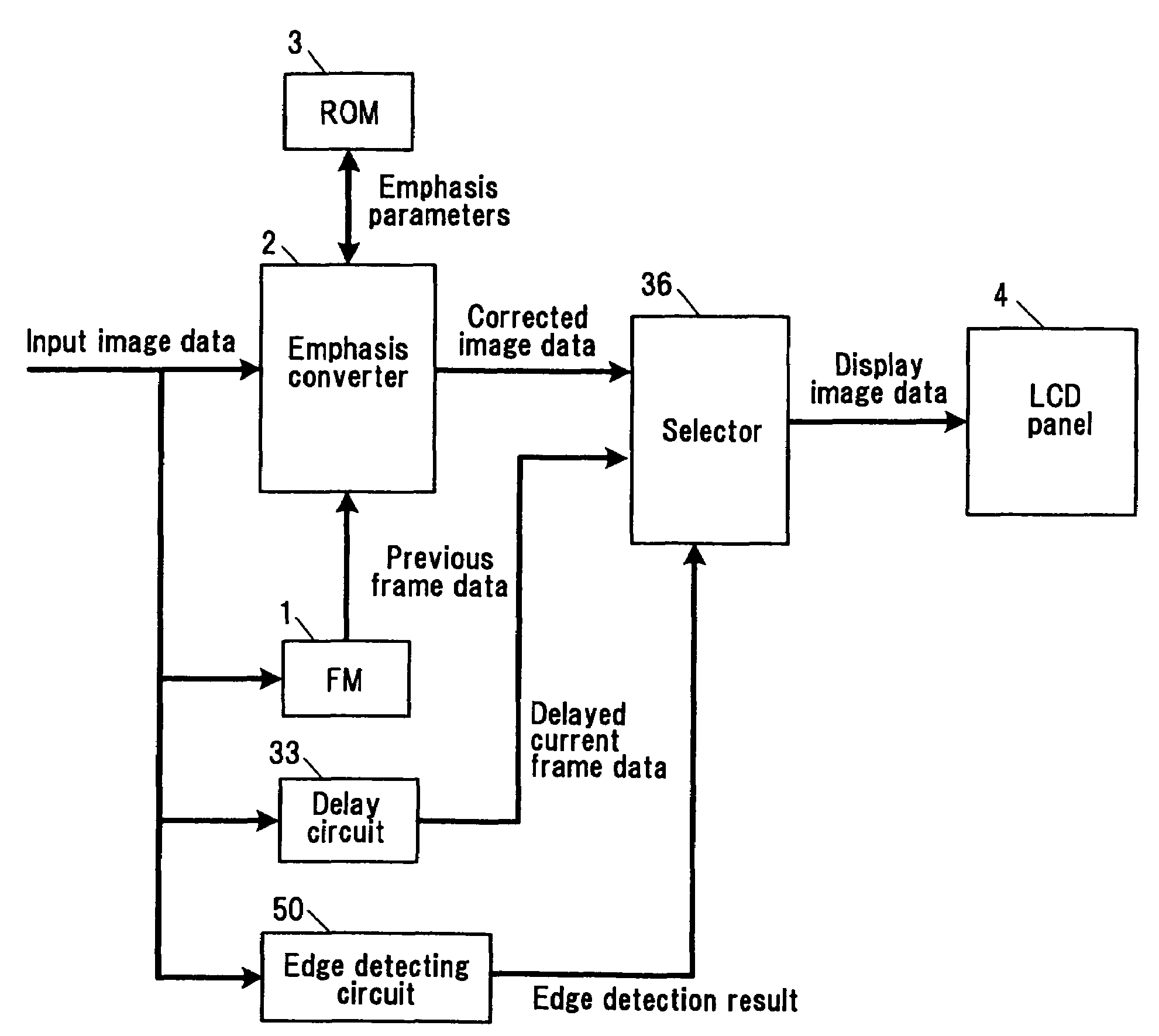

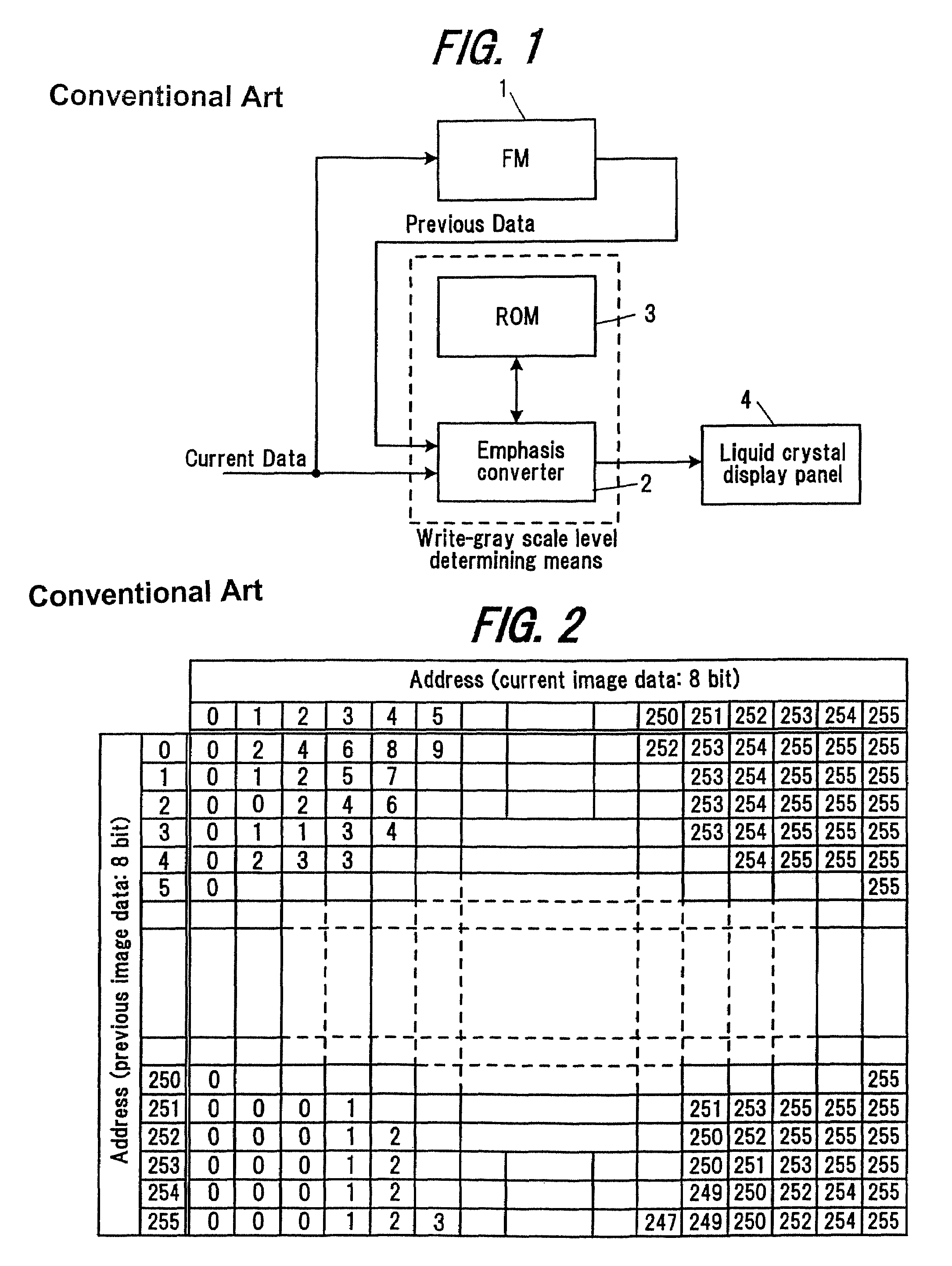

Crystal display device

InactiveUS20040263495A1Additional componentReduce image qualityCathode-ray tube indicatorsInput/output processes for data processingPattern recognitionDisplay device

Owner:SHARP KK

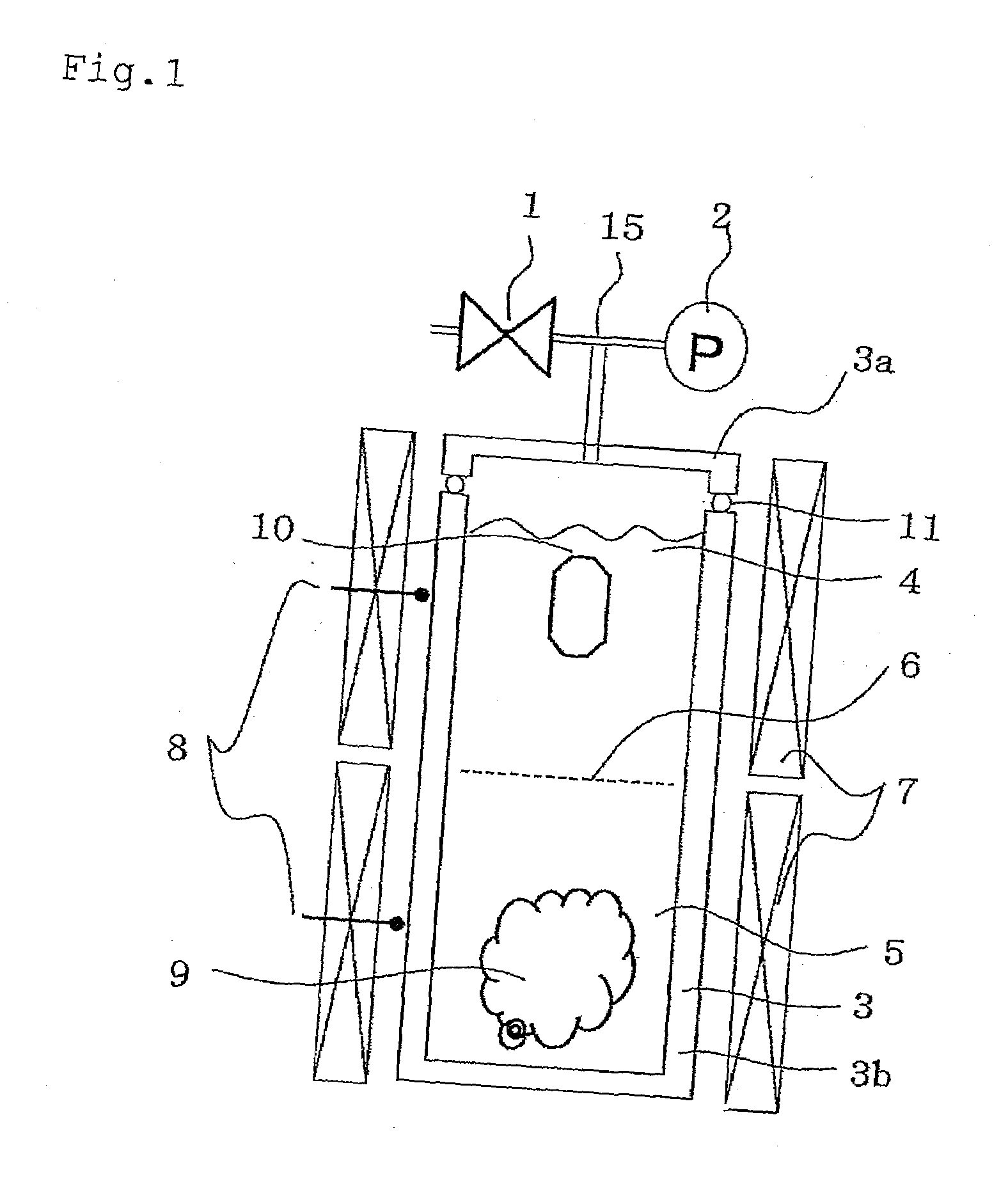

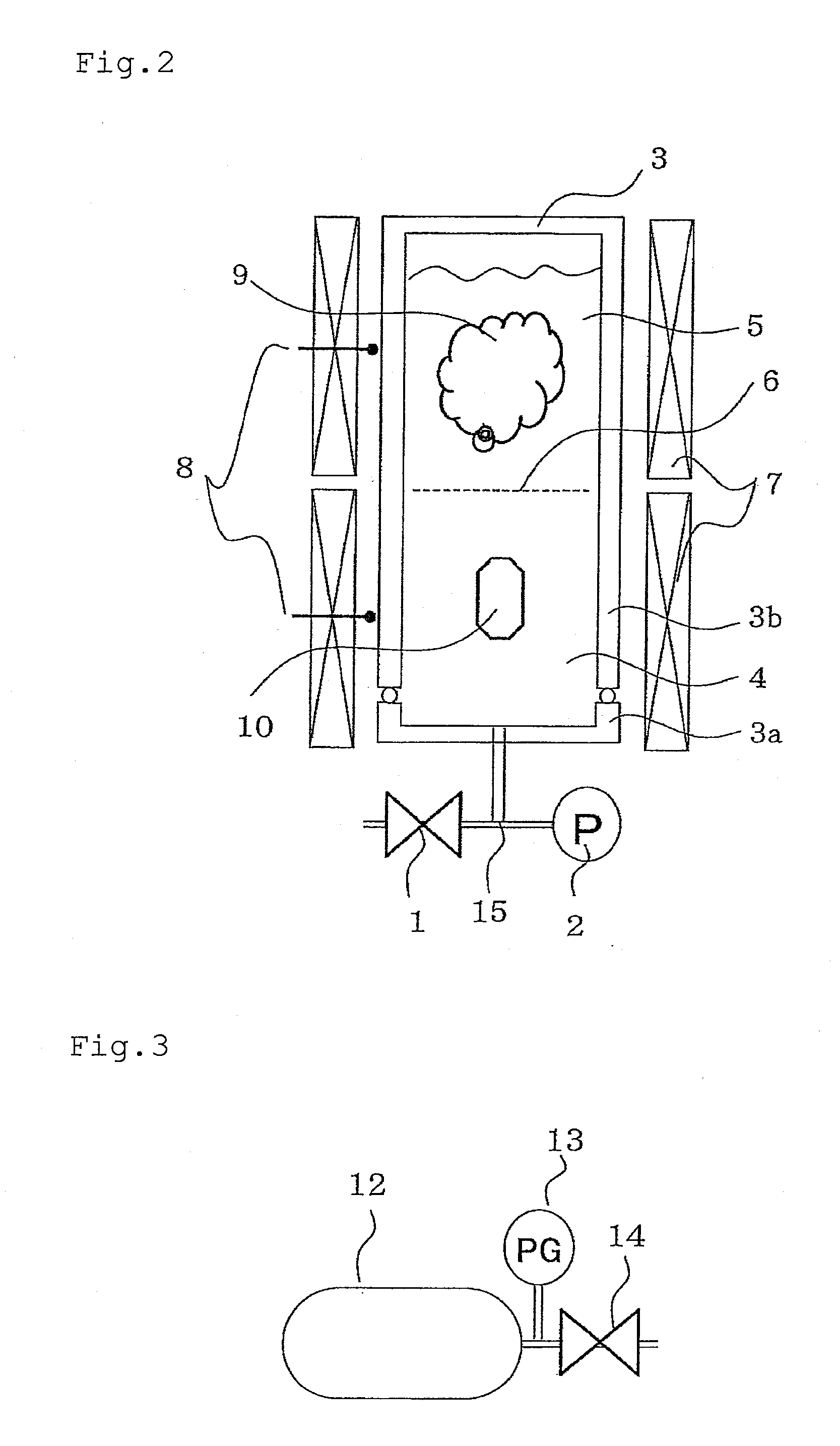

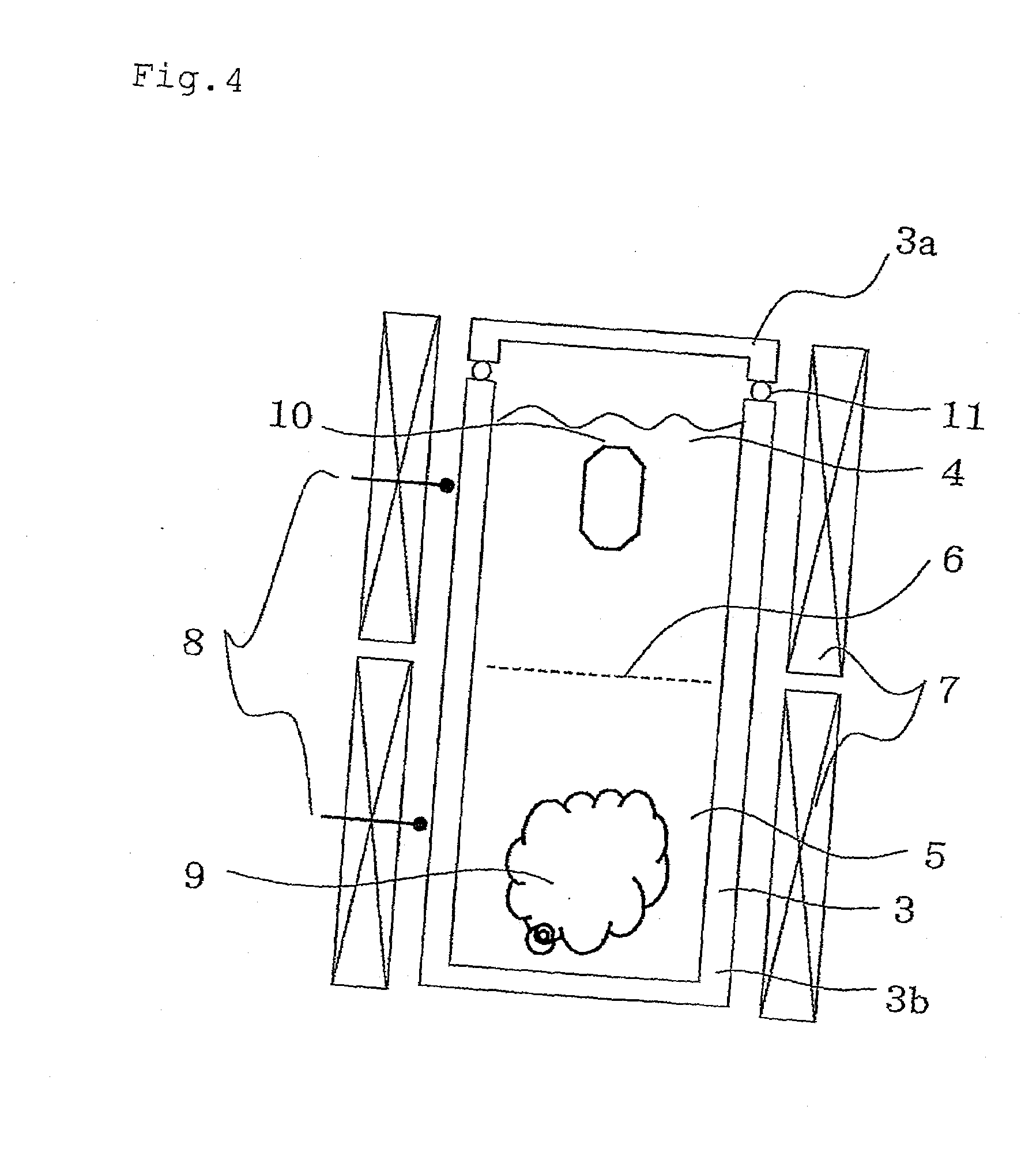

Crystal production process using supercritical solvent, crystal growth apparatus, crystal and device

InactiveUS20090092536A1Efficient productionEasy to controlPolycrystalline material growthFrom normal temperature solutionsSolventCrystal growth

To control the precipitation position of a crystal and increase the yield of the crystal by performing the crystal growth according to the solvothermal method while allowing a predetermined amount of a substance differing in the critical density from the solvent to be present in the reaction vessel; and to prevent mixing of an impurity into the crystal and improve the crystal purity.

Owner:MITSUBISHI CHEM CORP +1

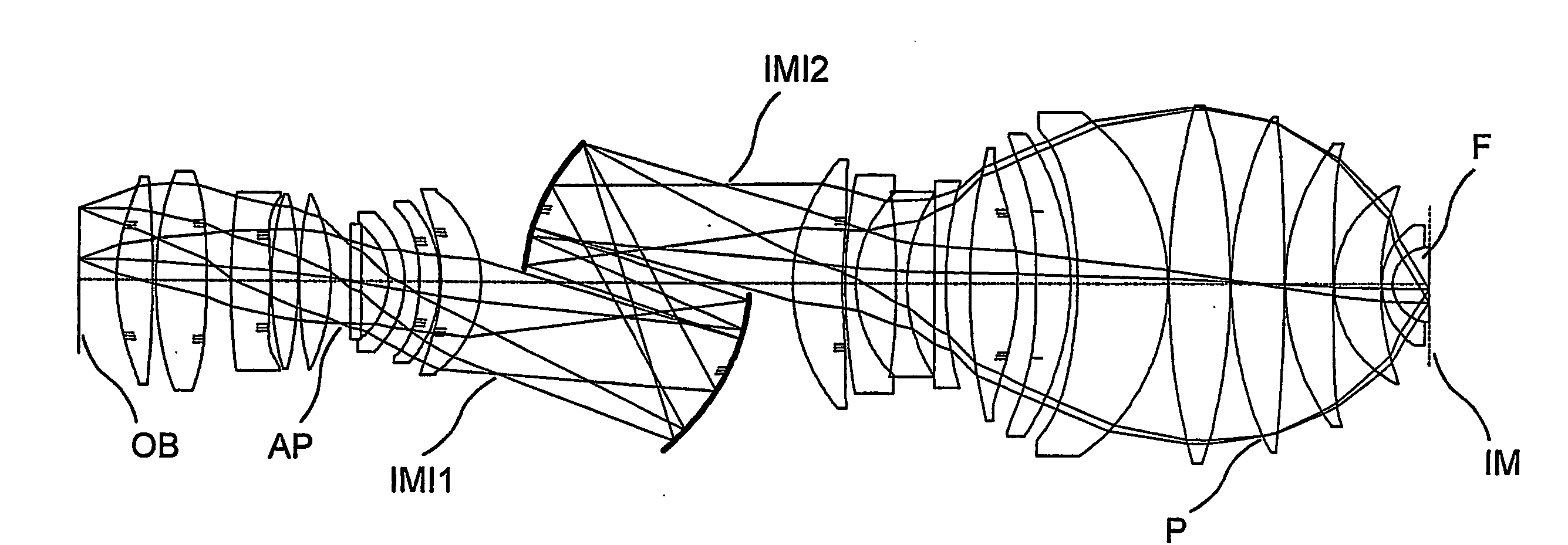

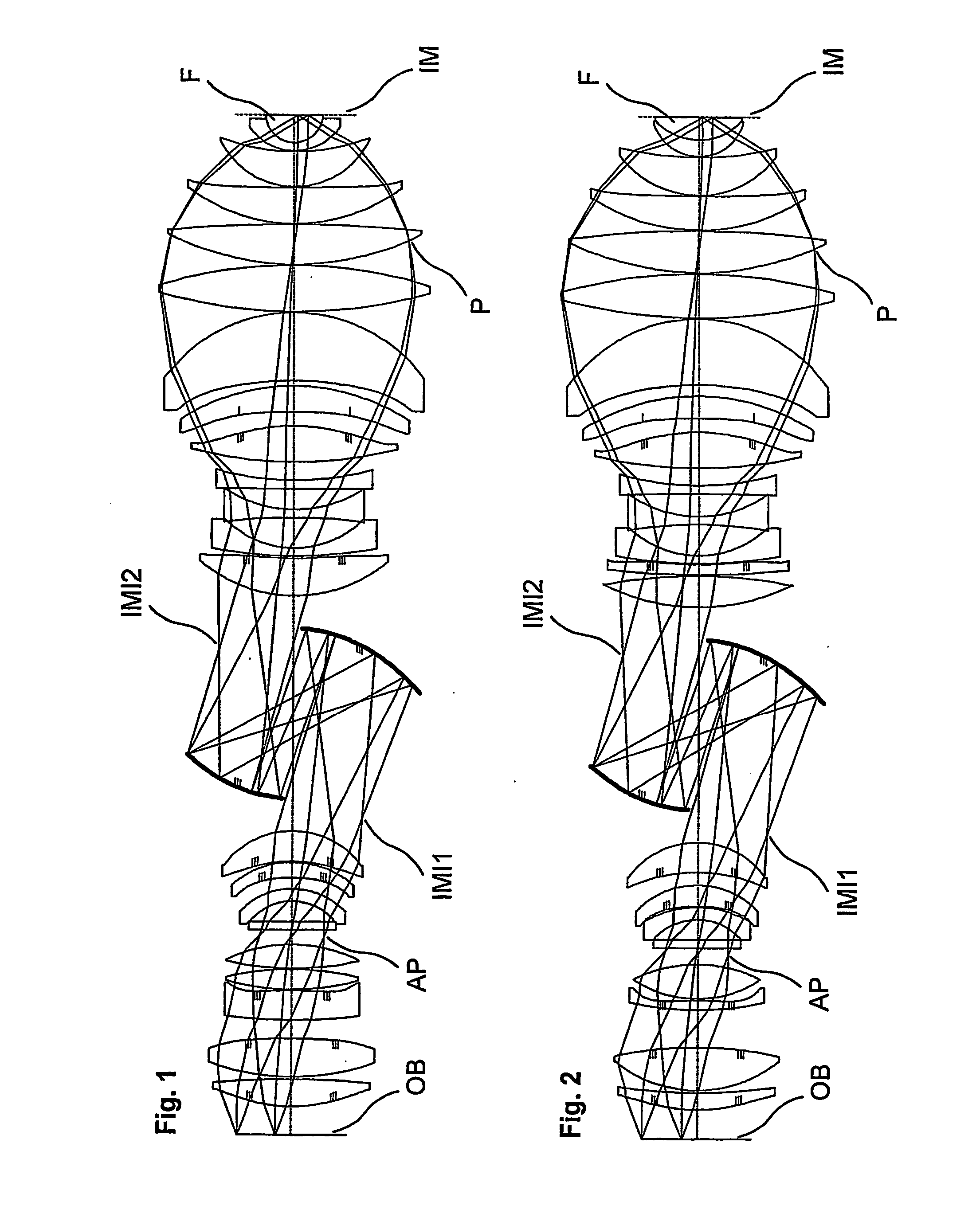

Objectives as a microlithography projection objective with at least one liquid lens

InactiveUS20060221456A1Great freedomExpand accessPhotomechanical exposure apparatusMicrolithography exposure apparatusRefractive indexLength wave

The invention relates to an objective designed as a microlithography projection objective for an operating wavelength. The objective has a greatest adjustable image-side numerical aperture NA, at least one first lens made from a solid transparent body, in particular glass or crystal, with a refractive index nL and at least one liquid lens (F) made from a transparent liquid, with a refractive index NF. At the operating wavelength the first lens has the greatest refractive index nL of all solid lenses of the objective, the refractive index nF of the at least one liquid lens (F) is bigger than the refractive index nL of the first lens and the value of the numerical aperture NA is bigger than 1.

Owner:CARL ZEISS SMT GMBH

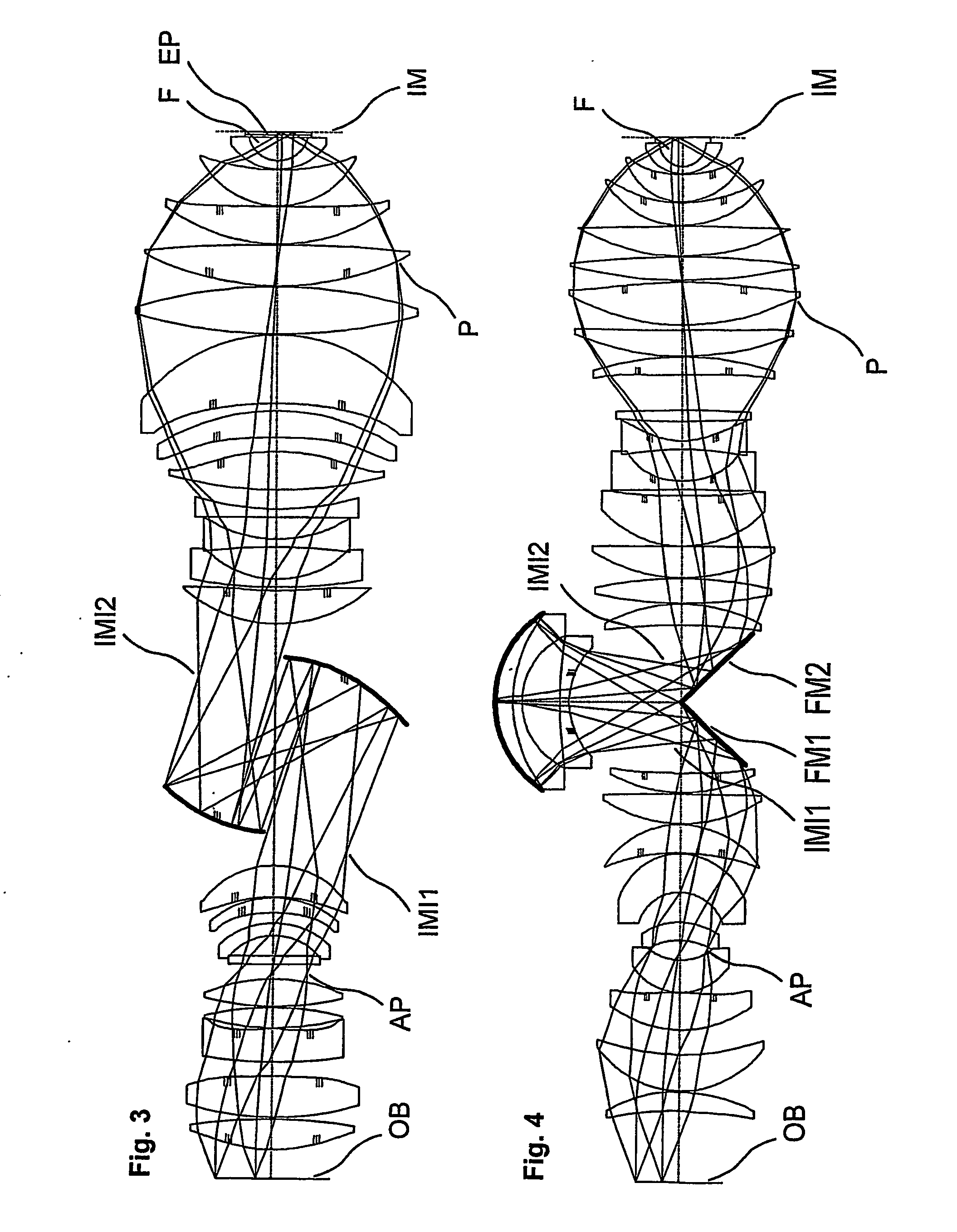

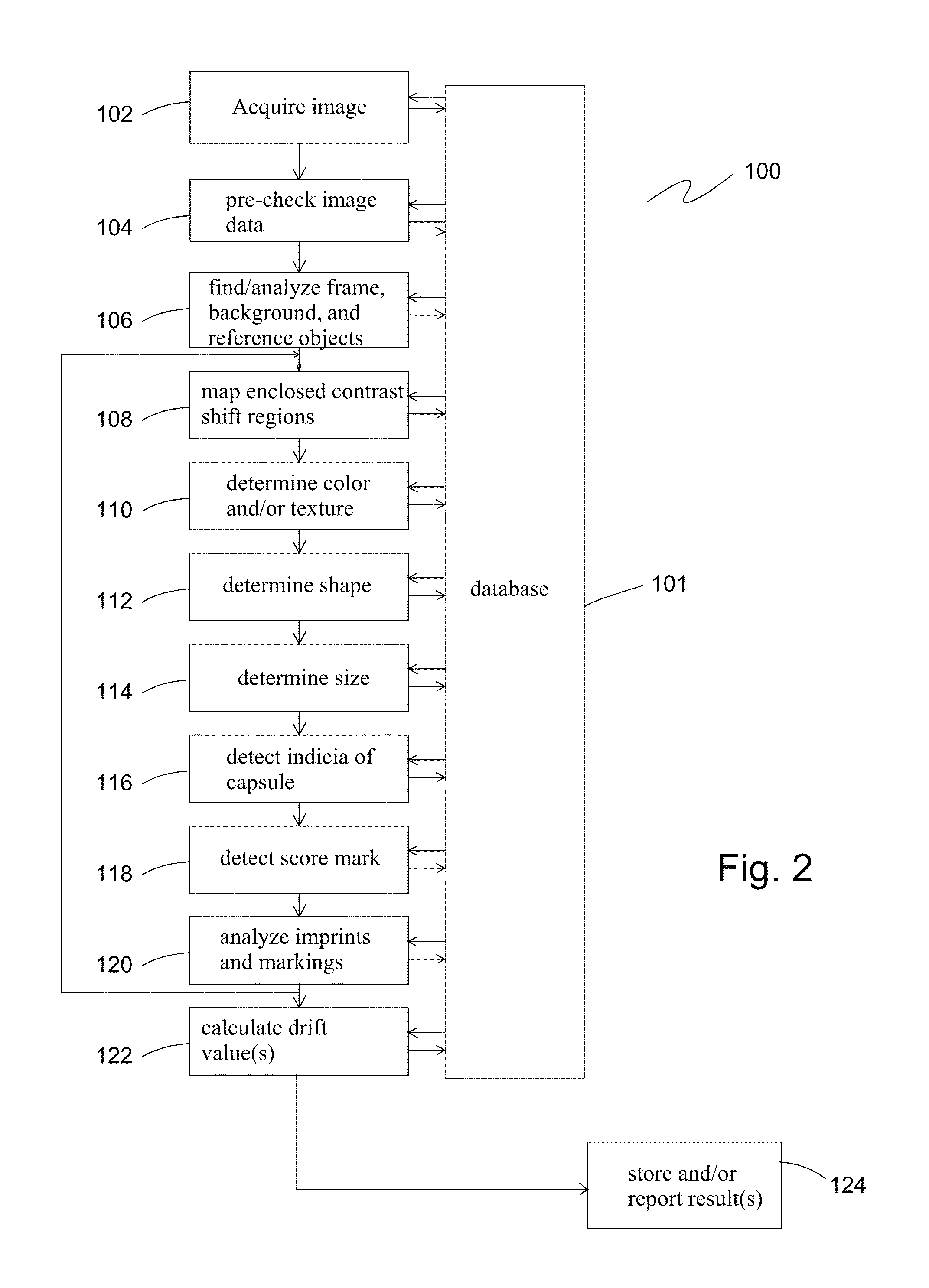

Pill identification and counterfeit detection method

Disclosed is a computer-implemented method of pill analysis including the steps of acquiring a pill image having an image frame and detecting contrast shifts within the image frame to locate at least one object with an object outline. A first value for the object(s) is determined, where the value is an area, a position, a length, a width, an angle, a color, a brightness, a code, a shape, a crystal pile size, a crystal geometry, a substance identity, or a character identity. Based on the first and second values, the computer outputs a result to a user.

