Patents

Literature

62results about How to "Reduce defect concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for reducing defect concentration in crystals

ActiveUS20060096521A1Reduce defect concentrationRelieve pressureAfter-treatment detailsUltra-high pressure processesDiamond crystalHigh pressure cell

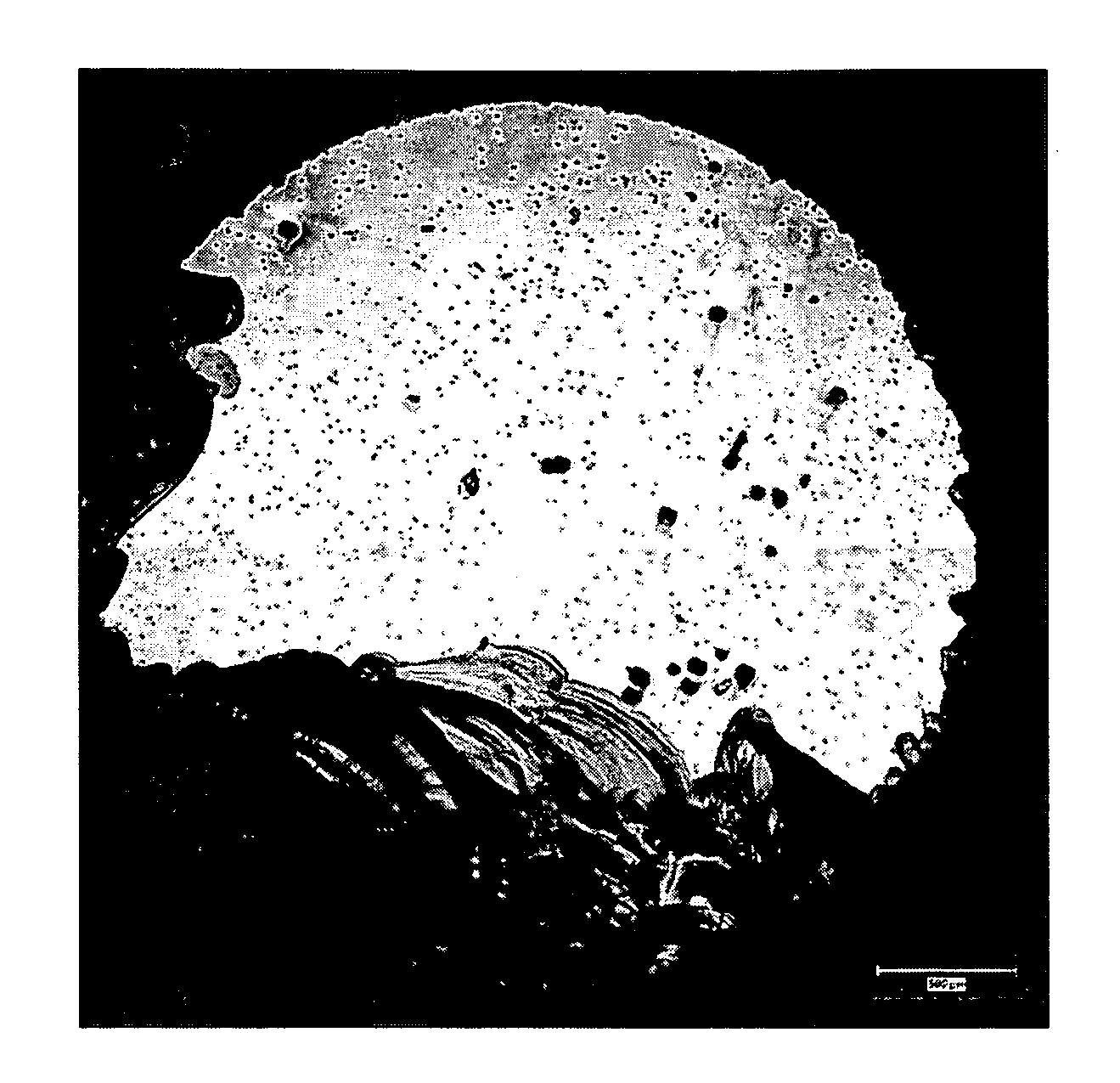

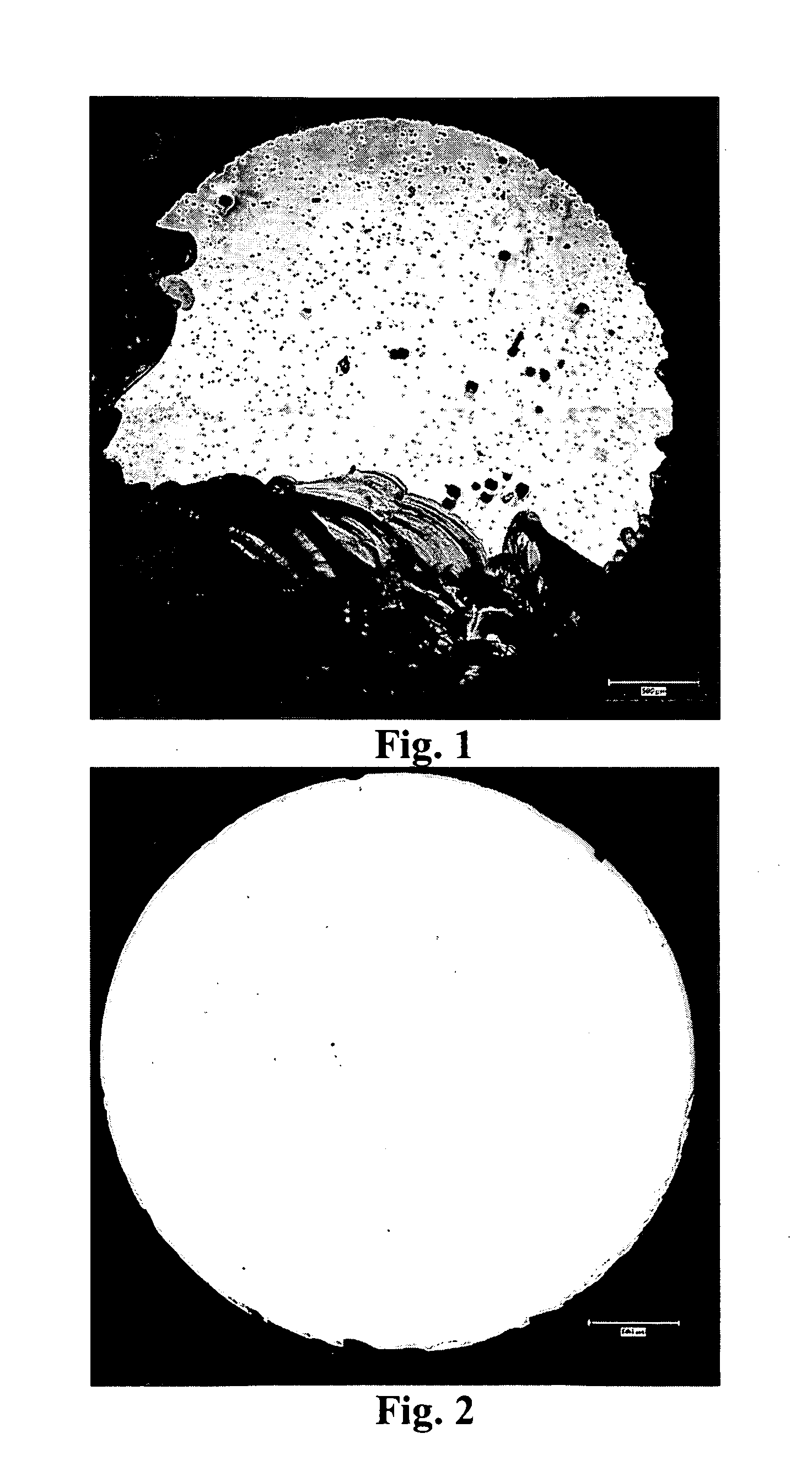

A method for removing defects at high pressure and high temperature (HP / HT) or for relieving strain in a non-diamond crystal commences by providing a crystal, which contains defects, and a pressure medium. The crystal and the pressure medium are disposed in a high pressure cell and placed in a high pressure apparatus, for processing under reaction conditions of sufficiently high pressure and high temperature for a time adequate for one or more of removing defects or relieving strain in the single crystal.

Owner:SLT TECH

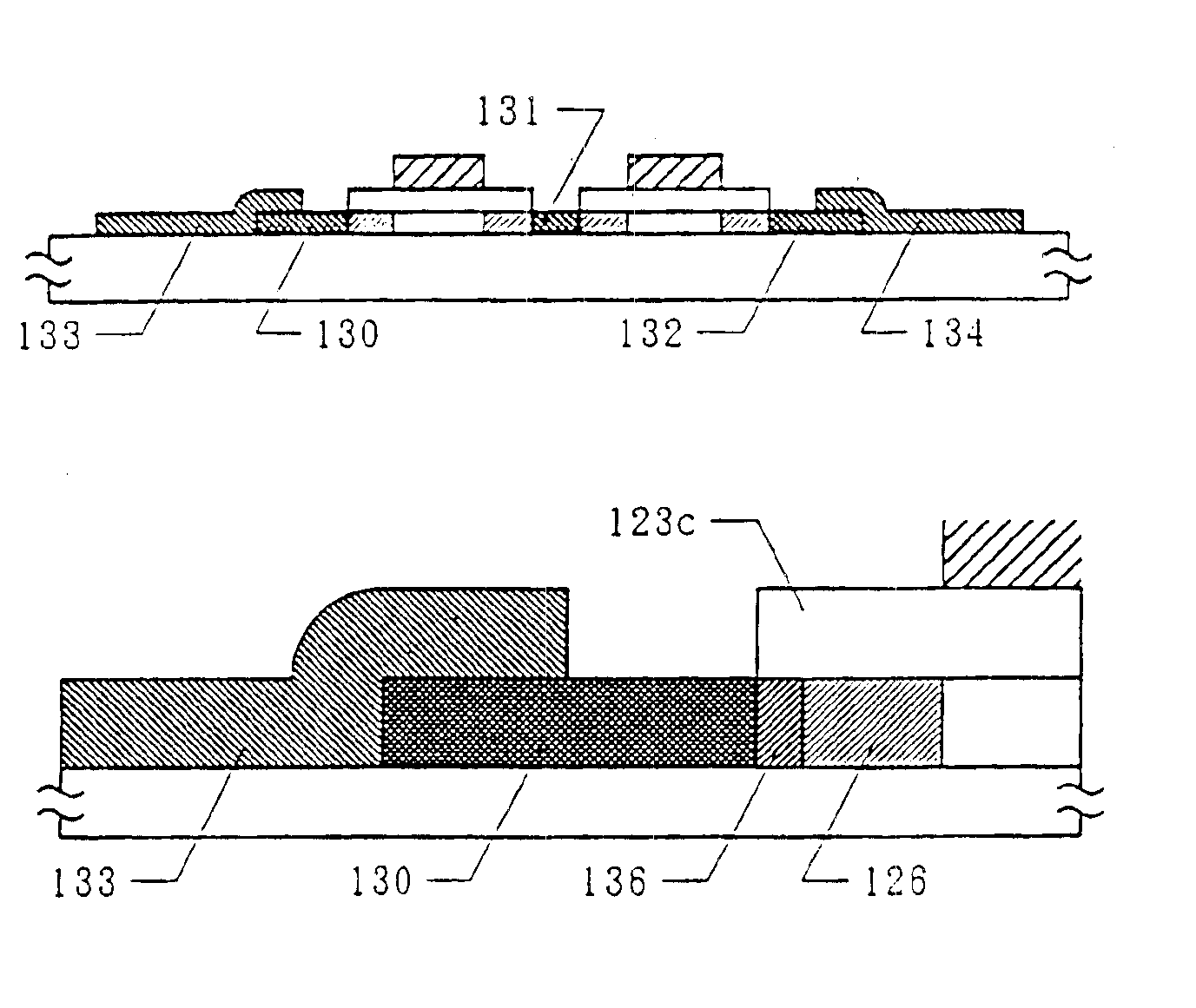

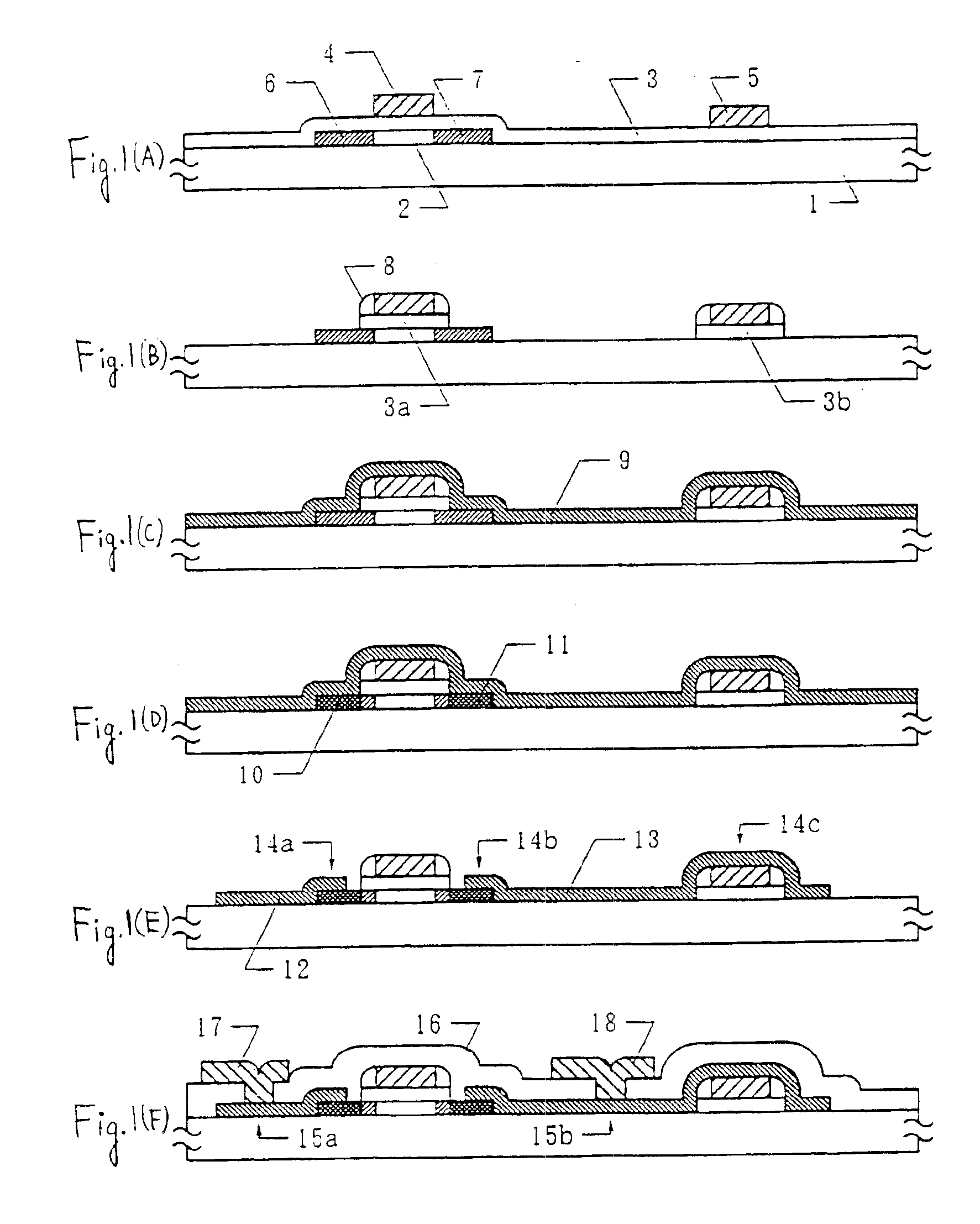

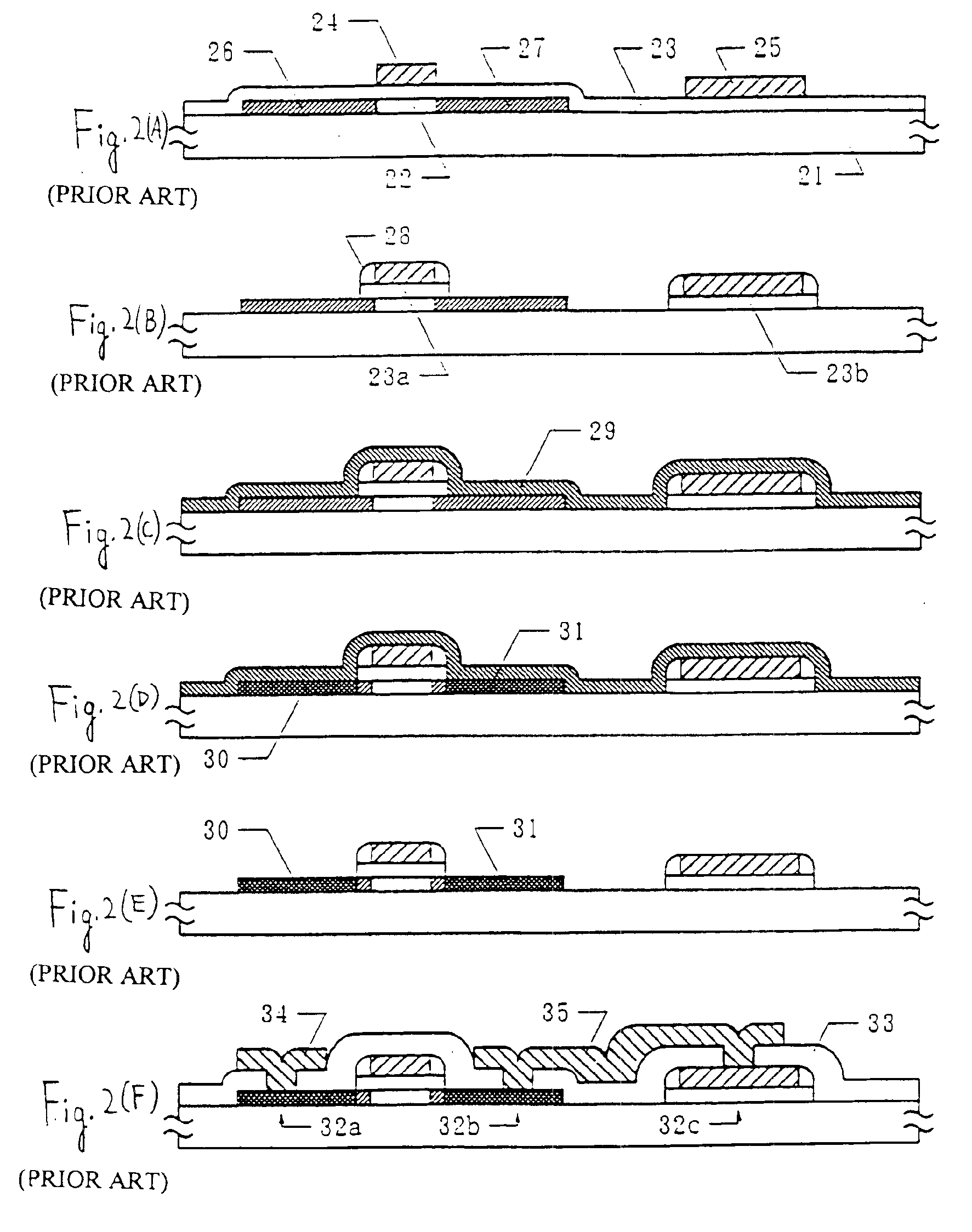

Semiconductor device that include silicide layers

InactiveUS6882018B2Increase contactEffective preventionTransistorSemiconductor/solid-state device detailsContact padSemiconductor

Owner:SEMICON ENERGY LAB CO LTD

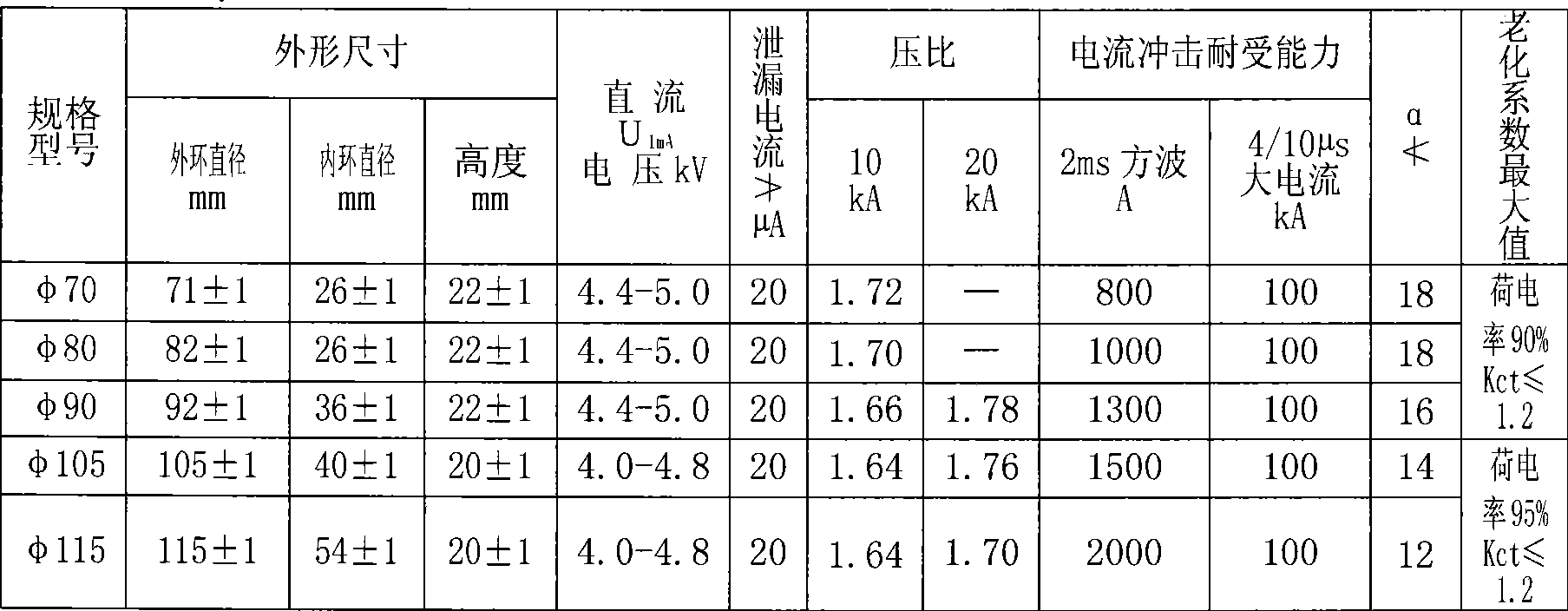

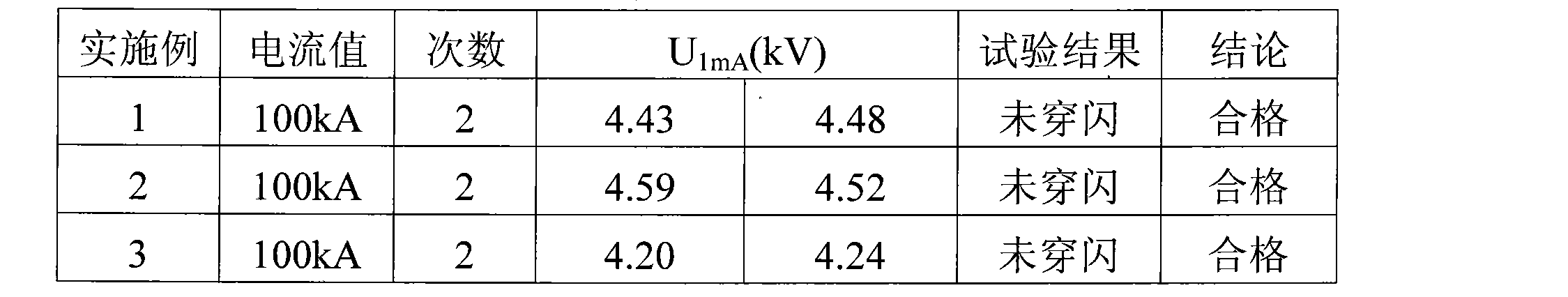

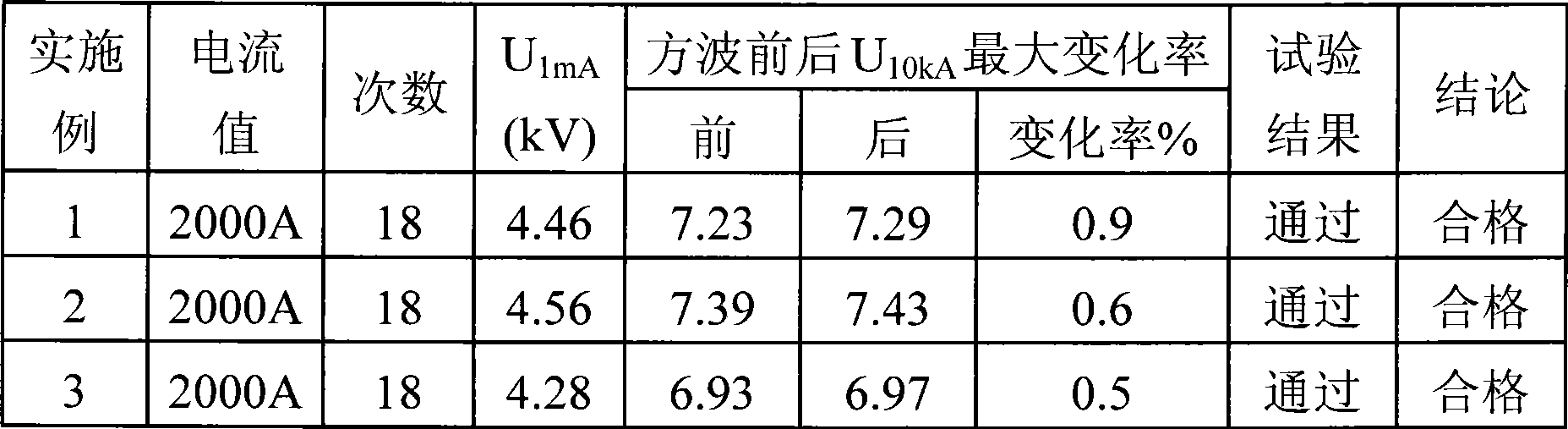

Formula of direct current zinc oxide resistance chip

ActiveCN101503292AUniform and stable structureReduce defect concentrationVaristor coresSesquioxideAntimony trioxide

The invention discloses a formulation of an AC zinc oxide resistance chip. The formulation is characterized by comprising the following additives and a main material ZnO by weight percentage: 4.0 to 4.9 percent of Bi2O3, 3.0 to 4.0 percent of Sb2O3, 0.5 to 1.0 percent of SiO2, 2.0 to 3.0 percent of Co2O3, 0.50 to 0.80 percent of Cr2O3, 0.50 to 0.80 percent of MnCO3, 0.70 to 0.90 percent of NiO, 0.03 to 0.05 percent of aluminum nitrate, 0.10 to 0.20 percent of glass dust, 0.07 to 0.10 percent of B2O3 and 85.0 to 88.0 percent of ZnO. The formulation of the resistance chip has the following characteristics and advantages: the nickel protoxide and the glass dust are introduced into the formulation, so that the stability and the aging performance of the internal structure of the resistance chip is more excellent; and 2, dosage of cobalt sesquioxide, dibismuth trioxide and diantimony trioxide are added in the formulation, the mixture ratio of each composition is more reasonable, and the non-linearity coefficient of the resistance chip can be improved, the pressure ratio is reduced, the circulation capability is improved, and the comprehensive performance is excellent.

Owner:FUSHUN ELECTRIC PORCELAIN MFG CO LTD

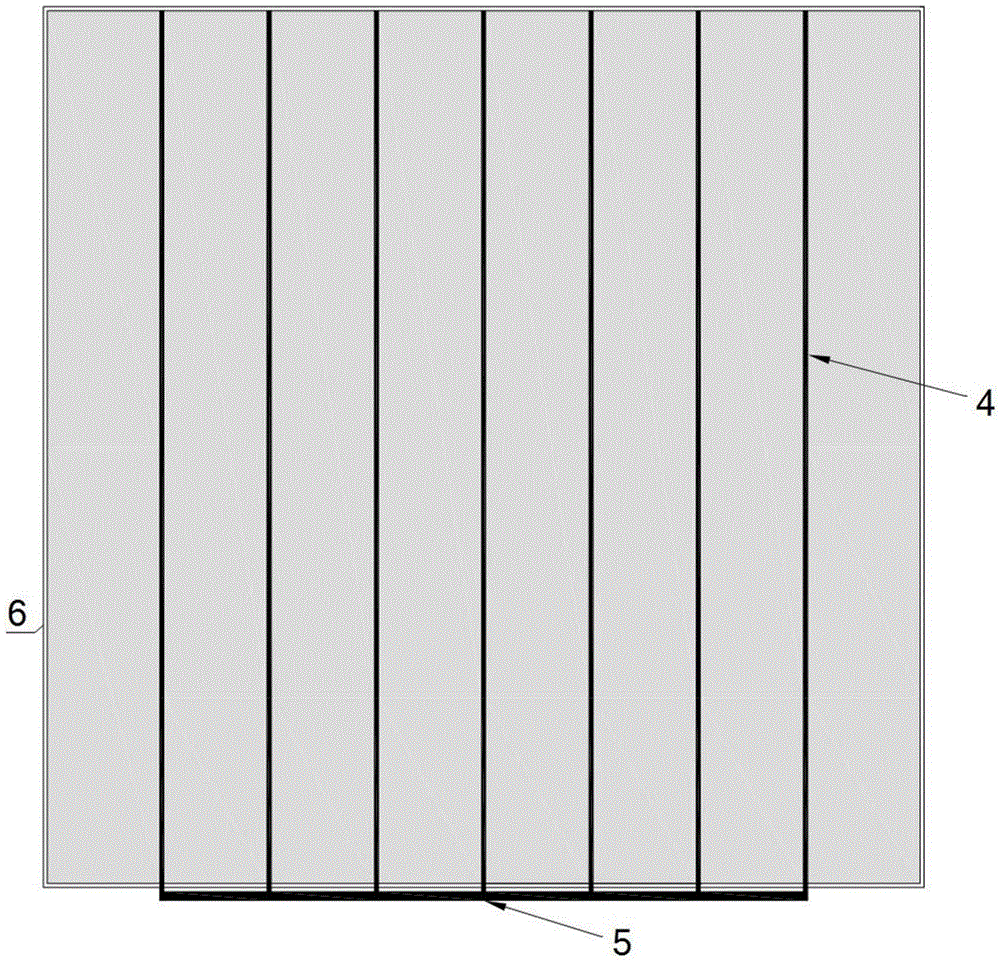

Perovskite type solar cell with sputtering ZnO as electron transfer layer and preparation

InactiveCN104319349APreferred c-axis orientationReduce defect concentrationSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsHole transport layer

The invention provides a perovskite type solar cell with sputtering ZnO as an electron transfer layer and preparation and relates to solar cells. The perovskite type solar cell is provided with a transparent conducting glass substrate, the ZnO electron transfer layer, a perovskite type material layer, a hole transfer layer and a metal back electrode layer from bottom to top in sequence. The preparation comprises the steps that the transparent conducting glass substrate is preprocessed, a ZnO thin film is prepared on the transparent conducting glass substrate, and heating and annealing are conducted, in other words, the ZnO electron transfer layer is sputtered; a DMF solution of PbI2 is prepared, the ZnO electron transfer layer is coated with the DMF solution of the PbI2 in a spinning mode to prepare a PbI2 thin film, the PbI2 thin film is then steeped into an isopropanol solution of CH3NH3I, and thus the perovskite type material layer is obtained; 2,2',7,7'-Tetrakis[N,N-di(4-methoxyphenyl)amino]-9,9'-spirobifluorene, an acetonitrile solution of lithium bis(trifluoromethanesulphonyl)imide and 4-tert-butylpyridine are dissolved in a chlorobenzene solution, the perovskite type material layer is then coated with the solution in a spinning mode, the hole transfer layer is obtained, then the metal back electrode layer is obtained, and the perovskite type solar cell is obtained.

