A flux-cored wire for soldering diphasic stainless steel

A technology of duplex stainless steel and flux-cored welding wire, applied in welding medium, welding equipment, welding/cutting medium/material, etc., to achieve the effect of fine spatter particles, good pitting corrosion resistance and less spatter particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

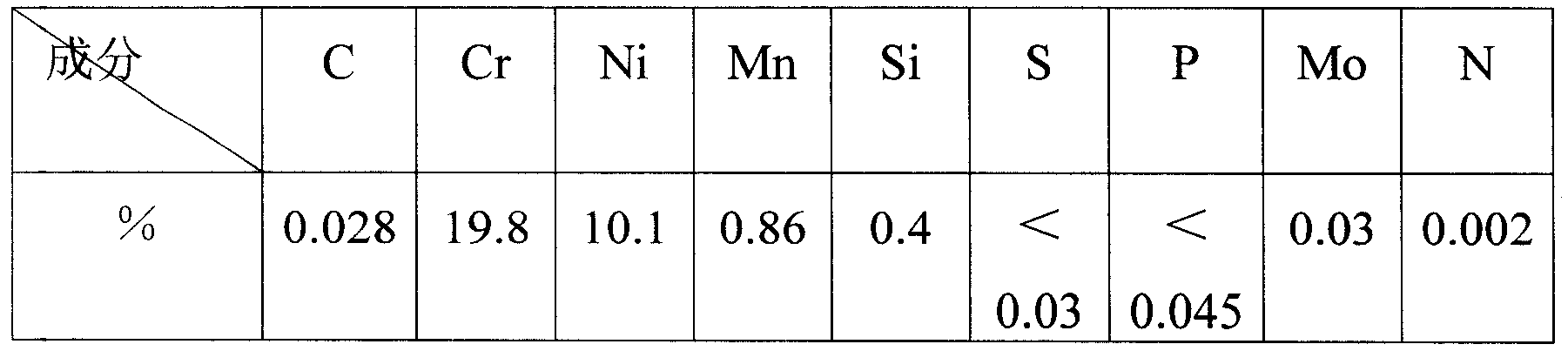

[0030] All the welding wires in the examples are produced by the "FCWM50 Flux Core Wire Drawing Machine" manufactured by Kunming Heavy Machinery Factory: 304L austenitic stainless steel strips with a width of 8-12mm and a thickness of 0.25-0.5mm are selected. First roll it into a U shape, and then add mixed medicinal powder with a particle size of 80 mesh sieves into the U-shaped groove, and the filling rate of the medicinal powder is 17-24%. Close the U-shaped groove so that the powder is wrapped in it.

[0031] The specific implementation plan is as follows:

[0032] 1. Use 8×0.25 (width 8mm, thickness 0.25mm) 304L stainless steel strip. Roll it into a U shape first. Get 35 grams of metallic chromium powder, 13 grams of metallic molybdenum powder, 3 grams of metallic nickel powder, 5 grams of metallic manganese powder, 4 grams of aluminum-magnesium alloy powder, 1 gram of ferrosilicon powder, 5 grams of quartz powder, 0 gram of zircon powder, Feldspar powder 4 grams, rutile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com