Method for preparing high-capacity long-life lithium ion battery lithium manganate cathode material

A technology for battery lithium manganate and positive electrode materials, which is applied in battery electrodes, chemical instruments and methods, manganate/permanganate, etc., and can solve the problems of limiting the utilization rate of positive electrode materials, poor high-temperature cycle performance, and low energy density, etc. problems, achieve the effects of reducing irreversible capacity loss, improving high-temperature performance reliably, and improving high-temperature performance significantly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

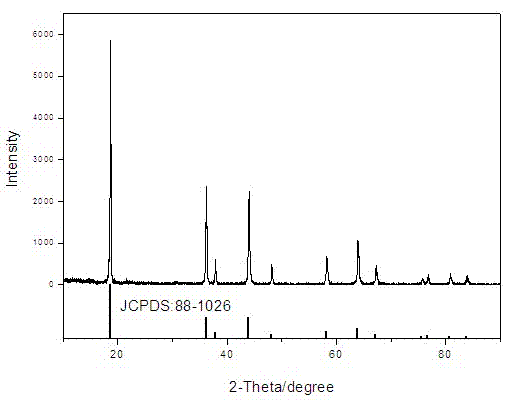

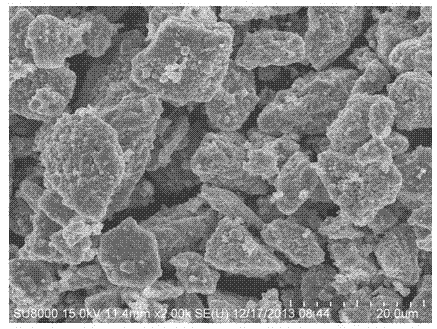

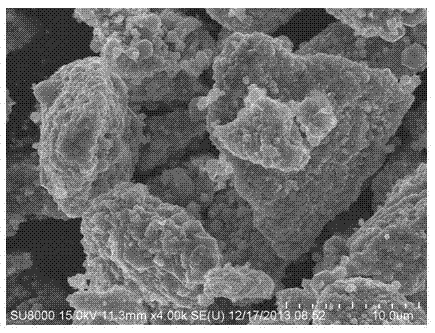

Image

Examples

specific Embodiment approach 1

[0030] Specific implementation mode 1: In this implementation mode, the secondary doping active material calcined lithium manganate material is prepared according to the following steps:

[0031] Lithium carbonate and manganese sulfate were weighed according to the molar ratio Li:Mn=1.05:2, and mixed evenly in the mixed solution of deionized water and ethanol, and the temperature was raised from room temperature to 500°C at a heating rate of 5°C / min, and pre-calcined for 6 h , then raised to 900°C at the same heating rate, calcined for 16 h, classified to remove fine particles, and magnetically adsorbed metal ions to obtain lithium manganate;

[0032] The obtained lithium manganate is mixed into the above-mentioned lithium source at a rate of 0.025 (mass ratio of lithium) for the second time and mixed evenly;

[0033] The above mixture was put into an industrial kiln in an air atmosphere, and calcined at a temperature increase rate of 5 °C / min from room temperature to 700 °C f...

specific Embodiment approach 2

[0035] Specific implementation mode 2: In this implementation mode, the secondary doping active material calcined lithium manganate material is prepared according to the following steps:

[0036] Weigh lithium carbonate, manganese sulfate and titanium powder according to the molar ratio Li:Mn:M=1.05:1.95:0.05, and mix them uniformly in the mixed solution of deionized water and ethanol, and raise the temperature from room temperature to 500°C, pre-calcined for 6 hours, then raised to 900°C at the same heating rate, calcined for 16 hours, classified to remove fine particles, and magnetically adsorbed metal ions to obtain titanium-doped lithium manganate;

[0037] The obtained titanium-doped lithium manganese oxide is secondarily mixed with 0.02 (mass ratio of lithium) above lithium source and mixed evenly;

[0038] The above mixture was put into an industrial kiln in an air atmosphere, and calcined at a temperature increase rate of 5 °C / min from room temperature to 700 °C for 8 ...

specific Embodiment approach 3

[0040] Specific implementation mode three: In this implementation mode, the secondary doping active material calcined lithium manganate material is prepared according to the following steps:

[0041] Mole ratio Li:Mn:M 1 :M 2 =1.05:1.95:0.025:0.025 Weigh lithium carbonate, manganese sulfate, magnesium powder and aluminum powder, and mix them evenly in the mixed solution of deionized water and ethanol, and raise the temperature from room temperature to 500°C at a rate of 5°C / min. Pre-calcined for 6 hours, then raised to 1000°C at the same heating rate, calcined for 10 hours, classified to remove fine particles, and magnetically adsorbed metal ions to obtain magnesium-aluminum double-doped lithium manganate;

[0042] The obtained magnesium-aluminum double-doped lithium manganate is mixed into the above-mentioned lithium source at a rate of 0.03 (mass ratio of lithium) for a second time and mixed uniformly;

[0043]The above mixture was put into an industrial kiln in an air atm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com