Owner:EYENODE

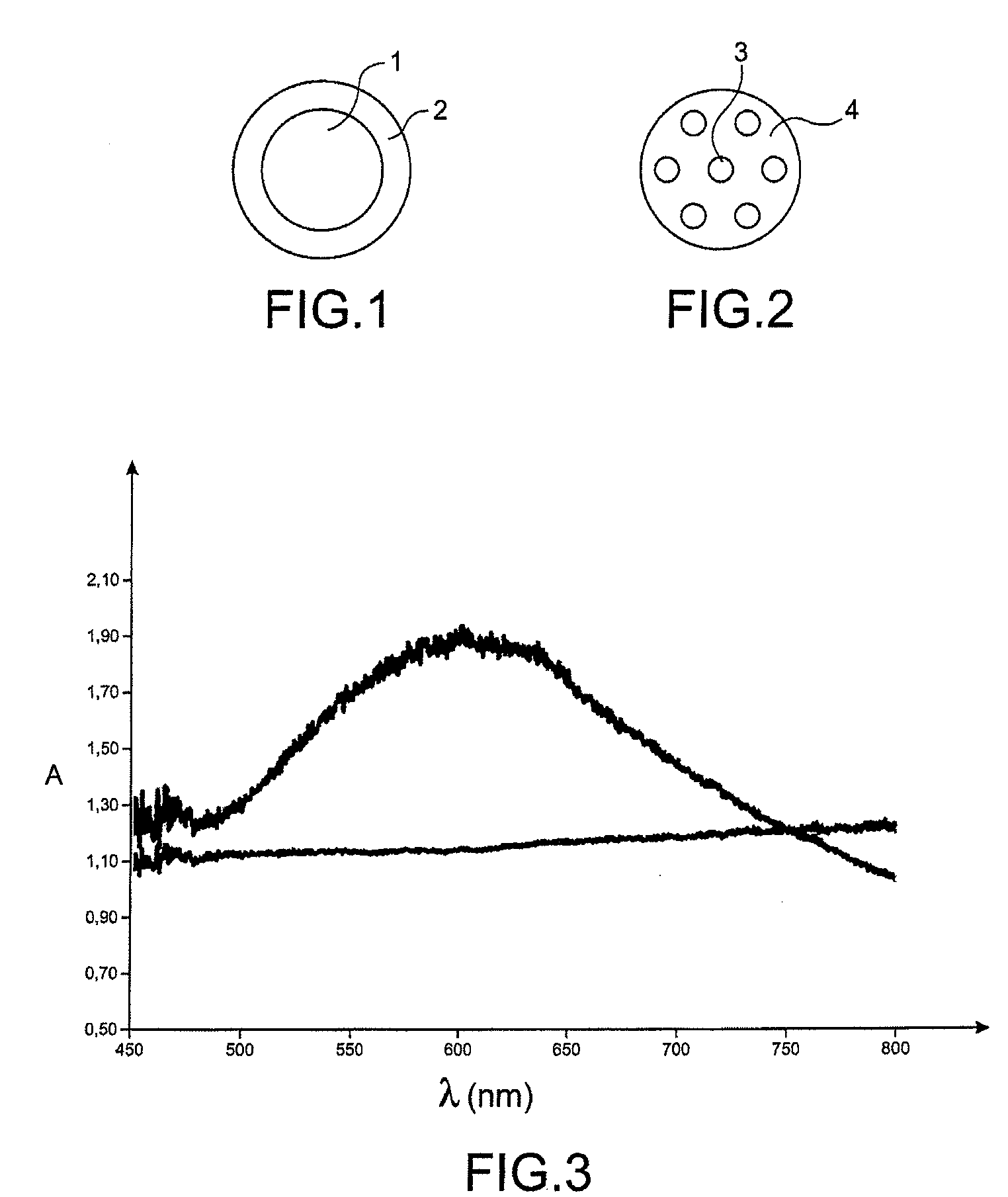

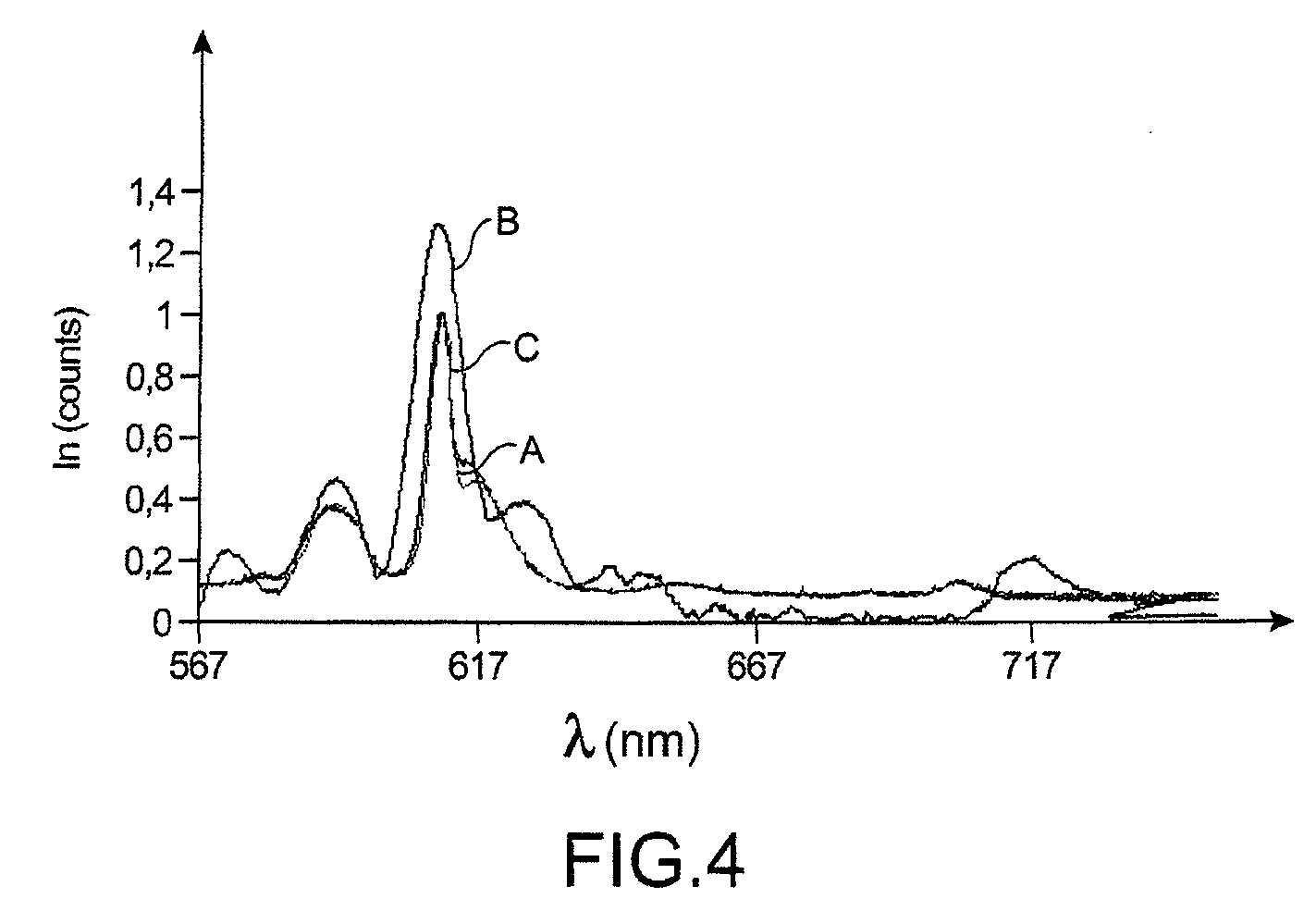

Coated Nanoparticles, in Particular Those of Core-Shell Structure

InactiveUS20090169892A1Adequate chemical reactivityGood dispersionPigmenting treatmentMaterial nanotechnologyNanoparticleInorganic materials

Bead comprising at least two non-agglomerated solid nanoparticles of core structure comprising only a solid core, or of core-shell structure comprising a solid core surrounded by a solid envelope or shell made up of an inorganic material, said nanoparticles being coated with a non-porous metal oxide.Process for preparation of the said bead.Material such as glass, a crystal, a ceramic or a polymer containing said beads.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Optical device

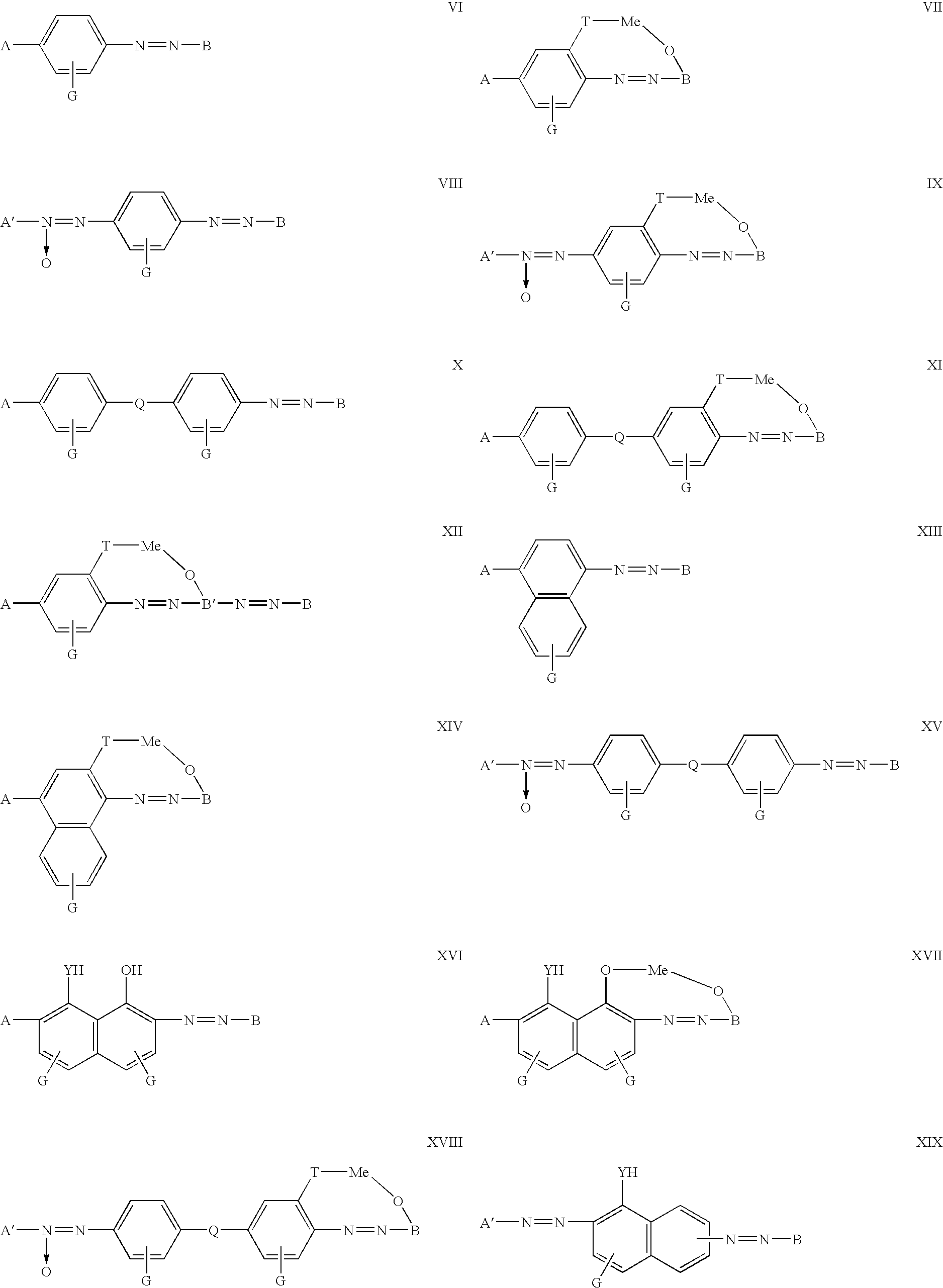

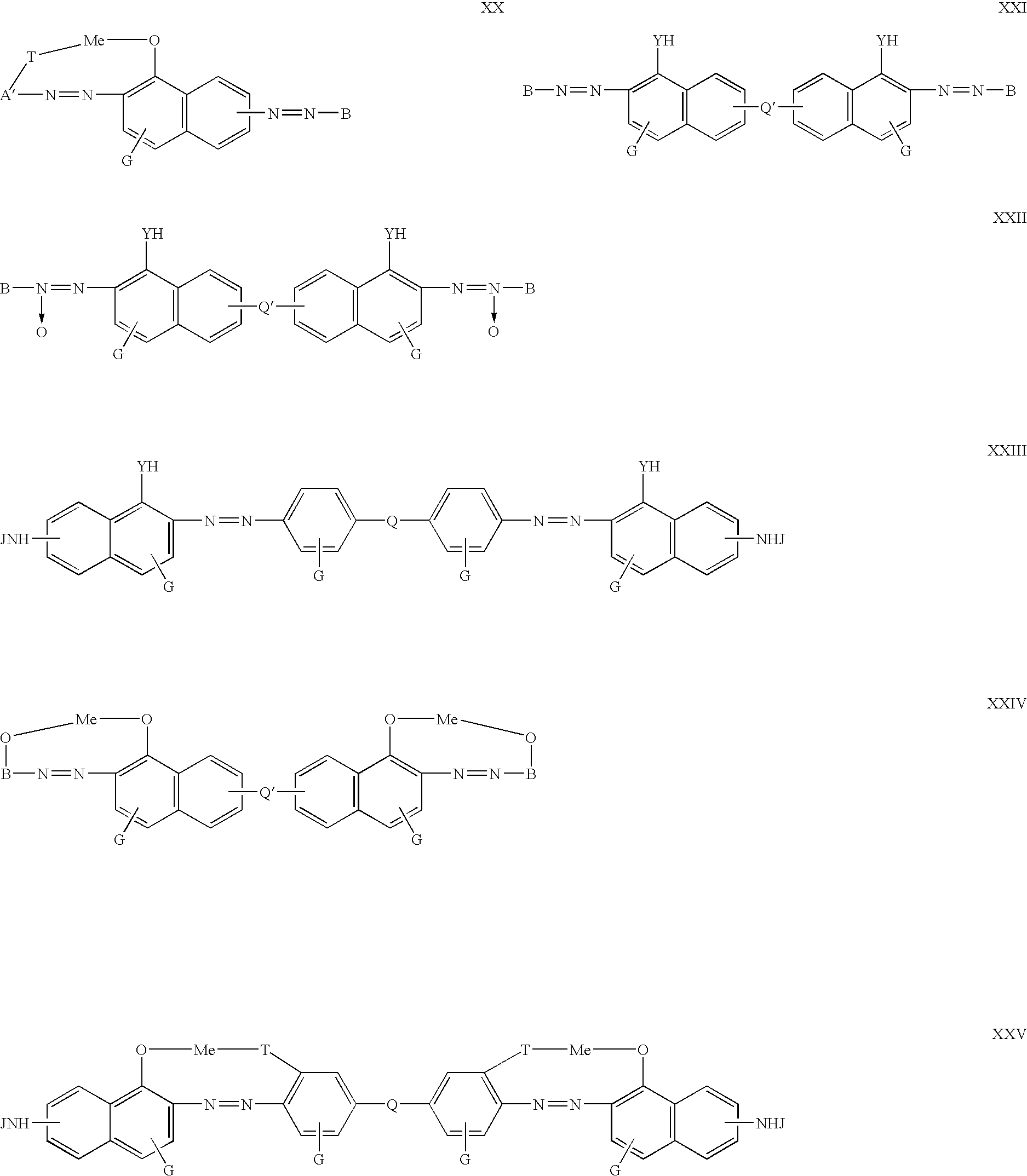

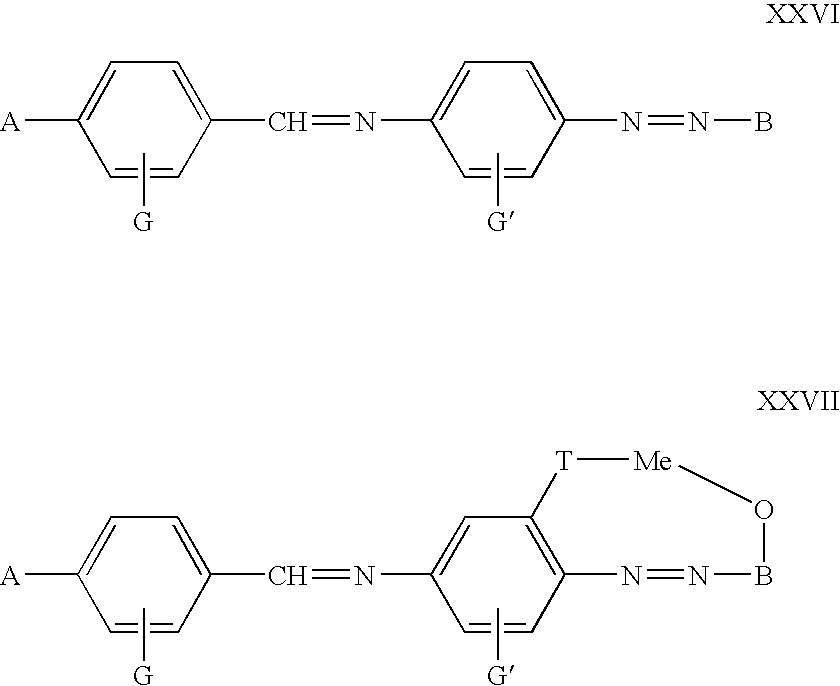

InactiveUS20040232394A1Liquid crystal compositionsMethine/polymethine dyesPolarizerElectromagnetic radiation

The invention relates to optical devices for producing and / or transforming polarised electromagnetic emission by means of anisotropic absorption and / or optical rotation effects and / or birefringence and can be used as different polarizers (dichroic, reflecting), lagging layers (retarders), liquid-crystal displays and indicators and also for producing polarising glass for building construction and for sun and antiglare glasses, masks, aprons and faceplates. The inventive optical device is based on at least one molecularly oriented layer of a low-molecular or oligomeric dichroic material which can form a stable lyotropic liquid crystal structure. The projection of at least one anisotropically absorbing fragment of a molecule of the dichroic material on the surface of the molecularly oriented layer of a dipole moment of optical transition is disposed in a parallel position to the optical axis of the molecularly oriented layer at least within several ranges of wavelength of the electromagnetic emission.

Owner:IR GVON KHAN

Full-automatic ornament grinding and polishing machine

ActiveCN102152190AReduce volumeSimple structureEdge grinding machinesMetal working apparatusEngineeringManipulator

The invention relates to a grinding and polishing machine for processing ornamental artificial gems, crystals or glass beads, in particular to a full-automatic ornament grinding and polishing machine. The invention discloses the full-automatic ornament grinding and polishing machine with the characteristics of one-step product forming, integration of all working procedures, high production efficiency and simple structure. The invention realizes the full-automatic processing of crystal diamonds and other ornaments by using one machine. In a main scheme provided by the invention, a spindle assembly is arranged in the middle of a rack, the upper end of the spindle assembly is provided with a turntable, the turntable is provided with a plurality of cantilevers which are uniformly distributed by taking a center axis position of the spindle assembly as a center, and the tail end of each cantilever is provided with a mechanical arm; a feeding and discharging integrated assembly, at least onefront grinding integrated assembly, at least one front polishing integrated assembly, a through-connection integrated assembly, at least one rear grinding integrated assembly and at least one rear polishing integrated assembly are respectively distributed on the rack in a working sequence; and all the assemblies are connected end to end.

Owner:ZHEJIANG JINJIU MACHINERY

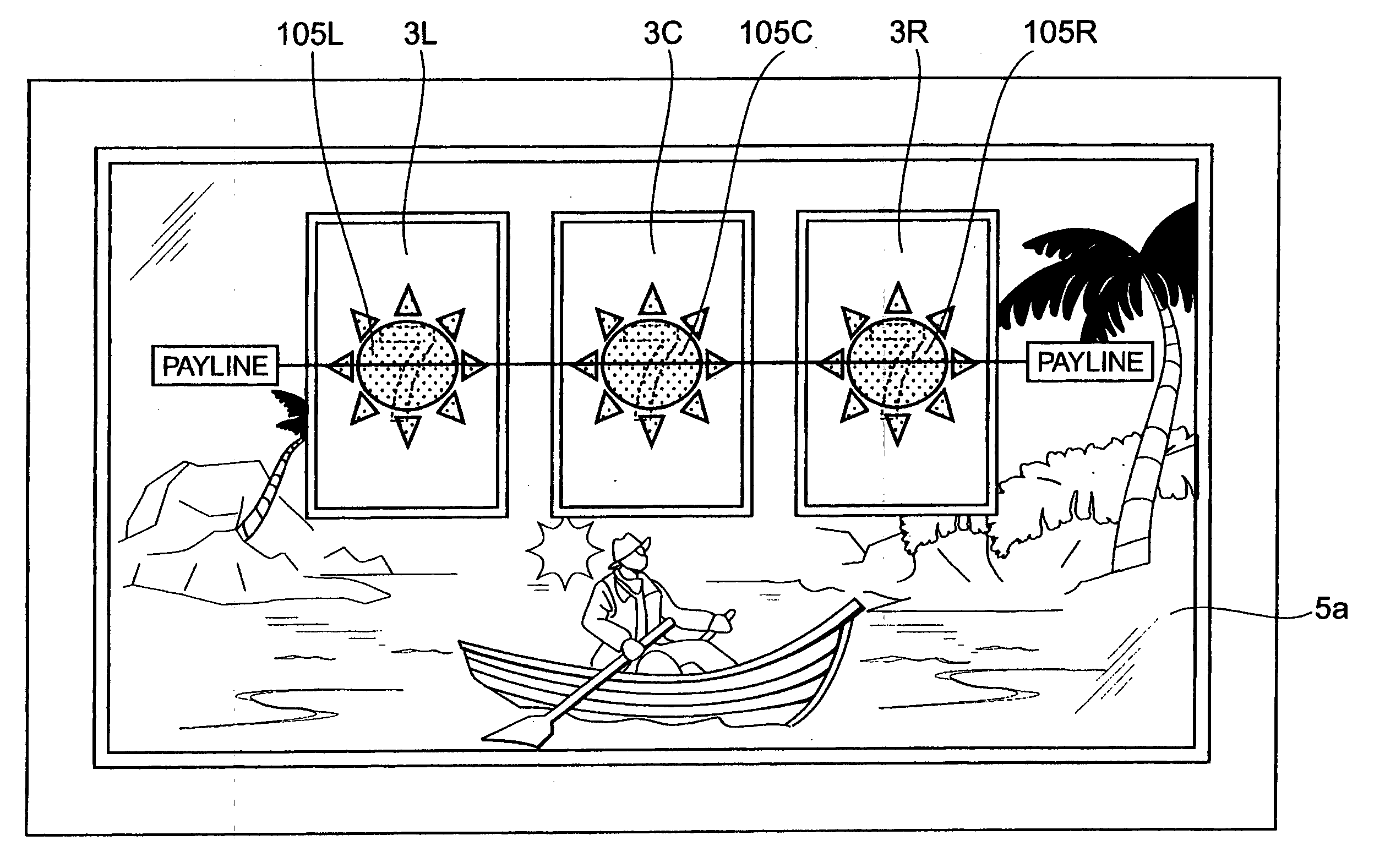

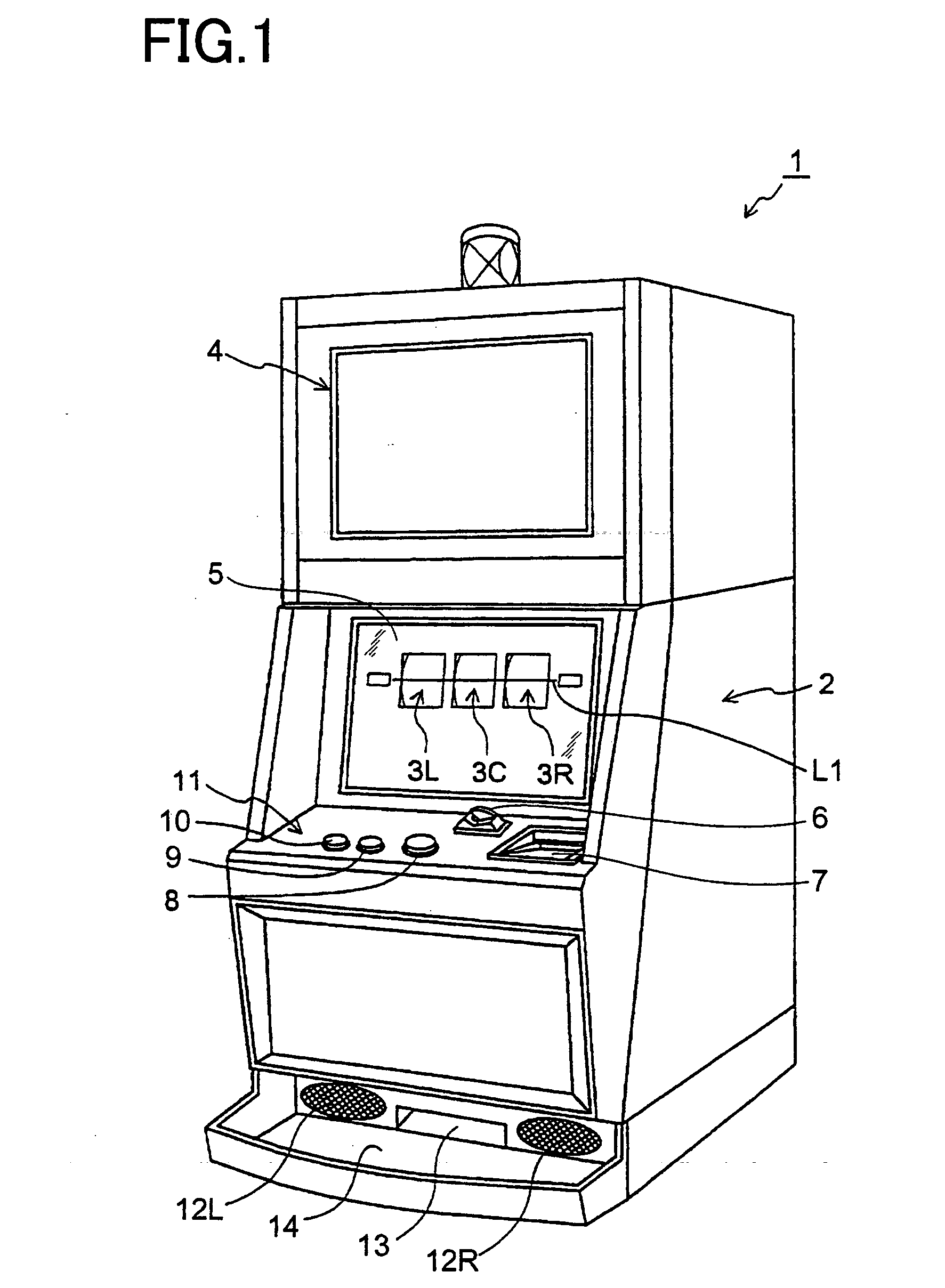

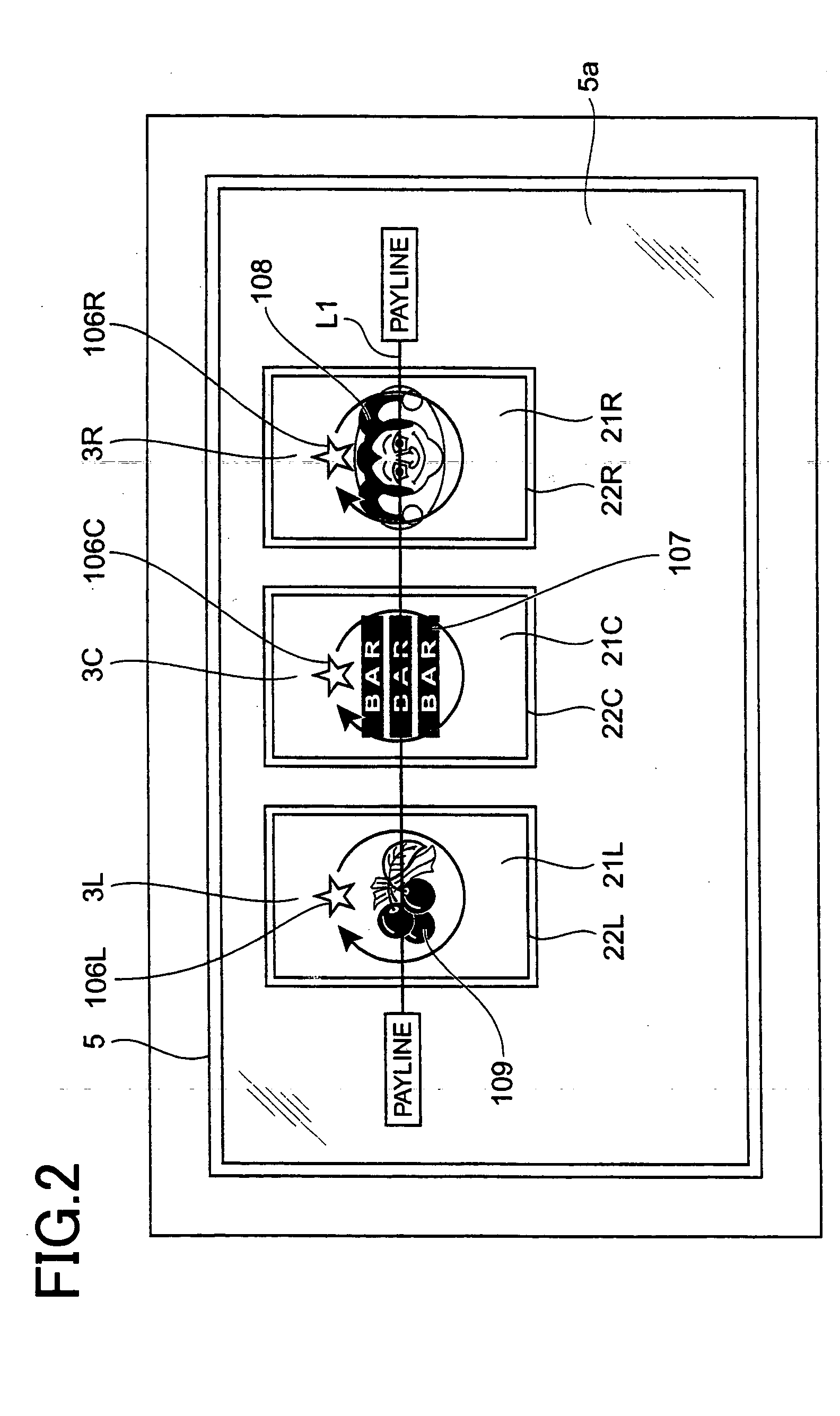

Gaming machine

InactiveUS20050282616A1Easy to seeRoulette gamesApparatus for meter-controlled dispensingLiquid-crystal displaySuperimposition

In the slot machine 1, there are provided a variable display device having a rotation member on an outer periphery of which a plurality of symbols are formed and the LED lamps arranged within the rotation member, a liquid crystal display device arranged in front of the variable display device, the liquid crystal display device having a light transmittable area through which light passes from a rear side thereof, wherein illumination control of the LED lamps is conducted so as to turn on the LED lamps when the display image on the light transmittable area is able to be displayed without superimposition with the display symbol and so as not to turn on the LED lamps when the display image on the light transmittable area is not able to be displayed without superimposition with the display symbol.

