Patents

Literature

104results about How to "Good high temperature cycle performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

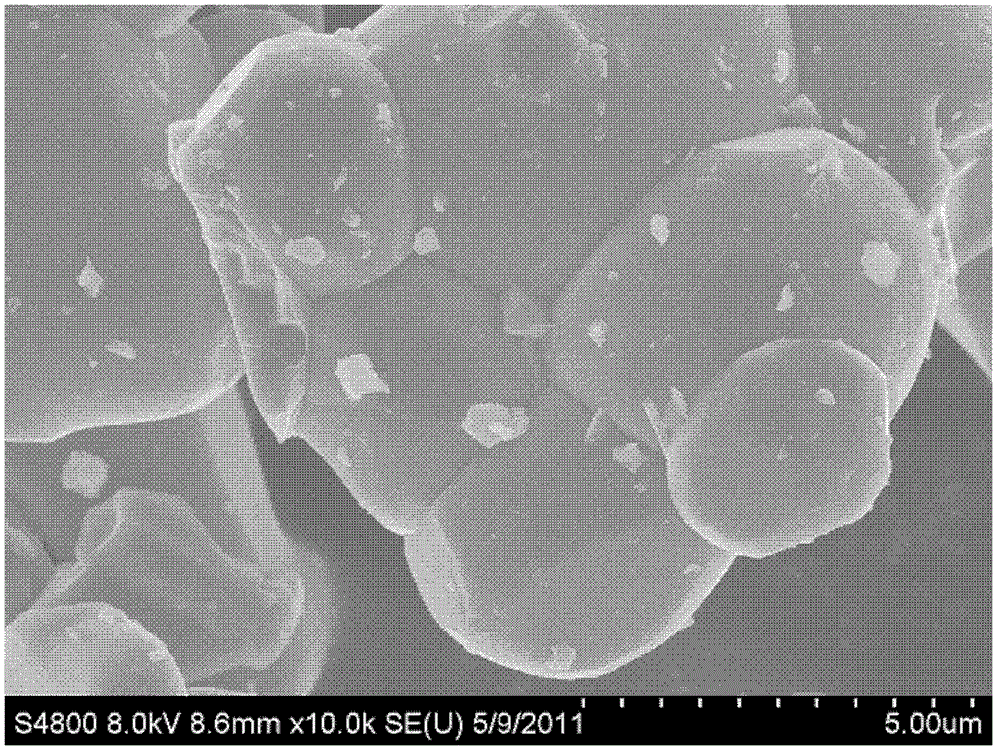

Lithium manganese oxide material and preparation method thereof

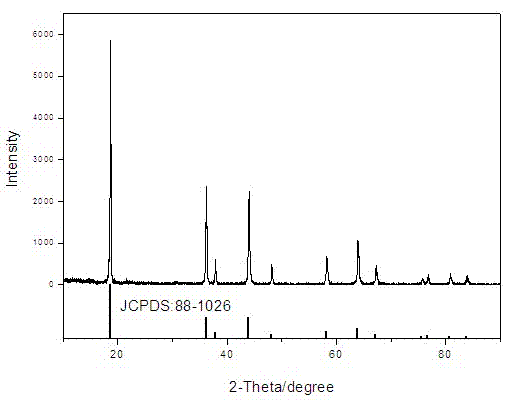

InactiveCN102054985AEasy to prepareNormal temperature is goodCell electrodesHigh temperature storagePhysical chemistry

The invention discloses a lithium manganese oxide material and a preparation method thereof, in particular to a high-crystallinity lithium manganese oxide material and a preparation method thereof, wherein the high-crystallinity lithium manganese oxide material is used for coating a lithium ion battery. The lithium manganese oxide material is obtained by being coated on a lithium manganese oxide precursor with the one-time crystal particle of 0.01-20mum and has the general formula of LiaMn2-b-cMbGcO4-d-eXdZe, wherein M and X are doped elements, G and Z are coating elements of which the concentration is distributed in a decreasing gradient from outside to inside, a is not less than 0.9 and is not more than 1.2, b is not less than 0 and is not more than 0.2, c is more than 0 and is not more than 0.2, d is not less than 0 and is not more than 0.2, and e is not less than 0 and is not more than 0.2. The material serves as the positive pole material of the lithium ion battery, has better normal-temperature and high-temperature cycle performance and excellent high-temperature storage performance, is simple in preparation and easy to operate, control and carry out industrial production.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

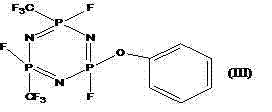

Lithium ion battery with nickel-based cathode, and electrolyte therefor

ActiveCN103208653AGood high temperature performanceGood low temperatureSecondary cellsElectrolytic agentOrganic solvent

The invention belongs to the technical field of lithium ion batteries and particularly relates to electrolyte for a lithium ion battery with a nickel-based cathode. The electrolyte comprises non-aqueous organic solvent, lithium salt, boron-containing lithium salt additive, cyclic ether compound and cyclic phosphonitrile compound. The cyclic phosphonitrile compound is hexaphenoxycyclotriphosphazene or cyclic phosphonitrile derivative. Compared with the prior art, the electrolyte is provided with the boron-containing lithium salt additive capable of improving high temperature performance of the lithium ion secondary battery with nickel-based cathode material, the cyclic phosphonitrile compound, and the cyclic ether compound, and the addition of the cyclic phosphonitrile compound and the cyclic ether compound enables the battery to be fine in high temperature performance, low temperature performance and cycle performance. In addition, the invention discloses the lithium ion battery comprising the electrolyte.

Owner:DONGGUAN AMPEREX TECH

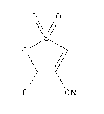

Lithium ion battery electrolyte with high-temperature and low-temperature properties

ActiveCN103000944AImprove wettabilityLower impedanceSecondary cellsElectrolytic agentOrganic solvent

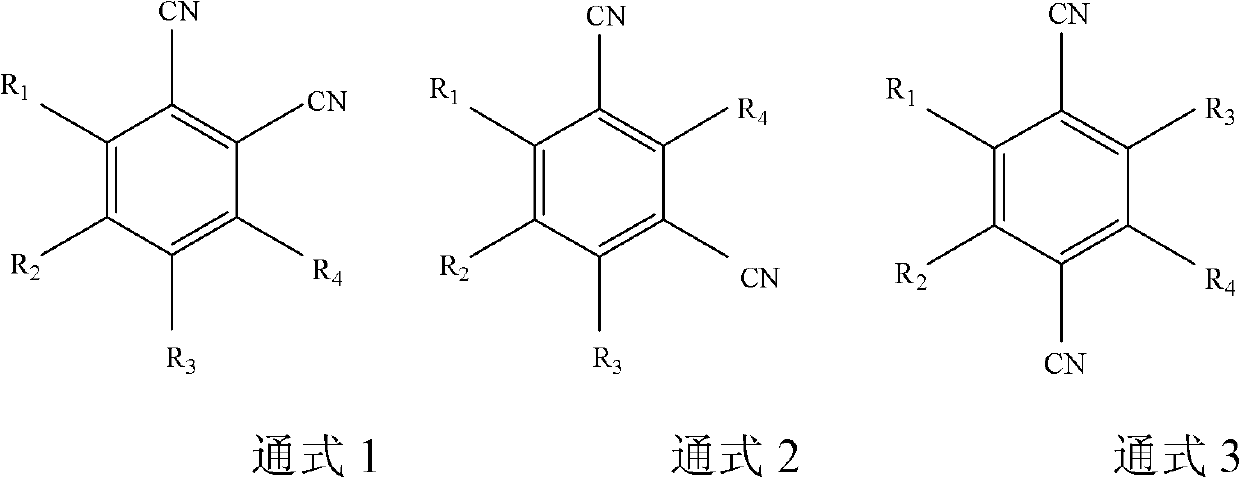

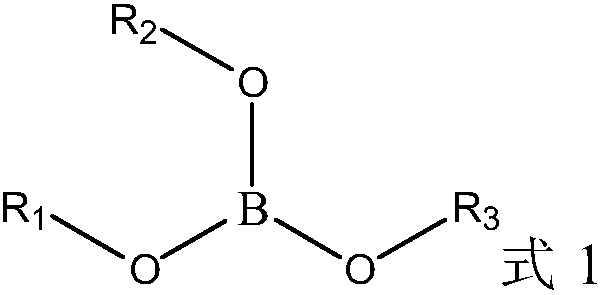

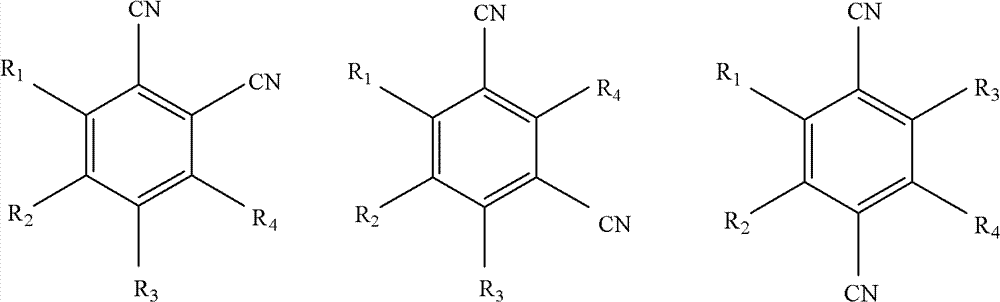

The invention relates to lithium ion battery electrolyte, and mainly relates to lithium ion battery electrolyte with high-temperature and low-temperature properties, which belongs to the field of a lithium ion battery. The lithium ion battery electrolyte with the high-temperature and low-temperature properties comprises organic solvents, lithium salt and additives, wherein the organic solvents comprise linear carbonic ester, cyclic carbonate, linear carboxylic acid ester and cyclic carboxylic acid ester; the additives comprise a high-temperature additive and a multifunctional additive which is expressed by a structural formula 1 and accounts for 0.5%-15% in the total mass of the electrolyte; and according to the structural formula 1 shown in the specification, R1 is one of H, F, CH2=CH and CH3-CH=CH, and R2 is one of H, F, CN and CH2=CH. The electrolyte provided by the invention has a wide working temperature window and a good discharging property, and can not only solve the problem of low discharging efficiency at a low temperature of -40 DEG C, but also meet the requirement on circulation at a high temperature of 60 DEG C.