Owner:昆山惟华光能有限公司

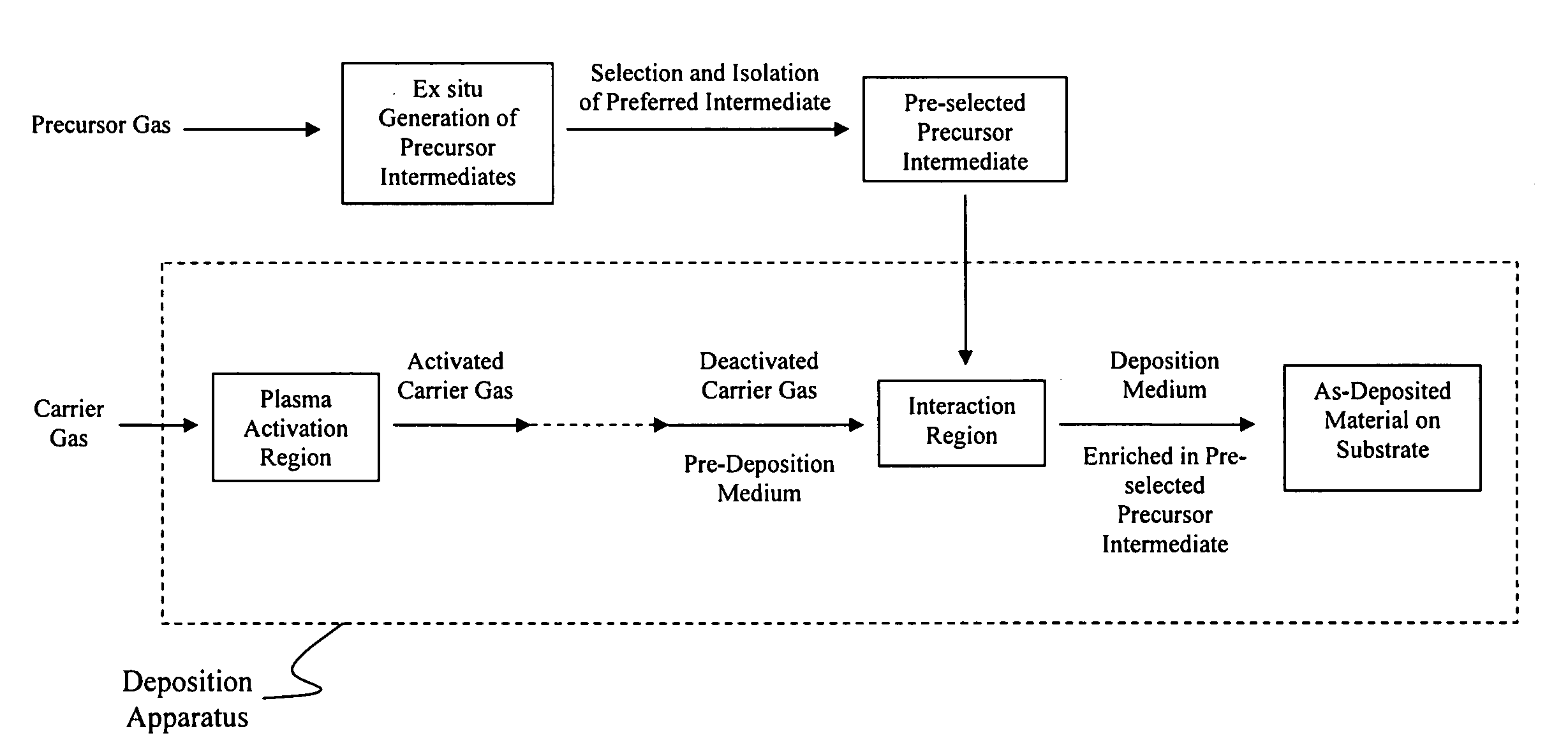

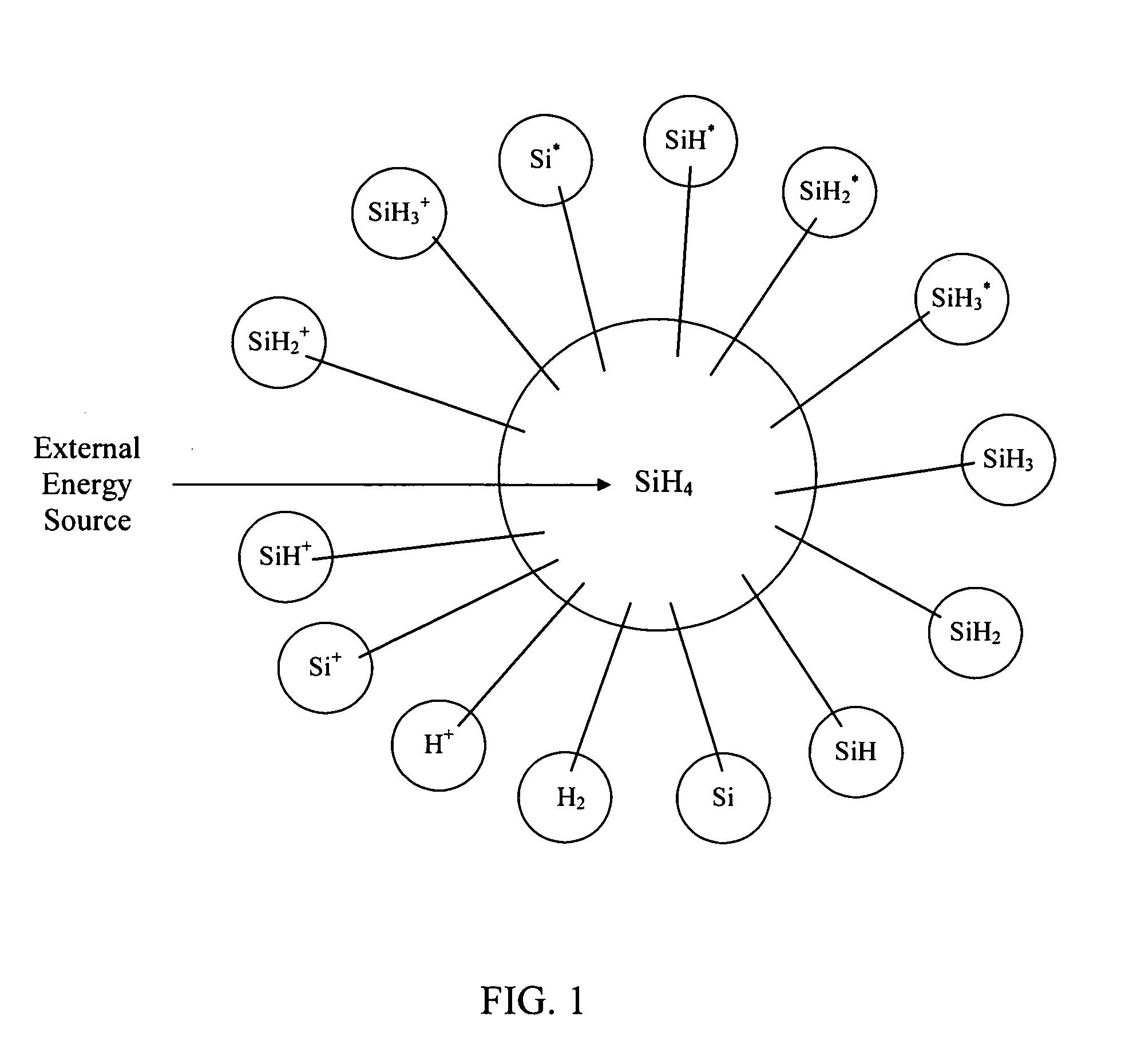

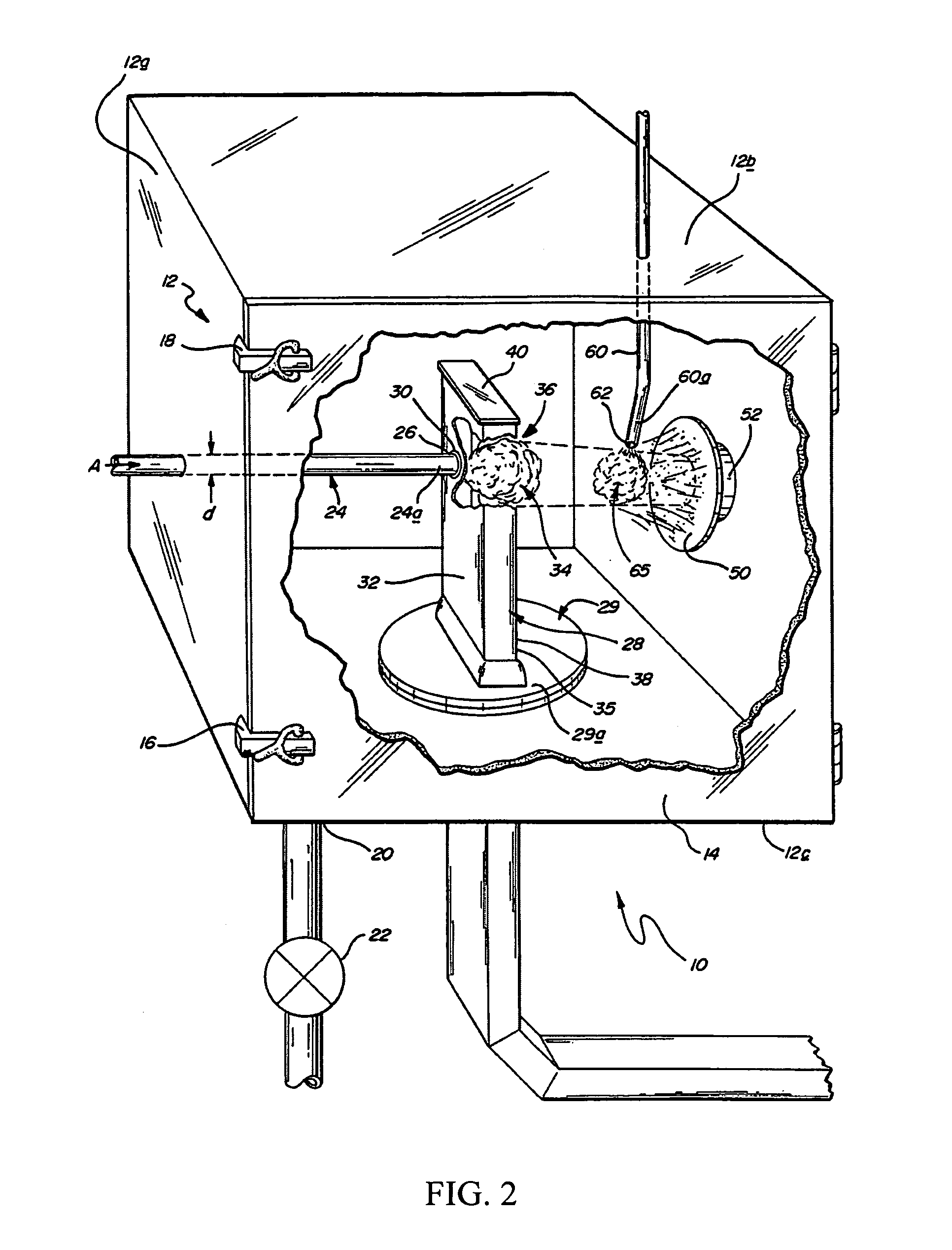

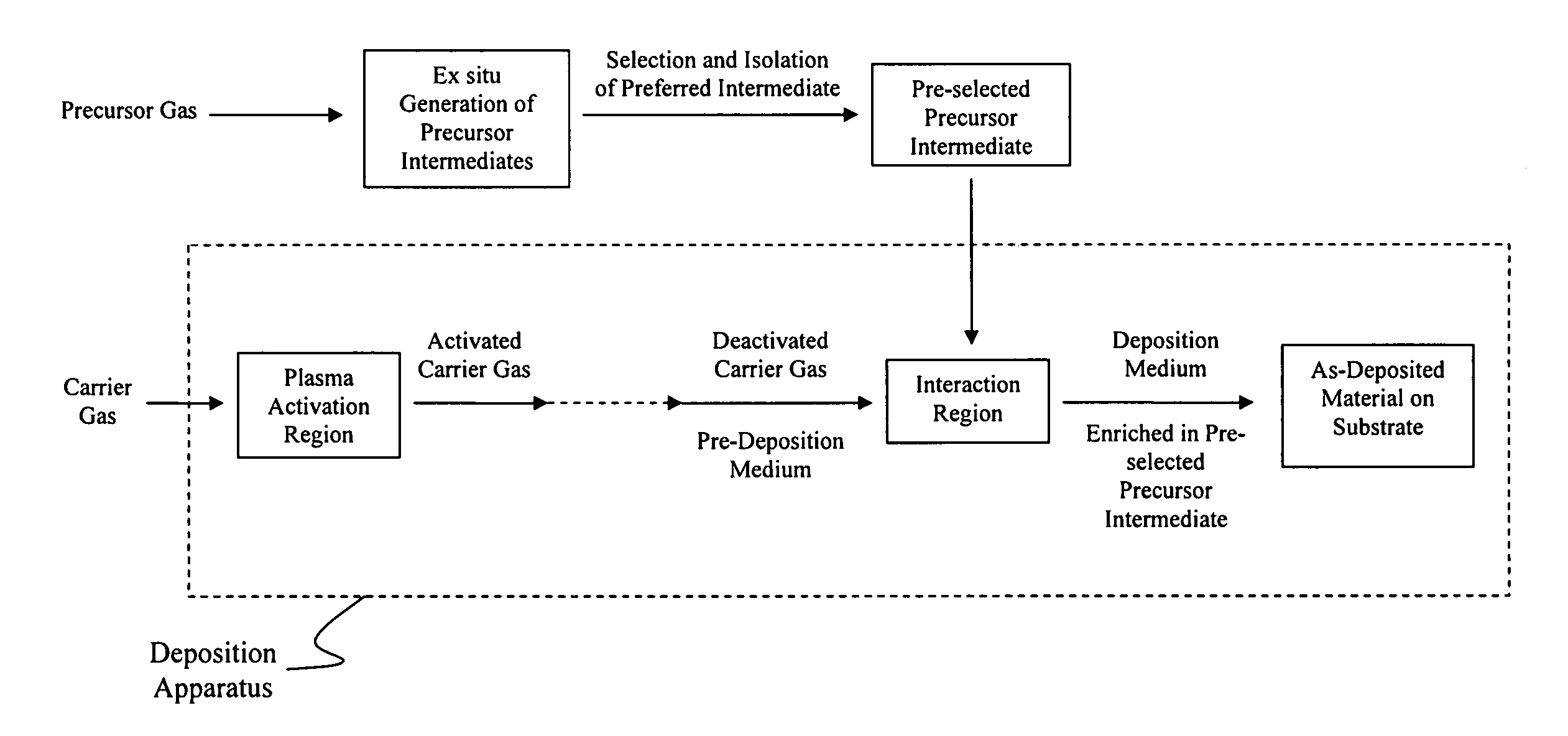

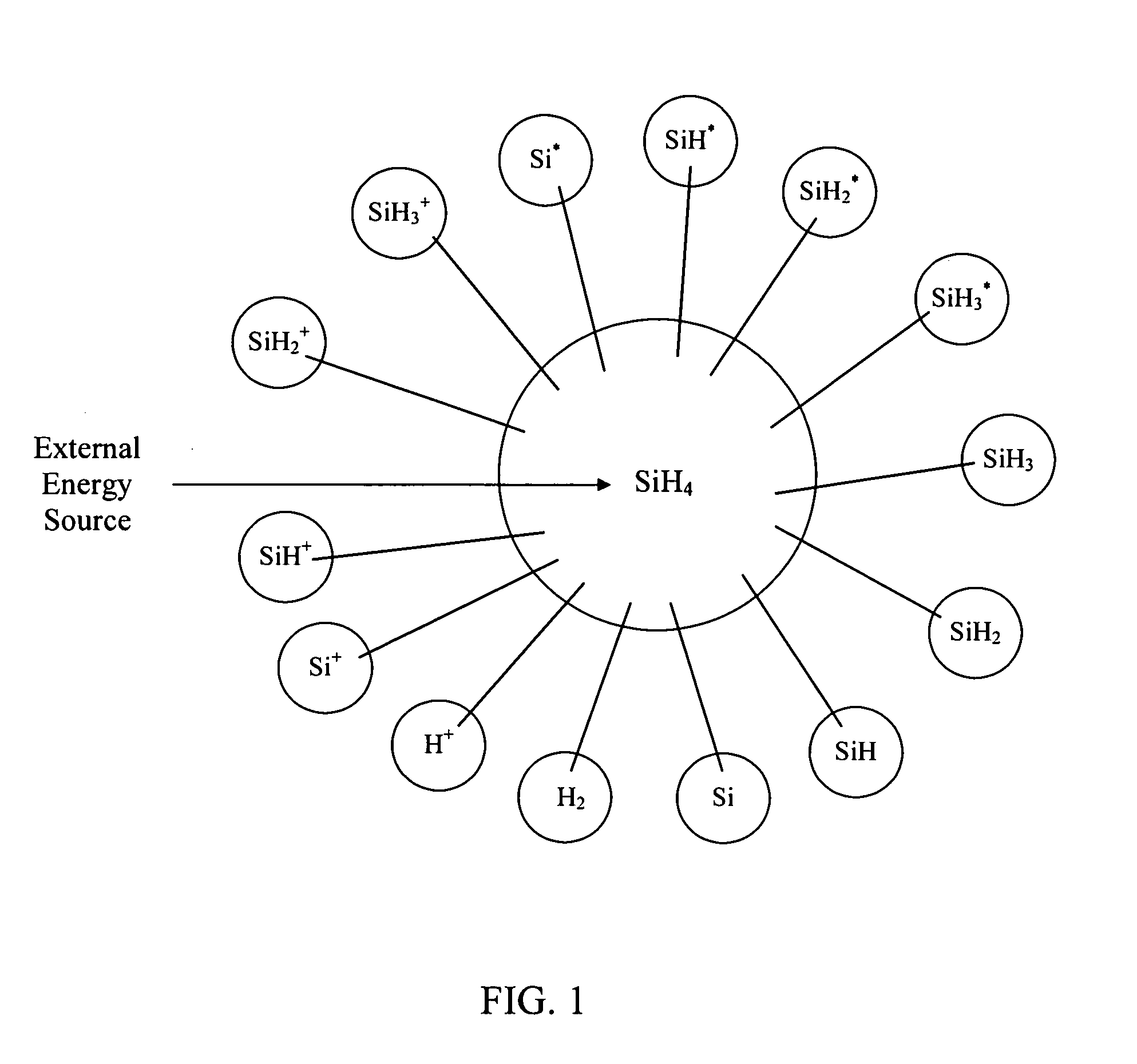

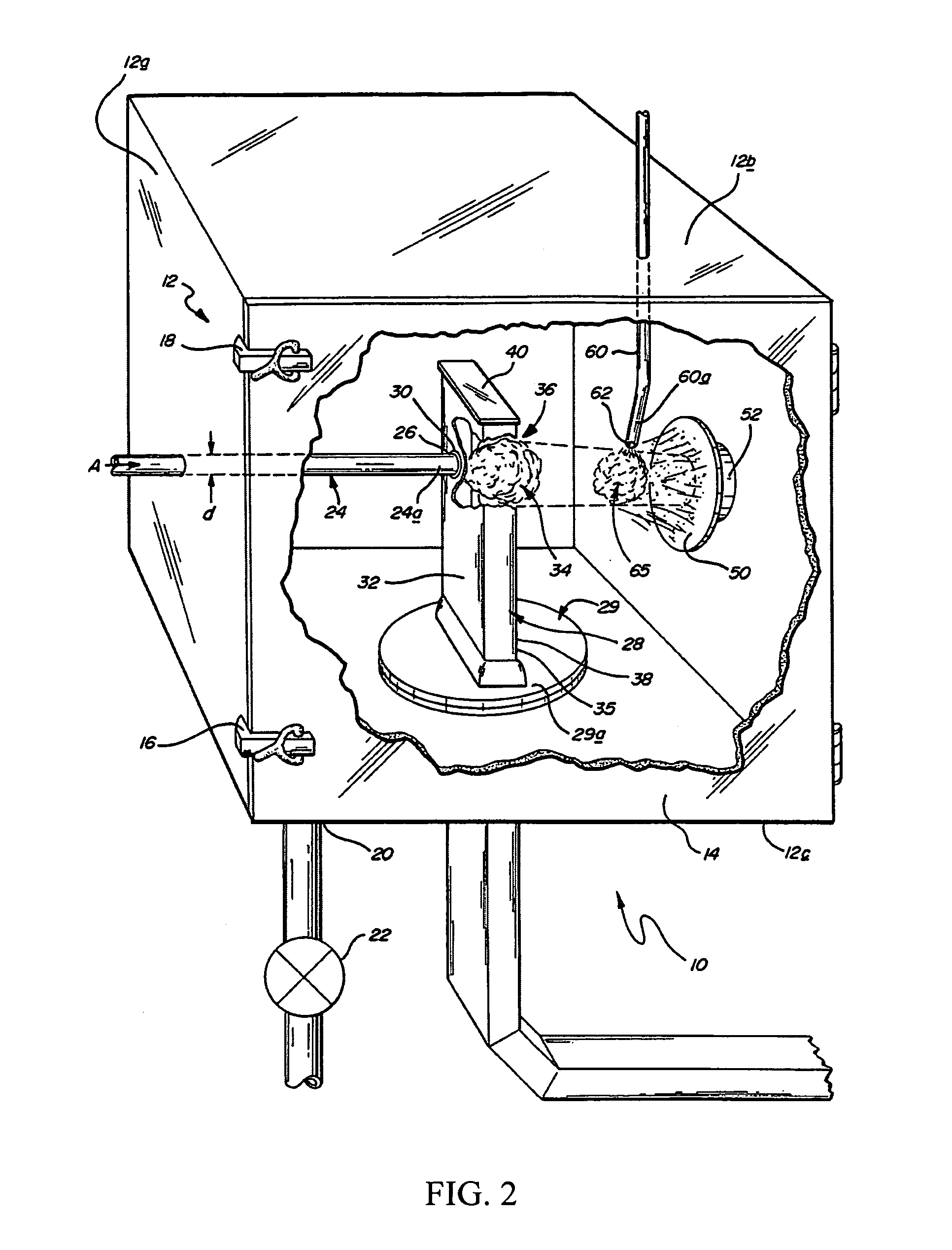

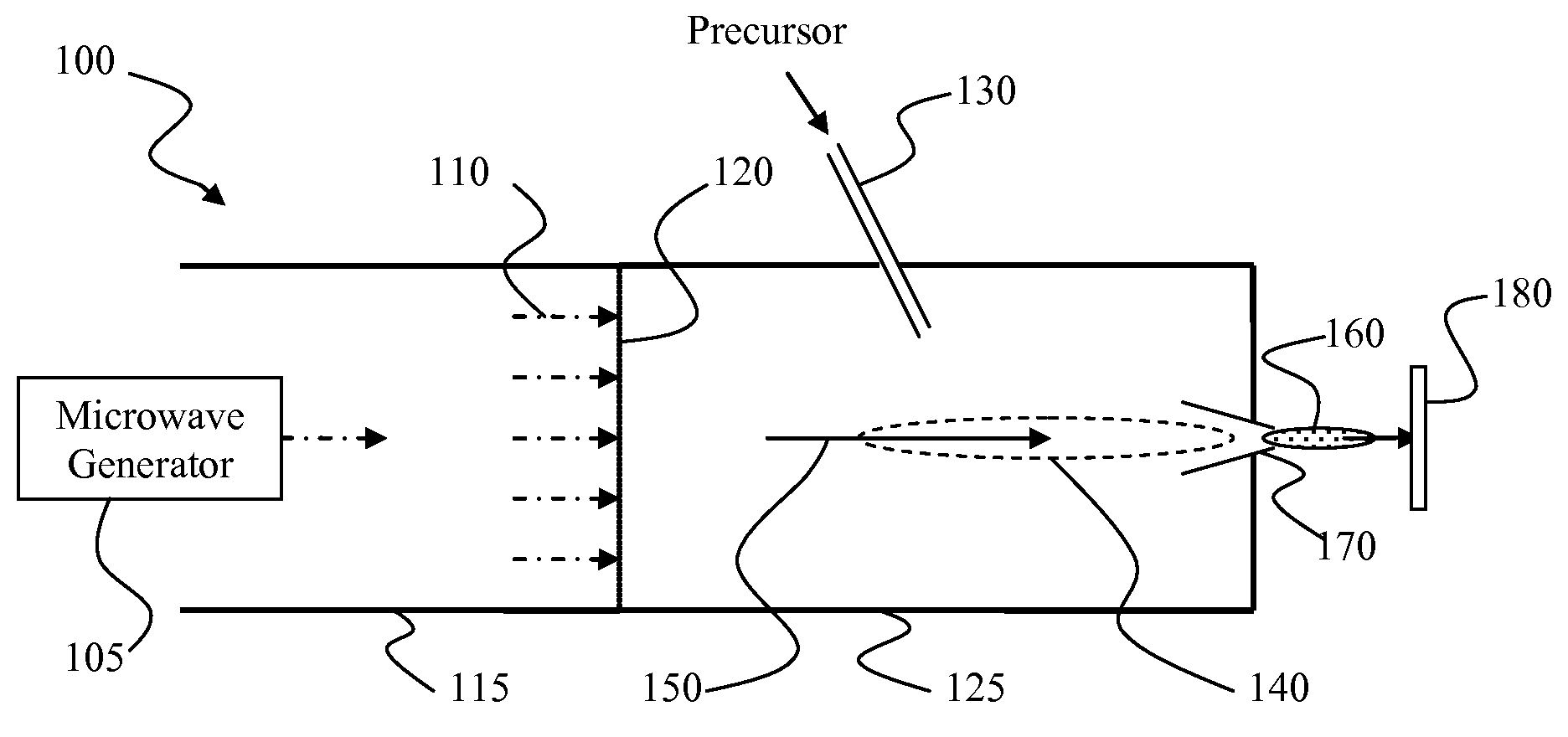

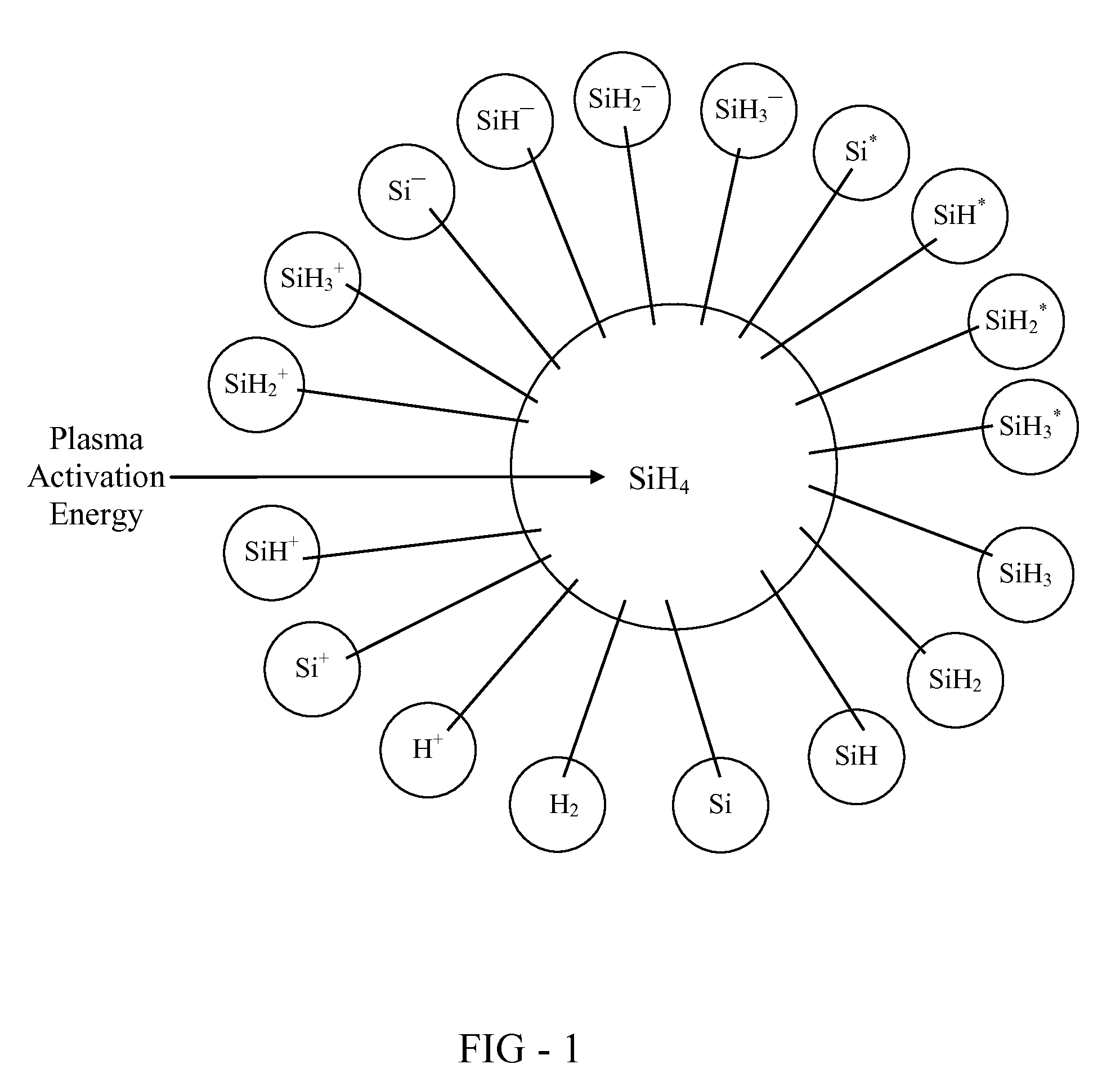

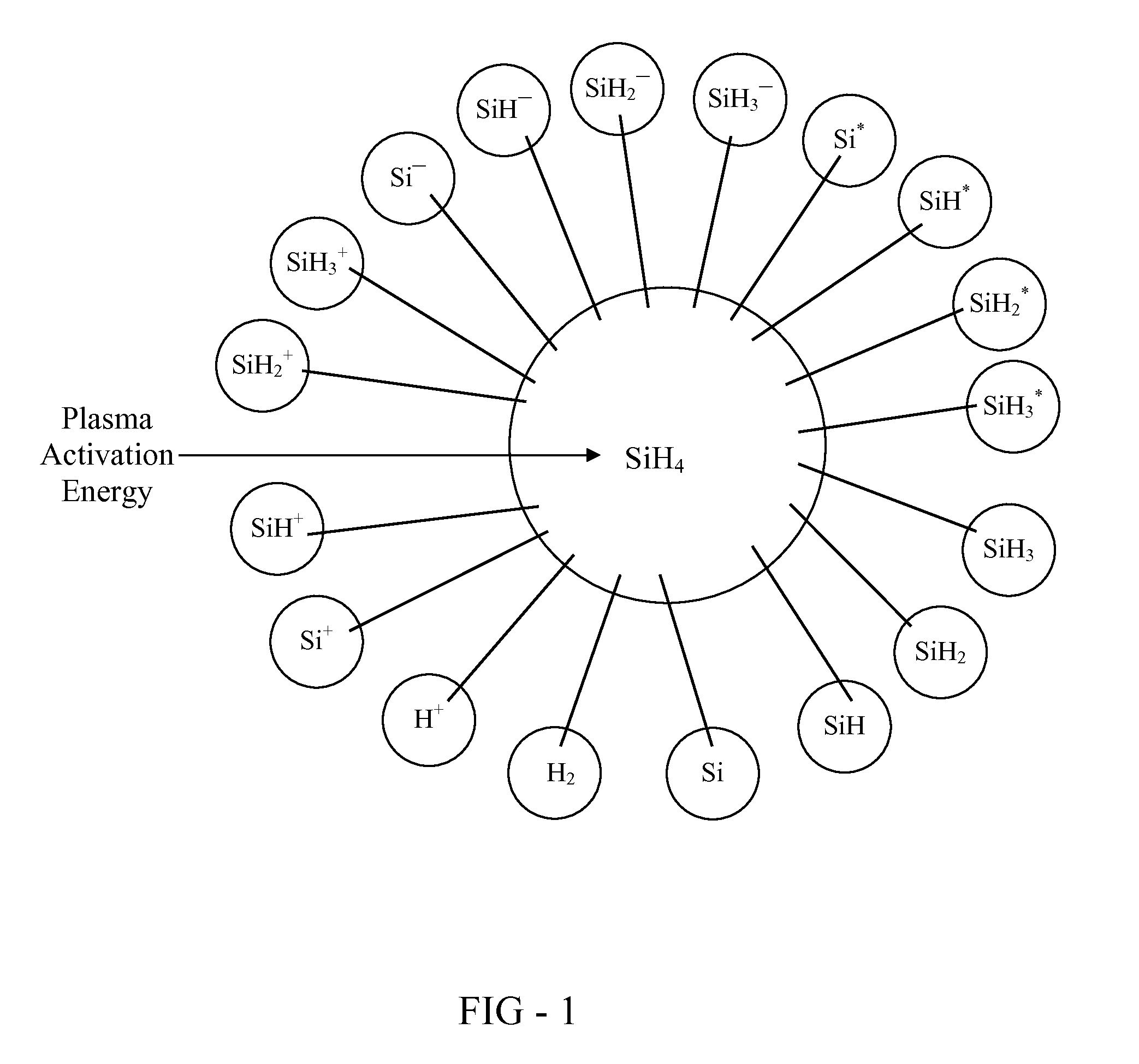

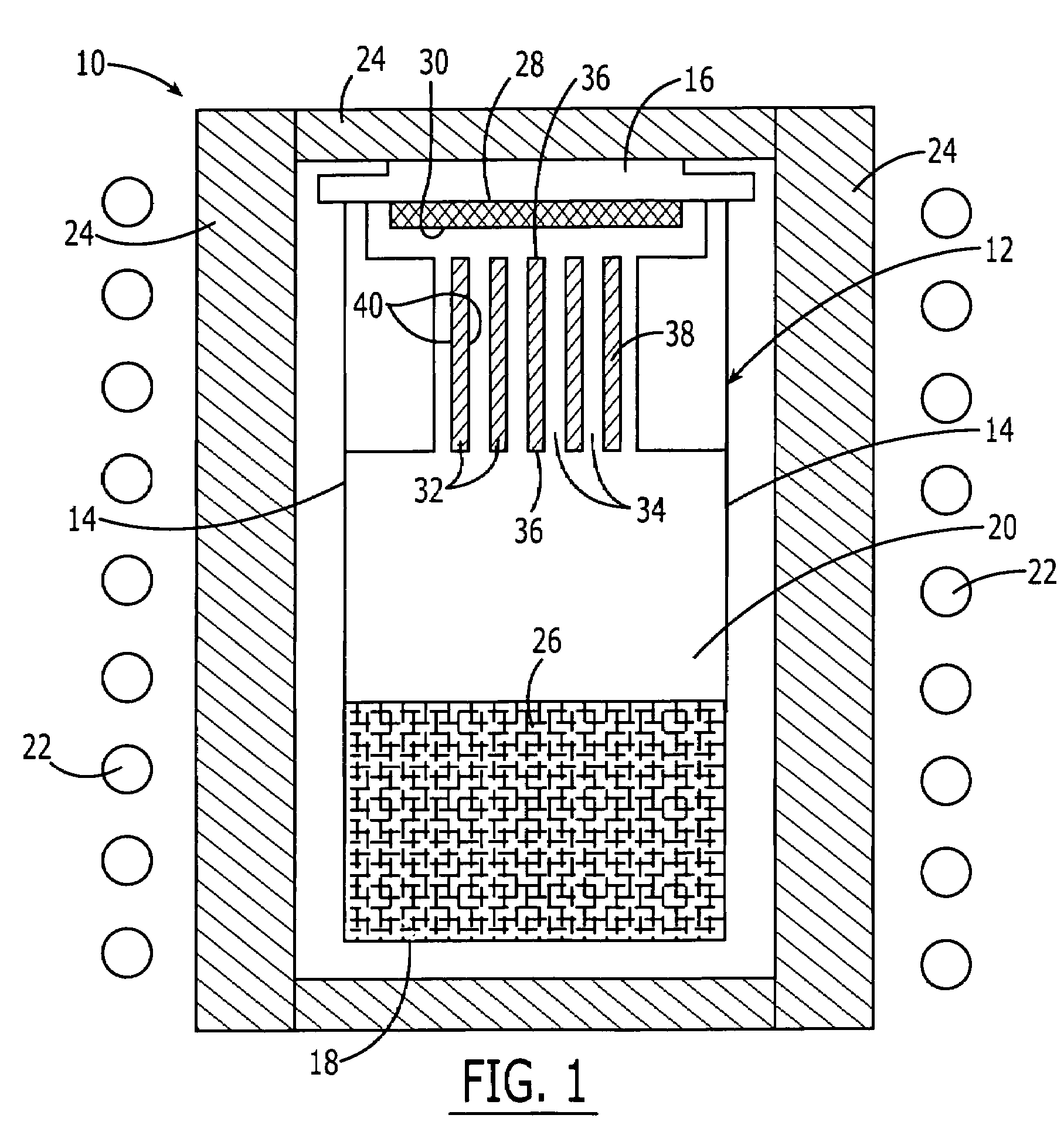

High Speed Thin Film Deposition via Pre-Selected Intermediate

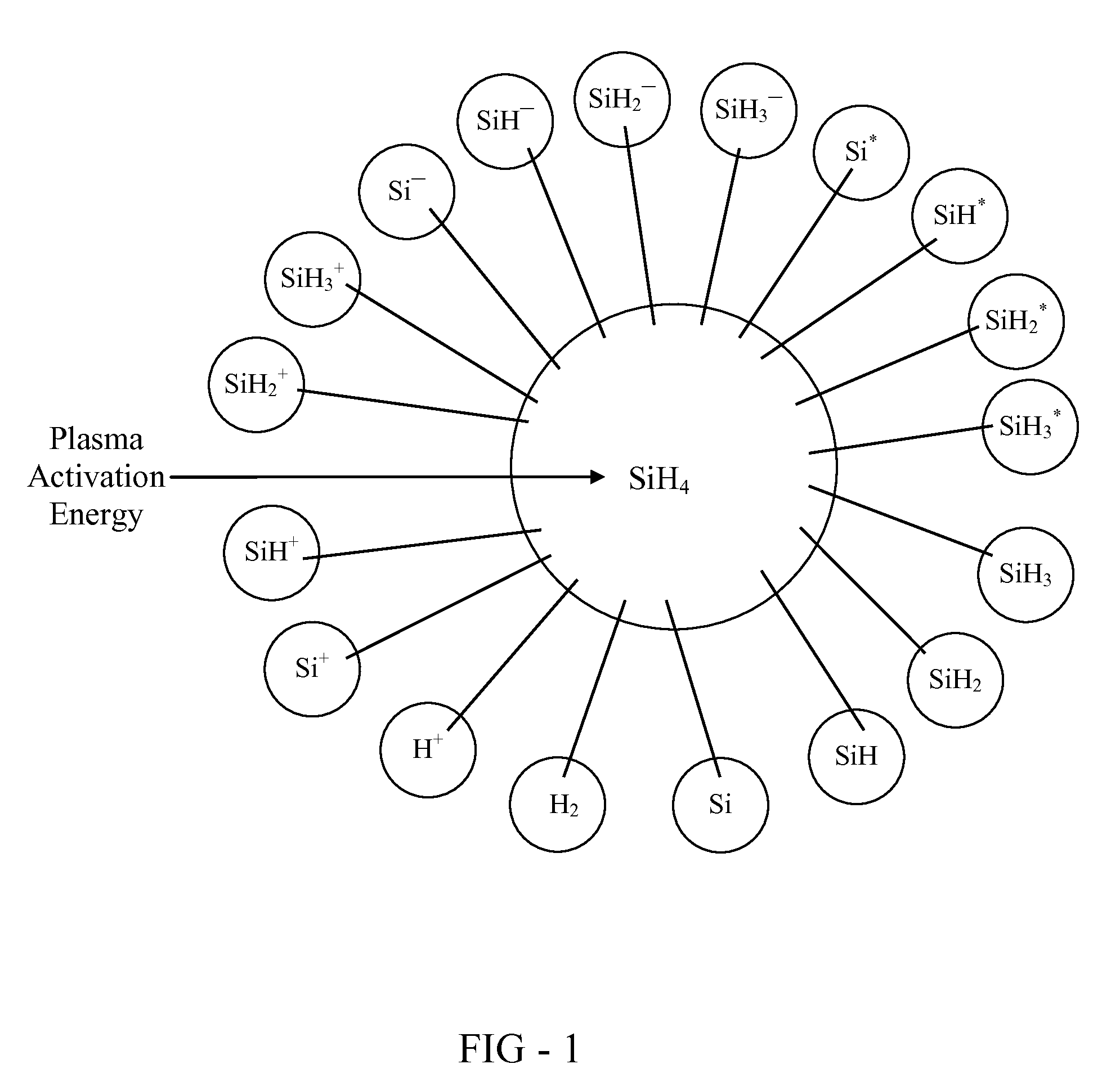

InactiveUS20100068870A1Improve throughputIncrease in film formation ratePolycrystalline material growthFinal product manufactureHigh rateFilm material

A method and apparatus for the unusually high rate deposition of thin film materials on a stationary or continuous substrate. The method includes delivery of a pre-selected precursor intermediate to a deposition chamber and formation of a thin film material from the intermediate. The intermediate is formed outside of the deposition chamber and includes a metastable species such as a free radical. The intermediate is pre-selected to include a metastable species conducive to the formation of a thin film material having a low defect concentration. By forming a low defect concentration material, deposition rate is decoupled from material quality and heretofore unprecedented deposition rates are achieved. In one embodiment, the pre-selected precursor intermediate is SiH3. The method further includes combining the pre-selected precursor intermediate with a carrier gas, preferably in a deactivated state, where the carrier gas directs the transport of the pre-selected precursor intermediate to a substrate for deposition of the thin film material.

Owner:OVSHINSKY TECH

High speed thin film deposition via pre-selected intermediate

InactiveUS8252112B2High materialReduce defect concentrationPolycrystalline material growthFinal product manufactureHigh rateMaterial quality

A method and apparatus for the unusually high rate deposition of thin film materials on a stationary or continuous substrate. The method includes delivery of a pre-selected precursor intermediate to a deposition chamber and formation of a thin film material from the intermediate. The intermediate is formed outside of the deposition chamber and includes a metastable species such as a free radical. The intermediate is pre-selected to include a metastable species conducive to the formation of a thin film material having a low defect concentration. By forming a low defect concentration material, deposition rate is decoupled from material quality and heretofore unprecedented deposition rates are achieved. In one embodiment, the pre-selected precursor intermediate is SiH3. The method further includes combining the pre-selected precursor intermediate with a carrier gas, preferably in a deactivated state, where the carrier gas directs the transport of the pre-selected precursor intermediate to a substrate for deposition of the thin film material.