Owner:UNIVERSAL ENTERTAINMENT CORP

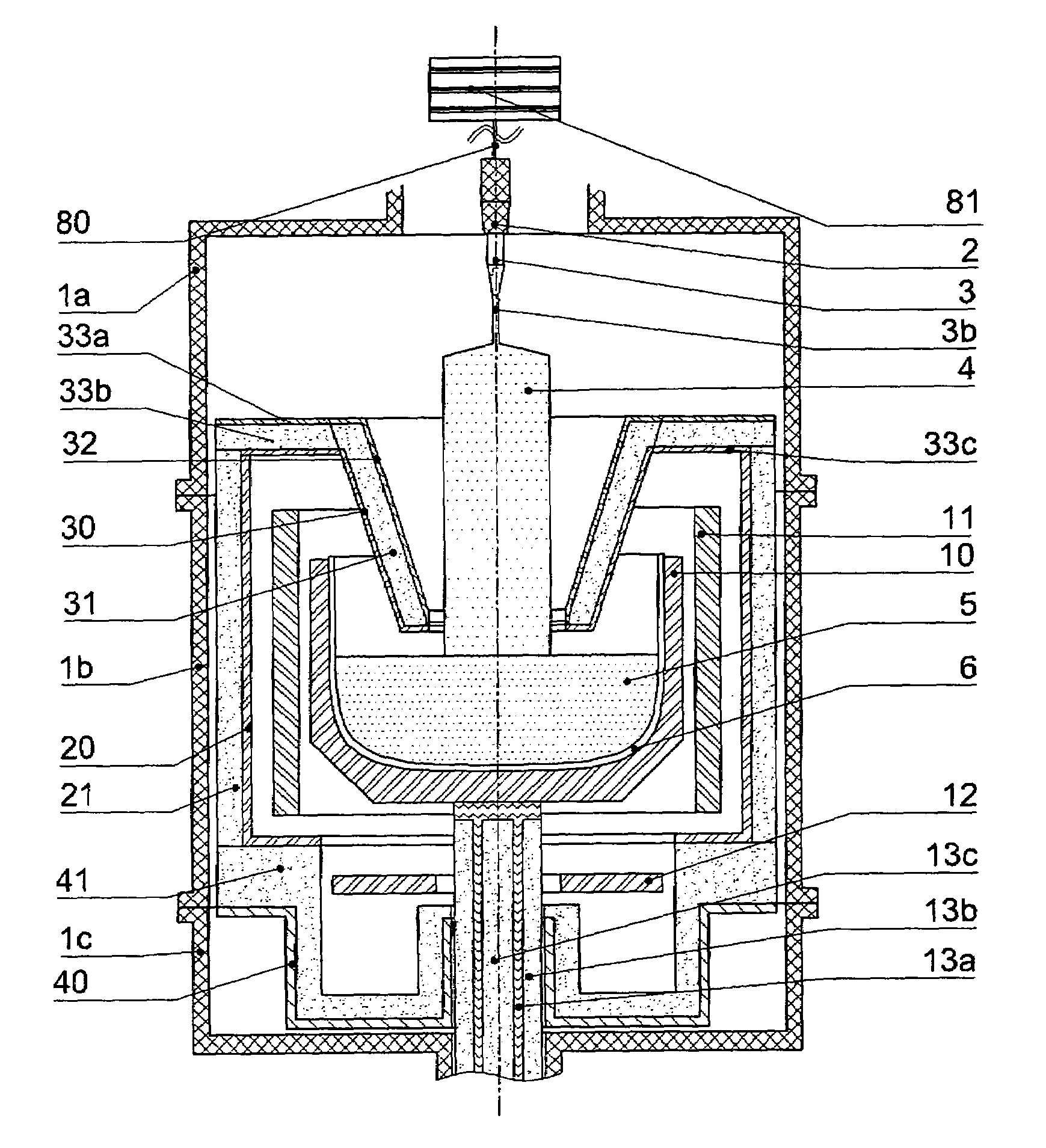

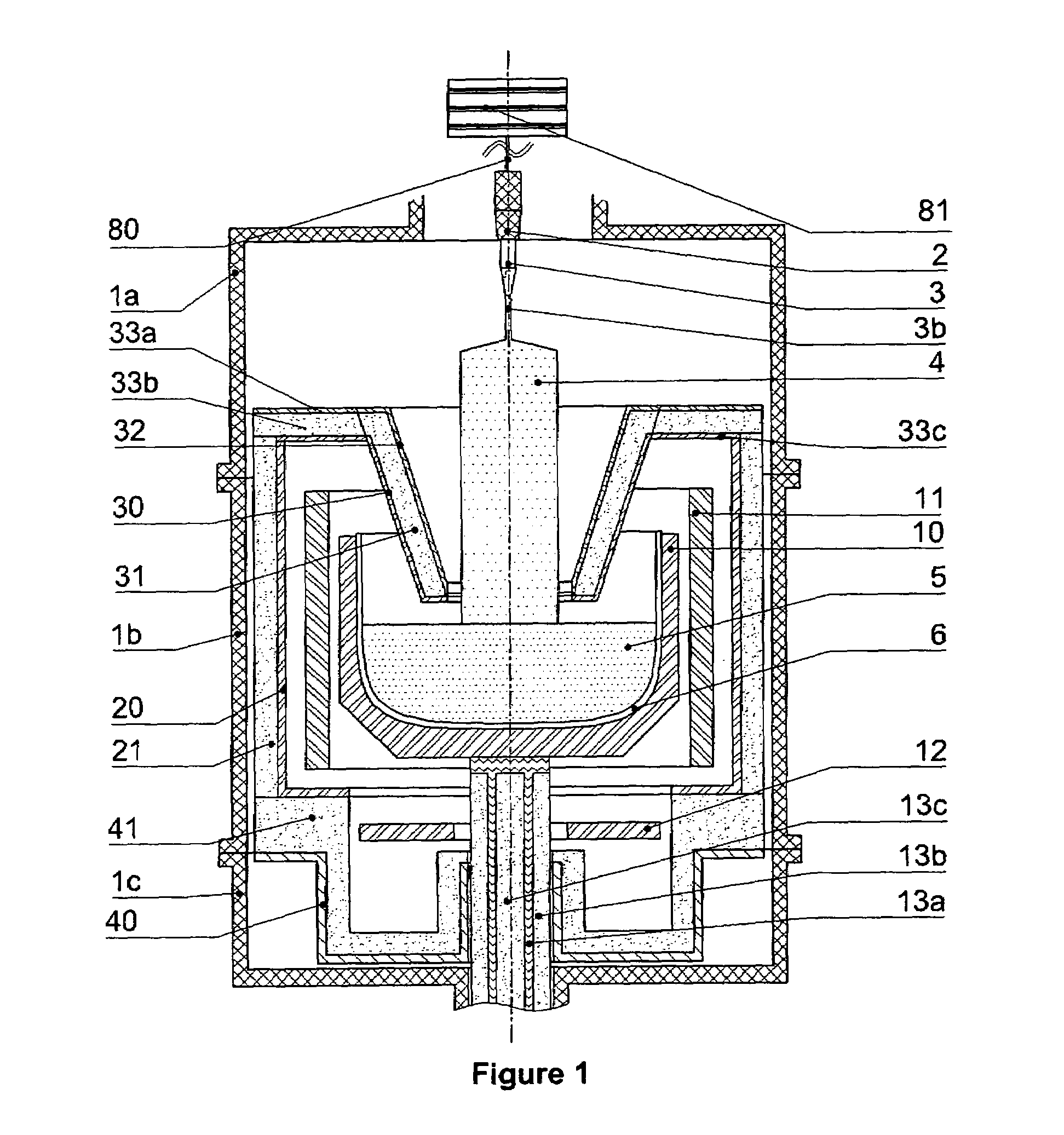

Crystal manufacturing

ActiveUS20080053372A1Low production costImprove productivityAfter-treatment apparatusPolycrystalline material growthHot zoneProduction rate

An implementation of a Czochralski-type crystal growth has been shown and embodied. More particularly, a furnace with suitable insulation and flow arrangement is shown to improve the cost-efficiency of production of crystals. That is achieved by the shown new hot-zone structure, gas flows and the growth process which can decrease the power consumption, increase the lifetime of hot-zone parts and improve the productivity, e.g., by giving means for opening the hot-zone and easily adapting the hot-zone to a new crystal diameter.

Owner:OKMETIC OY

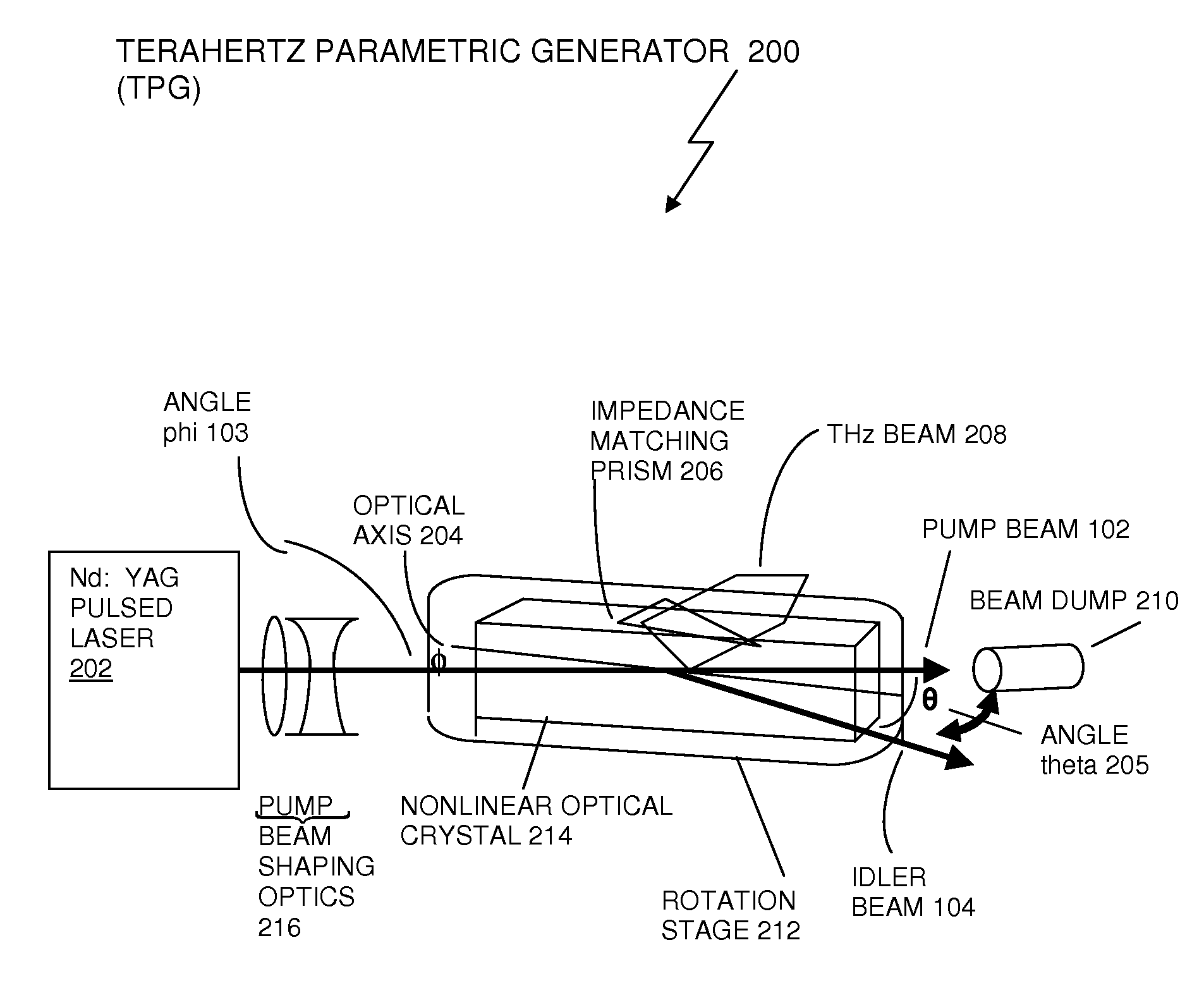

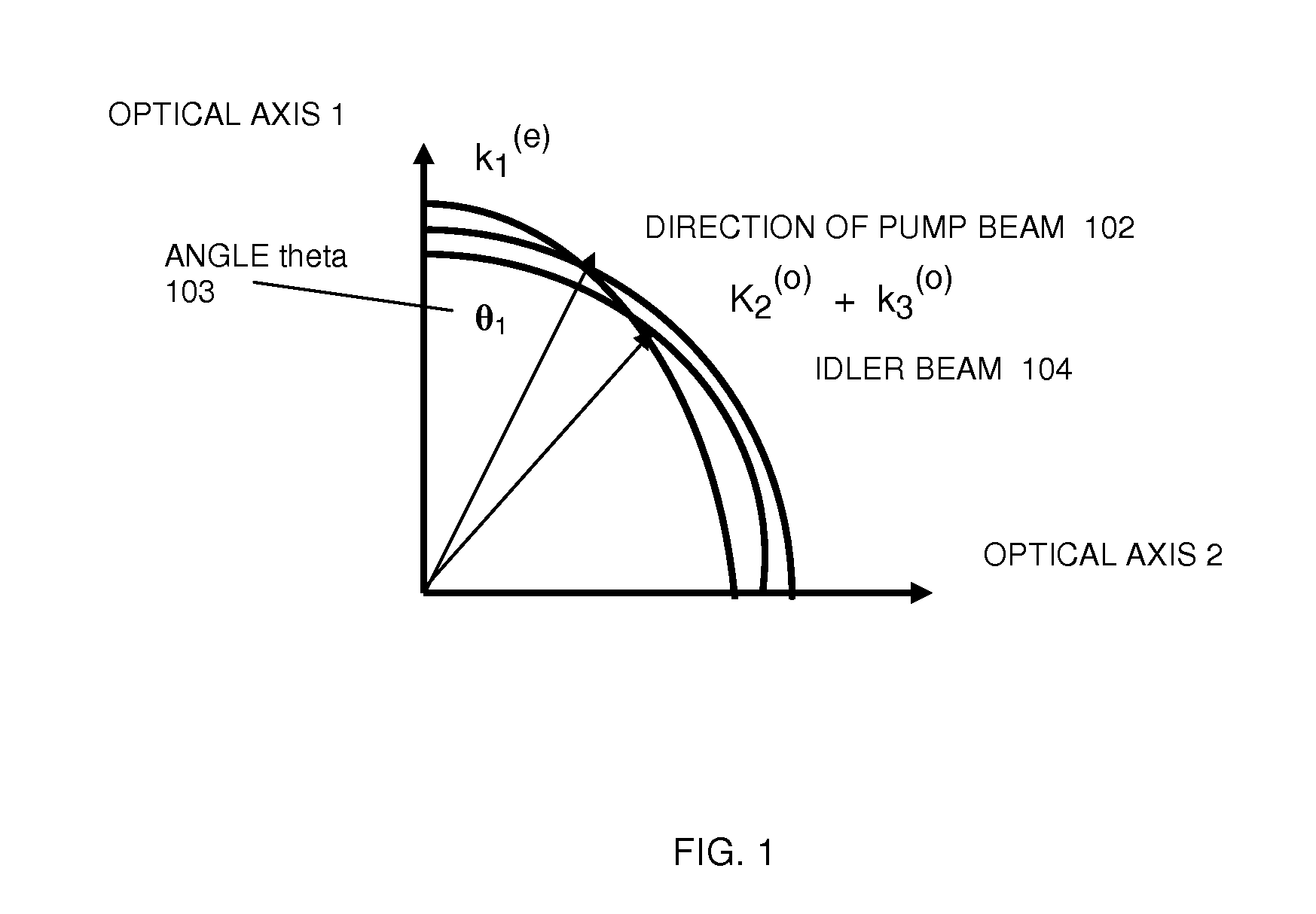

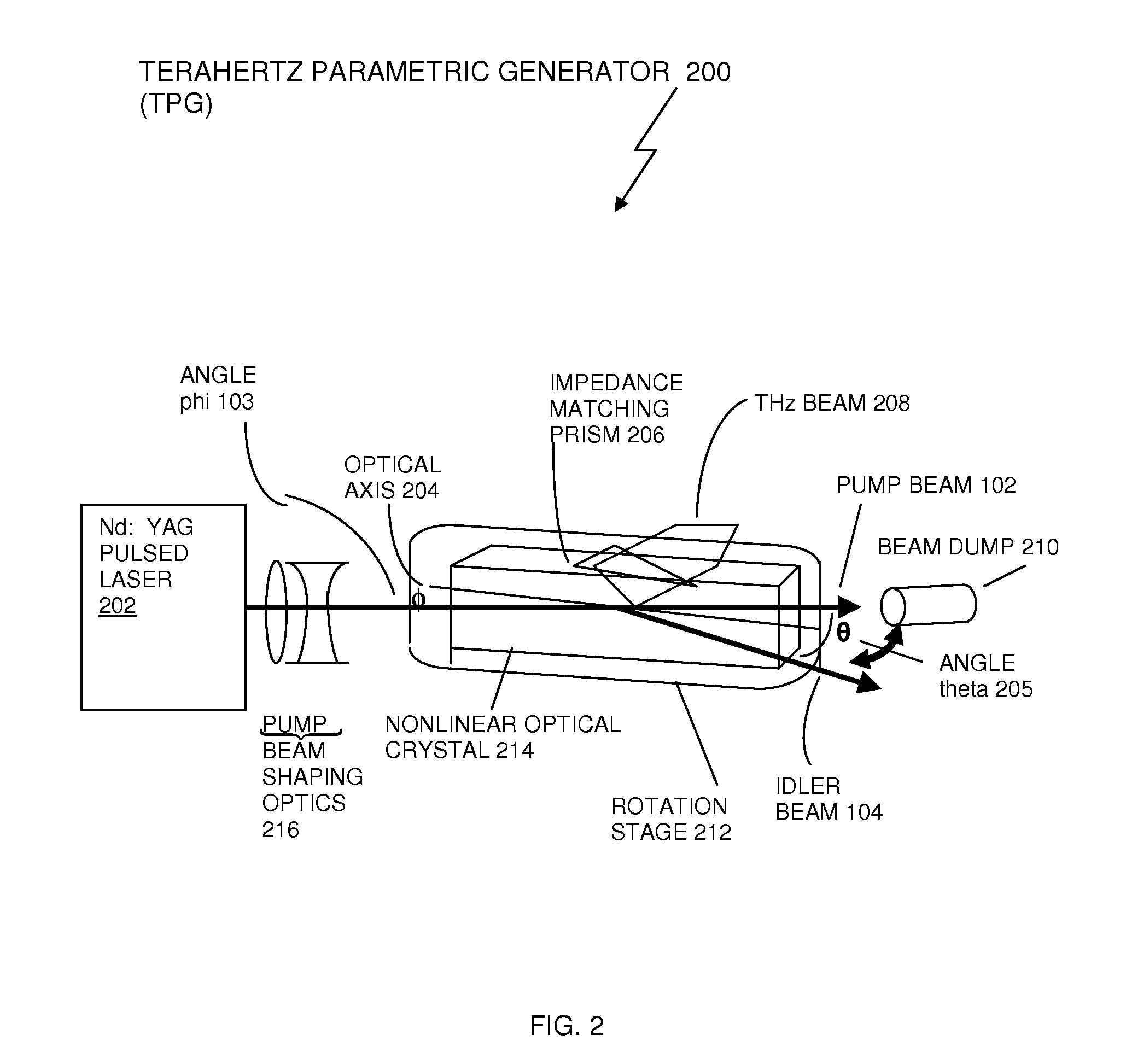

Recycling pump-beam method and system for a high-power terahertz parametric source

InactiveUS20100290487A1Increase output powerHigh repetition rateLaser detailsSolid masersNonlinear optical crystalBeam source

A method and a system are implemented in the fabrication of a portable high power terahertz beam source that can produce a tunable, high power terahertz beam over the frequency from 0.1 THz to 2.5 THz. The terahertz source employs a recycling pump beam method and a beam quality control device. The beam quality control device may or may not be required for a high power terahertz beam generation. In exemplary embodiments, a lithium niobate (LiNbO3) crystal or a lithium niobate crystal doped with 5% magnesium oxide (LiNbO3:MgO) can be used. Other nonlinear optical crystals, including GaSe can be used in place of the LiNbO3 crystal. Through proper alignment of a pump beam, along with recycling a pump beam, high conversion efficiency is achieved, and a high output power beam is produced at terahertz frequencies.

Owner:US GOVT AS REPRESENTED BY THE SEC OF THE NAVY CHIEF OF NAVAL OPERATIONS OFFICE OF COUNSEL ONR NRL CODE OOCCIP

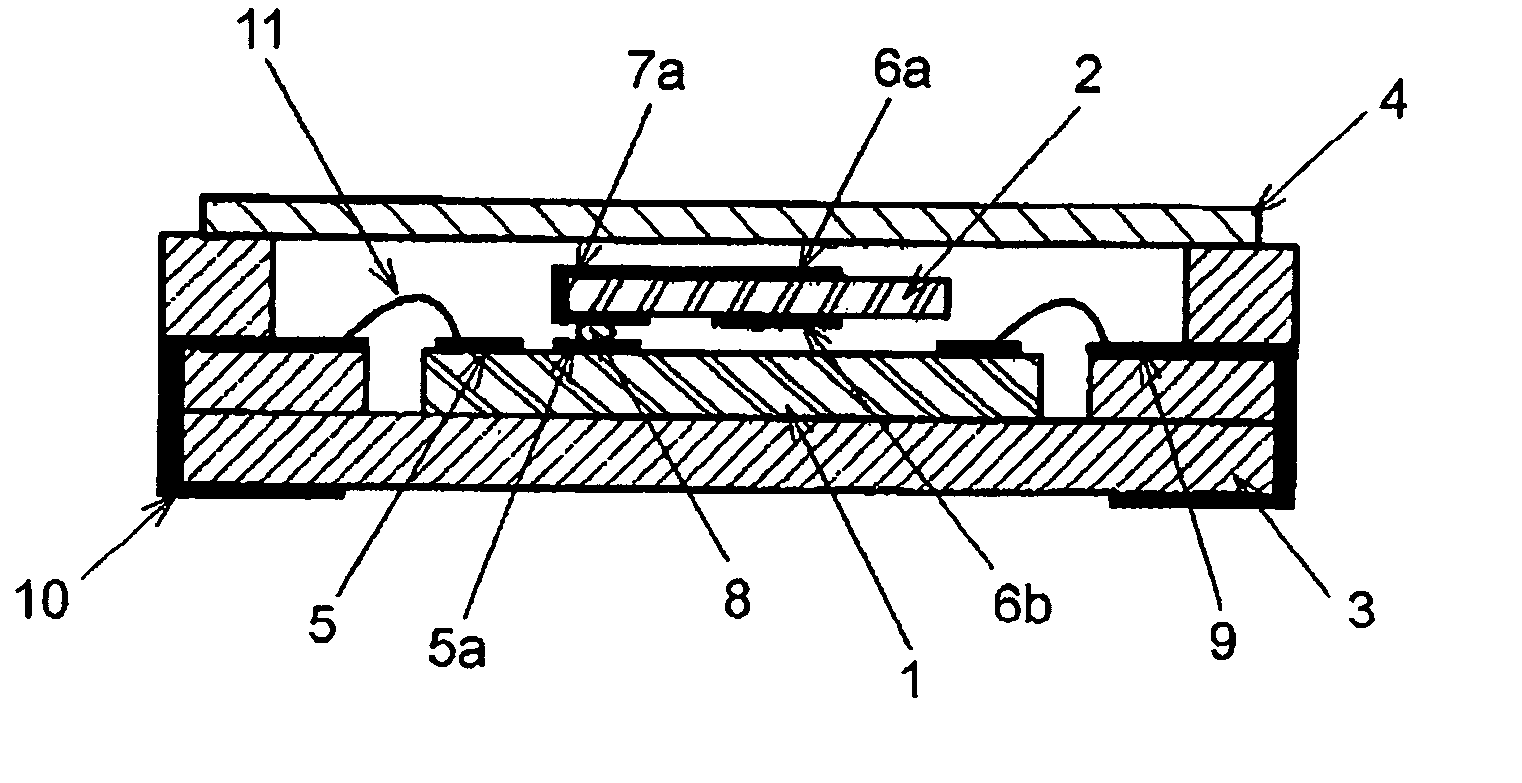

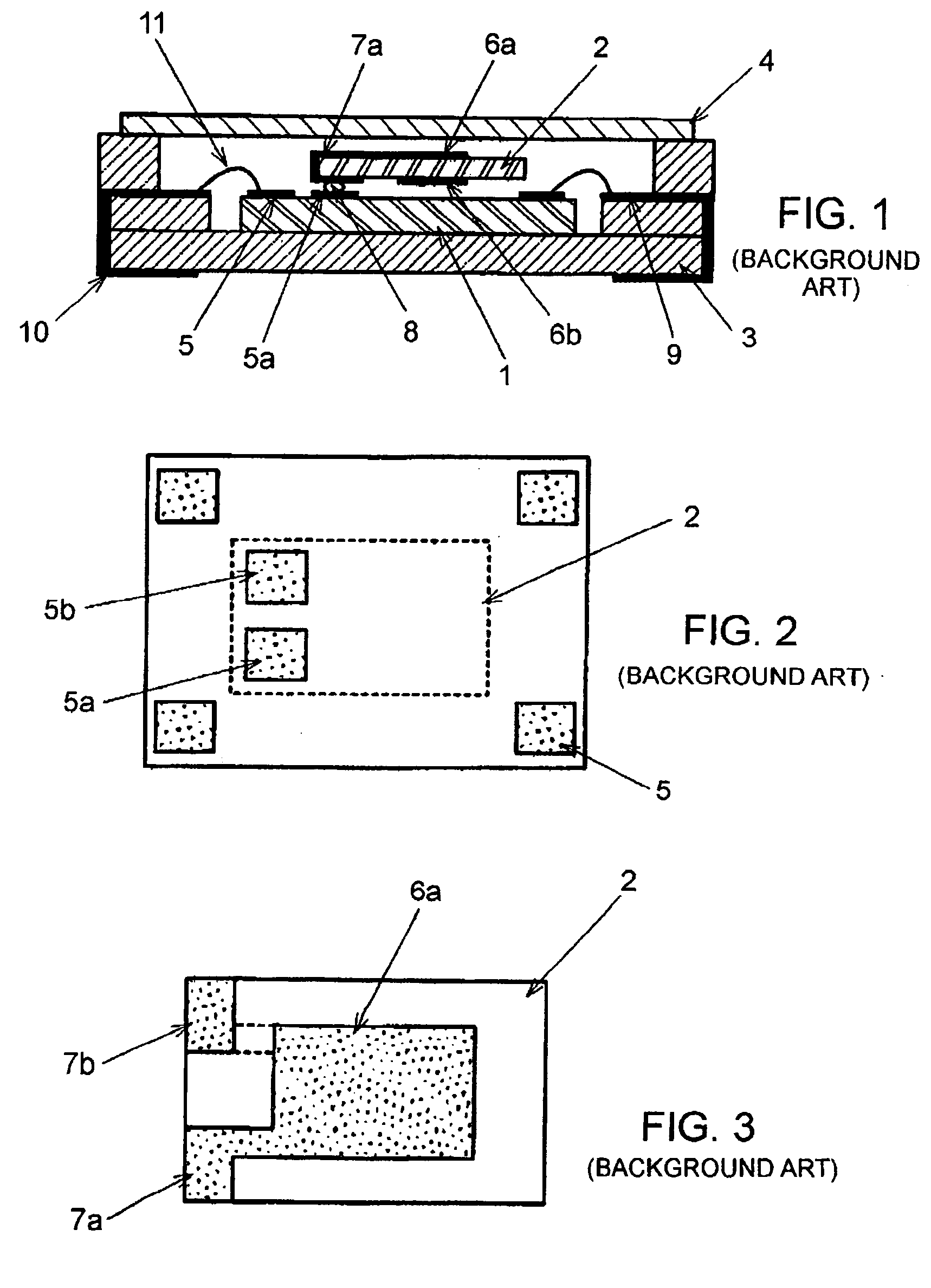

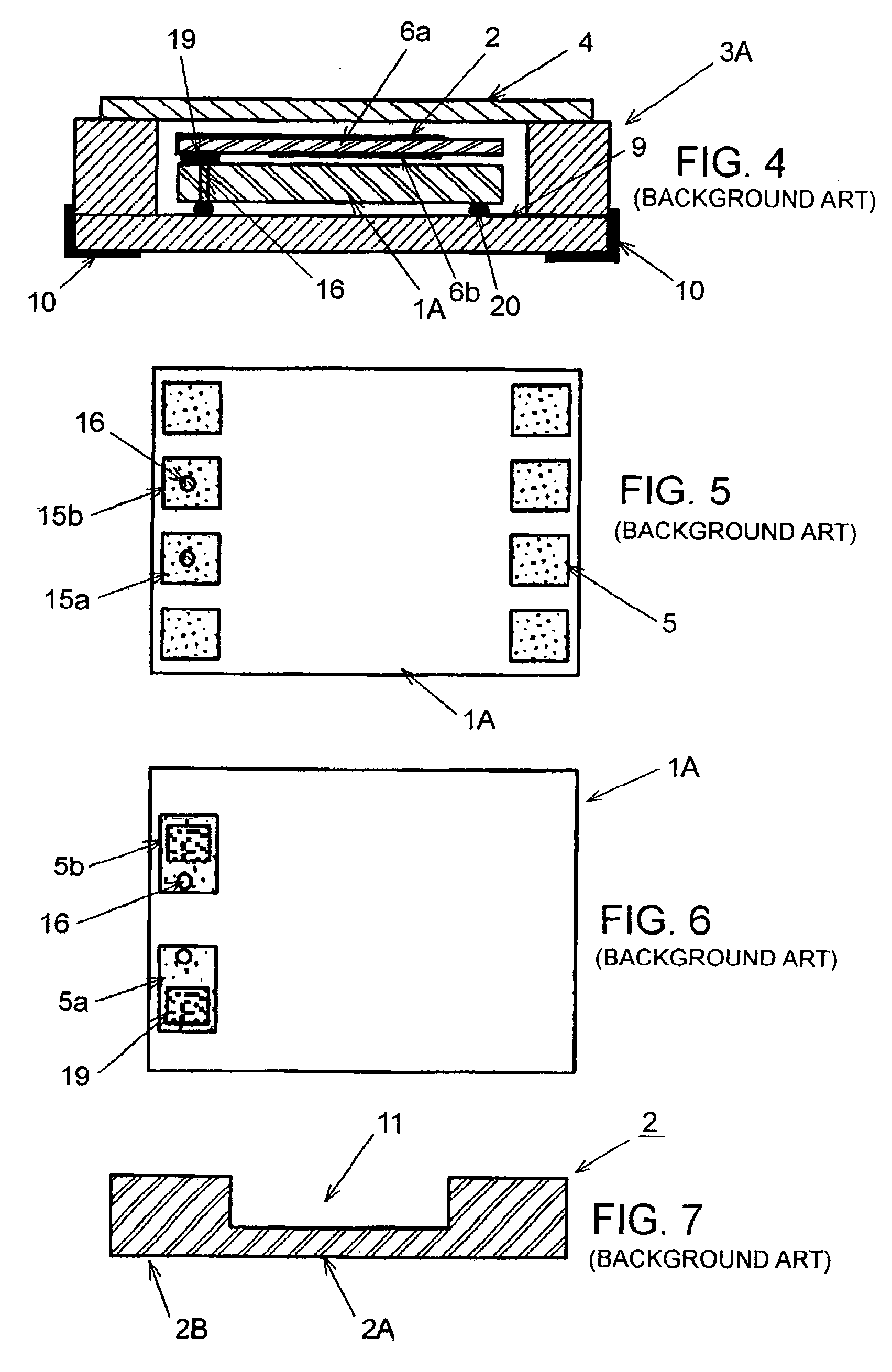

Surface mount crystal oscillator

InactiveUS20060055479A1InhibitionGood oscillation characteristicPiezoelectric/electrostriction/magnetostriction machinesOscillations generatorsSurface mountingEngineering

Owner:NIHON DEMPA KOGYO CO LTD

Liquid crystal display device

InactiveUS20070019120A1Increase brightnessImprove display qualityNon-linear opticsCapacitanceLiquid-crystal display

A liquid crystal display device includes a pair of substrates; a liquid crystal sealed between the substrates; plural pixel regions each having a first pixel electrode formed on one of the pair of substrates and a second pixel electrode separated from the first pixel electrode; a TFT having a source electrode which is electrically connected to the first pixel electrode; a control capacitance portion which has a control capacitance electrode electrically connected to the source electrode and opposed to at least part of the second pixel electrode via an insulating film, and which thereby establishes capacitive coupling between the source electrode and the second pixel electrode; linear projections formed on the other substrate; and apertures formed in the first and second pixel electrodes so as to occupy parts of overlap regions of the linear projections and the first and second pixel electrodes as viewed perpendicularly to the substrate surfaces, for controlling the positions of singular points of alignment vectors of the liquid crystal.