Owner:HUZHOU CHUANGYA POWER BATTERY MATERIALS

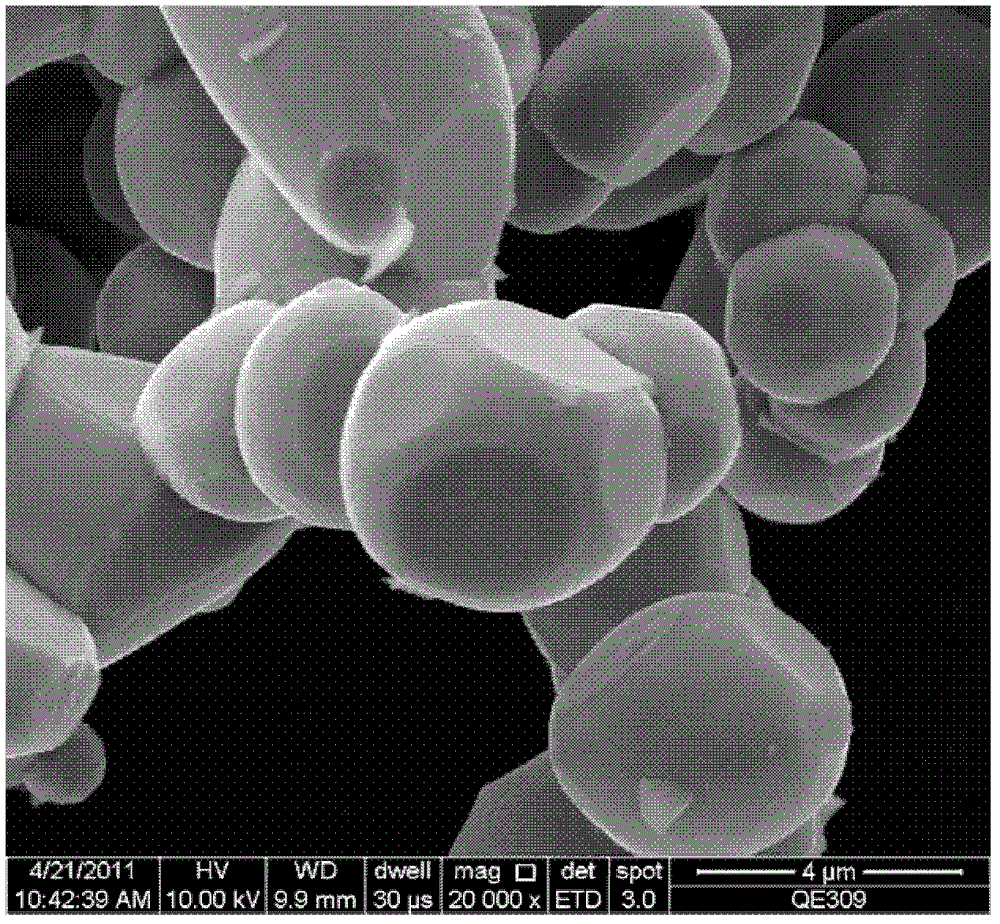

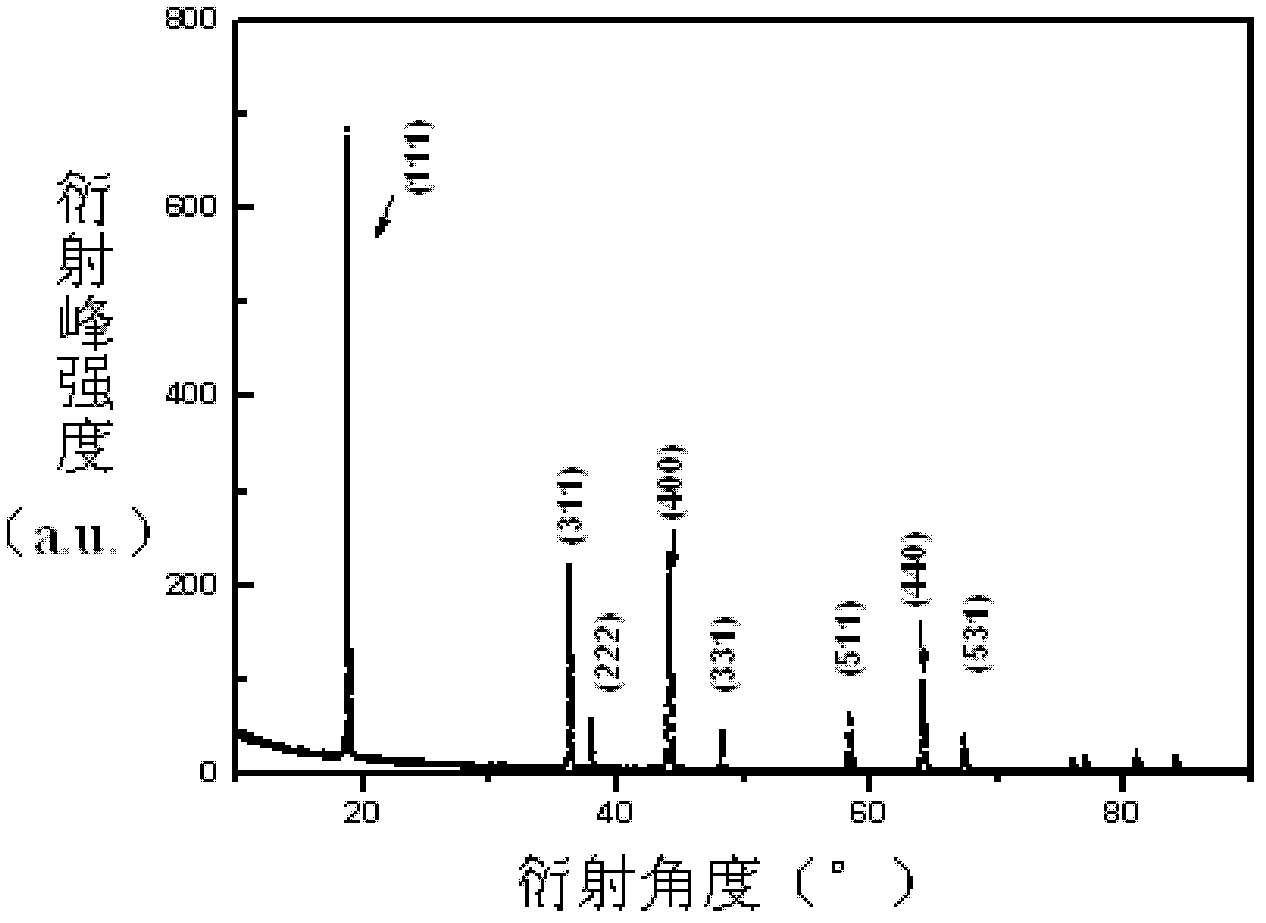

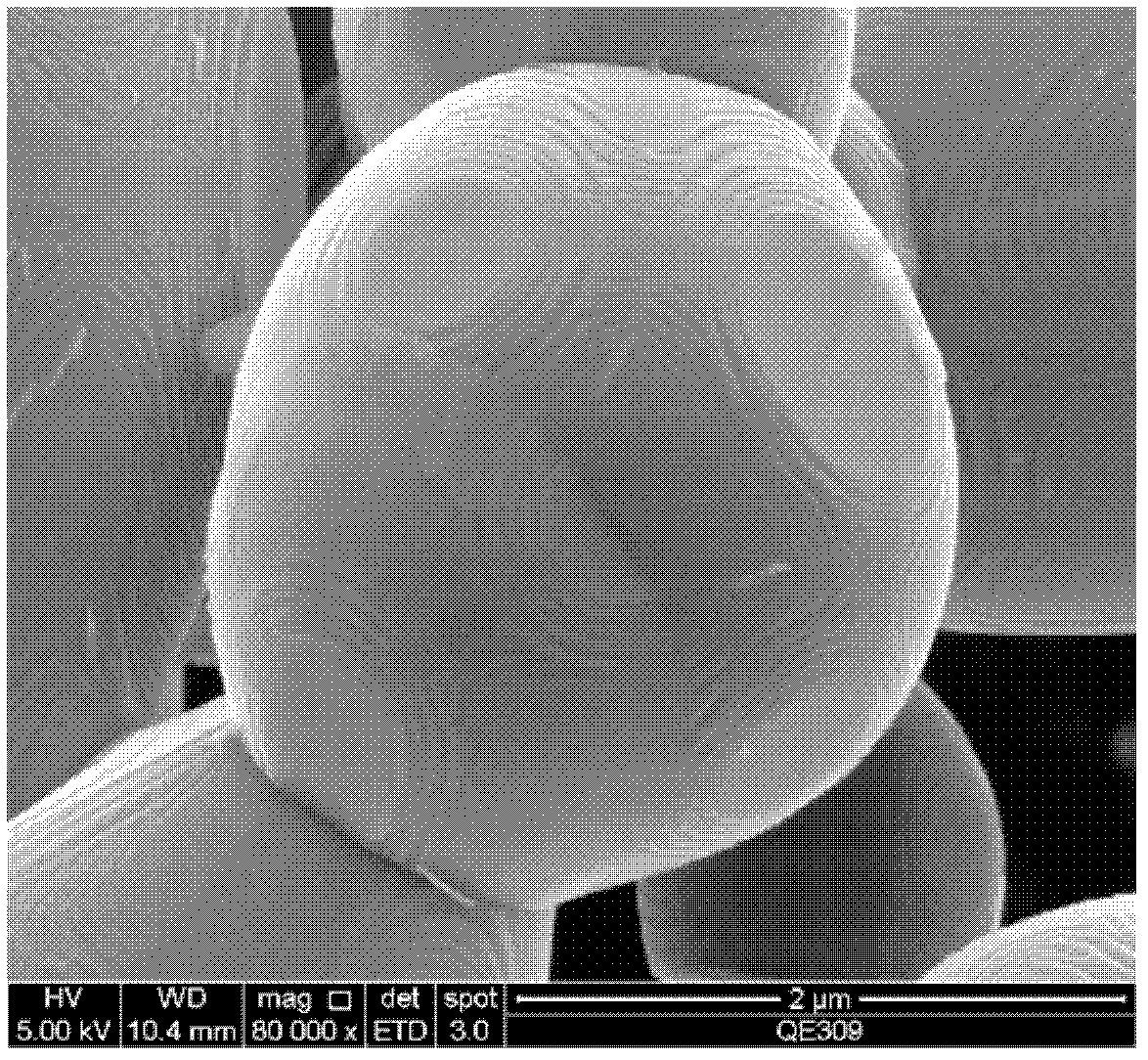

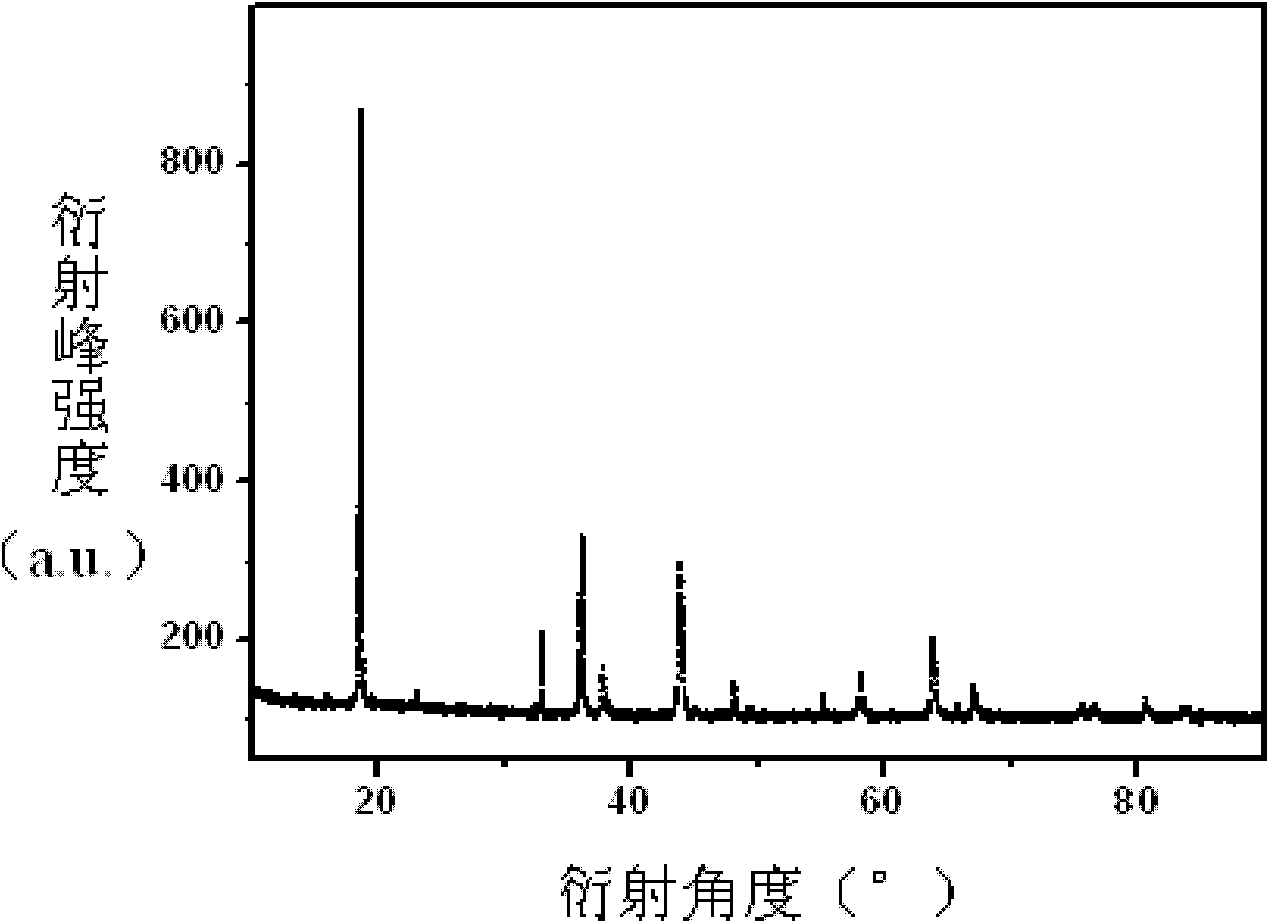

Cathode material of lithium ion battery, and preparation method thereof and lithium ion battery

