High-efficiency heat-dissipating luminous high-power LED packaging structure

A LED packaging, high-power technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reduced light output, increased chip temperature, and accelerated light attenuation of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

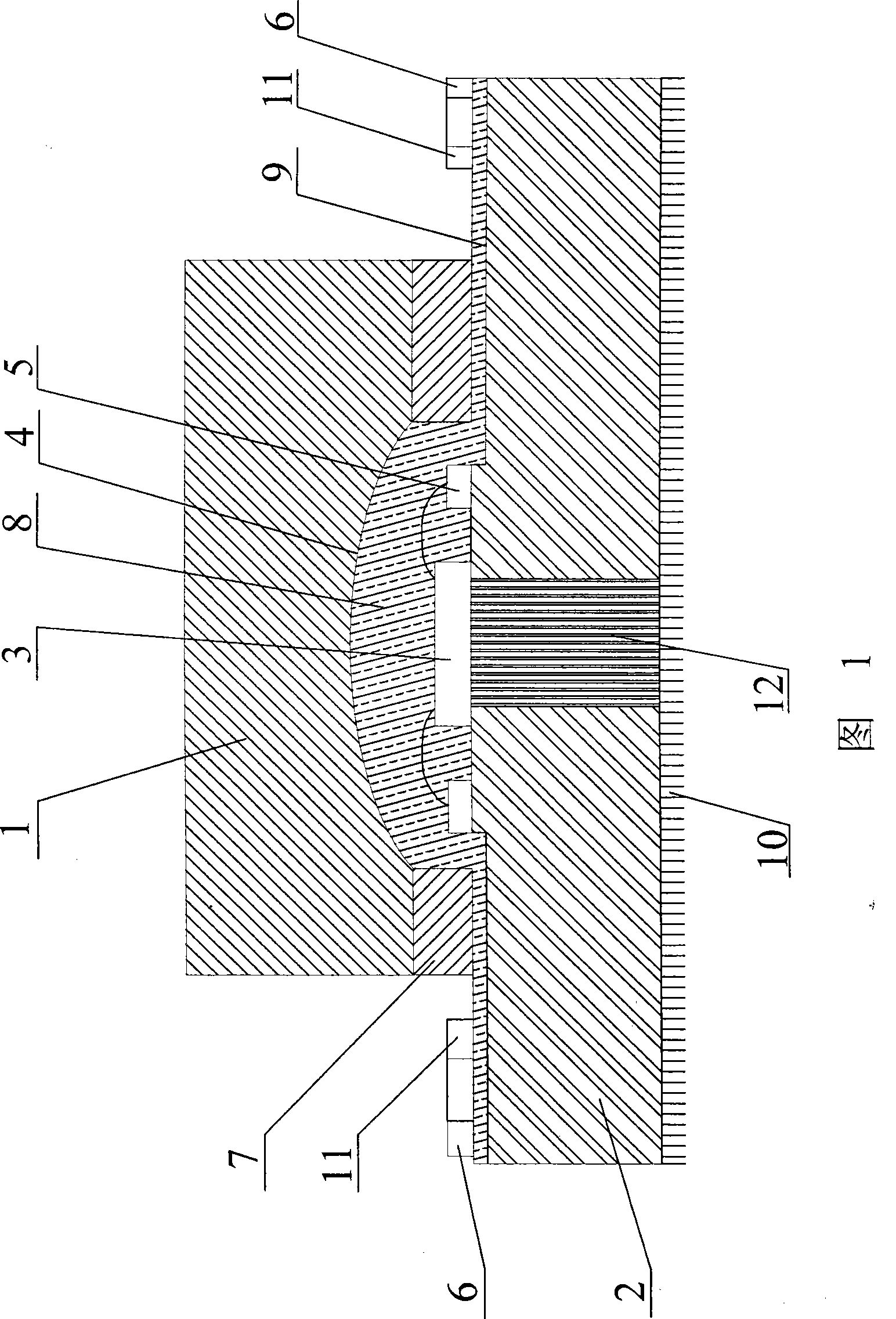

[0042] The lens 1 is a cuboid plate with a length of 3-10mm, a width of 2-9mm and a thickness of 1-5mm. In the crystal crystal lens 1, there is a mounting recess 4 in the center of the body of the lens 1, and the outer diameter of the mounting recess 4 is based on the standard not greater than the body of the lens 1. This mounting recess 4 is used to place the LED light-emitting chip 3, and During the encapsulation process, it is used to inject the cavity of silica gel 8.

[0043] The substrate 2 is a plate body of 3-14mm, 2-9mm wide, and 1-10mm thick. On the body of the crystal crystal substrate 2, there are different positive and negative light-emitting electrodes 5 formed on the substrate 2 according to different needs. The negative light-emitting electrode 5 is an electrode connected to the LED light-emitting chip 3. There are positive and negative connection electrodes 6 connected to the external power supply on the body of the crystal crystal substrate 1, and the electri...

