An aluminum nitride film growing method and application thereof

A technology of aluminum nitride film and growth method, applied in electrical components, nanotechnology, circuits, etc., can solve the problems of low lattice mismatch, line defects, dislocations, cracks, etc., and achieve the suppression of surface cracks. The method is simple and easy OK, high crystal quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

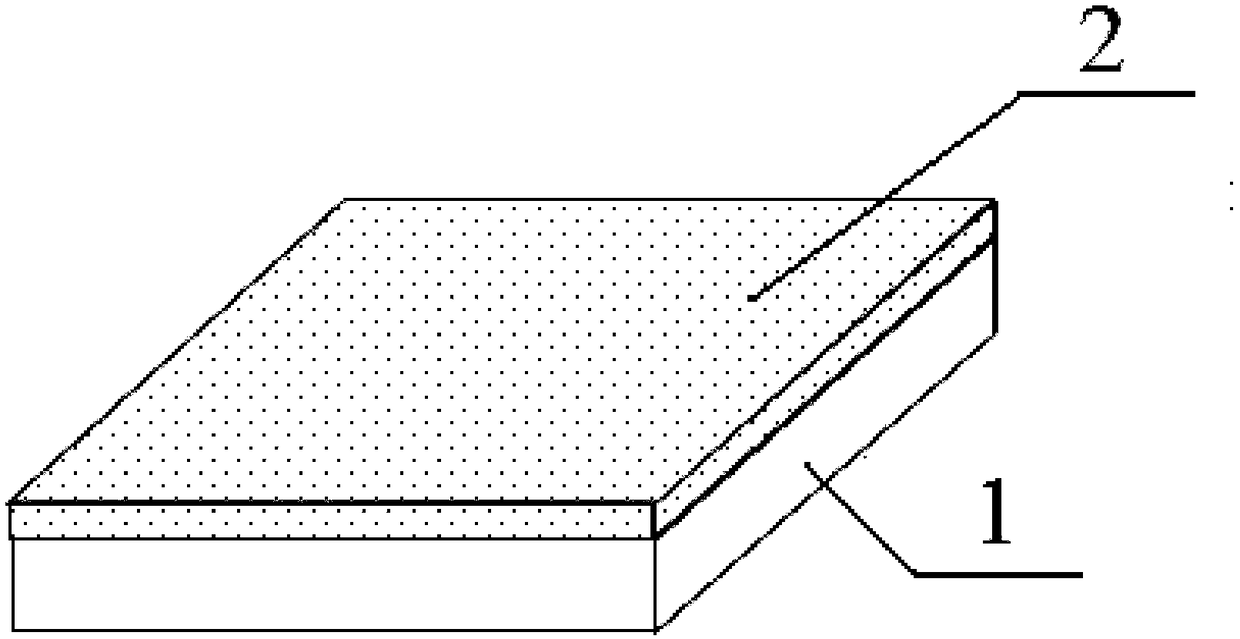

[0065] The growth method of aluminum nitride film of the present invention comprises the following steps:

[0066] 1) Take a 2-inch sapphire substrate, raise the temperature of the reaction chamber of the metal-organic chemical vapor deposition (MOCVD) equipment to 1200°C, control the pressure of the reaction chamber at 100mbar, and feed trimethylaluminum at 300ml / min and 10000mL / min Ammonia gas was introduced to react, and after 30 minutes, a first aluminum nitride layer with a thickness of 500 nm was formed on the substrate layer.