Owner:SHARP KK

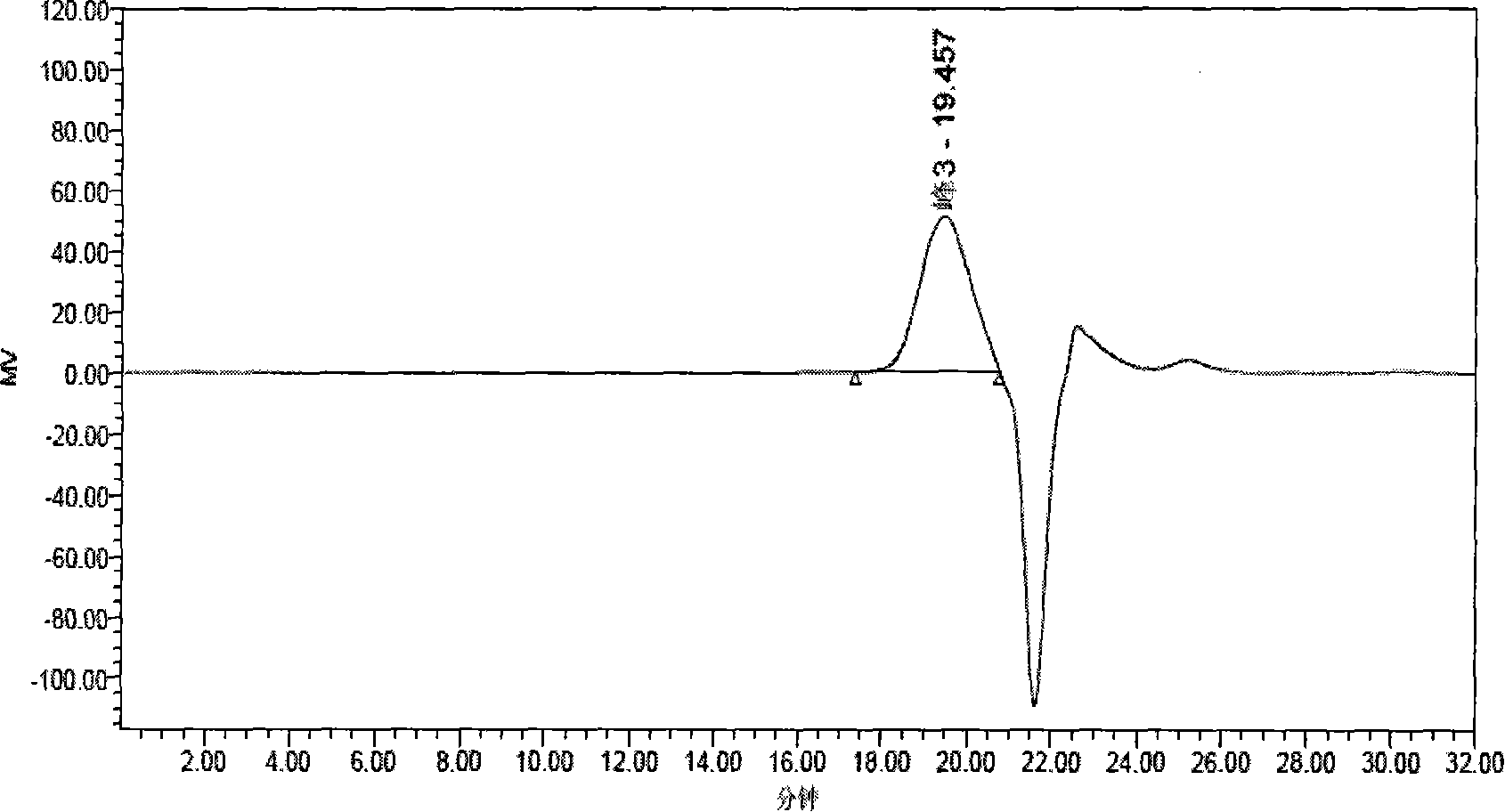

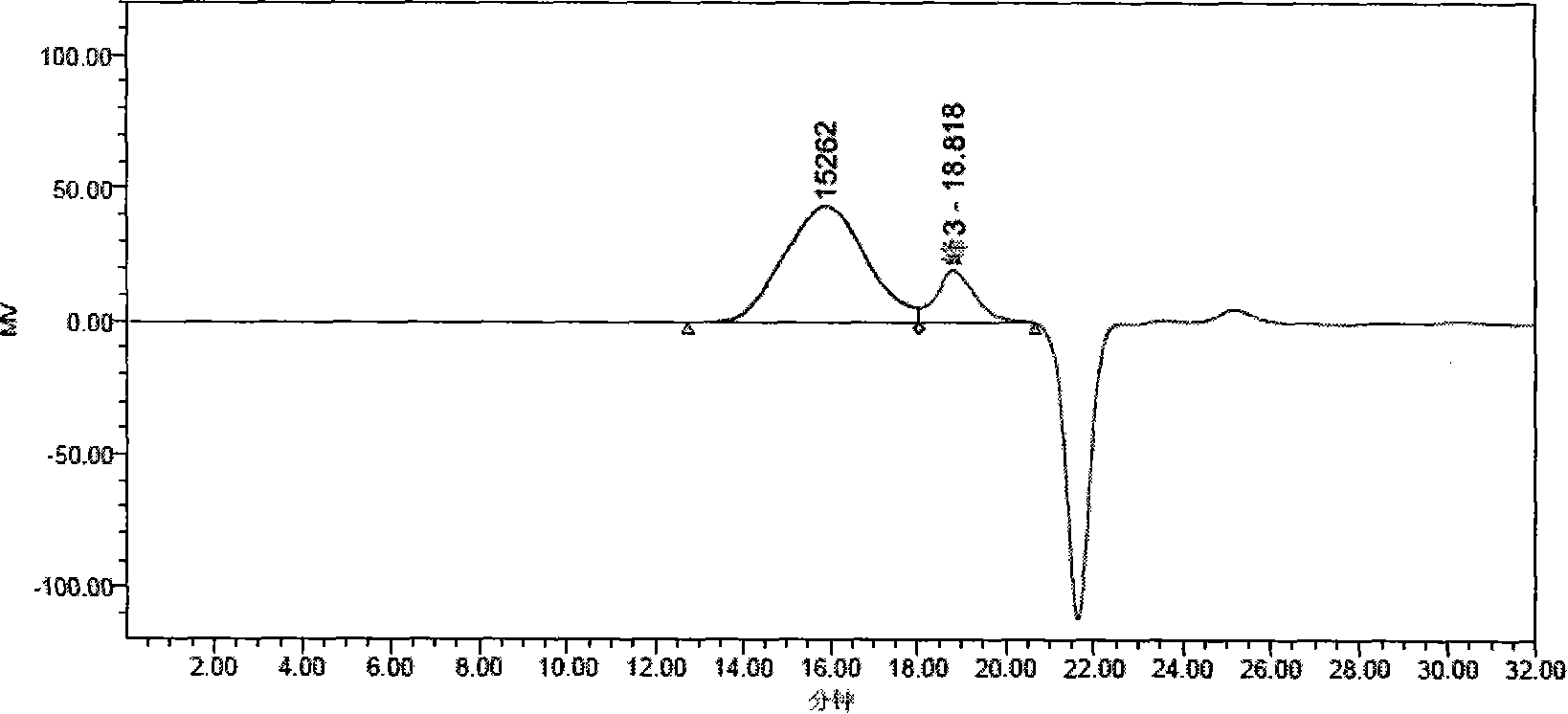

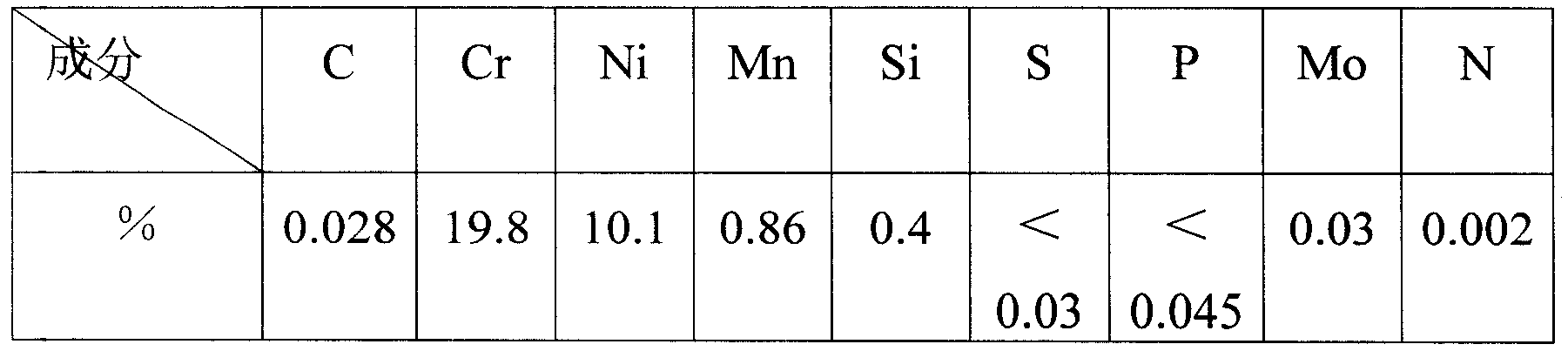

A flux-cored wire for soldering diphasic stainless steel

The invention relates to a flux-cored wire for welding duplex stainless steel, and the flux-cored wire is used in the welding field of the material processing technology. During the welding of the duplex stainless steel, joint pitting erosion and impact elasticity can not be met by utilizing austenite stainless steel welding material. The invention provides the flux-cored wire for welding the duplex stainless steel, 17 percent to 24 percent flux-cored powder is filled into stainless steel belt. The invention is characterized in that the mass percent of the components of the flux-cored is as follows: 35 percent to 40 percent of chromium powder, 11 percent to 15 percent of molybdenum powder, 2 percent to 4 percent of nickel powder, 3 percent to 5 percent of manganese powder, 1 percent to 5 percent of magnesia chrome, 1 percent to 3 percent of ferrosilicon, 4 percent to 9 percent of rock crystal, 2 percent to 6 percent of feldspar, 21 percent to 30 percent of rutile, 0.5 percent to 4 percent of Al2O3, 0 percent to 5 percent of zircon, 0.5 percent to 3 percent of Bi2O3, and 0.5 percent to 3 percent of manganese nitride. The invention leads the duplex stainless steel welding joint to have the anti good pitting erosion performance and the good impact elasticity.

Owner:CHANGZHOU XINDE WELDING MATERIAL TECH

Nano cerium oxide polishing liquid composition

The invention provides a cerium oxide polishing liquid suitable for polishing rock crystals, photomask quartz glass, semiconductor devices and glass-prepared hard disks and polishing low-dielectric-constant materials for interlayer insulating films of semiconductor devices of siloxane and the like. The polishing liquid contains surface modified nano cerium oxide, silicon dioxide, a dispersing agent, an oxidizing agent, an alkaline compound, an alcohol compound and water. Preferably, stearic acid treated nano cerium oxide is selected, the particle size is preferably 10-100 nm, and the mass content is 1-10%; preferably, the particle size of the colloidal silicon dioxide is 40-100 nm, and the mass content is 0.1-5%; preferably, the polishing liquid contains 0.01-5% of the high-molecular dispersing agent, 1-10% of the hydrogen peroxide oxidizing agent, and the balance an alcohol-water mixture, wherein the pH value of a slurry is 8-10. The nano cerium oxide polishing liquid selects the surface modified nano cerium oxide, has addition of a proper amount of the silicon dioxide, thereby reducing the grinding trigger time and improving the processing stability.

Owner:天津西美半导体材料有限公司

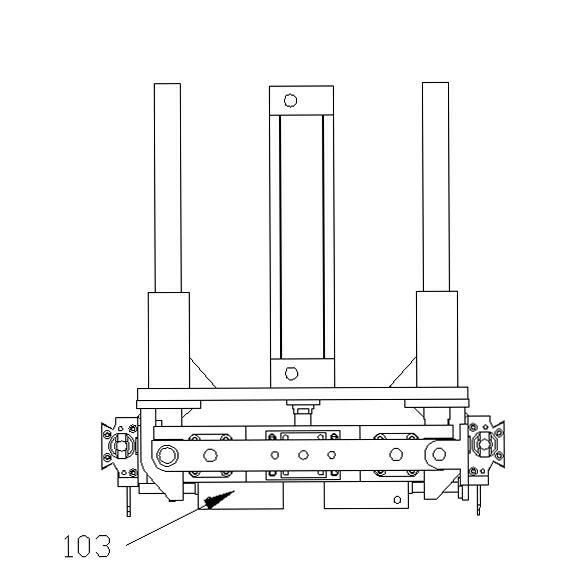

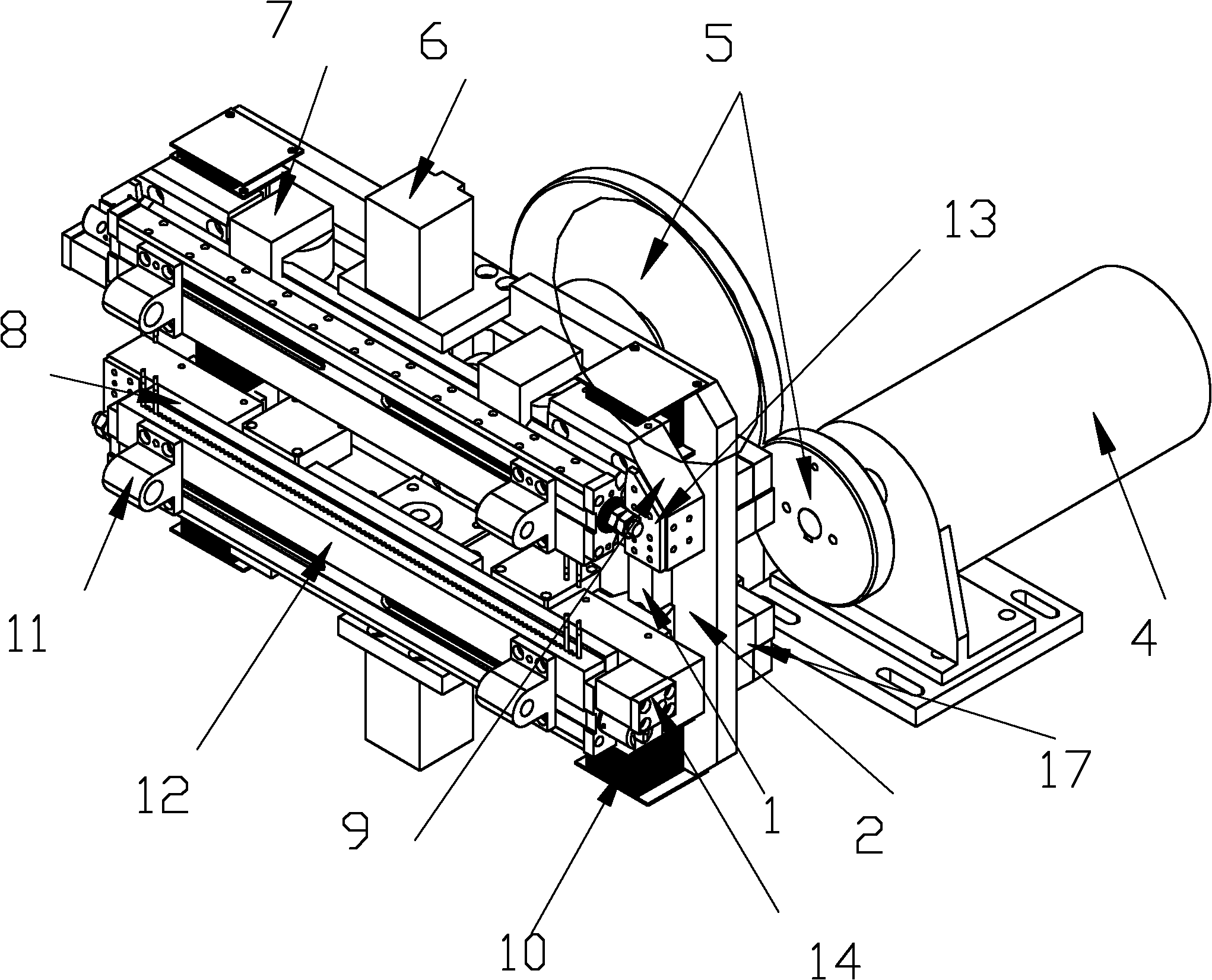

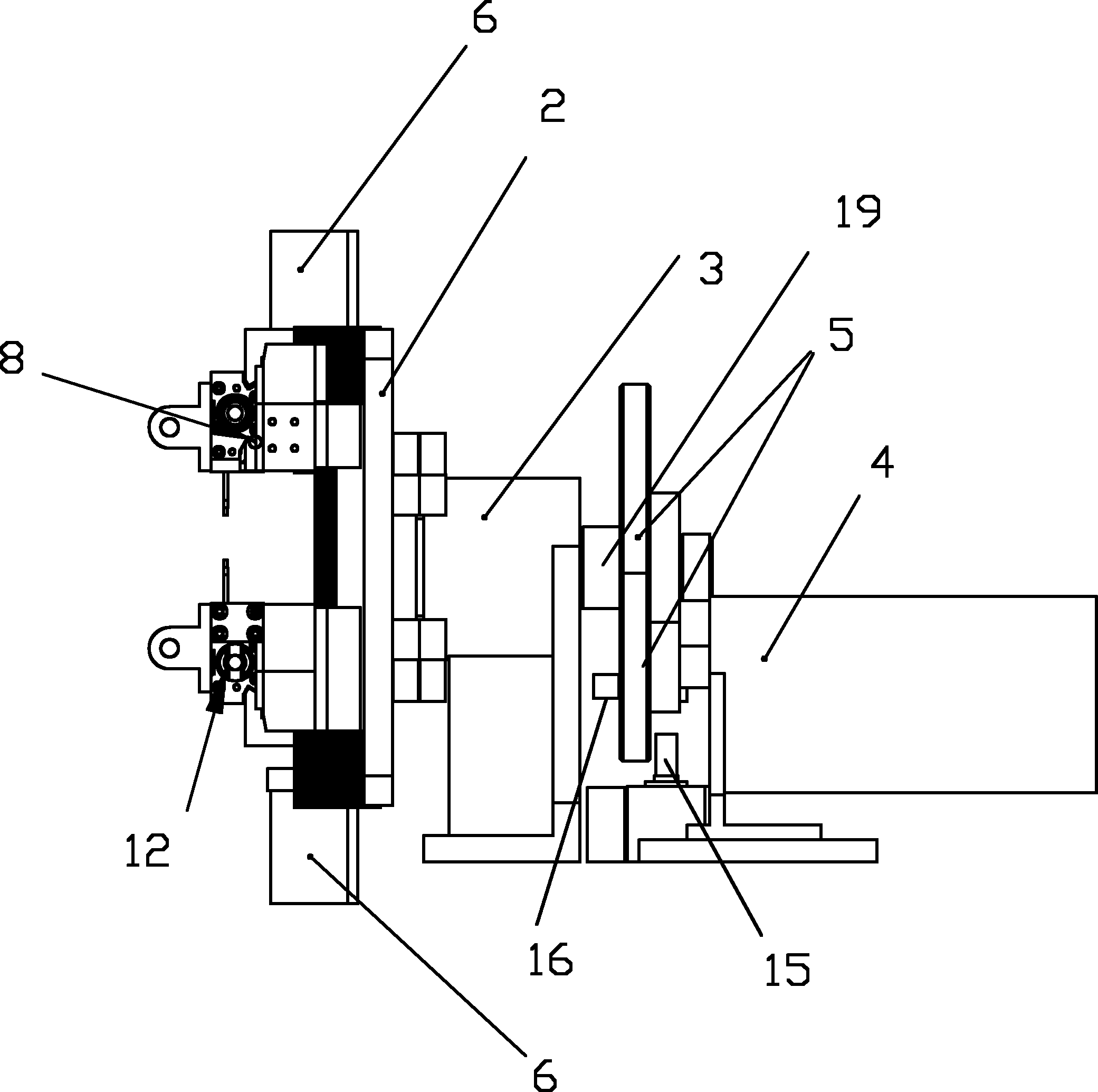

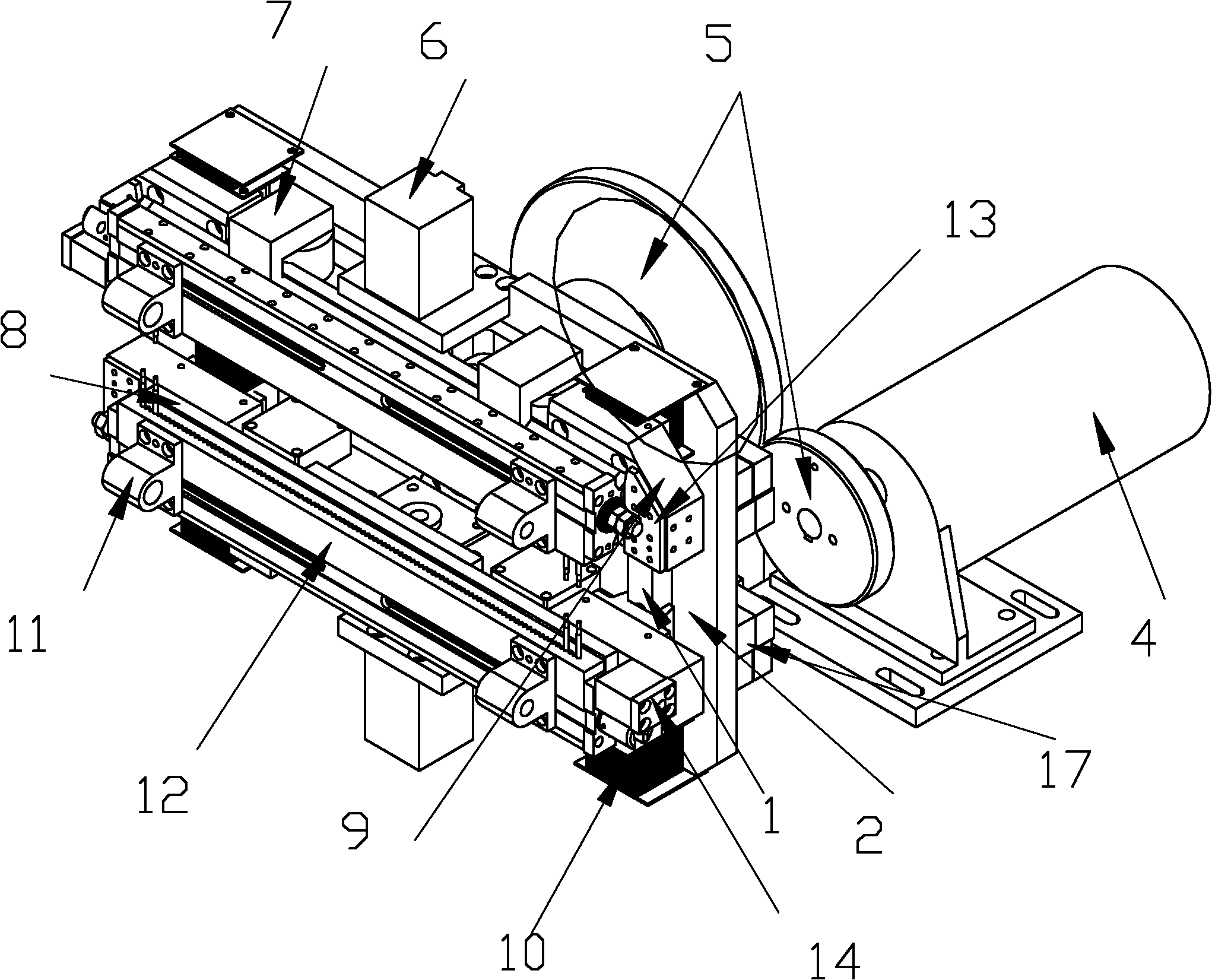

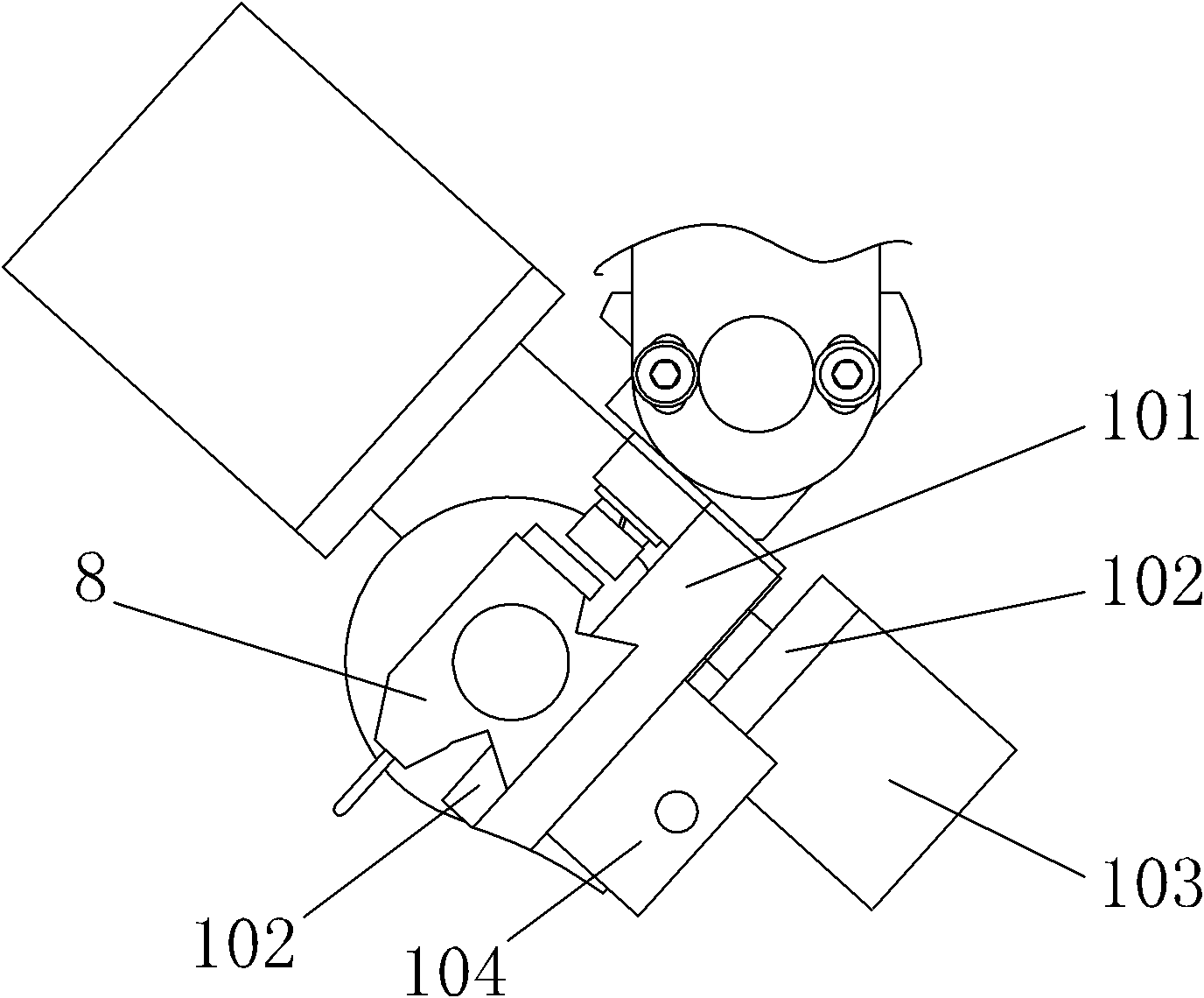

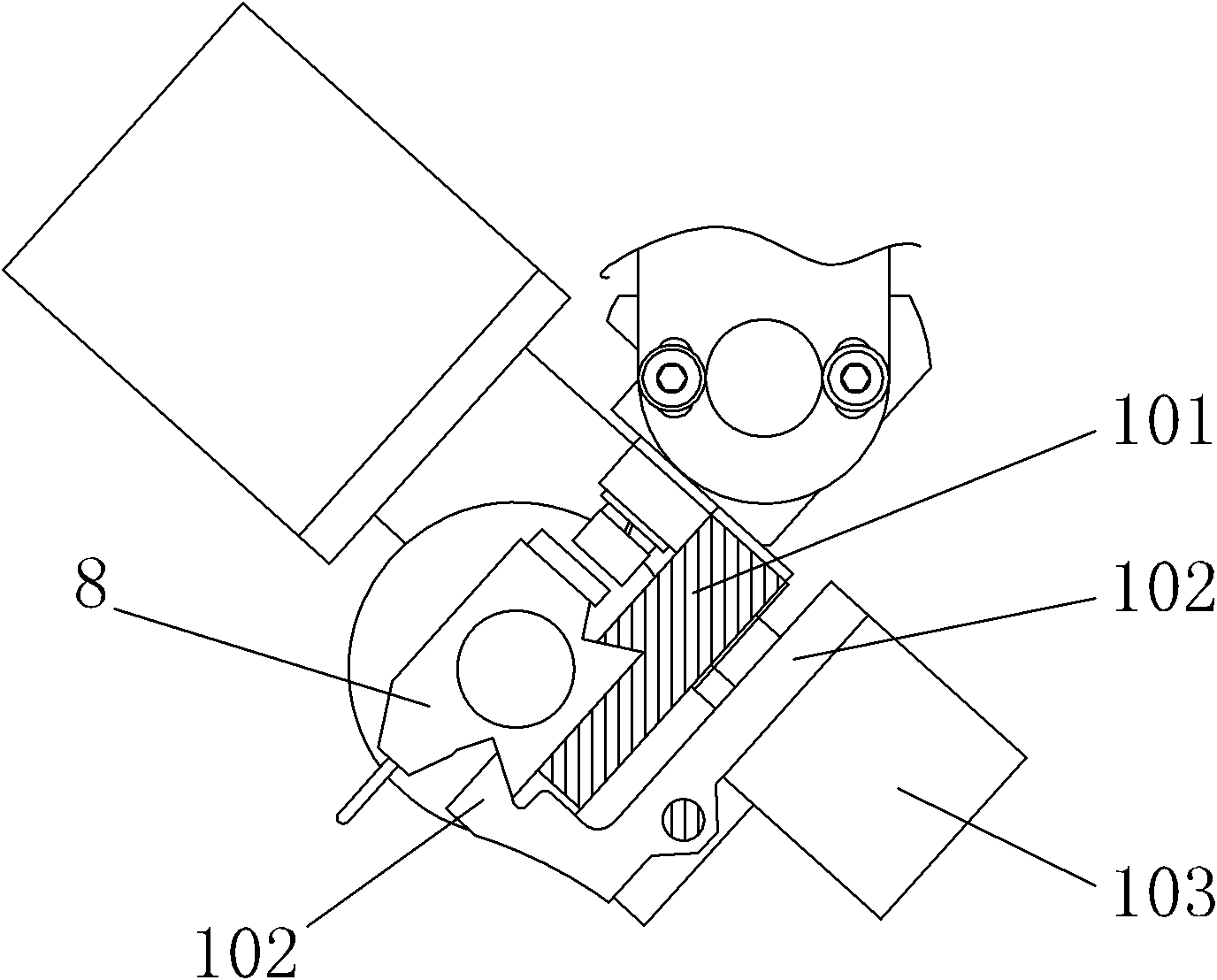

Adapter assembly of polishing and burnishing machine for decorations

ActiveCN102152188AReduce volumeRealize automatic position swapEdge grinding machinesMechanical engineeringRock crystal

The invention relates to an adapter assembly of a polishing and burnishing machine for processing decorations, artificial gems or crystals or glass beads, in particular to an adapter assembly of a polishing and burnishing machine for decorations. The invention provides an improvement on the adapter assembly in a full-automatic polishing and burnishing machine for decorations, mainly aiming at the defects of large labor strength, low production efficiency and complex machine structure and the like in the prior art; and the invention realizes the purposes of high production efficiency, low labor strength and simple structure. By use of the adapter assembly, the decorations can be full-automatically and continuously processed on one machine. The technical scheme of the invention is as follows: an adapter plate is installed at one side of an adaptor seat, the adaptor plate is connected with a reduction gear by a central shaft, the reduction gear is connected with a reduction motor, and a slide block guide rail is installed on the adaptor plate; an upper and a lower groups of elevating assemblies are installed on the adaptor plate, wherein each elevating assembly comprises a fixture positioning block which is movably connected to the slide block guide rail and capable of sliding along the slide block guide rail, and a fixture positioning block elevating cylinder which is installed adjacent to the end part of the adaptor plate and capable of driving the fixture positioning block to move on the slide block guide rail.

