Patents

Literature

119results about How to "Reduce irreversible capacity loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

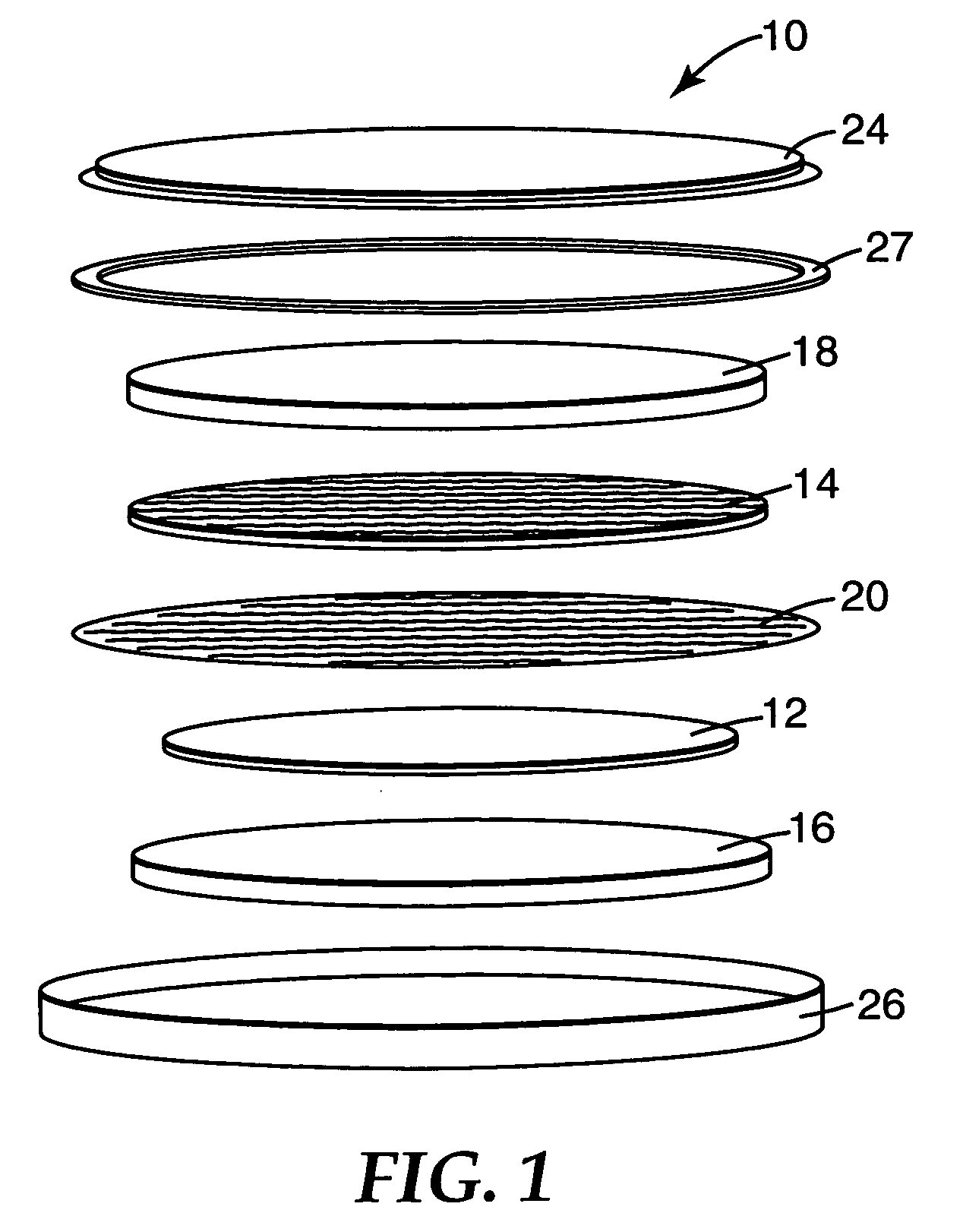

Polyimide electrode binders

ActiveUS20060099506A1Improve cycle lifeIncrease capacityLi-accumulatorsNon-aqueous electrolyte accumulator electrodesDiaminePolyimide

Irreversible first cycle capacity loss in lithium secondary cells having a cell electrode based on a powdered material and a binder may be significantly decreased or eliminated by using an aliphatic or cycloaliphatic polyimide binder. Compared to conventional polyimide binders prepared by reacting an aromatic dianhydride and a diamine, the disclosed polyimide binders have decreased aromatic carbonyl content, may be less likely to undergo electrochemical reduction, and may be less likely to consume electrons that might otherwise help lithiate the electrode.

Owner:JOHNSON MATTHEY PLC

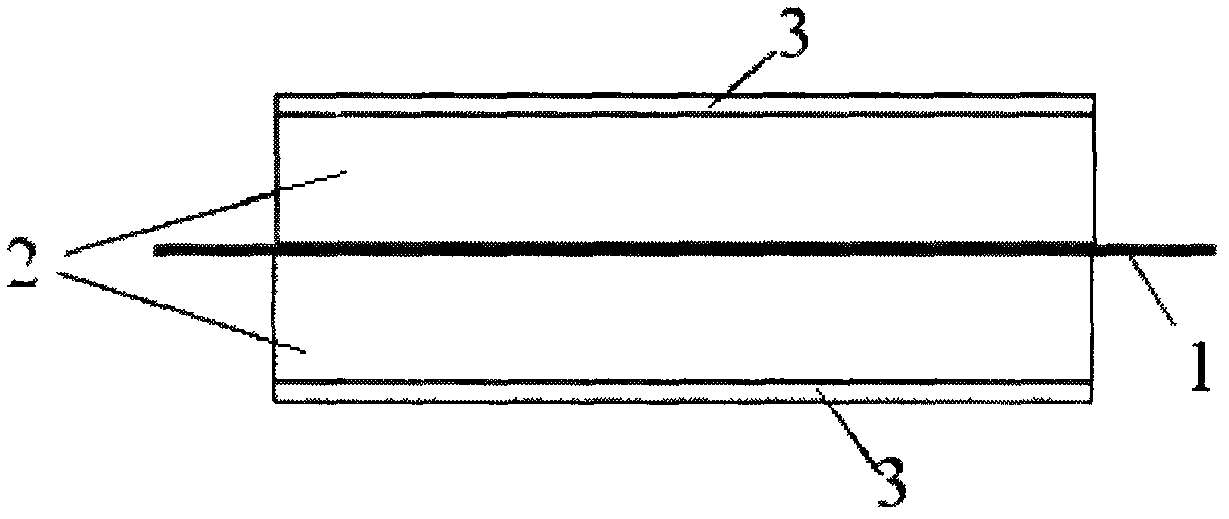

Method for preparing lithium ion battery

InactiveCN102610861AIncrease energy densityDoes not affect activityFinal product manufactureElectrolyte accumulators manufactureCapacity lossEngineering

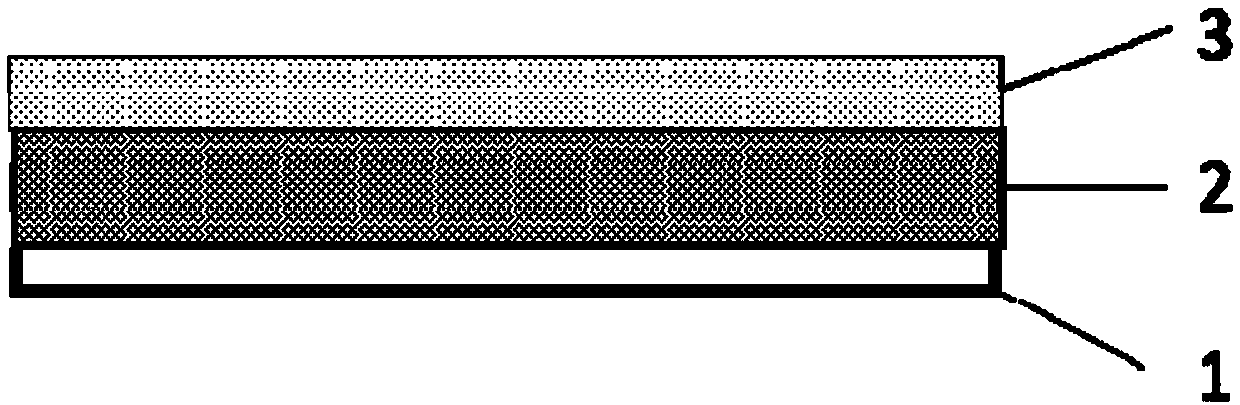

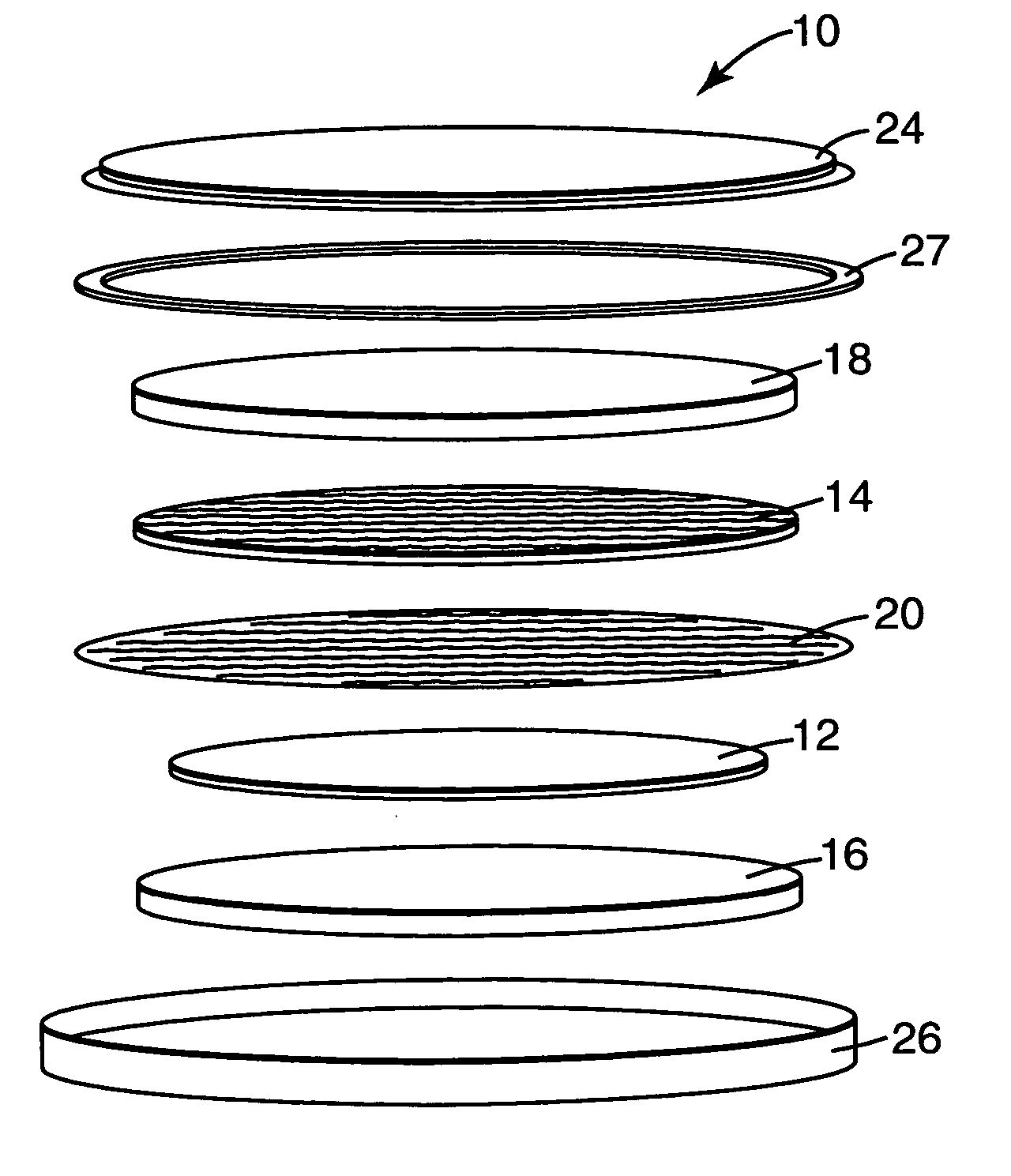

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a method for preparing a lithium ion battery. The method includes steps: firstly, pressing metal lithium sheets on at least one surface of a cathode sheet and forming a processed cathode sheet; secondly, assembling an anode sheet, a diaphragm and the processed cathode sheet into a cell, packing the cell into a package bag, filling liquid into the package bag, and allowing the packaging bag to stand still so that a solid electrolyte [SEI (solid electrolyte inter-phase)] film is formed on the surface of the cathode sheet; and thirdly, carrying out formation capacity operation and obtaining the lithium ion battery. Compared with the prior art, the method has the advantages that the cathode sheet and the metal lithium sheets are pressed together when the battery is assembled, the SEI film is formed on the surface of an anode material by means of standing and storing before formation of the integral battery while activity of a cathode material and activity of electrolyte are unaffected, the SEI film is formed in advance, irreversible capacity loss of initial charge is effectively reduced, and energy density of the battery is increased.

