Preparation method of carbon/carbon nanotube coated lithium iron phosphate composite material by in situ synthesis

A technology for coating lithium iron phosphate and carbon nanotubes, which is applied to structural parts, electrical components, battery electrodes, etc., can solve the problems of complex preparation process and high cost, and achieve simple preparation process, good consistency, high carbon package coverage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

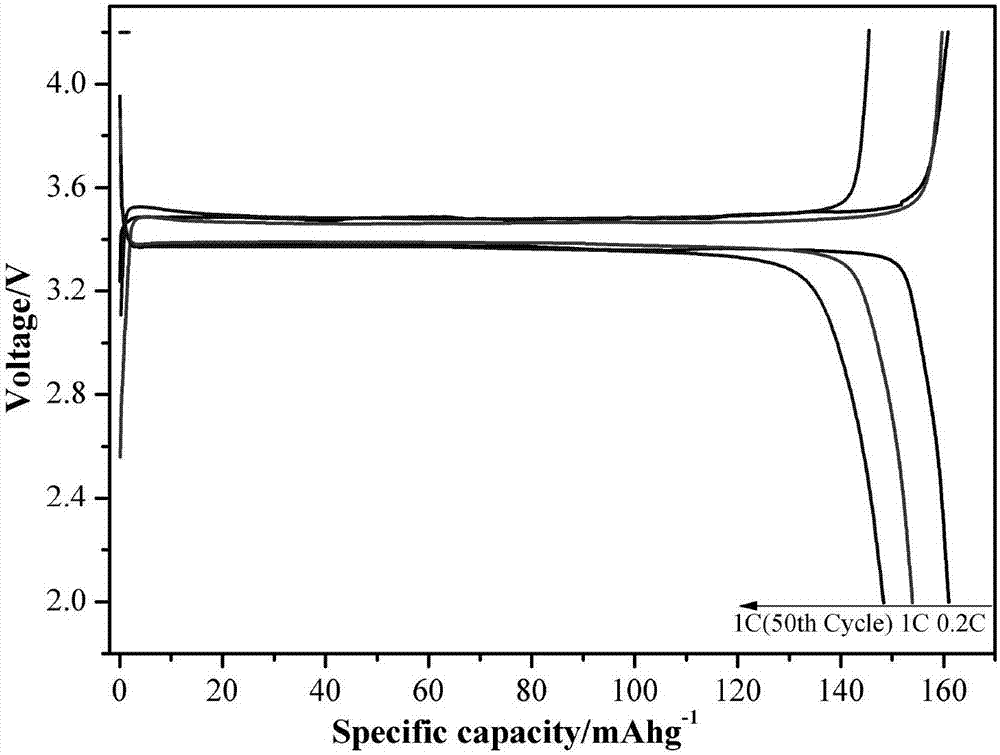

[0031] (1) Preparation of the positive electrode sheet of the battery: The synthesized carbon / carbon nanotube-coated lithium iron phosphate composite material and the binder polyvinylidene fluoride (PVDF) were weighed at a mass ratio of 8:2. Mix the binder and the organic solvent N-methylpyrrolidone (NMP) and dissolve it, add carbon / carbon nanotube-coated lithium iron phosphate composite material and stir well to form a slurry, coat it on the surface of carbon-coated aluminum foil, and roll it after drying Press to get the battery positive plate.

[0032] (2) Battery assembly and performance testing: CR2016 button cells were used to test the electrochemical performance of carbon / carbon nanotube-coated lithium iron phosphate composites. The positive electrode sheet after rolling was punched into a positive electrode sheet with a diameter of 12 mm, and after accurate weighing, the effective mass of the carbon / carbon nanotube-coated lithium iron phosphate composite material was c...

Embodiment 1

[0035] In-situ synthesis of carbon / carbon nanotube-coated lithium iron phosphate composite material in this embodiment comprises the following steps:

[0036] S1. Weigh 10 parts of 500-mesh iron powder and add it to 40 parts of phosphate for mixing, control the pH of the solution to 2.0 and perform high-speed ball milling for 3 hours, add the oxidant hydrogen peroxide drop by drop and continue to stir and mix evenly until the dark green Fe(H 2 PO 4 ) 3 The color of the solution gradually recedes and stops adding hydrogen peroxide to form an insoluble ferric phosphate dihydrate.