Owner:ZHEJIANG JINJIU MACHINERY

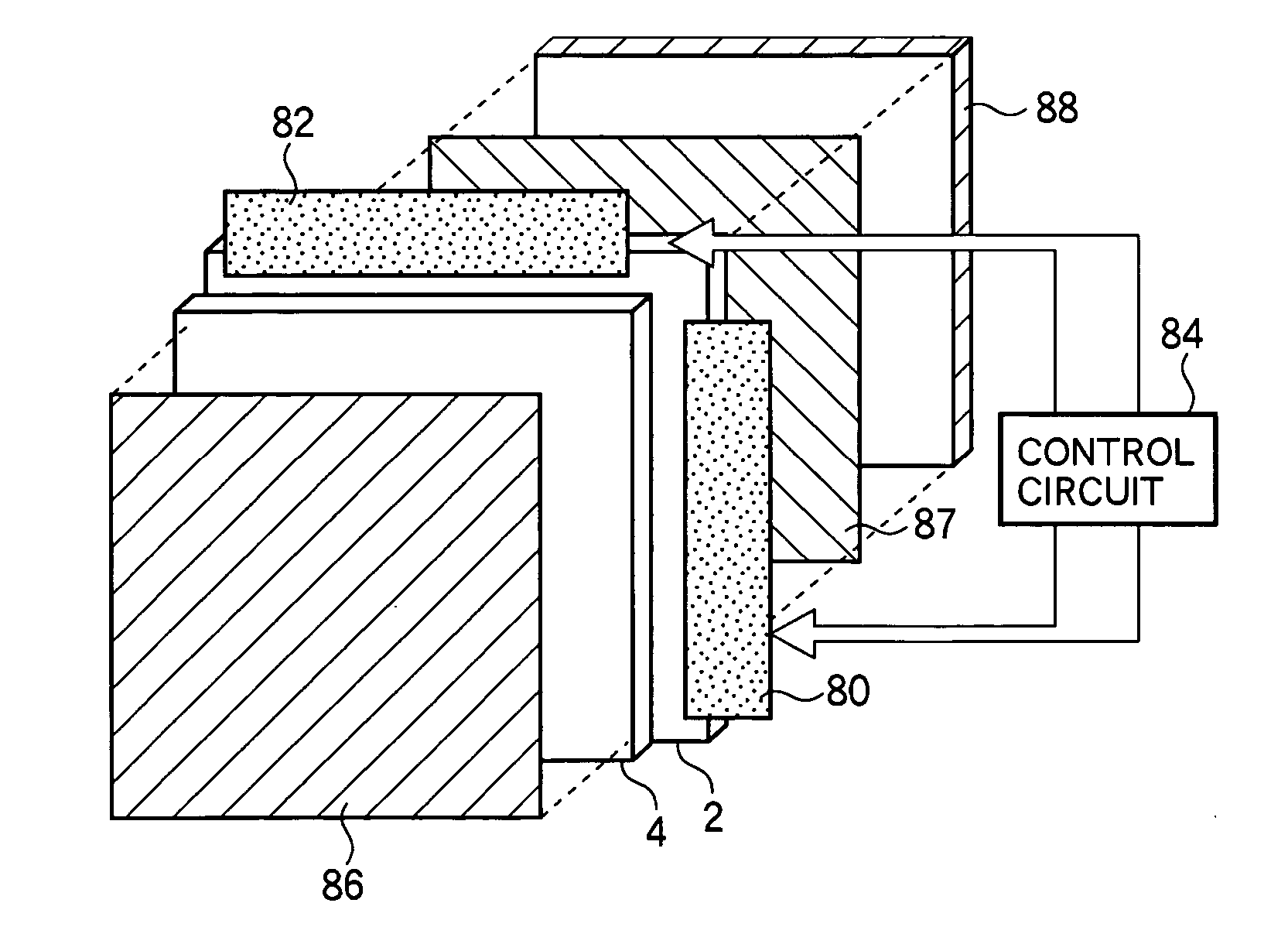

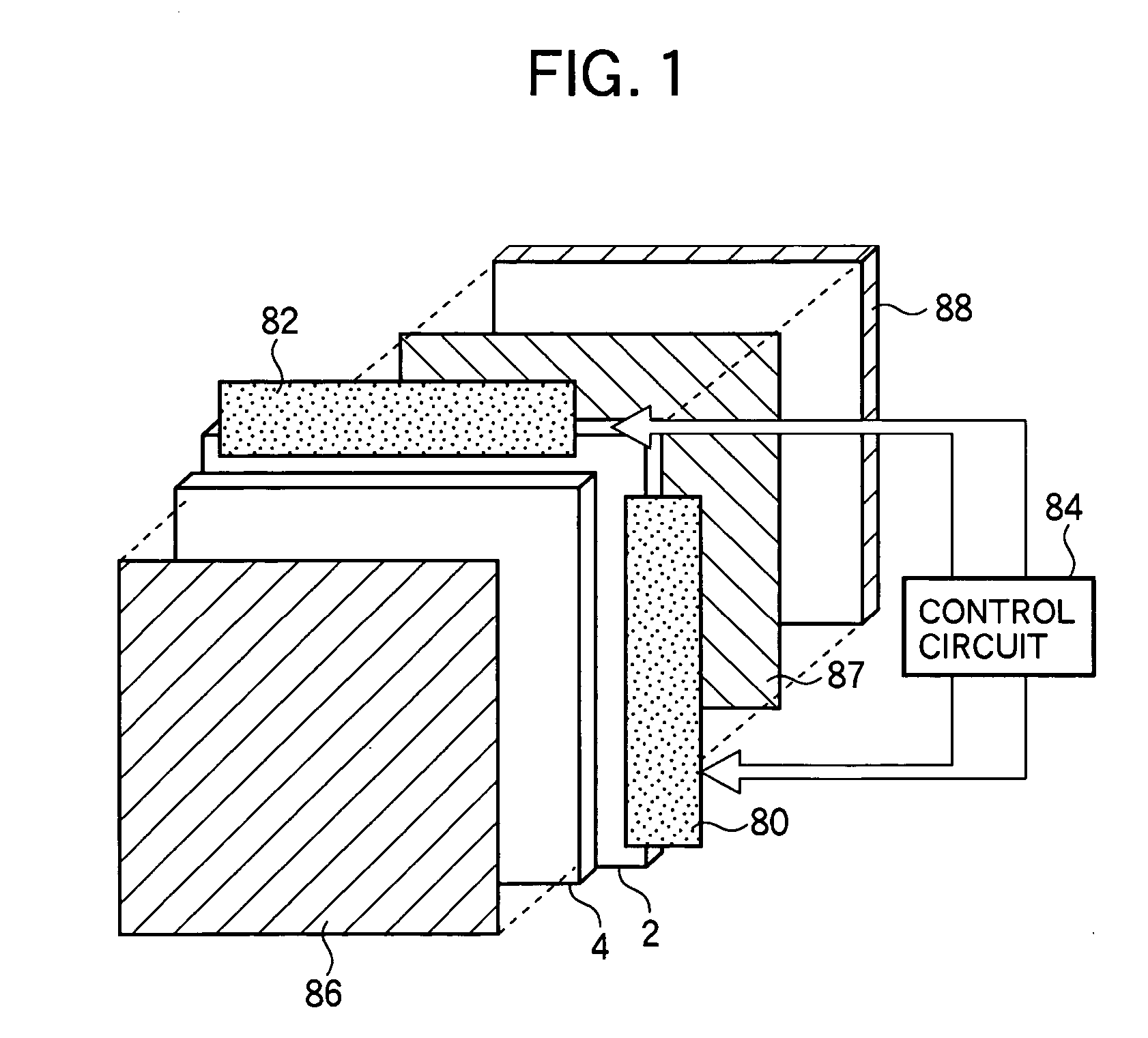

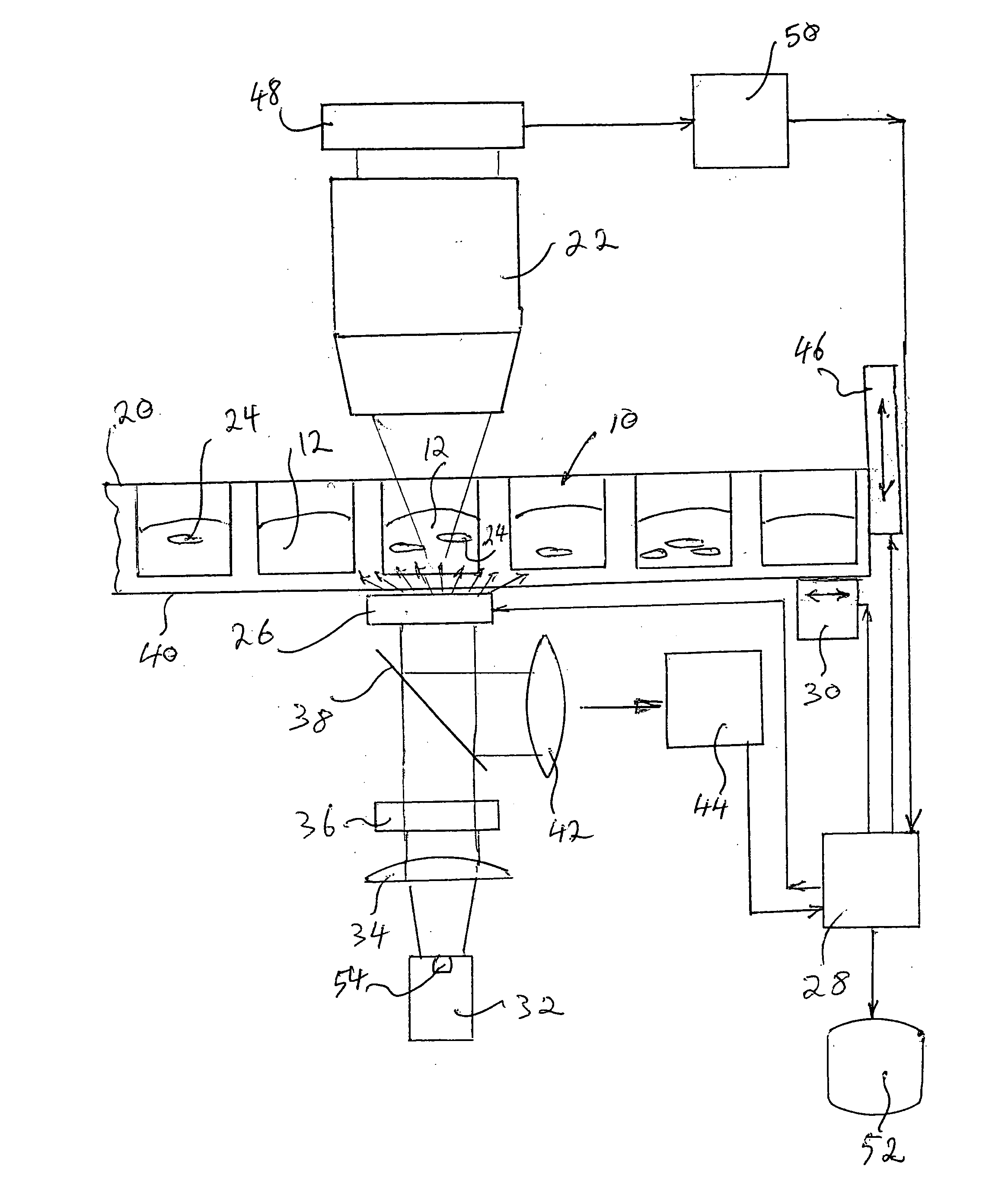

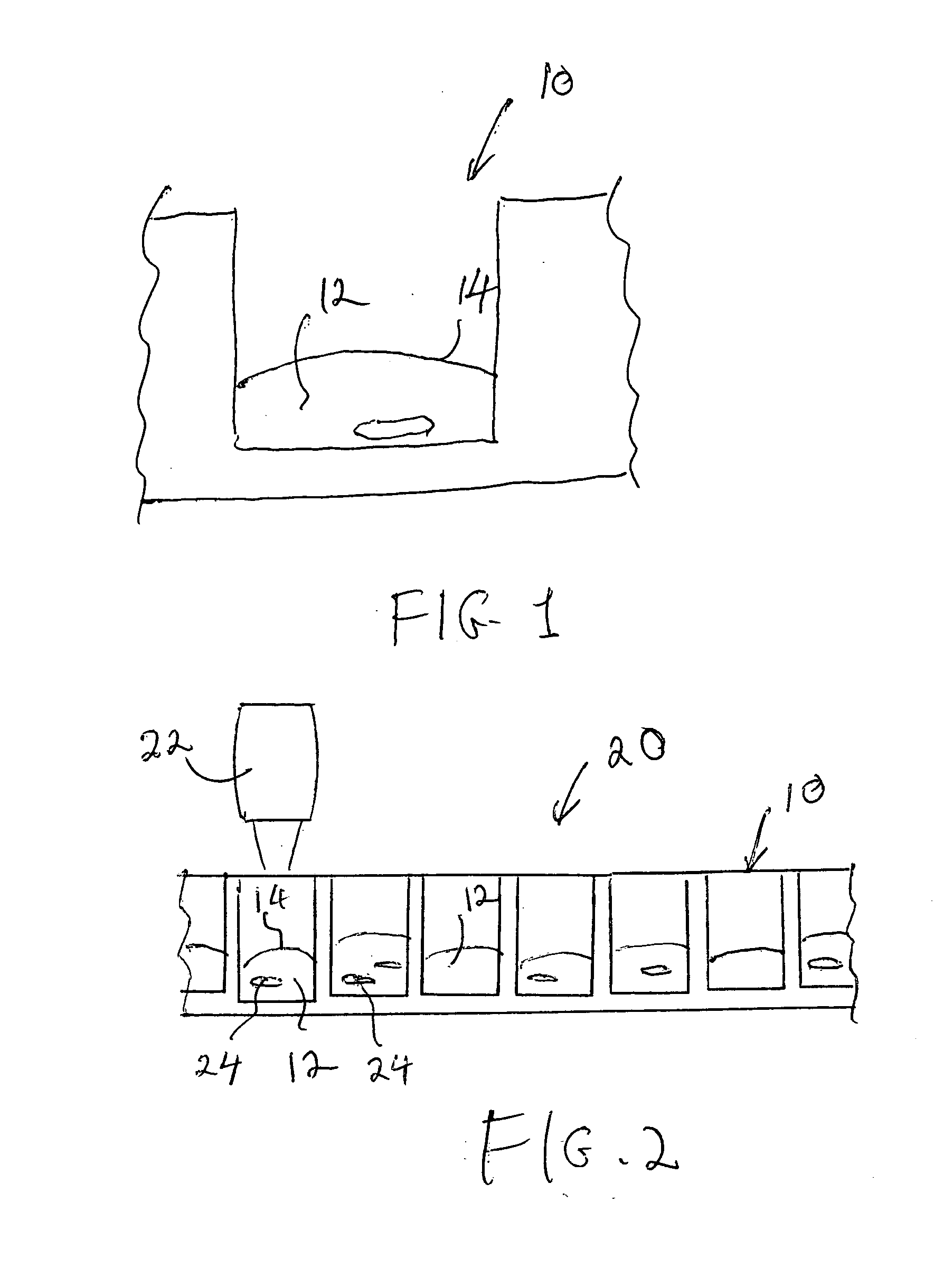

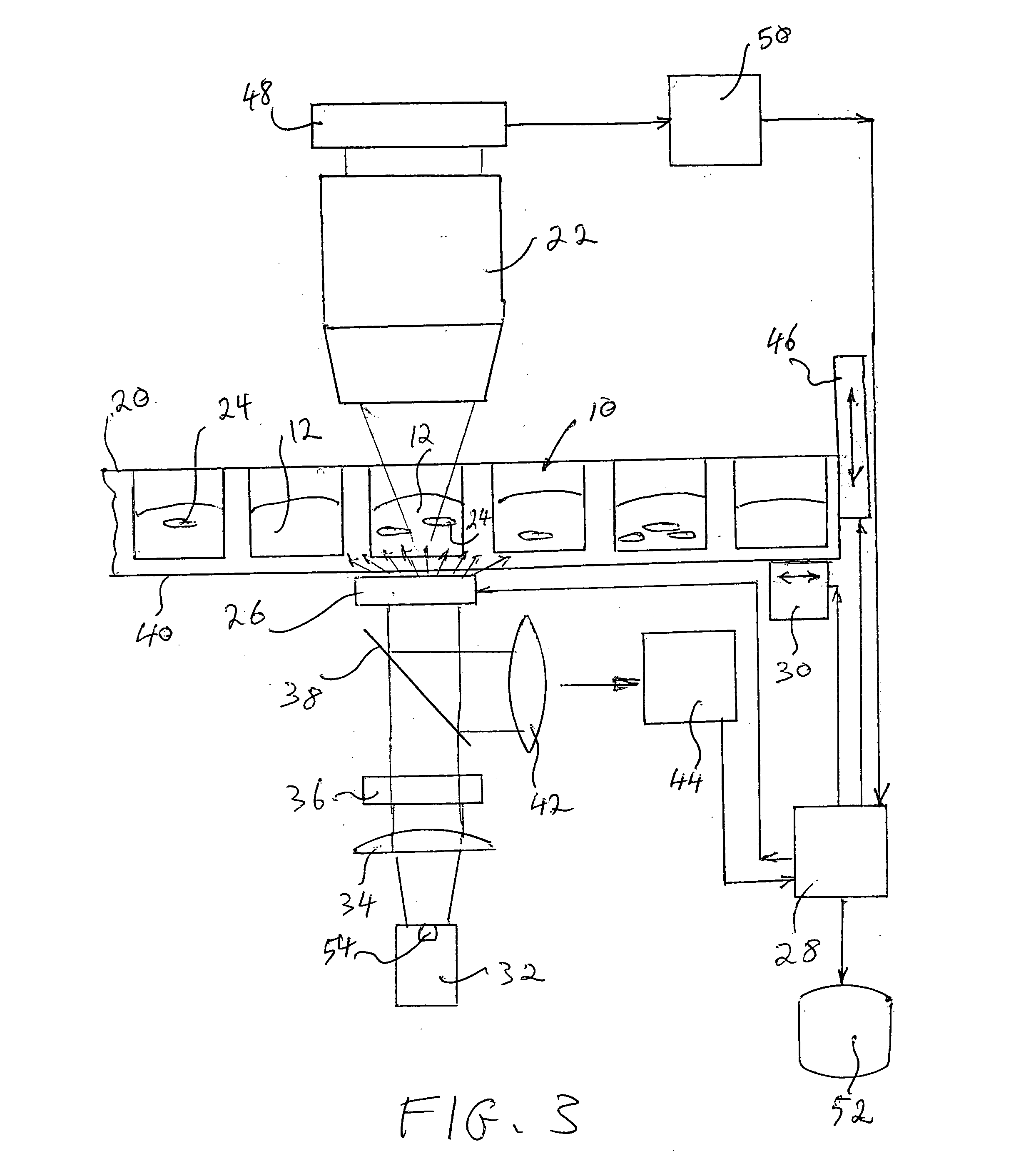

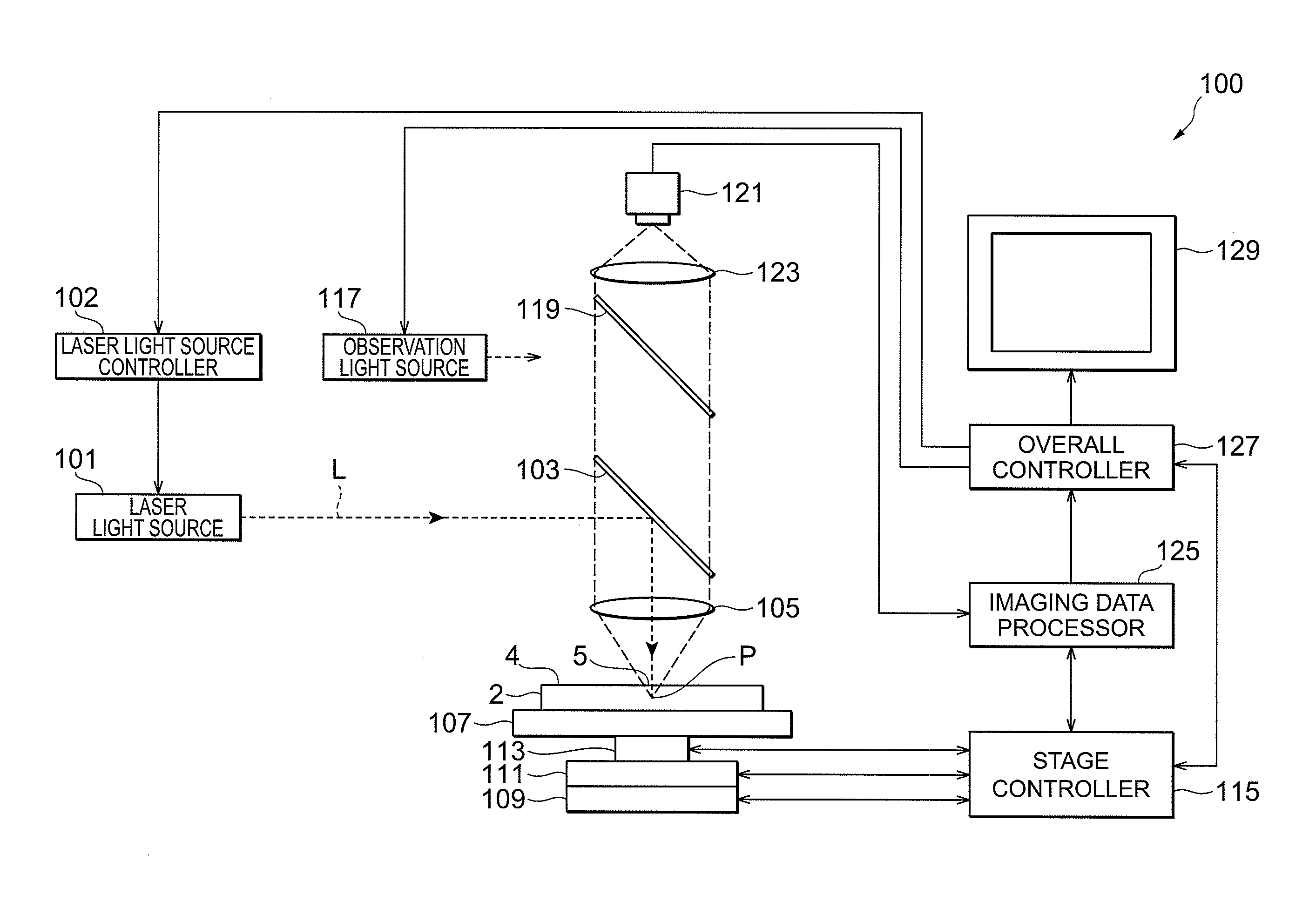

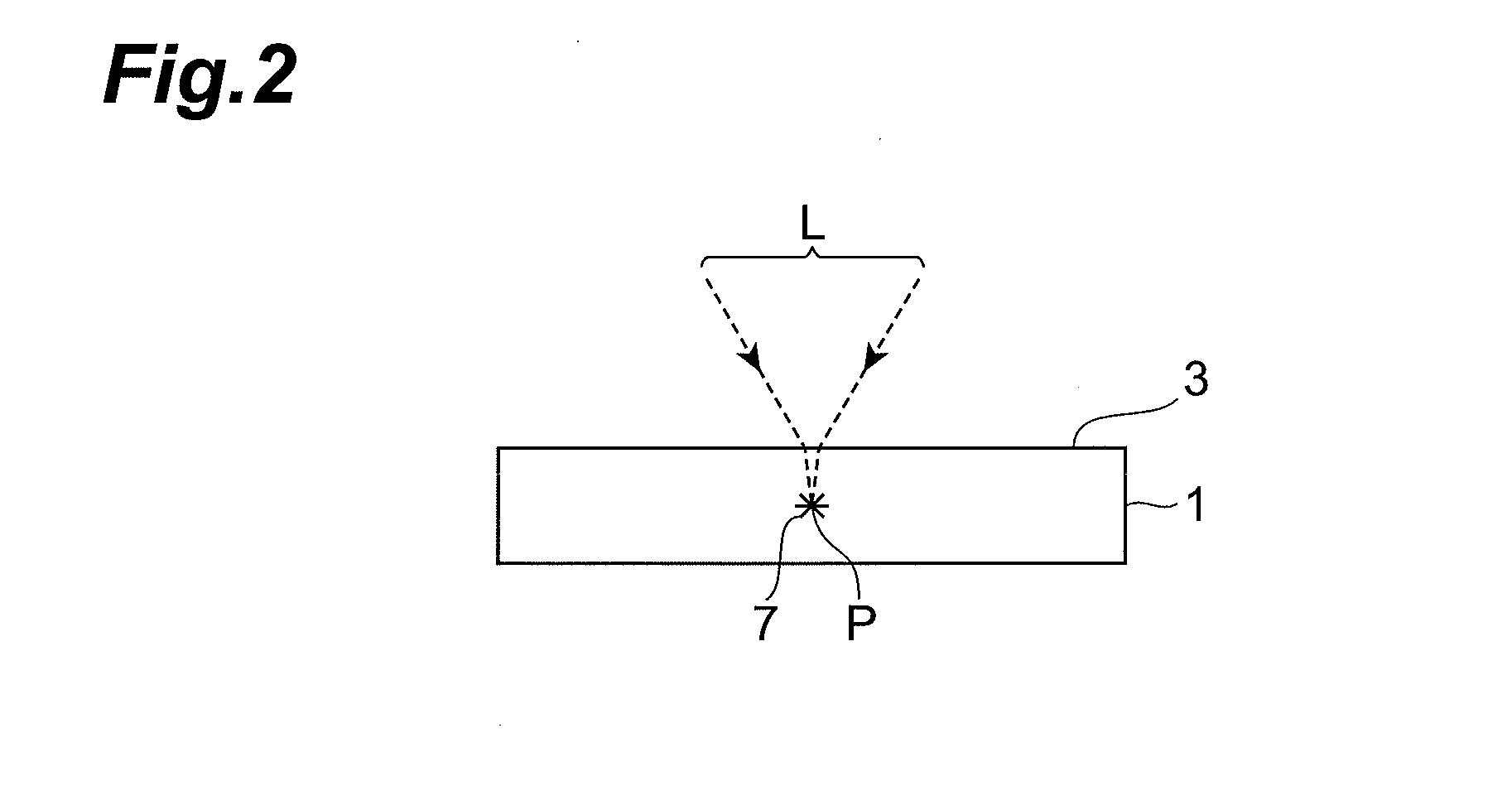

Crystal detection with scattered-light illumination and autofocus

A scatter shutter is used to alternately provide non-scattered illumination for autofocus purposes and diffuse illumination for imaging purposes in a microscope system for high-throughput testing of protein samples in a multi-well tray. As the tray is being scanned continuously through the microscope objective for data acquisition, the scatter shutter is intermittently deactivated to allow collimated light to focus on the underside of the tray and produce autofocus signals, and then activated to produce diffused light and to image the protein sample in each well. The timing of each step is synchronized so as to place the droplet in focus prior to energizing the scatter shutter and switching to the imaging mode.

Owner:WAHL MICHAEL +1

Painting and calligraphy learning machine

ActiveCN103824486AMaster quicklyImprove learning effectTeaching apparatusLearning machineMagnifying glass

The invention discloses a painting and calligraphy learning machine comprising a workbench, an optical transmission system, a digital analysis system, an imaging projection system and a power supply system. The desktop of the workbench is mainly formed by a light scattering plate and a crystal soft light plate laid on the light scattering plate. A curtain is arranged under the light scattering plate. The optical transmission system comprises a main light source, and a polariscope, an enoscope and a prism through which light emitted from the main light source passes in sequence. The digital analysis system comprises a back Fresnel lens arranged in front of the prism, a front Fresnel lens arranged in front of the back Fresnel lens and a crystallite integration piece arranged in front of the front Fresnel lens. An electronic liquid crystal screen or a picture clamp is arranged between the front Fresnel lens and the back Fresnel lens. The imaging projection system comprises a collecting lens parallely arranged in front of the crystallite integration piece, a magnifying lens parallely arranged in front of the collecting lens and a reflecting mirror arranged in front of the magnifying lens and inclined to the desktop of the workbench. The painting and calligraphy learning machine provides convenience for painting and calligraphy lovers to carry out imitation creation, and can help the painting and calligraphy lovers to quickly improve the painting and calligraphy learning effect.