Owner:NINGDE AMPEREX TECH +1

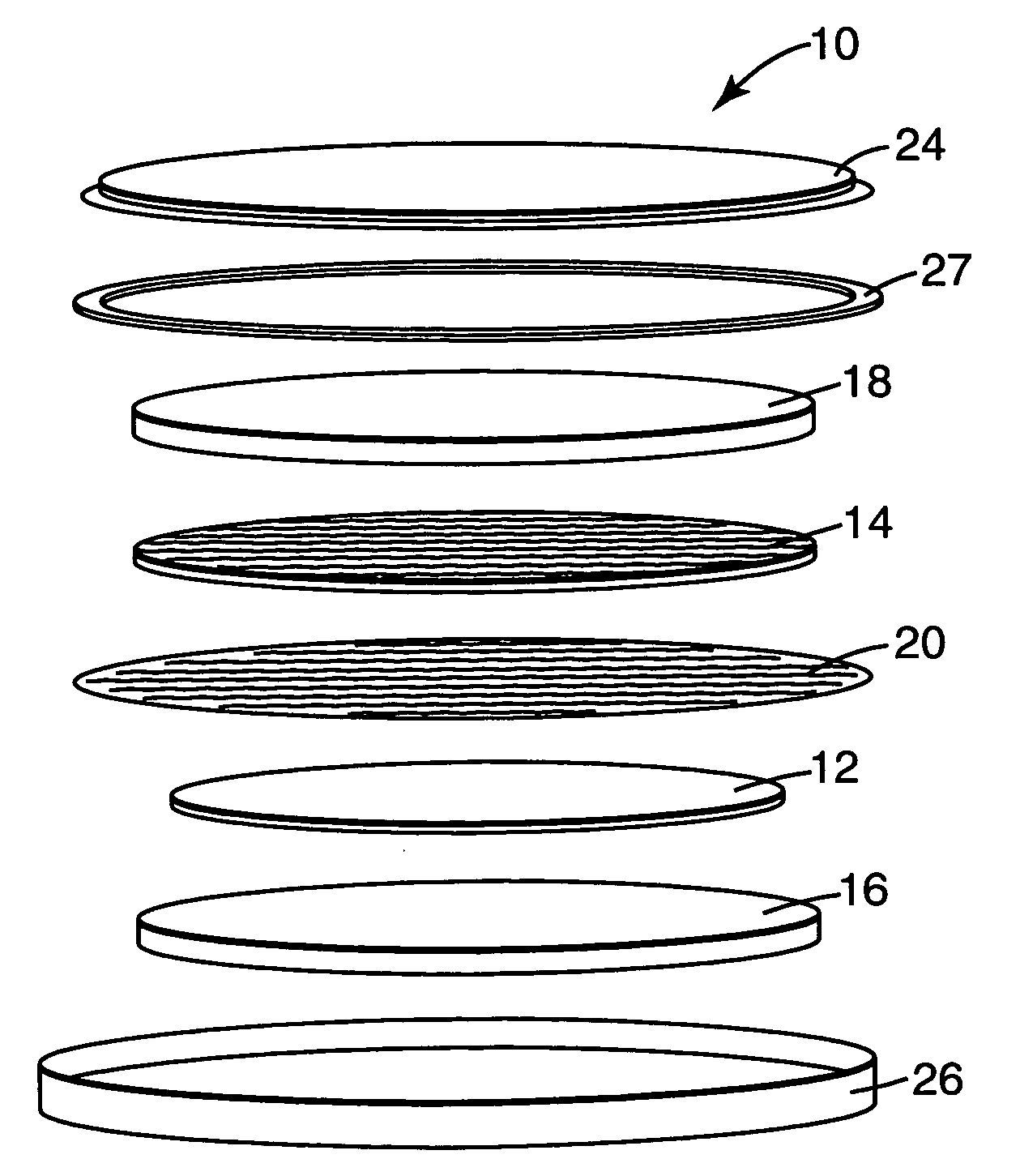

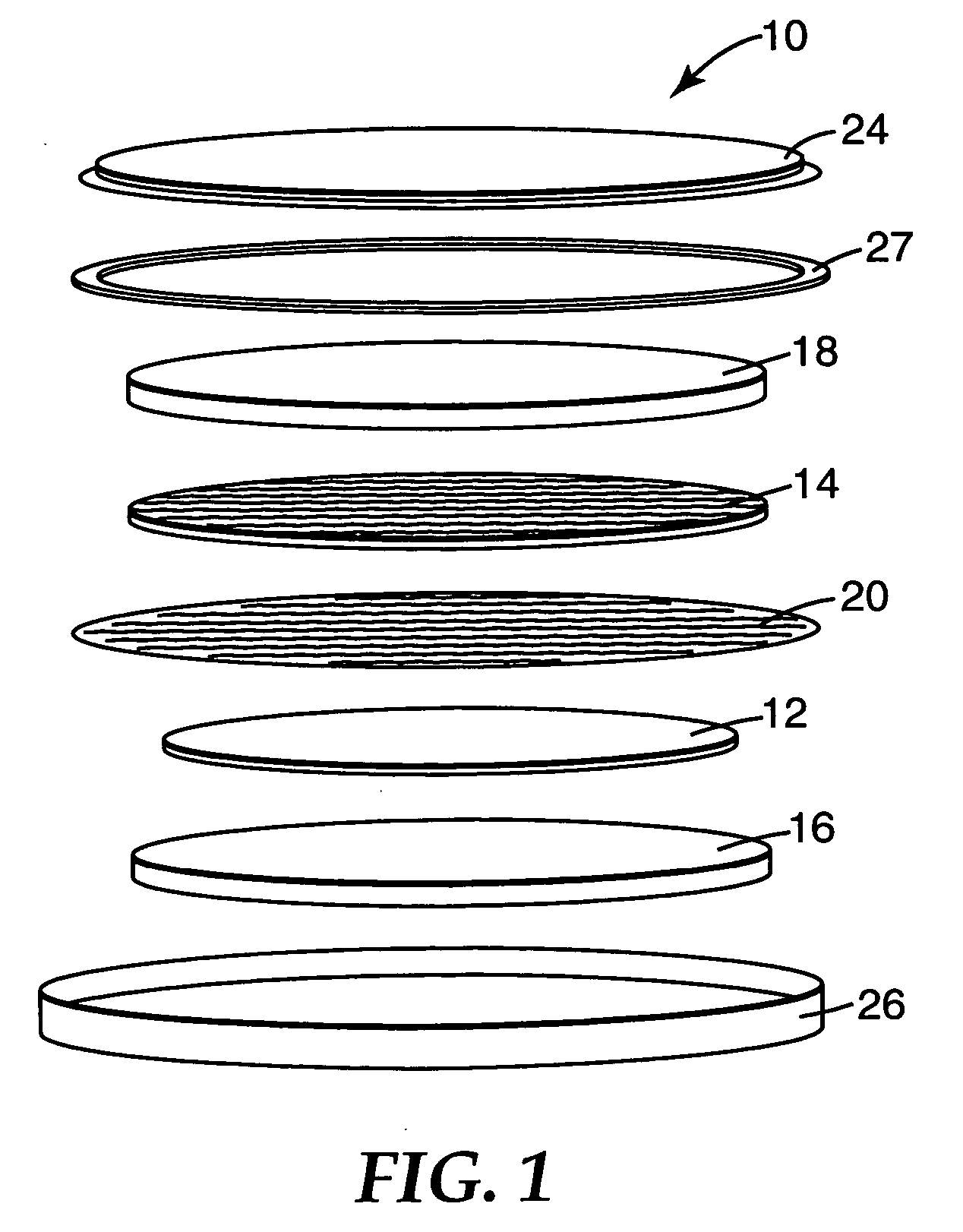

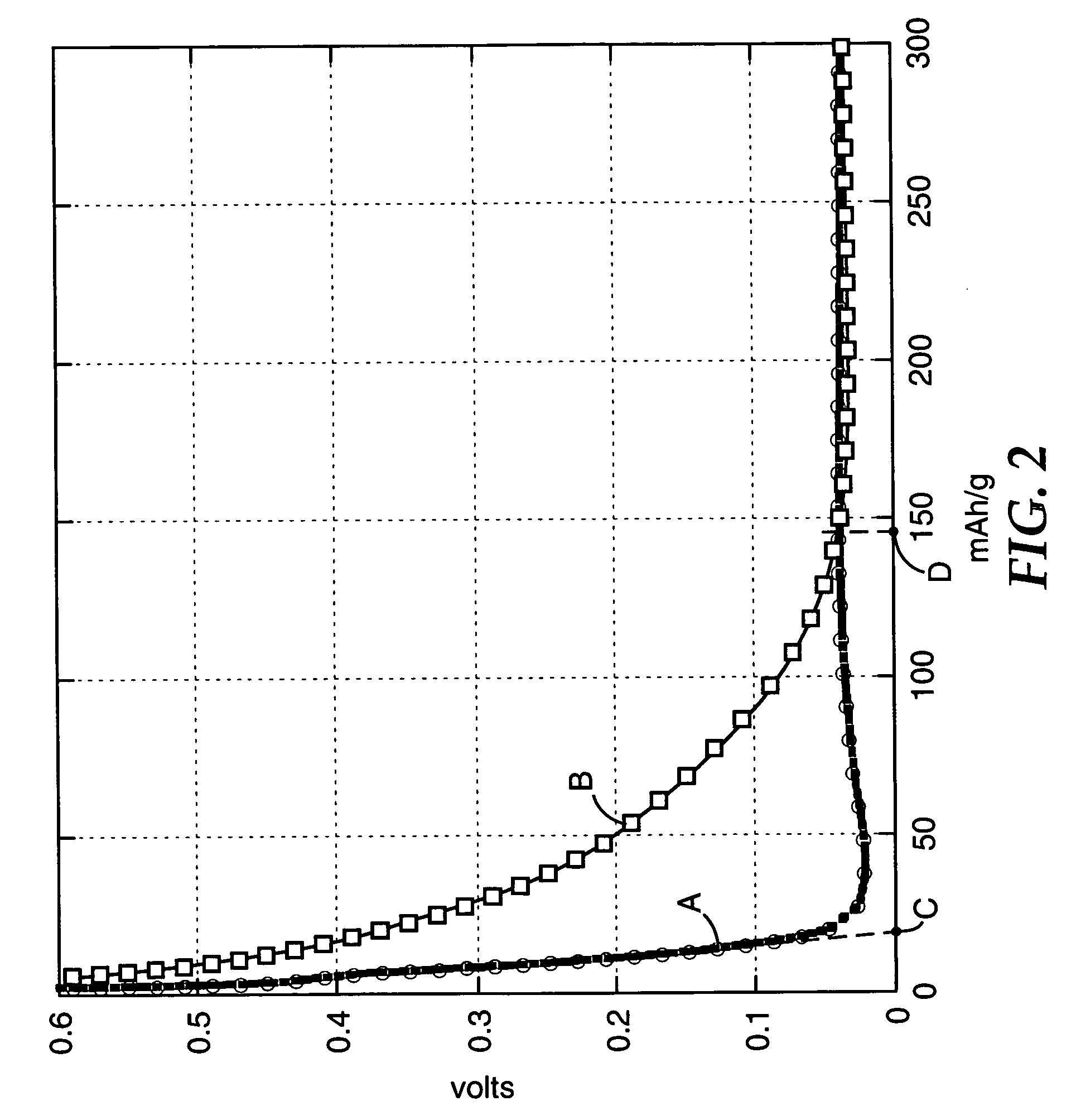

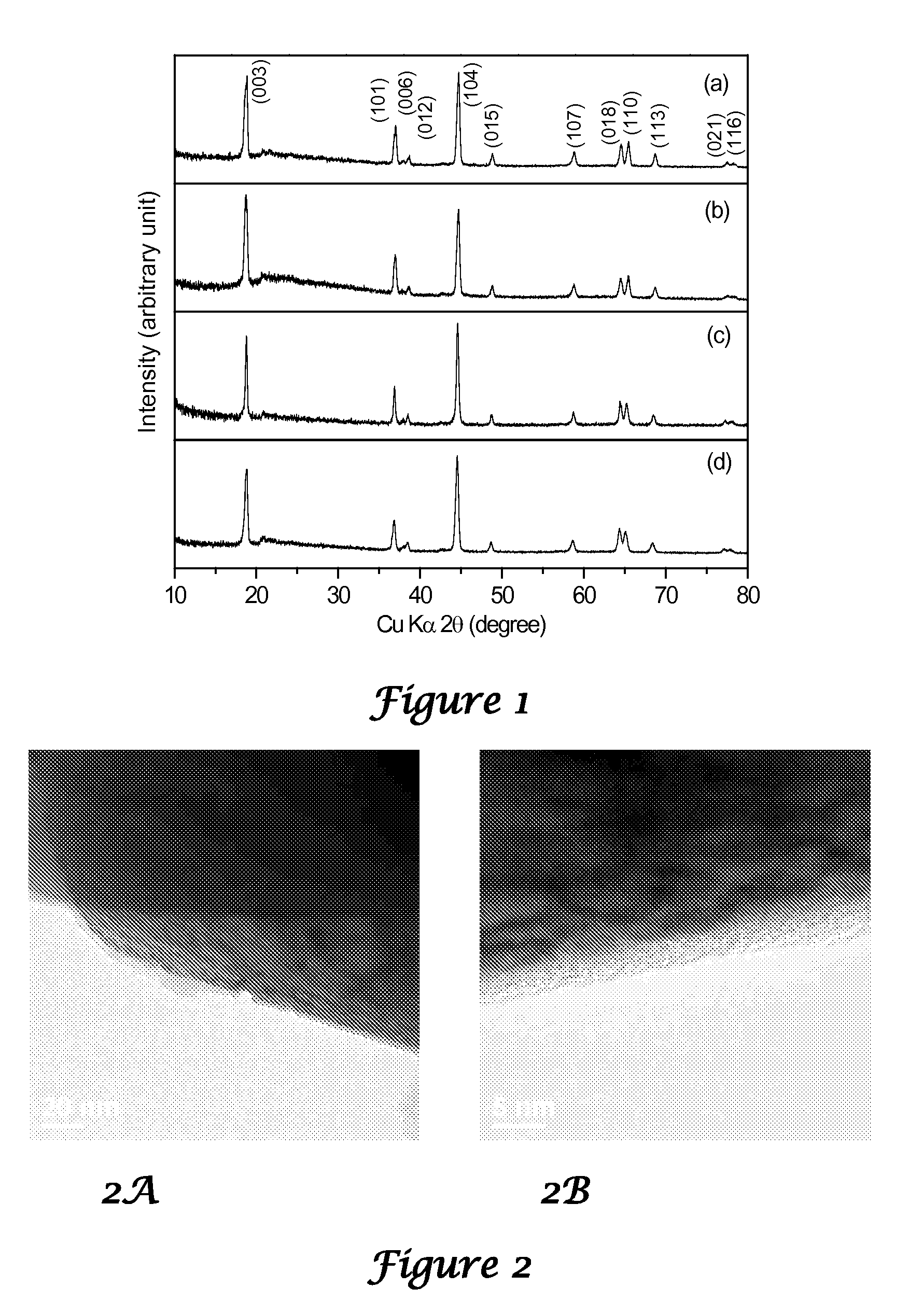

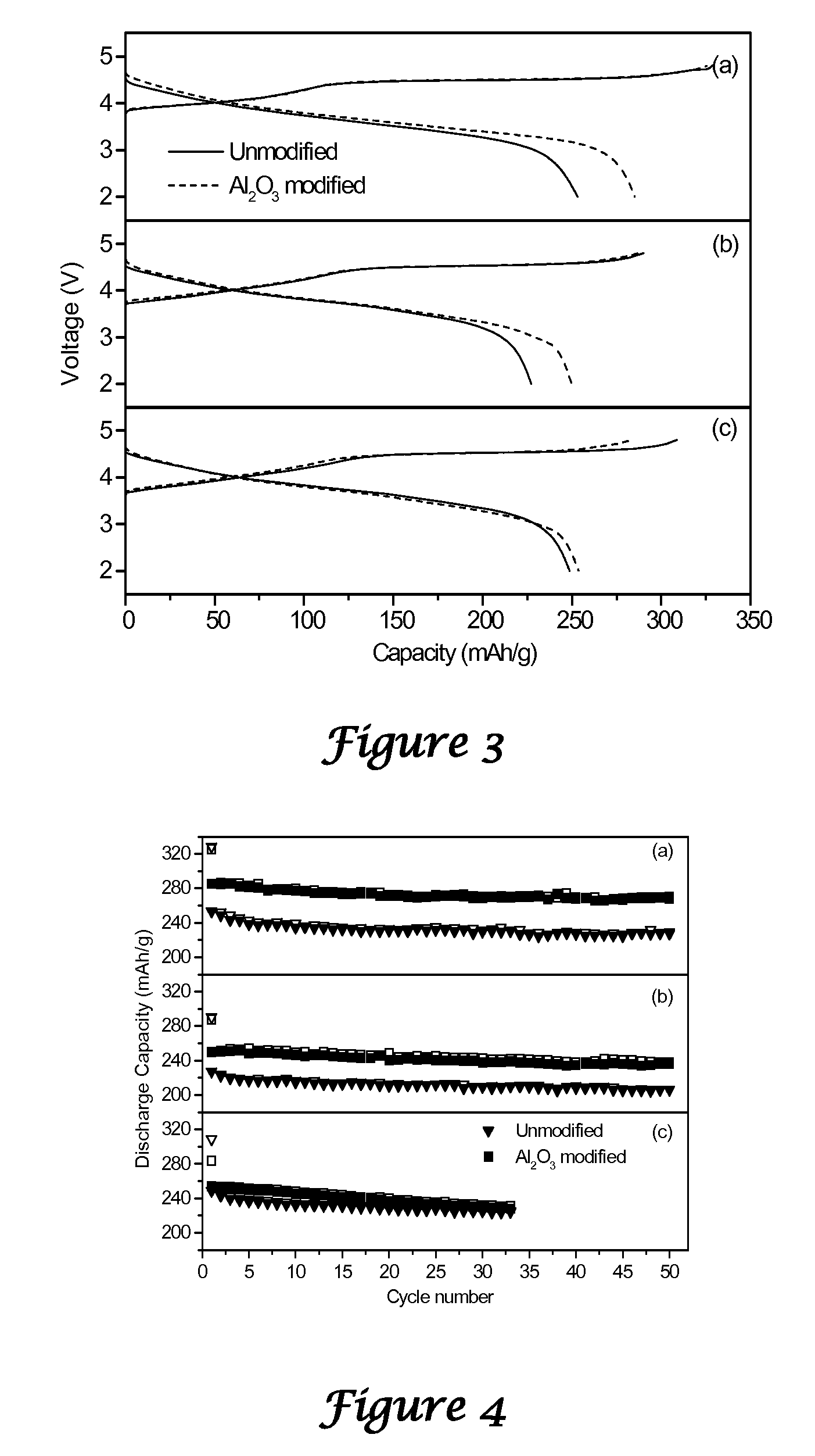

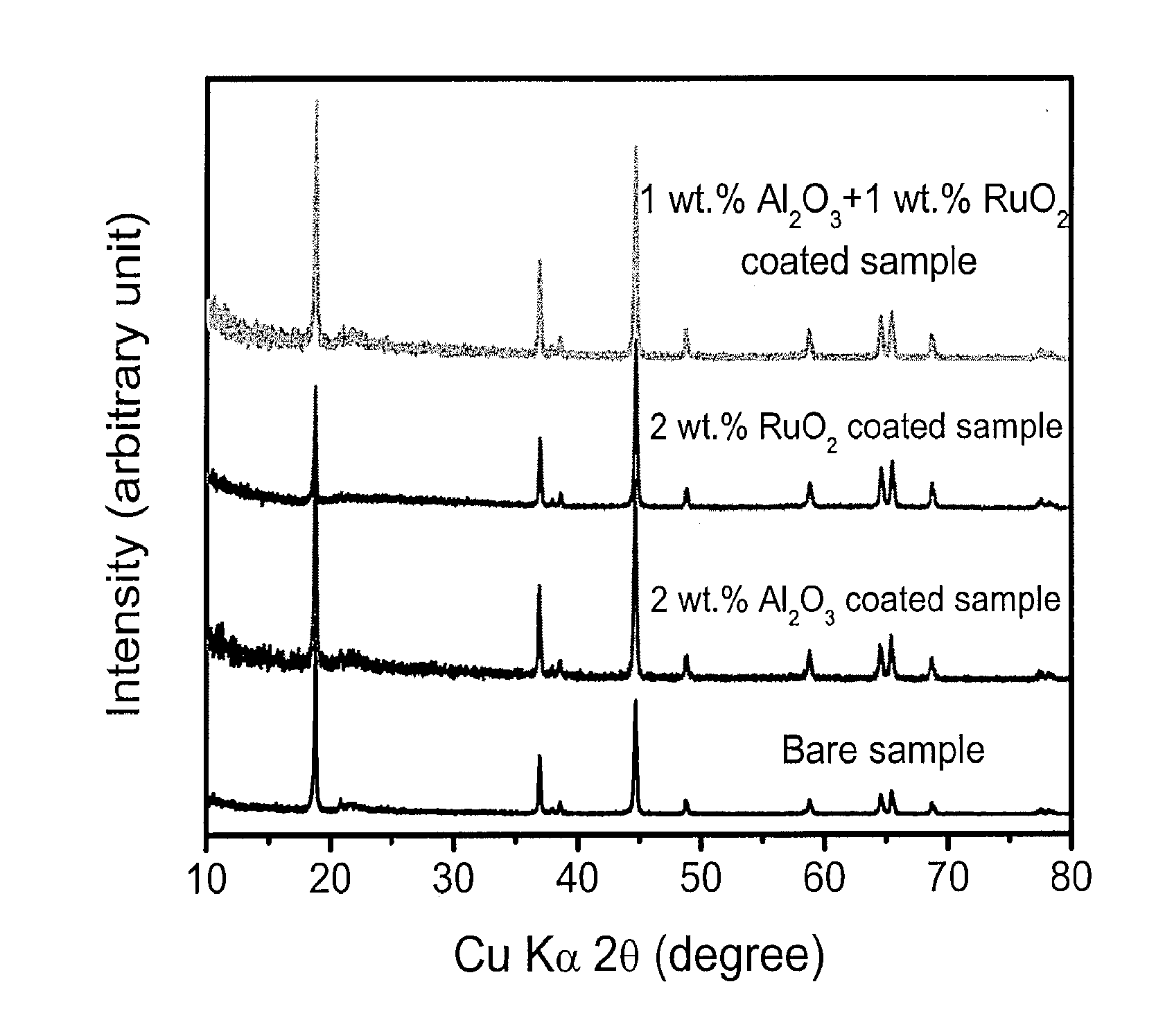

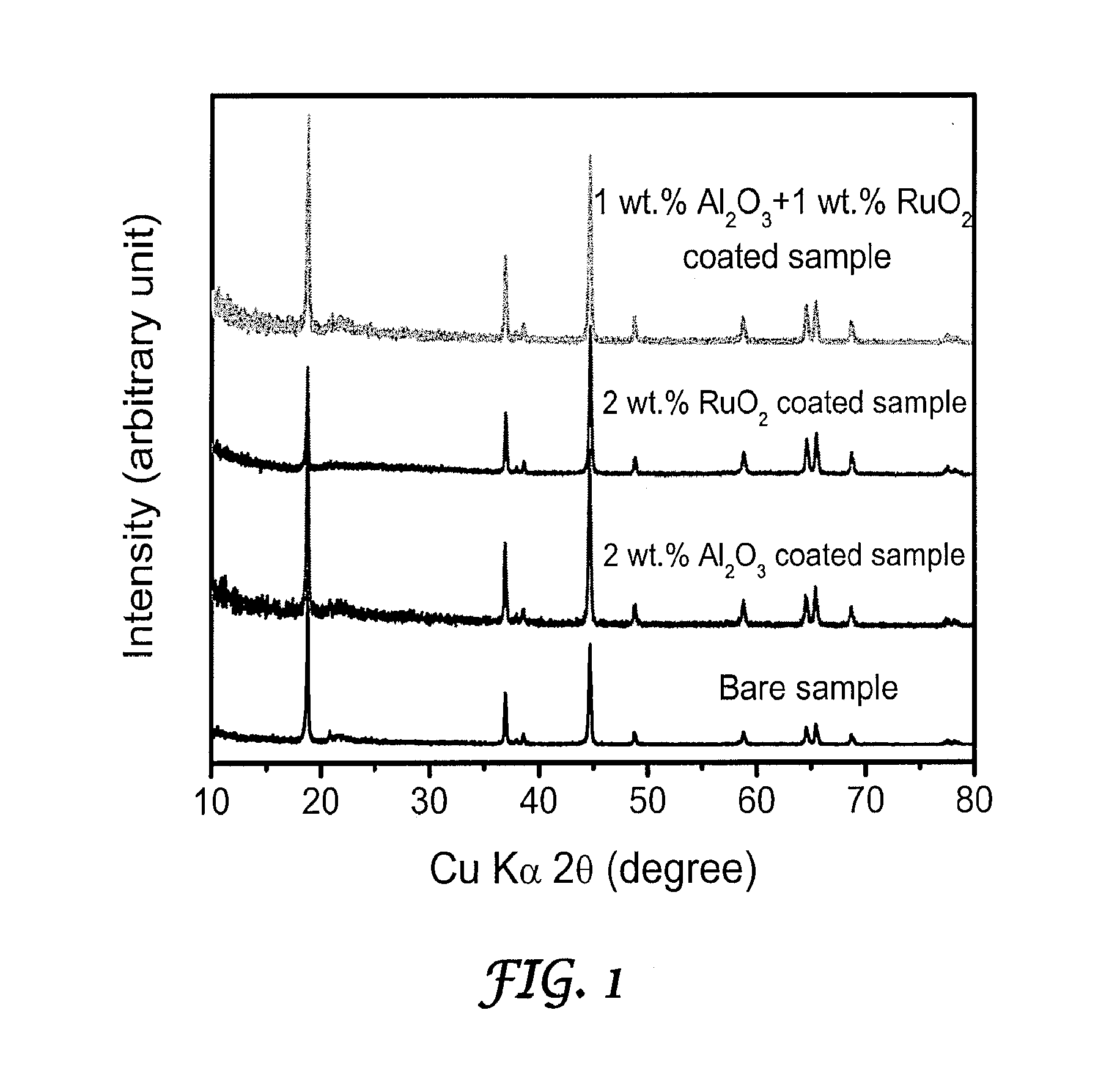

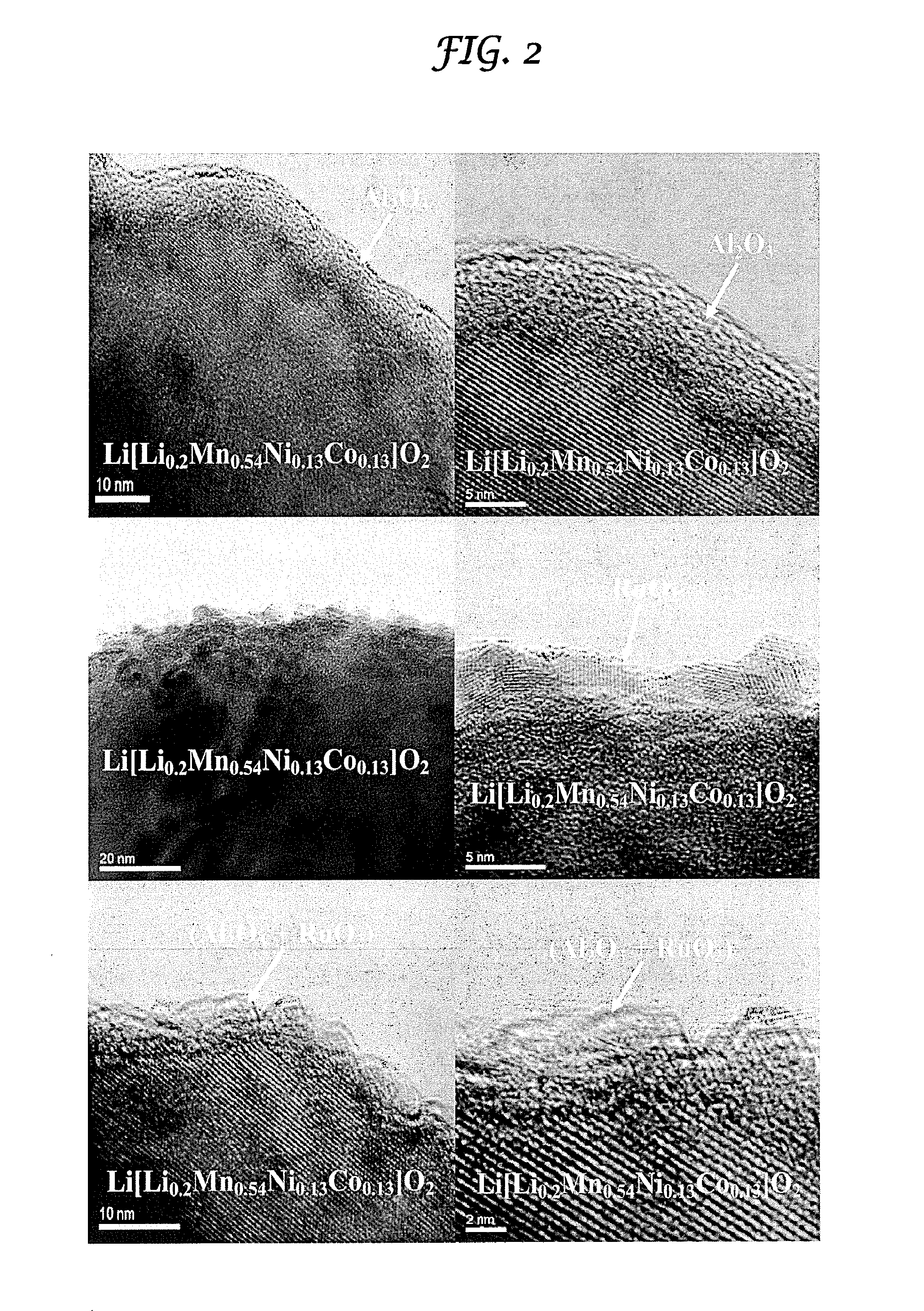

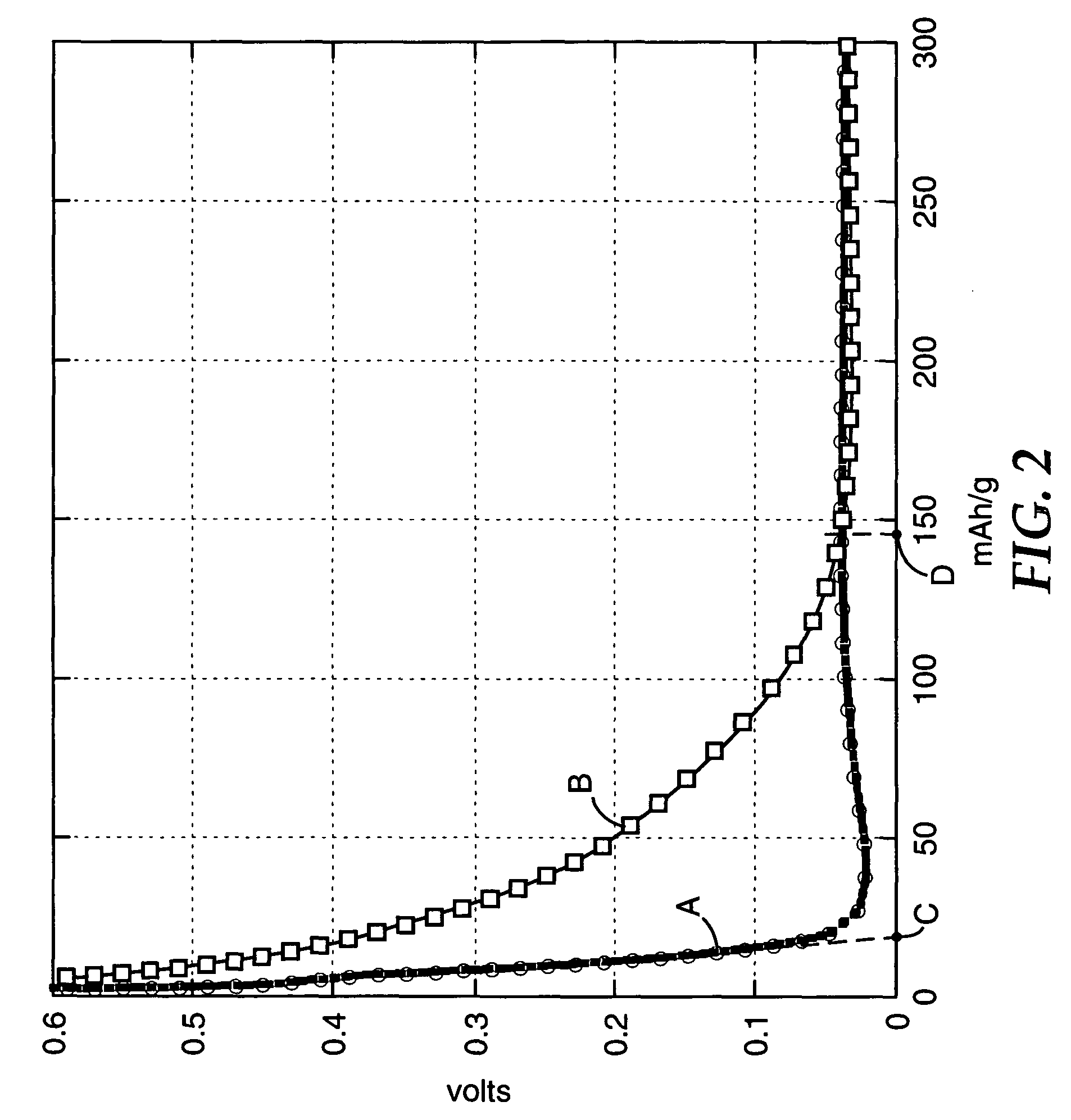