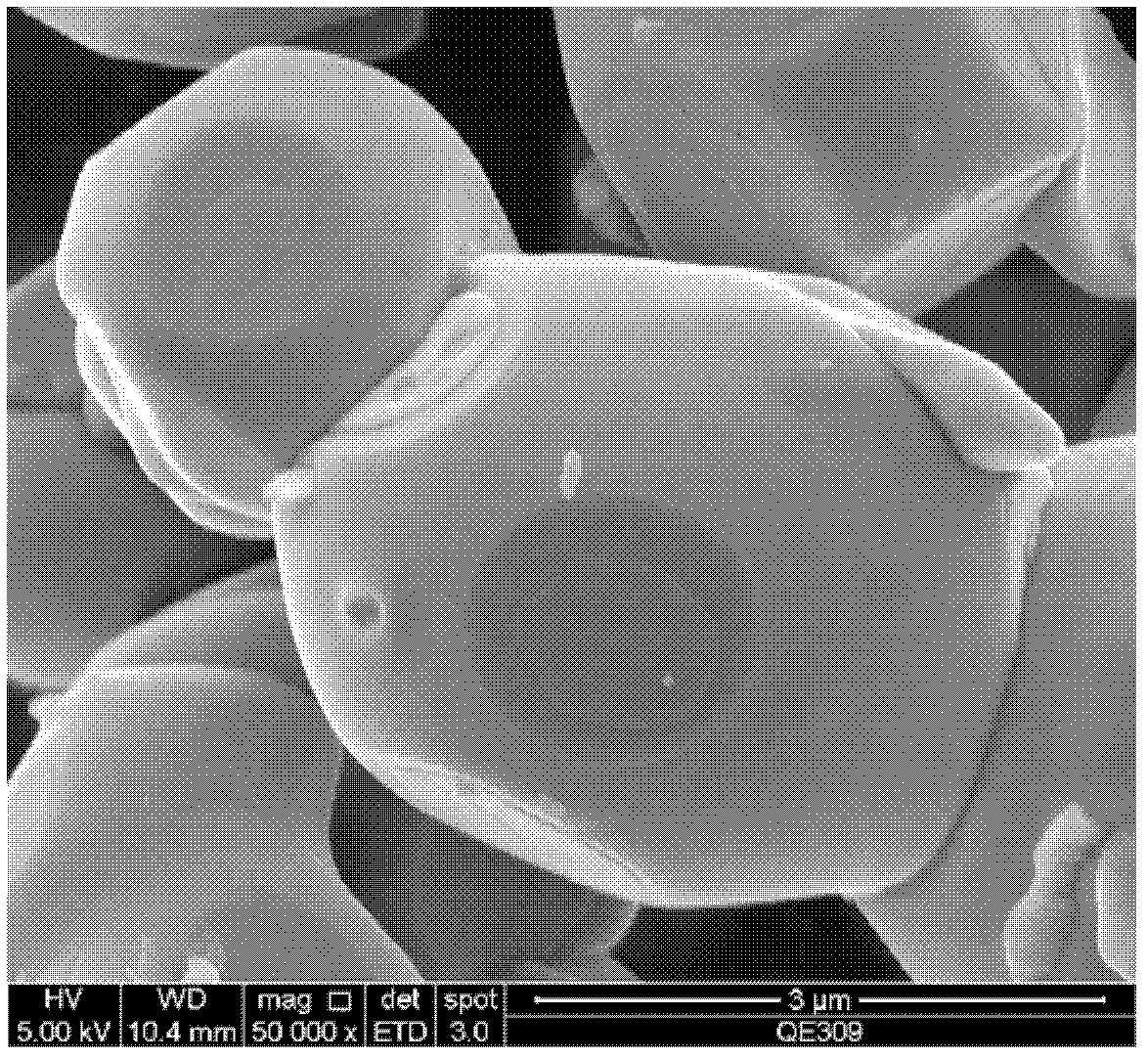

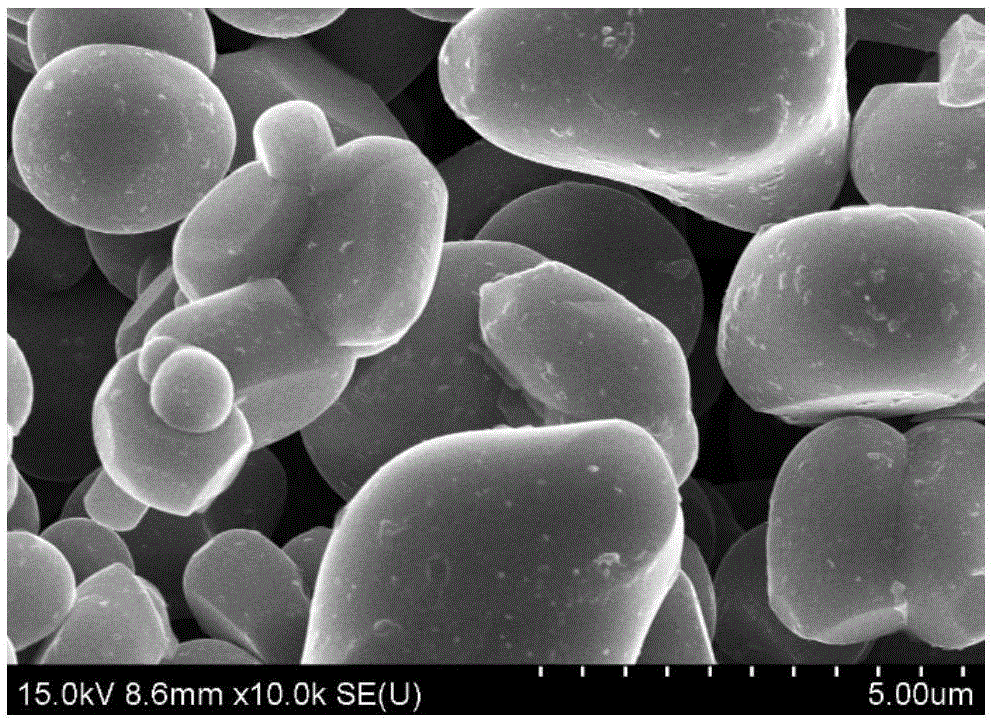

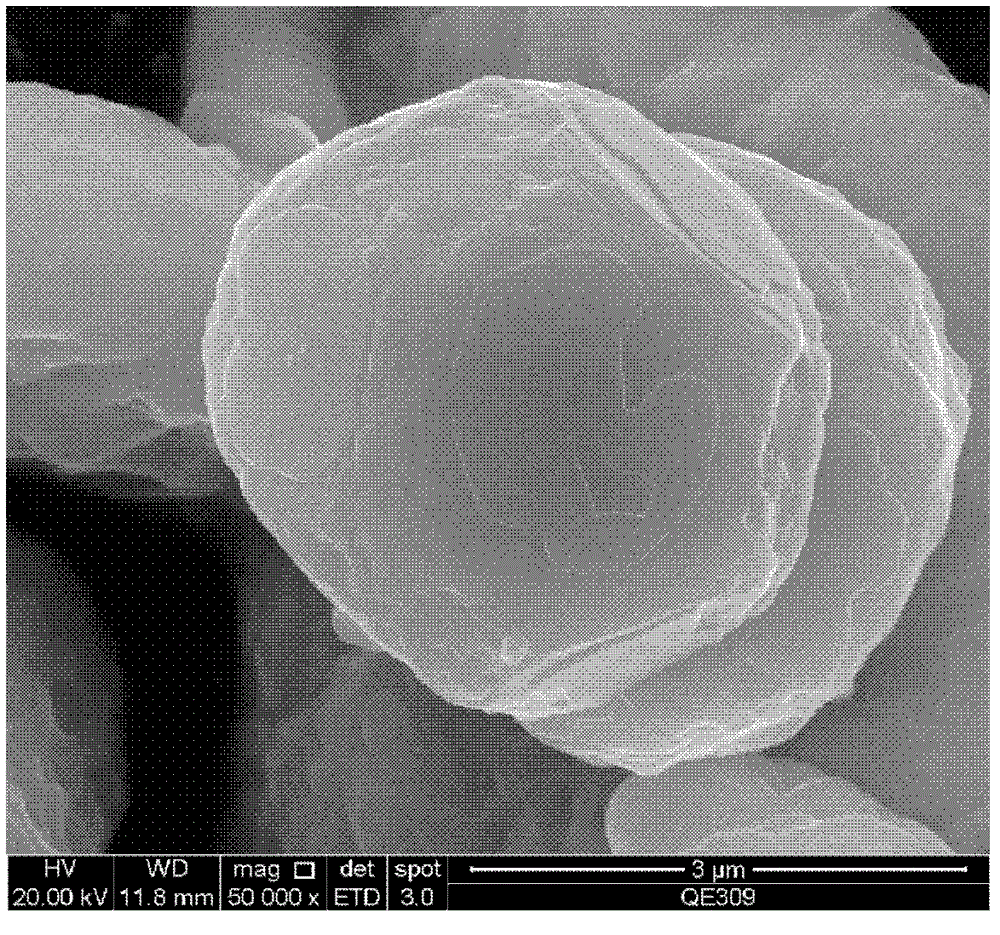

ActiveCN102800840ANot easy to dissolveGood high temperature cycle performanceCell electrodesSecondary cellsTemperature cyclingLithium electrode

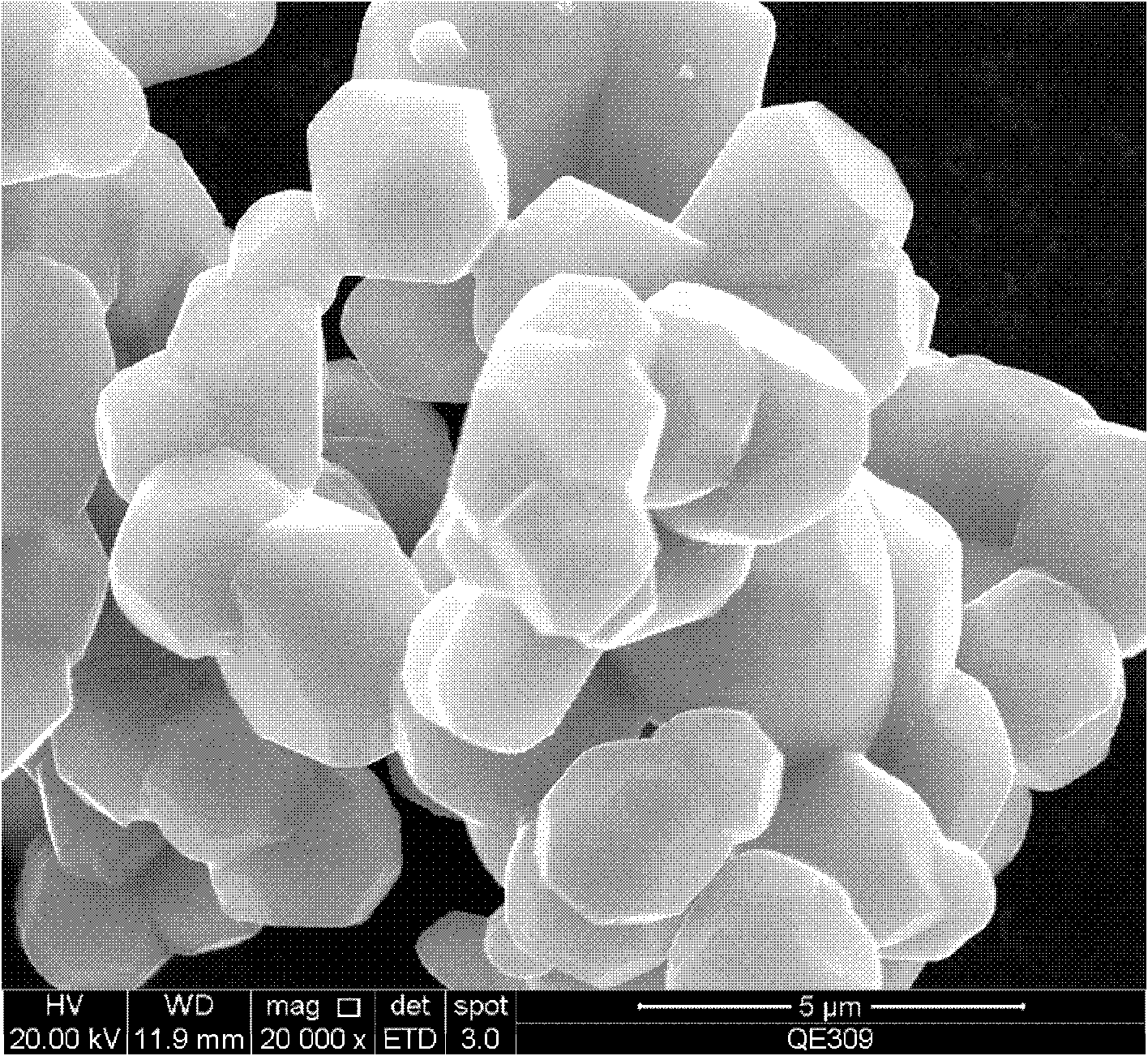

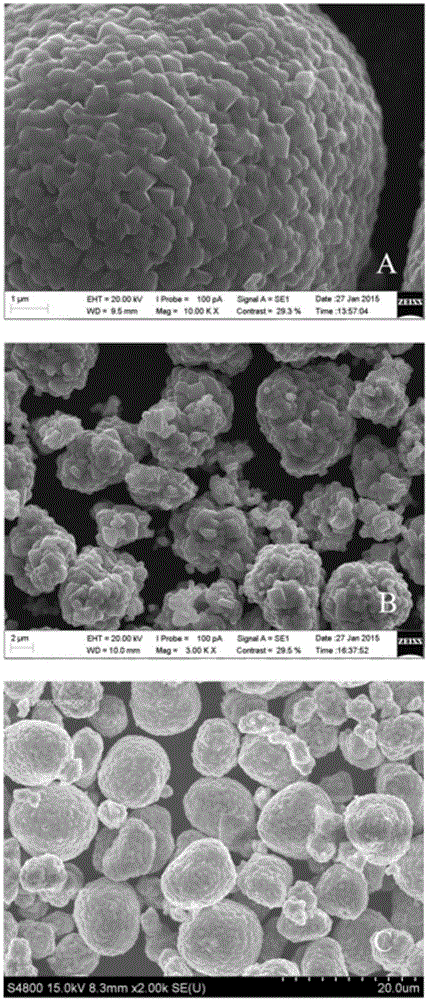

The invention provides a cathode material of a lithium ion battery. The cathode material is composed by the atomic ratio shown in formula (I): Lia(MxMn2-x)(O4-yZy), wherein a is greater than or equal to 0.8 and less than or equal to 1.2; x is greater than or equal to 0 and less than or equal to 1; y is greater than or equal to 0 and less than or equal to 1; M is one or more selected from Li, Na, K, Ca, Mg, Al, Ti, Sc, Ge, V, Cr, Zr, Co, Ni, Zn, Cu, La, Ce, Mn, Hf, Nb, Ta, Mo, W, Ru, Ag, Sn, Pb and Si; and Z is one or more selected from OH, halogens, N, P, S and O. Primary particles of the cathode material have sphere-like morphologies, wherein (111) face is connected with adjacent equivalent crystal face through a curved surface having no clear edges. The invention also provides a preparation method for the cathode material of the lithium ion battery and the lithium ion battery. The cathode material provided by the invention has good high-temperature cycling performance and good filling property.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High-voltage cathode material for lithium ion battery and preparation method thereof

ActiveCN104022280ADissolution controlIncrease working voltageCell electrodesSecondary cellsHigh energySodium-ion battery

The invention discloses a high-voltage cathode material for a lithium ion battery. The high-voltage cathode material is a clad material, the core material has the general formula of [LiaNibCocMdO2]; the shell material has the general formula of [LipNixCoyMnzO2]; the cathode material of the lithium ion secondary battery has the general formula of[LiaNibCocMdO2] [LipNixCoyMnzO2]; the content of the core material is 50-99.5wt%, the content of the shell material is 0.05-50wt%. The preparation method comprises the steps of preparing the core material; preparing the precursor [NixCoyMnz (OH)2] of the shell material; cladding; and carrying out sintering twice or many times. According to high-voltage cathode material disclosed by the invention, advantages of Ni and Co elements can be given a full play, the high-voltage cathode material has the advantages of high operation voltage and high energy density as well as excellent high-temperature cycle performance and the dissolution amount of Co can be controlled well.