Owner:SHANDONG BEIDOU REFRIGERATION EQUIP

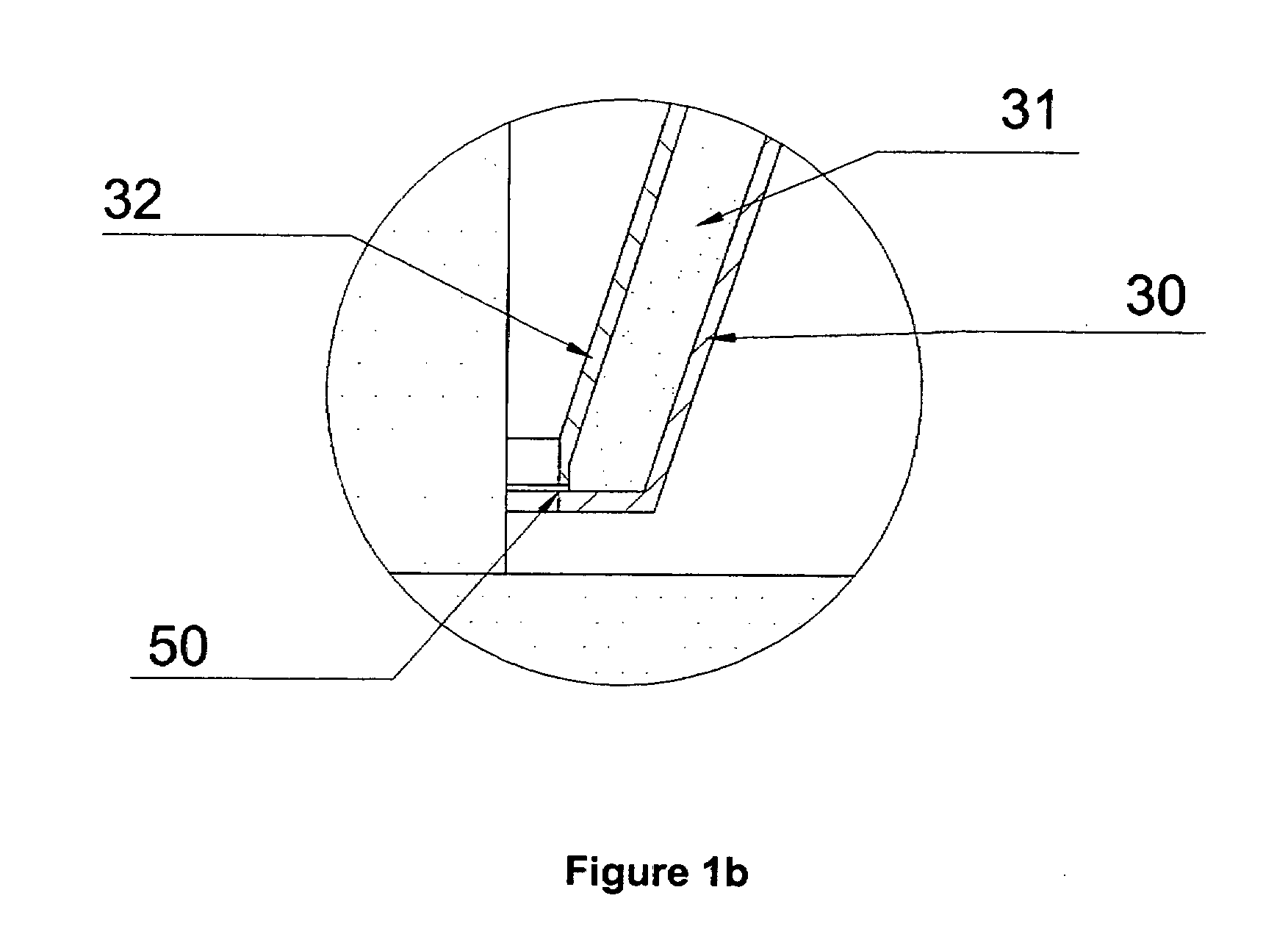

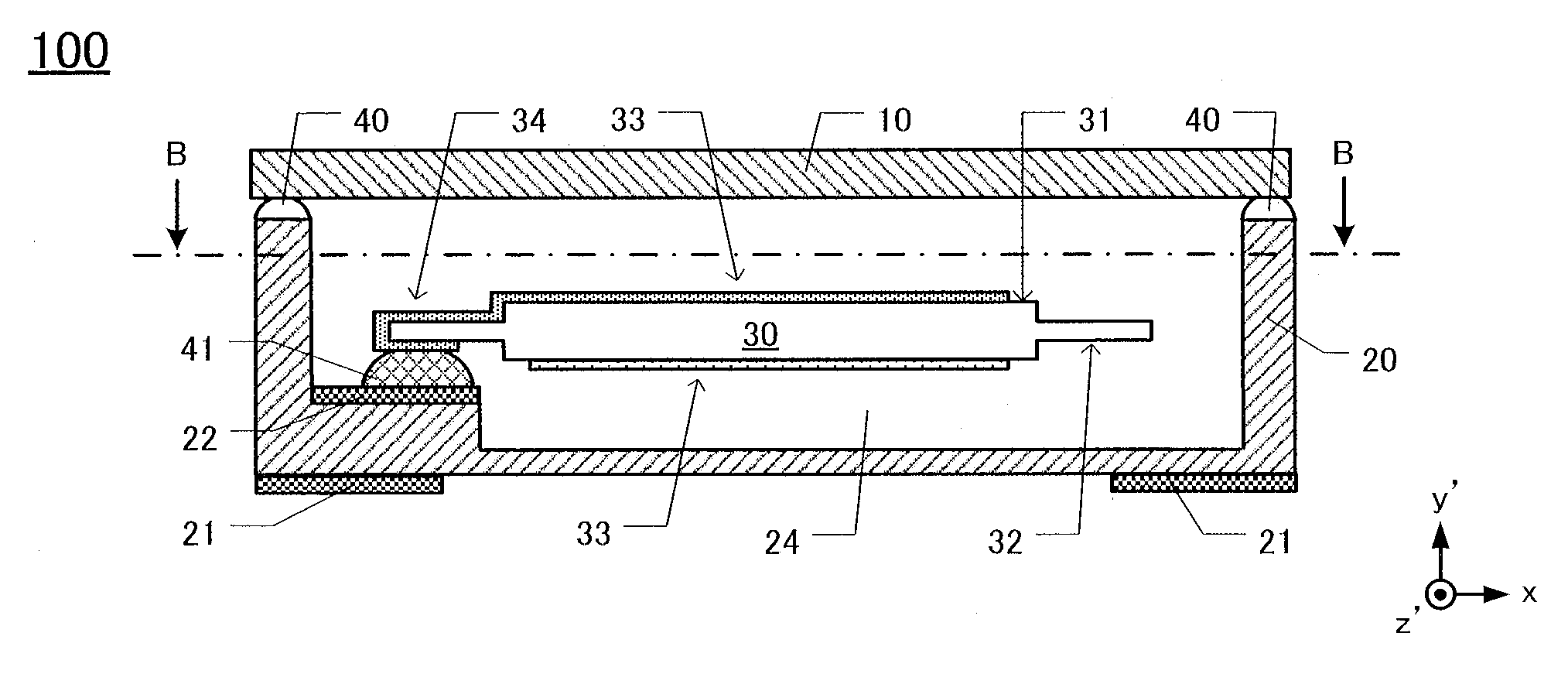

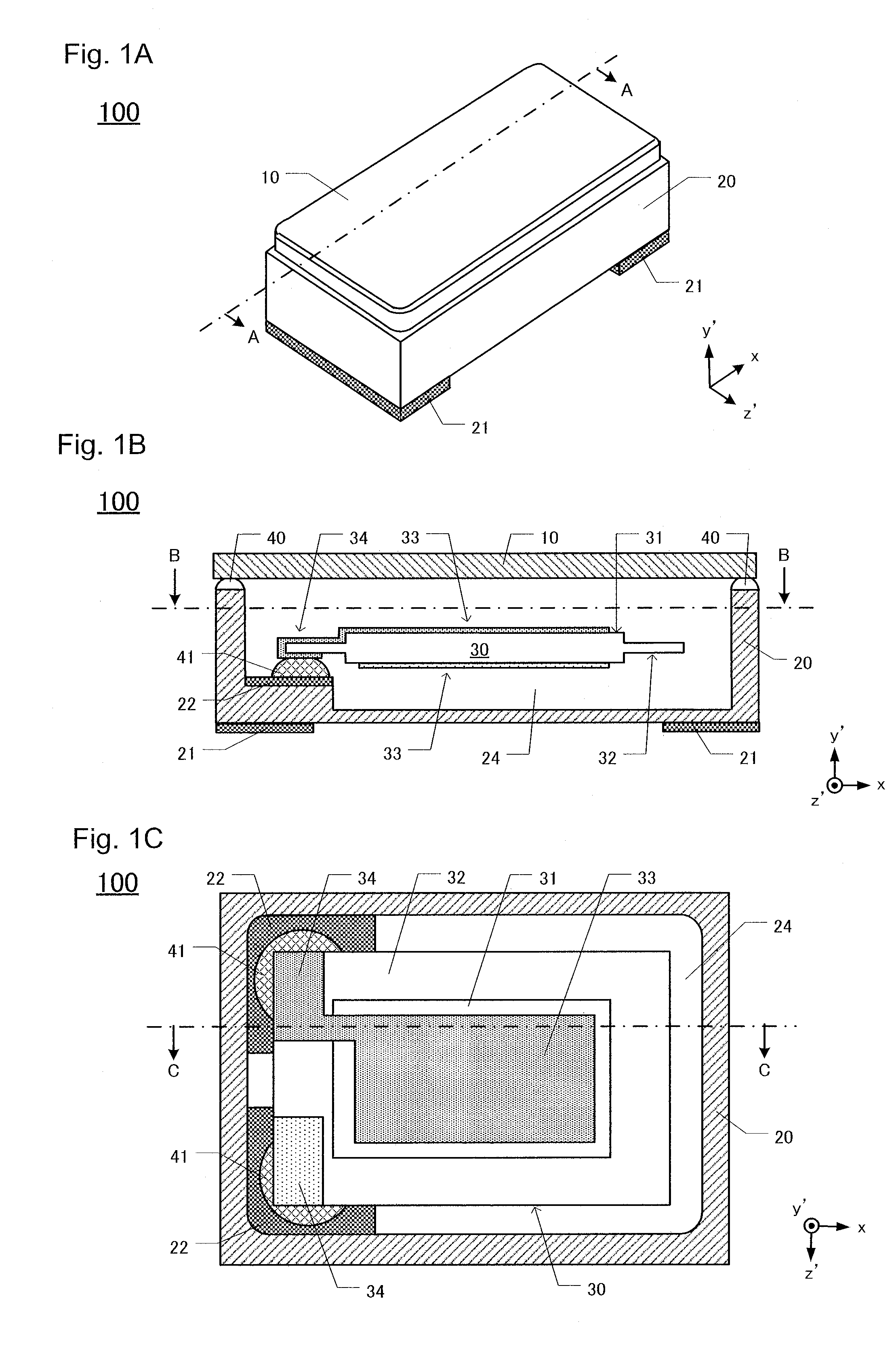

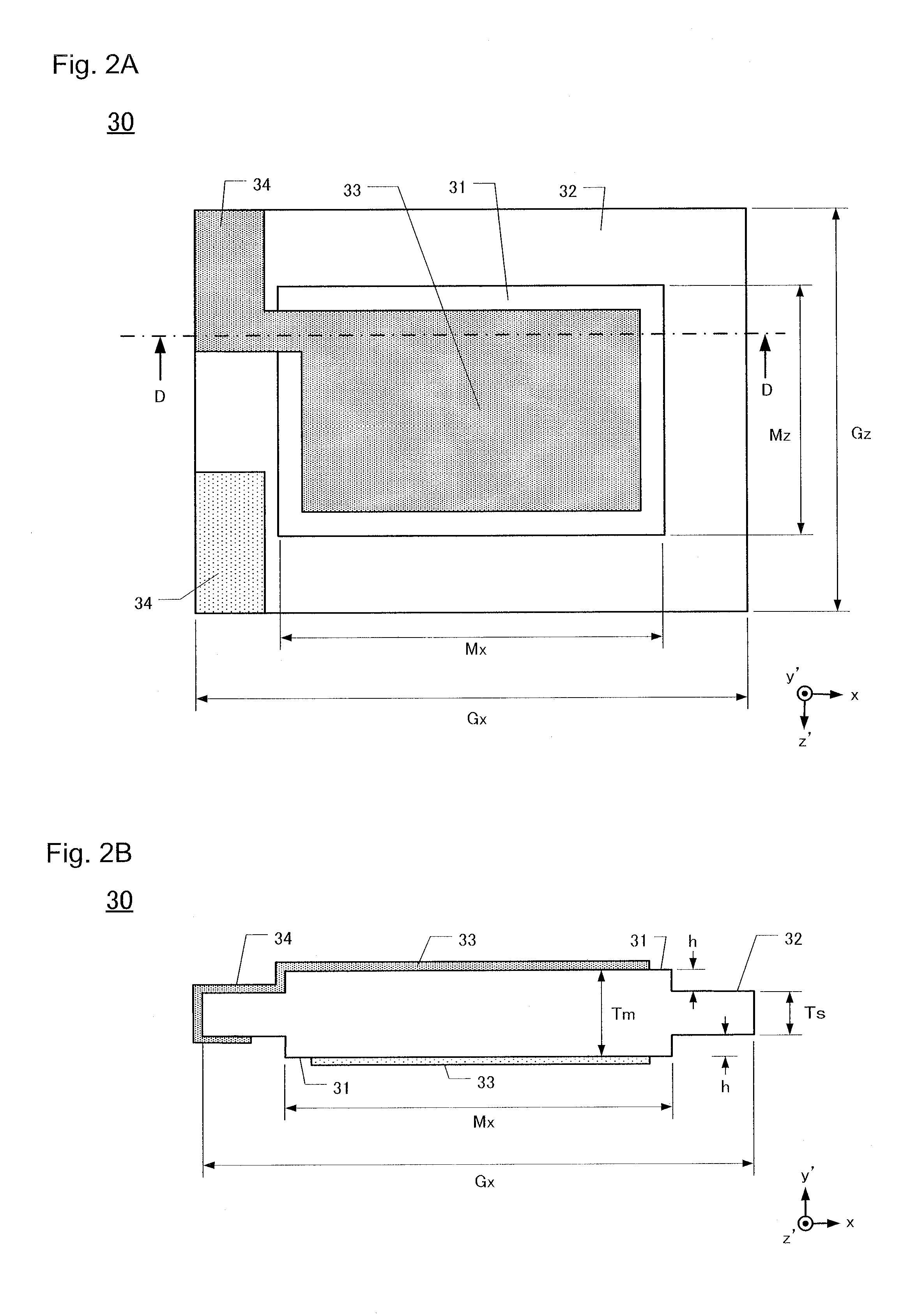

Mesa-Type At-Cut Quartz-Crystal Vibrating Piece and Quartz-Crystal Device

InactiveUS20120056514A1Prevent degradationReduce scrap ratePiezoelectric/electrostriction/magnetostriction machinesImpedence networksRock crystalQuartz

To provide an AT-cut quartz-crystal vibrating piece in which size of the vibrating unit is adjusted to appropriate value, so that the unnecessary vibration is inhibited and degradation of its characteristics is prevented. A mesa-type AT-cut quartz-crystal vibrating piece for vibrating at 38.400 MHz comprising a rectangular excitation unit (31) and a peripheral region (32) formed on the periphery of the excitation unit and having a thickness less than than the thickness of the excitation unit, is represented by the following equation:Mx / Gx=0.09×n−0.06 (n: natural number) (1)Length of a crystallographic x-axis direction of the excitation unit is defined as Mx (mm) and length of the crystallographic x-axis direction of the peripheral region and excitation unit is defined as Gx (mm).

Owner:NIHON DEMPA KOGYO CO LTD

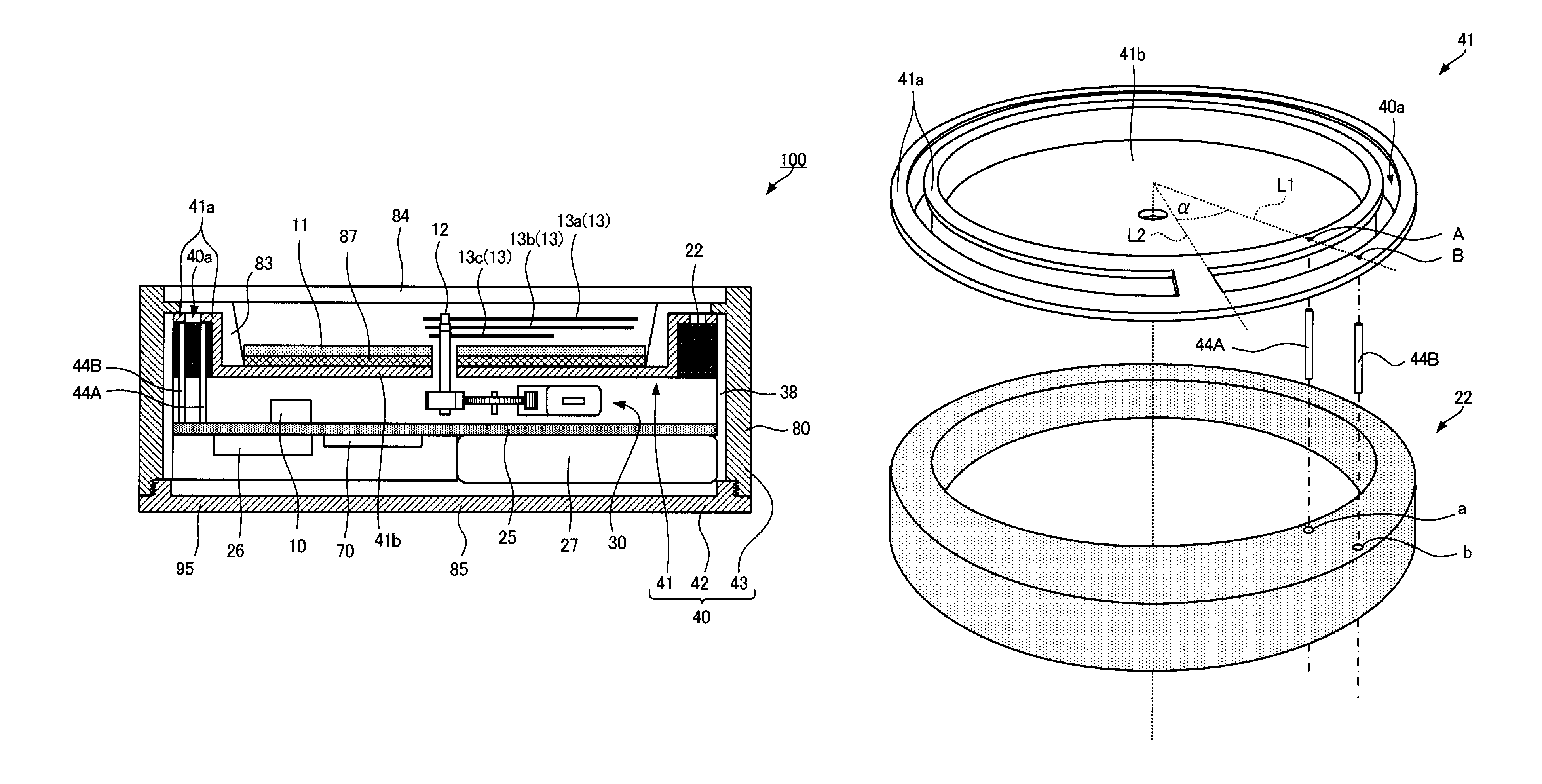

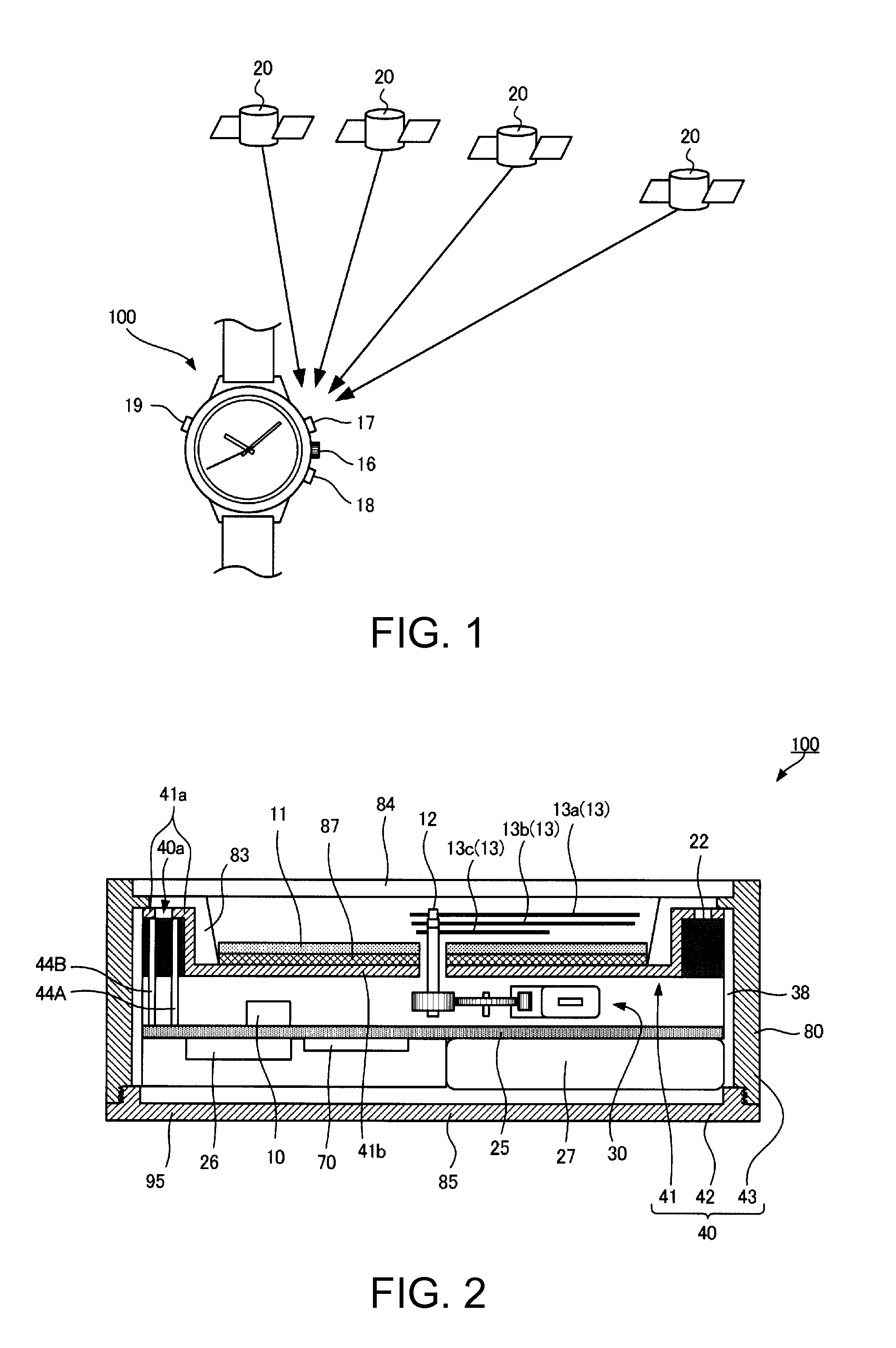

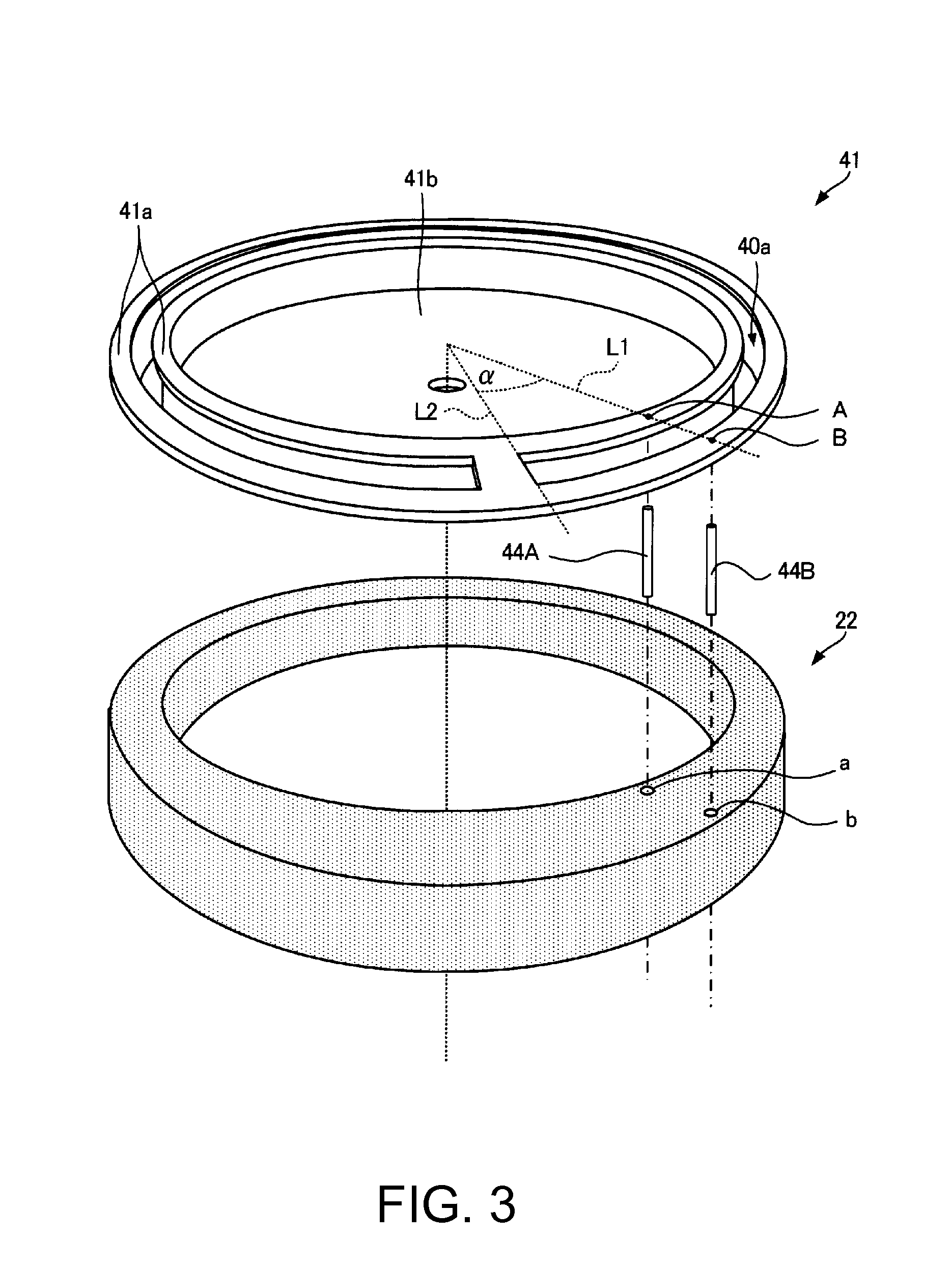

Electronic timepiece with internal antenna

ActiveUS8570838B2Improve reception performanceReception performance does not dropAntenna supports/mountingsSynchronous motors for clocksDielectricElectricity

An electronic timepiece with internal antenna maintains sufficiently high reception performance of circularly polarized waves even when having a metal external case. The timepiece has a cylindrical case; a crystal that covers the opening on the face side of the case; a drive mechanism that arranged inside the case; a metal antenna; and a dielectric. The antenna houses the drive mechanism and has a cylindrical side part, a bottom part that covers the opening on the back side of the side part, and an antenna electrode that contacts the inside of the side part. The back cover covers the back side of the case and is also the bottom part. The dielectric extends circumferentially to the side part, and contacts the antenna electrode in the face-back cover direction. A slot extending circumferentially is formed in the antenna electrode. Part or all of the slot is covered by the dielectric.

Owner:SEIKO EPSON CORP

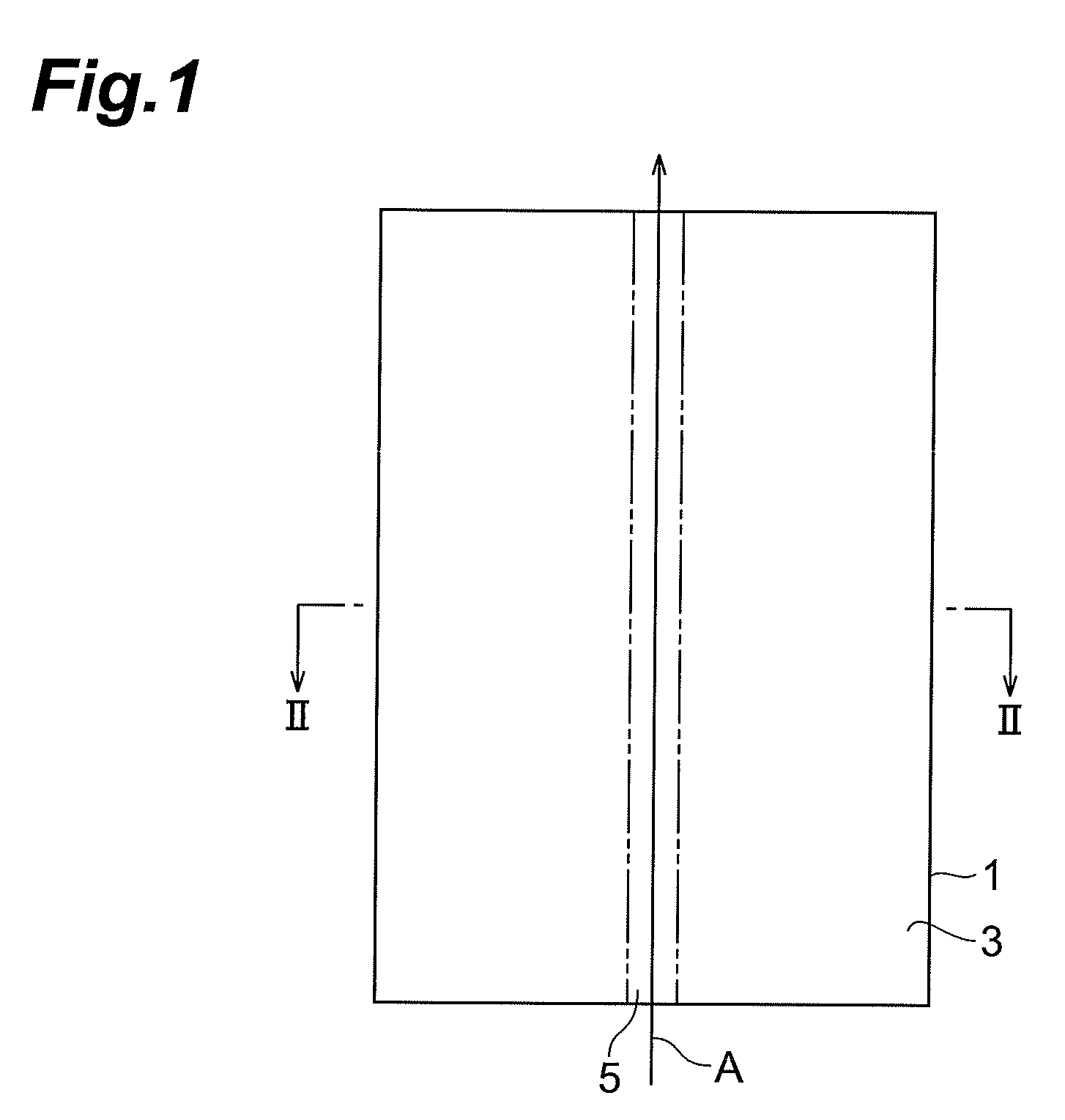

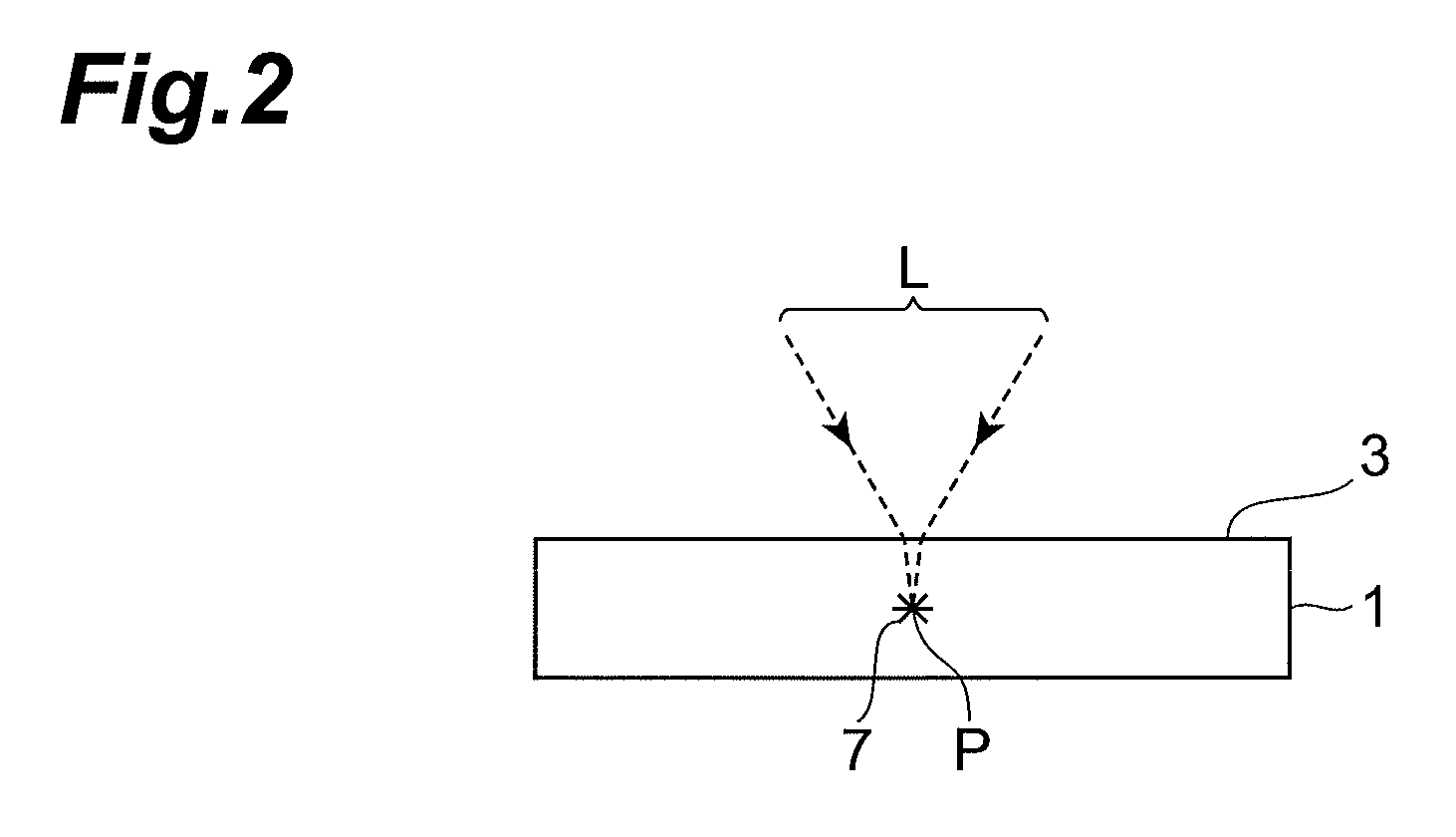

Laser processing method and method for manufacturing light-emitting device

ActiveUS20120077296A1Little strengthHigh precisionSemiconductor/solid-state device manufacturingFine working devicesLaser processingSingle crystal

A plurality of modified parts are formed at a first formation pitch for a line arranged along the M-plane of a single-crystal sapphire substrate to construct a modified region and cause a fracture occurring from the modified region to reach a principal surface of the single-crystal sapphire substrate. A plurality of modified parts are formed at a second formation pitch narrower than the first formation pitch for a line arranged along the A-plane of the single-crystal sapphire substrate to construct a modified region and cause a fracture occurring from the modified region to reach the principal surface of the single-crystal sapphire substrate. Along the lines, a knife edge is pressed against a wafer from the side of the single-crystal sapphire substrate opposite from the principal surface of the single-crystal sapphire substrate where the fractures have reached, to cut the wafer along the lines.