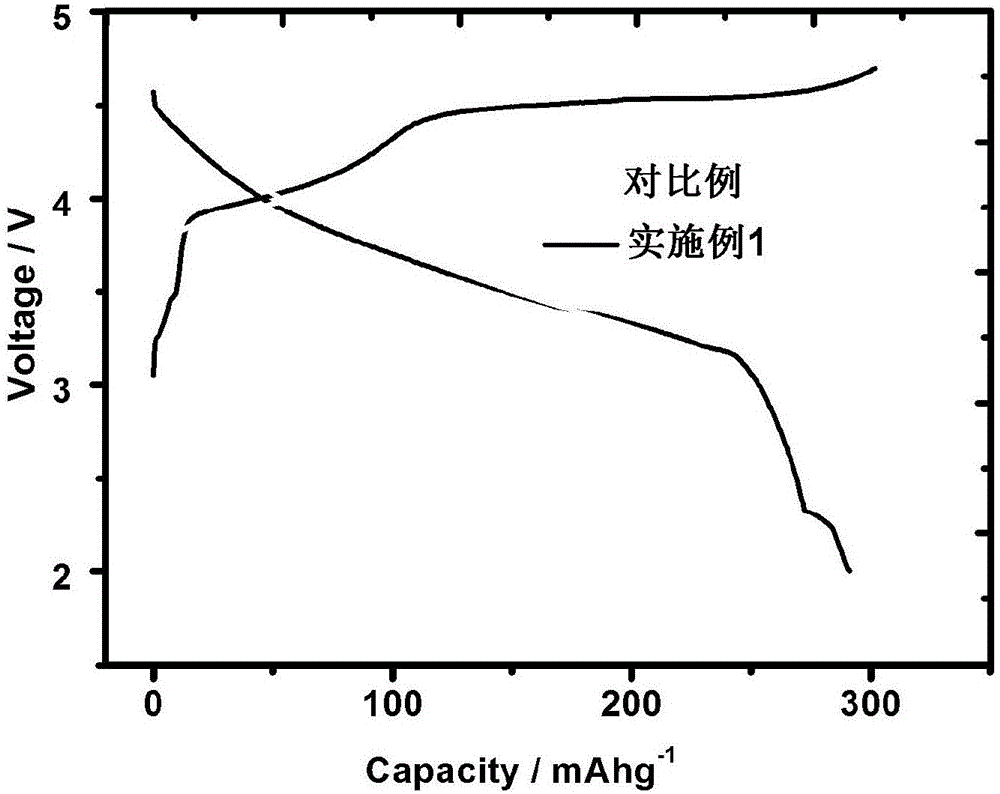

Surface and Bulk Modified High Capacity Layered Oxide Cathodes with Low Irreversible Capacity Loss

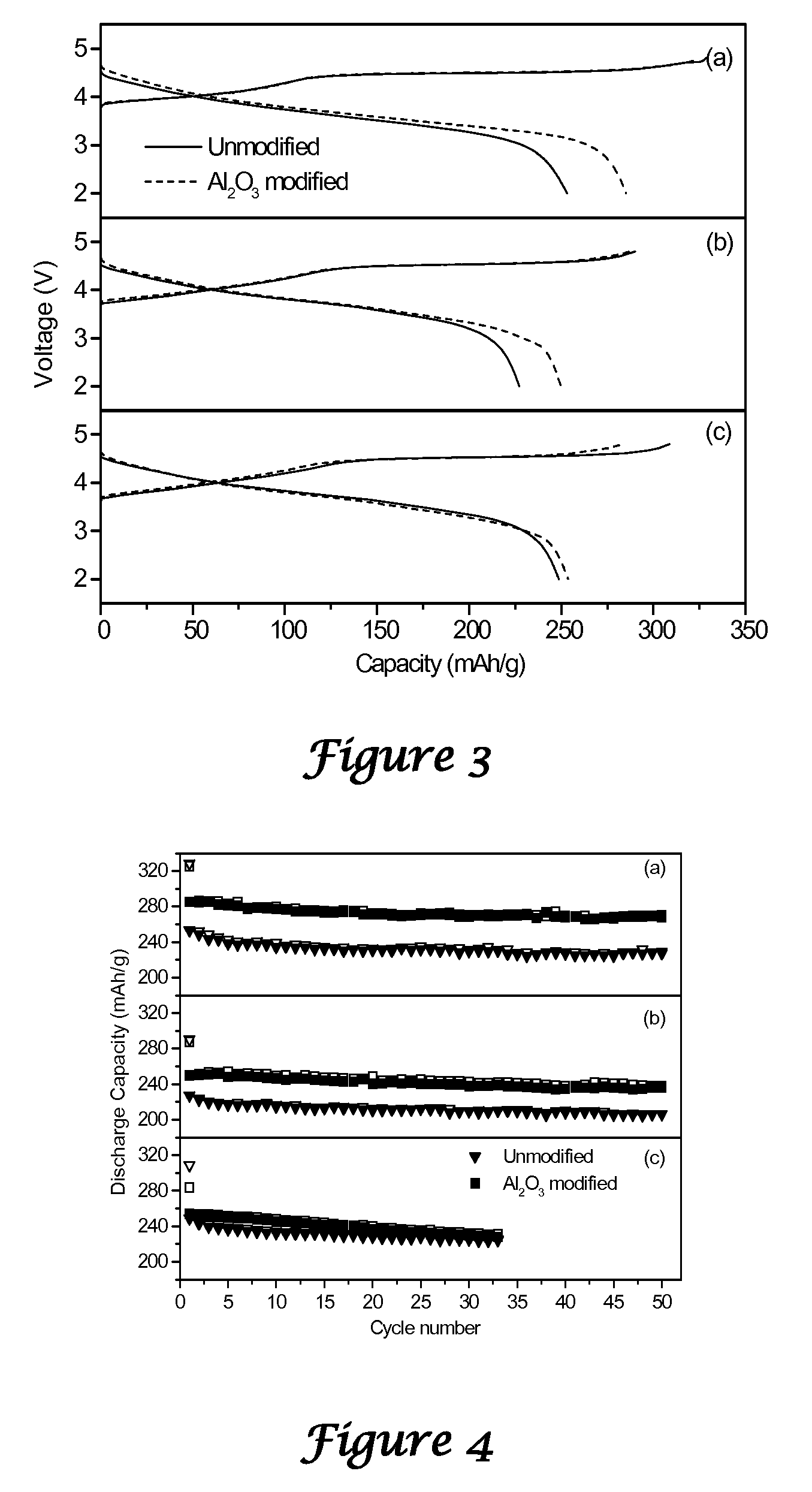

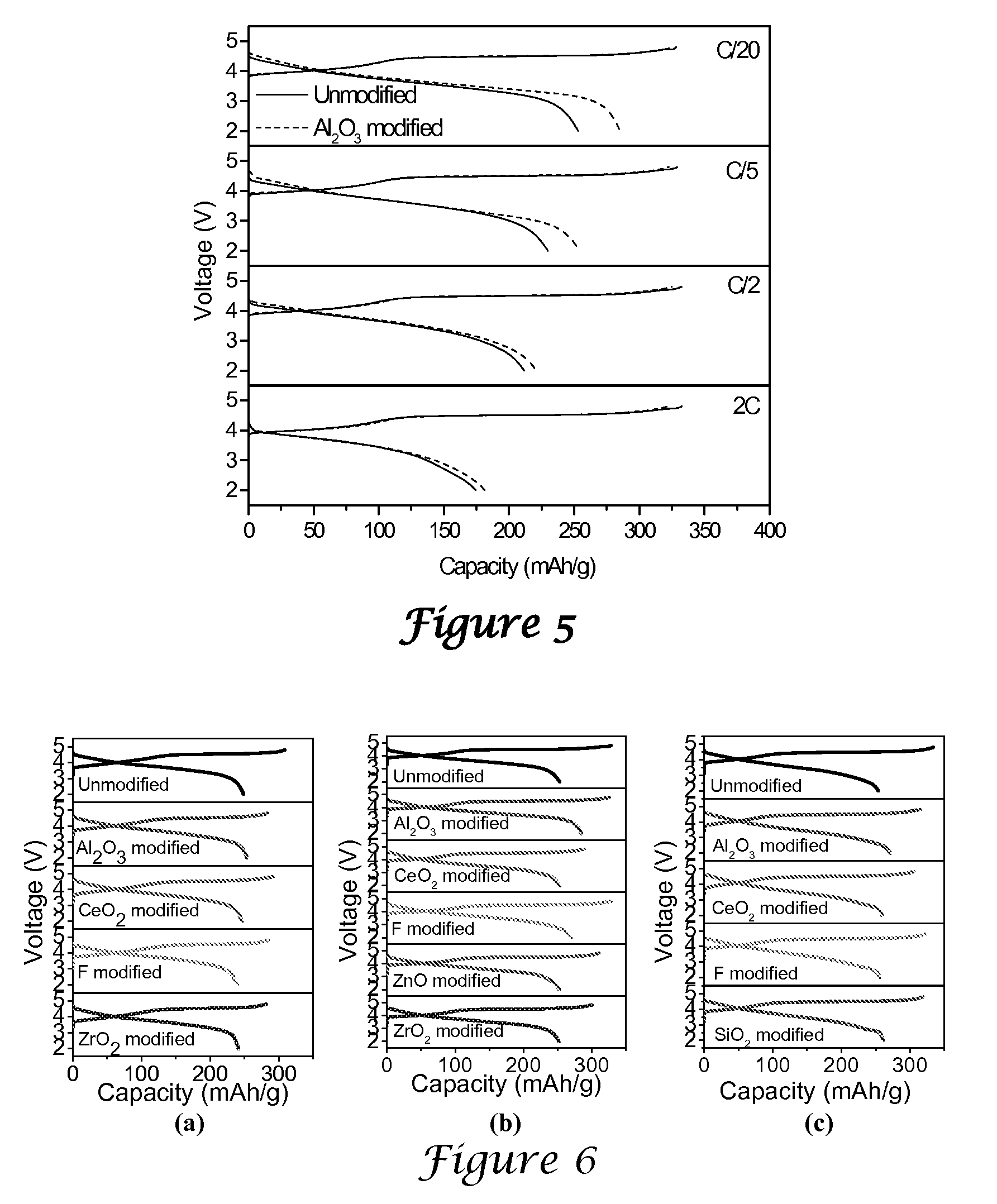

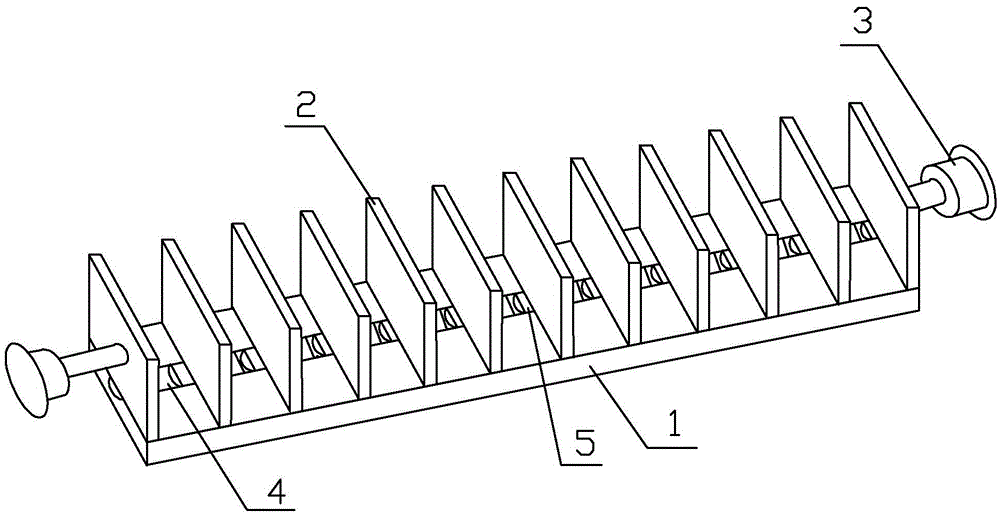

InactiveUS20090224212A1Large capacityLow costNon-metal conductorsConductive materialCapacity lossCrystal structure