Embodiment 2

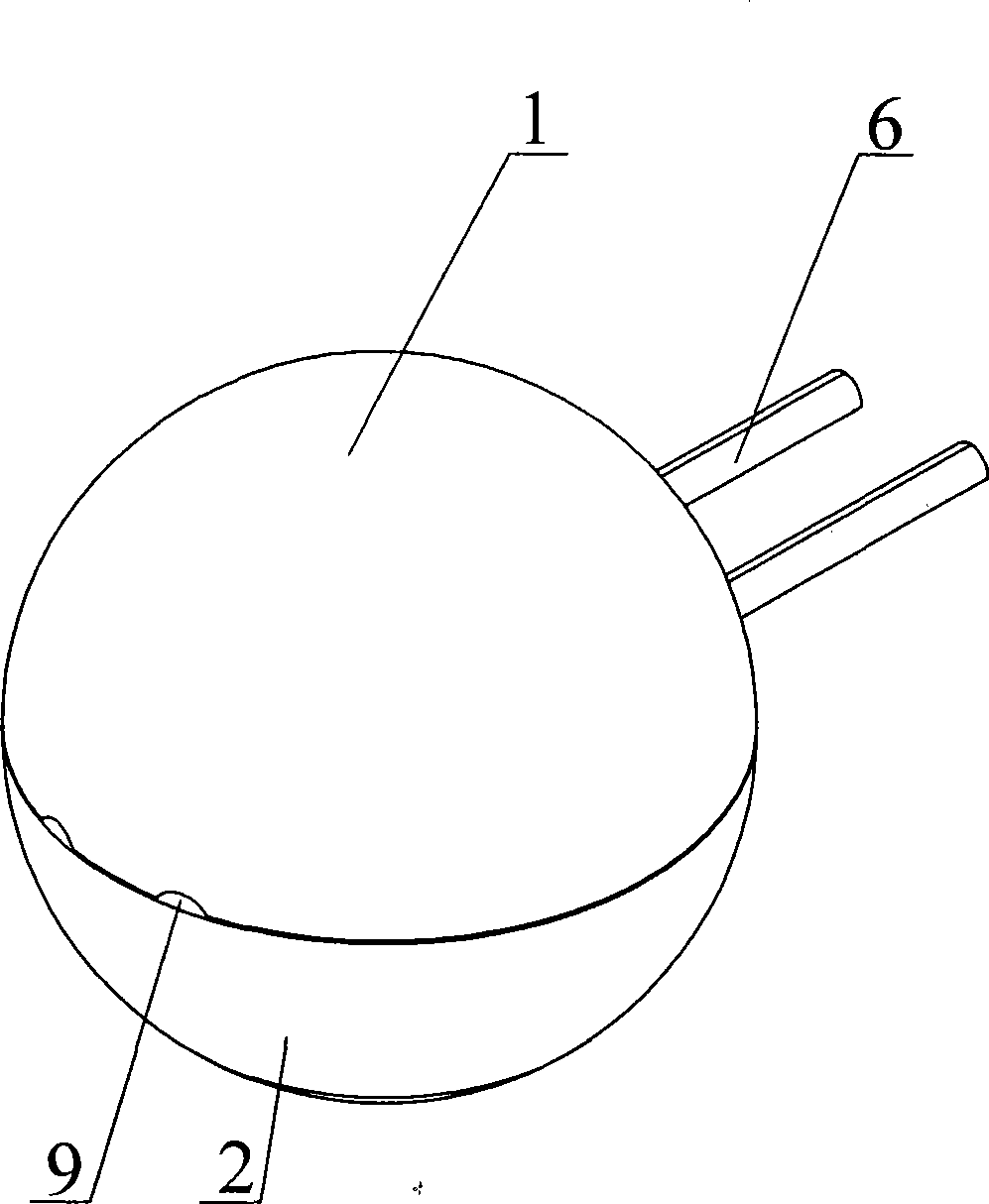

[0047] Both the lens 1 and the substrate 2 are hemispherical, and two ditches are opened on the upper surface of the substrate 2 through its body, and the ditch on one side of the LED light-emitting chip 3 forms a glue filling channel 9, and the ditch on the other side of the LED light-emitting chip 3 is formed to facilitate The foot-like connection is the channel into which the electrode 6 is inserted.

[0048] According to the above packaging scheme, the shape of the crystal substrate and the crystal lens 1 can be a hemisphere, and the plane of the hemisphere used as the substrate 2 has a light-emitting electrode 5 . Where the light-emitting electrode 5 is connected to the external power supply, there is a concave ditch according to the connection electrode 6, which is used as an insertion hole for connecting the legs with the external power supply, and this group of ditch is parallel to both sides of the LED light-emitting chip 3. The appearance of the crystal lens is a hem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com