Owner:HAMAMATSU PHOTONICS KK

Crystal display device

InactiveUS7397457B2Prevent image degradationCathode-ray tube indicatorsInput/output processes for data processingPattern recognitionDisplay device

Owner:SHARP KK

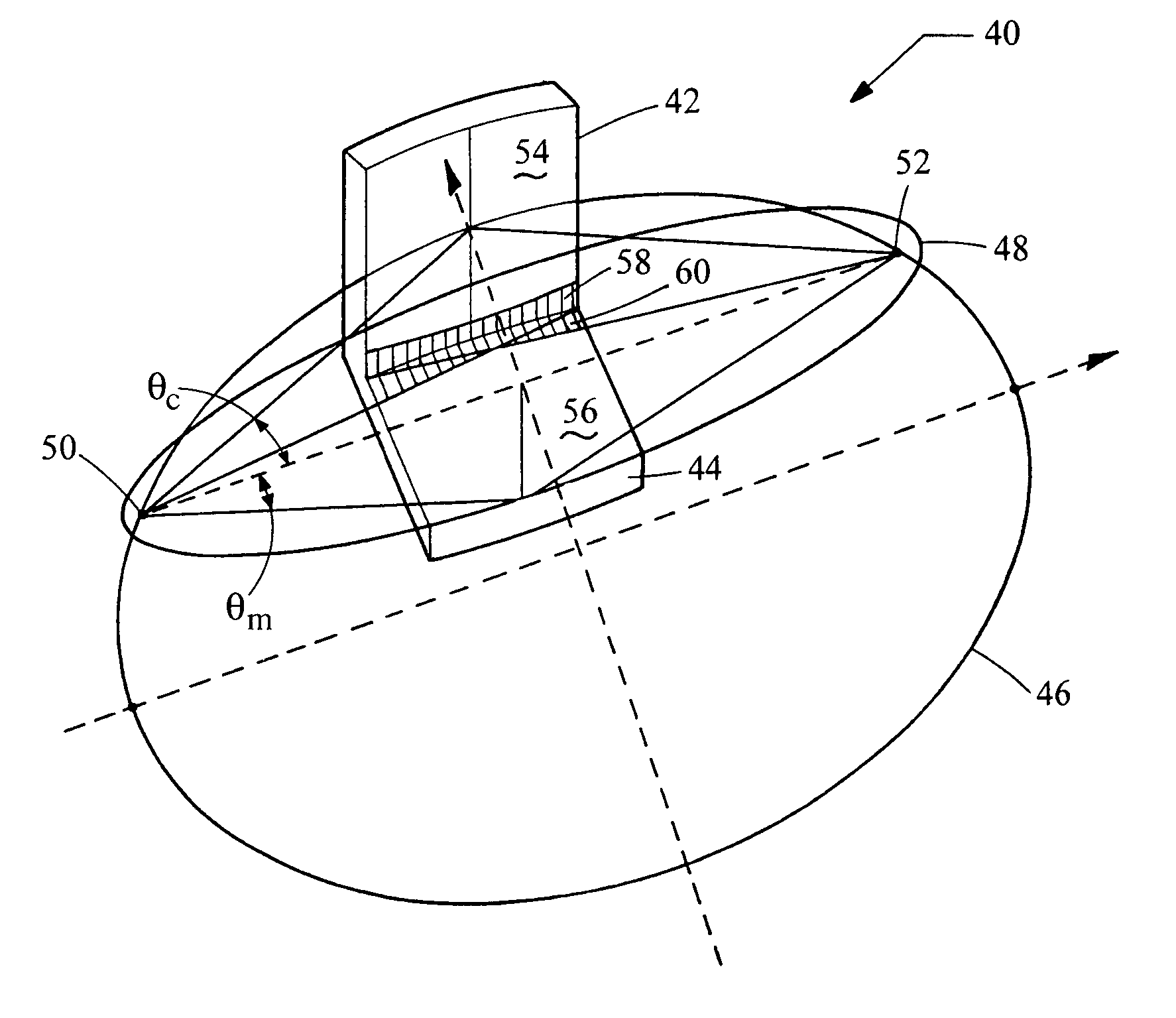

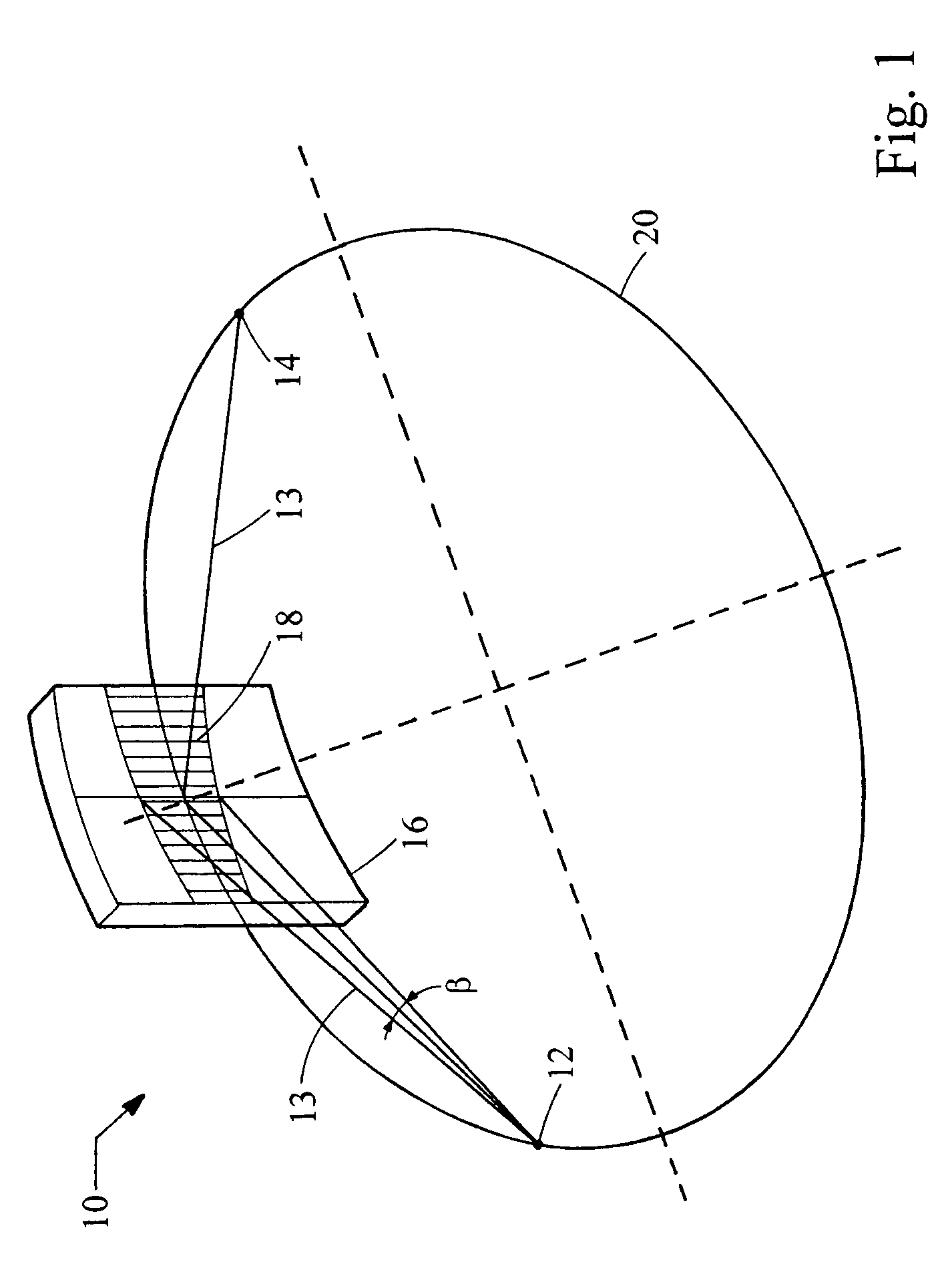

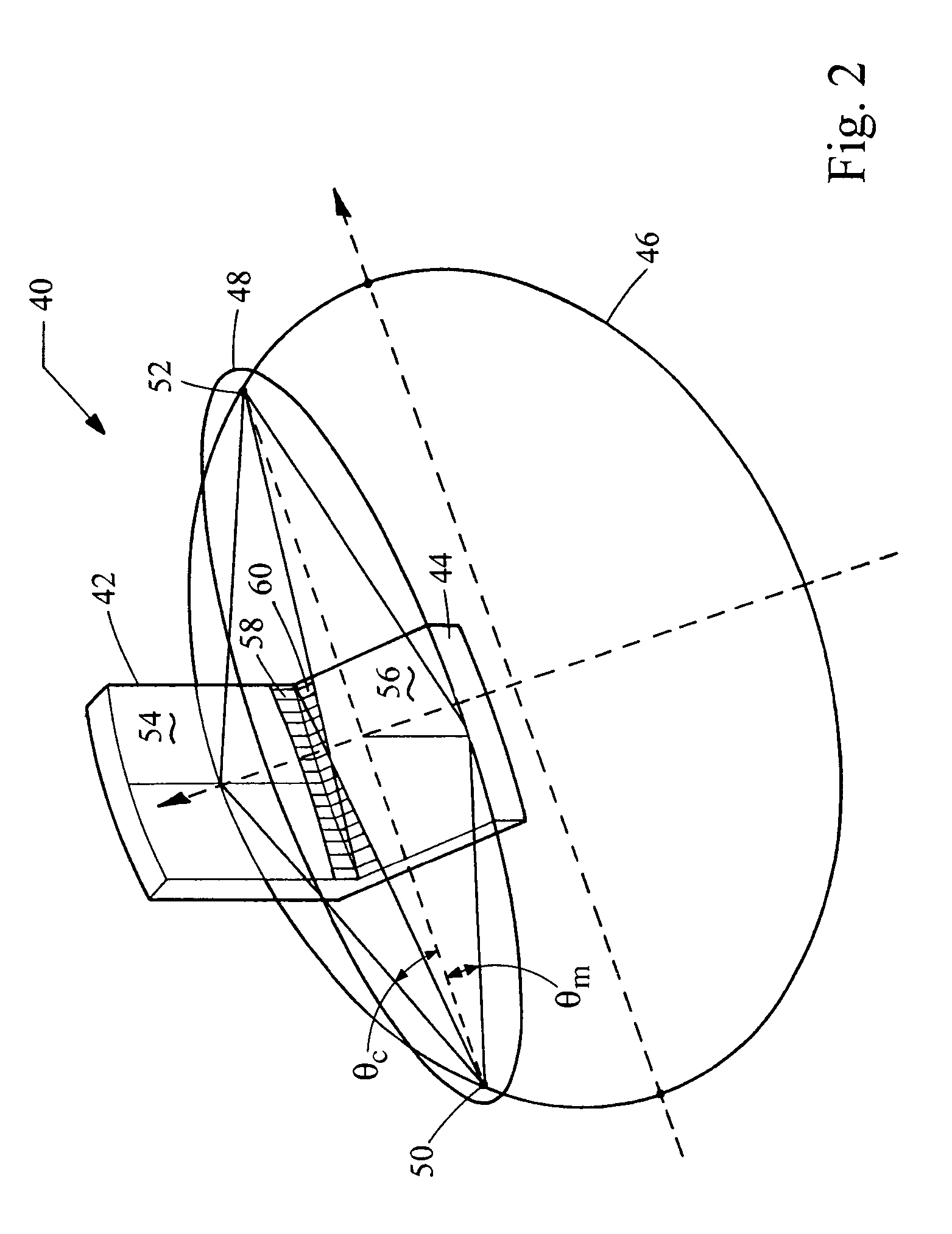

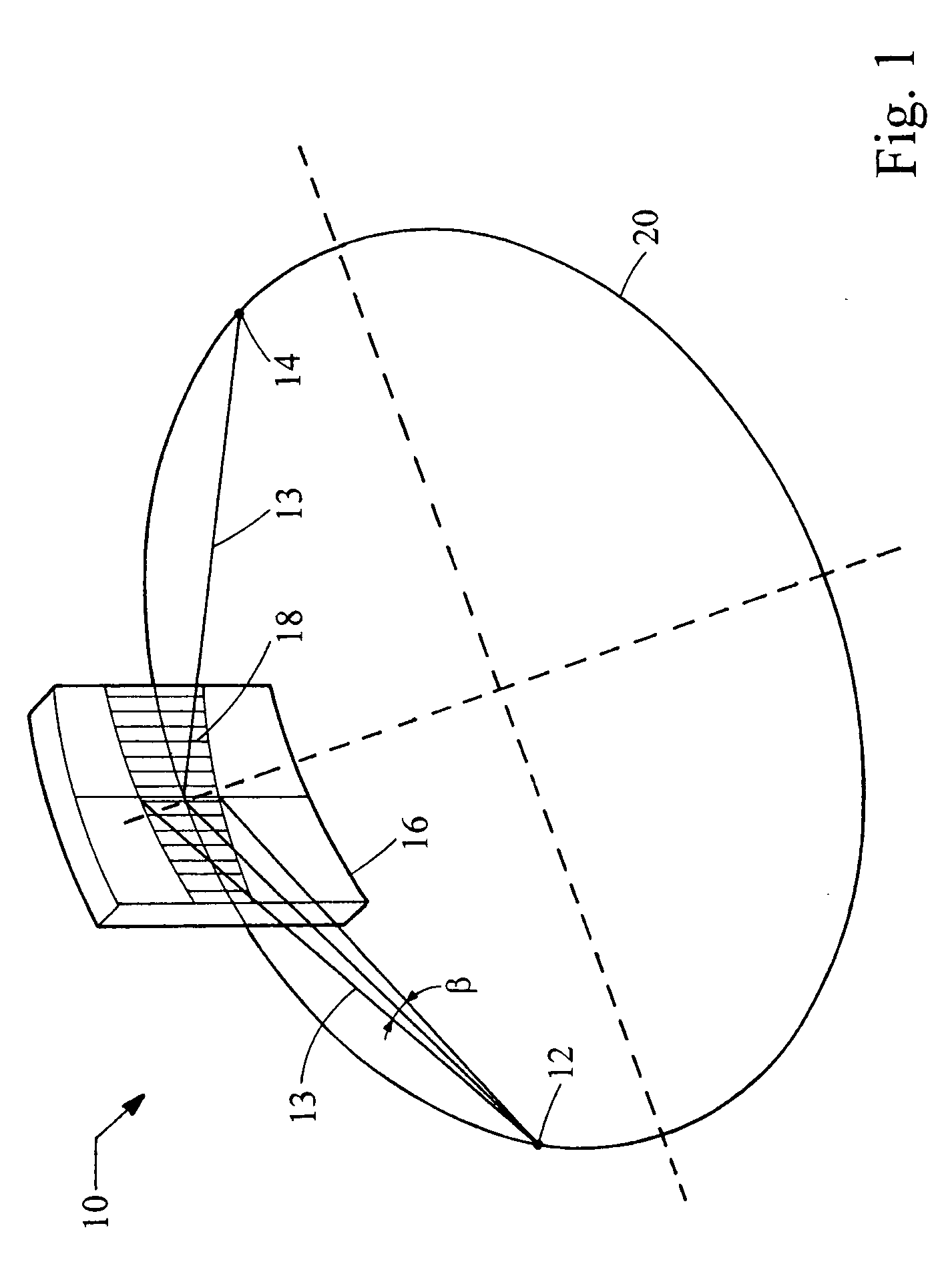

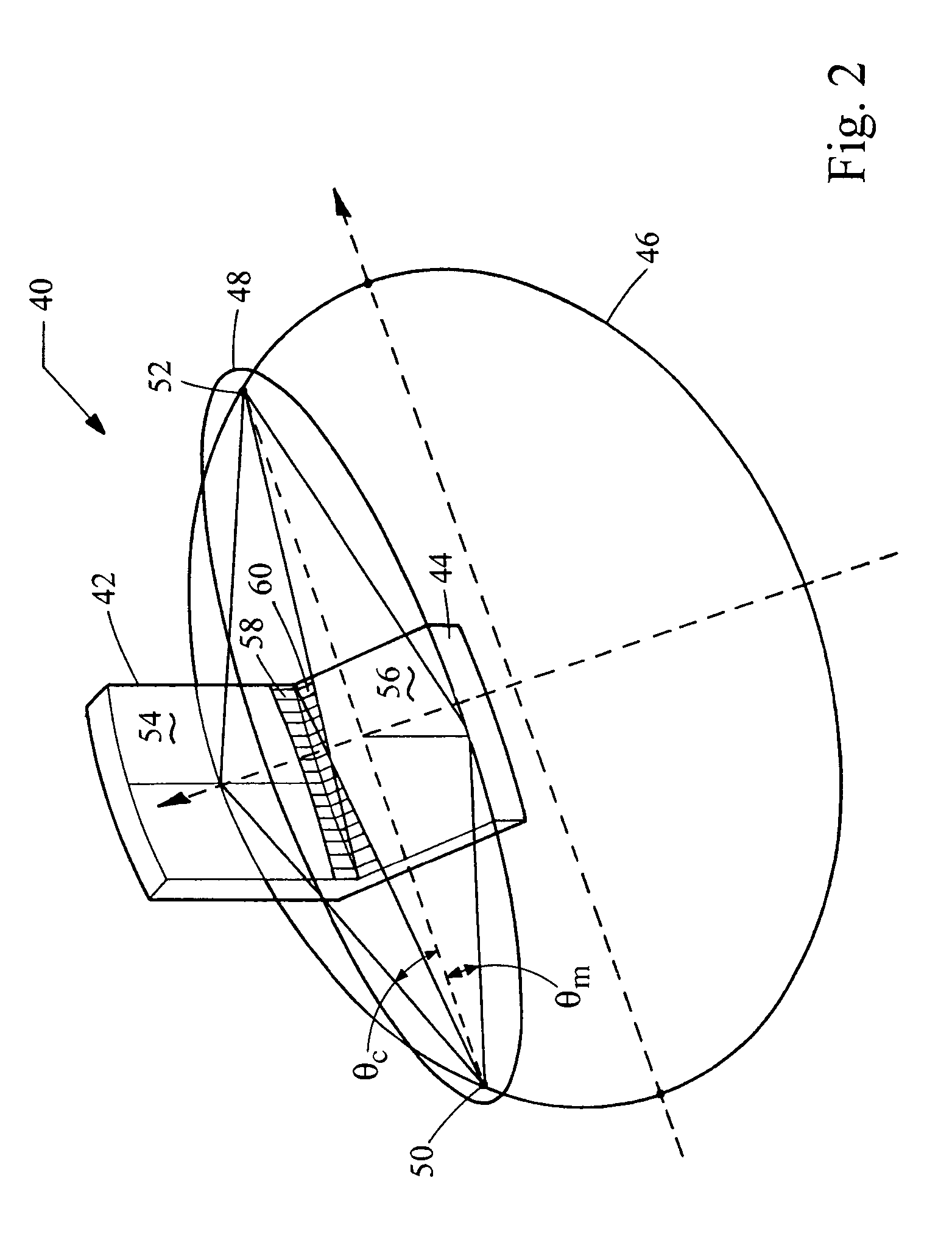

Beam conditioning system

ActiveUS7076026B2NanoinformaticsHandling using diffraction/refraction/reflectionLight beamOptoelectronics

The present invention provides an x-ray beam conditioning system with a Kirkpatrick-Baez diffractive optic including two optical elements, of which one of the optical elements is a crystal. The elements are arranged in a side-by-side configuration. The crystal can be a perfect crystal. One or both diffractive elements can be mosaic crystals. One element can be a multilayer optic. For example, the multilayer optic can be an elliptical mirror or a parabolic mirror with graded d-spacing. The graded d-spacing can be either lateral grading or depth grading, or both.