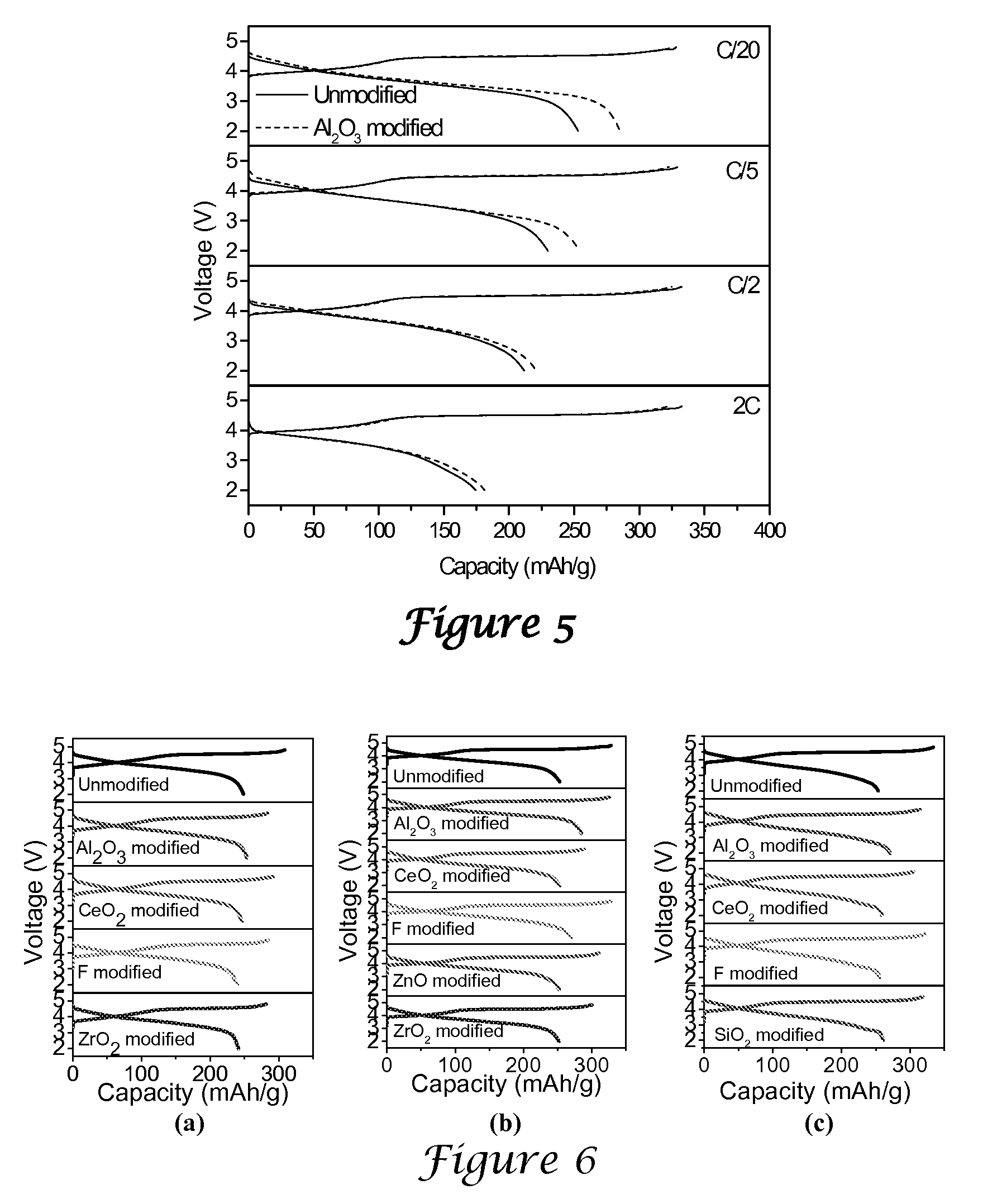

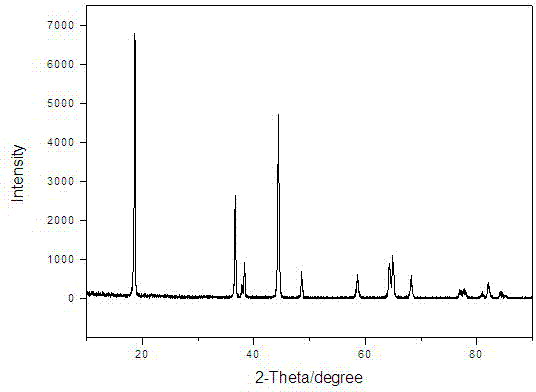

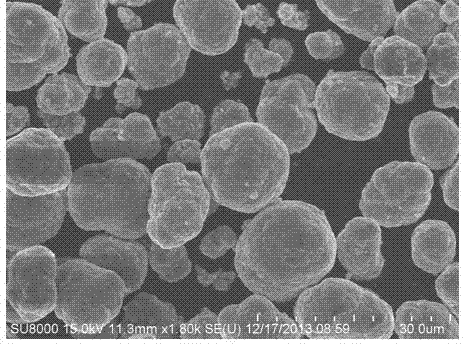

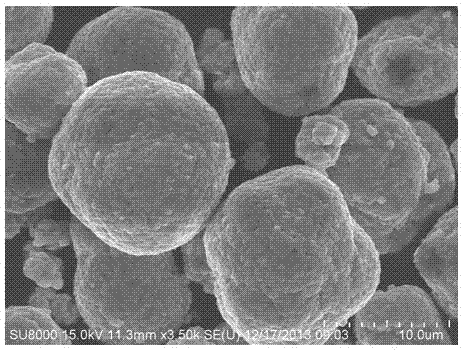

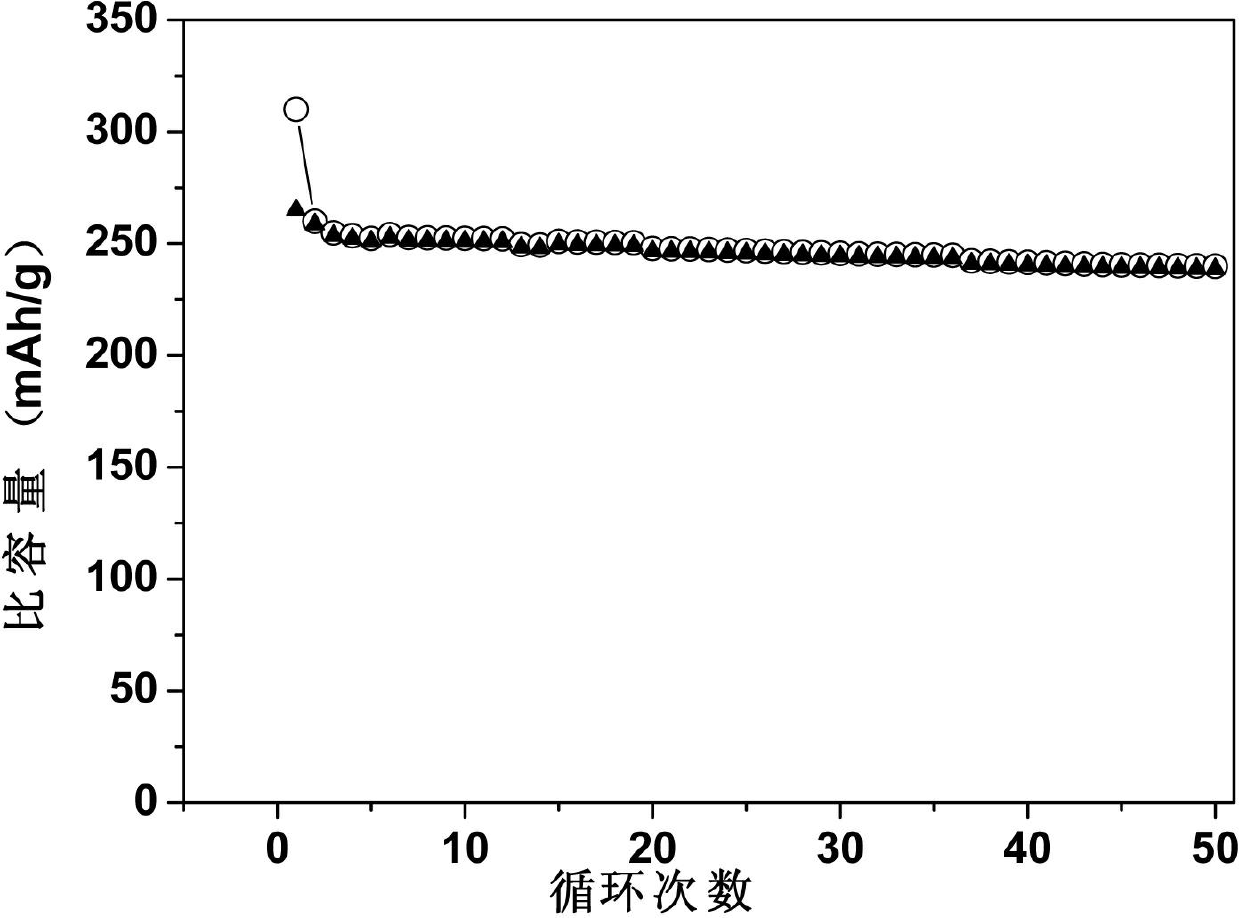

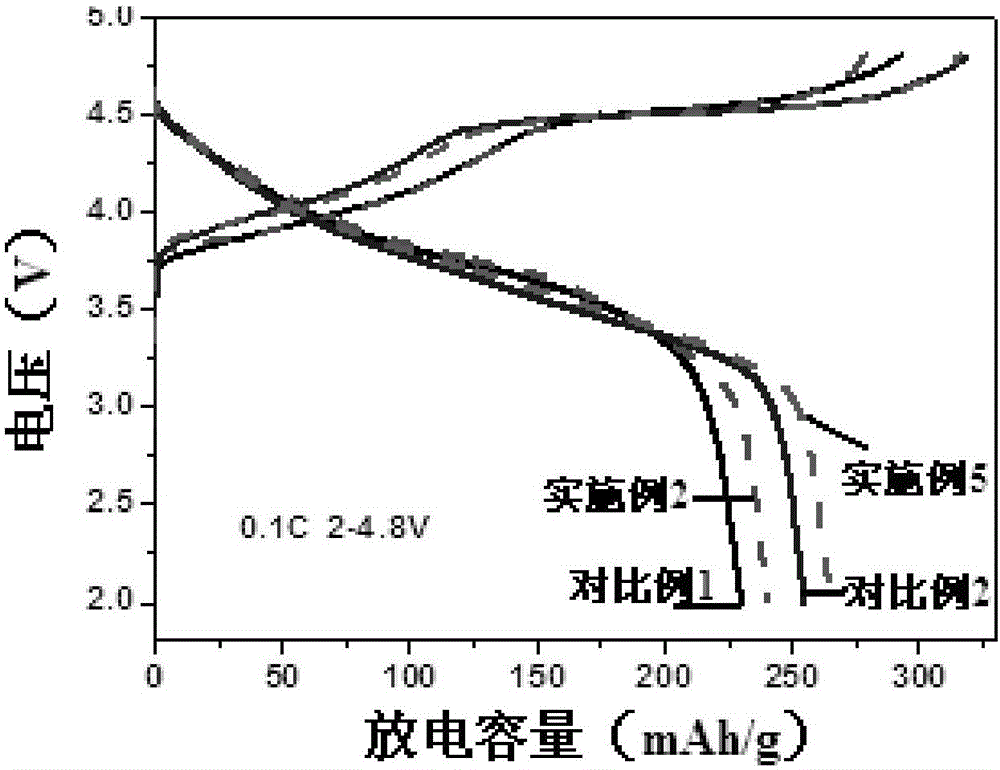

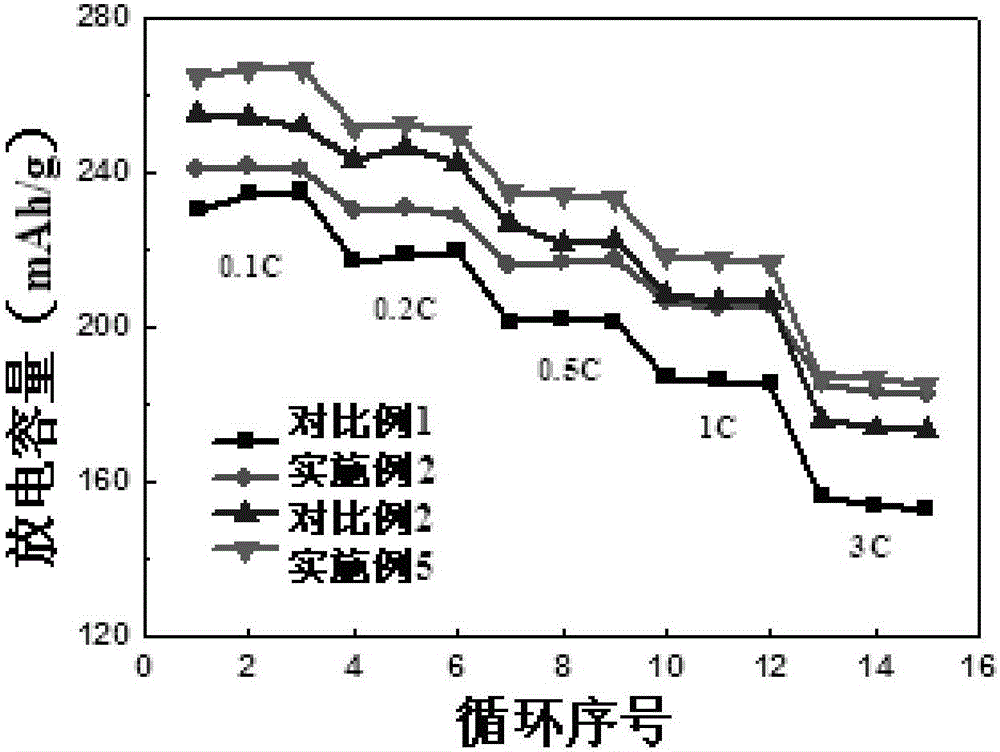

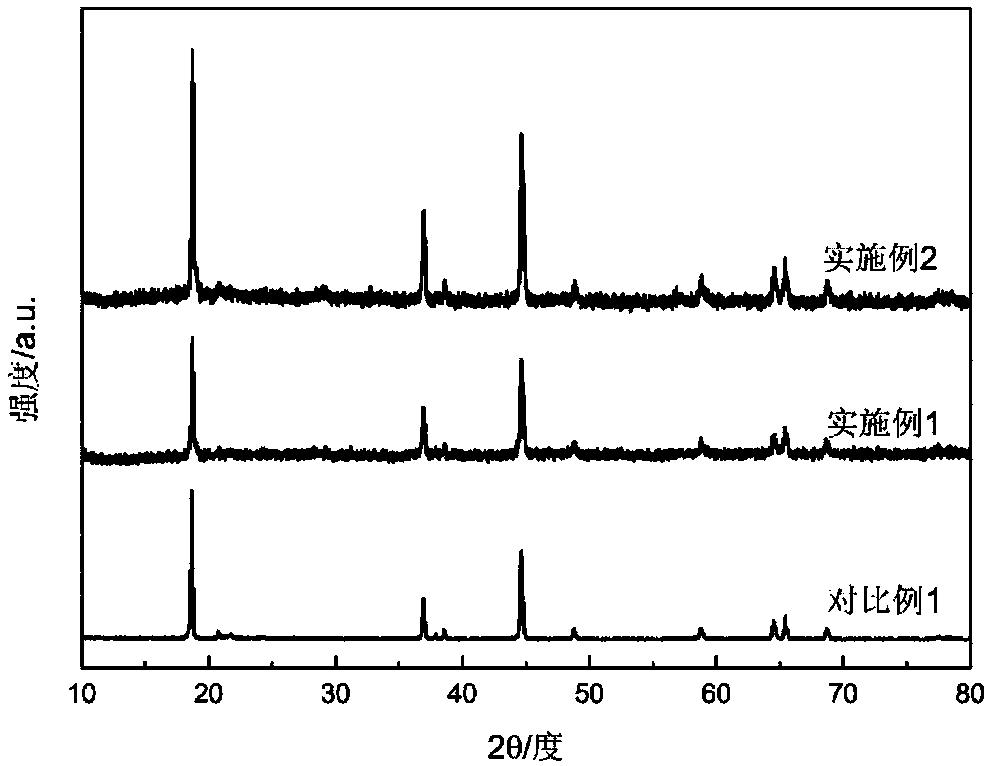

The present invention includes compositions, surface and bulk modifications, and methods of making of (1−x)Li[Li1 / 3Mn2 / 3]O2.xLi[Mn0.5-yNi0.5-yCo2y]O2 cathode materials having an O3 crystal structure with a x value between 0 and 1 and y value between 0 and 0.5, reducing the irreversible capacity loss in the first cycle by surface modification with oxides and bulk modification with cationic and anionic substitutions, and increasing the reversible capacity to close to the theoretical value of insertion / extraction of one lithium per transition metal ion (250-300 mAh / g).

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

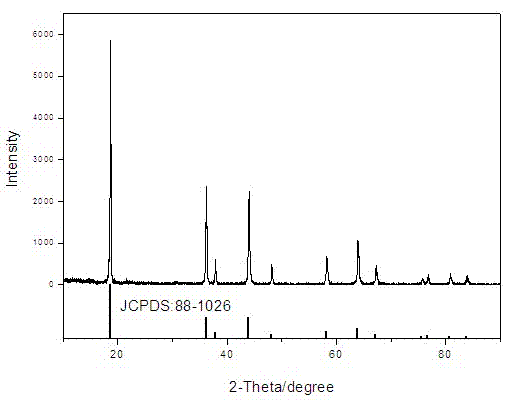

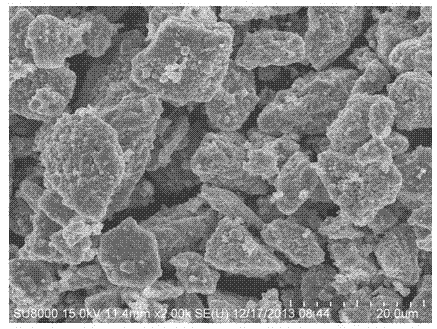

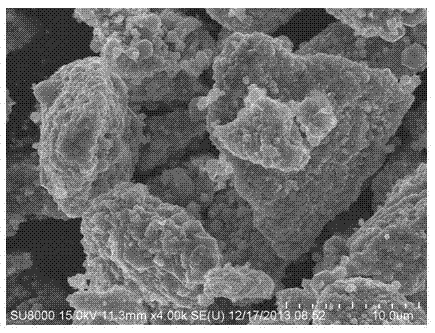

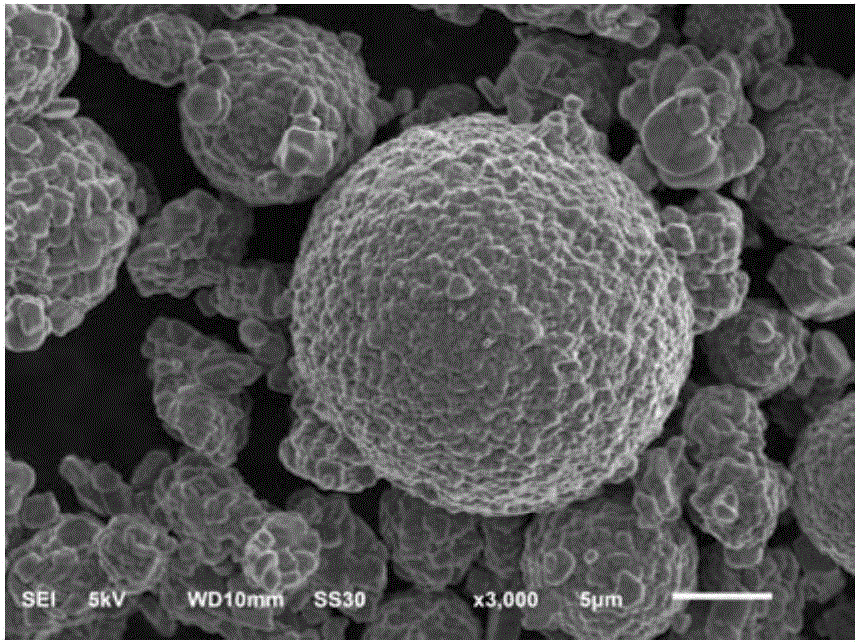

Method for preparing ternary anode material of long-service-life and high-capacity lithium ion battery

ActiveCN103682316AIncrease capacityImprove cycle performanceCell electrodesCapacity lossMaterial synthesis

A method for preparing a ternary anode material of a long-service-life and high-capacity lithium ion battery and belongs to the technical field of material synthesis. The method comprises the following steps: weighing a lithium source and NixCoyMnz(OH)2, uniformly mixing, pre-burning at a temperature of 400-600 DEG C for 2-6 h, and forging at a temperature of 700-1000 DEG C for 6-16 h; uniformly mixing the ternary anode material, the lithium source and nanometer TiO2; forging at a temperature of 700-950 DEG C for 3-8 h to obtain the ternary anode material which is prepared by twice lithium adding and twice forging. The ternary anode material is prepared through twice lithium adding and twice forging, and the extra lithium source which is introduced through twice lithium adding and twice forging is electrochemically pre-embedded in an anode. Meanwhile, the Li+ diffusion rate can be effectively increased through the doping of Ti4+, and the irreversible capacity loss is reduced. In an interval of 2.3-4.6 V, a discharging platform is prolonged, and the first discharging capacity, the cyclic performance and the rate performance of the material are obviously improved. The method is simple, effective, economical and practical and has a remarkable industrial application effect.

Owner:HARBIN INST OF TECH

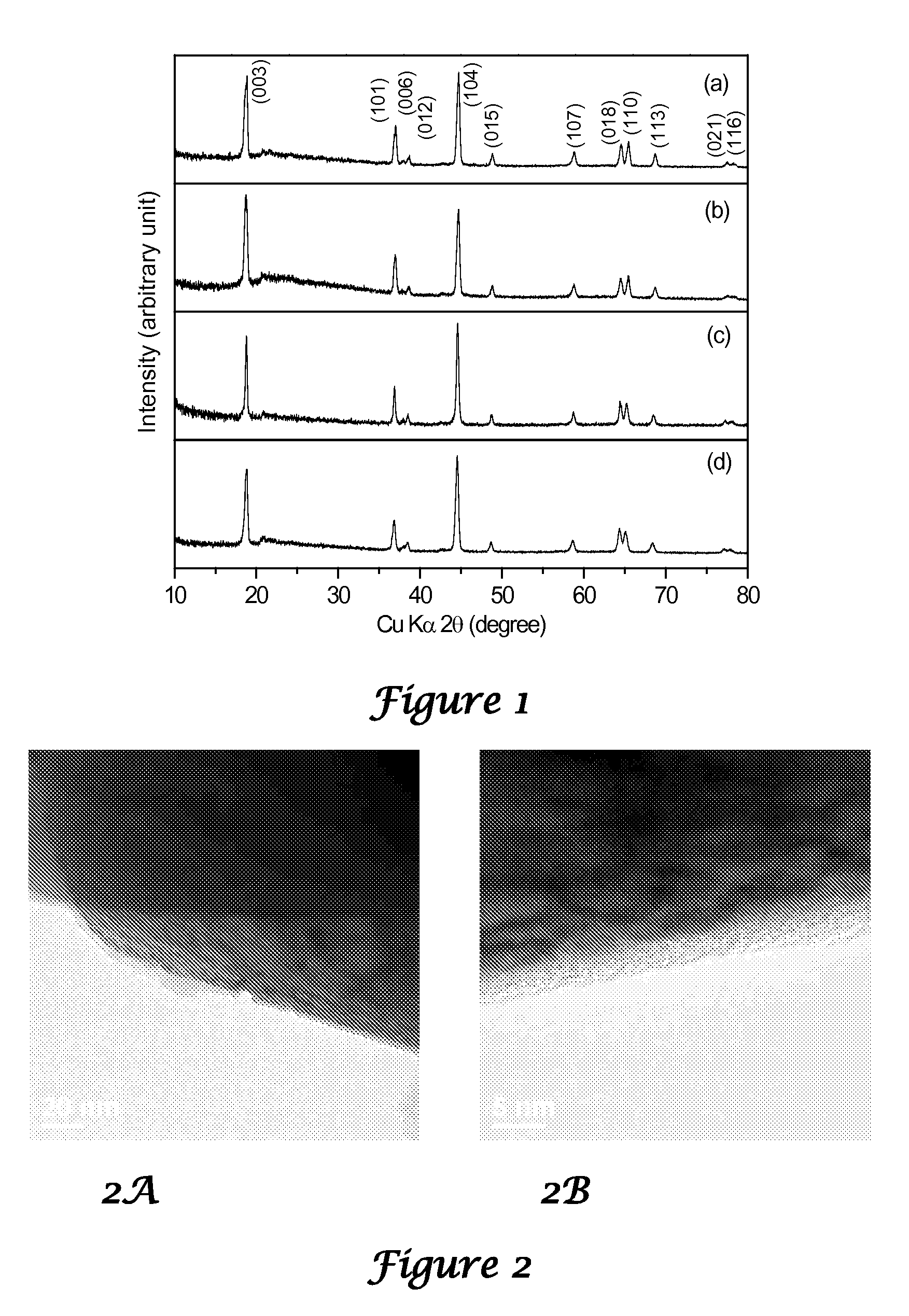

High capacity layered oxide cathods with enhanced rate capability

InactiveUS20130040201A1Inhibitory responseIncrease probabilityNon-aqueous electrolyte accumulator electrodesCapacity lossElectrical conductor

The present invention provides a surface modified cathode and method of making surface modified cathode with high discharge capacity and rate capability having a lithium-excess Li[M1-yLiy]O2 (M=Mn, Co, and Ni or their combinations and 0<y≦0.33) cathode surface with a surface modification comprising lithium-ion coated sample conductor, or an electronic conductor, or a mixed lithium-ion and electronic conductor to suppress the elimination of oxide ion vacancies, reduce the solid-electrolyte interfacial (SEI) layer thickness, reduce the irreversible capacity loss in the first cycle, and enhance the rate capability.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Surface and bulk modified high capacity layered oxide cathodes with low irreversible capacity loss

InactiveUS7678503B2Large capacityLow costElectrode carriers/collectorsAlkali metal oxidesOxide cathodeSurface modification

The present invention includes compositions, surface and bulk modifications, and methods of making of (1−x)Li[Li1 / 3Mn2 / 3]O2.xLi[Mn0.5-yNi0.5-yCo2y]O2 cathode materials having an O3 crystal structure with a x value between 0 and 1 and y value between 0 and 0.5, reducing the irreversible capacity loss in the first cycle by surface modification with oxides and bulk modification with cationic and anionic substitutions, and increasing the reversible capacity to close to the theoretical value of insertion / extraction of one lithium per transition metal ion (250-300 mAh / g).

