Irradiation resistance nano-porous membrane

A nanoporous, anti-radiation technology, used in reactors, shielding, nuclear engineering, etc., can solve problems such as non-release, and achieve the effect of reducing defect concentration, excellent anti-irradiation swelling, and improving anti-irradiation swelling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Using the single crystal Si (100) cleaned by RCA method as the substrate, the SiO on the Si surface was cleaned 2 Oxide layer and some impurities. The anti-radiation nano film is deposited by magnetron sputtering. Before deposition, the temperature of the substrate was room temperature. During the deposition process, pure Ar, N 2 , the flow rates are fixed at 5 sccm and 20 sccm respectively. The target power was 150 W when depositing nanoporous CrN films. After the deposition time reaches 8000 s, a uniform nanoporous CrN film with a thickness of about 450 nm is formed. During the whole process of reactive magnetron sputtering, the sample stage rotates on the same plane to maintain the uniformity of the long film.

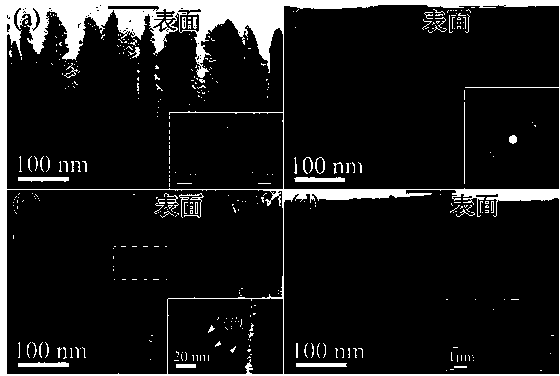

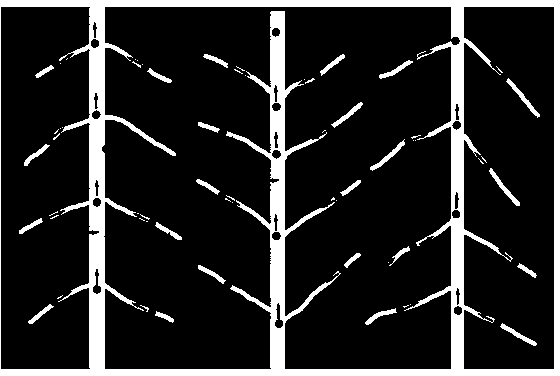

[0022] Analyze the sample prepared in this embodiment, figure 1 (a) is the cross-sectional transmission electron micrograph and the corresponding plane and cross-sectional scanning electron micrograph of the nanoporous CrN thin film prepared by this ex...

Embodiment 2

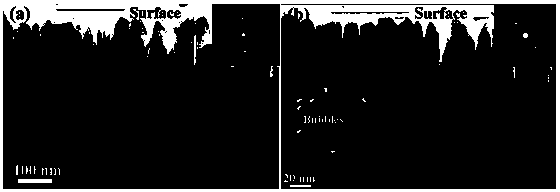

[0024] V thin films were deposited on silicon substrates with a sputtering power of 150 W and a film thickness of 450 nm. With 40 keV He + Ions were irradiated with a dose of 1×10 17 ions / cm 2 . The peak concentration of He was 5 at.%, and the peak displacement damage was 9 dPa. It can be seen from Figure (3) that only helium bubbles with a size of less than 1 nm appeared in the sample after high-dose irradiation. The existence of nanopores greatly inhibited the growth of helium bubbles and greatly improved the radiation resistance of the material. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com