Owner:NANTONG RESHINE NEW MATERIAL

Cathode material of lithium ion battery and preparation method of cathode material

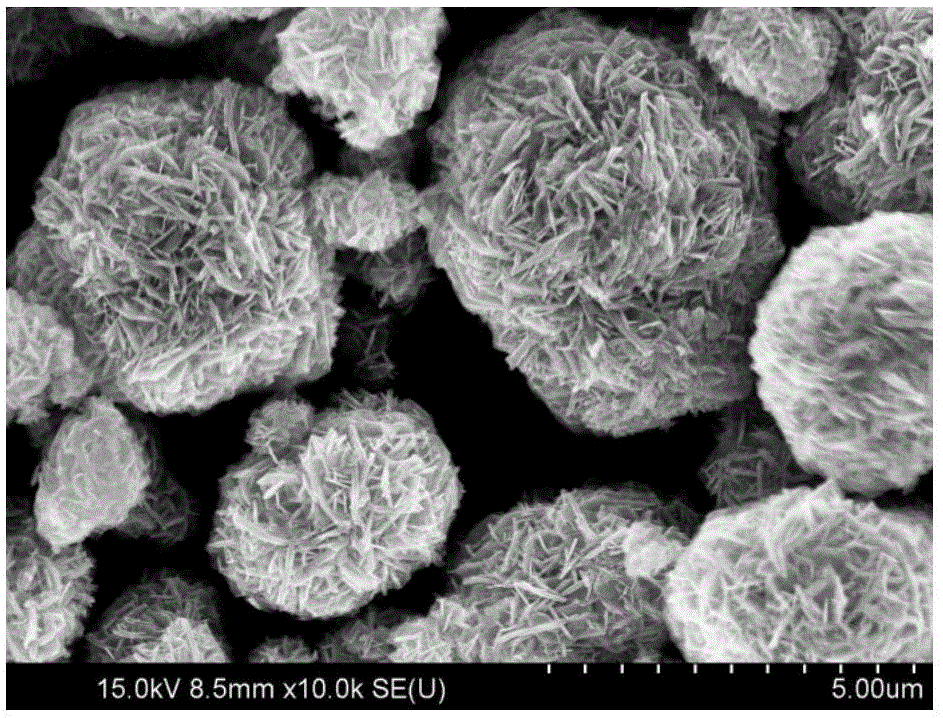

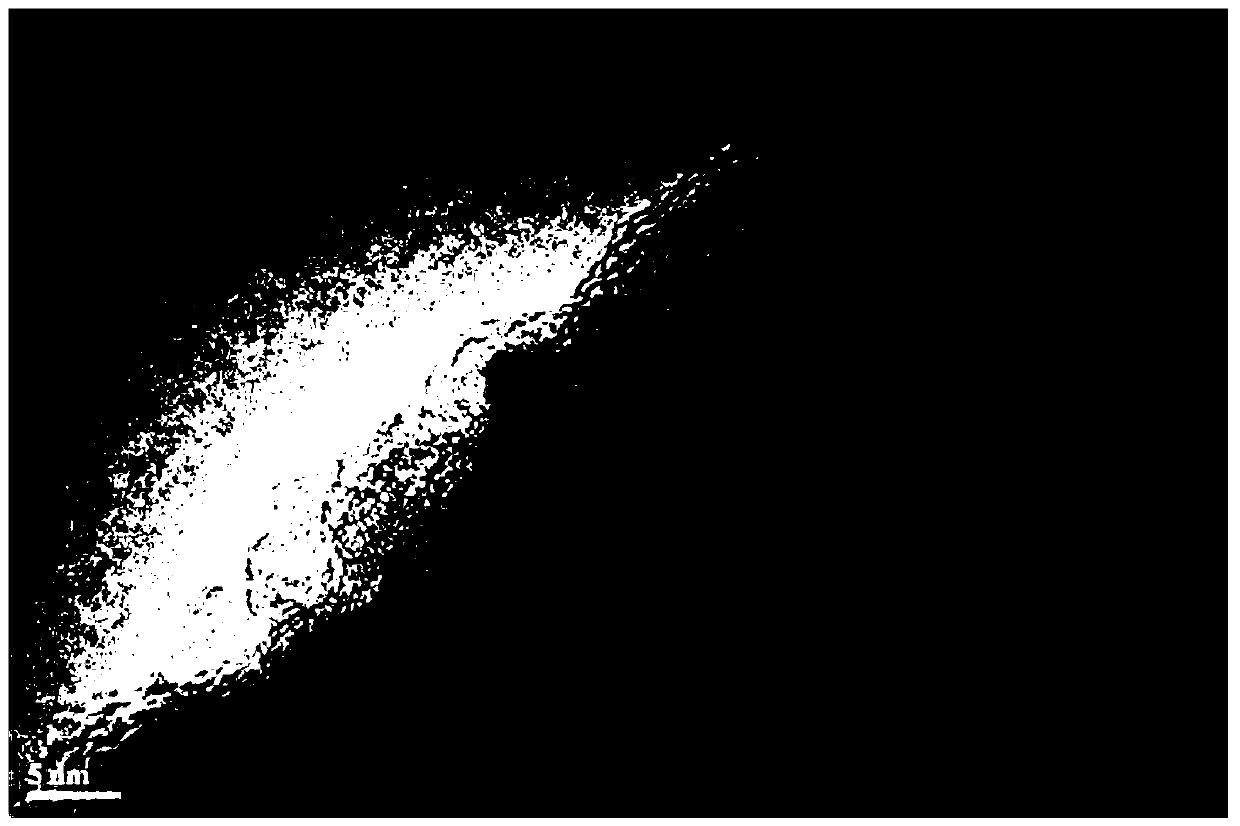

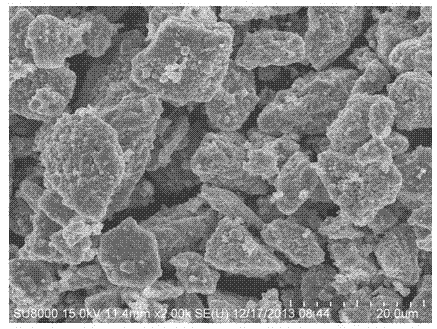

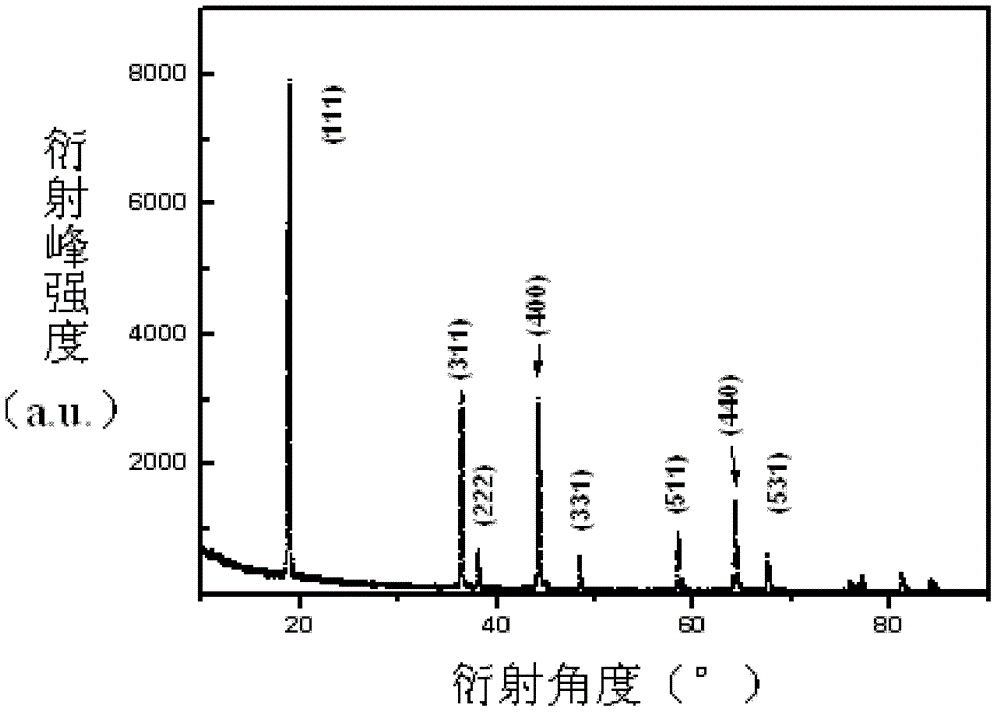

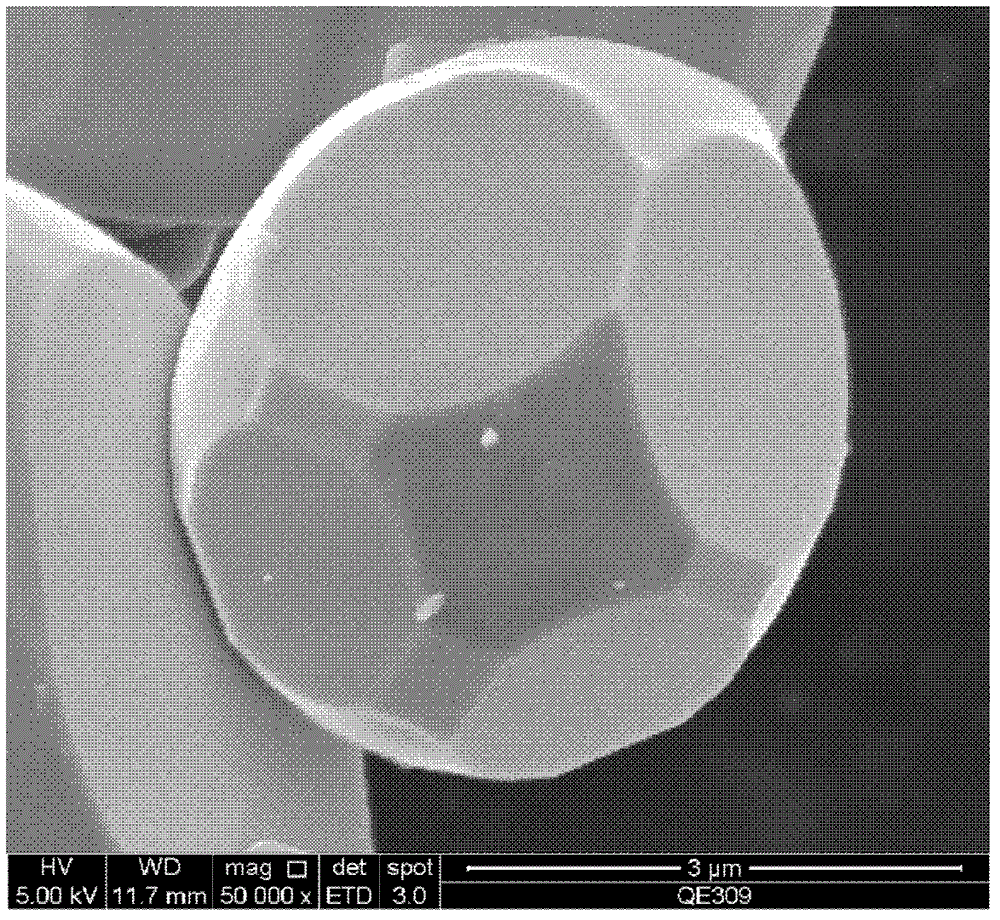

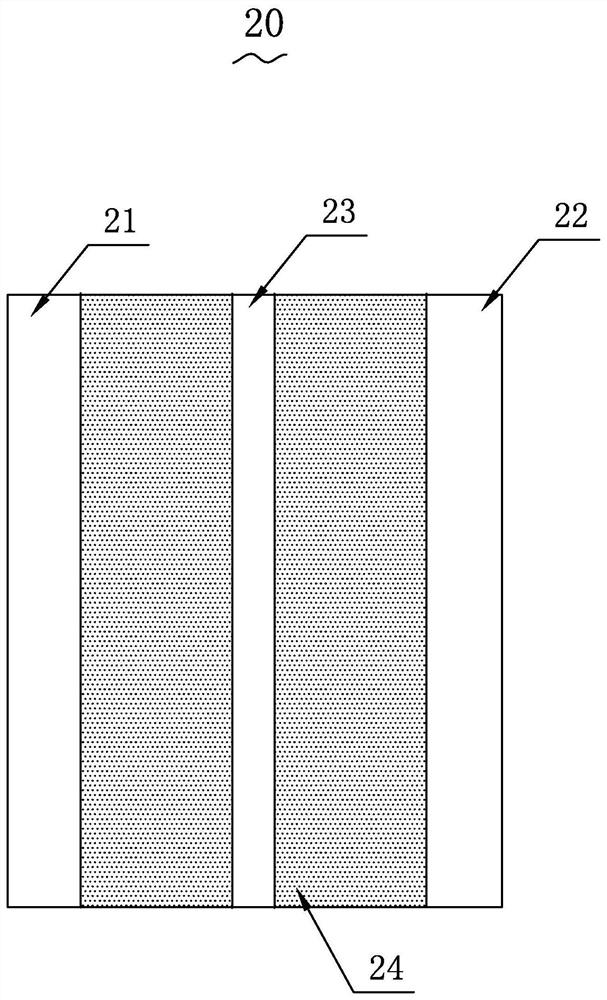

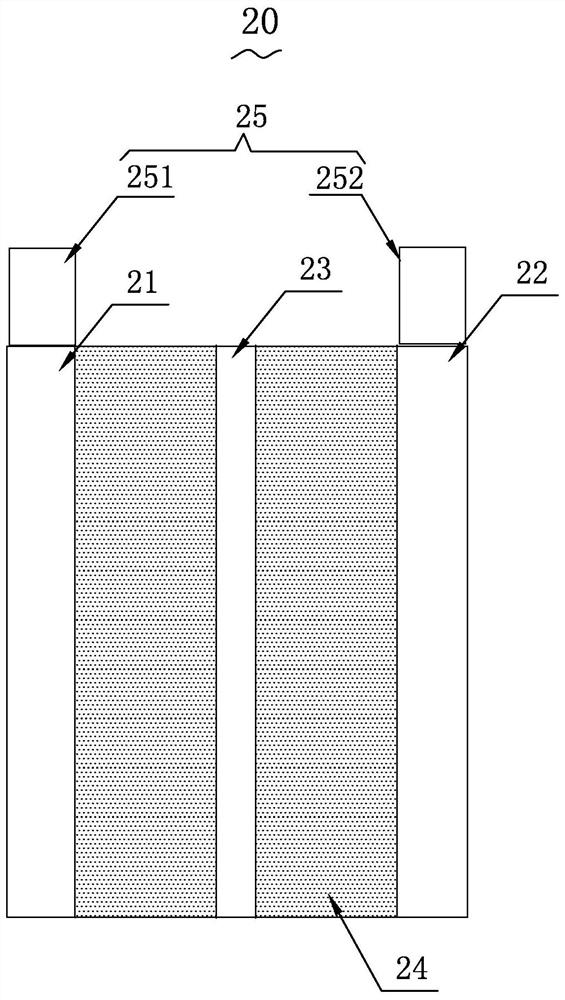

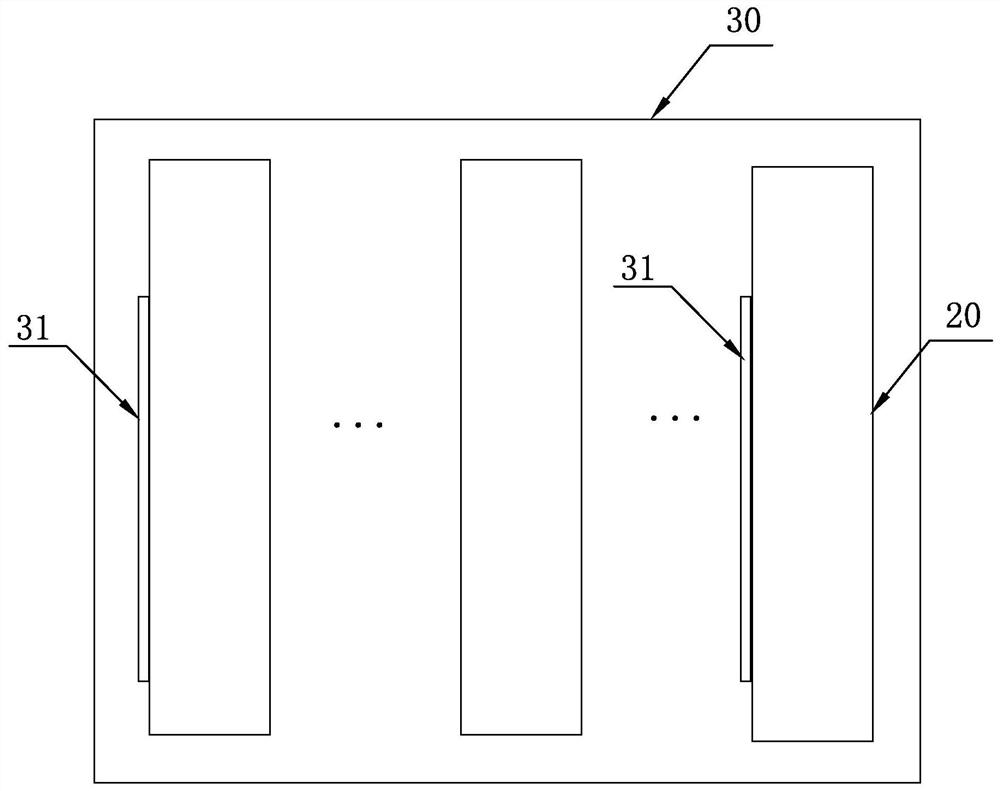

ActiveCN102683669ASmall specific surface areaGood high temperature cycle performanceCell electrodesManganesePhysical chemistry

The invention discloses a cathode material of a lithium ion battery. The cathode material has an atomic ratio of LiaMxMn(2-x)O(4-y)Zy. Primary particles of the cathode material of the lithium ion battery are substantially spherical, and the surface of each primary particle consists of 2 to 120 multilayer crystal dislocation frustums. The invention provides a preparation method of the cathode material of the lithium ion battery. The cathode material of the lithium ion battery is prepared by annealing, cooling and grinding a lithium manganate precursor in a roasting treatment mode of repeatedly changing roasting temperature. The invention has the advantages that by repeatedly changing the roasting temperature in the roasting process, the prepared cathode material of the lithium ion battery has a dislocation structure, and the mobility of ions and electrons from the inner part of the material to the outer part of the material is improved, and the magnification performance of a lithium manganate material is improved. Because the cathode material is substantially spherical, the specific surface area of the lithium manganate material is reduced, and manganese is difficult to dissolve, so the cathode material of the lithium ion battery is high in high-temperature cycle performance.