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Method for effectively screening self-discharging batteries

The invention relates to a method for effectively screening self-discharging batteries. The method comprises the following steps: (1) determining low-voltage-state voltage knee points of batteries by using a trickle charge method; (2) carrying out charging and discharging on the batteries, allowing the voltage of the batteries to be finally located at the low-voltage-state voltage knee points, and after the voltage of the batteries tends to be stable, measuring and recording the voltage OCV1 of each battery; (3) storing the batteries at a set temperature for a period of time and measuring and recording the voltage OCV2 of each battery; and (4) calculating the voltage drop value delta V of each battery, wherein delta V satisfies the equation that delta V = OCV1 - OCV2, and if the voltage drop value delta V of a battery exceeds a set value, the battery is a self-discharging battery need to be screened out. The method provided by the invention is more scientific, accords with principles, can more accurately screen out self-discharging lithium ion batteries and reduces irreversible capacity loss of batteries in the phase of screening of self-discharge; thus, excellent electrochemical performance and safety performance of batteries in subsequent usage are guaranteed.

Owner:杭州师腾新能源科技有限公司

Lithium supplement paste for lithium secondary battery and preparation method of lithium secondary battery

InactiveCN110767880AIncrease energy densityCycle performance unchangedFinal product manufactureCell electrodesOrganic solventPhysical chemistry

The invention provides lithium supplement paste for a lithium secondary battery. The lithium supplement paste comprises a lithium-containing compound, a conductive agent, a bonding agent and an organic solvent, wherein the bonding agent is a bonding agent which can be dissolved in a non-aqueous electrolyte solution. In the obtained lithium secondary battery, the cycle property of the battery is enabled not to be changed, and the energy density of the lithium secondary battery is remarkably improved.

Owner:MICROVAST POWER SYST CO LTD

Cathode active material and preparation method thereof, cathode material and lithium ion battery

ActiveCN102569774AExtended Diffusion PathImprove stabilityCell electrodesSecondary cellsManganeseSodium-ion battery

The invention provides a cathode active material and a preparation method thereof, a cathode material and a lithium ion battery. The cathode active material is provided with a kernel and a shell wrapped on the surface of the kernel, wherein the kernel is made of a lithium-enriched manganese-based material; the composition of the lithium-enriched manganese-based material is Li1+xMnaMbOz, wherein x is more than or equal to 0 and less than or equal to 1, a is more than 0 and less than or equal to 2, b is more than or equal to 0 and less than or equal to 2, z is more than or equal to 2 and less than or equal to 5, and M is selected from one or more of Co, Ni, Fe, Mg, Ca, Sn, Ti, Zr, Zn and Cr; and the shell is made of boron oxide. The rate capability and the circulation performance of the lithium ion battery prepared by adopting the cathode active material are high.

Owner:BYD CO LTD

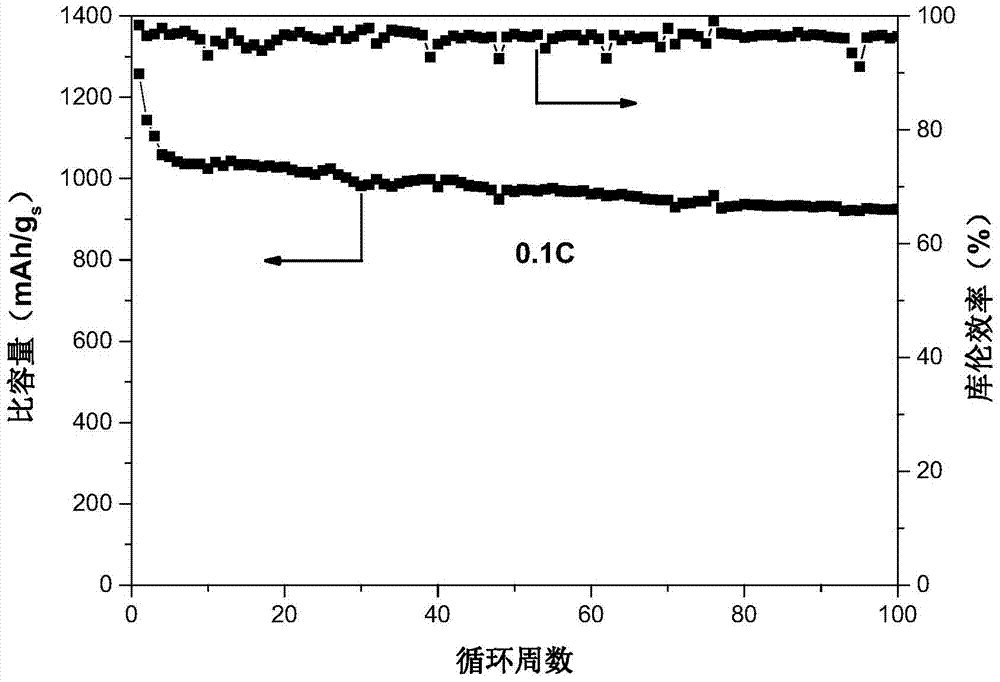

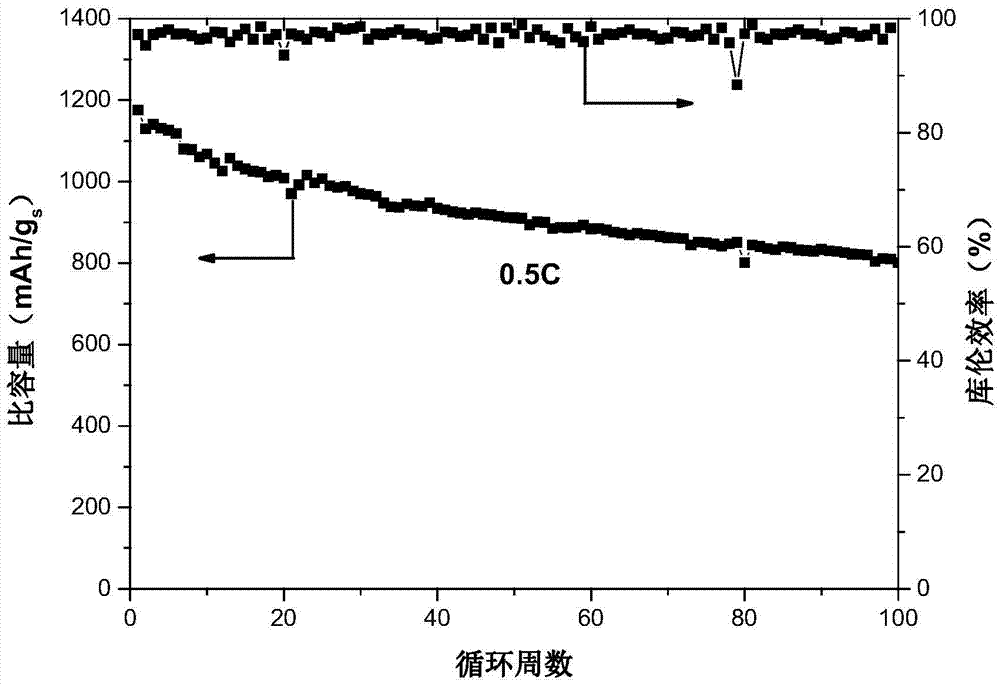

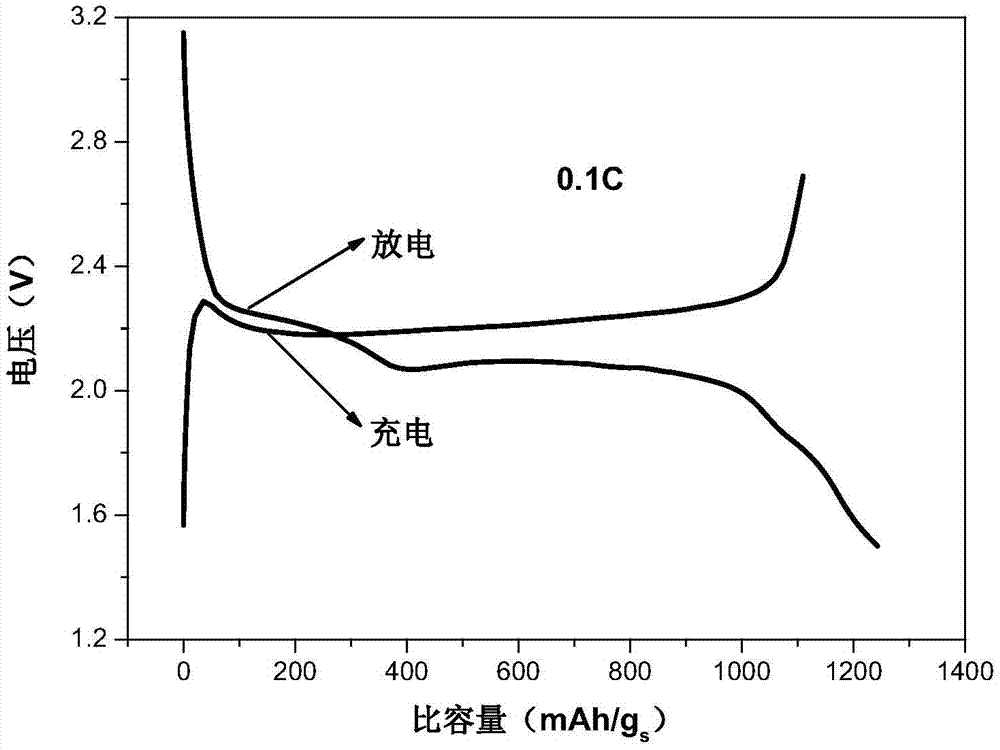

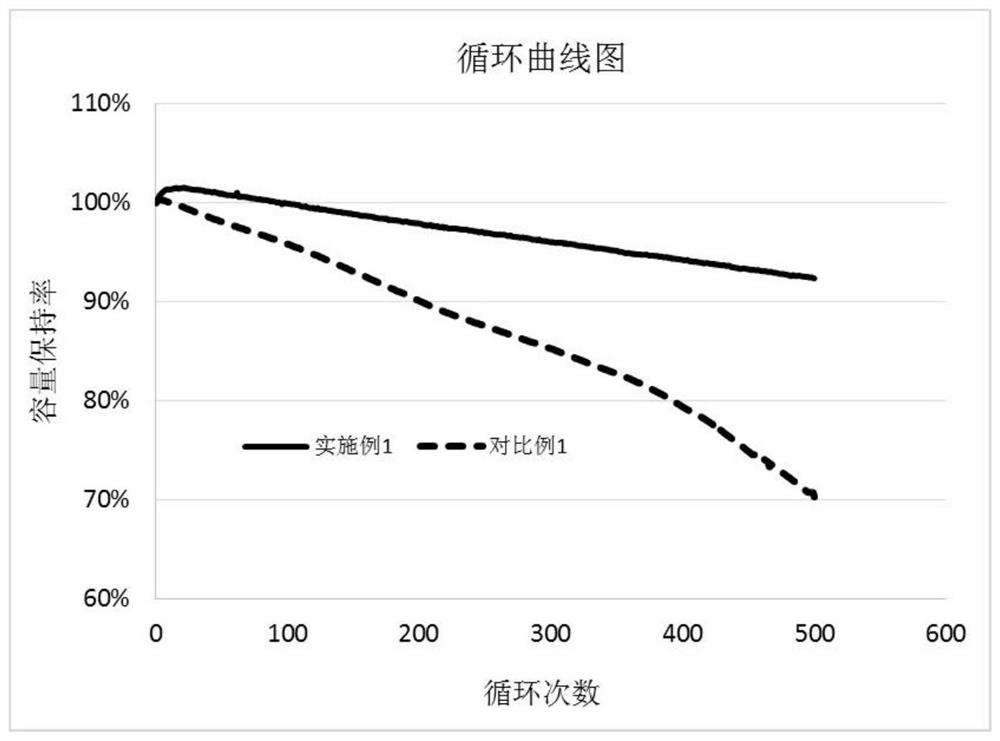

Nitrogen-rich eggshell type lithium sulfur battery anode material and preparation method and application thereof

InactiveCN105449209AImprove adsorption capacityThe first discharge specific capacity is highCell electrodesLi-accumulatorsChemical adsorptionMelamine formaldehyde resin

The invention discloses a lithium sulfur battery anode material and preparation method thereof, melamine formaldehyde resin rich in nitrogen is taken as a carbon source and nitrogen source, a nitrogen-rich hollow eggshell with the diameter of 100-300 nm is prepared with a nanometer SiO2 casting method, the interfacial adsorption of polysulfide is enhanced by the aid of the combined effect of physical adsorption and chemical adsorption, migration and shuttle effects of the polysulfide are effectively restrained, and charge and discharge stability of a lithium sulfur battery is enhanced. At the same time, an eggshell structure is formed after the hollow eggshell is filled with sulfur, and an interior gap exists between a sulfur inner core and a polymer shell so as to accommodate volume expansion in a sulfur atom lithiation process. The lithium sulfur battery anode material is applied to preparation of a lithium sulfur battery anode and the lithium sulfur battery. The lithium sulfur battery has excellent cycle performance and capacity retention ratio.

Owner:DALIAN UNIV OF TECH

Start-stop battery electrolyte and lithium ion battery

InactiveCN110556580AImprove conductivityImprove thermal stabilitySecondary cellsOrganic electrolytesDifluorophosphatePhosphate

The invention belongs to the technical field of lithium ion batteries and discloses a start-stop battery electrolyte and a lithium ion battery. The electrolyte is prepared from the following components in percentage by mass: 12-20% of lithium salt, 78-85% of a carbonic ester organic solvent and 1-3% of a functional additive. The lithium salt is prepared from the following components: 0.5-16% of lithium hexafluorophosphate and 0.5-18% of lithium bis(fluorosulfonyl)imide. The functional additive comprises at least two of the following components in percentage by mass: 0.3-1.5% of vinylene carbonate, 0.5-1% of ethylene sulfate, 0.5-1% of lithium difluorophosphate and 0.1-0.5% of lithium difluorobisoxalate phosphate. The positive electrode of the lithium ion battery is super nano lithium ironphosphate LFP, the particle size D50 is 0.2-2.0 microns, and the negative electrode of the lithium ion battery is at least one of artificial graphite, natural graphite, mesocarbon microbeads, soft carbon and hard carbon. The start-stop battery electrolyte disclosed by the invention has relatively high conductivity, relatively low interface impedance and relatively good thermal stability, gives consideration to high-temperature and low-temperature performance of the battery, and has outstanding power and cycle performance.

Owner:CAMEL GRP WUHAN OPTICS VALLEY R&D CENT CO LTD

Lithium ion battery negative electrode for reducing irreversible capacity loss and preparation method of lithium ion battery negative electrode

ActiveCN105470476AReduce irreversible capacity lossIncrease energy densityCell electrodesSecondary cellsCurrent collectorEnergy density

The invention discloses a lithium ion battery negative electrode for reducing irreversible capacity loss. The lithium ion battery negative electrode comprises a negative electrode current collector and a negative electrode paste, wherein the negative electrode paste is coated on the surface of the negative electrode current collector and comprises the following constituents based on mass: 25-45% of negative electrode active substance, 0.3-5% of conductive agent, 0.3-5% of binding agent, 0-2% of surfactant, 0.0001-0.01% of lithium salt and 50-70% of water, and the percentage sum of all constituents is 100%. With the lithium ion battery negative electrode disclosed by the invention, the irreversible capacity loss of the battery can be effectively reduced, and the energy density of the battery is improved. The invention also provides a preparation method of the lithium ion battery negative electrode for reducing the irreversible capacity loss. The process step is simple, and the method is high in operability, is easy to implement, and can be completely applied to industrial production of a lithium ion battery at a large scale.

Owner:WANXIANG 123 CO LTD

High-capacity lithium-enriched positive electrode material and preparation method thereof

ActiveCN104134797AHigh crystallinityUniform and controllable particle sizeCell electrodesSecondary cellsLithiumCalcination

The invention belongs to the field of electrochemistry and particularly relates to a high-capacity lithium-enriched positive electrode material and a reparation method thereof. The molecular formula of the high-capacity lithium-enriched positive electrode material is Li[Li<x-beta>Na<beta>Mn<1-y-z-alpha>Co<y>Ni<z>Y<alpha>]O2, wherein x is more than or equal to 0 and less than or equal to 0.6, y is more than 0 and less than or equal to 0.4, z is more than 0 and less than or equal to 0.4, alpha is more than or equal to 0 and less than or equal to 0.1 and beta is more than or equal to 0 and less than or equal to 0.2; the result of (1-y-z-alpha) is more than 0 and the result of (x-beta) is more than 0. The lithium-enriched positive electrode material containing Na and Y has the characteristics of low first-time irreversible capacity, large electrochemical capacity, high cycling stability, excellent rate performance and the like. The preparation method has the advantages that a preparation process is simple, raw materials are cheap and easily available, the cost is low, the high-temperature calcination time is very short, the repeatability is good and the industrialization is easy to realize.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Method for preparing high-capacity long-life lithium ion battery lithium manganate cathode material

ActiveCN103682315AIncreased diffusion rateIncrease the reversible specific capacityCell electrodesManganates/permanganatesCapacity lossMaterial synthesis

The invention relates to a method for preparing a high-capacity long-life lithium ion battery lithium manganate cathode material and belongs to the technical field of material synthesis. The method comprises the following steps: 1, weighing out one or more lithium sources, a manganese salt and one or more doped trace metal elements for uniformly mixing, preburning for 2-6 hours at 400-600 DEG C, calcining for 6-16 hours at 700-1000 DEG C, removing tiny particles in a grading mode, and magnetically adsorbing metal ions to obtain lithium manganate or primary doped lithium manganate; 2, secondarily doping the lithium sources into the lithium manganate or primary doped lithium manganate obtained by the step 1 for uniformly mixing; 3, calcining the mixture for 3-8 hours at 600-850 DEG C to obtain a primary or secondary doped calcined lithium manganate material. According to the method, as active materials are introduced for two times, the diffusion rate of Li+ is effectively increased, the irreversible capacity loss is reduced, the reversible specific capacity of the cathode material is increased, and the cycling stability of the cathode material is improved. The process is simple, the high-temperature performance is improved obviously and reliably, and the prepared lithium manganate material has high capacity and good high-temperature cycle performance.

Owner:哈尔滨博尔特能源科技有限公司

Polyimide electrode binders

ActiveUS7972725B2Decreased aromatic carbonyl contentReduce irreversible capacity lossNon-aqueous electrolyte accumulator electrodesLi-accumulatorsCapacity lossDiamine

Irreversible first cycle capacity loss in lithium secondary cells having a cell electrode based on a powdered material and a binder may be significantly decreased or eliminated by using an aliphatic or cycloaliphatic polyimide binder. Compared to conventional polyimide binders prepared by reacting an aromatic dianhydride and a diamine, the disclosed polyimide binders have decreased aromatic carbonyl content, may be less likely to undergo electrochemical reduction, and may be less likely to consume electrons that might otherwise help lithiate the electrode.

Owner:GELION TECH PTY LTD

Ce1-xZrxO2 nano solid solution homogenate modified lithium ion battery anode material and preparation method thereof

ActiveCN106058241AHigh initial capacityExcellent rate performanceCell electrodesSecondary cellsSolid phasesLithium electrode

The invention belongs to the technical field of lithium ion battery material manufacturing process and discloses a Ce1-xZrxO2 nano solid solution homogenate modified lithium ion battery anode material and a preparation method thereof. A LiNixCoyM(1-x-y)O2 material preparation process includes: forming a coating of a nanoscale metal oxide according to a homogeneous precipitation method, wherein the nanoscale metal oxide refers to Ce1-xZrxO2 nano solid solution; after coating is finished, drying the coating, heating to 200-1000 DEG C at a heating temperature of 1-5DEG C / min, keeping the temperature for 2-20h, and naturally cooling to obtain the Ce1-xZrxO2 nano solid solution homogenate modified LiNixCoyM(1-x-y)O2 material. The prepared LiNixCoyM(1-x-y)O2 material has excellent high-temperature cycle performance and electrochemical interface stability. Compared with a traditional solid-phase method, the modification method is high in uniformity and reliability.