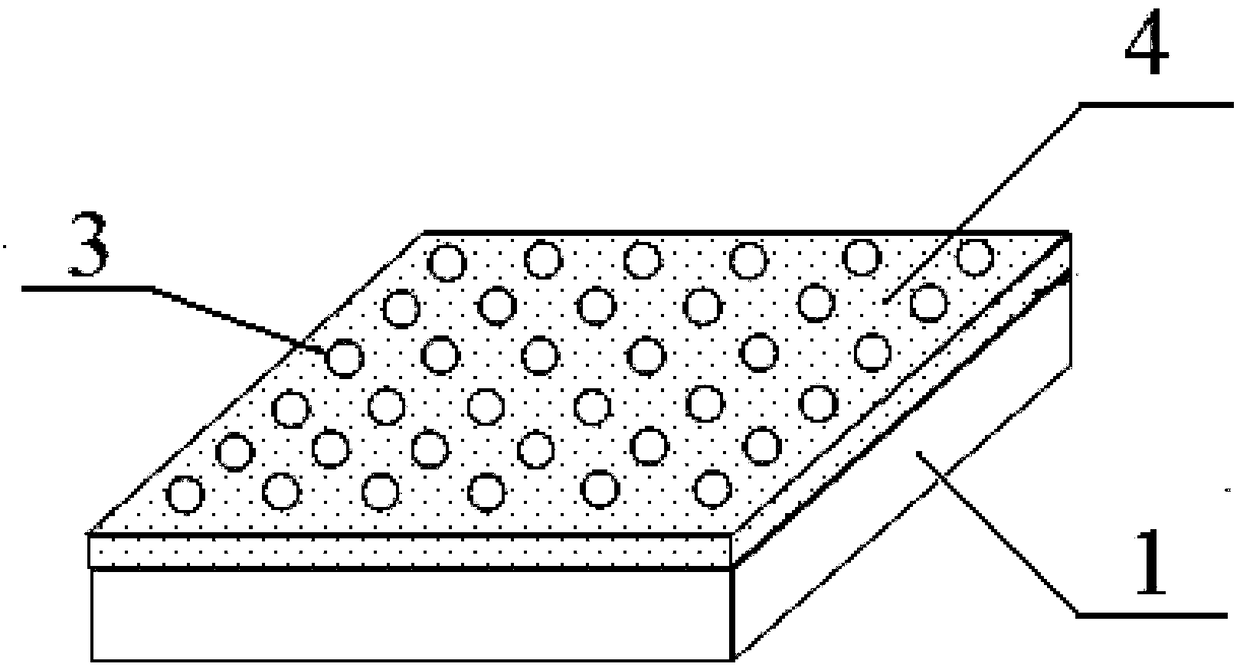

[0067] 2) Take out the substrate layer with the first aluminum nitride layer from the reaction chamber, and etch the nano-scale cylinder depressions on the first aluminum nitride layer to form the aluminum nitride layer with column depressions, wherein the cross-section of the cylinder depressions The diameter of the circle is 200nm, the depth of the cylinder is 300nm, and the distance between the depressions of the cylinders is 500nm;

[0068] ...

Embodiment 2

[0074] The growth method of aluminum nitride film of the present invention comprises the following steps:

[0075] 1) Take a 4-inch sapphire substrate, raise the temperature of the reaction chamber of the metal-organic chemical vapor deposition (MOCVD) equipment to 1200°C, control the pressure of the reaction chamber at 100mbar, and feed trimethylaluminum at 300ml / min and 10000mL / min Ammonia gas was introduced to react, and after 45 minutes, a first aluminum nitride layer with a thickness of 7500 nm was formed on the substrate layer.

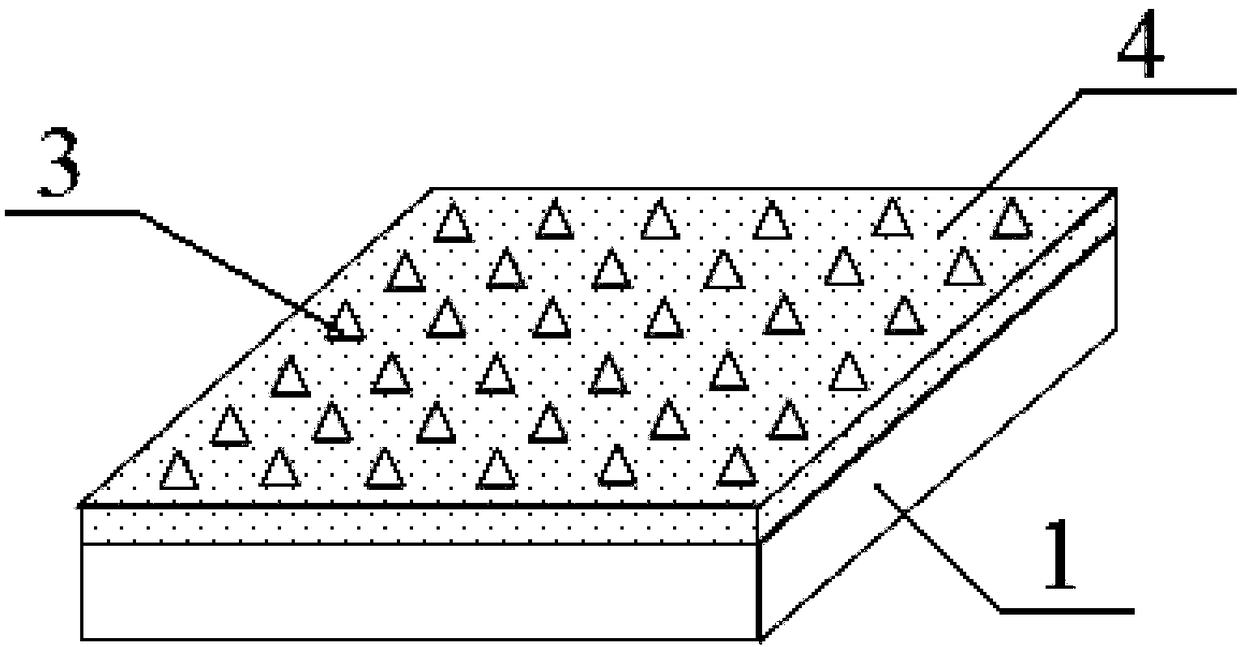

[0076] 2) Take out the substrate layer with the first aluminum nitride layer from the reaction chamber, etch the nano-scale regular triangular prism depressions on the first aluminum nitride layer to form a columnar depression aluminum nitride layer, wherein the regular triangular prism depressions The side length of the cross-sectional triangle is 300nm, the depth of the regular triangular prism is 500nm, and the distance between the regular tr...

Embodiment 3

[0083] The growth method of aluminum nitride film of the present invention comprises the following steps:

[0084] 1) Take a 2-inch sapphire substrate, raise the temperature of the reaction chamber of the metal-organic chemical vapor deposition (MOCVD) equipment to 1200°C, control the pressure of the reaction chamber at 100mbar, and feed trimethylaluminum at 300ml / min and 10000mL / min Ammonia gas was introduced to react, and after 45 minutes, a first aluminum nitride layer with a thickness of 750 nm was formed on the substrate layer.

[0085] 2) Take out the substrate layer with the first aluminum nitride layer from the reaction chamber, etch the nano-scale regular hexagonal prism depression on the first aluminum nitride layer to form a columnar depression aluminum nitride layer, wherein the regular hexagonal prism depression The side length of the regular hexagon in the cross section is 100nm, the depth of the regular hexagonal prism is 300nm, and the distance between the regu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com