Owner:宁波富理电池材料科技有限公司

Electrolyte additive and application thereof

InactiveCN104577200AImprove cycle stabilityImprove securityOrganic chemistrySecondary cellsPower flowPhysical chemistry

The invention discloses an electrolyte additive and an apparition thereof. The additive contains a thiophene compound. The additive, which is used for a lithium ion battery, is capable of inhibiting the continuous electrochemical oxidation reaction of the electrolyte and the anode material, improving the electric conductivity of the anode material, improving the cycle performance and the high current discharge performance of the battery, and improving the safety performance and the rate performance of the battery.

Owner:NINGDE AMPEREX TECH

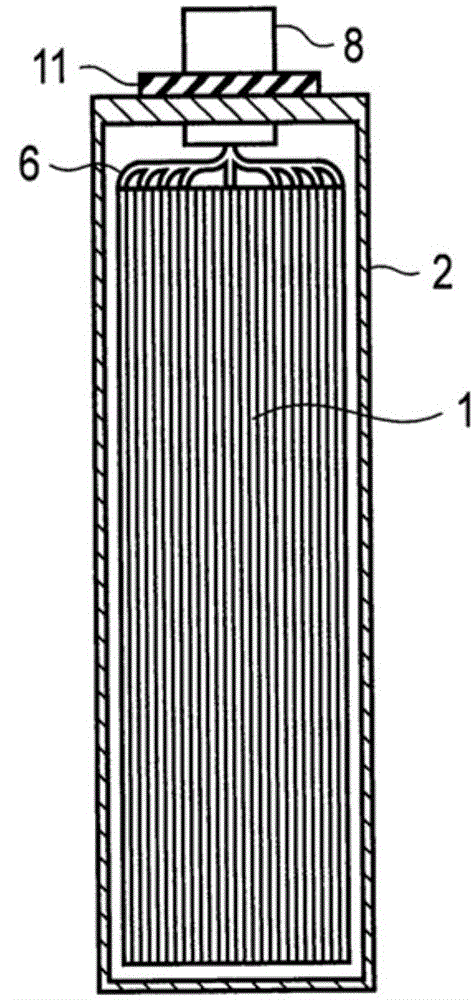

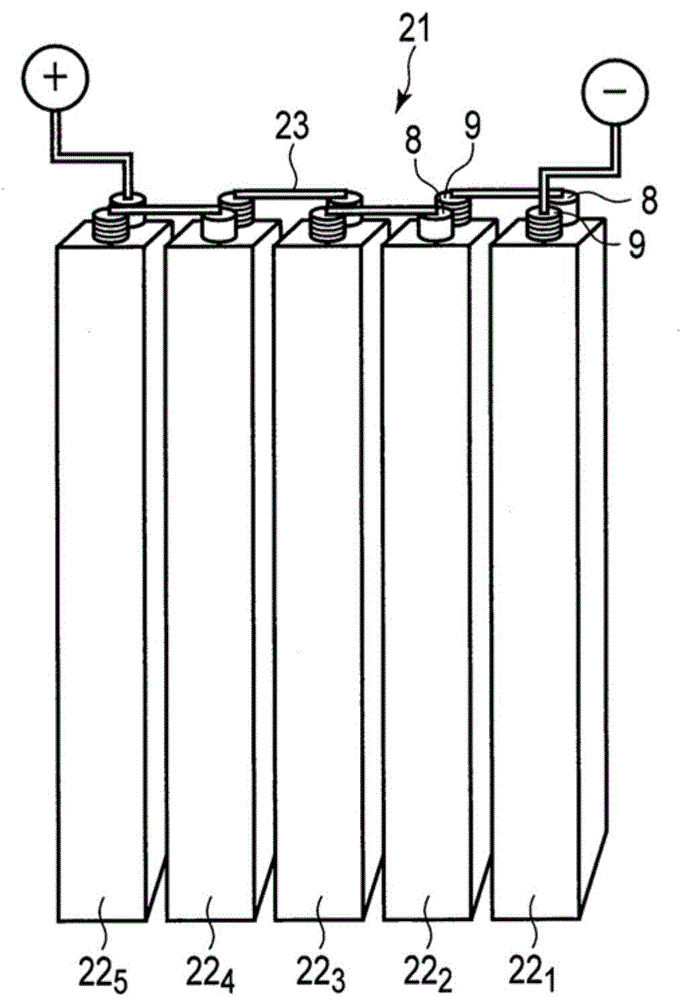

Li-ion secondary battery formation method

ActiveCN101212067AAvoid delaminationIncrease capacityFinal product manufactureSecondary cells charging/dischargingLithiumEngineering

The invention relates to a formation method of lithium iron secondary battery. The method comprises the processes: the battery is charged under the formation temperature of the lithium iron secondary battery; the charge process comprises the processes: the continuous current of a first current is used for charging to the first voltage; the continuous voltage of the first voltage is used for charging to the cutoff current; the continuous current of a second current is used for charging to the second voltage. The second voltage is higher than the first voltage and the second current is higher than the first current. As the battery is carried out the formation using the formation method of the invention, the battery has a good comprehensive electrical-chemical performance such as a higher capacity, high-temperature circulation performance and a discharge performance for big current.