Owner:OVSHINSKY TECH

Gallium Nitride Substrates and Functional Devices

ActiveUS20160049554A1Reduce luminous intensityImprove uniformityPolycrystalline material growthLiquid-phase epitaxial-layer growthPeak valueWavelength

The maximum value of peak intensities of cathode luminescence of a wavelength corresponding to a band gap of gallium nitride and in a measured visual field of 0.1 mm×0.1 mm is 140 percent or higher of an average value of the peak intensities of the cathode luminescence, provided that the peak intensities of the cathode luminescence are measured on a surface of the gallium nitride substrate.

Owner:NGK INSULATORS LTD

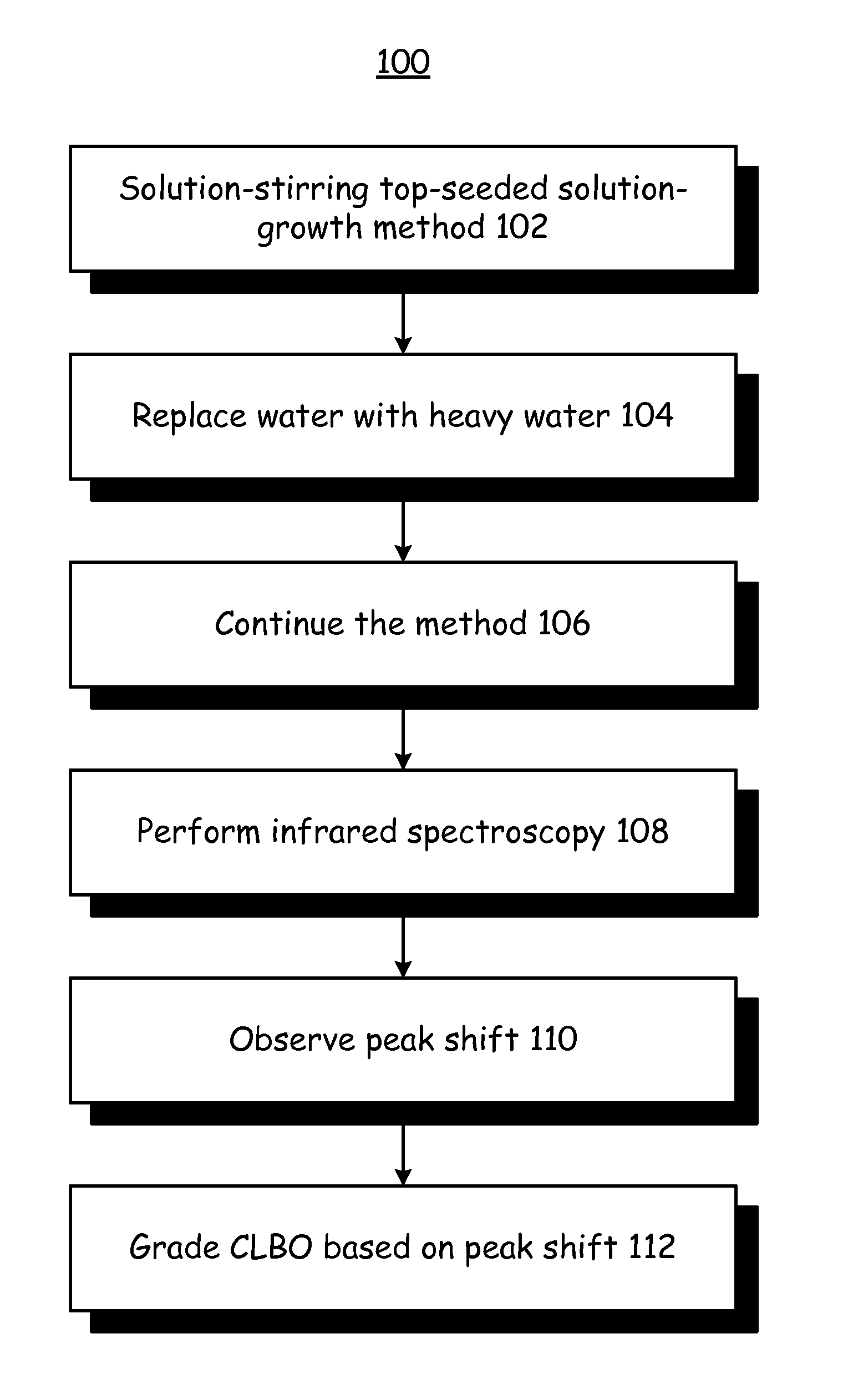

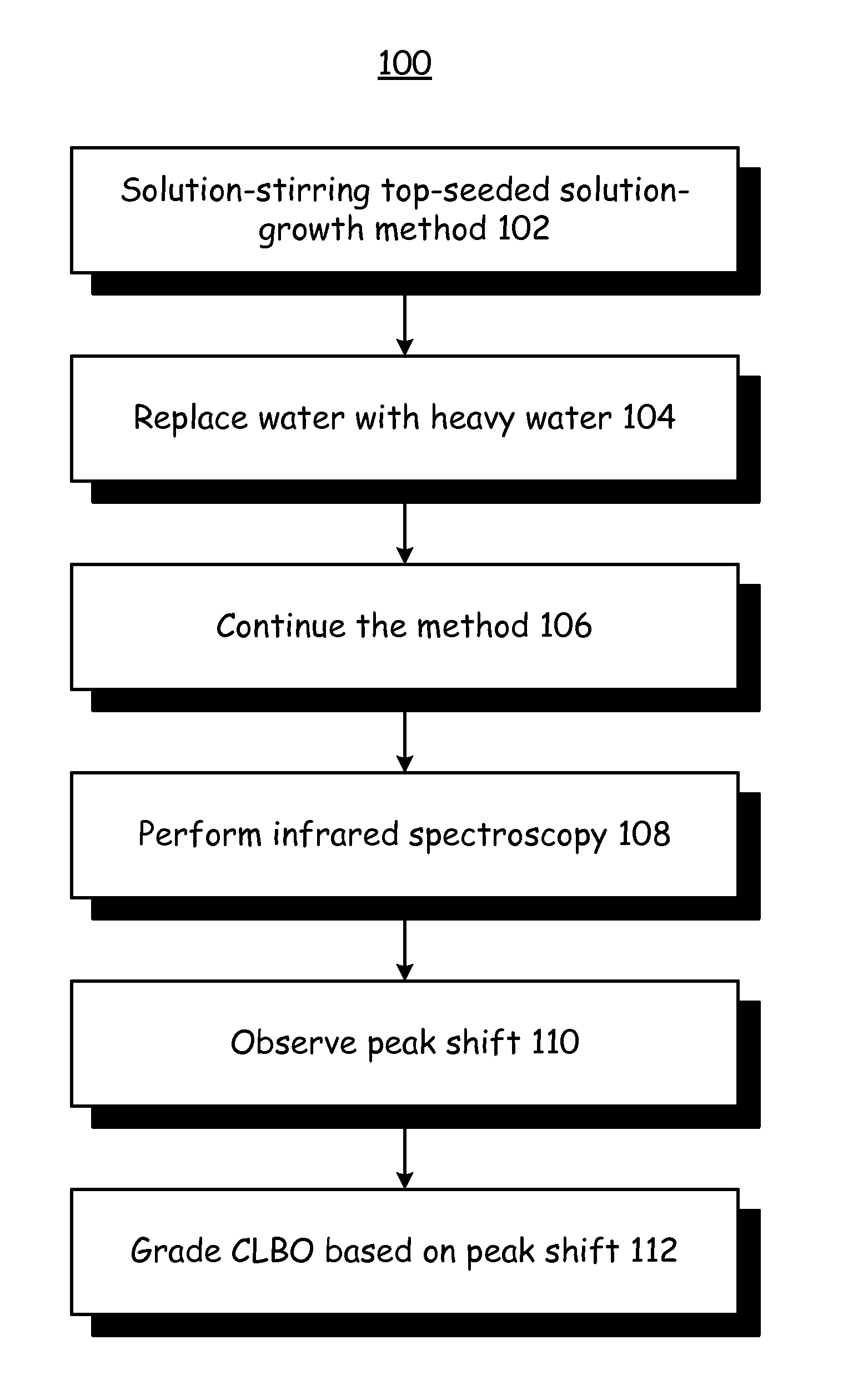

CLBO crystal growth

ActiveUS9023152B2Reduce vibrational energyReduces vibrationally-assisted absorptionPolycrystalline material growthFrom normal temperature solutionsCrystal growthHeavy water

A solution-stirring top-seeded solution-growth method for forming CLBO of the type where water is added to a precursor mixture, where heavy water is substituted for the water.

Owner:KLA TENCOR TECH CORP

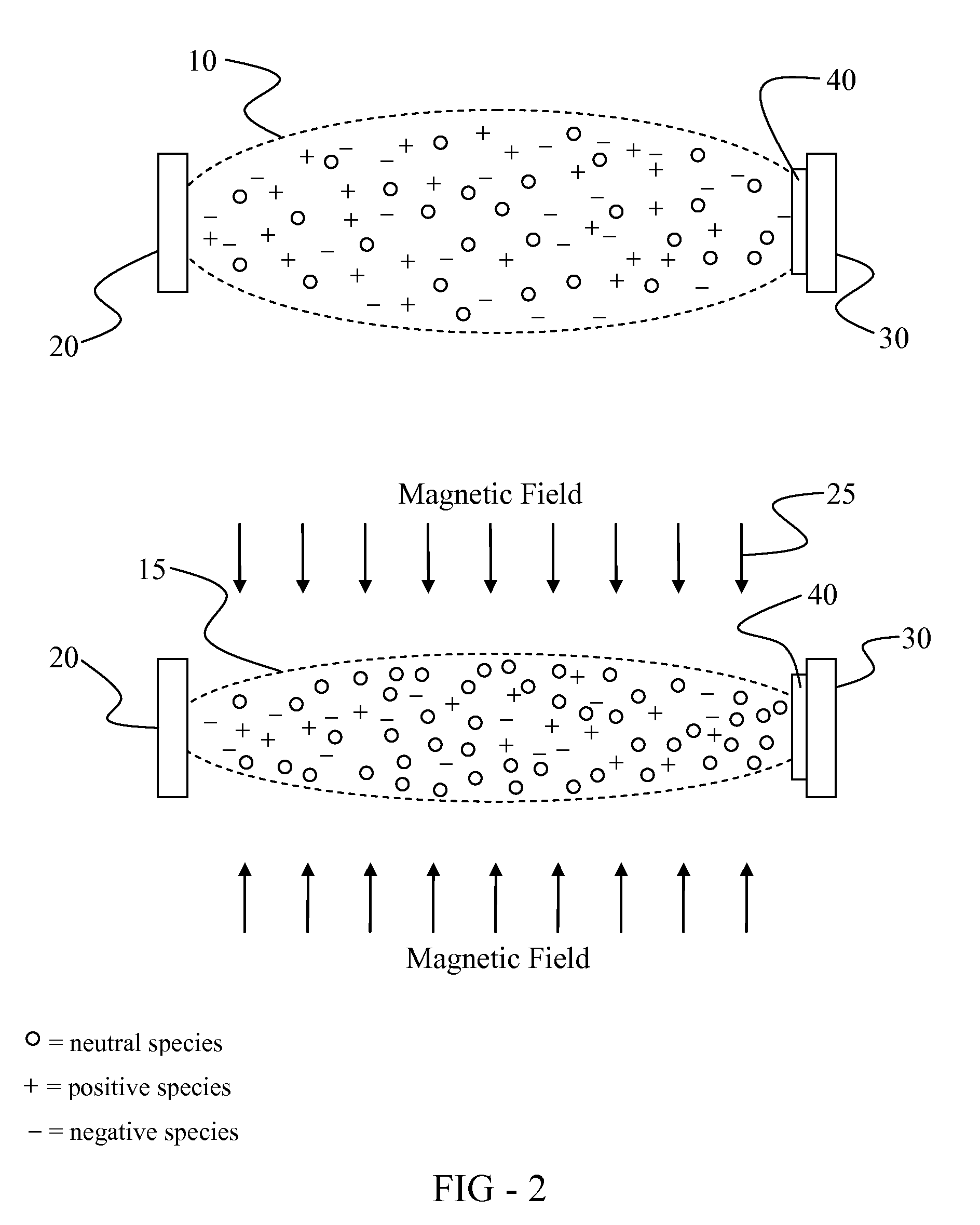

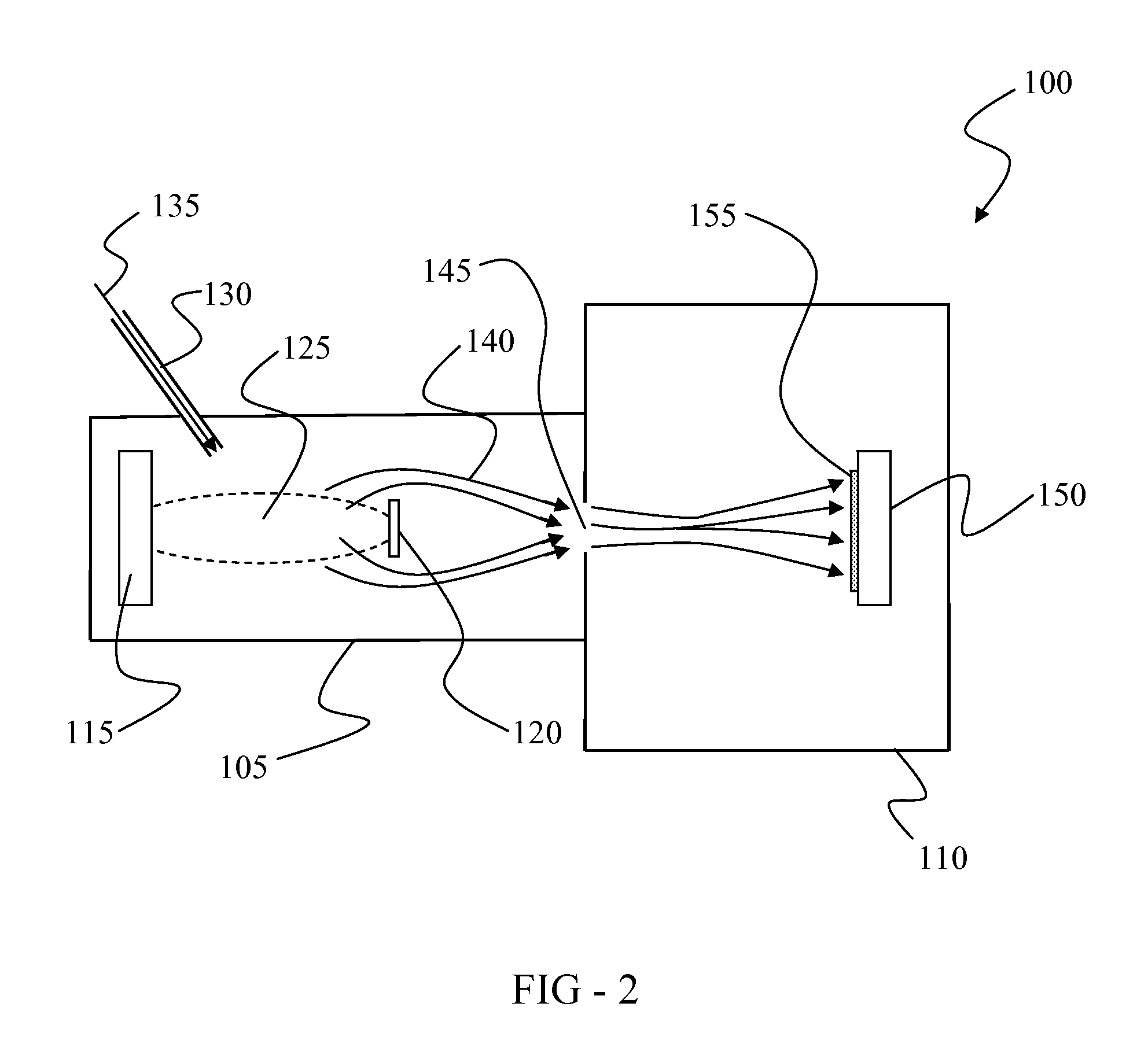

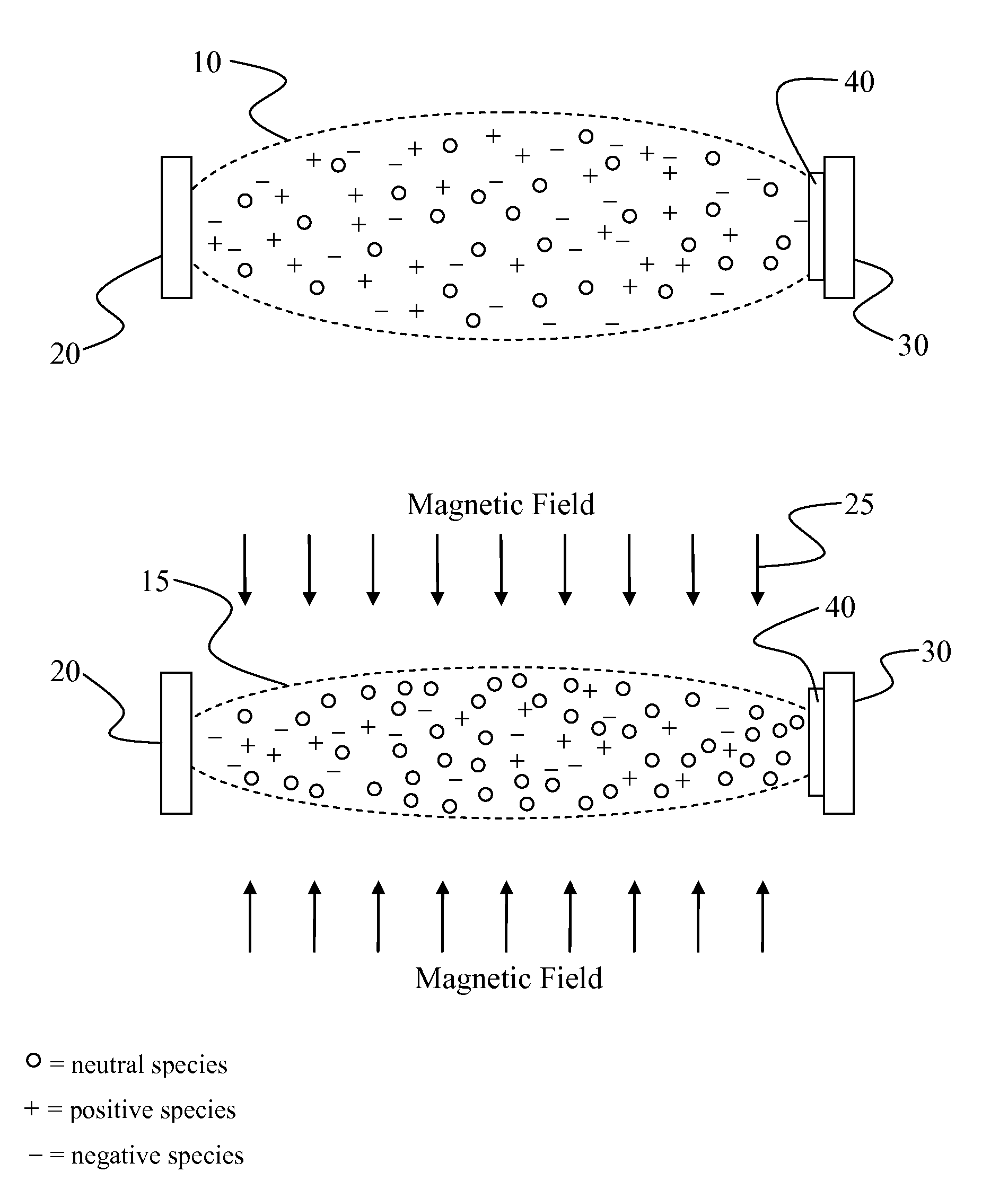

Thin Film Deposition via Charged Particle-Depleted Plasma Achieved by Magnetic Confinement

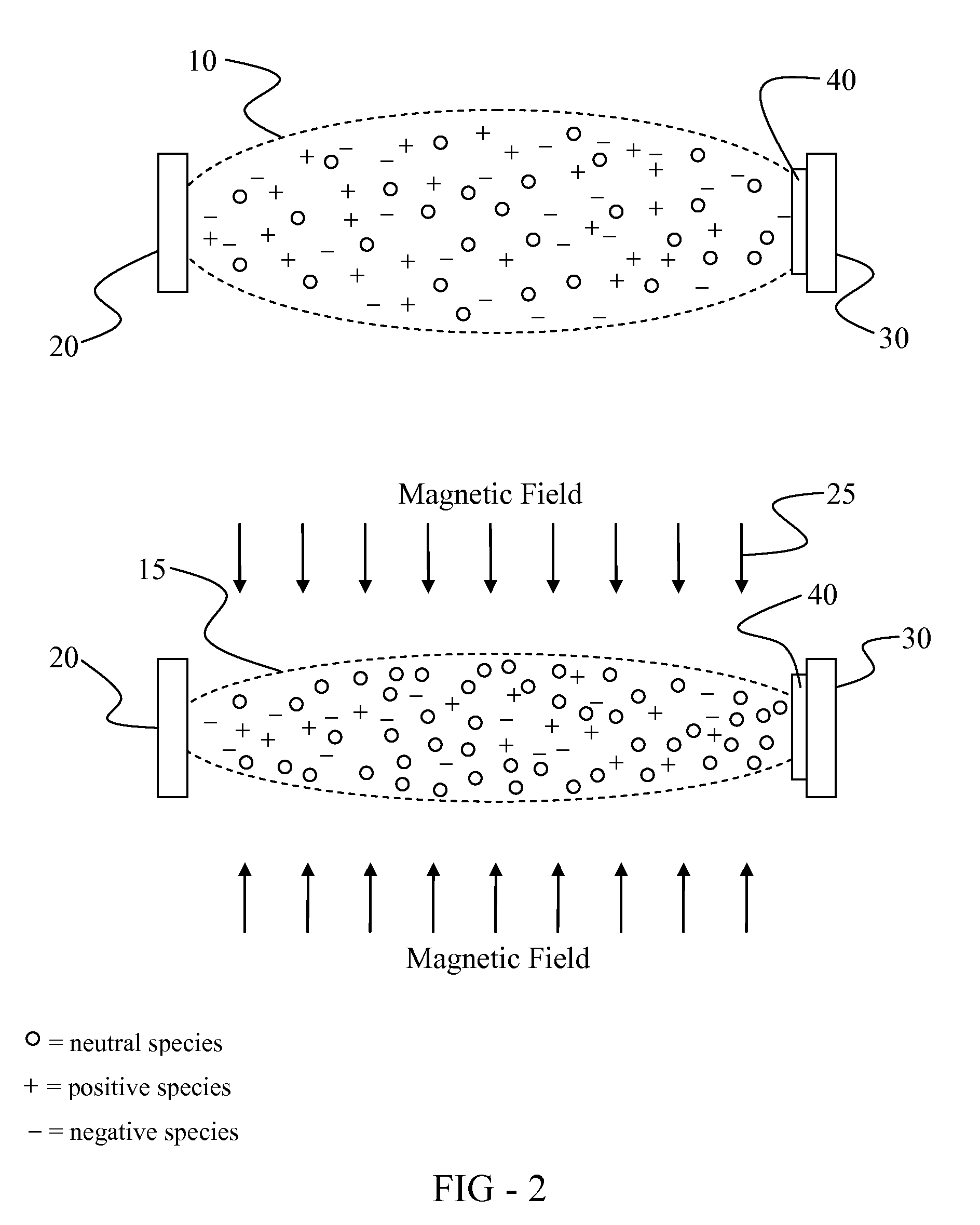

InactiveUS20100273315A1Improve concentrationSeparationElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma depositionLow density

A method and apparatus for forming thin film materials via a plasma deposition process in the presence of a magnetic field. A precursor is delivered to a deposition chamber and activated to form a plasma. The plasma may be initiated in the presence of a magnetic field or subjected to a magnetic field after initiation. The plasma includes ionized and neutral species derived from the precursor and the magnetic field manipulates the plasma to effect a reduction in the population of ionized species and an enhancement of the population of neutral species. A thin film material is subsequently formed from the resulting neutral-enriched deposition medium. The method permits formation of thin film materials having a low density of defects. In one embodiment, the thin film material is a photovoltaic material and the suppression of defects leads to an enhancement in photovoltaic efficiency.