Owner:TIANJIN B&M SCI & TECH

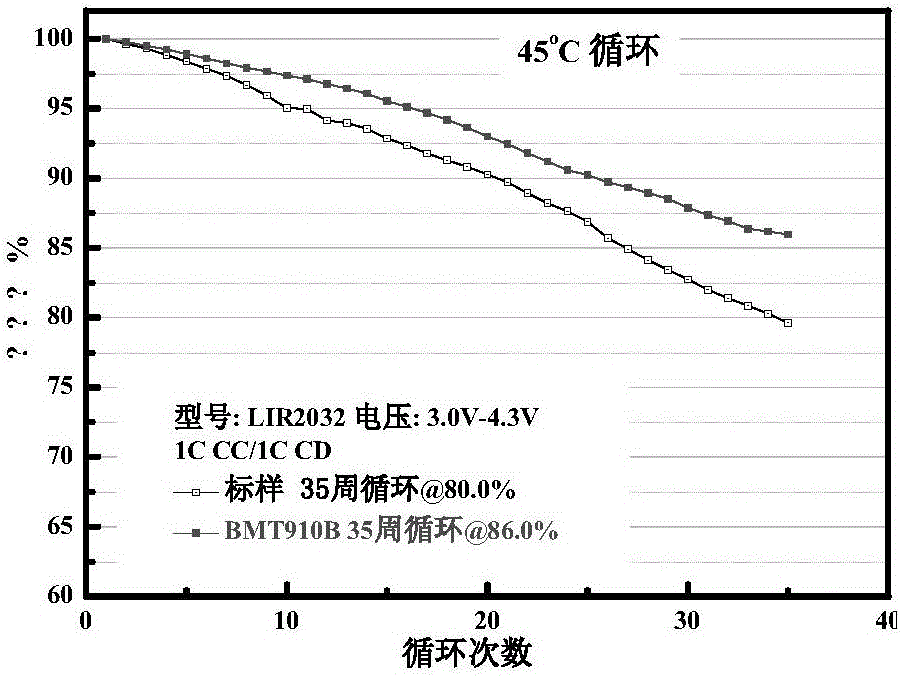

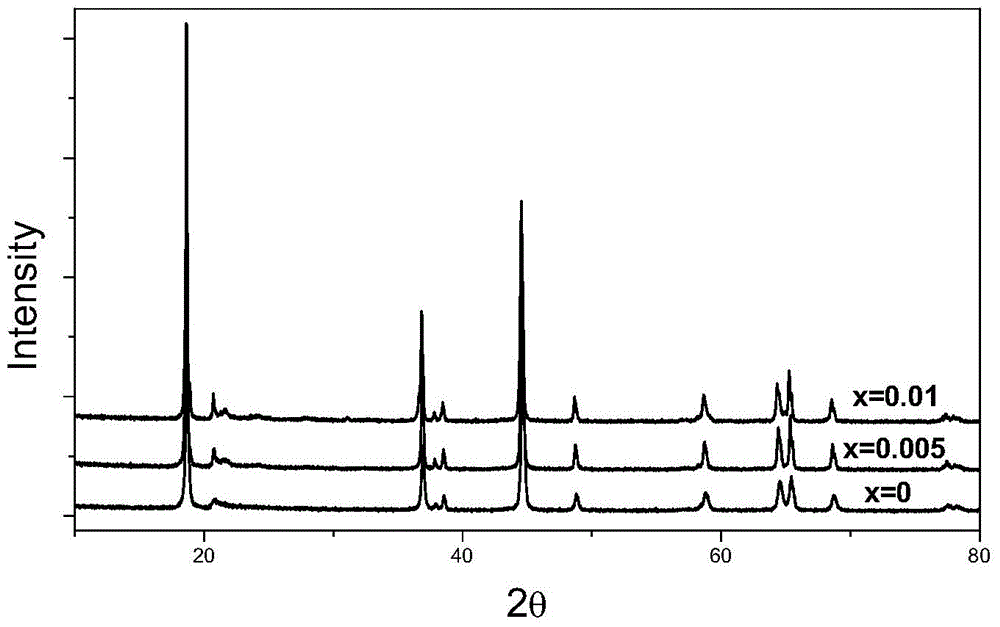

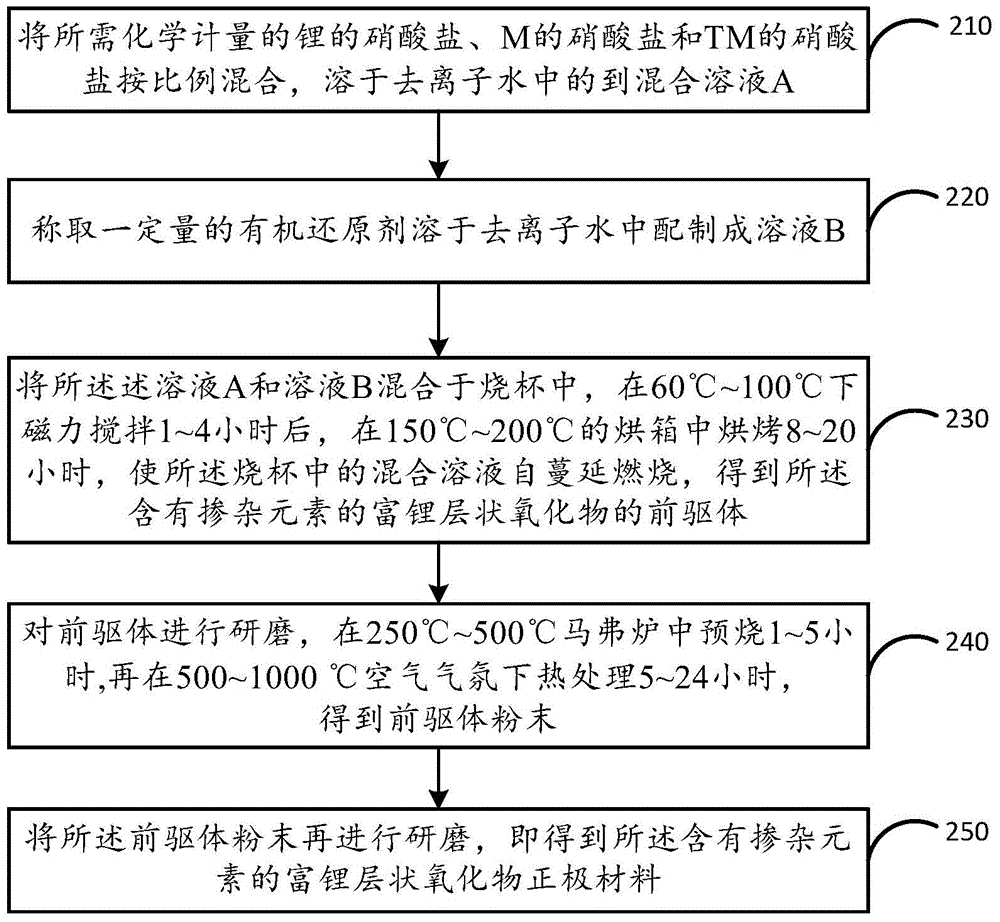

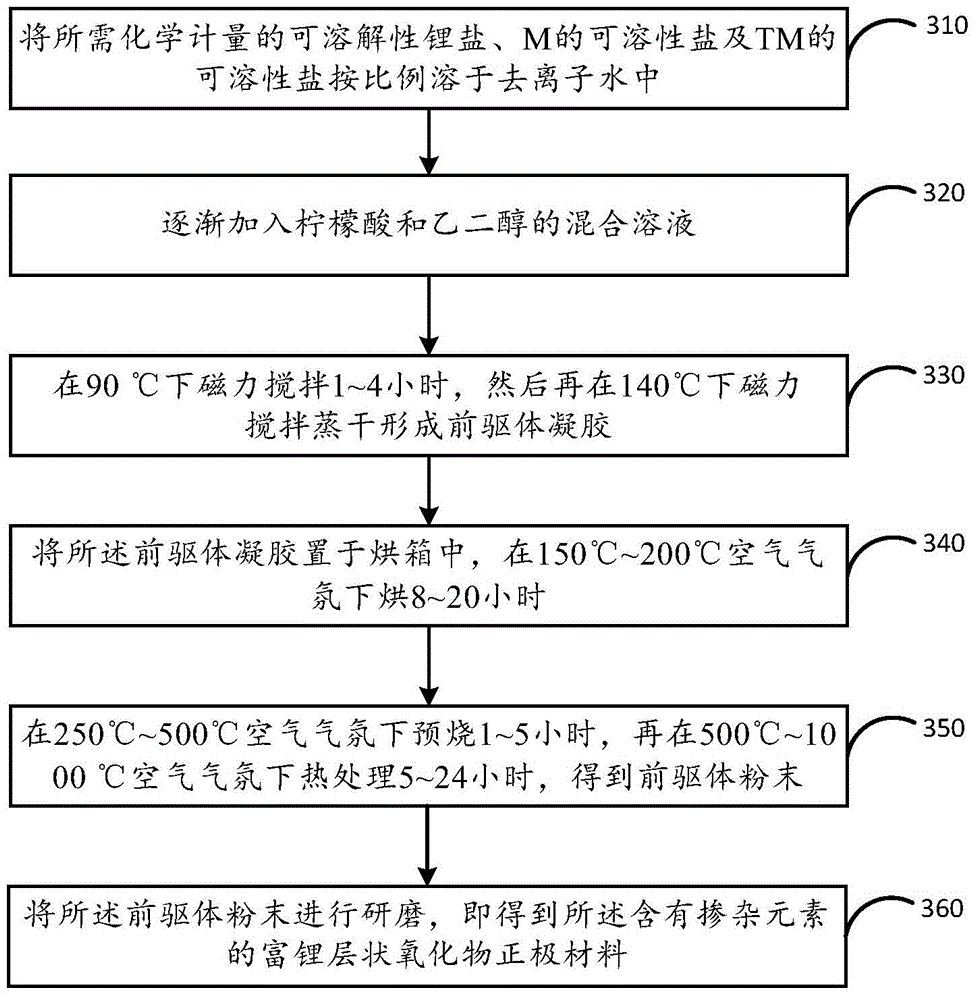

Doping method of lithium-rich layered oxide positive electrode material, material and preparation method

ActiveCN106299328AImprove conductivityImproved magnification performanceCell electrodesSecondary cellsLithiumPhysical chemistry

The invention discloses a doping method of a lithium-rich layered oxide positive electrode material, the material and a preparation method. The method comprises the steps of partially substituting lithium ions Li<+> of a lithium layer in a lithium-rich layered oxide by divalent positive ions Mn<+> and above to obtain the lithium-rich layered oxide positive electrode material containing a doping element.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Silicon monoxide-graphite composite anode material for lithium ion battery and preparation method thereof

InactiveCN110828811AOvercome the defect of low first effectImprove first-time efficiencyNegative electrodesSecondary cellsSilicon monoxideLithium-ion battery

The invention discloses a spherical monoxide-graphite composite anode material for a lithium ion battery and a preparation method thereof. The preparation method comprises the steps of: performing ball-milling treatment of silicon monoxide raw materials and natural graphite raw materials, then performing spray drying of the mixture with asphalt, aluminum isopropoxide and other organic carbon sources, and finally, performing high-temperature disproportionation reaction and carbonization treatment in an inert atmosphere to finally obtain the spherical silicon monoxide-graphite composite anode material coated with amorphous carbon and mutually fused with silicon monoxide particles and the graphite particles. The synthesis process is simple, the process conditions are easy to control, and industrialization is easy to implement; the prepared spherical silicon monoxide-graphite composite anode material is good in circulation and small in expansion coefficient, and can be used as the new generation of the lithium ion power battery anode material.

Owner:TIANJIN B&M SCI & TECH

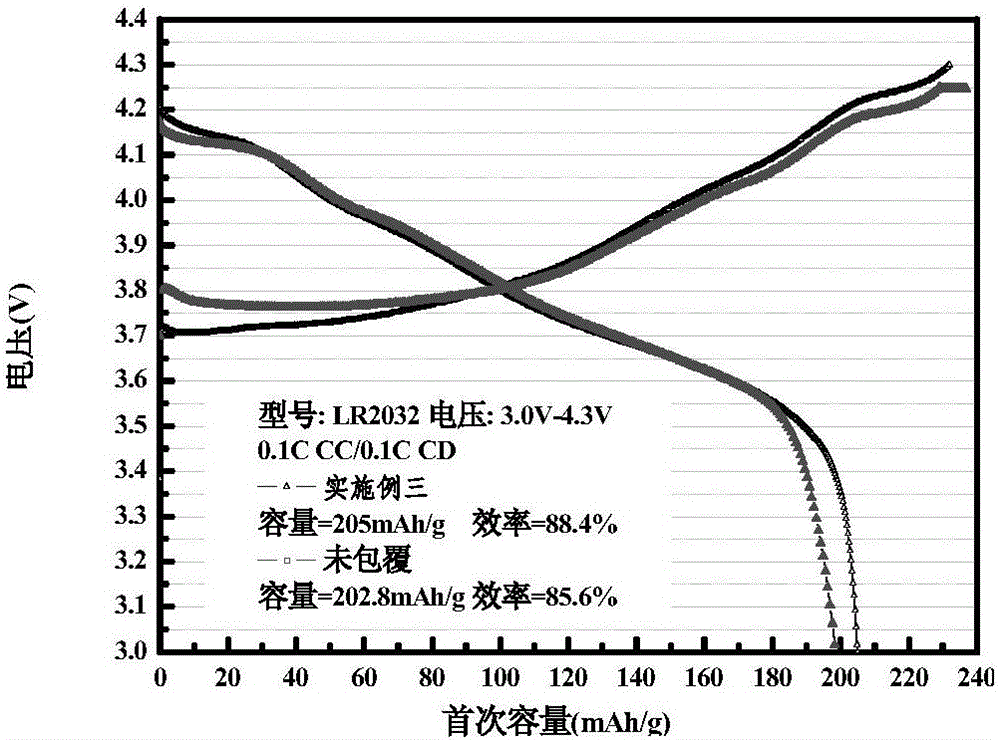

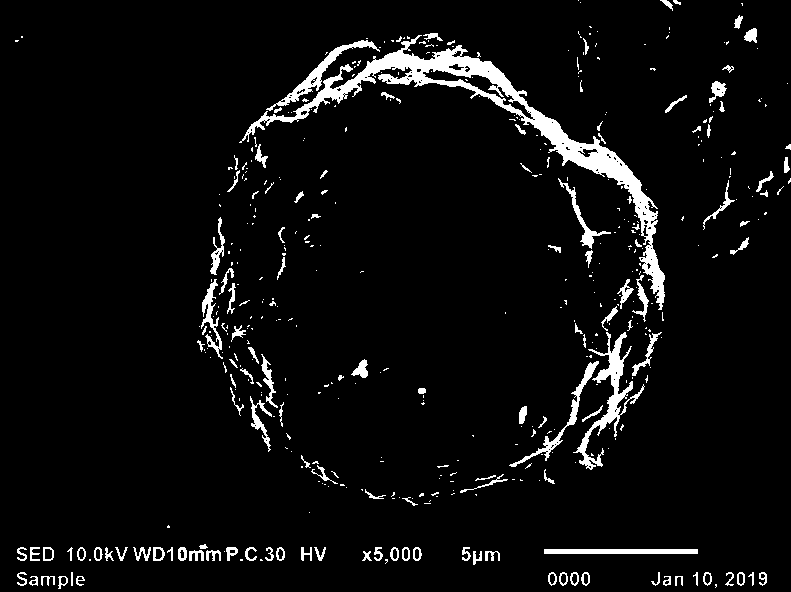

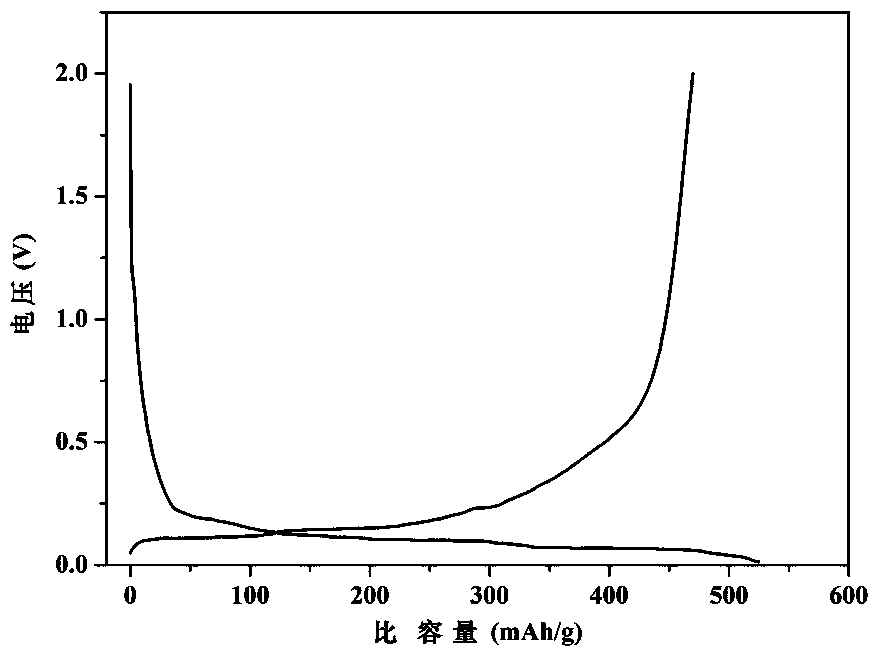

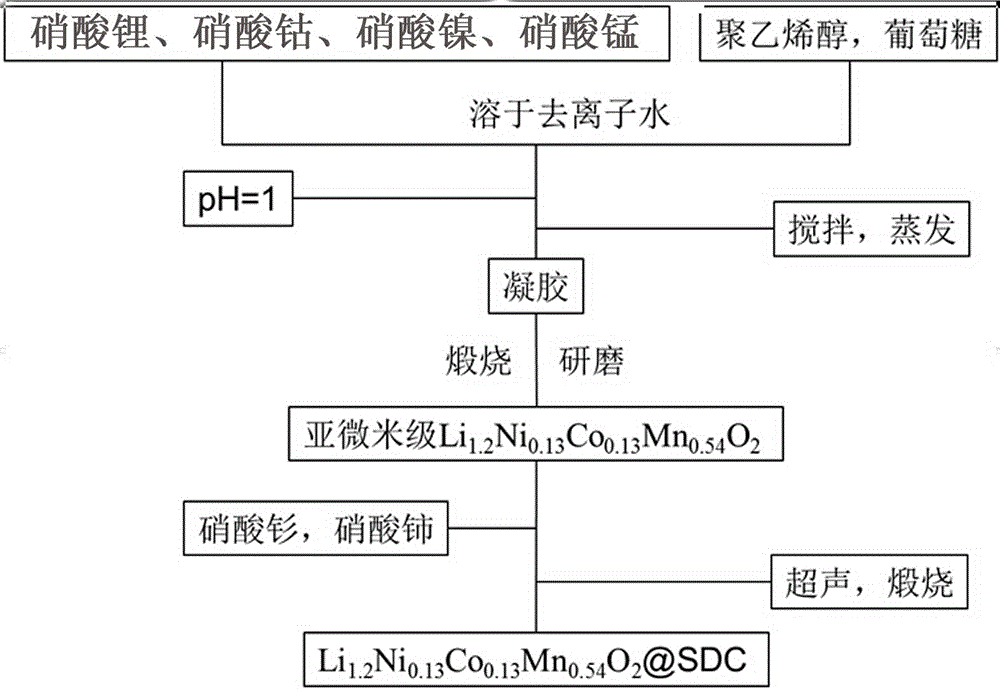

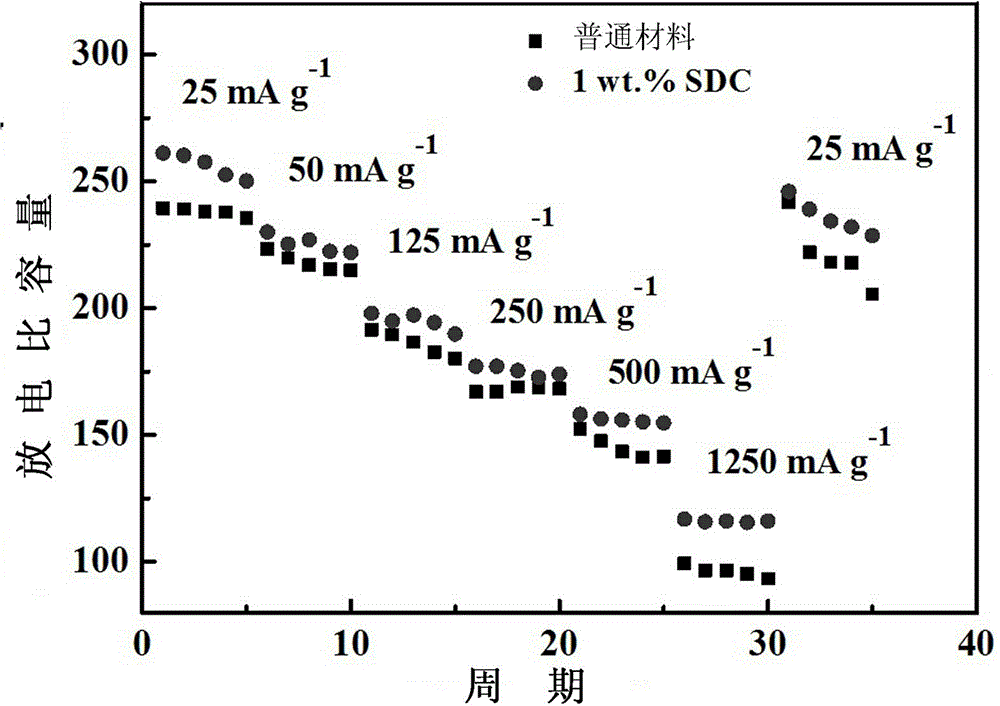

Method for modifying surface of anode material Li1.2Ni0.13Co0.13Mn0.54O2 for lithium ion battery

The invention relates to the technical field of anode material for a lithium ion battery, and in particular relates to a method for modifying the surface of anode material Li1.2Ni0.13Co0.13Mn0.54O2 for the lithium ion battery. The method comprises the following steps: A. preparing lithium-rich anode material Li1.2Ni0.13Co0.13Mn0.54O2 powder; B. dispersing the Li1.2Ni0.13Co0.13Mn0.54O2 powder prepared in the step A into a solution of samarium nitrate and cerium nitrate; carrying out ultrasonic treatment, magnetic stirring, evaporation, drying and calcination treatment to obtain coated anode surface modification material Li1.2Ni0.13Co0.13Mn0.54O2 @ samarium-doped cerium oxide (SDC) with different SDC mass fractions. After the surface modification method is used, all the electrical properties of the lithium anode material can be comprehensively improved, namely, the first-time irreversible capacity of the material is reduced, the specific discharge capacity is increased, and the rate capability is improved; furthermore, the method is simple in technology, easy to operate, low in cost and environment-friendly, thus being suitable for large-scale industrial production.