Owner:SHANGHAI BYD

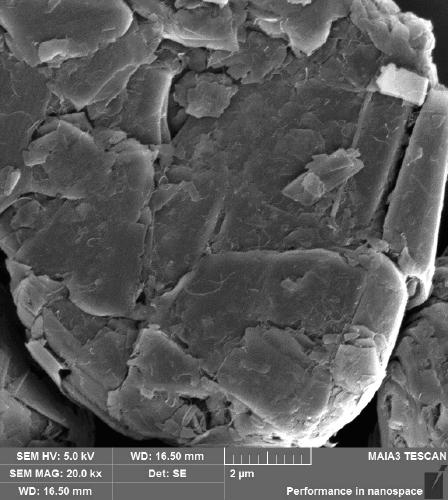

Battery cathode material, preparation method thereof and lithium ion battery

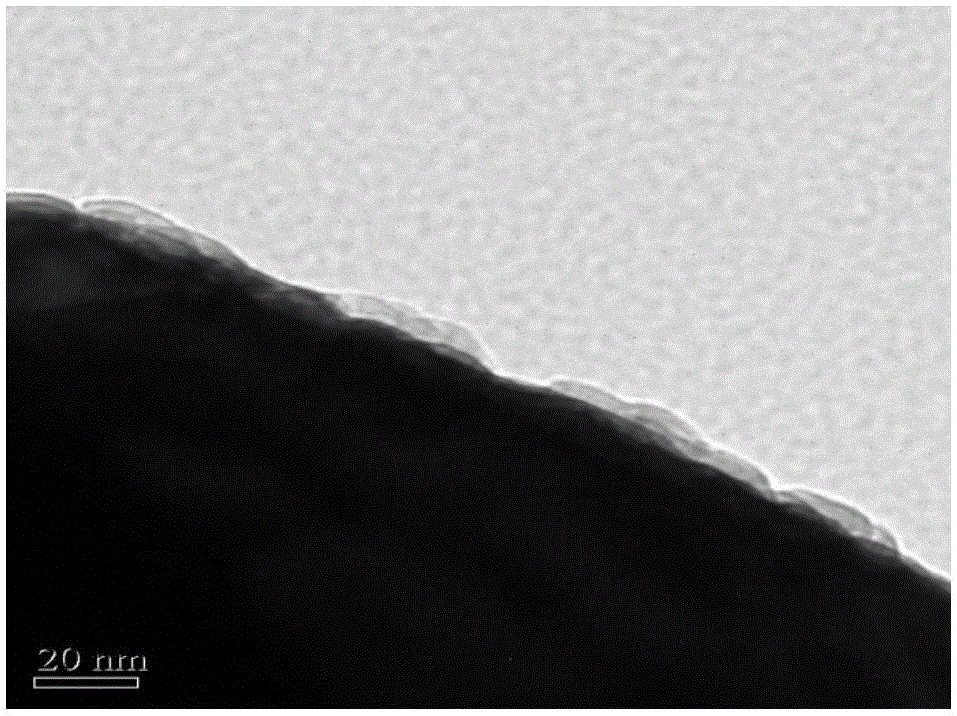

InactiveCN105161710AGood high temperature cycle performanceCell electrodesSecondary cellsStructural stabilityCorrosion

The invention provides a battery cathode material. The battery cathode material comprises a single-crystal structurized substrate and a coating layer, wherein the coating layer coats the surface of the substrate and is aluminum oxide or zirconium oxide. The battery cathode material provided by the invention comprises the single-crystal structurized substrate; by the single-crystal structurized substrate, particle breakage caused by positive sheet grinding during the battery fabrication process can be prevented; and meanwhile, with the joint effects of a doping element in the battery cathode material and the coating layer, the structural stability of the cathode material can be improved, the corrosion of an electrolyte to the material is relieved, and a lithium ion battery prepared from the cathode material has favorable high-temperature cycle performance. The invention also provides a preparation method of the battery cathode material and the lithium ion battery.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

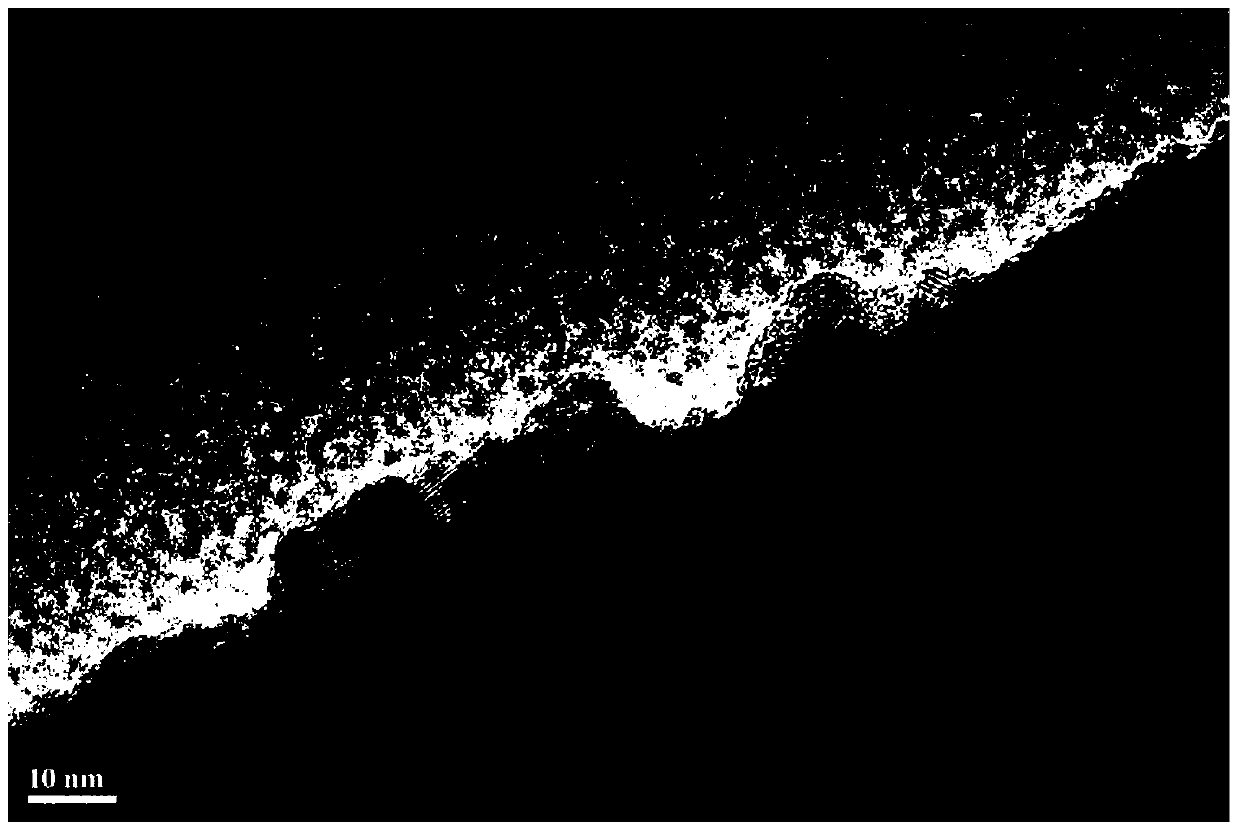

Preparation method of coated lithium manganate

The invention provides a preparation method of coated lithium manganate. The method includes the steps of: preparing a metal oxide; adding lithium manganate to water, stirring to disperse and form a suspension, and adjusting the pH value of the suspension to 6-8; adding the prepared metal oxide into the suspension, stirring for 0.8-1.5 h; and centrifuging, washing and drying the products obtained in the step 3, and calcining to obtain the metal oxide coated lithium manganate. The technical scheme provided by the invention can synthesize a lithium manganese oxide coated layer in nano scale and having uniform thickness in water system, and the coated lithium manganate has better high temperature cycle performance than the LiMn2O4 synthesized by a conventional method. When applied to lithium ion battery, the coated lithium manganate can improve the stability and service life of the battery.

Owner:SHANGHAI ELECTRICGROUP CORP +1

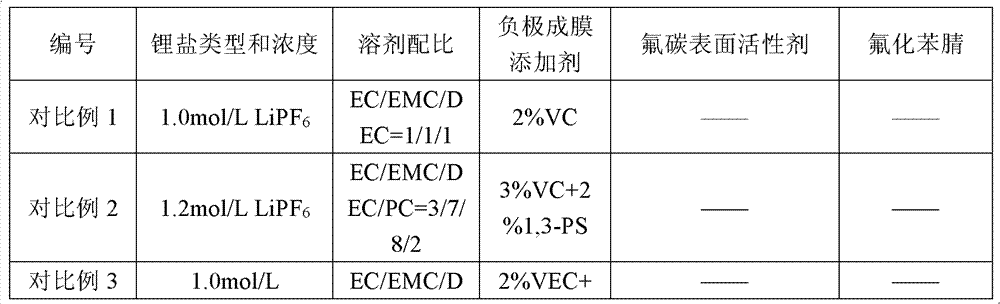

Electrolyte for improving high-temperature property of lithium manganate battery

ActiveCN102956918AReduce decomposition gasInhibition of dissolutionSecondary cellsLithiumOrganic solvent

The invention discloses electrolyte for improving a high-temperature property of a lithium manganate battery, and belongs to the technical field of electrolytes for lithium ion secondary batteries. The electrolyte comprises a nonaqueous organic solvent, lithium salt and a cathode film formation additive; and the electrolyte is characterized by further comprising a cyanophenyl fluoride additive and a fluorocarbon surfactant. In the primary charging process, a layer of protection film is formed on the surface of an anode by cyanophenyl fluoride, the decomposing and gas forming of the electrolyte on the surface of the anode are reduced, the dissolving of Mn<2+> ions in positive active materials can be restrained in subsequent processes of charging and discharging, and the high-temperature property of the lithium manganate battery is improved; and by virtue of adding the fluorocarbon surfactant, the surface tension of the electrolyte of the lithium ion secondary battery is reduced, the adsorption and infiltration of a positive sheet, a negative sheet and a membrane on the electrolyte are effectively improved, the stable and uniform state of the electrolyte in the battery is quickly achieved, and the cycle life of the battery can be prolonged. By utilizing the cyanophenyl fluoride additive and the fluorocarbon surfactant, the lithium manganate battery has an excellent high-temperature cycle property.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

Electrolyte and secondary lithium battery

ActiveCN108123172AGood high temperature cycle performanceImprove high temperature storage performanceLi-accumulatorsOrganic electrolytesHigh temperature storageDifluorophosphate

The invention provides an electrolyte and a secondary lithium battery. The electrolyte comprises a lithium salt, an organic solvent and additives. The additives include fluoroborate and lithium difluorophosphate. When the electrolyte is applied to the secondary lithium battery, the secondary lithium battery simultaneously has excellent high-temperature cycle performance, high-temperature storage performance, low-temperature discharge performance and large-rate charge performance, and the low-temperature lithium precipitation of the secondary lithium battery is also significantly suppressed.

Owner:CONTEMPORARY AMPEREX TECH CO

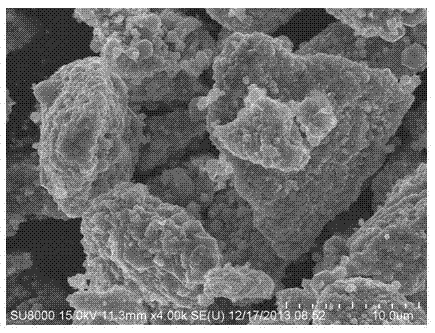

Method for preparing high-capacity long-life lithium ion battery lithium manganate cathode material

ActiveCN103682315AIncreased diffusion rateIncrease the reversible specific capacityCell electrodesManganates/permanganatesCapacity lossMaterial synthesis

The invention relates to a method for preparing a high-capacity long-life lithium ion battery lithium manganate cathode material and belongs to the technical field of material synthesis. The method comprises the following steps: 1, weighing out one or more lithium sources, a manganese salt and one or more doped trace metal elements for uniformly mixing, preburning for 2-6 hours at 400-600 DEG C, calcining for 6-16 hours at 700-1000 DEG C, removing tiny particles in a grading mode, and magnetically adsorbing metal ions to obtain lithium manganate or primary doped lithium manganate; 2, secondarily doping the lithium sources into the lithium manganate or primary doped lithium manganate obtained by the step 1 for uniformly mixing; 3, calcining the mixture for 3-8 hours at 600-850 DEG C to obtain a primary or secondary doped calcined lithium manganate material. According to the method, as active materials are introduced for two times, the diffusion rate of Li+ is effectively increased, the irreversible capacity loss is reduced, the reversible specific capacity of the cathode material is increased, and the cycling stability of the cathode material is improved. The process is simple, the high-temperature performance is improved obviously and reliably, and the prepared lithium manganate material has high capacity and good high-temperature cycle performance.