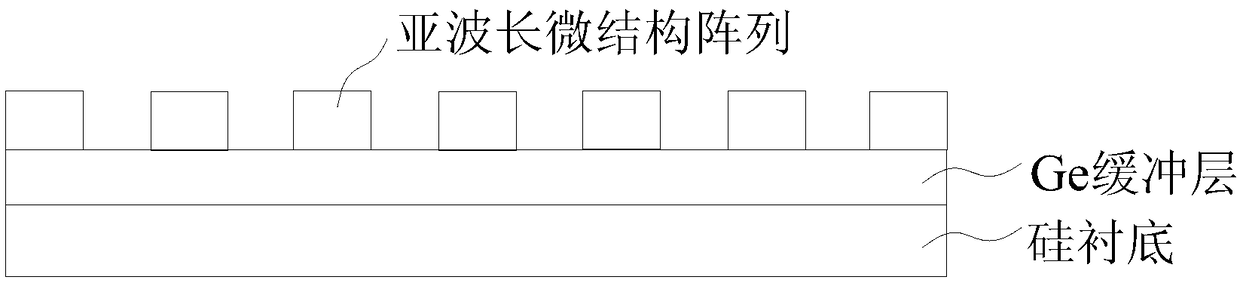

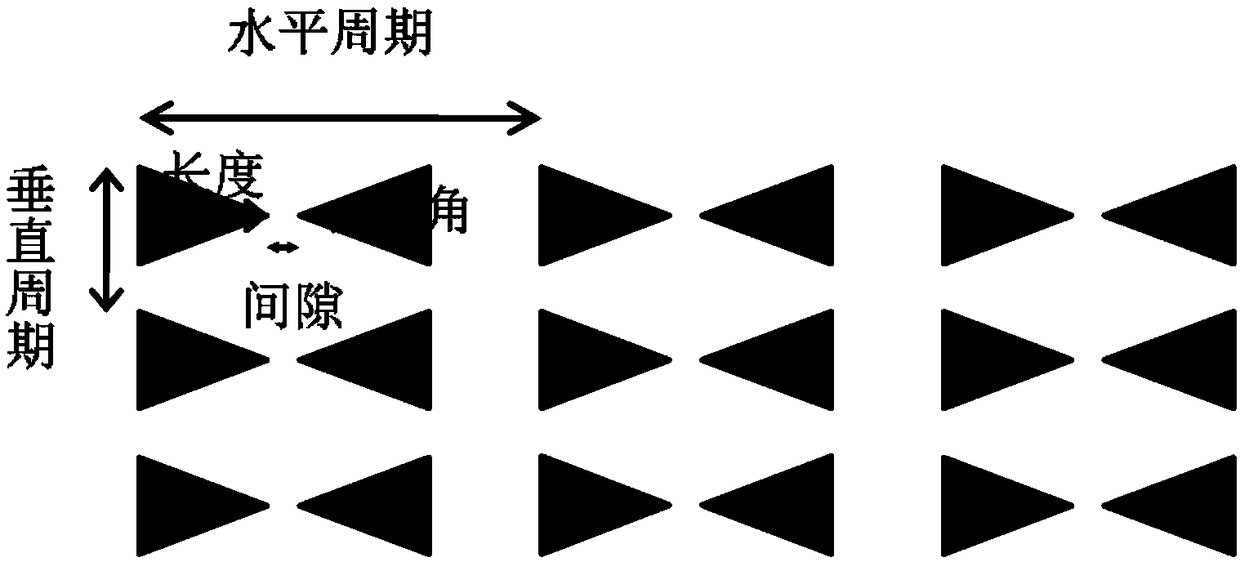

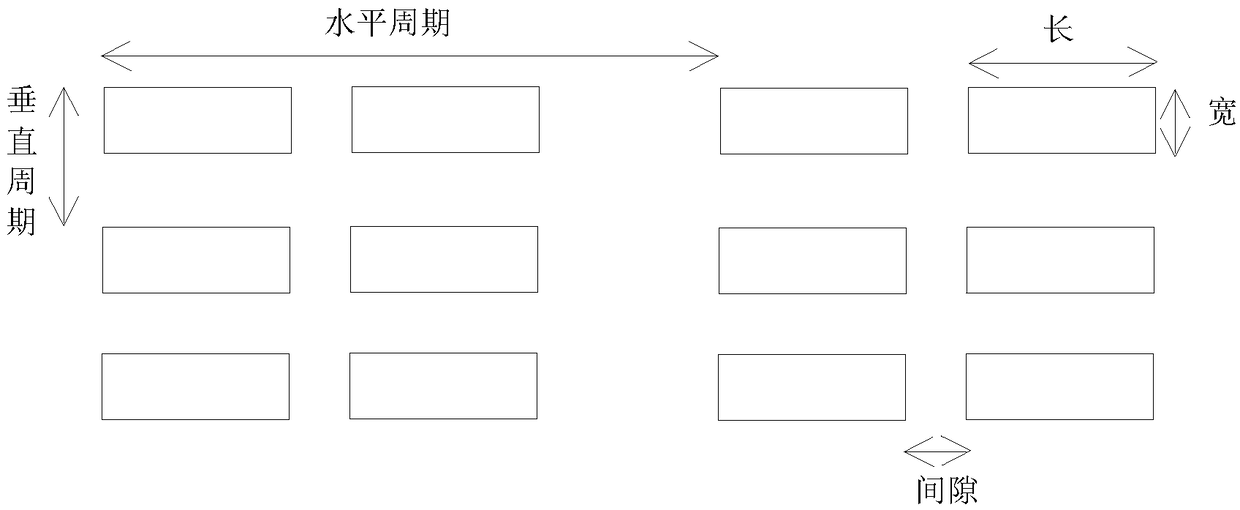

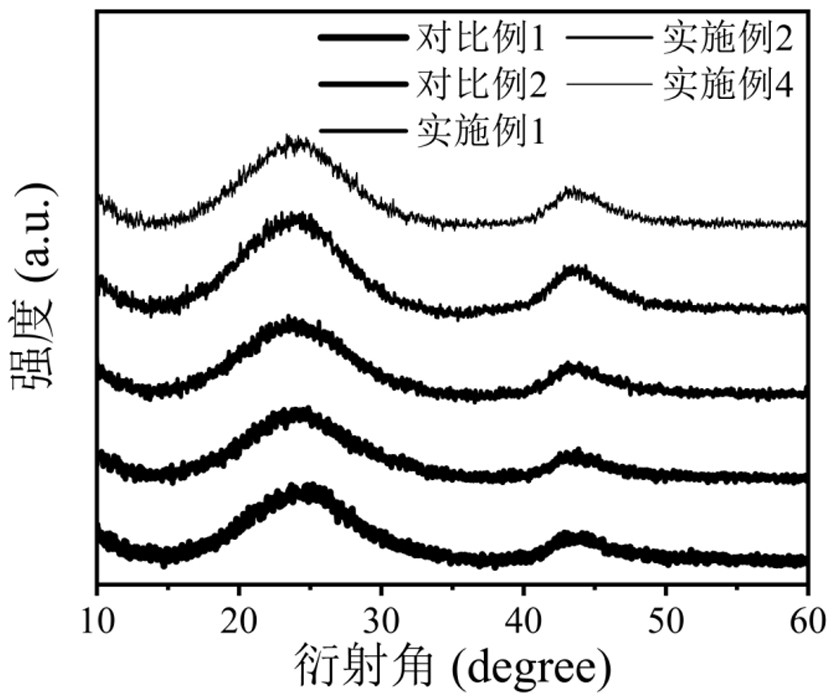

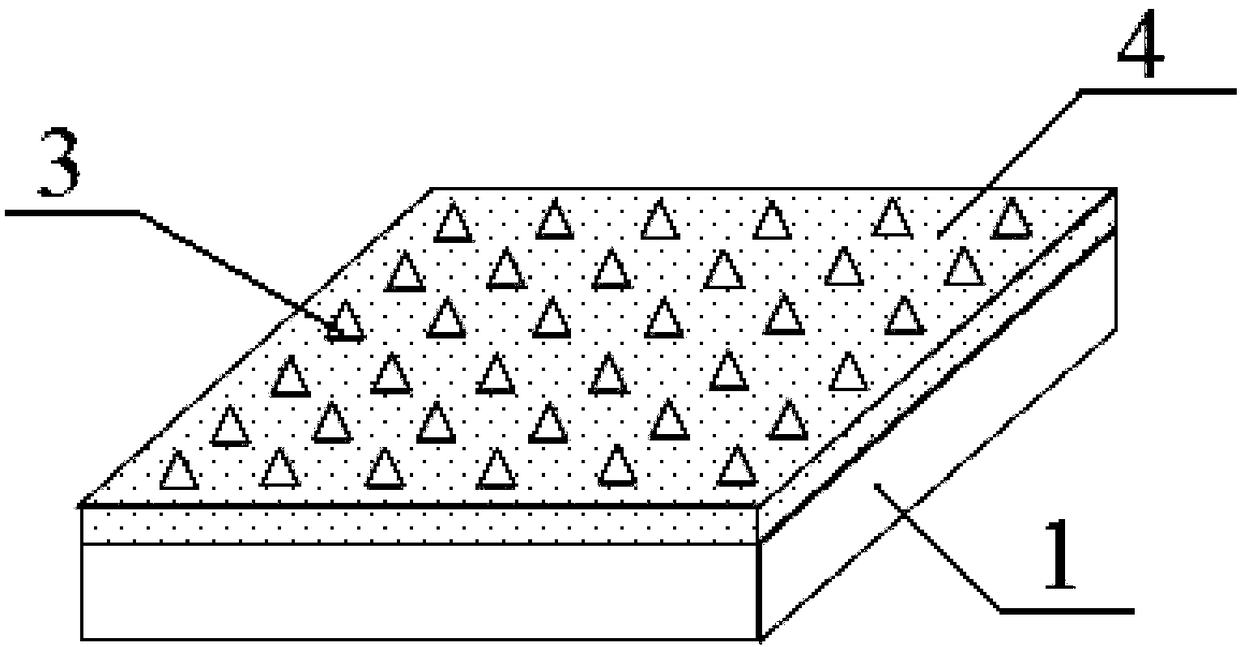

Silicon-based chip with mid-infrared spectrum signal enhancement function, and preparation method thereof

ActiveCN108807587AImprove stabilityHigh mass productionFinal product manufactureAntenna supports/mountingsMid infraredWavelength

The invention discloses a silicon-based chip with a mid-infrared spectrum signal enhancement function. The silicon-based chip comprises a silicon substrate, wherein the silicon substrate is sequentially provided with a Ge buffer layer and a heavily-doped Ge layer; and a sub-wavelength microstructure array is etched on the heavily-doped Ge layer. The invention further discloses a preparation methodof the silicon-based chip with the mid-infrared spectrum signal enhancement function. Compared with a III-V group semiconductor, the silicon-based chip with the mid-infrared spectrum signal enhancement function has weak lattice absorption characteristics, and is more suitable for being used as a molecular sensor chip material; and silicon is used as a substrate, so that the silicon-based chip canbe integrated with an electronic device in a monolithic integration mode conveniently, thereby highly improving stability and the yield of the device.

Owner:ZHEJIANG UNIV

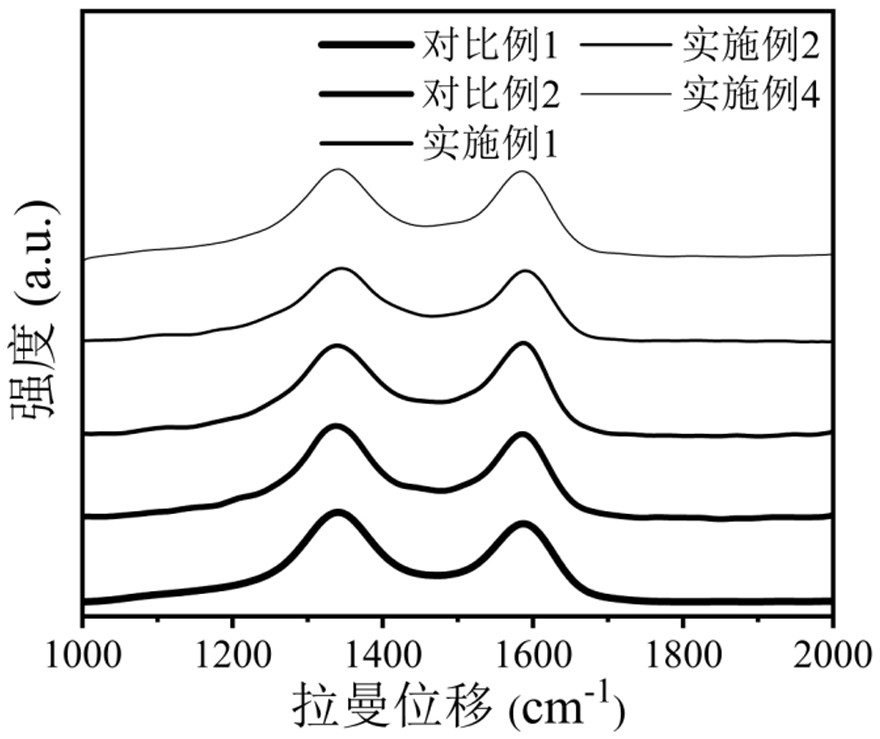

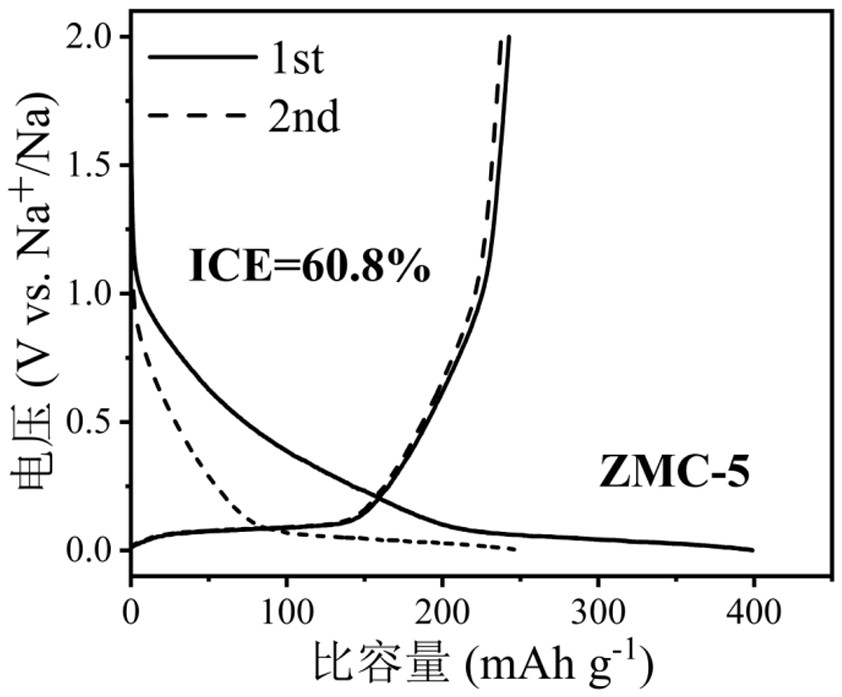

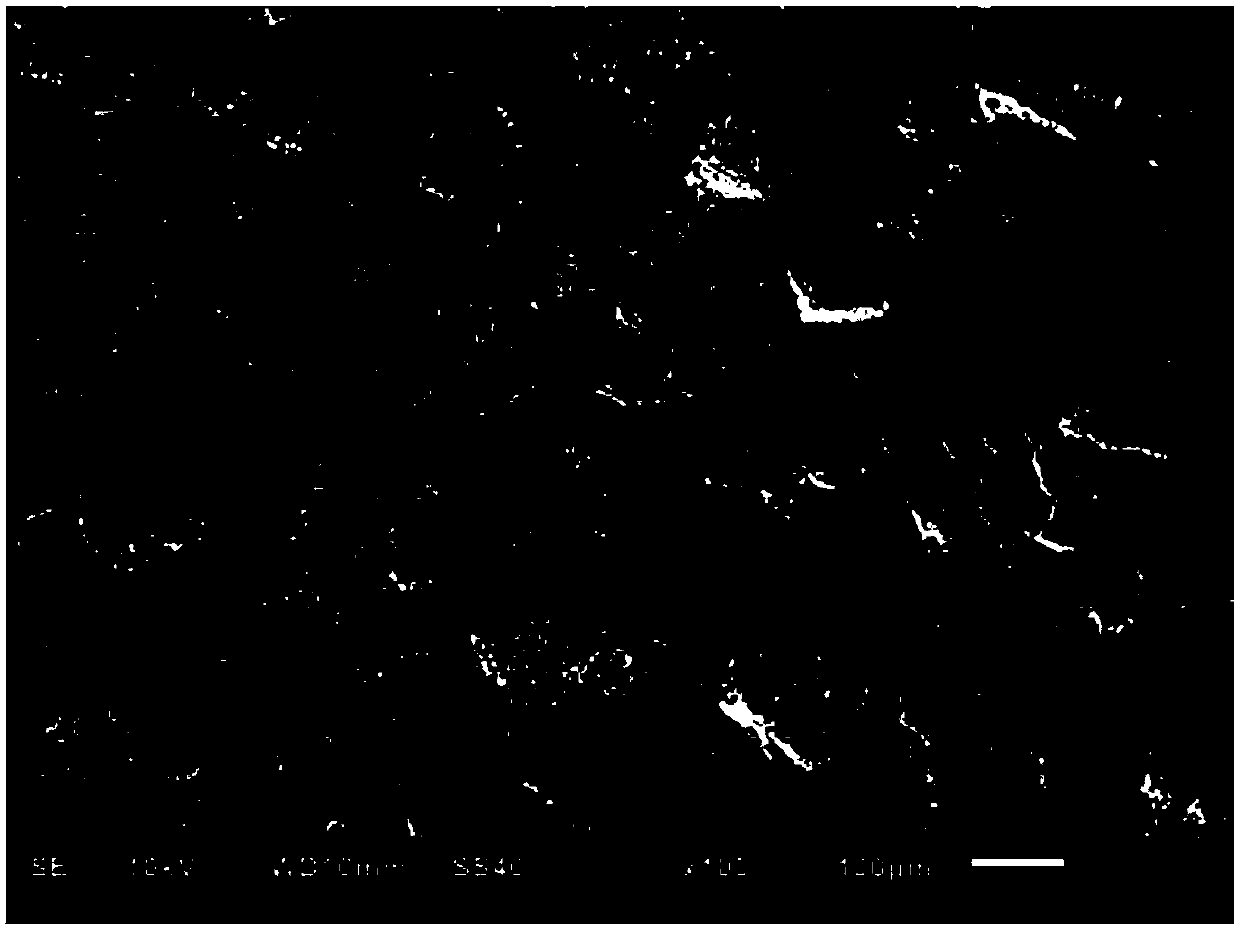

Sodium-ion battery carbon negative electrode material prepared based on waste wood chips and preparation method thereof

PendingCN113651307AReduce defect concentrationReduce irreversible capacity lossNegative electrodesSecondary cellsBiomass carbonElectrical battery

The invention relates to a sodium-ion battery carbon negative electrode material prepared based on waste wood chips and a preparation method thereof. Waste wood chips are used as a biomass carbon source and subjected to pre-carbonization and low-heating-rate high-temperature carbonization treatment, metal heteroatoms are removed by washing with an acid pickling solution, and drying is performed to obtain a hard carbon sodium-ion battery negative electrode material. The waste wood chips are used as a biomass raw material, a large amount of chips generated in the production process of wood products can be fully utilized, and the material has the advantages of being environmentally friendly, low in cost and the like. A low-carbonization heating rate pyrolysis method is adopted, so that the effects of reducing defect concentration, increasing interlayer spacing and improving graphitization degree are achieved, and the electrochemical performance of the material is effectively improved. The hard carbon negative electrode material prepared by the method has relatively high first coulombic efficiency and reversible specific capacity, shows excellent cycling stability and rate capability, and is an ideal sodium-ion battery negative electrode material.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

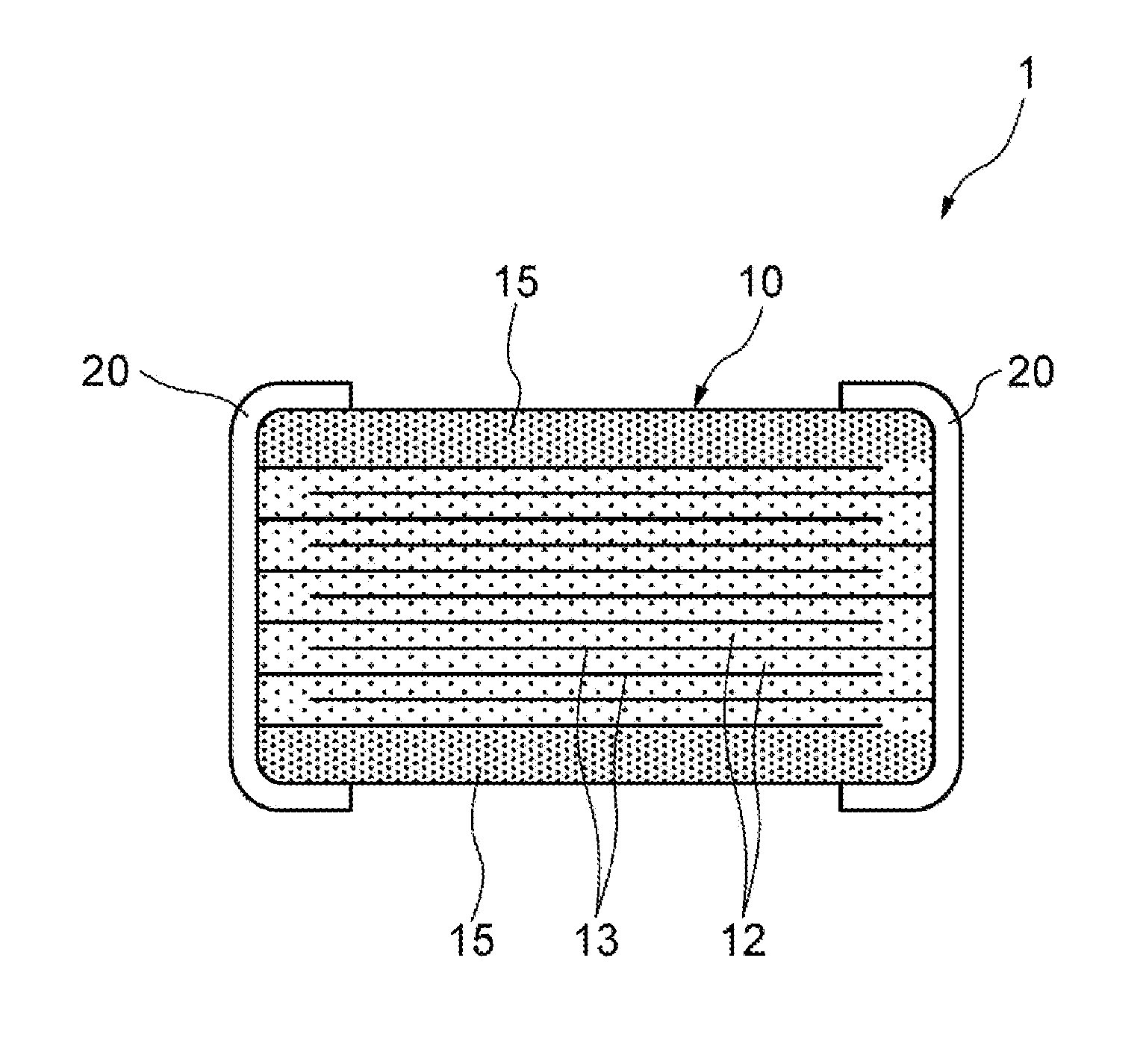

Dielectric ceramic, multi-layer ceramic capacitor and method of manufacturing the same

ActiveUS9281125B2Suppress generationAvoid grain growthFixed capacitor dielectricStacked capacitorsDielectricCeramic capacitor

Owner:TAIYO YUDEN KK

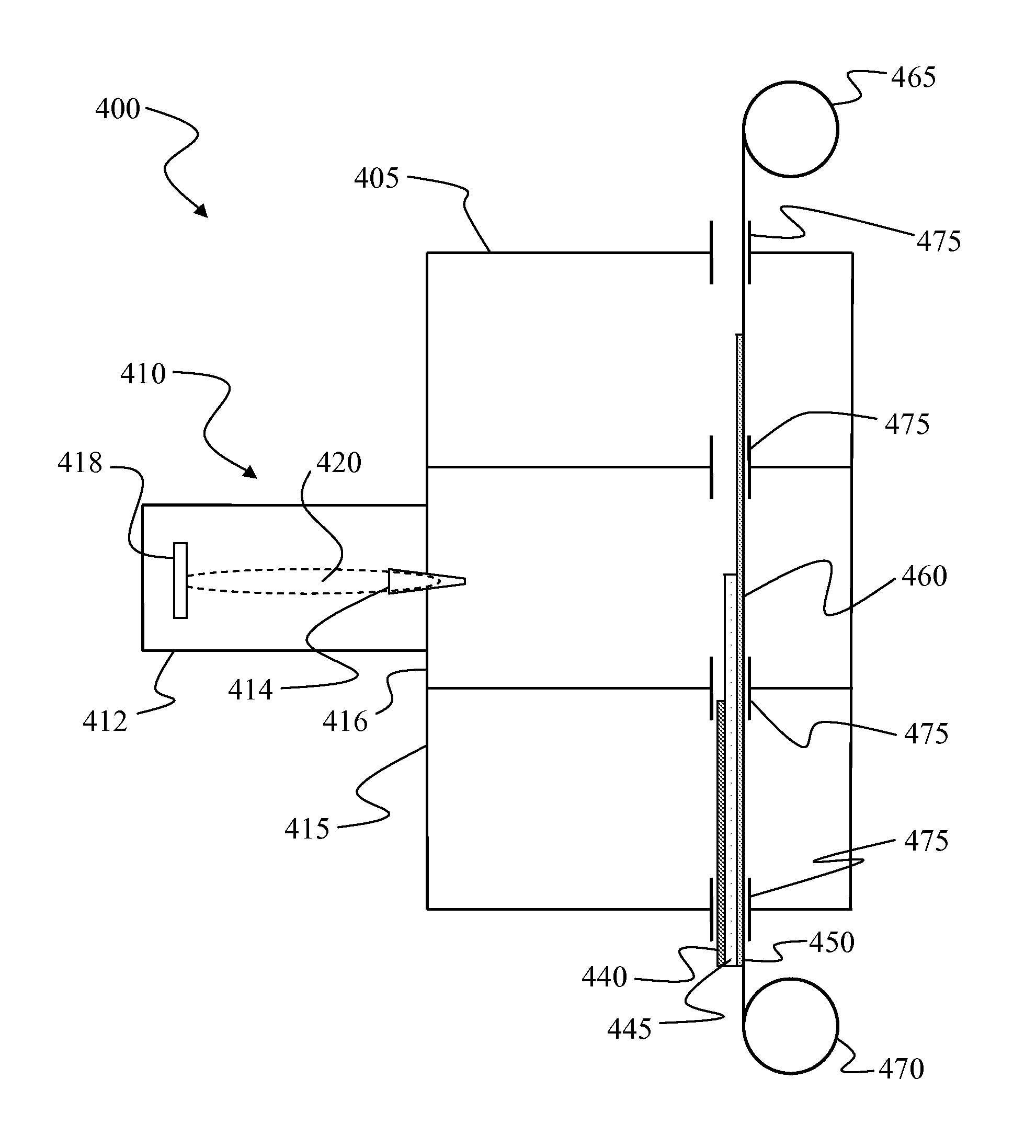

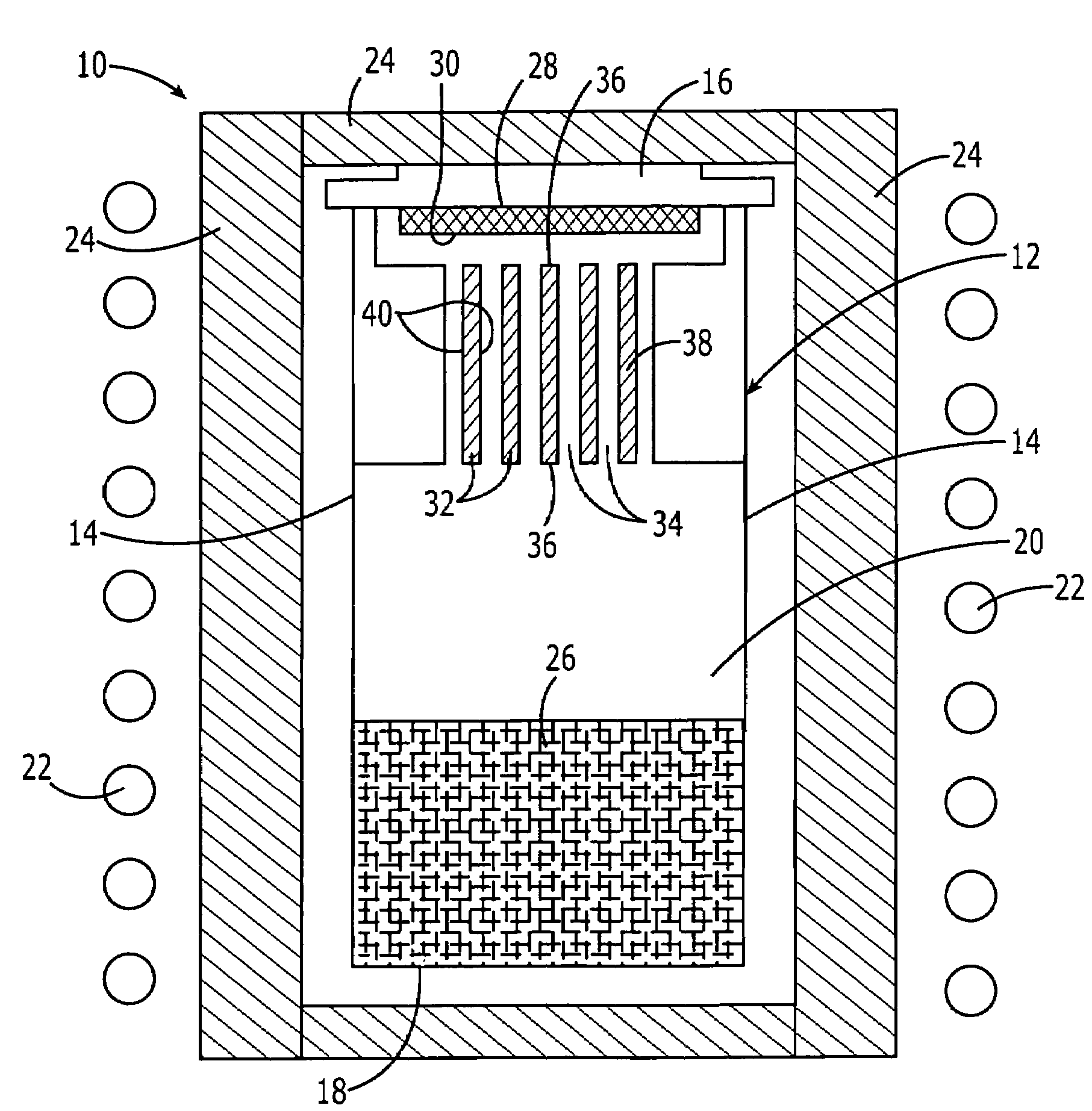

Remote Plasma Apparatus for Manufacturing Solar Cells

InactiveUS20100089318A1Improve distributionReduce defect concentrationElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaSolar energy conversion efficiency

A continuous thin film deposition apparatus that includes a remote plasma source. The source forms a plasma from a precursor and delivers a modified form of the plasma as a charge-depleted deposition medium to a deposition apparatus for formation of a thin film material. The thin film may be formed on a continuous web or other moving substrate. The charge-depleted deposition medium may be formed within the remote plasma source and delivered to an operatively coupled deposition apparatus or the charge-depleted deposition medium may form as the plasma exits the remote plasma source. The initial plasma is formed within the remote plasma source and includes a distribution of charged species (electrons and ions). The charge-depleted deposition medium contains a reduced concentration of the charged species and permits deposition of thin film materials having lower defect concentration. In one embodiment, the thin film material is a solar material and the lower defect concentration provides a higher solar conversion efficiency.

