Filler wire for fusion welding of low-activation martensitic steel and its use method

A martensitic steel and filler wire technology, applied in welding medium, welding equipment, welding equipment, etc., can solve problems such as improving crystallization cracks, restricting mechanical properties of welded joints, and weakening weld strength and hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

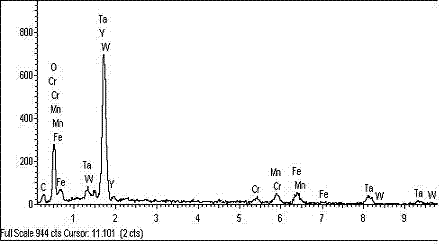

[0020] Example 1: A filler wire for fusion welding of low activation martensitic steel, its specific chemical composition is: C0.12%; Cr9.8%; W2.0%; Ta0.5%; Y0.5%; Mn0.3%; P≤0.003%; S≤0.003%; the balance is Fe.

[0021] The TIG welding butt joint test was carried out for the 5mm thick fusion reactor CLAM steel plate. Before welding, the welding groove (60°V type) and the surface of the filler wire were polished with metallographic sandpaper, cleaned with acetone, and then TIG welded. Double-sided forming technology, its welding parameters: number of welding layers is 3 layers, welding voltage U=11~13V, welding current I=50~100A, shielding gas is Ar, flow rate is 10~15L / min, welding speed is 1~ 2mm / s; After welding, the welded sample is heat treated at 760°C / 30min.

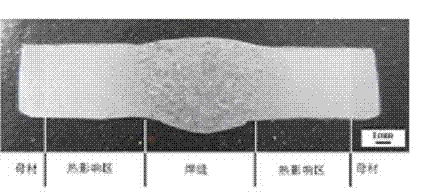

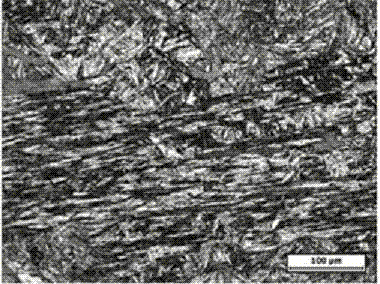

[0022] The microstructure observation and mechanical performance test were carried out on the welded part, and the results showed that: if figure 1 As shown, using this composition of welding consumables and corr...

Embodiment 2

[0023] Example 2: A filler wire for fusion welding of low activation martensitic steel, its specific chemical composition is: C0.10%; Cr10.0%; W1.8%; Ta0.4%; Y0.4%; Mn0.3%; P≤0.003%; S≤0.003%; the balance is Fe.

[0024] The TIG welding butt joint test was carried out on CLAM steel for fusion reactors with a thickness of 5mm. Before welding, the welding groove (60°V type) and the surface of the filler wire were polished with metallographic sandpaper, cleaned with acetone, and then TIG welded, using single-sided welding Double-sided forming technology, its welding parameters: number of welding layers is 3 layers, welding voltage U=11~13V, welding current I=50~100A, shielding gas is Ar, flow rate is 10~15L / min, welding speed is 1~ 2mm / s. After welding, the welded samples are heat treated at 760°C / 30min.

[0025] The microscopic observation and mechanical performance test of the welded part showed that: after welding, a well-formed welded joint can be obtained, no obvious massi...

Embodiment 3

[0026] Example 3: A filler wire for fusion welding of low activation martensitic steel, its specific chemical composition is: C0.10%; Cr10.5%; W1.5%; Ta0.3%; Y0.4%; Mn0.3%; P≤0.003%; S≤0.003%; the balance is Fe.

[0027] The TIG welding butt joint test was carried out on CLAM steel for fusion reactors with a thickness of 5mm. Before welding, the welding groove (60°V type) and the surface of the filler wire were polished with metallographic sandpaper, cleaned with acetone, and then TIG welded, using single-sided welding Double-sided forming technology, its welding parameters: number of welding layers is 3 layers, welding voltage U=11~13V, welding current I=50~100A, shielding gas is Ar, flow rate is 10~15L / min, welding speed is 1~ 2mm / s, heat treatment of the welded sample at 760°C / 30min after welding.

[0028] The microscopic observation and mechanical performance test of the welded part showed that: after welding, a well-formed welded joint can be obtained, no obvious massive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com