Owner:哈尔滨博尔特能源科技有限公司

Spinel nickel manganese-based oxide cathode material and preparation process thereof

ActiveCN102683668ASmall specific surface areaGood high temperature cycle performanceCell electrodesSurface energyManganese oxide

The invention provides a spinel nickel manganese-based oxide cathode material. The composition of the material by atomic ratio is represented as formula (I): LiaMx+yNi0.5-yMn1.5-xO4, (I), wherein, 0.9<=a<=1.1, 0<=x<=0.2, 0<=y<=0.1, M represents one of or a plurality of Mg, Al, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zr, Nb, Ag, Sn, Ce, Nd, Ta, W, Pt and Au. The invention also provides a preparation process of the spinel nickel manganese oxide cathode material. During the preparation process of the spinel nickel manganese oxide cathode material, a compound containing M is added as a doping element, so that the surface energy of the material is reduced during solid-phase synthesis, nickel elements and manganese elements are distributed evenly, impure phases can be avoided, and the high-temperature cycle performance of the obtained cathode material can be improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Electrolyte of lithium ion battery and lithium ion battery utilizing same

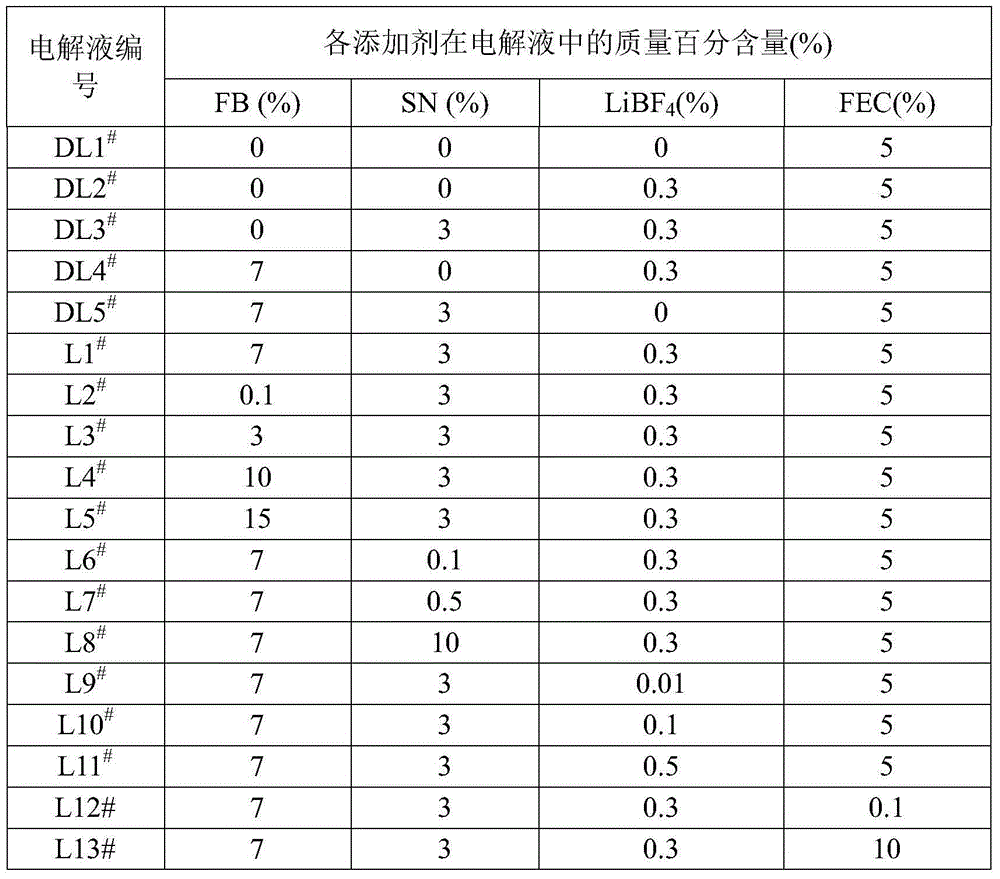

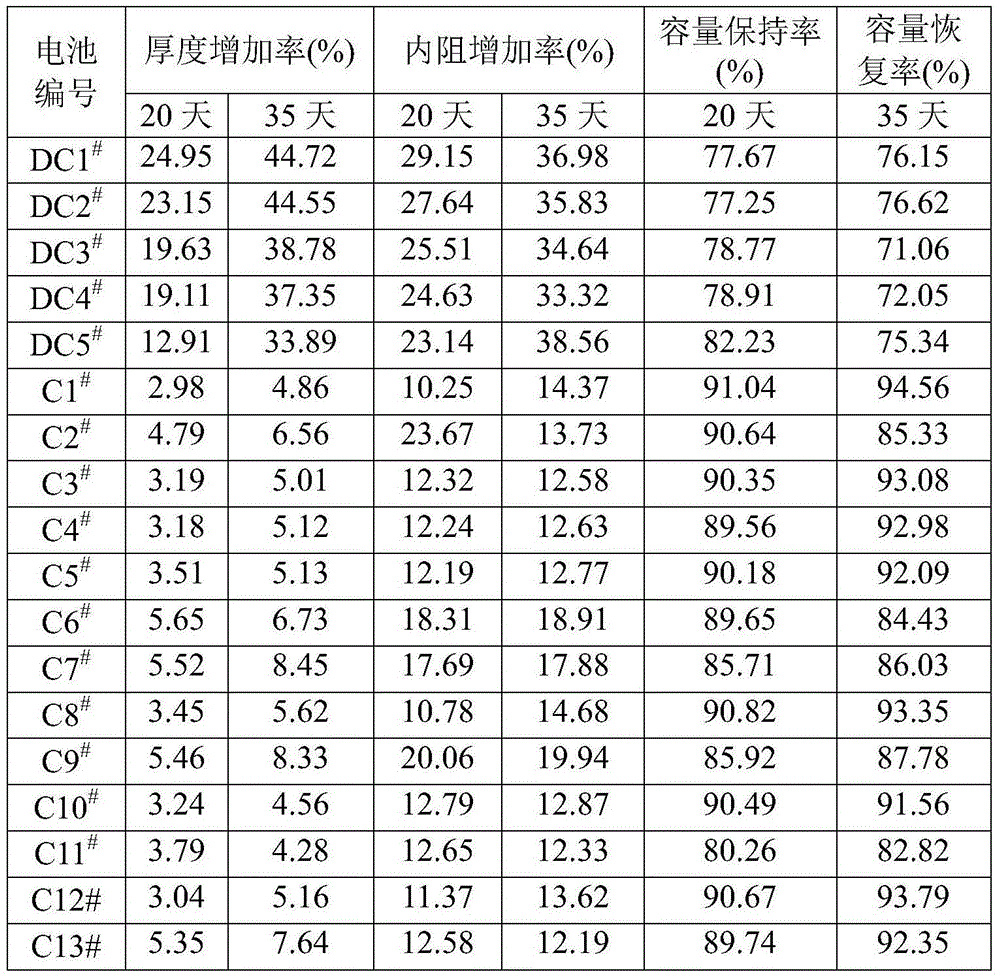

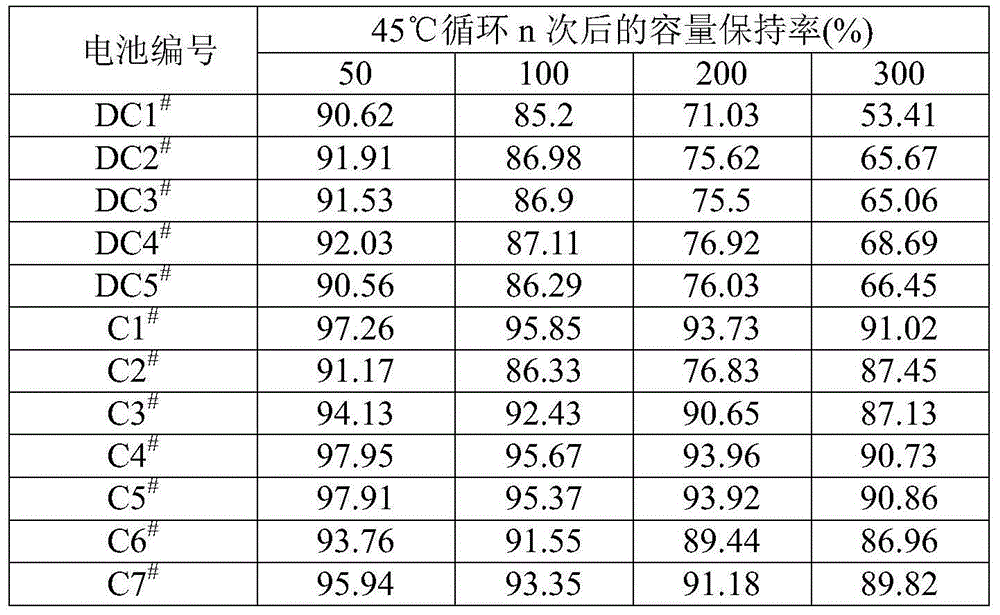

ActiveCN104466248AReduce oxidationIncrease loopSecondary cellsOrganic electrolytesOrganic solventInternal resistance

The invention discloses electrolyte of a lithium ion battery. The electrolyte comprises an organic solvent, electrolyte lithium salt and additives, wherein the additives include butanedinitrile, fluorobenzene and lithium tetrafluoroborate; the mass percentage of the fluorobenzene in the electrolyte is 0.1 to 15 percent; the mass percentage of the butanedinitrile in the electrolyte is 0.1 to 10 percent; the mass percentage of the lithium tetrafluoroborate in the electrolyte is 0.01 to 1 percent. By adopting the electrolyte, while the charging upper limit voltage and high temperature intermittent cycling performance of the lithium ion battery are improved, simultaneously the expansion rate of the battery is reduced, the internal resistance is reduced, and the stability and the safety of the lithium ion battery can be improved.

Owner:DONGGUAN AMPEREX TECH +1

Ternary material, preparation method thereof and battery slurry, positive electrode and lithium battery

ActiveCN108206281AIncrease compaction densityReduce thermal expansion and resistance changeNegative electrodesLi-accumulatorsTemperature cyclingSmall particle

The invention discloses a ternary material and a preparation method thereof and a battery slurry, a positive electrode and a lithium battery. The ternary material is represented by a general formula of LiNi<1-x-y>Co<x> M<y>O<2>, wherein M is Mn or Al, and 0<x<1, 0<y<1, x+y<1. The particulate matter of the ternary material comprises three layers of particles which include primary particles having acrystal structure, middle particles formed by partially fusing multiple primary particles and secondary balls formed by aggregating the intermediate particles. The particulate matter of the ternary material includes the three layers of particles at the same time, so that the material simultaneously has excellent low-temperature performance and rate performance of the small particles and excellenthigh-temperature storage and high-temperature cycling performance of big particles.

Owner:BYD CO LTD

Positive active material and preparation method and application thereof

InactiveCN106229477AHigh discharge specific capacityGood high temperature cycle performanceCell electrodesSecondary cellsSize differenceFully developed

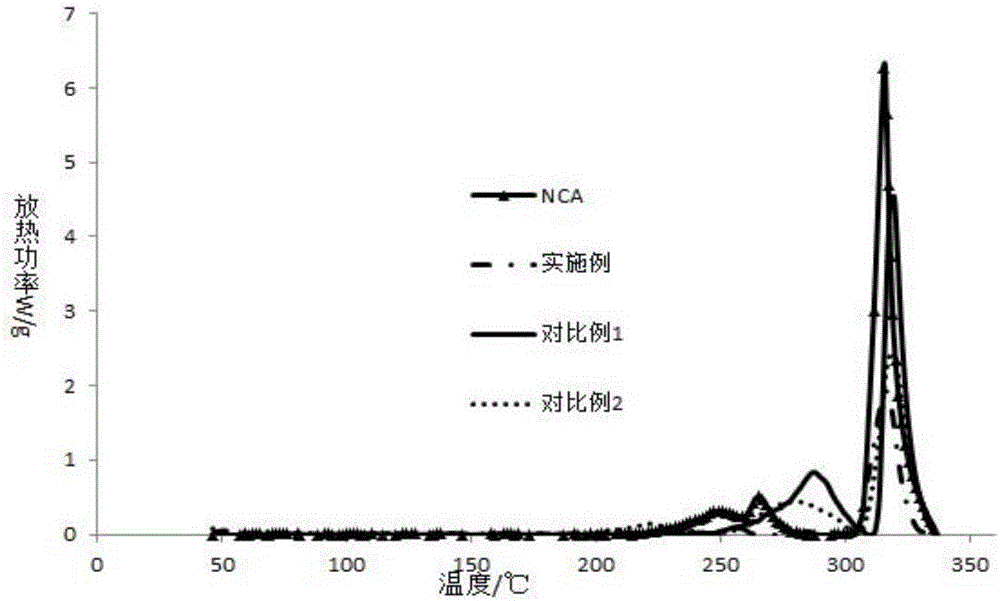

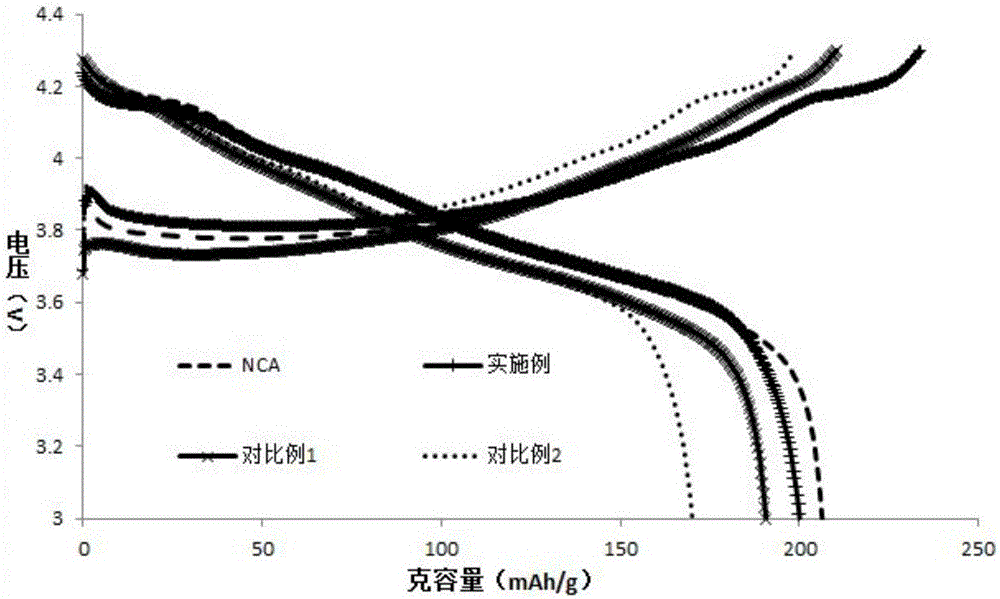

The invention discloses a positive active material and a preparation method and application thereof, and belongs to the technical field of lithium-ion batteries. The positive active material is prepared from LiNi0.82Co0.15Al0.03O2 and LiNi0.34Co0.32Mn0.34O2 at the ratio in mass percent of (60%-85%):(15%-40%), and D50 of the LiNi0.82Co0.15Al0.03O2 and the LiNi0.34Co0.32Mn0.34O2 is 10-15 microns and 1-6 microns respectively. Due to the presence of a grain size difference, the two active materials can be evenly mixed; on one hand, high discharge specific capacity of nickel-cobalt lithium aluminate is kept; and on the other hand, high safety performance and cycle performance of nickel-cobalt lithium manganate are fully developed. Compared with the lithium-ion battery of individually using a nickel-cobalt lithium aluminate or nickel-cobalt lithium manganate positive electrode material and the positive electrode material in a comparative example, the lithium-ion battery prepared from the positive electrode material disclosed by the invention has higher discharge capacity, excellent high-temperature cycle performance and excellent low-temperature performance and safety performance.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Electrolyte for lithium manganate battery