Owner:OVSHINSKY TECH

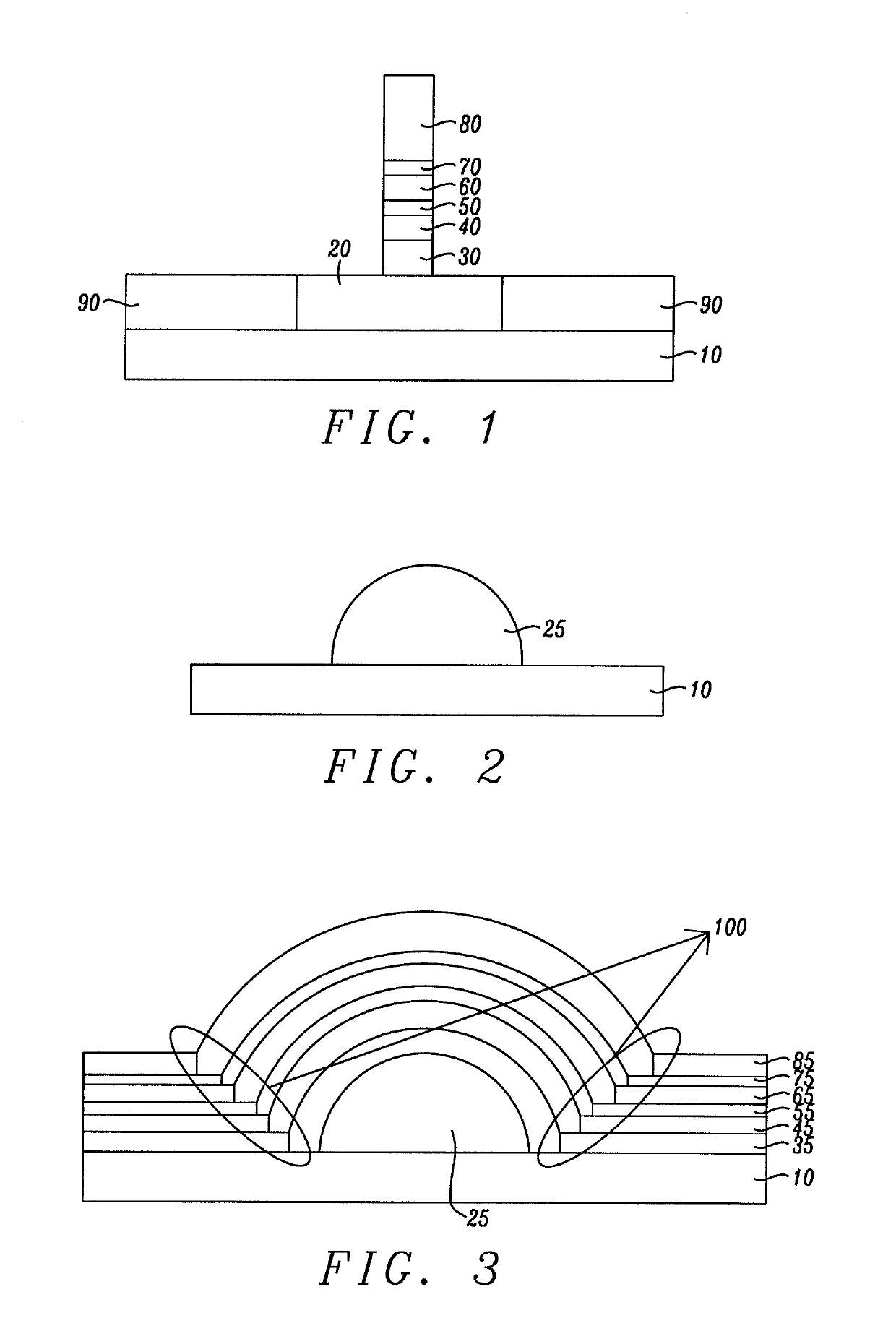

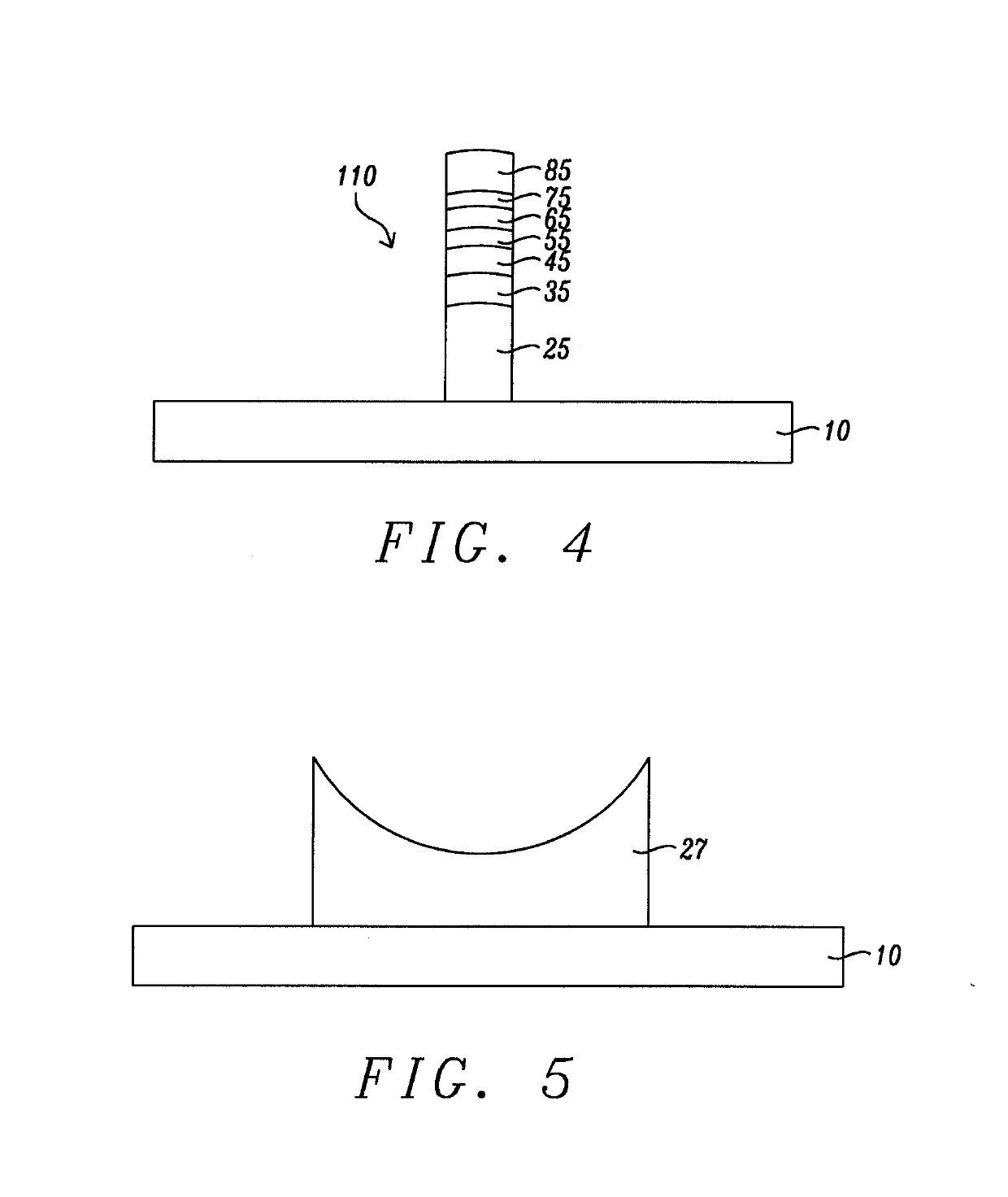

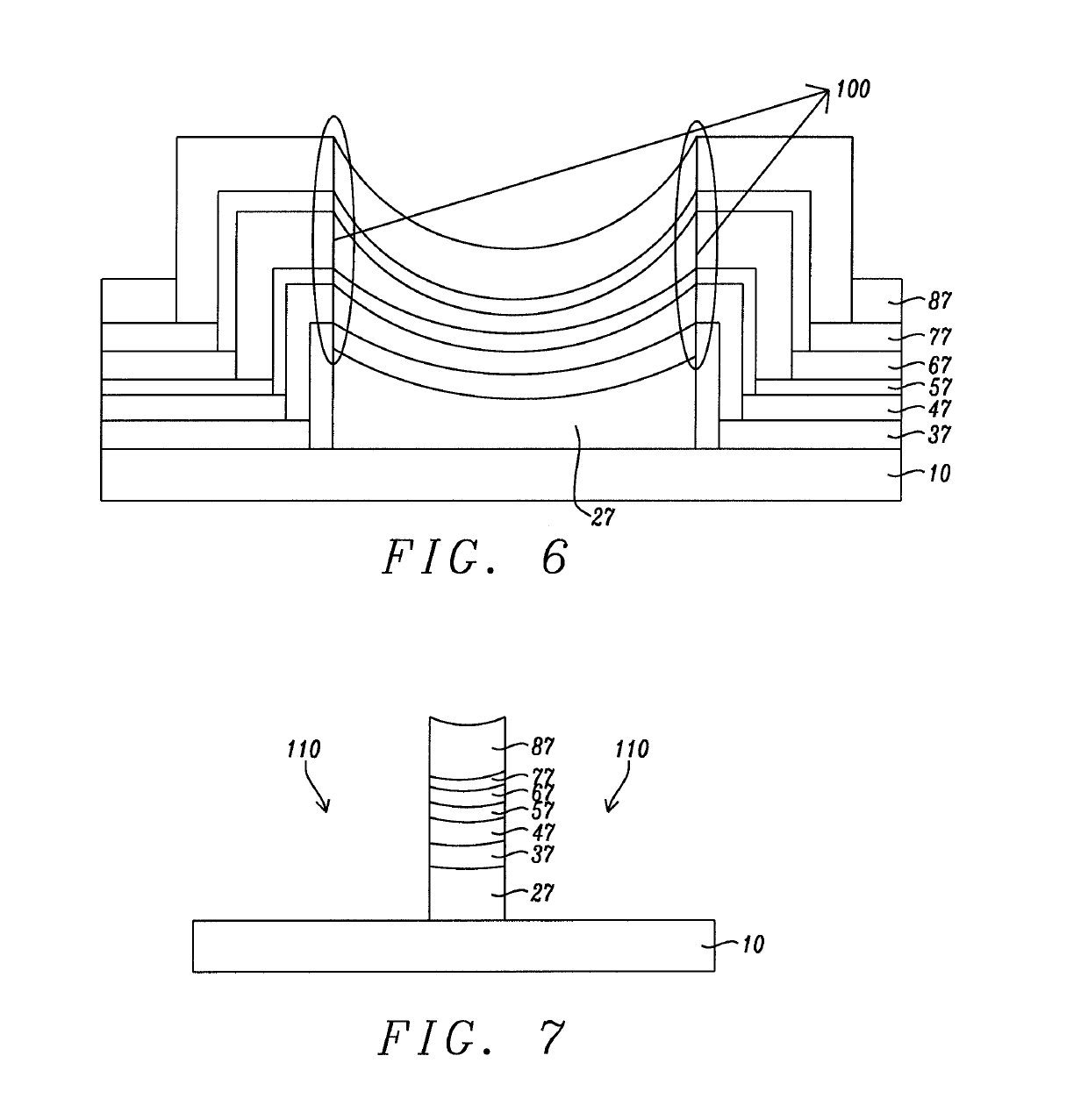

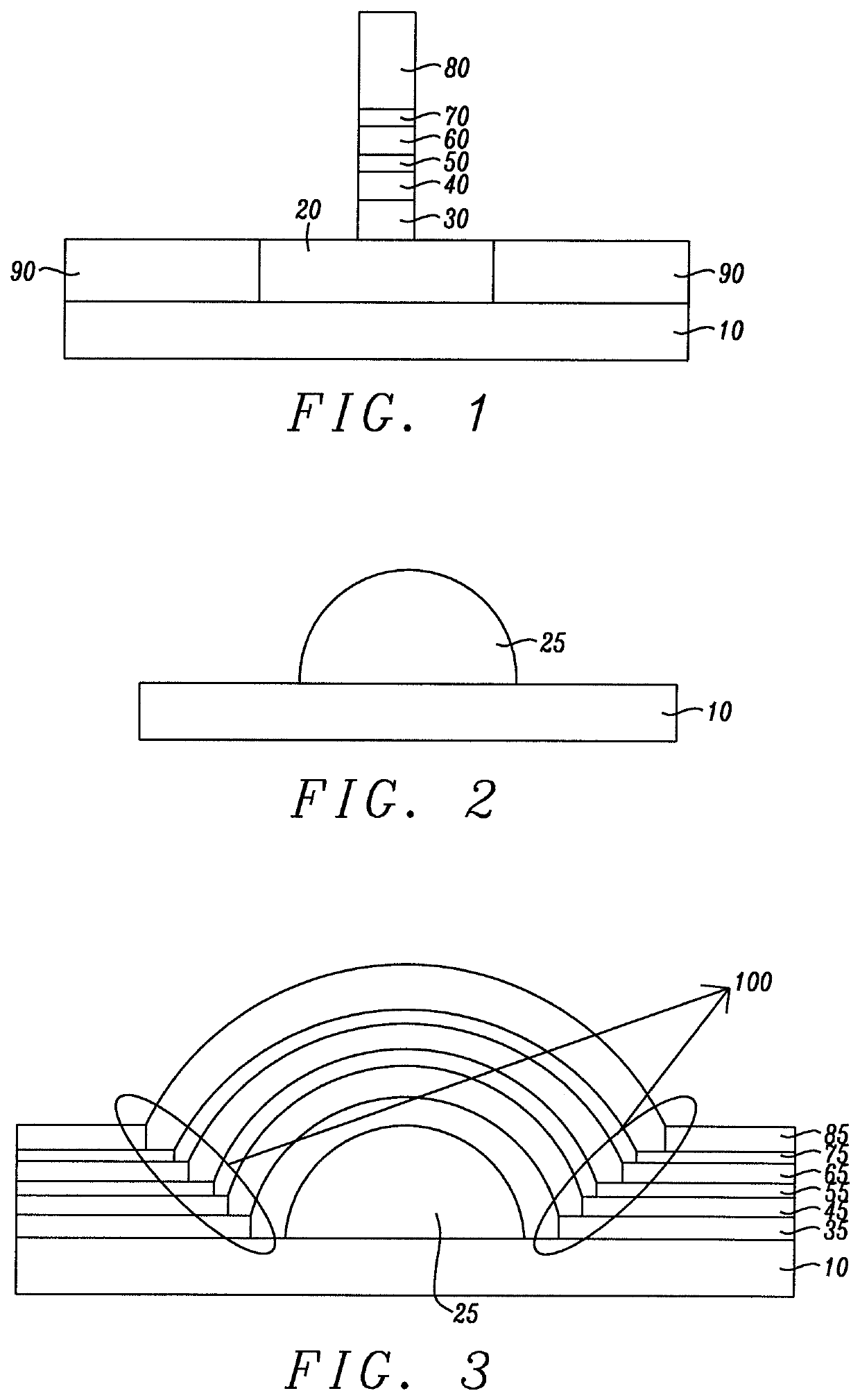

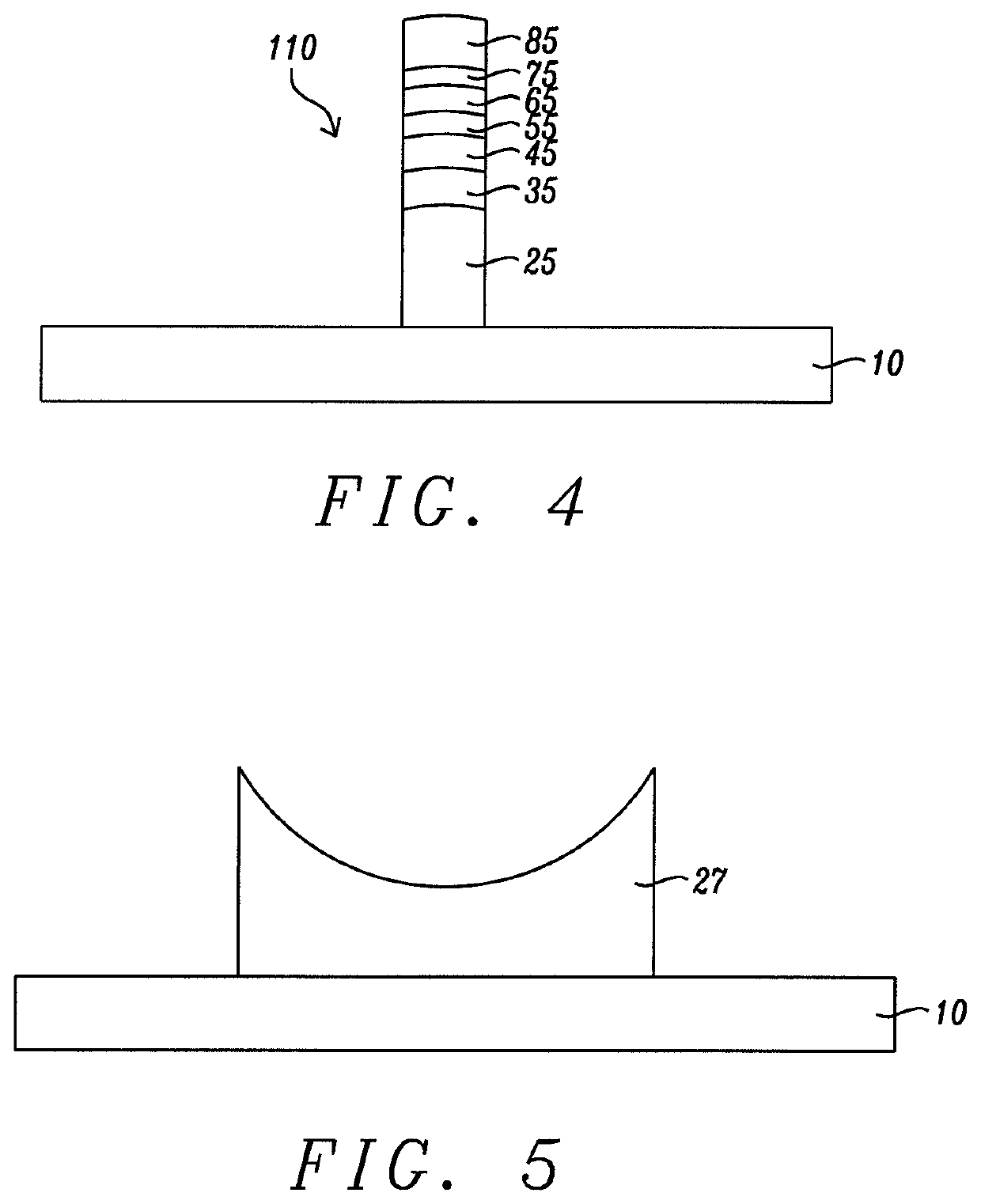

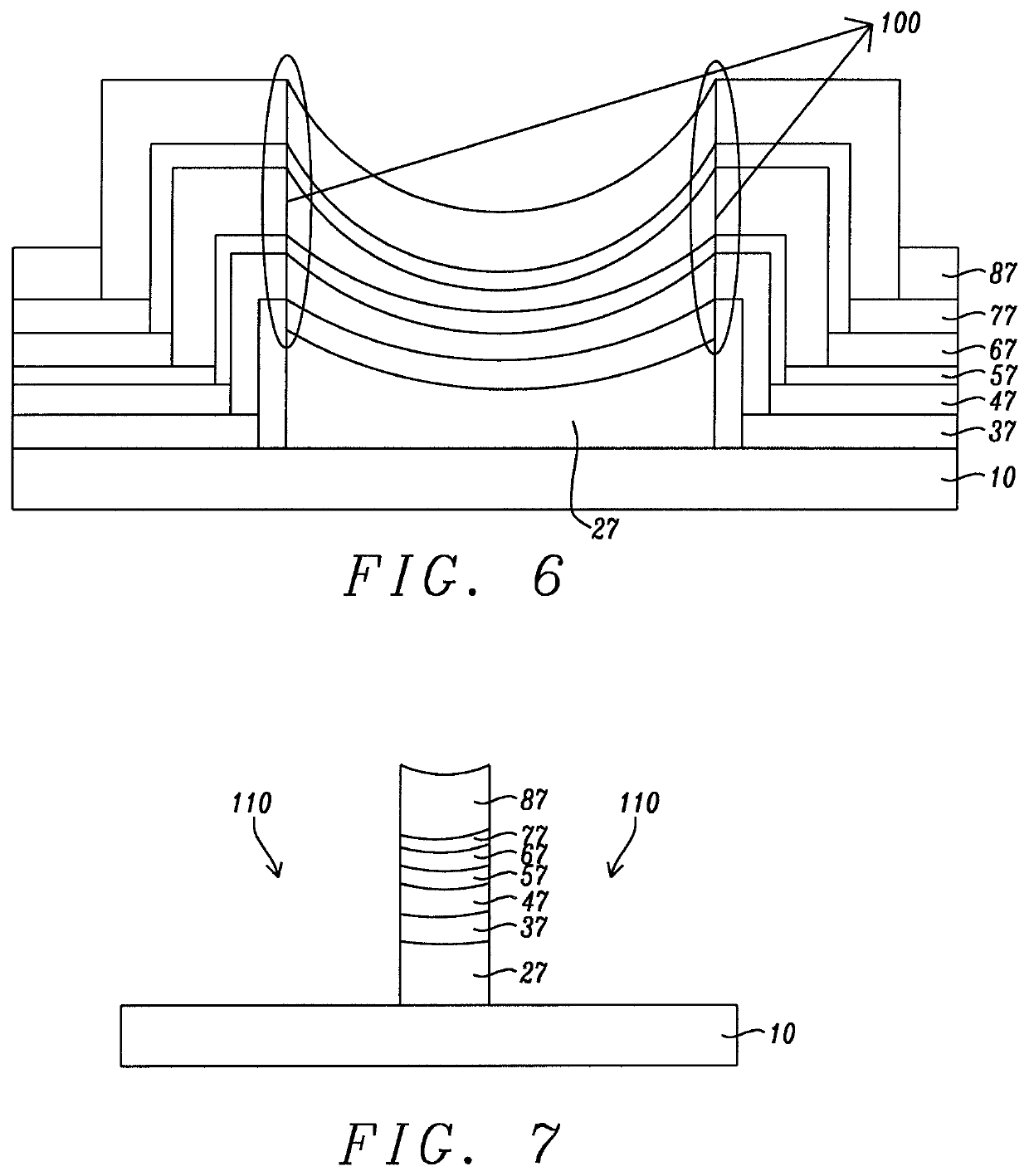

MTJ Device Performance by Controlling Device Shape

ActiveUS20190148630A1Improve performanceReduces interfacial defect concentrationMagnetic-field-controlled resistorsGalvano-magnetic material selectionAxis of symmetryEngineering

A layered thin film device, such as a MTJ (Magnetic Tunnel Junction) device can be customized in shape by sequentially forming its successive layers over a symmetrically curved electrode. By initially shaping the electrode to have a concave or convex surface, the sequentially formed layers conform to that shape and acquire it and are subject to stresses that cause various crystal defects to migrate away from the axis of symmetry, leaving the region immediately surrounding the axis of symmetry relatively defect free. The resulting stack can then be patterned to leave only the region that is relatively defect free.

Owner:TAIWAN SEMICON MFG CO LTD

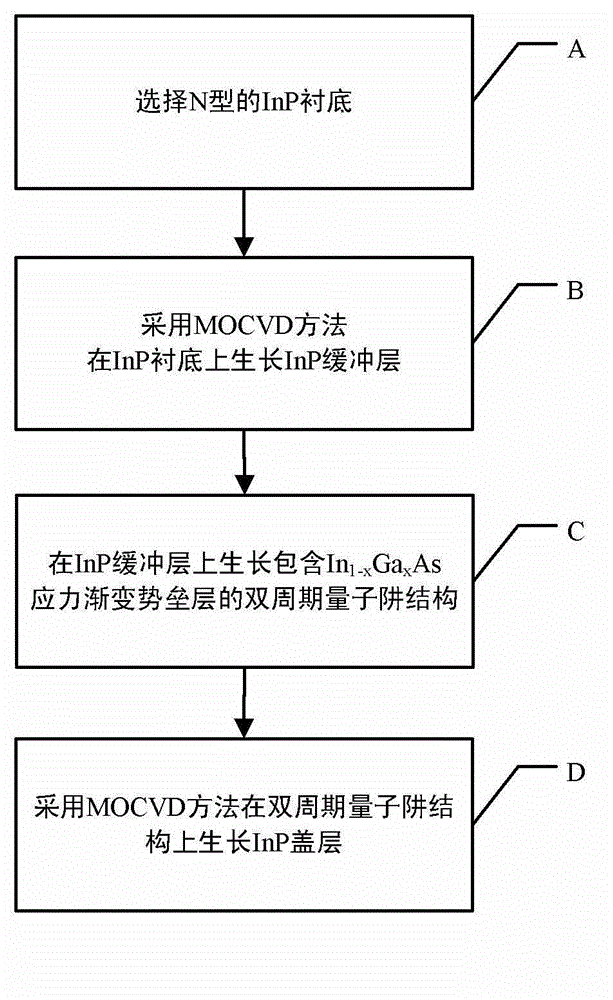

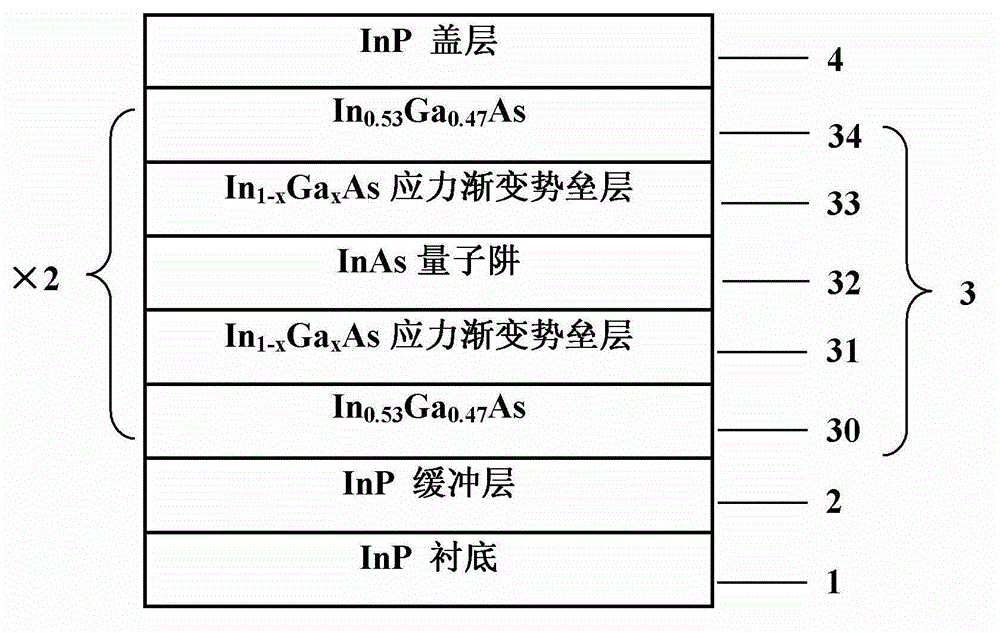

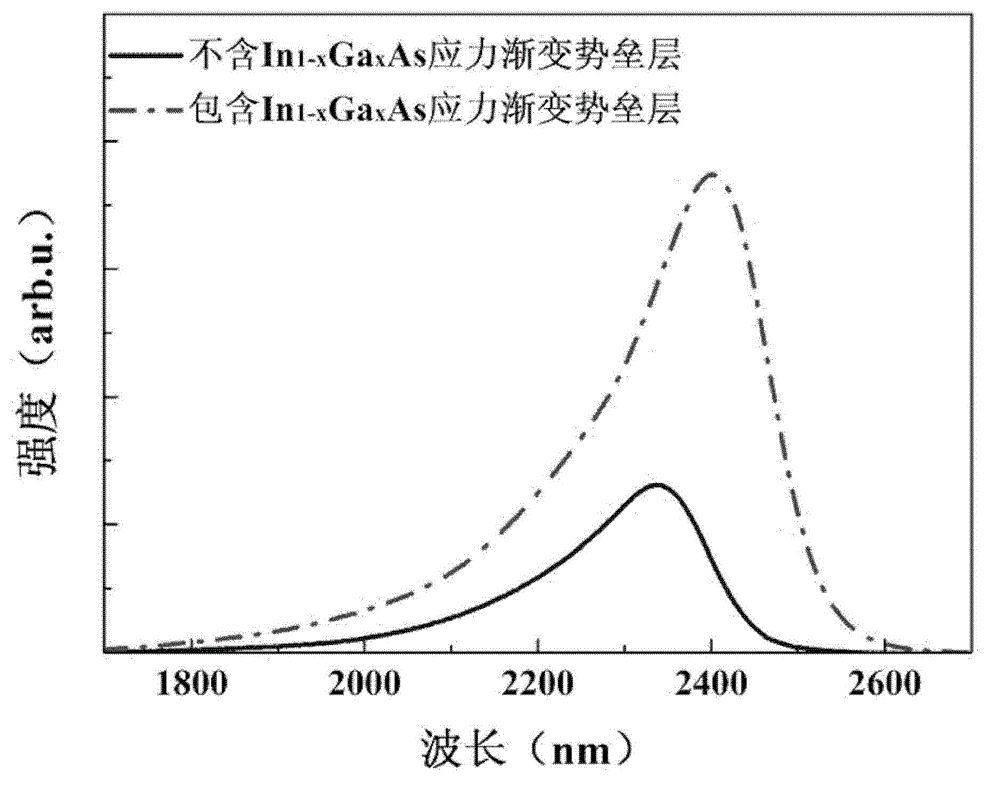

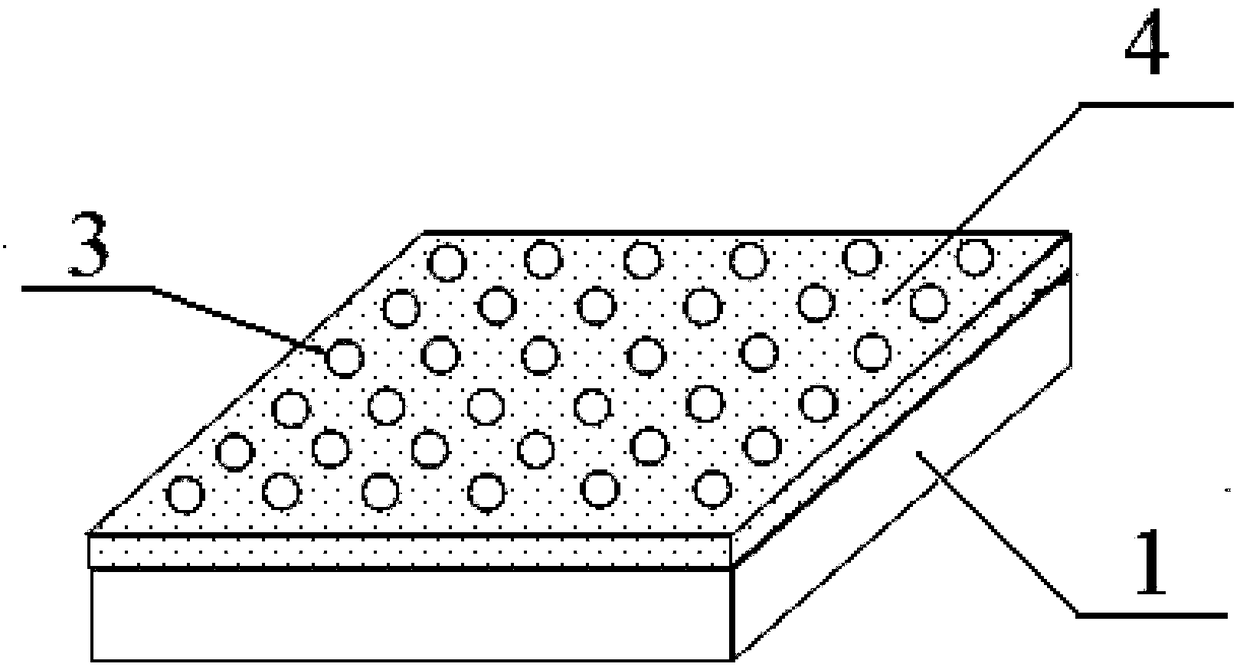

Method for growing InP base InAs quantum well

InactiveCN102983069AExtended emission wavelengthReduced band gapSemiconductor/solid-state device manufacturingQuantum wellLength wave

The invention provides a method for growing an InP base InAs quantum well. The method comprise the steps of growing an InP buffering layer on an InP substrate, growing an InAs quantum well structure on the InP buffering layer, and growing an InP cover layer on the InAs quantum well structure, wherein In[1-x]Ga[x]As stress gradation barrier layers are formed on the two sides of the InAs quantum well structure. According to the method, the In[1-x]Ga[x]As stress gradation barrier layers with gradual lattice constant are introduced on the two sides of the InAs quantum well to decelerate compression strain suffered by the InAs quantum well; defect concentrations in materials, which are produced due to the accumulated release of the strain, are reduced; the crystal quality of the InAs quantum well materials is improved; and luminous wavelengths of the InAs quantum well materials are extended.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

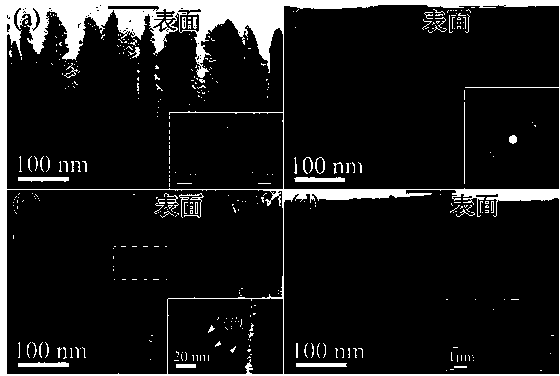

An aluminum nitride film growing method and application thereof

ActiveCN108538968AReduce defect concentrationImprove crystal qualityNanotechnologySemiconductor devicesThin membraneTrimethylaluminium

The invention provides an aluminum nitride film growing method and application thereof. The growing method comprises the steps of: 1) injecting trimethylaluminum and ammonia gas and growing a first aluminum nitride layer on a substrate; 2) performing nanoscale column body etching processing on the first aluminum nitride layer to obtain a column body recess aluminum nitride layer which has a plurality of nanoscale column body recesses; 3) controlling the temperature and the pressure of a reaction chamber and injecting trimethylaluminum and ammonia gas to grow a second aluminum nitride layer onthe column body recess aluminum nitride layer; 4) controlling the temperature and the pressure of the reaction chamber and injecting trimethylaluminum and ammonia gas to grow a third aluminum nitridelayer on the second aluminum nitride layer. The Mole-flow ratio of ammonia gas to trimethylaluminum in the step 3) is less than that in the step 4); the aluminum nitride film is the integration of thefirst aluminum nitride layer, the second aluminum nitride layer and the third aluminum nitride layer. The AlN thin film crystalline quality is remarkably improved.

