Adapter assembly of polishing and burnishing machine for decorations

A technology for adapter components and grinding and polishing machines, which is applied to grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., which can solve the problems of complex machine structure, high labor intensity, and low production efficiency, and achieve The effect of improving production efficiency, increasing the degree of automation, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

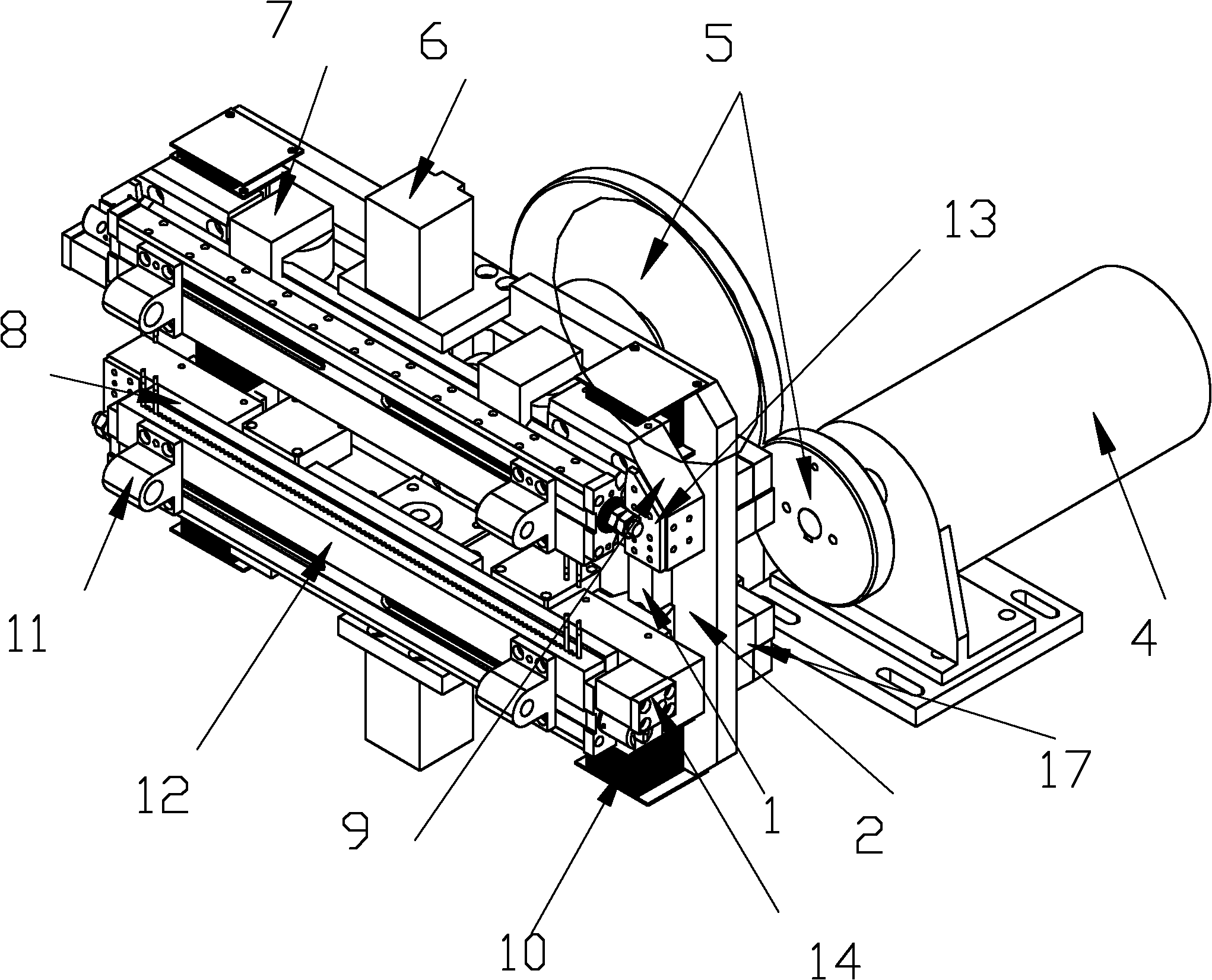

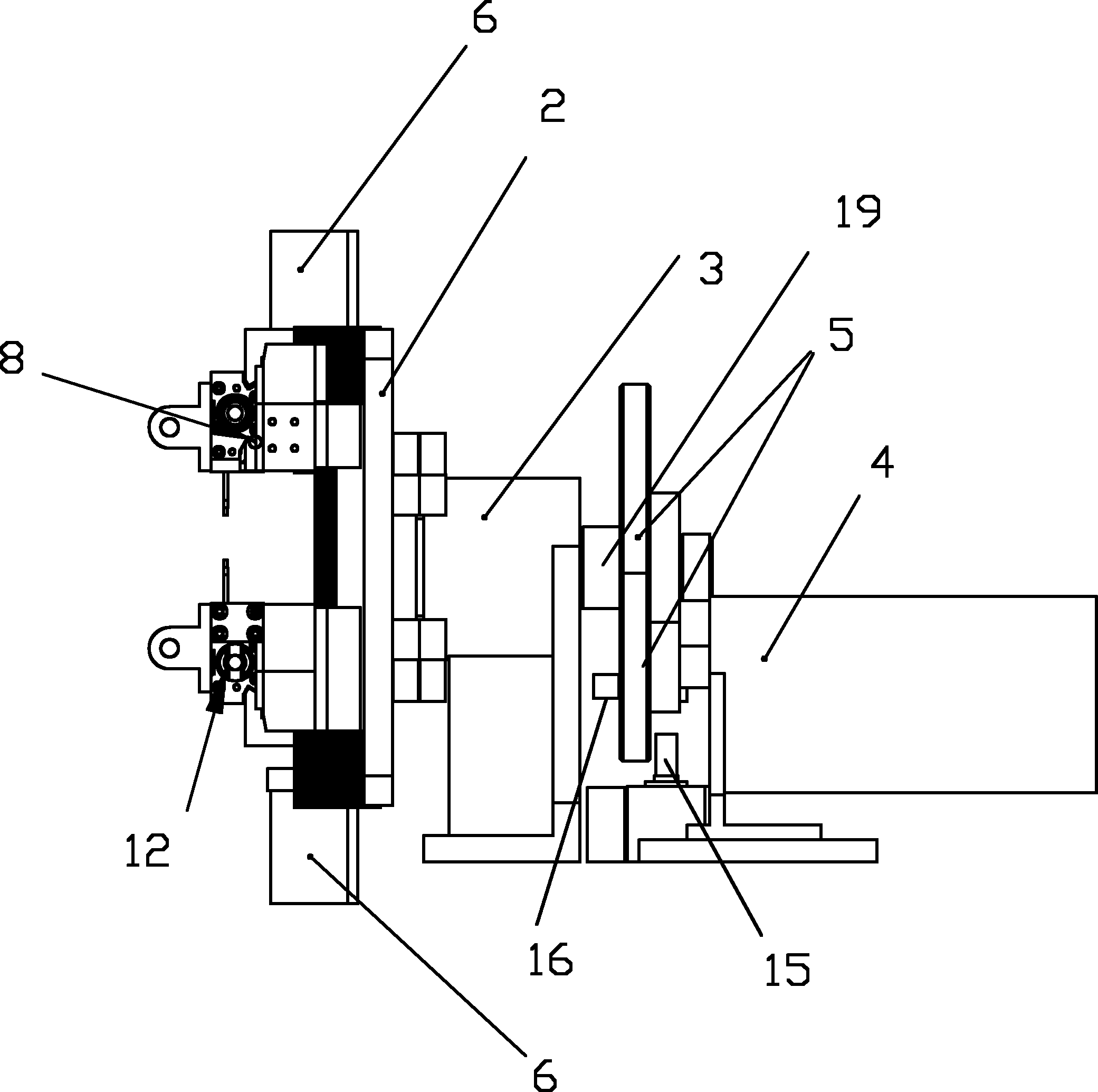