Owner:MCNAIR TECH +2

Electrolyte, preparation method thereof, high-energy-density lithium ion battery containing electrolyte and preparation method thereof

InactiveCN111769327AImprove solubilityIncrease the ionic conductivity of the electrolyteFinal product manufactureSecondary cellsVinylene carbonateOrganosolv

The invention discloses an electrolyte, a preparation method thereof, a high-energy-density lithium ion battery containing the electrolyte and a preparation method thereof. The electrolyte comprises alithium salt, a non-aqueous organic solvent, a negative electrode film-forming organic additive and a modified additive. The negative electrode film-forming organic additive is any one or at least two of fluoroethylene carbonate, 1, 2-difluoroethylene carbonate, chloroethylene carbonate and vinylene carbonate, and the modified additive is any one or at least two of potassium carbonate, sodium carbonate and lithium carbonate. The electrolyte provided by the invention can quickly form a layer of compact, stable and thin SEI film with good mechanical properties on the surfaces of negative electrode material particles. The high-energy-density lithium ion battery containing the electrolyte can relieve the problems of lithium battery capacity attenuation, particle pulverization and the like caused by volume expansion of a silicon-based negative electrode in the recycling process, and has good cycling stability and rate capability.

Owner:GUANG DONG GREENWAY TECH CO LTD

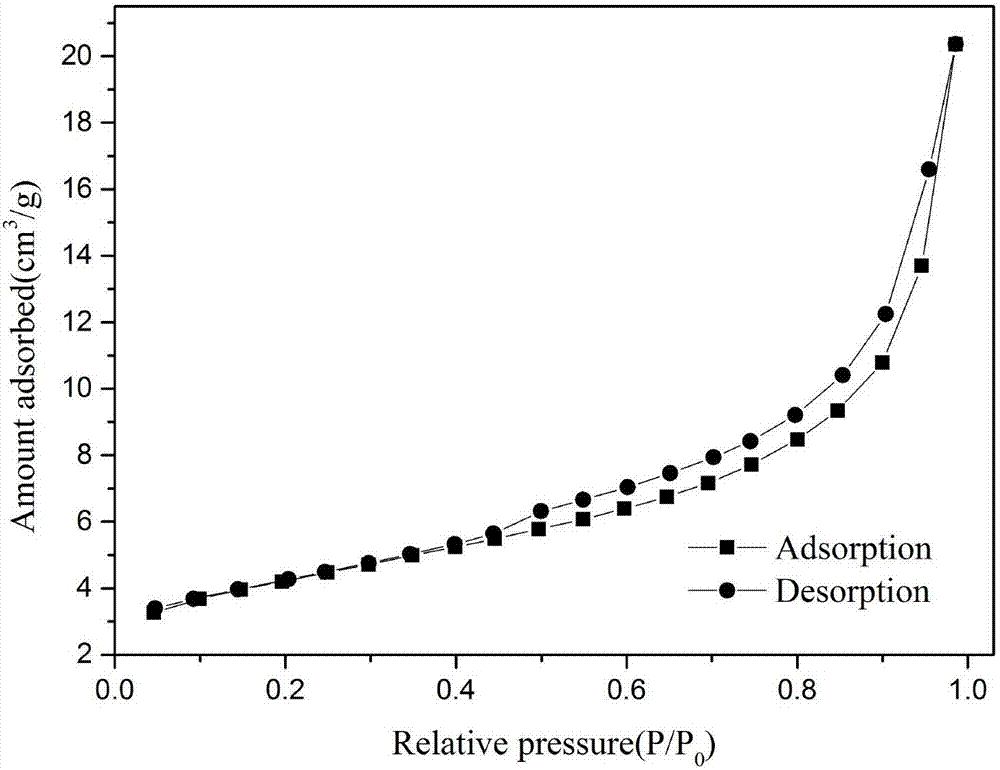

Preparation method of carbon/carbon nanotube coated lithium iron phosphate composite material by in situ synthesis

ActiveCN106876705AHigh carbon coverageImprove electrochemical performanceCell electrodesSynthesis methodsPhosphate

The invention provides a preparation method of a carbon / carbon nanotube coated lithium iron phosphate composite material by in situ synthesis, and relates to the technical field of battery materials. The preparation method provided by the invention comprises the steps of weighing raw materials of a lithium source, iron powder, a phosphate and a carbon source; first performing ball-milling on the iron powder and the phosphate and adding hydrogen peroxide; and then adding the lithium source and the carbon source to obtain a slurry, drying and sintering under the protection of reducing / inert gas to obtain the composite material. According to the preparation method provided by the invention, the carbon / carbon nanotube coated lithium iron phosphate composite material is prepared by employing an in-situ synthesis method, so the heat treatment time is short; the composite material has relatively high carbon coating rate, stable electrochemical property and relatively good consistency, the cycle performance and the rate performance are greatly improved, the whole preparation process is simple, and the preparation method has the advantages of safety, high efficiency, low cost and environmental protection, etc.

Owner:合肥国轩科宏新能源科技有限公司

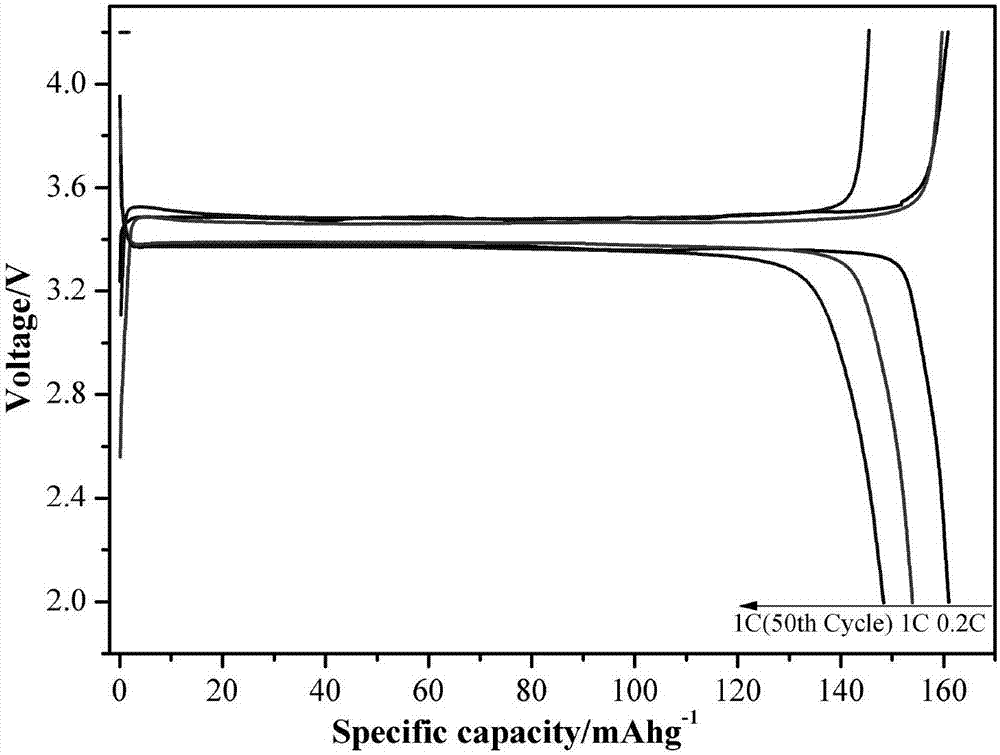

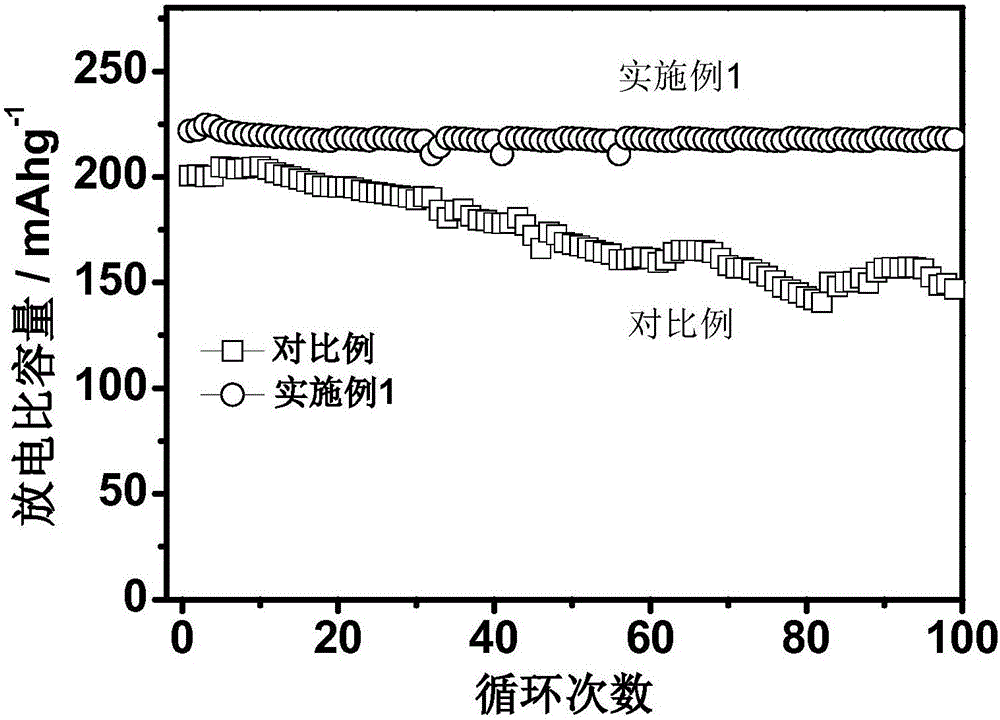

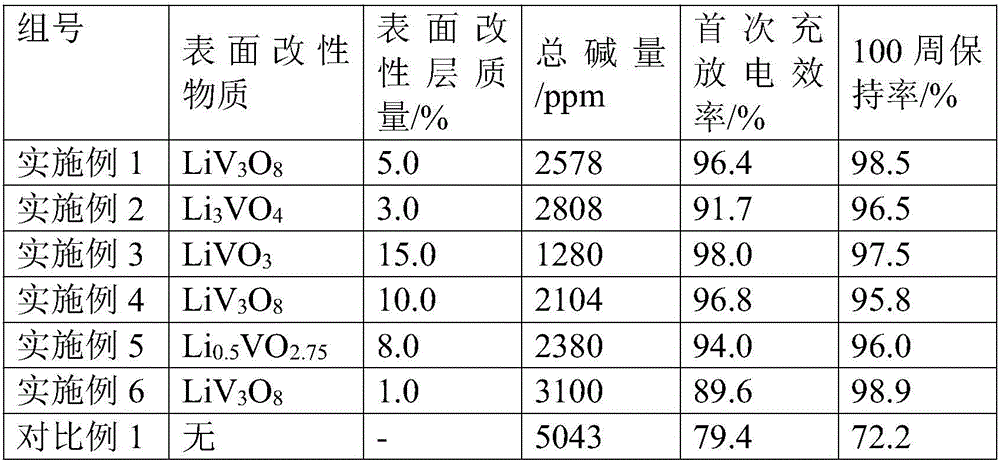

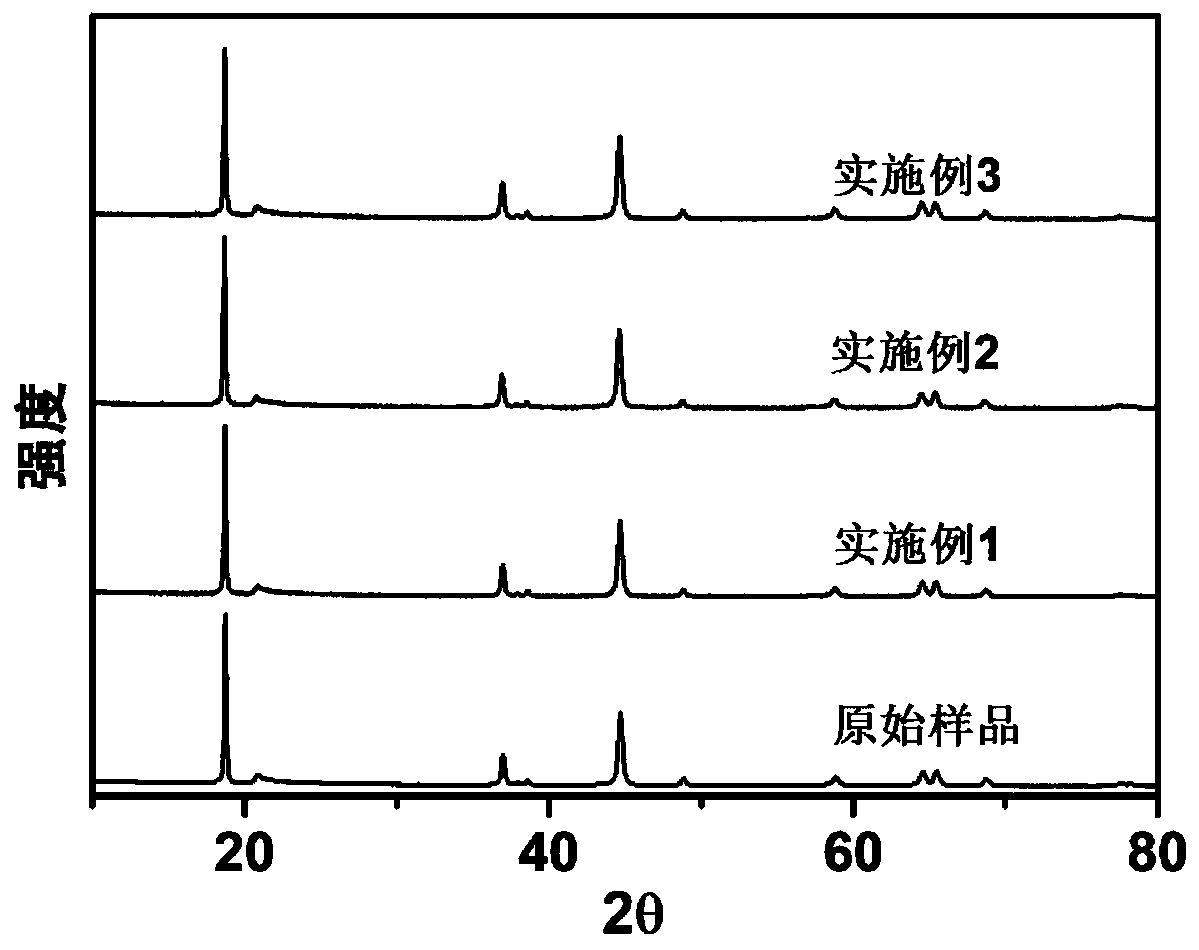

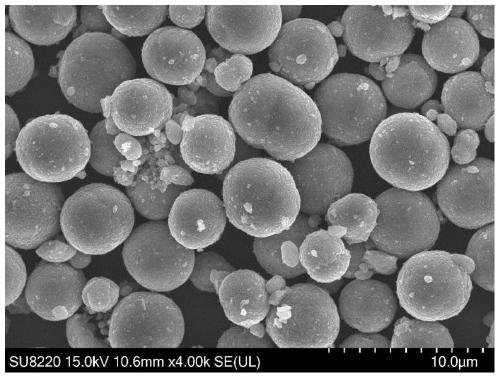

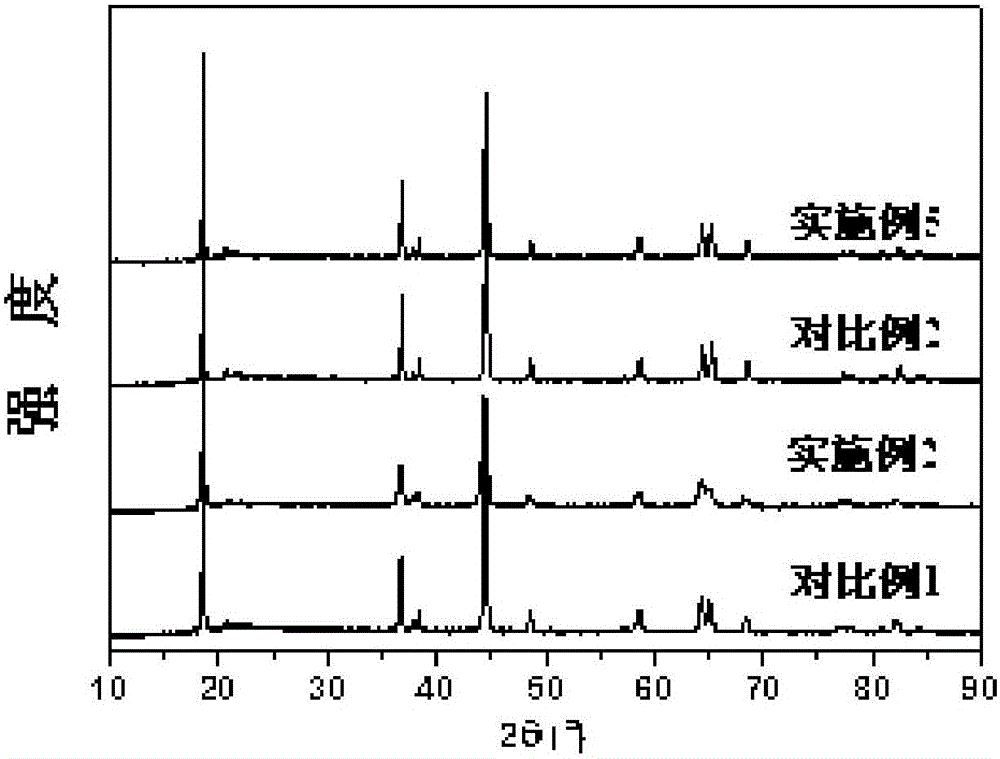

Lithium-rich manganese-based positive electrode material and preparation method thereof

ActiveCN106532018AReduce irreversible capacity lossFast ion mobilityCell electrodesSecondary cellsCapacity lossVanadium doping

The invention provides a lithium-rich manganese-based positive electrode material and a preparation method thereof. The lithium-rich manganese-based positive electrode material comprises a lithium-rich manganese-based core and a surface modification layer, wherein the lithium-rich manganese-based core comprises a chemical component with a general formula Li<1+x>Mn<y>M<z>O<r>, wherein M is at least one of Ni, Co, Al, Mg, Ti, Fe, Cu, Cr, Mo, Zr, Ru, Sn or V, x is smaller than or equal to 1 and greater than 0, y is smaller than or equal to 1 and greater than 0, z is smaller than 1 and greater than or equal to 0 and r smaller than or equal to 3 and greater than or equal to 1.8; the surface modification layer comprises a vanadium-doped gradient layer and a coating layer of a lithium vanadium oxide. The positive electrode material has a low initial charge-discharge irreversible capacity loss and excellent cycle performance and rate capability. According to the method, the bonding strength between the lithium vanadium oxide of the surface modification layer and the core of the lithium-rich manganese-based positive electrode material can be improved, the total alkali content of the material is reduced through reaction of the vanadium oxide and the residual lithium on the surface of the lithium-rich manganese-based positive electrode material is reduced and the problem of high-pressure cycle expansion of a battery is solved.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Surface-modified lithium-rich layered transition metal oxide as well as preparation method and application thereof

ActiveCN111081994AImprove structural stabilityImprove cycle stabilitySecondary cellsPositive electrodesMolten saltBattery cell

The invention belongs to the technical field of lithium ion battery anode materials, and discloses a surface-modified lithium-rich layered transition metal oxide as well as a preparation method and application thereof. The surface-modified lithium-rich layered transition metal oxide is prepared by the following steps that: a transition metal compound precursor, a lithium source and molten salt aremixed, and an obtained mixture is heated to 780-980 DEG C, is cooled to room temperature, cleaning, filtering and drying are performed, so that a lithium-rich layered transition metal oxide can be obtained; and the lithium-rich layered transition metal oxide is uniformly mixed with a carbon-nitrogen source, the mixture is placed in a protective atmosphere so as to be subjected to a hydrothermal reaction at 130-230 DEG C, an obtained product naturally cools, water washing, suction filtration, and drying are performed, so that the surface-modified lithium-rich layered transition metal oxide canbe obtained. The structure of the surface-modified lithium-rich layered transition metal oxide sequentially comprises the lithium-rich layered transition metal oxide, an oxygen vacancy-rich lithium-rich layered transition metal oxide-spinel structure oxide symbiotic layer and a nitrogen-doped carbon nano layer. The surface-modified lithium-rich layered transition metal oxide shows relatively highspecific discharge capacity and cycling stability as an anode material.