Owner:MAANSHAN JASON SEMICON CO LTD

Method and apparatus for the production of silicon carbide crystals

ActiveUS7387680B2Reduce defectsReduce defect concentrationAfter-treatment apparatusPolycrystalline material growthCrystal growthSeed crystal

A method and apparatus for growing silicon carbide crystals is provided. The apparatus includes a sublimation chamber with a plurality of spaced apart dividers that can direct the direction of silicon carbide crystal growth into passages between the dividers to form a plurality of silicon carbide crystal plates. The silicon carbide crystal plates can be used as seed crystals in subsequent sublimation steps in a manner that promotes the growth of silicon carbide crystals in different crystallographic directions to thereby terminate defect formation.

Owner:CREE INC

Composite encapsulating material with high heat conduction activity and preparation method thereof

ActiveCN107841669AImprove thermal conductivitySmall expansion coefficientSemiconductor/solid-state device detailsSolid-state devicesThermal expansionMetal matrix composite

The invention discloses a composite encapsulating material with high heat conduction activity and a preparation method thereof, and belongs to the field of metal based composite materials. The composite material consists of SnAg4Ti4 alloy powder, aluminum powder and diamond particle reinforcer, wherein volume percentage of diamond particles is 50%-70%, volume percentage of aluminum powder is 25%-49%, and volume percentage of SnAg4Ti4T alloy powder is 1%-5%. A preparation method for the composite encapsulating material comprises the following steps: preparing active brazing filler metal SnAg4Ti4 alloy powder through a vacuum gas-atomization powdering furnace, mechanically mixing powder, and putting mixed powder into a discharge plasma sintering furnace to prepare a diamond / aluminum composite material. The sintered composite material is relatively good in interface bonding, is relatively high in compactness, has heat conductivity of 703W / m.K, has a thermal expansion coefficient reduced to 7.9*10<-6> / K, and has compactness of 97.8% or more. The preparation method is strong in operability, is simple in process, and can be used for the fields of electronic encapsulating and the like.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

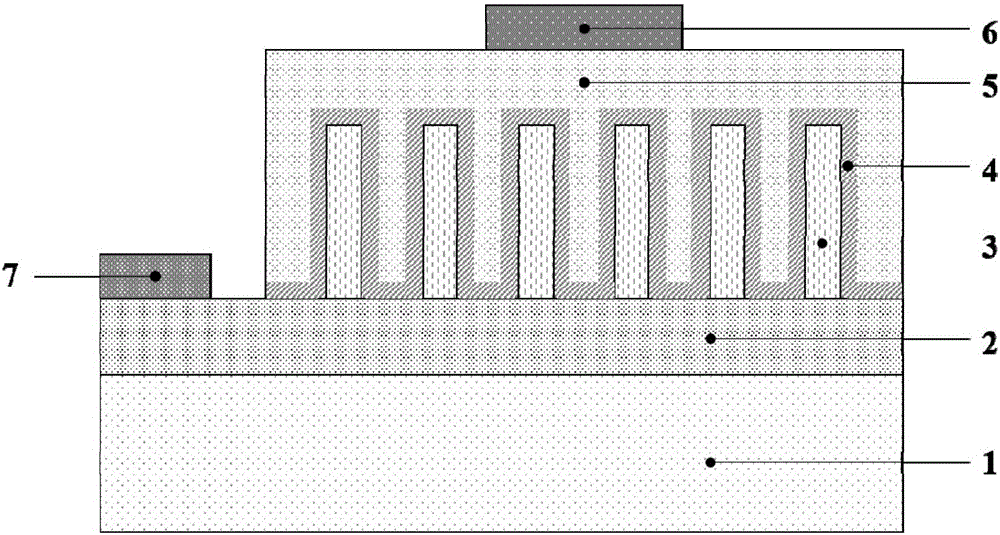

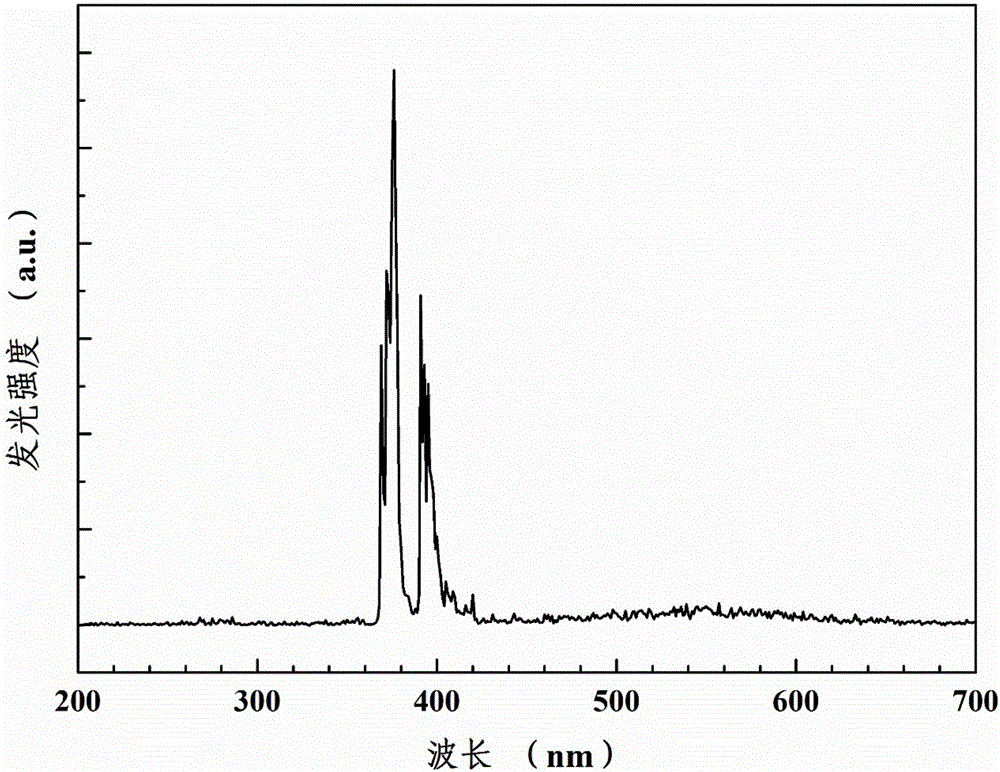

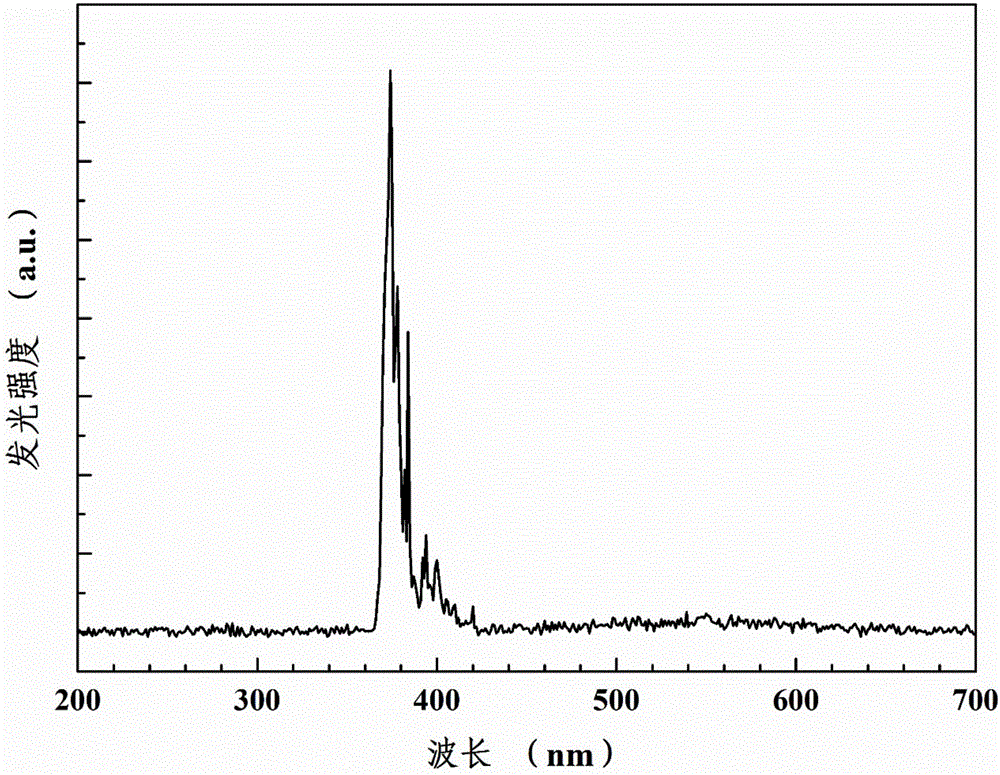

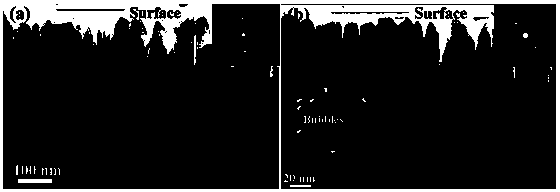

ZnO-based nanorod/ quantum well composite ultraviolet light-emitting diode and preparation method thereof

ActiveCN106601884AAchieving pure UV electroluminescenceReduce Mismatch ProblemsSemiconductor devicesExciton binding energyQuantum well

The invention discloses a ZnO-based nanorod / quantum well composite ultraviolet light-emitting diode and a preparation method thereof. The light-emitting diode comprises a substrate. The substrate is provided with an n-type ZnO thin film layer, a ZnO nanorod array, a ZnO / Zn1-xMgxO quantum well active layer, a p-type NiO thin film layer and a first electrode from the bottom up in sequence. A second electrode and the ZnO nanorod array are arranged on the n-type ZnO thin film layer in parallel; and the ZnO / Zn1-xMgxO quantum well active layer covers the ZnO nanorod array, 0.1<=x<=0.3. The light-emitting diode electroluminescent peak wavelength is around 374 nm, and full width at half maximum of the photoluminescence peak is around 17 nm; the light-emitting diode structure can give full play to the advantages of direct broadband gap and high exciton binding energy of the ZnO material and the like, so that polarization effect is reduced effectively, material and interface quality can be improved, effective area of the active layer is increased, light extraction efficiency is improved and spectrum monochromaticity is improved; and besides, low-temperature preparation can be realized, cost is low and industrialization can be realized easily.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

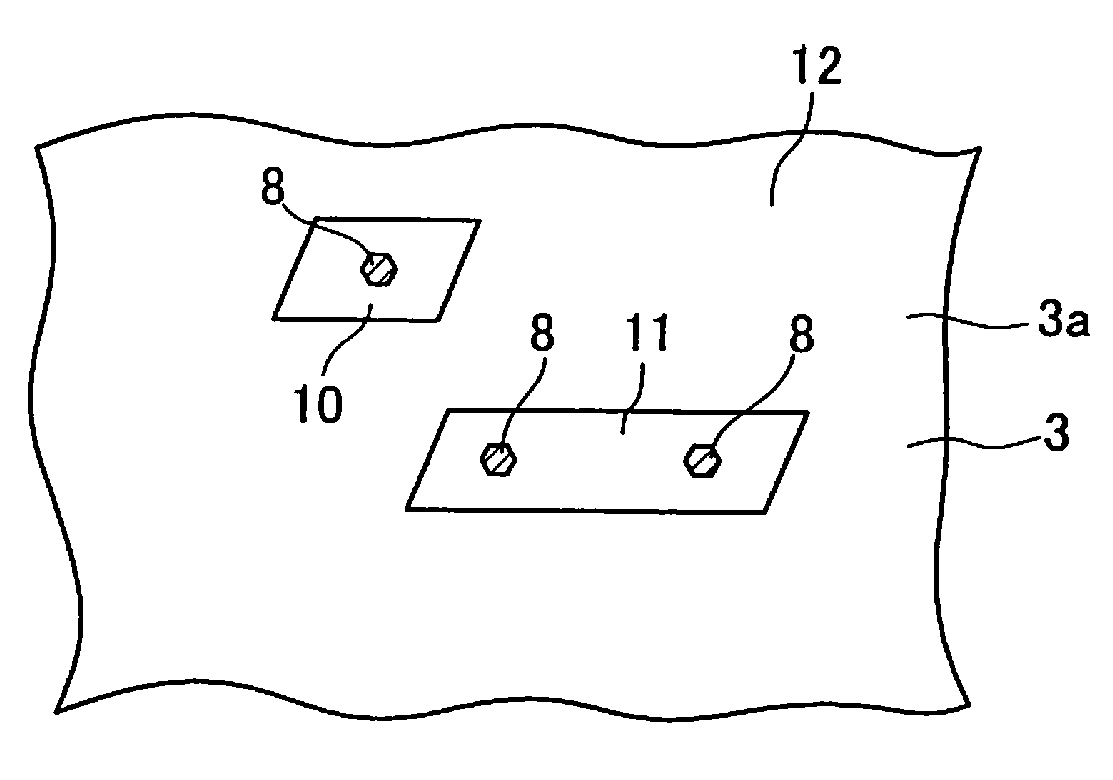

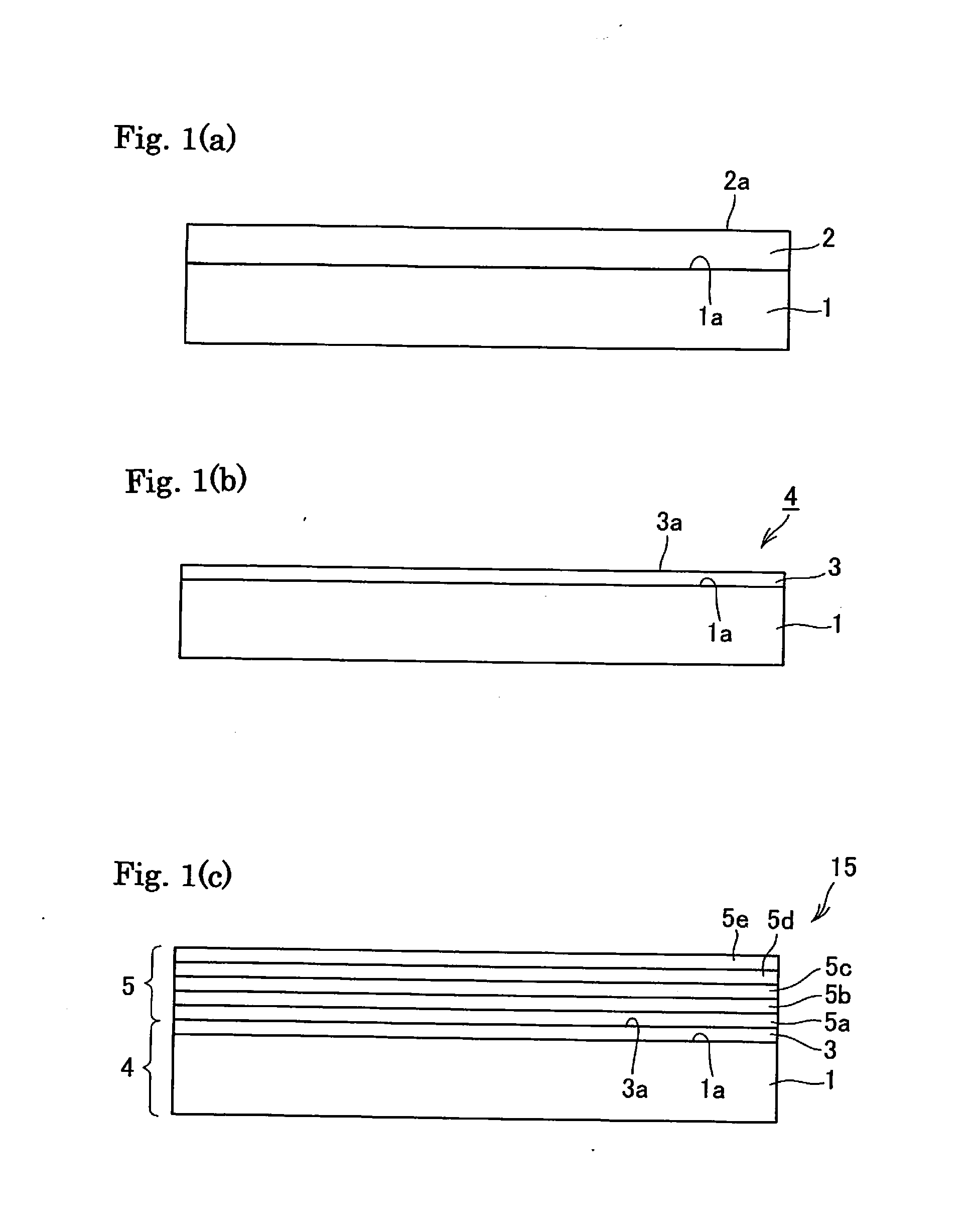

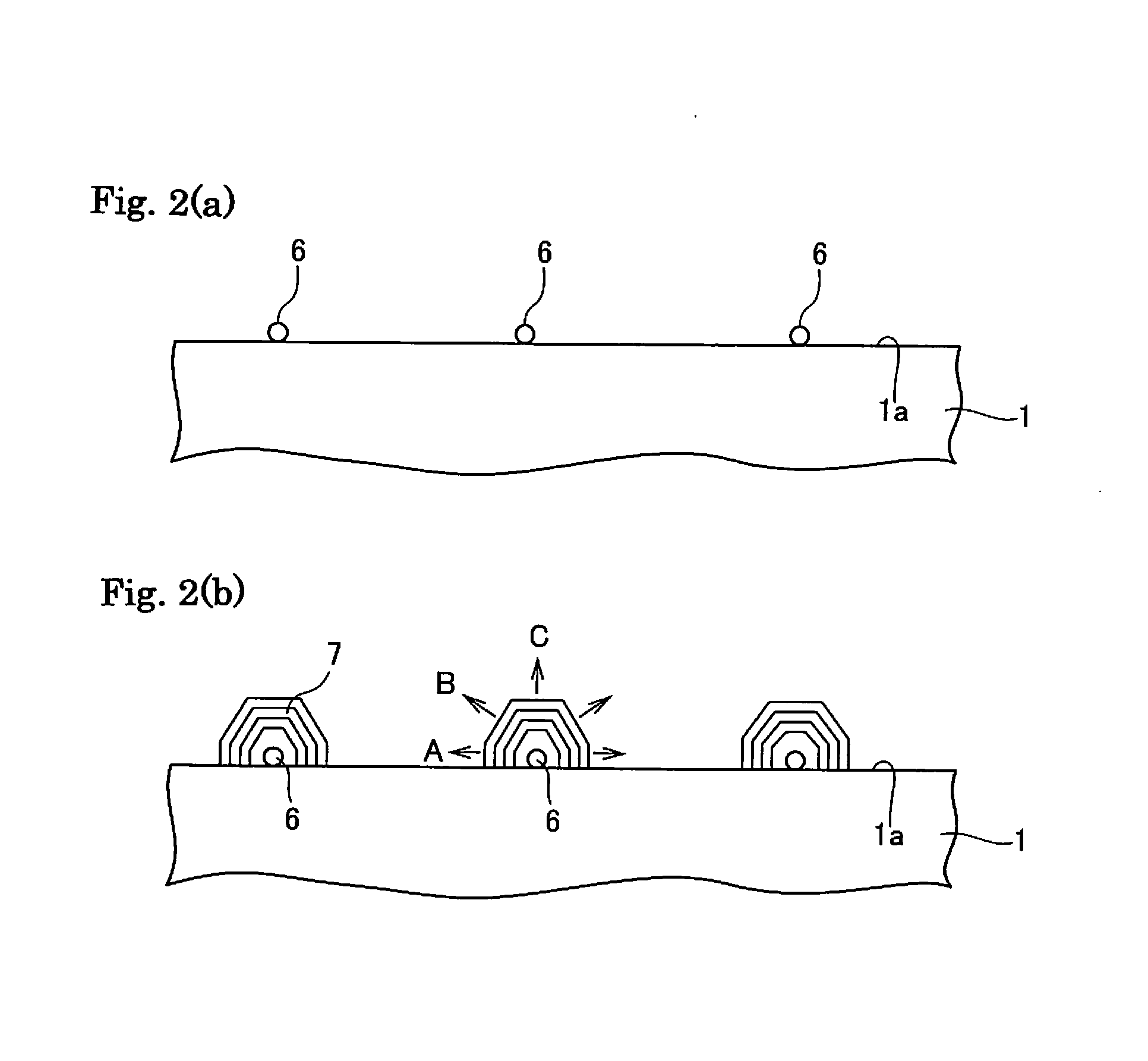

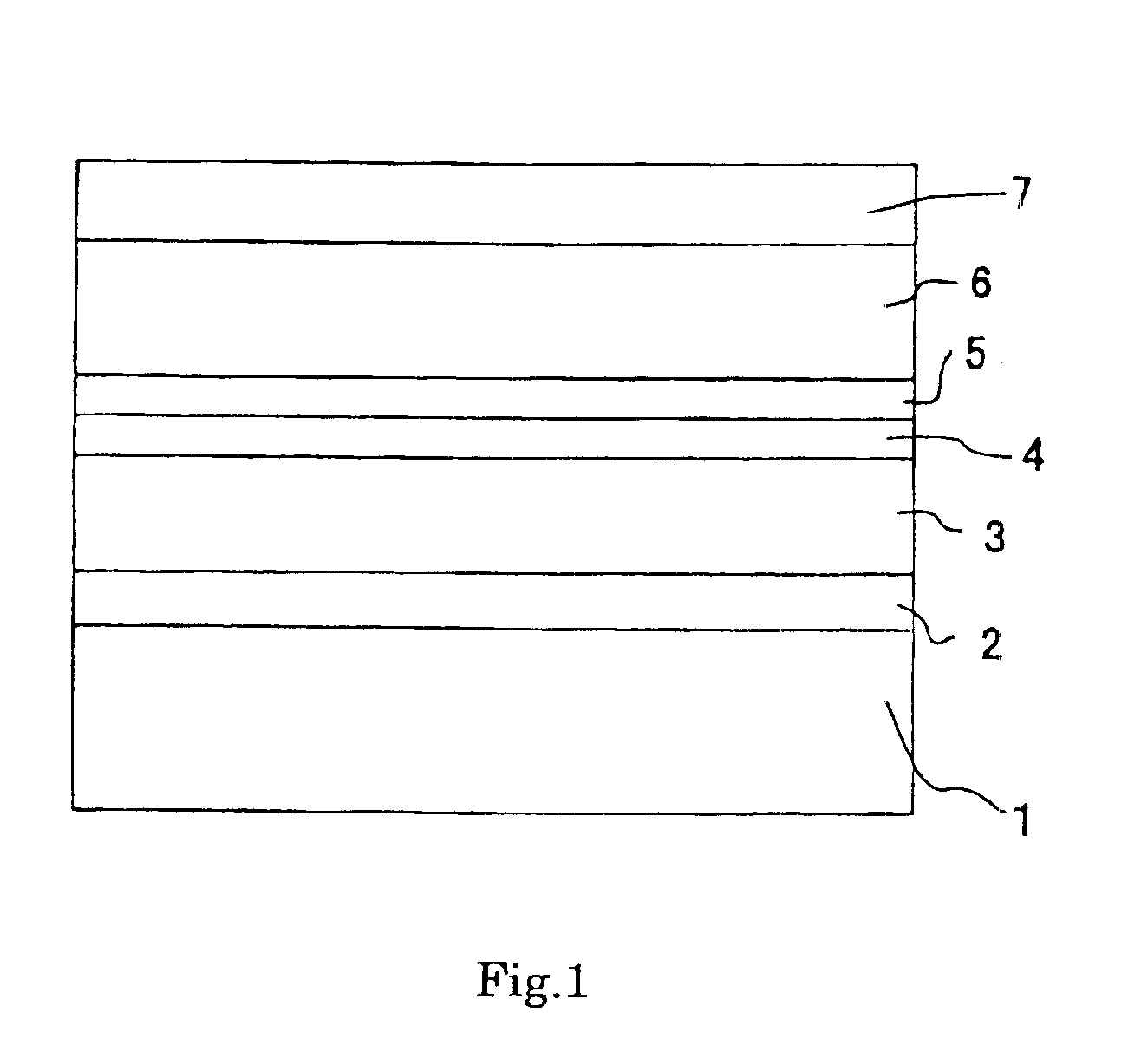

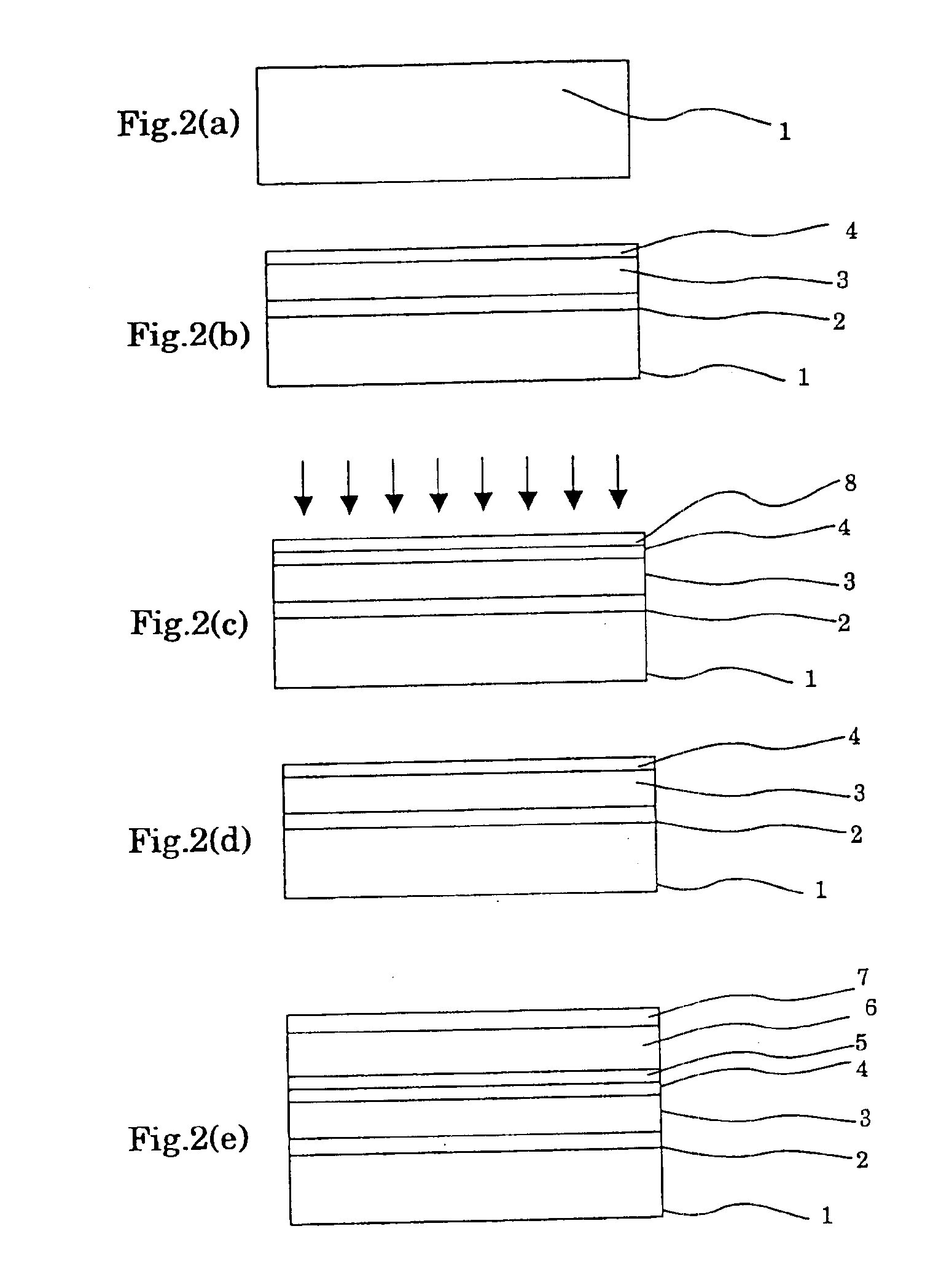

Manufacturing method for semiconductor substrate, and semiconductor device having a strained Si layer

InactiveUS6869897B2High degree of relaxation of strainReduce defect concentrationTransistorSemiconductor/solid-state device manufacturingTensile strainSemiconductor

The present invention provides a method for manufacturing a semiconductor substrate, comprising the step of: forming a first buffer Si layer on a substrate having a silicon surface; epitaxially growing, in sequence, a first strained SiGe layer and a first Si layer above the first buffer Si layer; implanting ions into the resulting substrate followed by annealing so as to relax the lattice of the first strained SiGe layer and to thereby providing tensile strain in the first Si layer and so that tensile strain is provided in the first Si layer; and epitaxially growing, in sequence, a second buffer Si layer and a second SiGe layer above the resulting substrate; and forming a second Si layer having tensile strain on the second SiGe layer.