[0037] S2. Add 200 parts of water, 6 parts of lithium carbonate, 0.5 part of glucose, 0.5 part of polyvinyl alcohol and 0.5 part of melamine to the above insoluble phosphoric acid dihydrate, mix and stir for 3 hours, then ball mill for 3 hours, control the speed at 500rpm, after the ball milling is completed Obtain milky yellow viscous slurry;

[0038] S3. Use a centrifugal spray drying tower to dr...

Embodiment 2

[0043] The preparation method of the present embodiment is the same as that of Example 1, the difference is only: the carbon source used is 0.6 part of glucose, 0.3 part of polyvinyl alcohol, and 0.6 part of melamine when synthesizing the carbon / carbon nanotube-coated lithium iron phosphate composite material; The constant temperature of the nitrogen atmosphere is 400°C, the constant temperature of the nitrogen-hydrogen mixed gas atmosphere is 900°C, and the content of amorphous carbon and carbon nanotubes is controlled to obtain a carbon / carbon nanotube-coated lithium iron phosphate composite material.

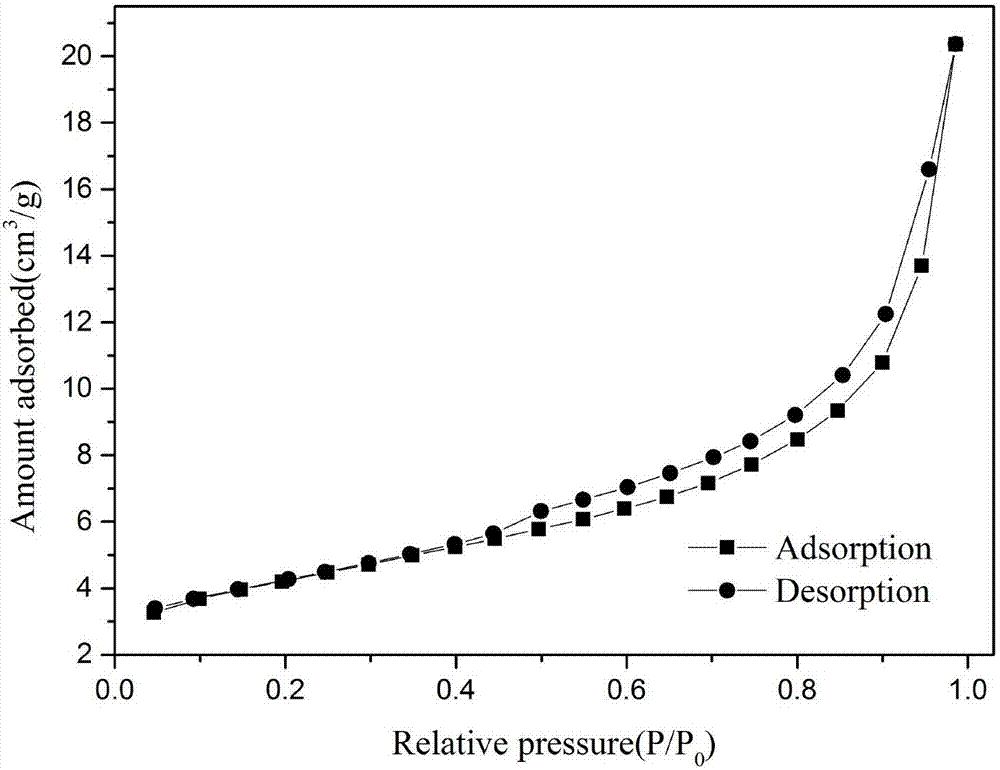

[0044] According to the same test method as in Example 1, the specific surface area analysis and electrical performance analysis of the in-situ synthesized carbon / carbon nanotube-coated lithium iron phosphate composite material obtained in this example were carried out. The carbon / carbon nanotube-coated iron phosphate prepared in this example The specific surface area of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com