Owner:OSMIC INC

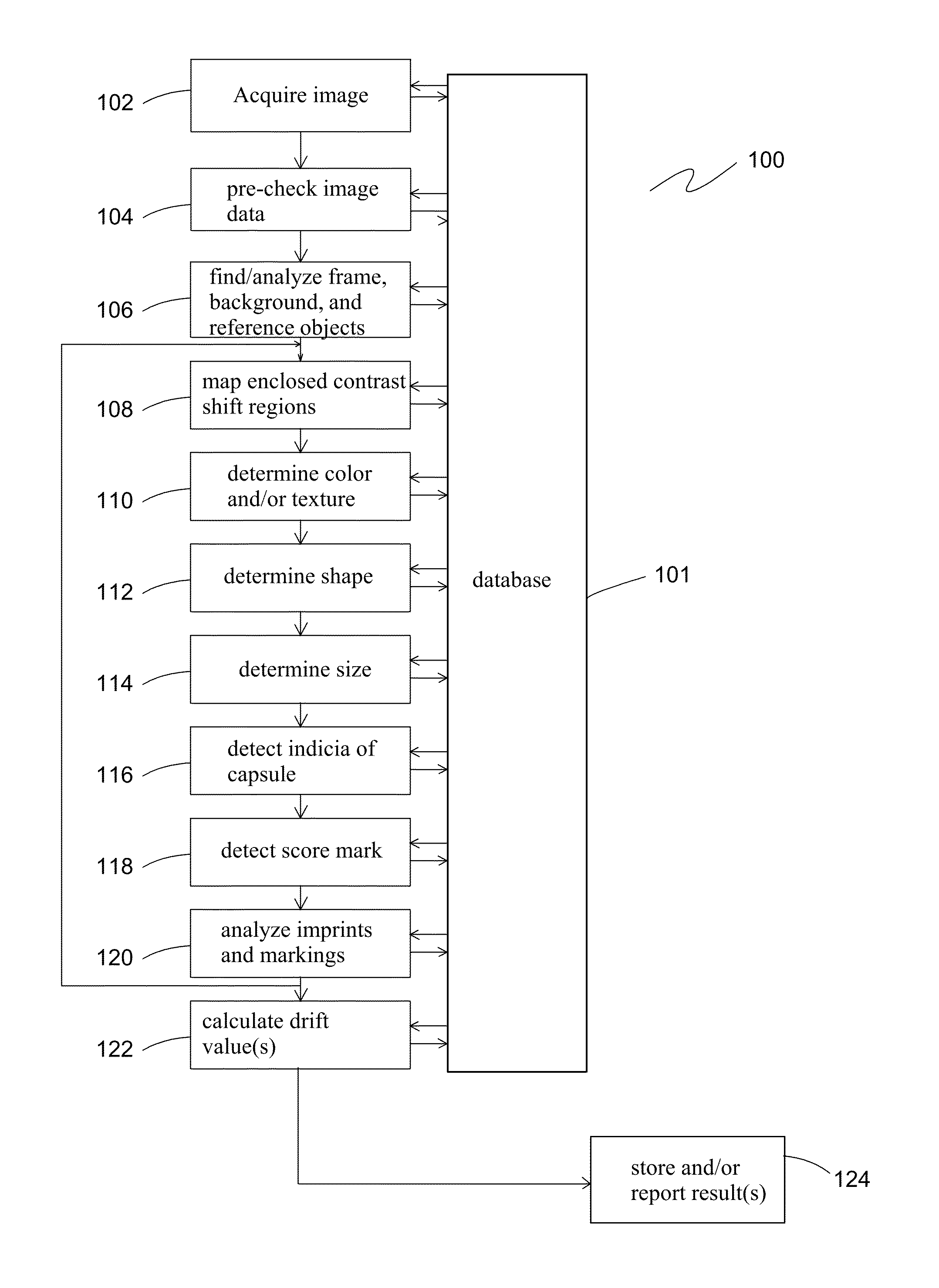

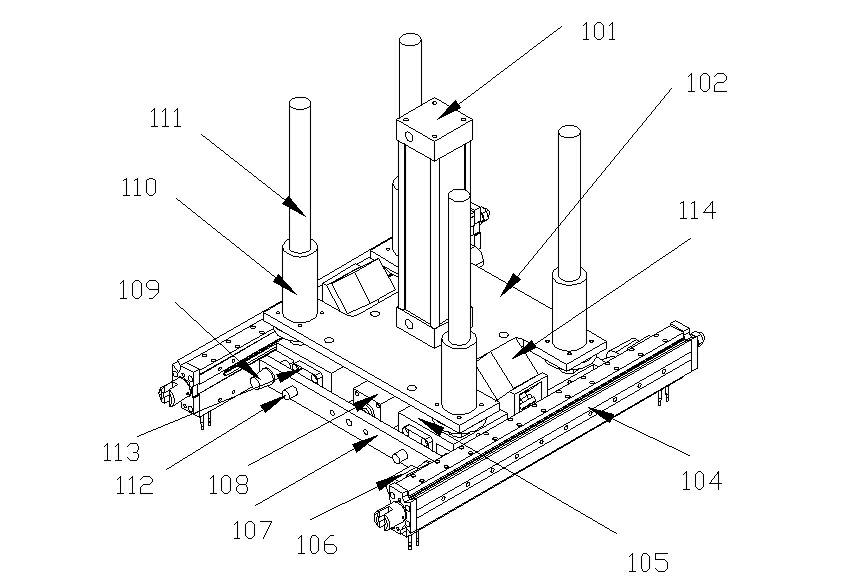

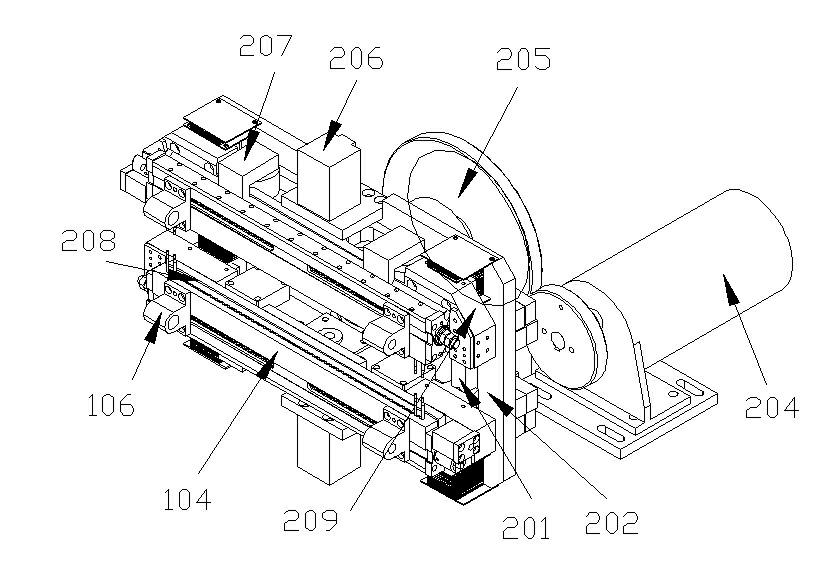

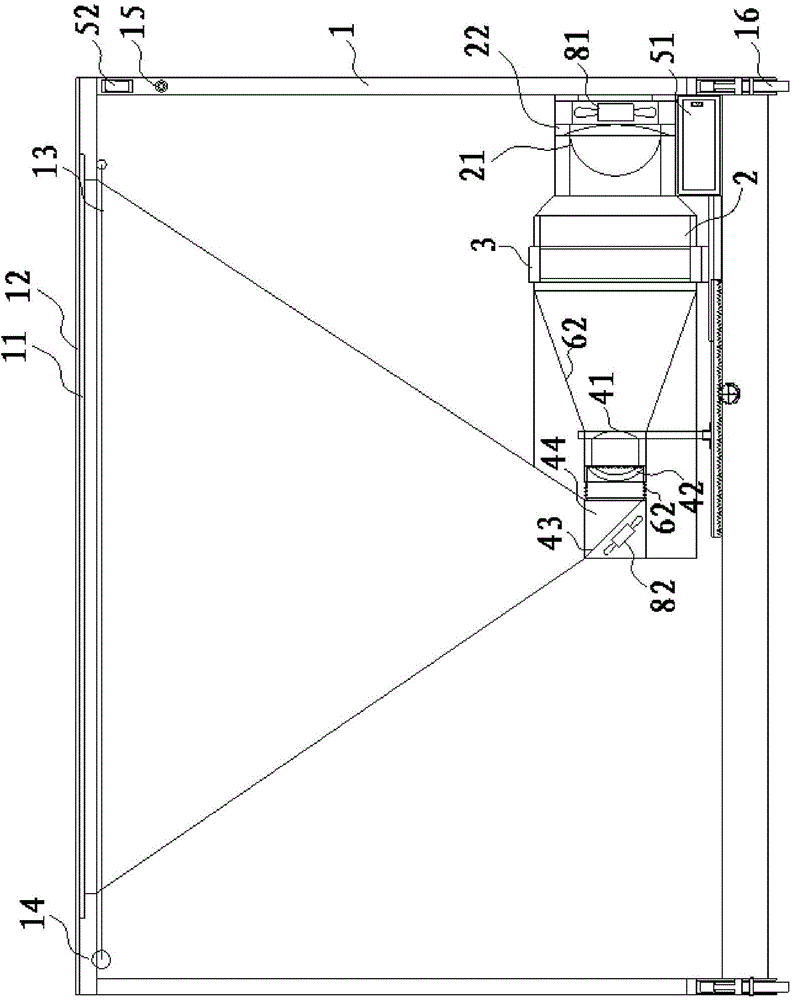

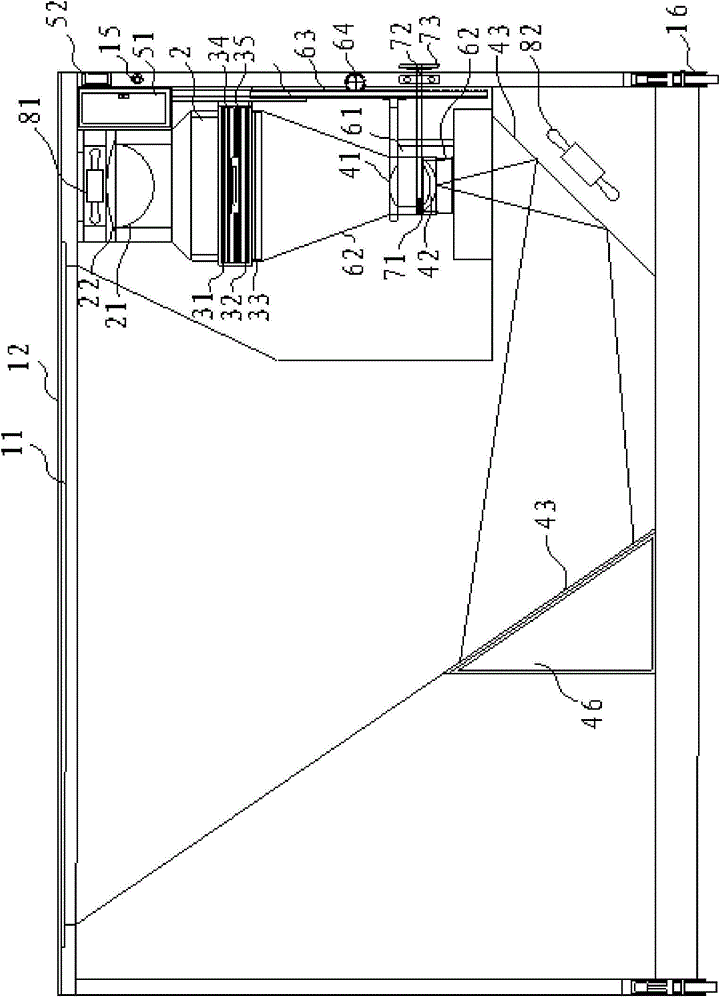

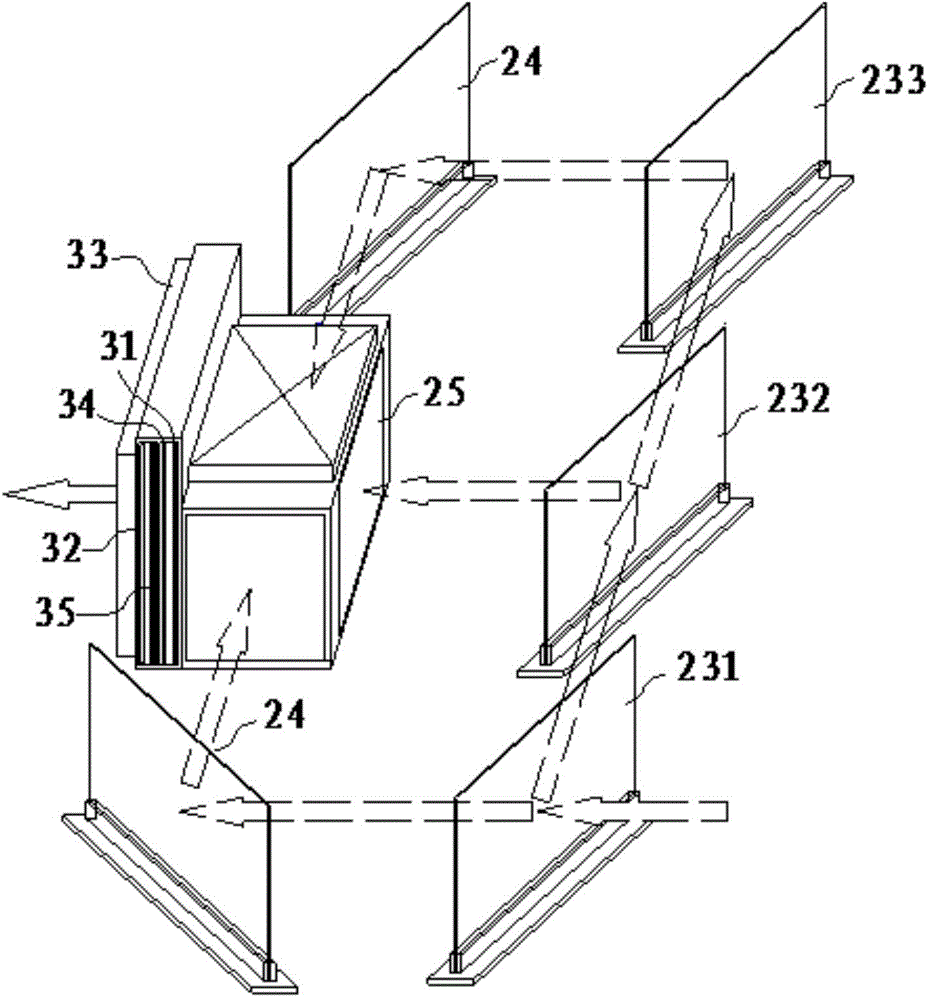

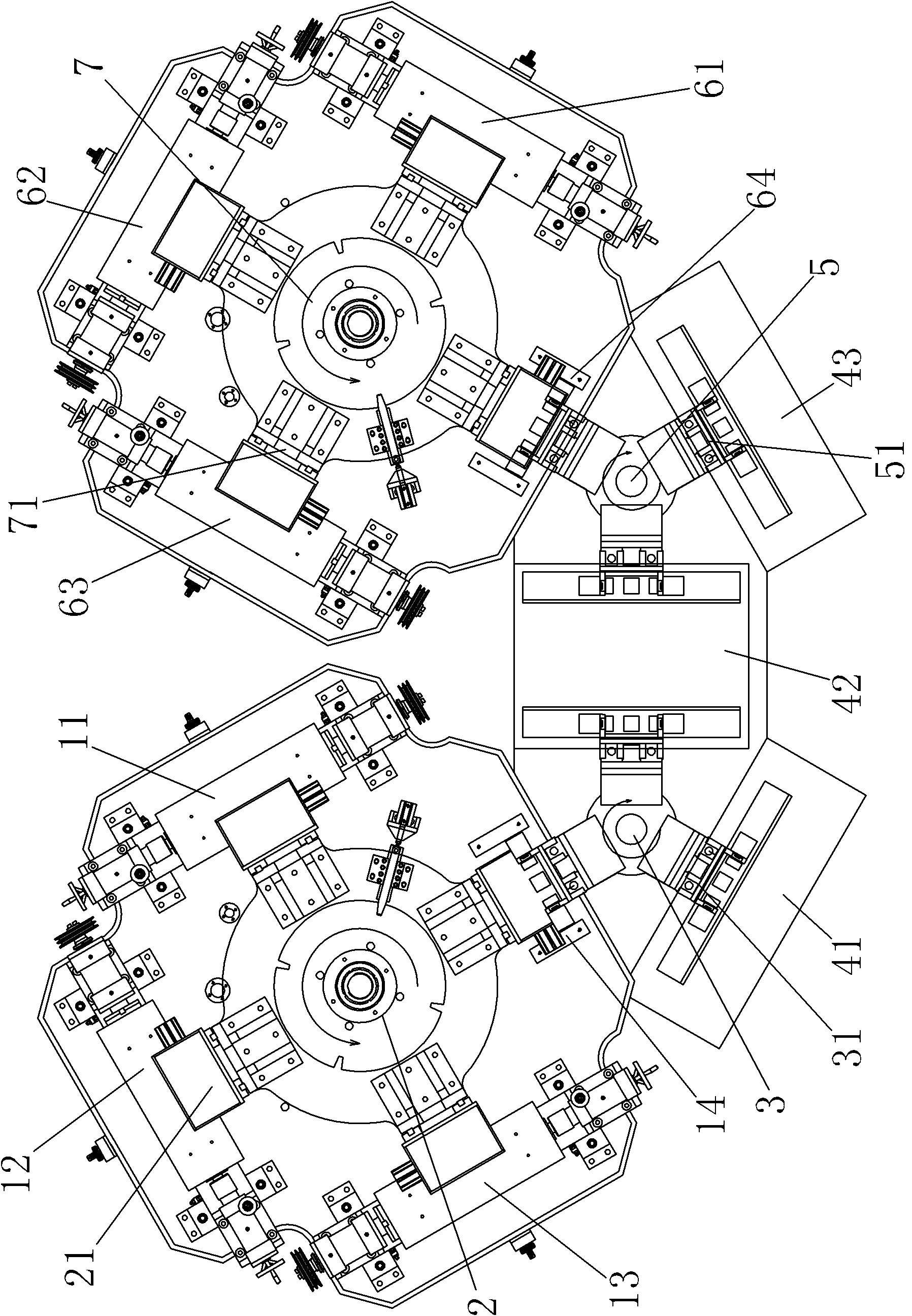

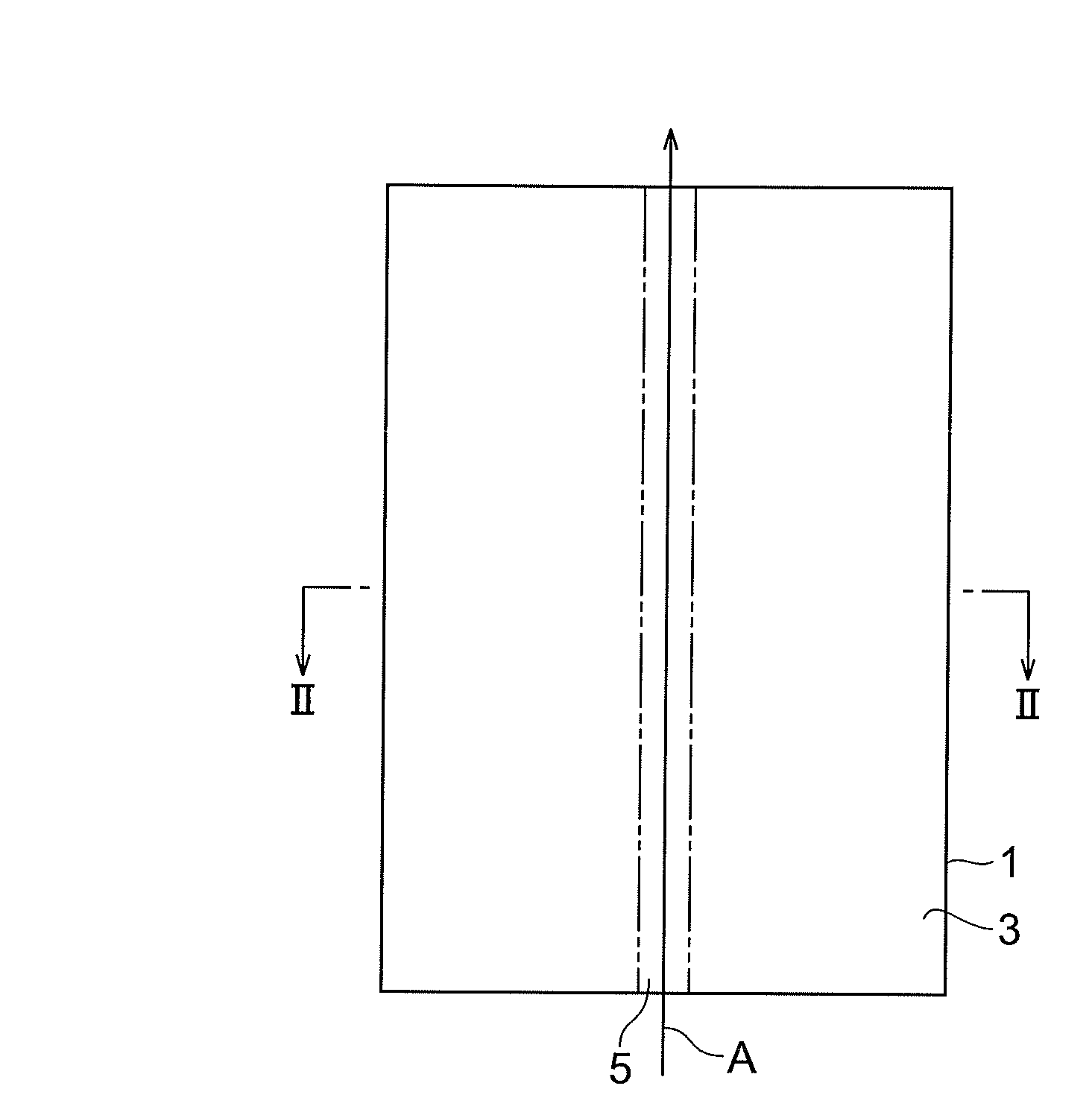

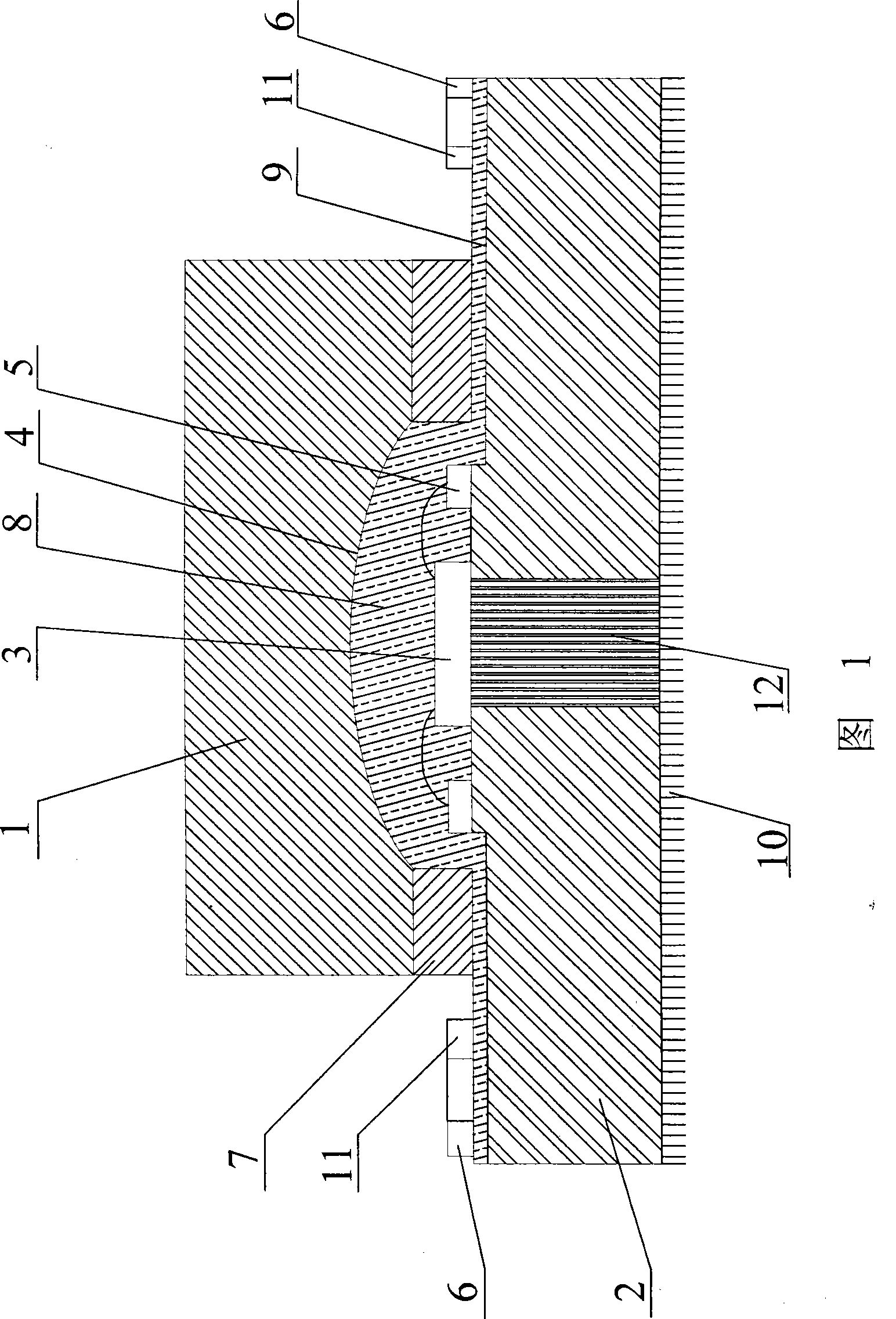

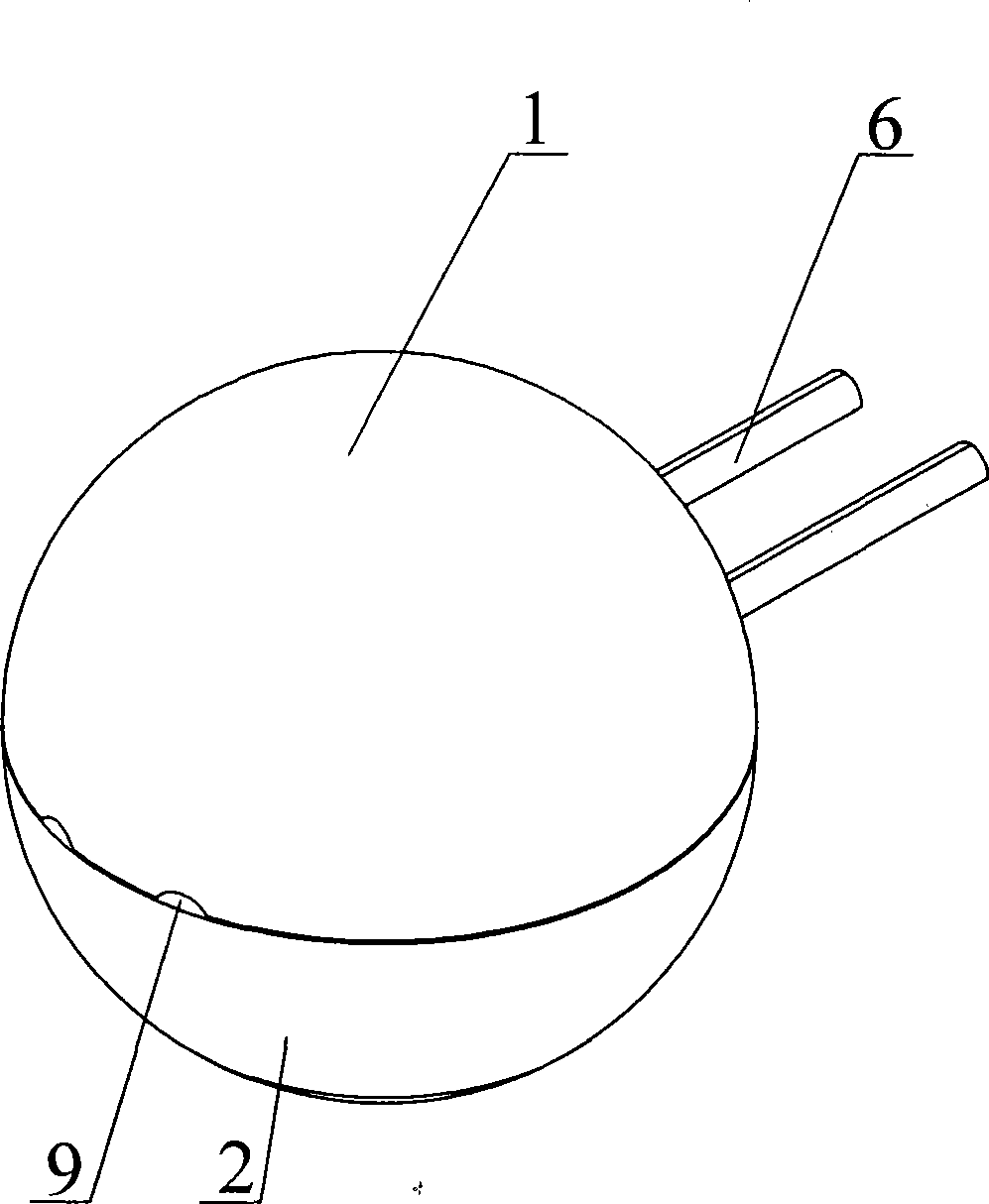

Crystal blank automatic grinding and polishing system, grinding and polishing machine and auxiliary machine thereof

InactiveCN102248460ASimplify the complexity of the actionGuarantee the quality of grinding and polishingEdge grinding machinesPolishing machinesEngineeringTransfer mechanism

The invention relates to a crystal blank automatic grinding and polishing system. The system comprises a first rotating stand, a second rotating stand, a loading station, a butting station, an unloading station, at least one first transfer mechanism and at least one second transfer mechanism, wherein the first rotating stand is provided with an upper semi-sphere grinding station and a polishing station, and a nose is arranged on the first rotating stand; the second rotating stand is provided with a lower semi-sphere grinding station and a polishing station, and a nose is arranged on the second rotating stand; the first transfer mechanism can pick up and release a clamp, and can transfer the clamp among the feeding station, the butting station and the nose on the first rotating stand; and the second transfer mechanism can pick up and release the clamp, and can transfer the clamp among the butting station, the discharge station and the nose on the second rotating stand. The invention also discloses a grinding and polishing machine and an auxiliary machine used by the system. By utilizing the technical scheme, the upper and the lower semi-sphere inclined planes of a crystal blank canbe automatically ground and polished to ensure the quality of grinding and polishing processing, and the advantages of the machine models can be sufficiently utilized to simplify the complex degree of the mechanism action. The crystal blank automatic grinding and polishing system, the polishing machine and the auxiliary machine are easy to manufacture and maintain.

Owner:虞雅仙

Laser processing method and method for manufacturing light-emitting device

ActiveUS8722516B2Improve accuracyEfficient cuttingSemiconductor/solid-state device manufacturingFine working devicesLaser processingSingle crystal

A plurality of modified parts are formed at a first formation pitch for a line arranged along the M-plane of a single-crystal sapphire substrate to construct a modified region and cause a fracture occurring from the modified region to reach a principal surface of the single-crystal sapphire substrate. A plurality of modified parts are formed at a second formation pitch narrower than the first formation pitch for a line arranged along the A-plane of the single-crystal sapphire substrate to construct a modified region and cause a fracture occurring from the modified region to reach the principal surface of the single-crystal sapphire substrate. Along the lines, a knife edge is pressed against a wafer from the side of the single-crystal sapphire substrate opposite from the principal surface of the single-crystal sapphire substrate where the fractures have reached, to cut the wafer along the lines.

Owner:HAMAMATSU PHOTONICS KK

High-efficiency heat-dissipating luminous high-power LED packaging structure

InactiveCN101436637AImprove thermal conductivityGood light transmissionSemiconductor devicesNegative luminescenceLuminous flux

The invention relates to a high-power LED packaging structure which radiates heat and illuminates efficiently and comprises a lens, a substrate and an LED luminous chip, wherein the lens is fixed on the upper surface of the substrate; the lower surface of the lens is provided with a raised mounting dent; the LED luminous chip is arranged on the upper surface of the substrate and is buckled and covered by the mounting dent; the upper surface of the substrate buckled and covered by the mounting dent is provided with a positive luminescence electrode and a negative luminescence electrode; the luminous electrodes are connected with the LED luminous chip through metal wires; the upper surface of the substrate is provided a positive connecting electrode and a negative connecting electrode which are connected with the luminous electrodes; the lower surface of the lens on the outer side of the mounting dent and the upper surface of the substrate are adhered through an annular adhesive layer; and a cavity formed by inner holes of the adhesive layer and the mounting dent is filled with silica gel; The substrate is provided with a gel-filling passage which is communicated with the cavity formed by inner holes of the adhesive layer and the mounting dent; and the lens and the substrate are made from quartz crystal. The high-power LED packaging structure has the advantages of high luminous flux, high led-out heat source, simple and practical structure and the like.

Owner:王海军

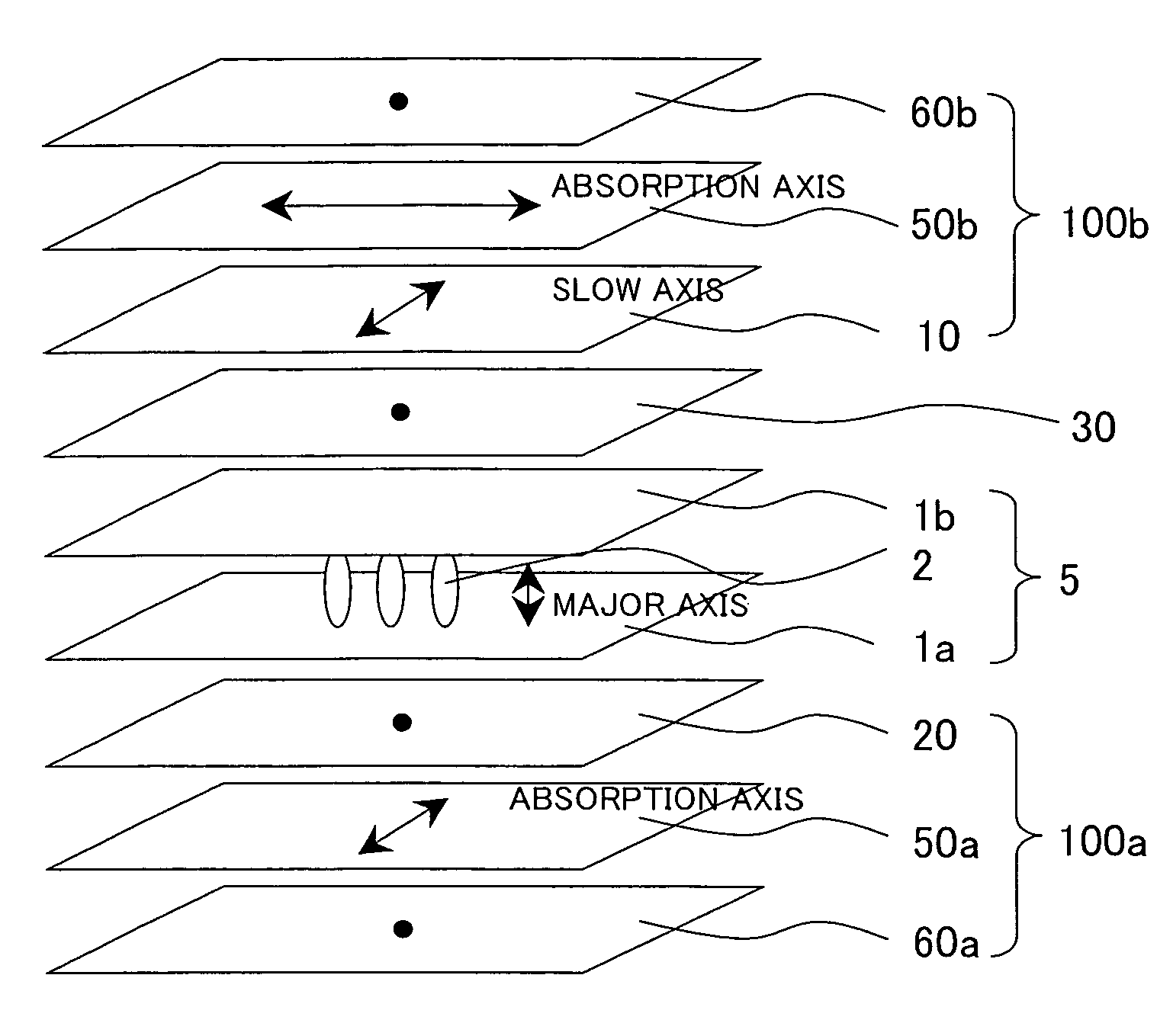

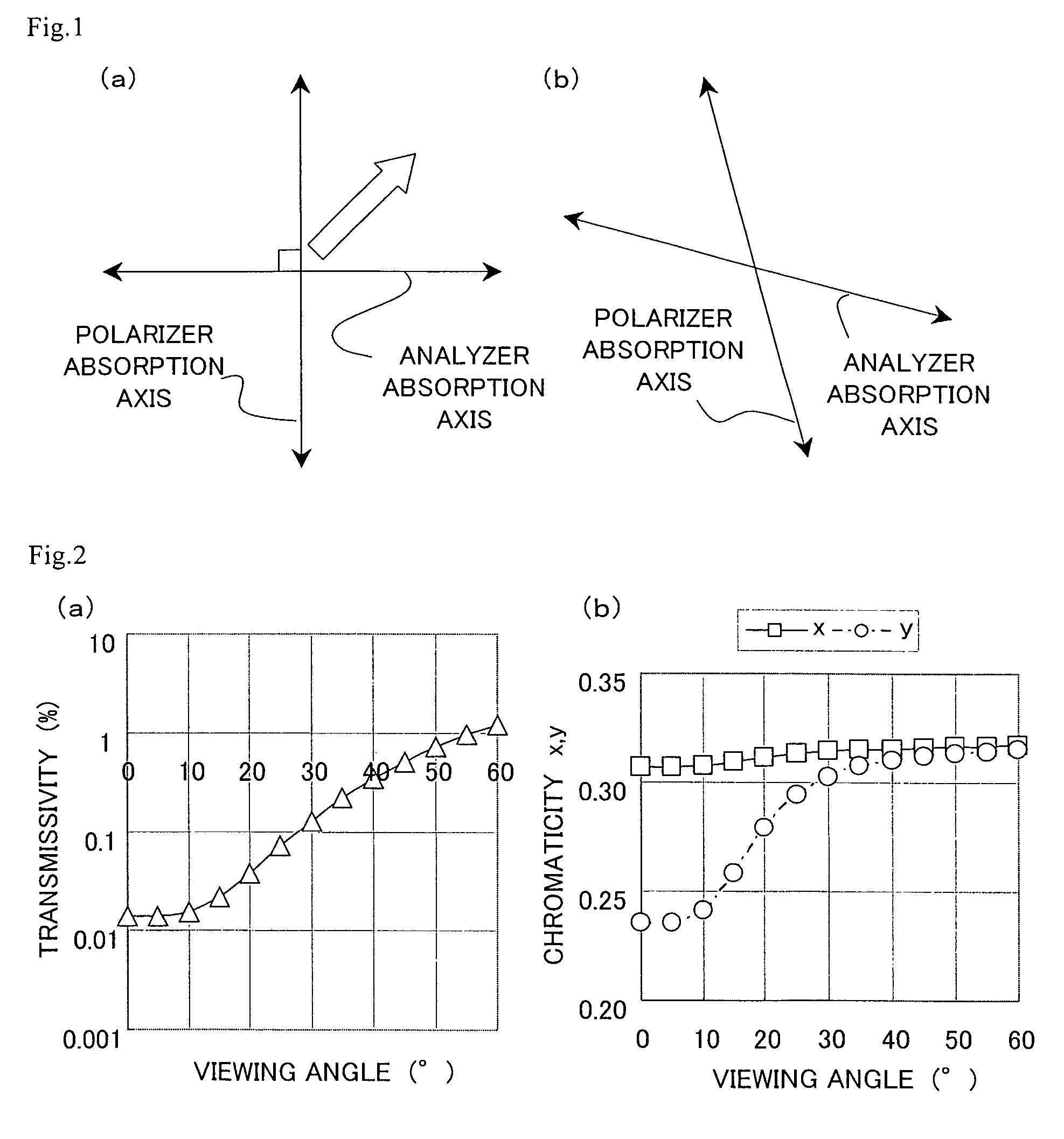

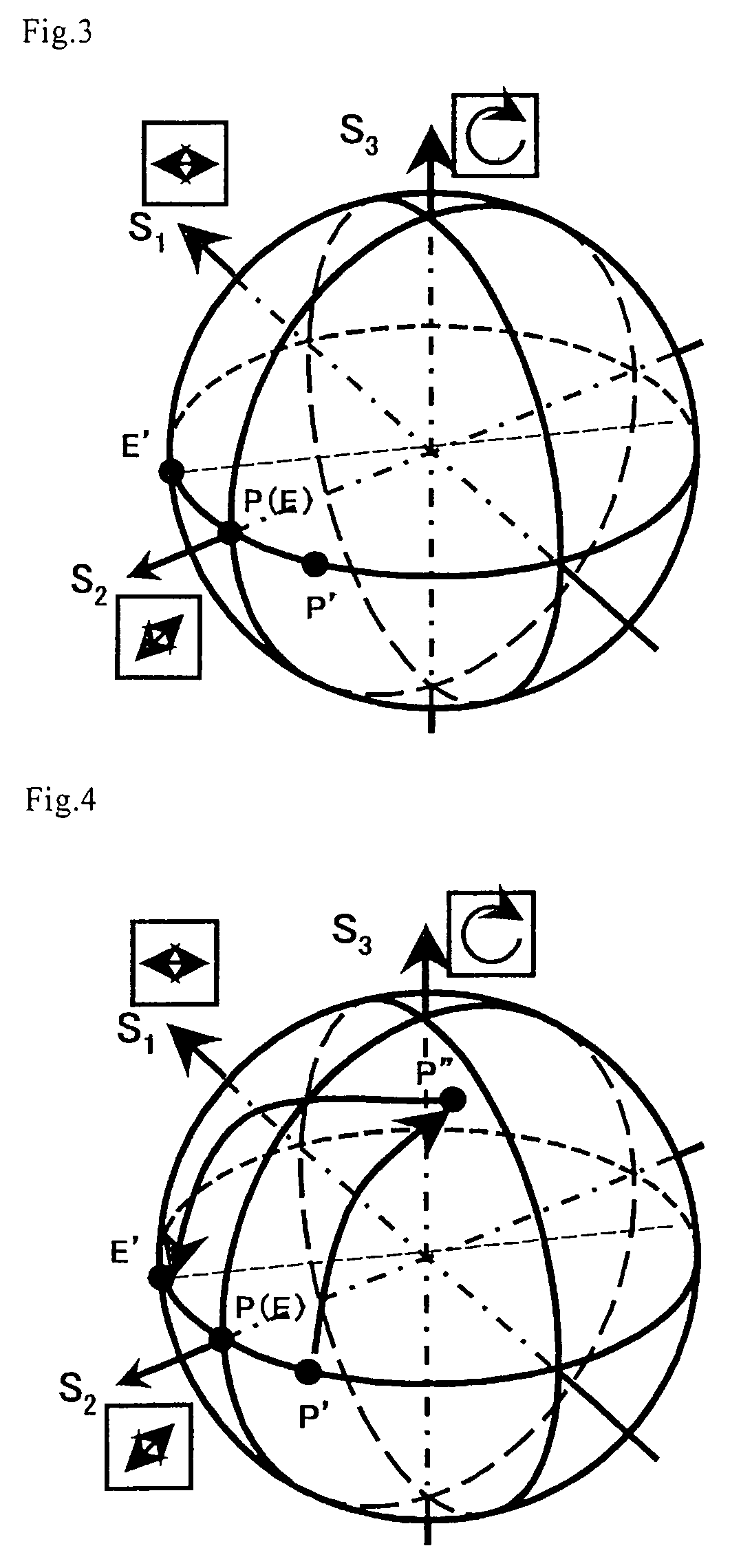

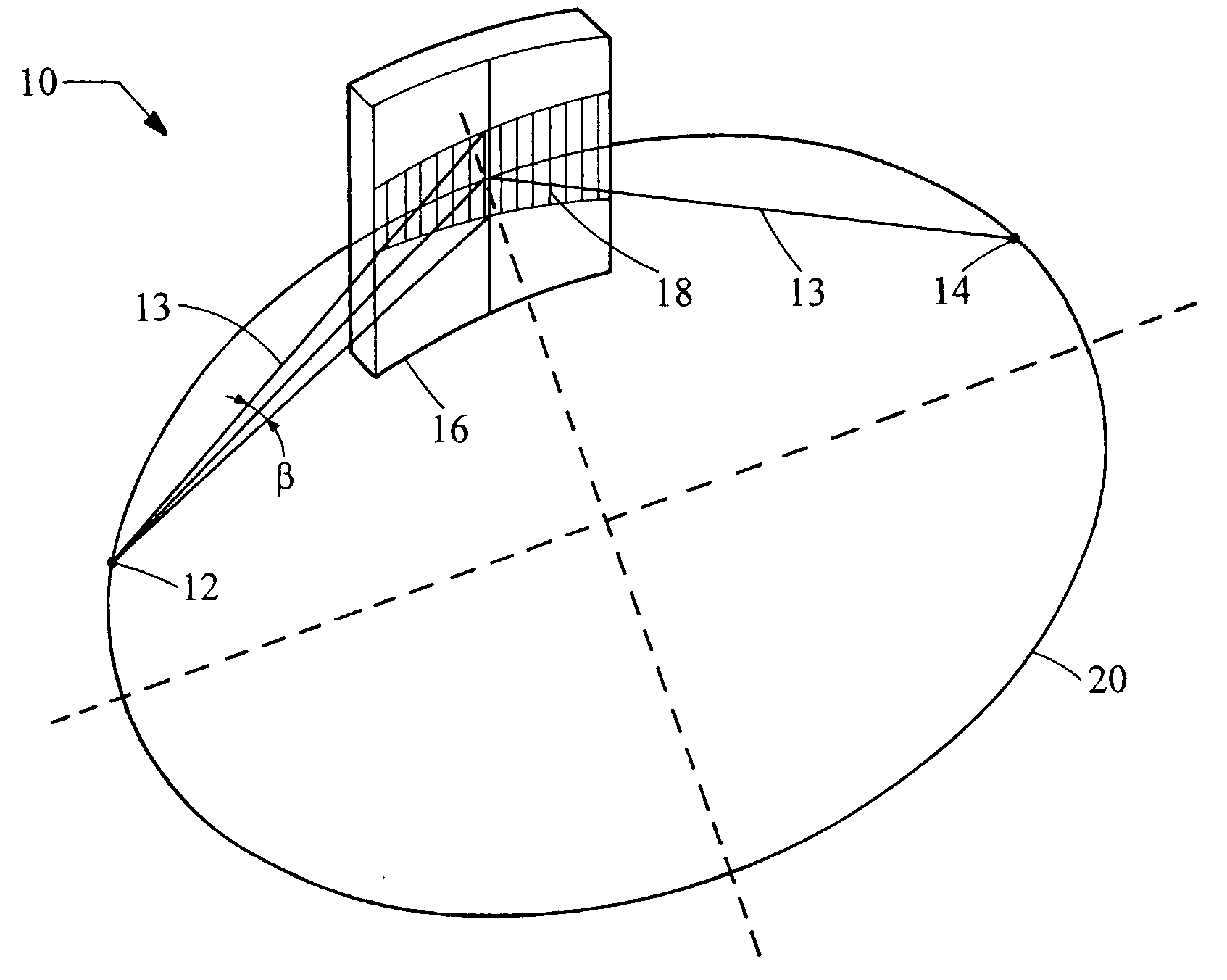

Retardation film, polarizing film, liquid crystal display, and method of designing retardation film

ActiveUS7948591B2Wide viewing angleImprove display qualityPolarising elementsThin material handlingCrystallographyDisplay device

To provide a retardation film in which the retardation condition is adjusted to achieve a liquid crystal display without coloration over a wide viewing angle range and having a high contrast ratio, and a method of designing the same, as well as a polarizing film and a liquid crystal display using the same. A liquid crystal display comprising a liquid crystal cell and polarizing films in a Cross-Nicol relationship with each other on both sides of the liquid crystal cell; wherein at least one polarizing film includes a retardation film having reverse wavelength dispersion property; and the liquid crystal display further includes a retardation film having a wavelength dispersion property substantially the same as a liquid crystal layer configuring the liquid crystal cell.

Owner:SHARP KK

Beam conditioning system

ActiveUS20050025281A1NanoinformaticsHandling using diffraction/refraction/reflectionLight beamOptoelectronics

The present invention provides an x-ray beam conditioning system with a Kirkpatrick-Baez diffractive optic including two optical elements, of which one of the optical elements is a crystal. The elements are arranged in a side-by-side configuration. The crystal can be a perfect crystal. One or both diffractive elements can be mosaic crystals. One element can be a multilayer optic. For example, the multilayer optic can be an elliptical mirror or a parabolic mirror with graded d-spacing. The graded d-spacing can be either lateral grading or depth grading, or both.

Owner:OSMIC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com