Owner:SHARP KK

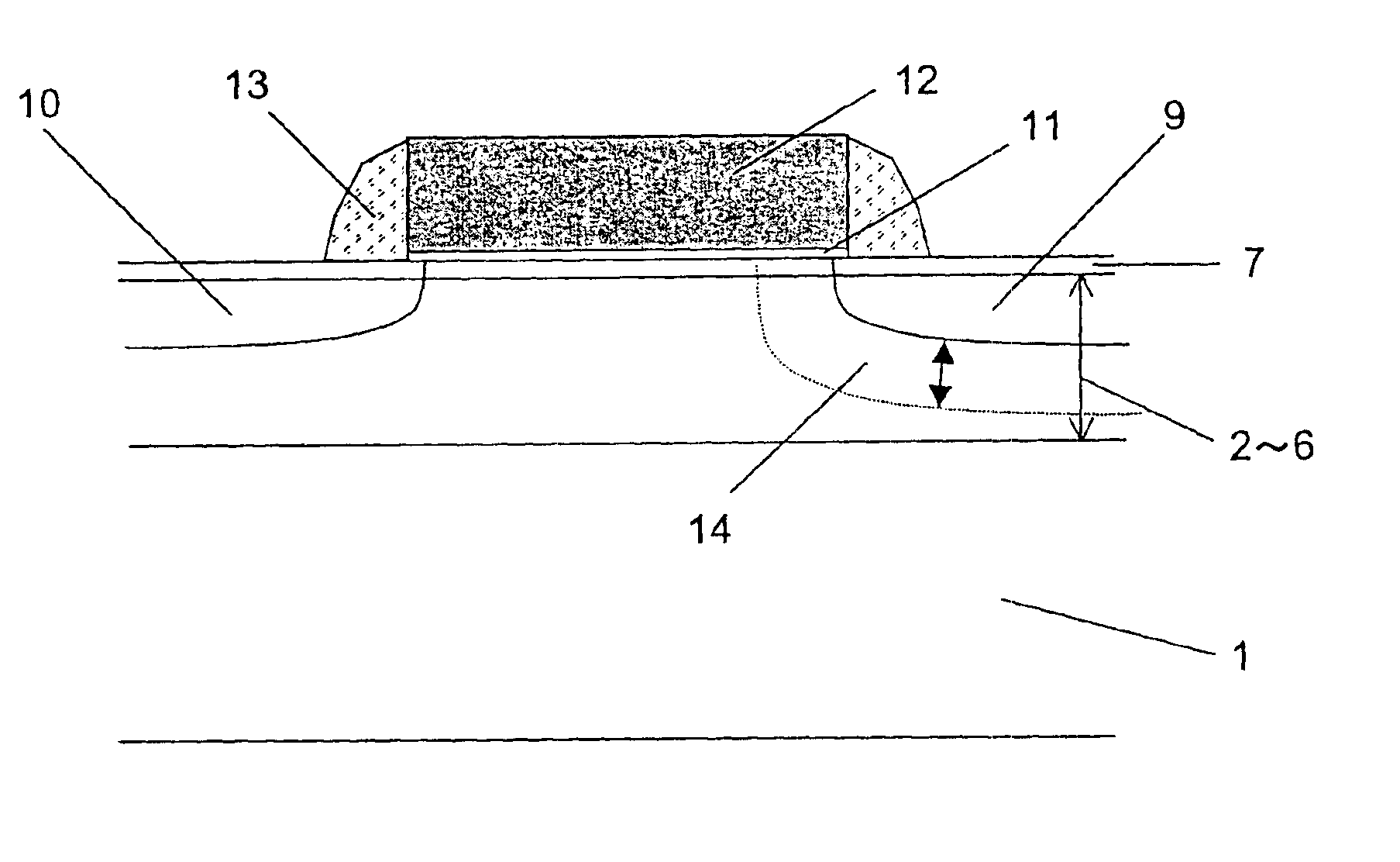

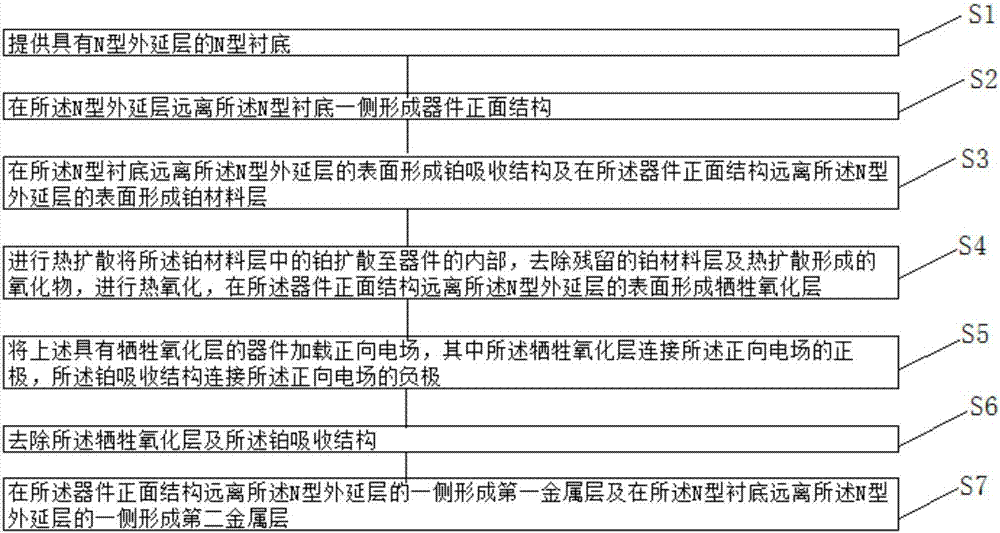

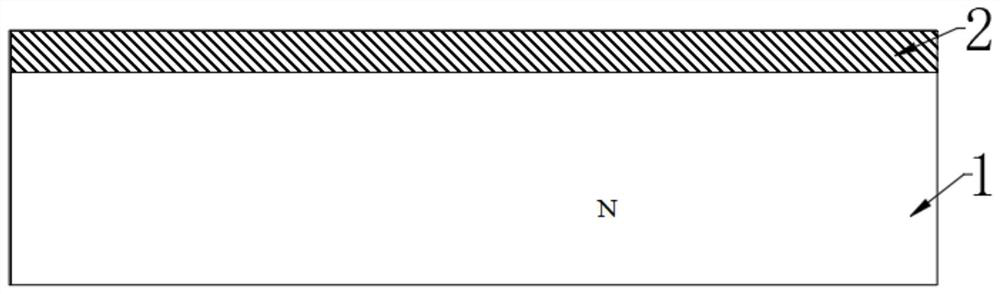

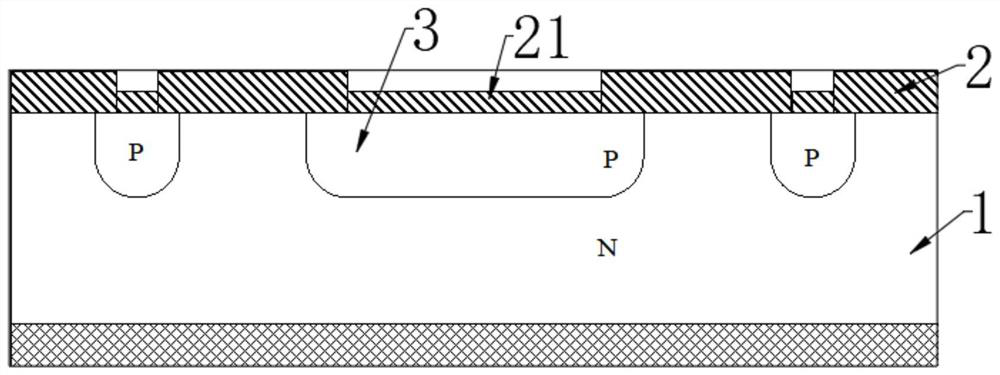

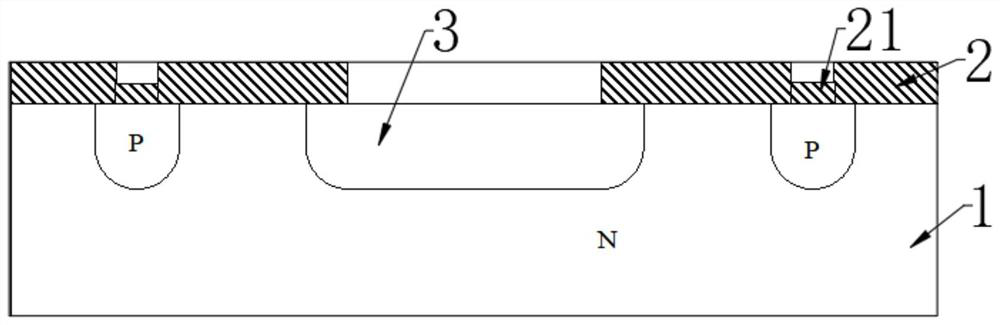

Manufacturing method of fast recovery diode

InactiveCN108010842AWon't spreadReduce defect concentrationSemiconductor/solid-state device manufacturingSemiconductor devicesPlatinumElectric field

The invention provides a manufacturing method of a fast recovery diode. The manufacturing method of the fast recovery diode comprises following steps: providing an N-type substrate with an N-type epitaxial layer; forming a device front structure at one side, far from the N-type substrate, of the N-type epitaxial layer; forming a platinum absorption structure on the surface, far from the N-type epitaxial layer, of the N-type substrate and forming a platinum material layer on the surface, far from the N-type epitaxial layer, of the device front structure; performing thermal diffusion to diffuseplatinum in the platinum material layer to the internal part of a device; removing the remaining platinum material layer and an oxide formed by thermal diffusion, performing thermal oxidation, and forming a sacrifice oxide layer on the surface, far from the N-type epitaxial layer, of the device front structure; loading a forward electric field to the device with the sacrifice oxide layer, whereinthe sacrifice oxide layer is connected with a positive voltage of the forward electric field, and the platinum absorption structure is connected with a negative voltage of the forward electric field;and removing the sacrifice oxide layer and the platinum absorption structure.

Owner:山东鲁磁电子有限公司

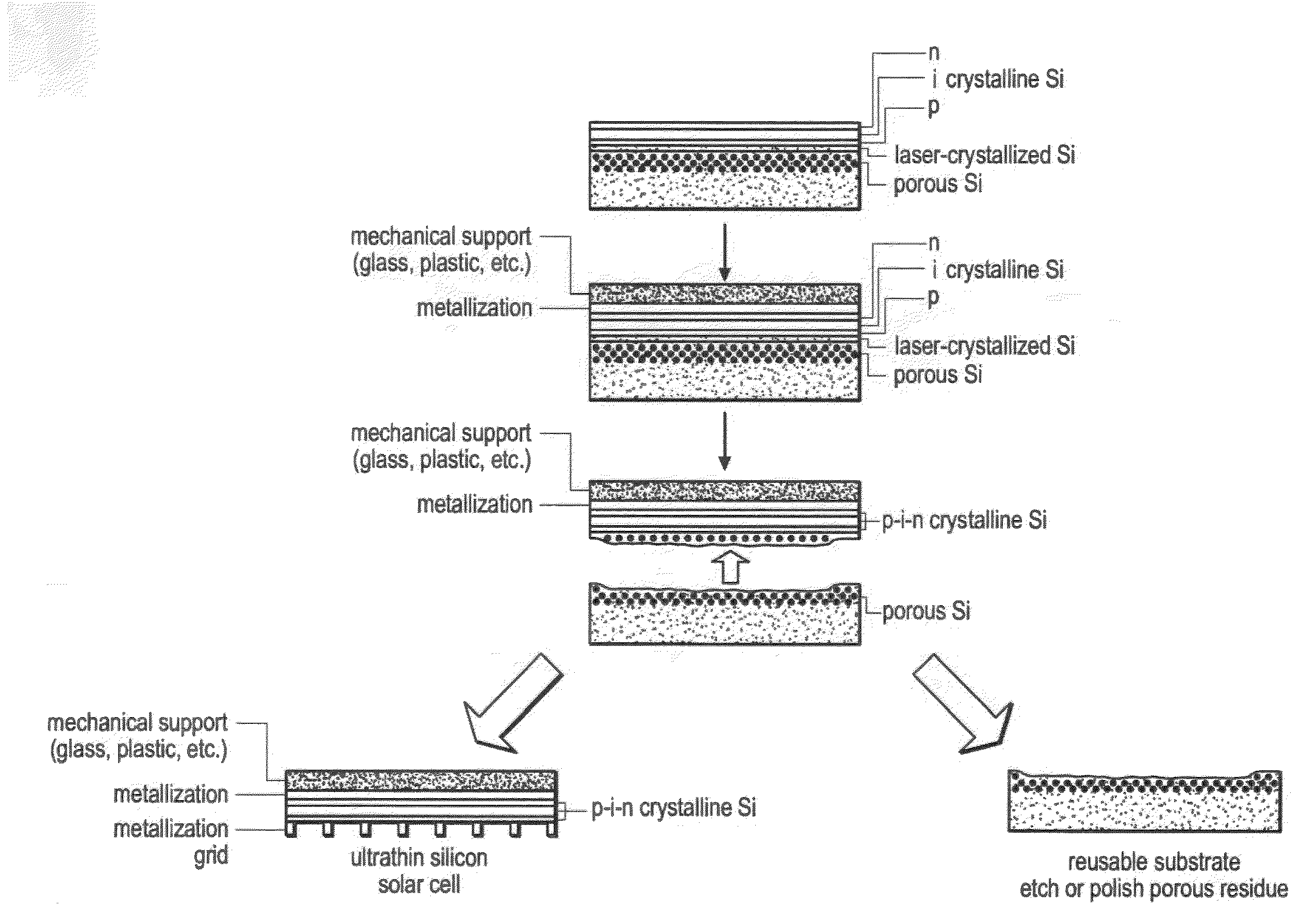

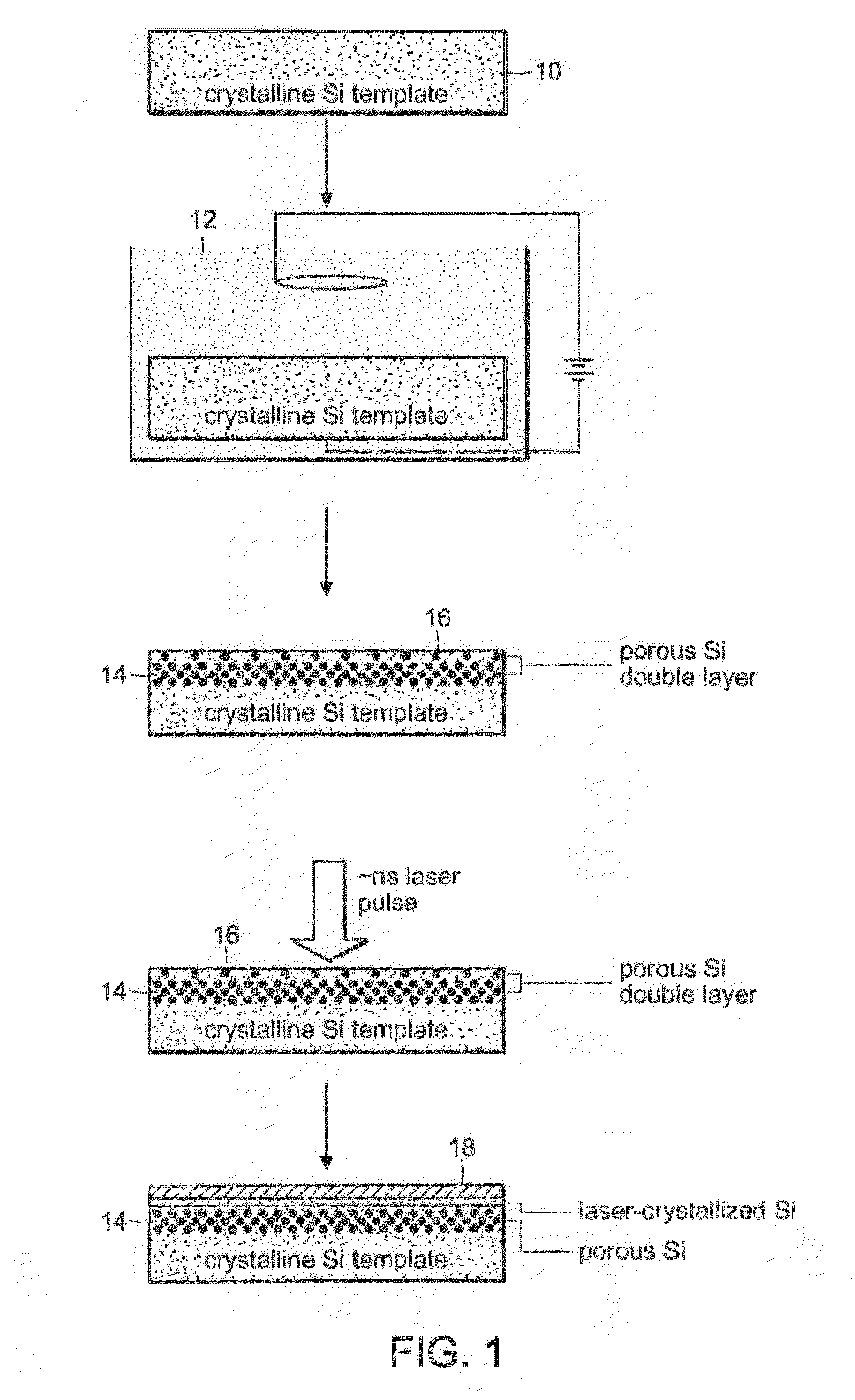

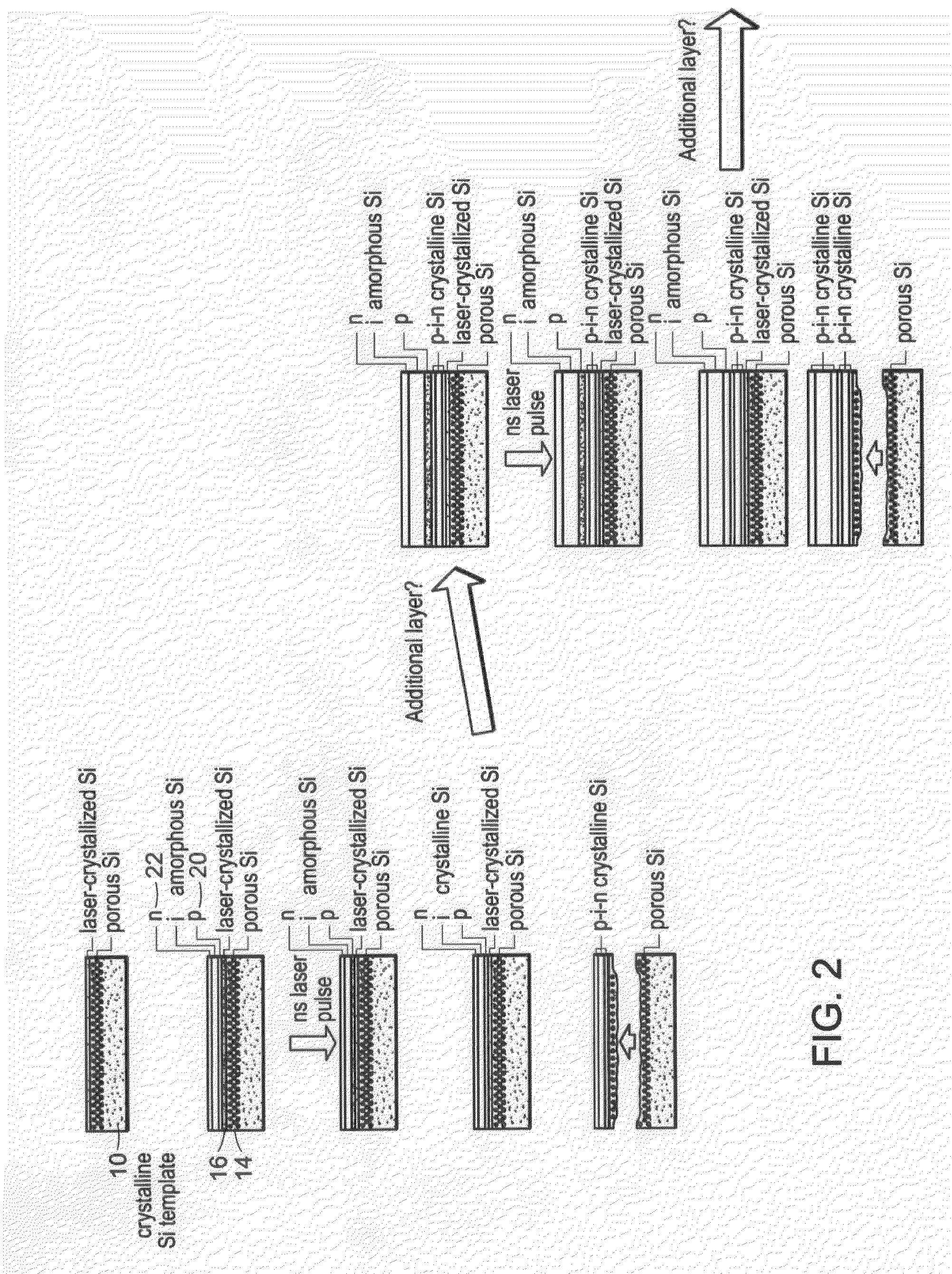

Method for producing thin layers of crystalline or polycrystalline materials

InactiveUS20130288463A1Large grainReduce defect concentrationFinal product manufactureSemiconductor/solid-state device manufacturingThin layerPolycrystalline material

Method for making thin crystalline or polycrystalline layers. The method includes electrochemically etching a crystalline silicon template to form a porous double layer thereon, the double layer including a highly porous deeper layer and a less porous shallower layer. The shallower layer is irradiated with a short laser pulse selected to recrystallize the shallower layer resulting in a crystalline layer. Silicon is deposited on the recrystallized shallower layer and the silicon is irradiated with a short laser pulse selected to crystalize the silicon leaving a layer of crystallized silicon on the template. Thereafter, the layer of crystallized silicon is separated from the template. The process of the invention can be used to make optoelectronic devices.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE +1