Owner:GUANGDONG UNIV OF TECH

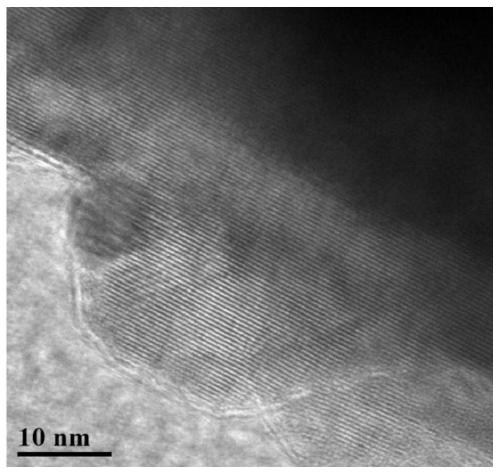

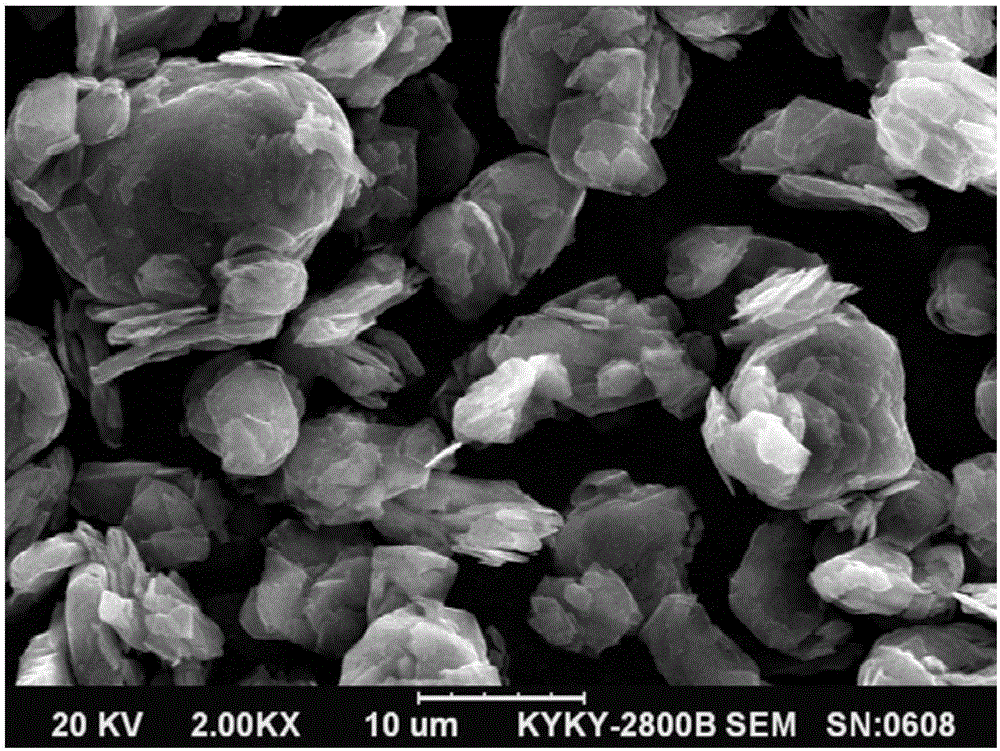

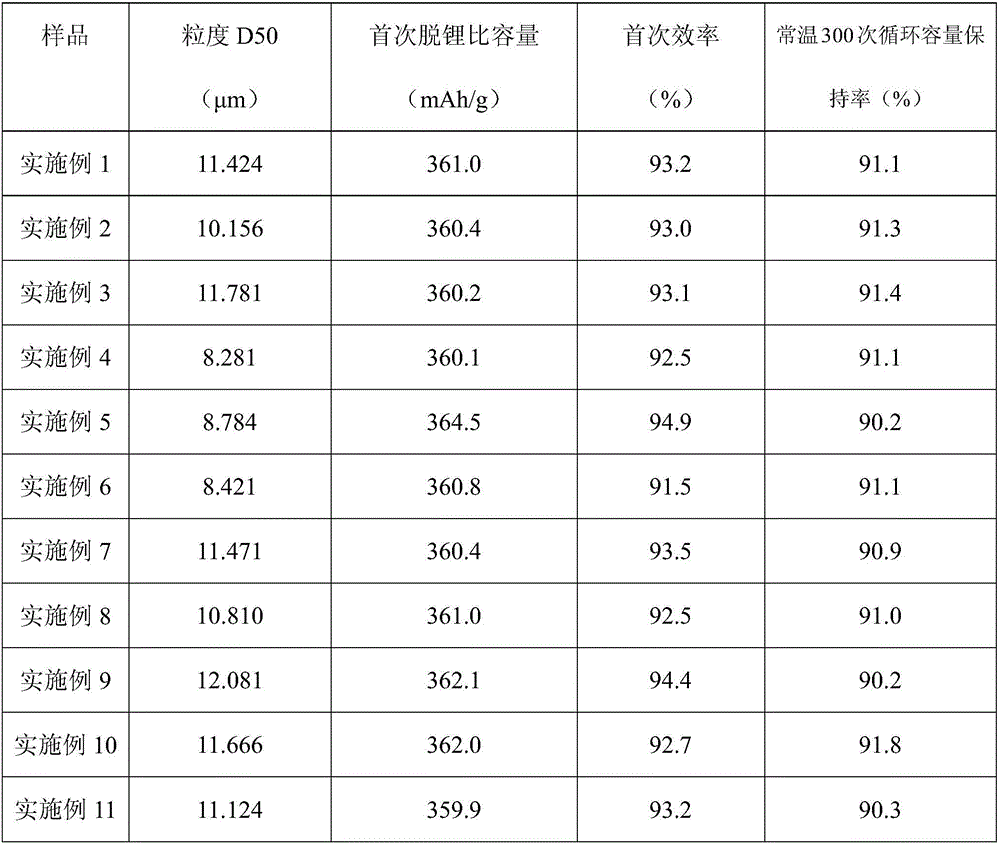

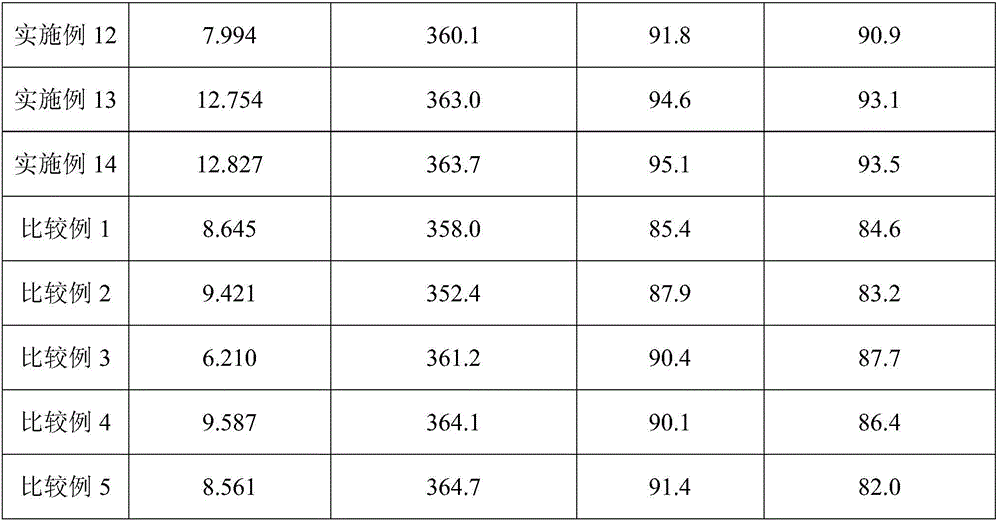

Graphite-based composite material and preparation method thereof and lithium ion battery comprising the composite material

ActiveCN106602067AHigh first efficiency andHigh specific capacityCell electrodesFinal product manufactureLithium electrodeAsphalt

The invention discloses a graphite-based composite material and a preparation method thereof and a lithium ion battery comprising the composite material. The method disclosed by the invention comprises the following steps: 1) uniformly mixing activated natural graphite and asphalt according to a proportion, adding to a fusion machine, charging inert gas and carrying out fusion and granulation under a certain temperature; and 2) carrying out carbonization treatment or graphitization treatment on a fusion and granulation product to obtain the graphite-based composite material. The battery which is assembled and whose negative electrode is prepared by adopting the graphite-based composite material has high capacity, and good rate capability and cycle performance; the initial lithium removal specific capacity is 360.1mAh / g or more, and the initial efficiency is 91.5% or more; and the room temperature charge-discharge cycles of the finished product battery is 300 weeks and the capacity retention rate is greater than 90%.

Owner:贝特瑞(江苏)新能源材料有限公司

Preparation method for negative electrode material of lithium-ion battery

ActiveCN106252637AReduce irreversible lossImprove the first Coulombic efficiencyCell electrodesSecondary cellsCarbon sourceNitrogen treatment

The invention belongs to the technical field of lithium-ion batteries, and in particular relates to a preparation method for a negative electrode material of the lithium-ion battery. The preparation method comprises the steps of ball-milling fine powder of artificial graphite wastes, SiO particles and organic carbon sources, thus acquiring mixed powder; then mixing the mixed powder with nitrogen-containing compounds; and nitriding in the atmosphere of protective gases at high temperatures of 300-1200 DEG C, thus acquiring the negative electrode material of the lithium-ion battery. According to the preparation method provided by the invention, the artificial graphite wastes can be better utilized for recycling, oxygen-containing functional groups on the surfaces of the artificial graphite wastes can be removed by nitrogen treatment, and primary coulombic efficiency, cycling stability and reversible capacity of the artificial graphite wastes can be improved. In addition, due to the mixture of silicon monoxide and the artificial graphite, both advantages can be integrated and both disadvantages can be weakened, and then the negative electrode material of the lithium-ion battery with high coulombic efficiency, good cycling performance, high capacity, high power and relatively small expansion can be acquired for the first time via effective coverage.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Preparation method of lithium ion battery negative electrode for reducing irreversible capacity loss

ActiveCN105470464AReduce irreversible capacity lossIncrease energy densityCell electrodesSecondary cellsCurrent collectorLithium electrode

The invention discloses a preparation method of a lithium ion battery negative electrode for reducing irreversible capacity loss. The preparation method mainly comprises the following steps of (1) weighing a negative electrode active substance, a conductive agent, a binding agent, a surfactant, a lithium salt and water, and then dissolving the lithium salt in the water accounting for 10-20% of total water to obtain a lithium salt solution for use; (2) uniformly mixing the surfactant and the remaining water, and then adding and uniformly dispersing the conductive agent to form a conductive adhesive; (3) adding and dispersing the negative electrode active substance in the conductive adhesive, adding the binding agent, uniformly stirring, and then carrying out vacuum defoaming to obtain a negative electrode paste; and (4) uniformly applying the negative electrode paste onto the surface of the negative electrode current collector, uniformly spraying the lithium salt solution, and drying the lithium salt solution to obtain the lithium ion battery negative electrode. The process step is simple, the device requirement is low, the operability is high, the irreversible capacity loss of a battery can be effectively reduced, the energy density of the battery is enhanced, and the preparation method can be completely applied to industrial production of the lithium ion battery at a large scale.

Owner:WANXIANG 123 CO LTD

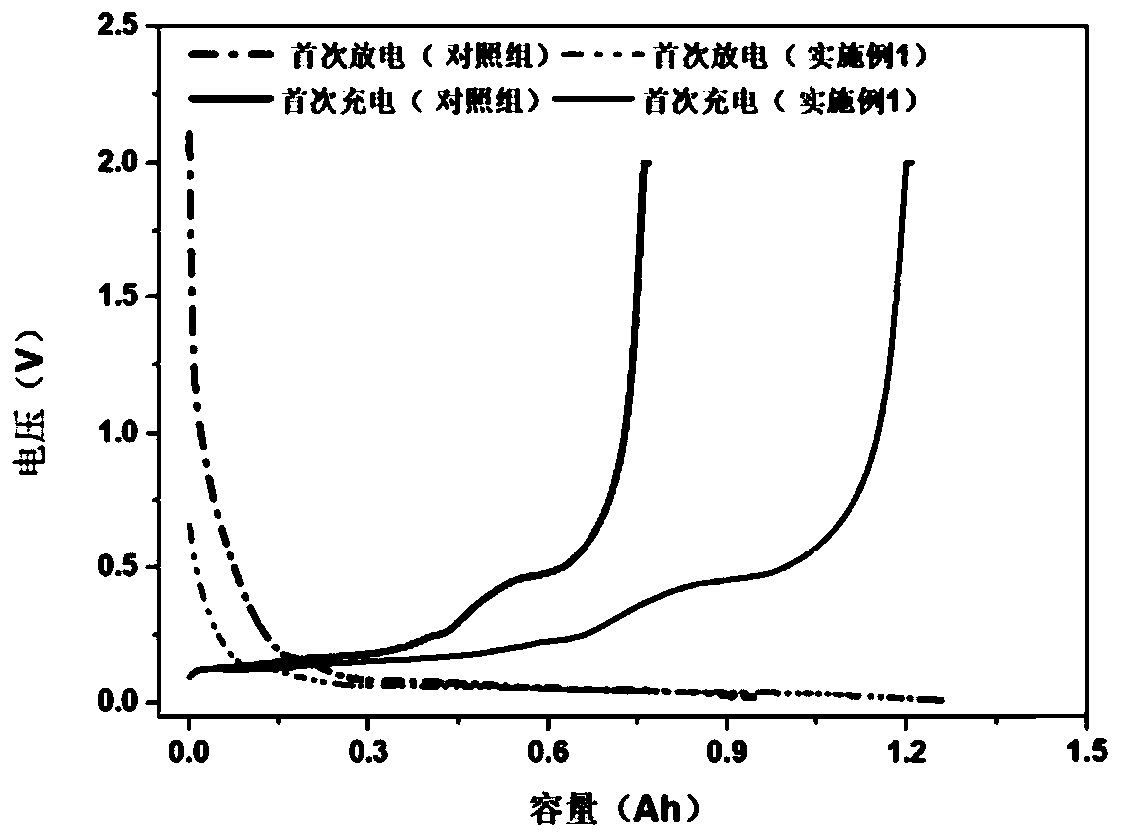

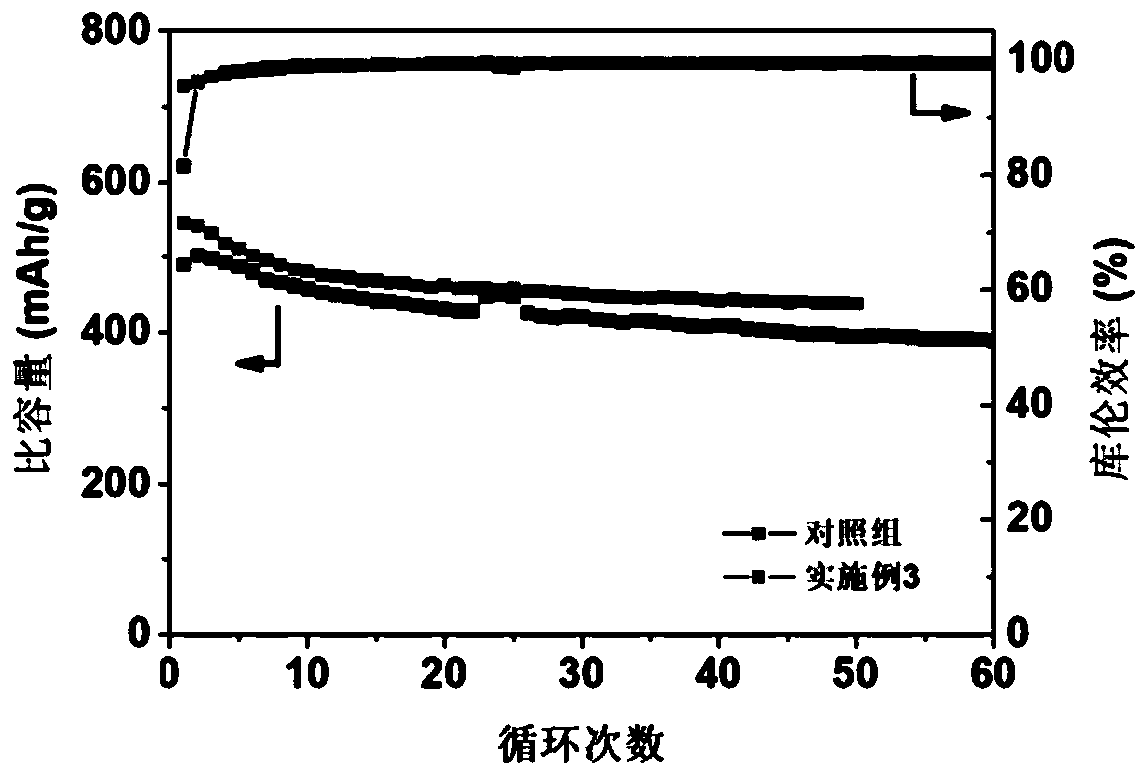

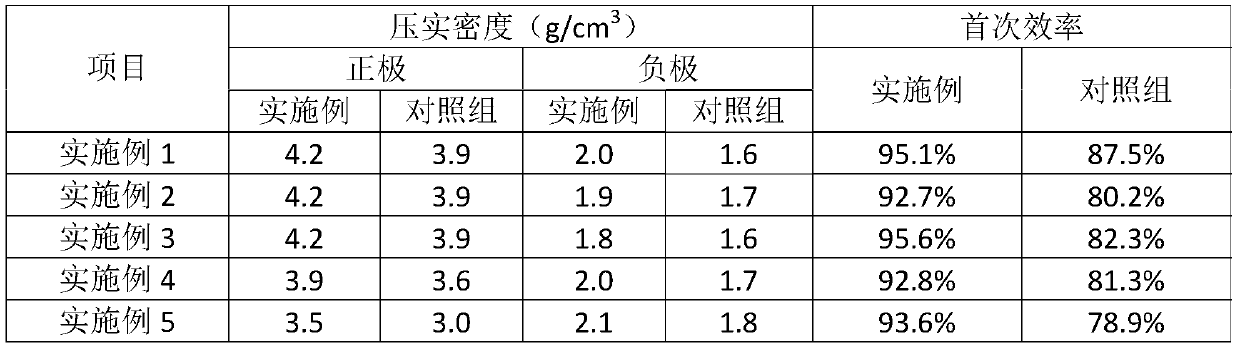

Positive pole piece, negative pole piece and high-energy density lithium ion battery

InactiveCN110993957AReduce irreversible capacity lossIncrease energy densityElectrode carriers/collectorsSecondary cellsCapacity lossOrganic solvent

The invention provides a positive pole piece, a negative pole piece and a high-energy density lithium ion battery. The positive pole piece comprises a negative current collector, and a conductive coating and an active material layer which are sequentially coated on the surface of the negative current collector, and the material of the active material layer is formed by mixing an anode active material, a conductive agent and a binder. According to the lithium ion battery disclosed by the invention, irreversible capacity loss caused by adopting high-specific-capacity anodes such as a silicon-based material, a tin-based material and a metal oxide is reduced, so that the energy density is improved; and moreover, the pole piece is prepared by adopting a solvent-free method, so that the compaction density of the pole piece is improved, the energy density is further improved, and the use of an organic solvent is avoided.

Owner:天津普兰能源科技有限公司

Surface in-situ coated lithium-enriched material and preparation method thereof

ActiveCN106486657AReduce irreversible capacity lossImprove uniformityCell electrodesSecondary cellsLithiumSpinel

The invention discloses a surface in-situ coated lithium-enriched material. Raw materials comprise a coating layer and a lithium-enriched material precursor, the raw material of the coating layer is a compound of a metal Me, the lithium-enriched material precursor is a mixture of at least one of oxide of MnMA, hydroxide, carbonate and oxalate and a lithium source, wherein Me and M are metal elements; and A is at least one of S, P, B and F. The invention further discloses a preparation method. A metal compound coats lithium-enriched material precursor particles, and then the lithium-enriched material precursor particles are sintered at high temperature to form a lithium-enriched material of which the surface is coated with spinel-containing oxide. The surface in-situ coated lithium-enriched material has the advantages that the surface stability and the conductivity of the surface in-situ coated lithium-enriched material are greatly improved, and therefore, the charging-discharging specific capacity, the efficiency, the multiplying power and the circling performance of the material are obvious improved. The surface in-situ coated lithium-enriched material is simple in preparation process, low in cost, good in result reproducibility and suitable for large-scale popularization.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Modification method of cerium-tin compound oxide coated lithium-rich manganese-based positive material

ActiveCN108172808AThe synthesis method is simpleUniform product distributionMaterial nanotechnologySecondary cellsSolventUltrasonic oscillation

The invention discloses a modification method of a cerium-tin compound oxide coated lithium-rich manganese-based positive material. The body of the material is a lithium-rich manganese-based positivematerial, and the surface coated substance of the material is a cerium-tin compound oxide material containing rich oxygen defects. The modification method comprises the following preparation steps: (1) dispersing the lithium-rich manganese-based positive material into a secondary water solvent, and forming a uniform mixed solution through ultrasonic oscillation to be marked as an A solution; (2) dispersing a metal salt containing Sn and Ce elements into the secondary water solvent, adding an alkaline source to adjust the pH of the solution to be 12, and marking the solution to be a B solution;(3) after uniformly mixing the A solution and the B solution, putting the mixture into water at the temperature of 140 to 220 DEG C inside a reaction still for heat treatment for 12 to 36 h, and washing, filtering and drying to obtain a precursor material; and (4) after sufficiently grinding the precursor material, carrying out calcinations at the temperature of 450 to 650 DEG C for 3 to 10 h, and cooling to room temperature so as to obtain the cerium-tin compound oxide coated lithium-rich manganese-based positive material. According to the method, the surface coating for the lithium-rich manganese-based positive material is realized through hydro-thermal treatment, the preparation technology is simple, and the obtained material is high in degree of crystallinity, high in capacity and good in rate capability.

Owner:UNIV OF SCI & TECH BEIJING

Sodium-ion battery carbon negative electrode material prepared based on waste wood chips and preparation method thereof

PendingCN113651307AReduce defect concentrationReduce irreversible capacity lossNegative electrodesSecondary cellsBiomass carbonElectrical battery

The invention relates to a sodium-ion battery carbon negative electrode material prepared based on waste wood chips and a preparation method thereof. Waste wood chips are used as a biomass carbon source and subjected to pre-carbonization and low-heating-rate high-temperature carbonization treatment, metal heteroatoms are removed by washing with an acid pickling solution, and drying is performed to obtain a hard carbon sodium-ion battery negative electrode material. The waste wood chips are used as a biomass raw material, a large amount of chips generated in the production process of wood products can be fully utilized, and the material has the advantages of being environmentally friendly, low in cost and the like. A low-carbonization heating rate pyrolysis method is adopted, so that the effects of reducing defect concentration, increasing interlayer spacing and improving graphitization degree are achieved, and the electrochemical performance of the material is effectively improved. The hard carbon negative electrode material prepared by the method has relatively high first coulombic efficiency and reversible specific capacity, shows excellent cycling stability and rate capability, and is an ideal sodium-ion battery negative electrode material.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com