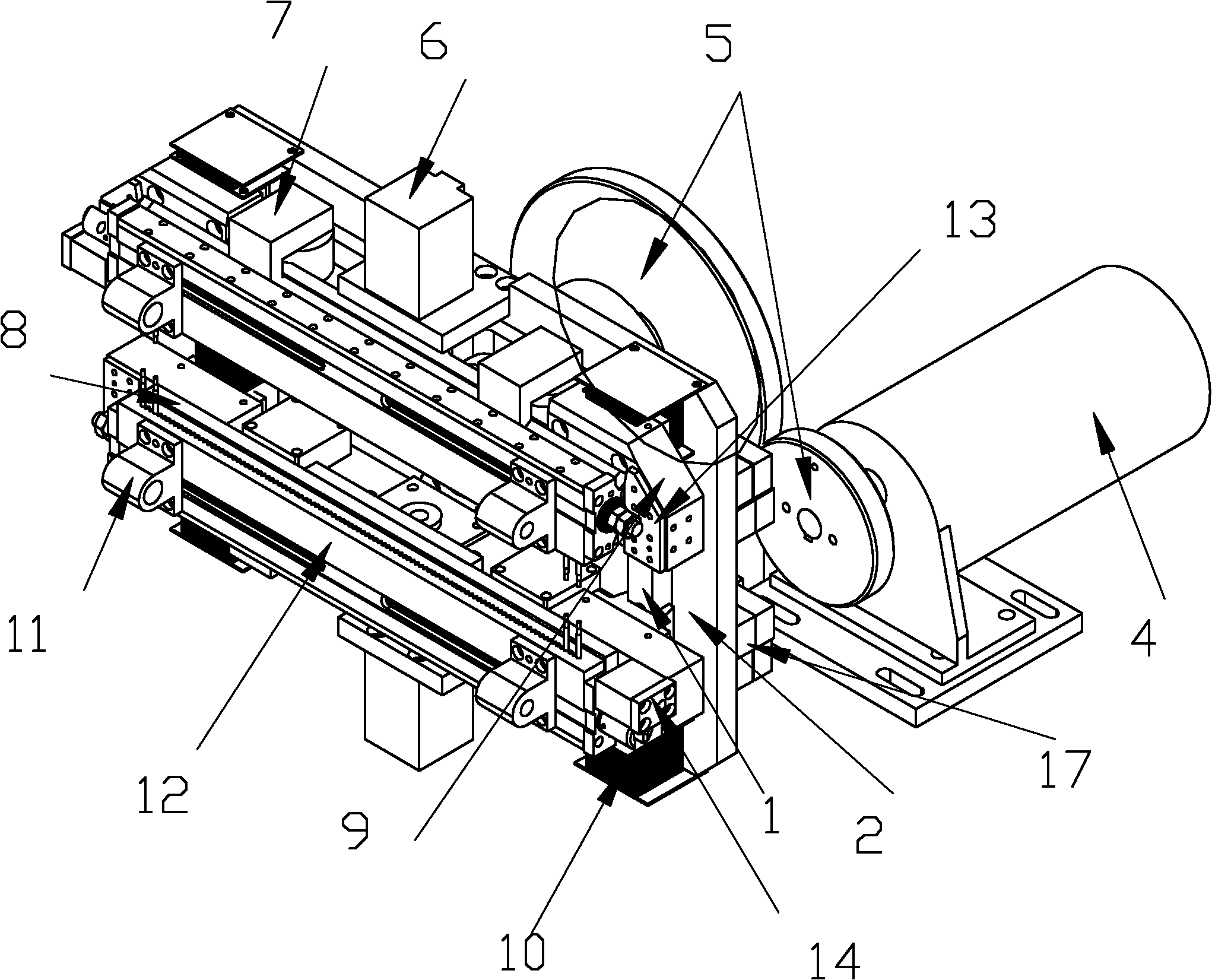

[0022] The adapter assembly of the jewelry grinding and polishing machine of the present invention includes: an adapter plate 2 is placed on one side of the adapter seat 3, the adapter plate is connected with the reduction gear 5 through the central shaft 19, the reduction gear is connected with the reduction motor 4, and the adapter plate The slider guide rail 1 is installed; the upper and lower sets of lifting components are installed on the adapter plate. The lifting component includes a fixture positioning block 9 that is movably connected on the slider guide rail and can slide along the slider guide rail, and can push the fixture positioning block on the slide. The clamp positioning block lifting cylinder 6 that is arranged on the adapter plate near the end that moves on the block guide rail. The fixture positioning block is provided with the fixture positioning groove 8 for installing the fixture 12 . A rotary clamping cylinder 7 is also arranged on the fixture positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com