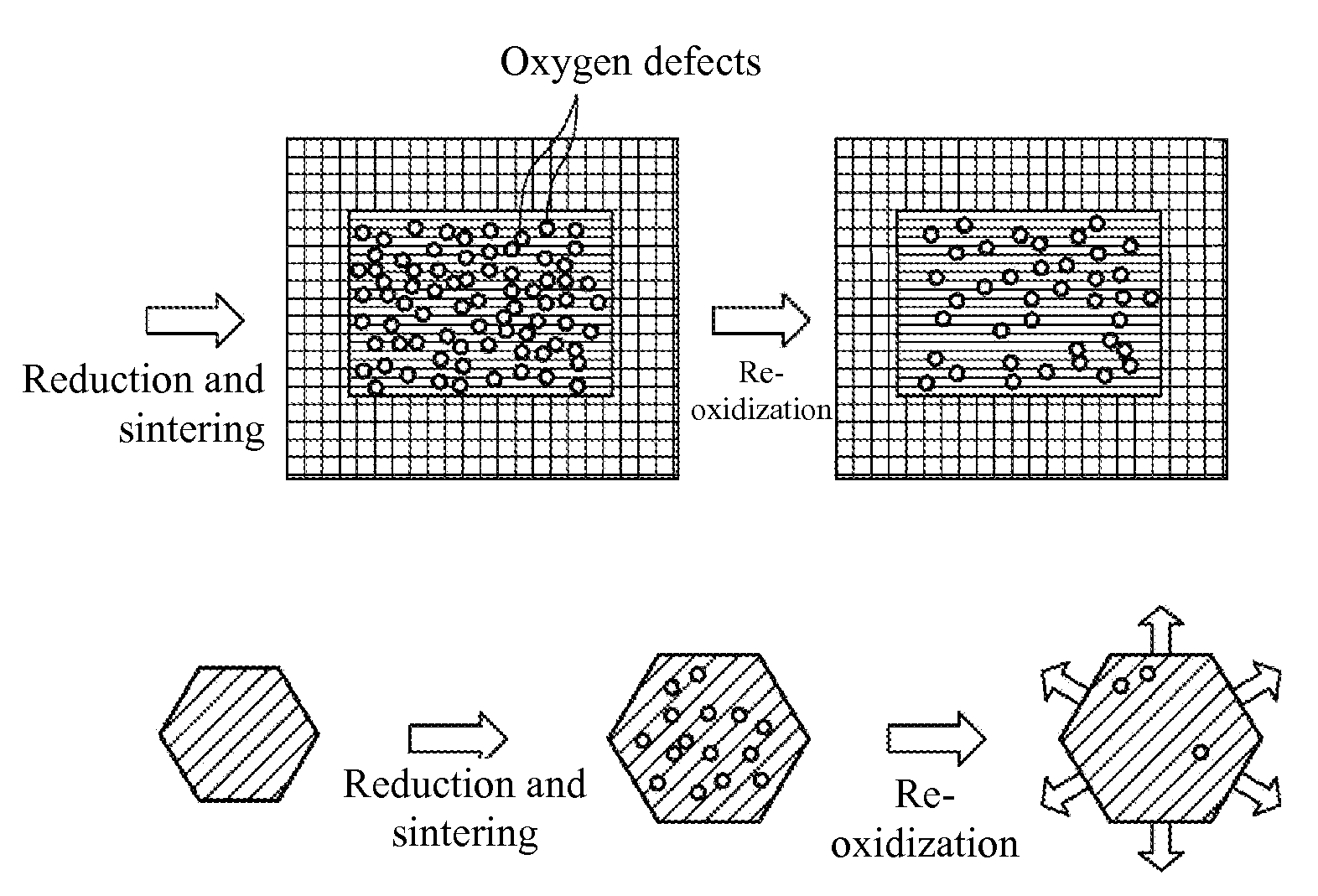

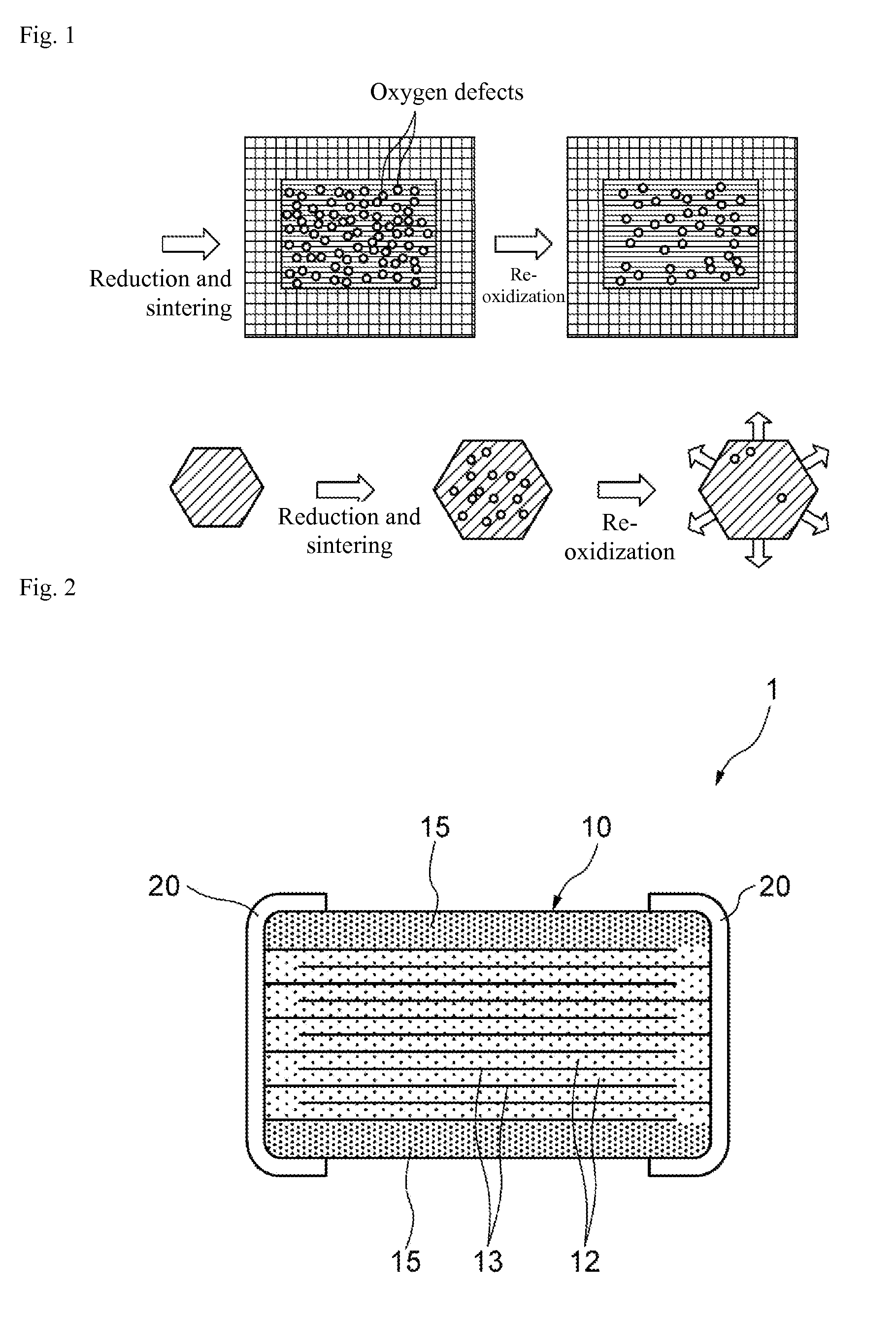

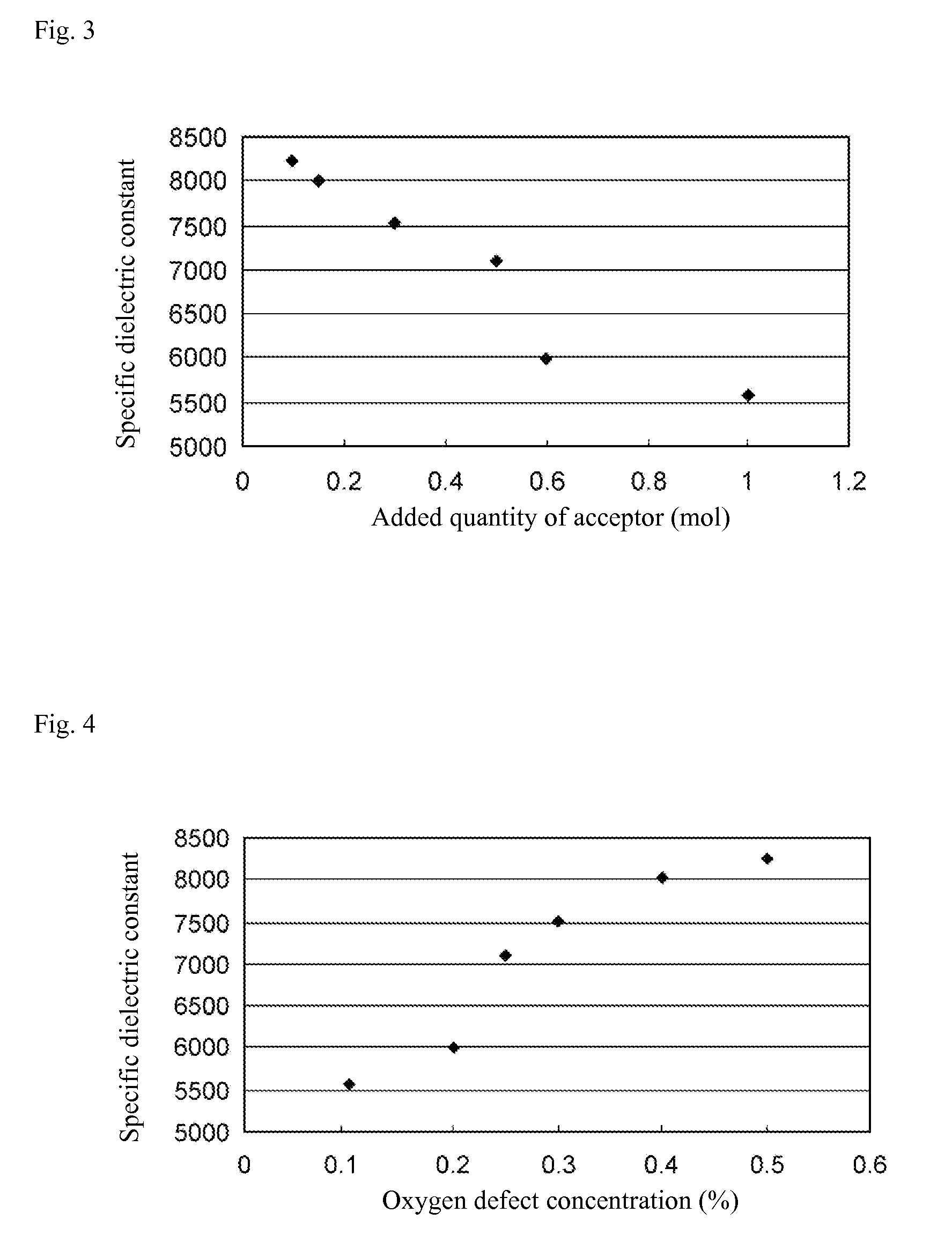

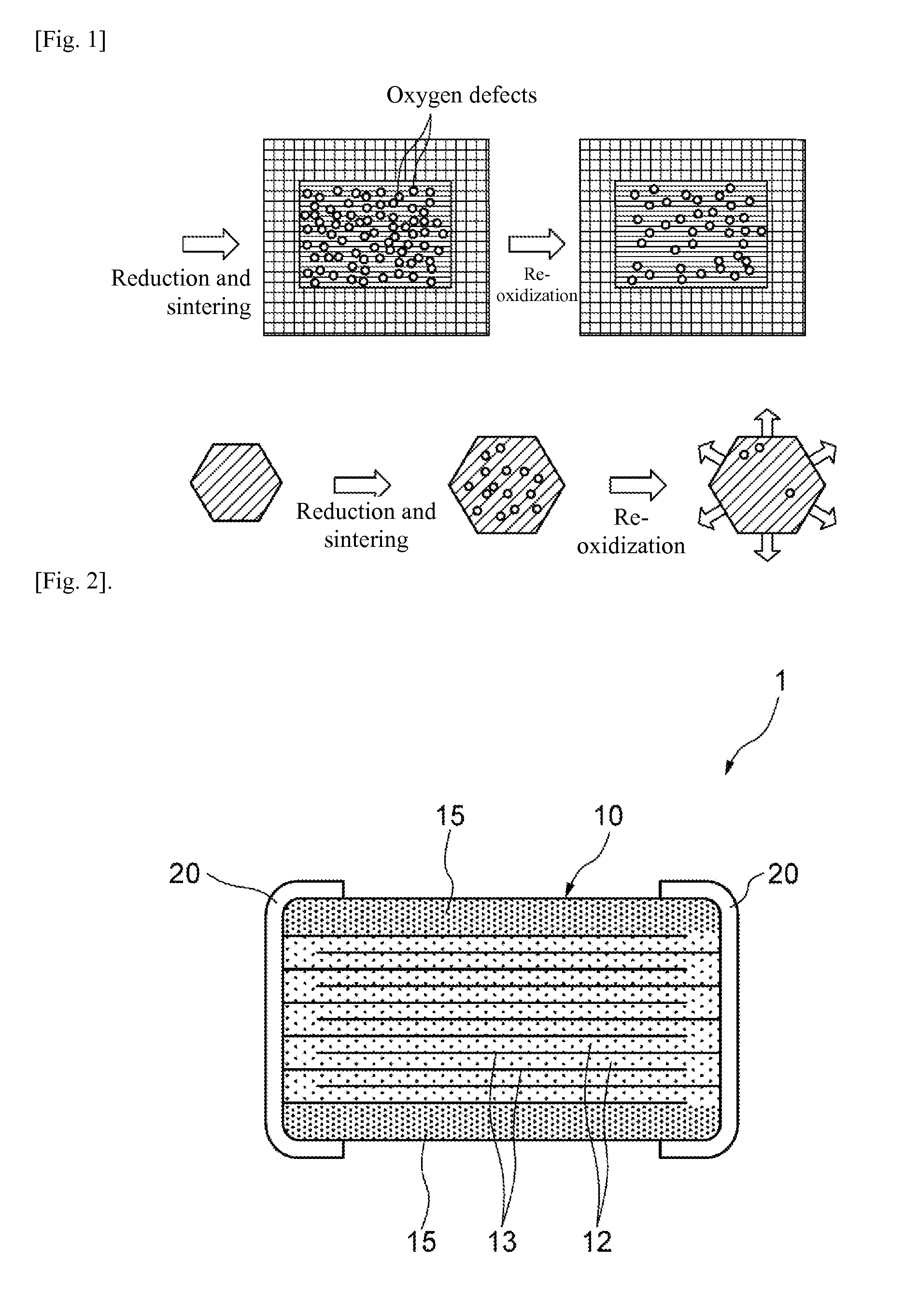

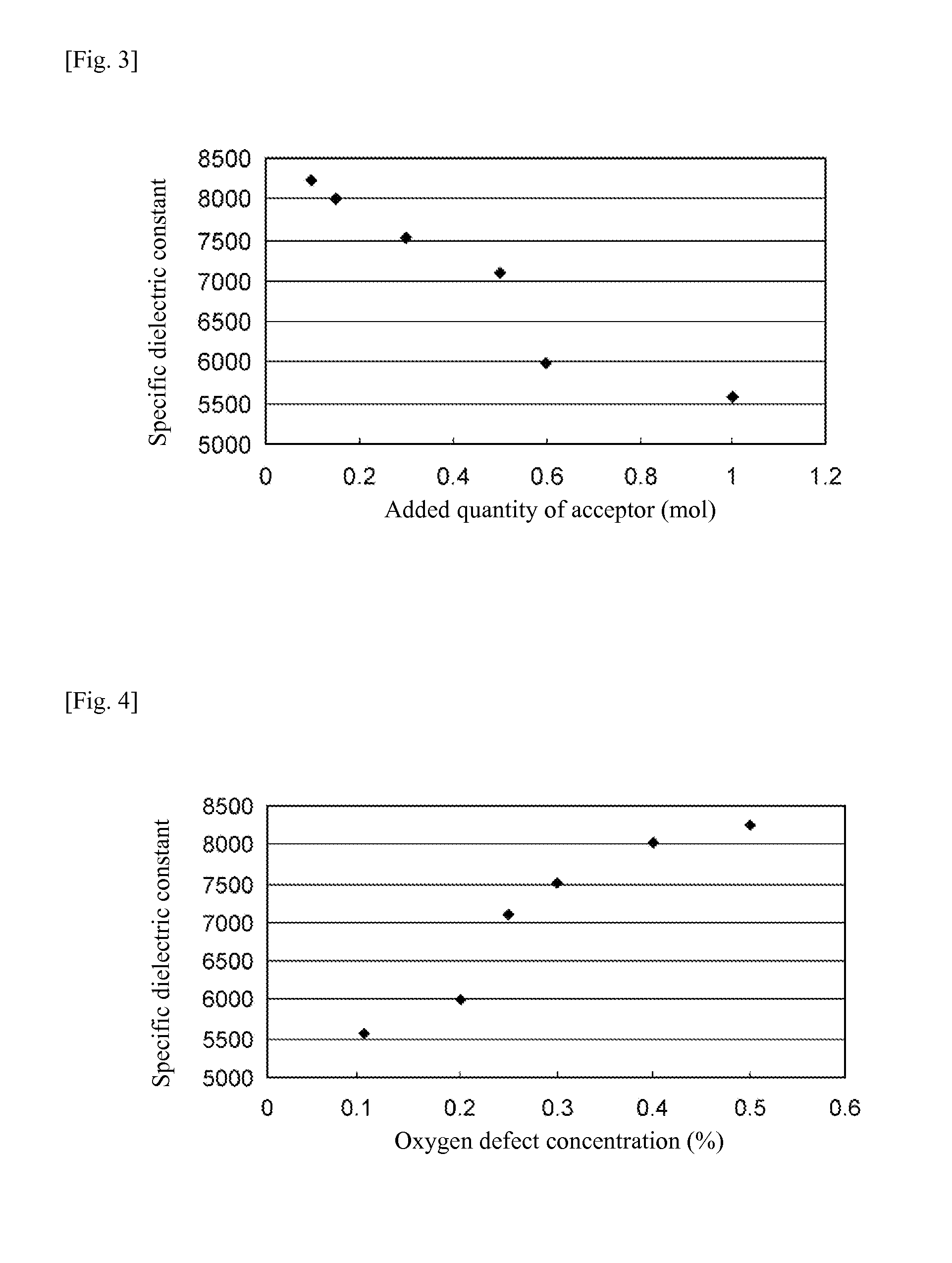

Dielectric ceramic, multi-layer ceramic capacitor and method of manufacturing the same

ActiveUS20140036407A1Suppress generationAvoid grain growthFixed capacitor dielectricStacked capacitorsDielectricCeramic capacitor

A dielectric ceramic is formed with sintered grains constituting the dielectric have an average grain size of 0.2 to 1.0 gm and an oxygen defect concentration of 0.2 to 0.5%. An acceptor element is added to the dielectric ceramic by no more than 0.5 mol per 100 mol of the primary component of BaTiO3. The oxygen defect concentration is temporarily increased by reduction and sintering, after which the oxygen defect concentration is reduced through the subsequent re-oxidization process. Crystal strain generated in the re-oxidization process increases the dielectric constant.

Owner:TAIYO YUDEN KK

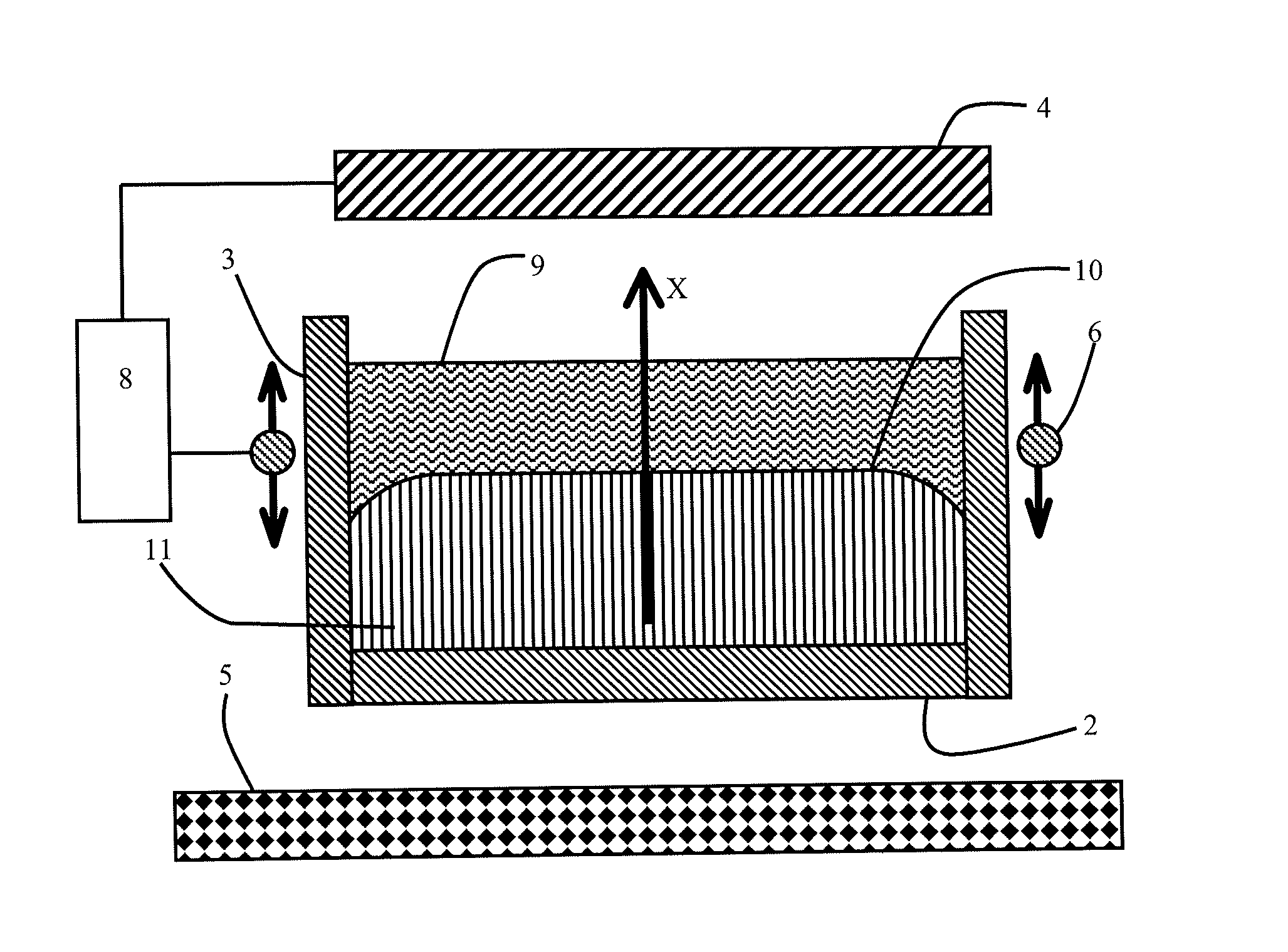

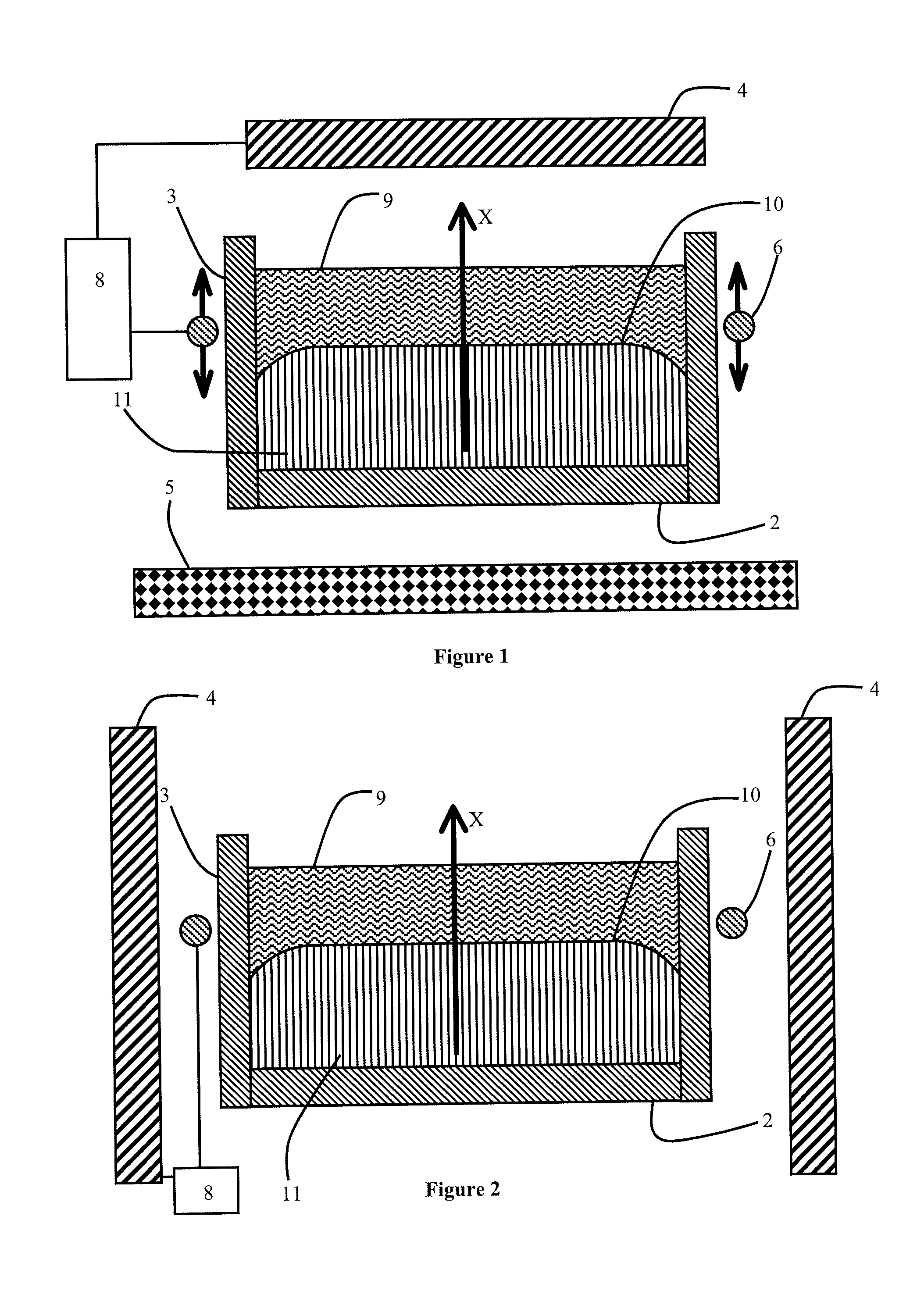

System for manufacturing a crystalline material by directional crystallization provided with an additional lateral heat source

InactiveUS20140190398A1Easy to manufactureReduce defect concentrationAfter-treatment apparatusPolycrystalline material growthCrucibleCrystalline materials

The crystallization system includes a crucible provided with a bottom and with side walls designed to contain the material to be solidified and a device for creating a main thermal gradient inside the crucible in a perpendicular direction to the bottom of the crucible. An additional inductive heating device is arranged at the level of the side walls of the crucible facing the liquid material and without overlapping with the solid phase. This additional inductive heating device is configured to heat a part of the crystalline material located in the vicinity of the triple contact line between the liquid material, the solidified material and the crucible so that the interface between the liquid material and the solidified material forms a convex meniscus in the vicinity of the triple contact line.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Platinum doping method of fast recovery diode

ActiveCN114093928AConductiveShort off timeSemiconductor/solid-state device manufacturingSemiconductor devicesMaterials sciencePolycrystalline silicon

The invention discloses a platinum doping method of a fast recovery diode in the technical field of semiconductor power devices. The platinum doping method comprises the following steps: growing an oxide layer on the front surface of an N-type silicon substrate; forming a doping window on the oxide layer and injecting boron ions to form a P-type doping region, then performing annealing treatment, and forming a thin oxide layer on the surface of the P-type doping region after annealing; forming a contact hole of a front electrode on the thin oxide layer; depositing polycrystalline silicon on the front surface of the oxide layer to form a polycrystalline silicon layer, wherein the polycrystalline silicon is in contact with the P-type doped region through a contact hole; and sputtering or evaporating a platinum metal layer on the back surface of the N-type silicon substrate. The diode chip prepared by the method has shorter turn-off time, smaller reverse overshoot current and higher softness; meanwhile, the electric leakage possibility of the chip is reduced, and the reliability of the chip is improved.

Owner:YANGZHOU GUOYU ELECTRONICS

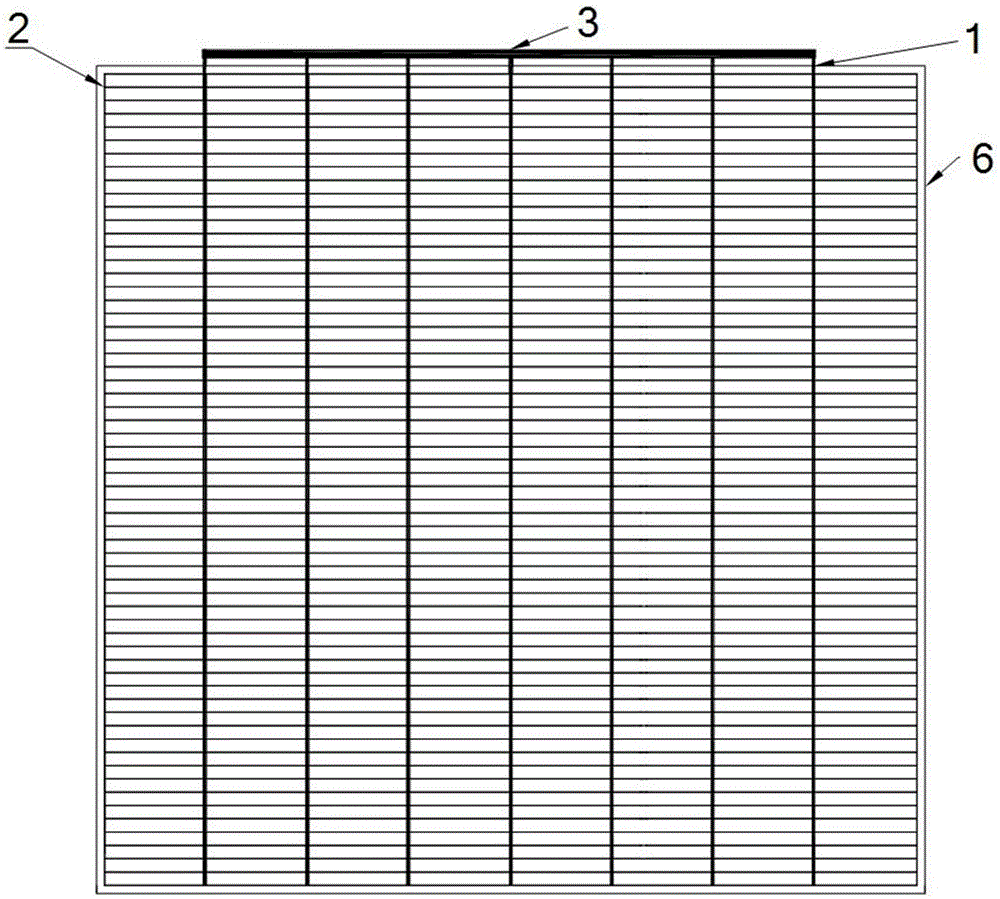

Crystalline silicon solar cell without Ag main grid line and manufacturing process therefor

InactiveCN105489692AImprove conversion efficiencyAchieve mass productionFinal product manufacturePhotovoltaic energy generationSlurrySilicon solar cell

The invention discloses a crystalline silicon solar cell without an Ag main grid line and a manufacturing process therefor. The crystalline silicon solar cell comprises a solar cell body, wherein the solar cell body comprises a light-receiving surface and a backlight surface; multiple light-receiving surface main grid lines and multiple light-receiving surface secondary grid lines are arranged on the light-receiving surface of the solar cell body; the light-receiving surface main grid lines and the light-receiving surface secondary grid lines are arranged in a perpendicular manner mutually; multiple backlight surface main grid lines are arranged on the backlight surface of the solar cell body; the light-receiving surface main grid lines and the backlight surface main grid lines are all manufactured by first conductive solder strips; and the light-receiving surface secondary grid lines are Ag secondary grid lines. The crystalline silicon solar cell without the Ag main grid line and the manufacturing process therefor have the beneficial effects that the Ag slurry consumption is greatly reduced, the cost is lowered, a sintering area between Ag and silicon is reduced, the defect concentration is lowered, and the conversion efficiency is improved; multiple main grid lines can be designed, so that the battery conversion efficiency is further improved; and quantity production can be realized, and the production cost is low.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Thin film deposition via charged particle-depleted plasma achieved by magnetic confinement

InactiveUS8017198B2Increase deposition rateImprove photovoltaic efficiencyElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma depositionLow density

Owner:OVSHINSKY TECH

MTJ device performance by controlling device shape

ActiveUS10944049B2Improve performanceReduce defect concentrationMagnetic-field-controlled resistorsGalvano-magnetic material selectionAxis of symmetryThin membrane

A layered thin film device, such as a MTJ (Magnetic Tunnel Junction) device can be customized in shape by sequentially forming its successive layers over a symmetrically curved electrode. By initially shaping the electrode to have a concave or convex surface, the sequentially formed layers conform to that shape and acquire it and are subject to stresses that cause various crystal defects to migrate away from the axis of symmetry, leaving the region immediately surrounding the axis of symmetry relatively defect free. The resulting stack can then be patterned to leave only the region that is relatively defect free.

Owner:TAIWAN SEMICON MFG CO LTD

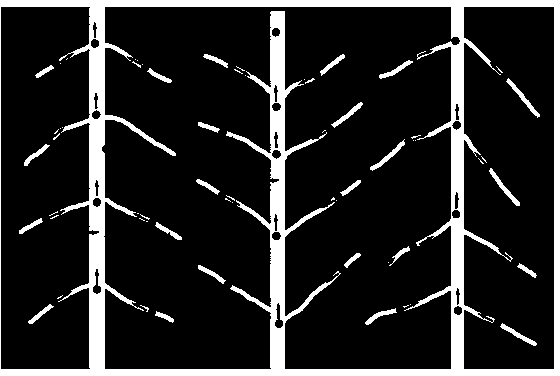

Irradiation resistance nano-porous membrane

ActiveCN103903664AImproves resistance to radiation swellingImprove the ability of amorphization, etc.ShieldingPorous membraneNanoporous membrane

The invention discloses an irradiation resistance nano-porous membrane, and belongs to the application field of advanced nuclear energy materials. The irradiation resistance nano-porous membrane comprises longitudinal nano-hole channels penetrating through the surface, the diameter of each longitudinal nano-hole channel is larger than 2 nanometers, the distance between every two adjacent longitudinal nano-hole channels is smaller than the scattering distance of interstitial atoms and the He gas, and branch-shaped nano-hole channels are transversely formed in each longitudinal nano-hole channel. The abundant hole channels of the nano-porous membrane can absorb the interstitial atoms, vacancies, transmutation gas and other flaws produced by irradiation and can also release gas atoms out of a material, the flaw content inside the material can be greatly reduced, the interstitial atoms, the vacancies and the transmutation gas are prevented from being gathered to form an atomic cluster, a cavity, bubbles and the like, and the radiation swelling resisting capability, the hardening resisting capability and the non-crystallizing capability of the material are greatly improved.

Owner:WUHAN UNIV

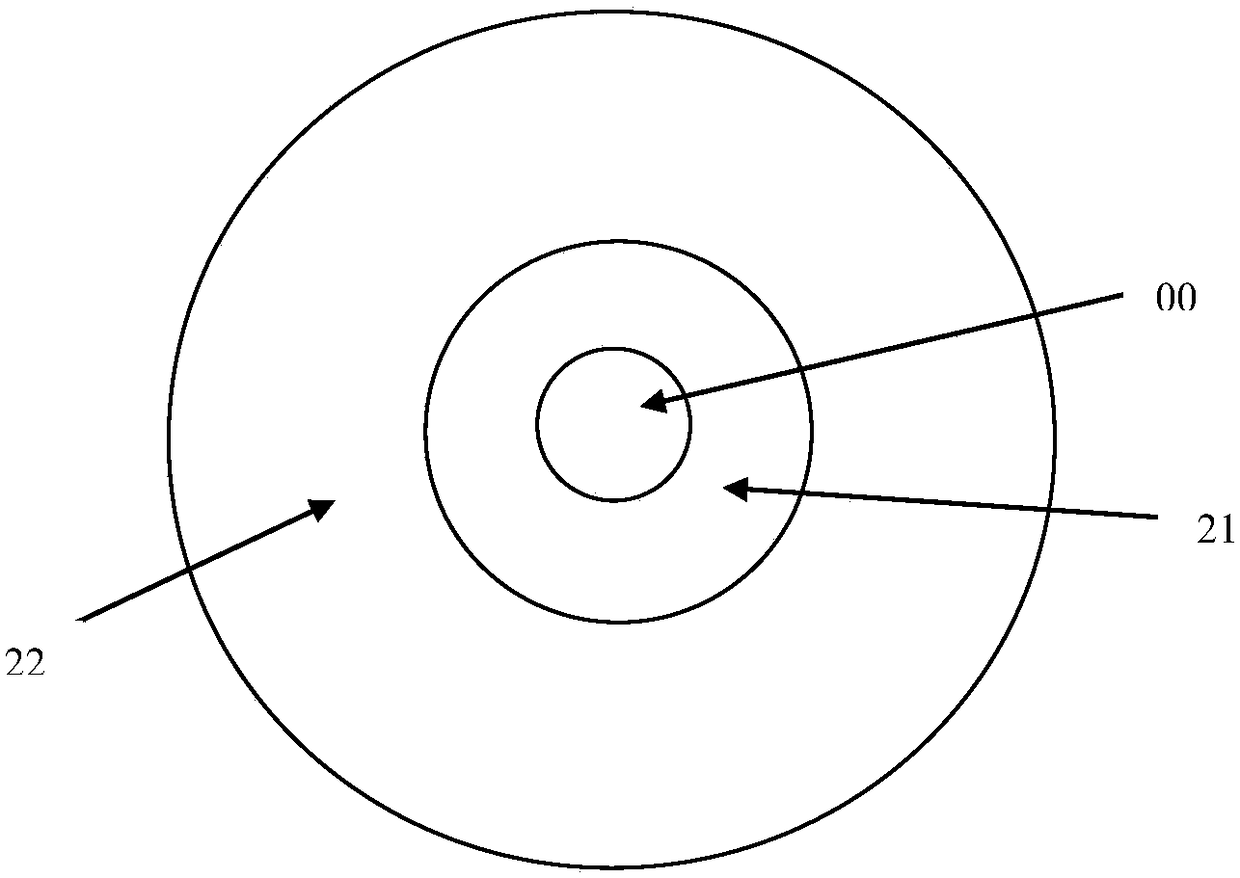

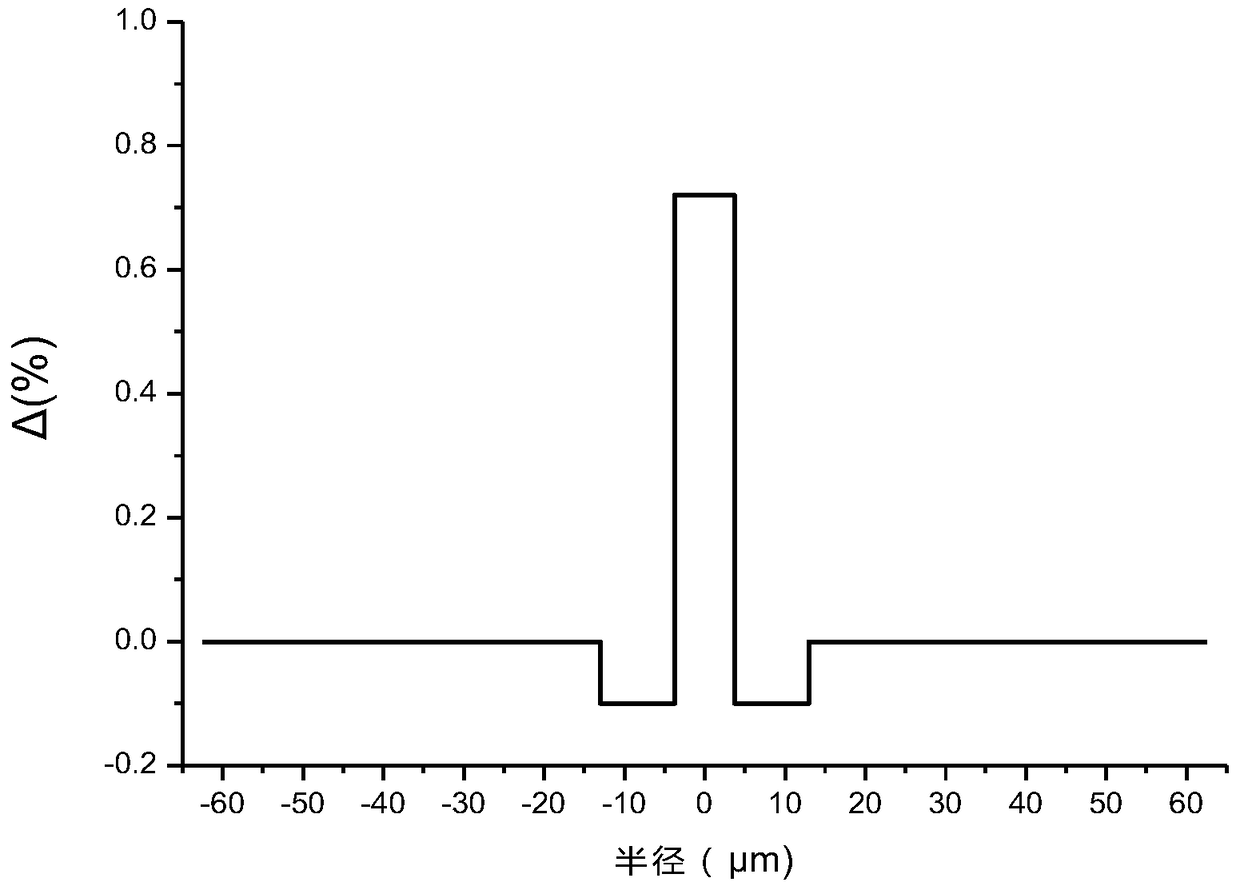

A single-mode fiber

ActiveCN105137536BLarge numerical apertureOptimize material structureOptical fibre with multilayer core/claddingUltrasound attenuationRelative refractive index

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com