The invention discloses electrolyte for a lithium manganate battery, and belongs to the technical field of electrolytes for lithium ion secondary batteries. The electrolyte comprises a nonaqueous organic solvent, a lithium salt and a cathode film formation additive; and the electrolyte is characterized by further comprising a fluorocarbon surfactant and a cyanophenyl fluoride additive. By virtue of adding the fluorocarbon surfactant, the surface tension of the electrolyte of the lithium ion secondary battery is reduced, the adsorption and infiltration of a positive sheet, a negative sheet and a membrane on the electrolyte are effectively improved, the stable and uniform state of the electrolyte in the battery is quickly achieved, and the cycle life of the battery can be prolonged; and in the primary charging process, a layer of protection film is formed on the surface of an anode by the cyanophenyl fluoride, the decomposing and gas forming of the electrolyte on the surface of the anode are reduced, the dissolving of Mn<2+> ions in positive active materials can be restrained in subsequent processes of charging and discharging, and the high-temperature property of the lithium manganate battery is improved. By virtue of adding the fluorocarbon surfactant and the cyanophenyl fluoride additive, the lithium manganate battery has an excellent high-temperature cycle property.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

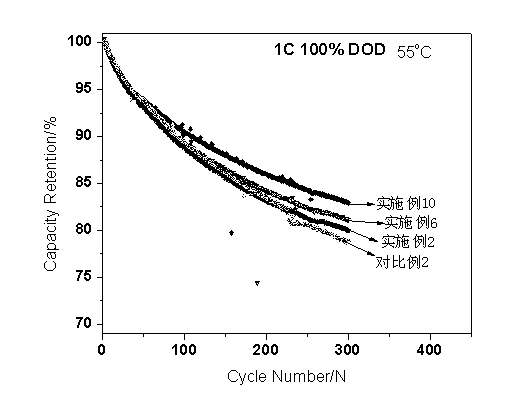

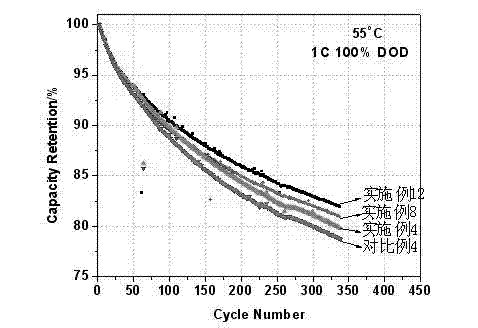

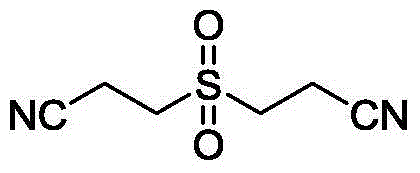

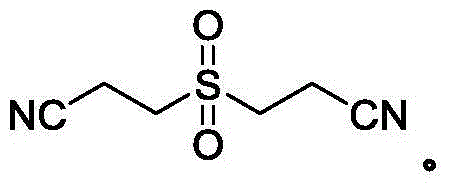

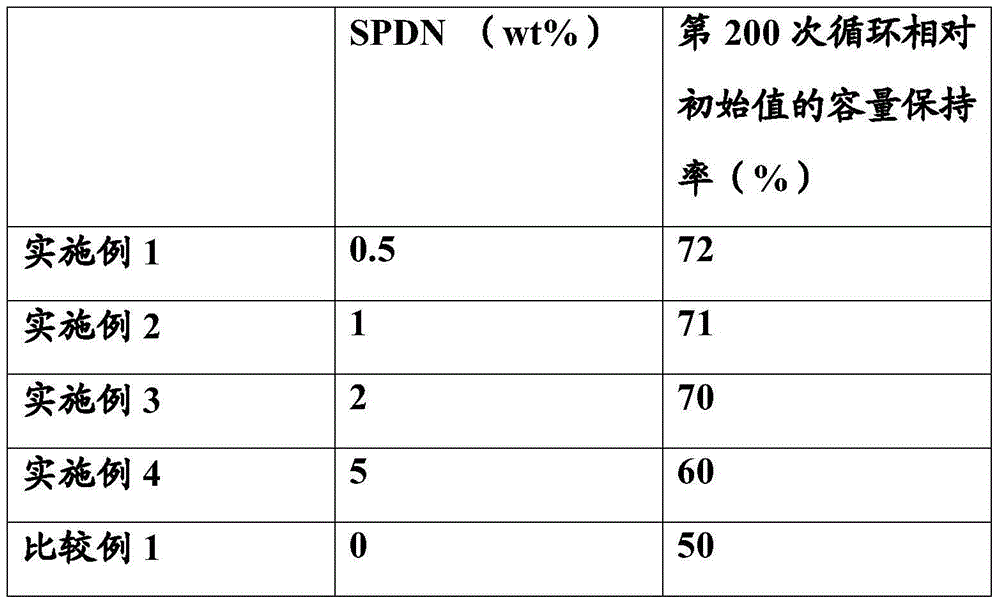

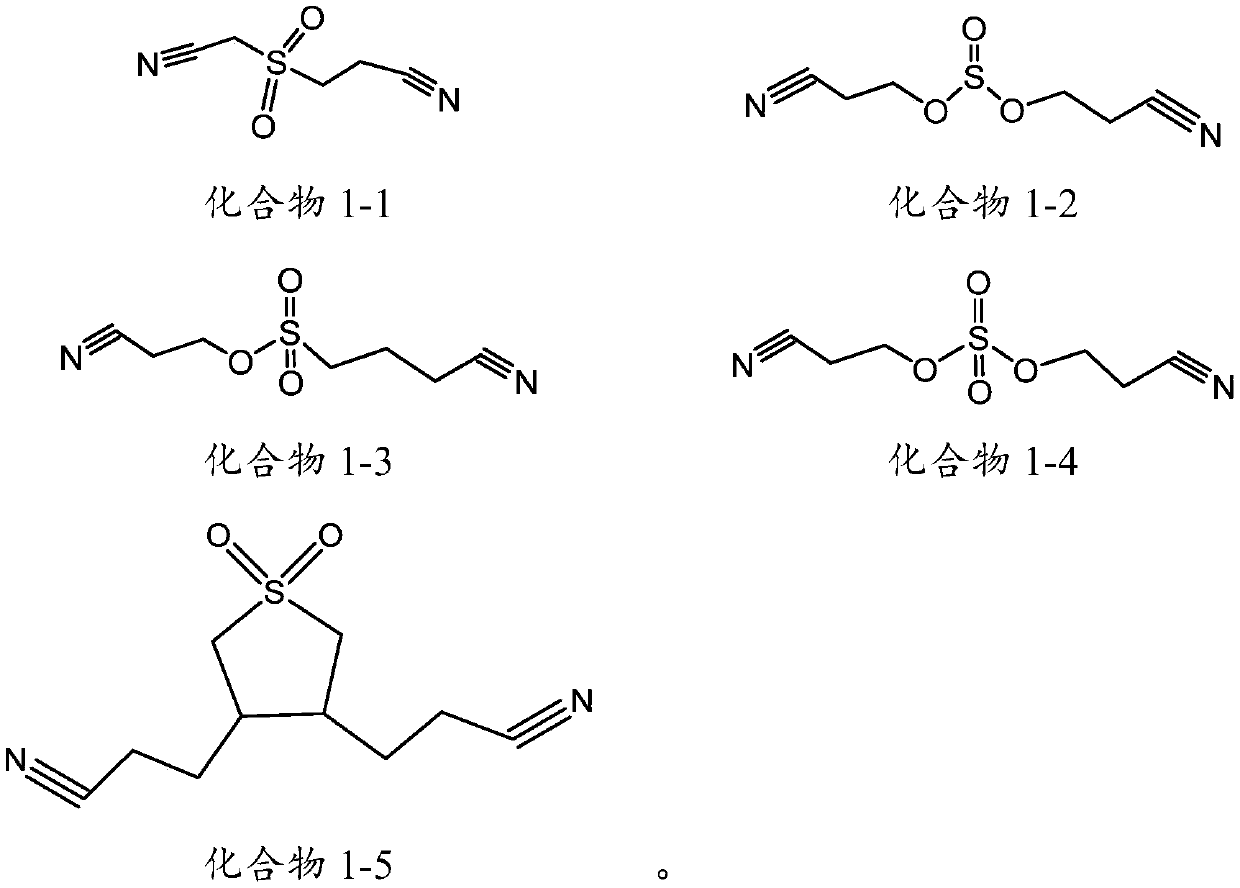

High-temperature electrolyte for lithium battery

InactiveCN104953177AGood high temperature cycle performanceImprove high temperature cycle performanceSecondary cellsOrganic solventPhysical chemistry

The invention provides high-temperature electrolyte for a lithium battery. The high-temperature electrolyte for the lithium battery comprises a nonaqueous organic solvent, a lithium salt and an electrolyte additive. The electrolyte additive is sulfuryl dipropanenitrile and is characterized by comprising two end cyano groups and one sulfonyl group, wherein the use amount of the electrolyte additive is 0.3wt%-5wt% of the total weight of the electrolyte. By use of the high-temperature electrolyte, the cycle performance of the lithium battery under a high temperature (55 DEG C) can be effectively improved.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

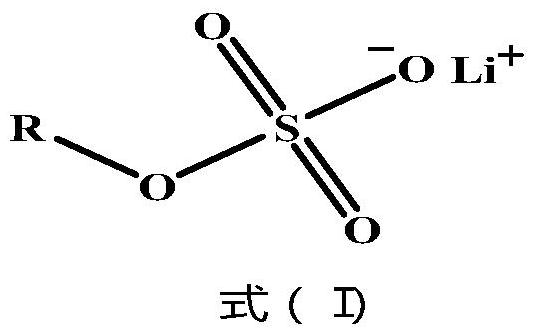

Lithium ion battery and electrolyte thereof

InactiveCN103107368AGood high temperature cycle performanceImprove high temperature cycle performanceSecondary cellsHigh temperature storage1,4-Butanediol

The invention discloses lithium ion battery electrolyte. The electrolyte comprises a non-aqueous solvent and lithium salt dissolved in the non-aqueous solvent, wherein the non-aqueous solvent contains 1,4-butanediol-sulfate which is as shown in formula I, and the total mass of the 1,4-butanediol-sulfate accounts for 0.5 to 15 percent of the total mass of the non-aqueous solvent. According to the lithium ion battery electrolyte, the decomposition reaction of the electrolyte can be effectively inhibited, so that the high-temperature storage performance and the high-temperature circulating performance of the lithium ion battery can be improved, and the improvement effect can be maintained for a long time. Furthermore, the invention discloses a lithium ion battery using the lithium ion battery electrolyte. The formula I is shown in details.

Owner:NINGDE AMPEREX TECH

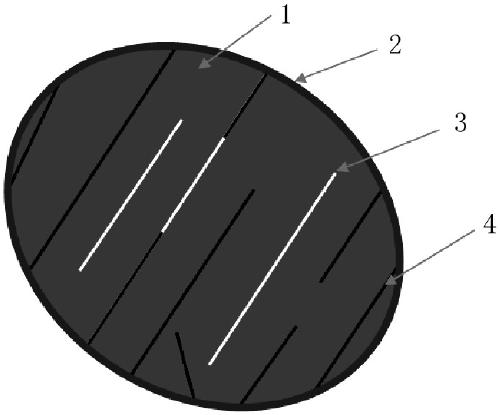

Long-cycle natural graphite-based modified composite material as well as preparation method and application thereof

ActiveCN111232971AGood high temperature cycle performanceLow costCell electrodesSecondary cellsGraphite electrodeAsphalt

The invention discloses a long-cycle natural graphite-based modified composite material as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing natural flake graphite with molten asphalt to coat the surface of the natural flake graphite with the asphalt, and then cooling; sequentially crushing and shaping the natural flake graphite coated with the asphalt on the surface to obtain spherical graphite; carrying out graphitization treatment on the spherical graphite, cooling, and carrying out scattering and screening treatment on the graphitized material; uniformly mixing the graphitized material with asphalt to coat the surface of the graphitized material with the asphalt to obtain a mixture; carbonizing the mixture, cooling, scattering, and screening to obtain the natural graphite-based modified composite material. When the composite material prepared by the method disclosed by the invention is used as a negative electrode material, relatively long cycle performance and relatively good electrochemical performance can be achieved, and the problem of high expansion of a natural graphite electrode is solved.

Owner:GUANGDONG DONGDAO NEW ENERGY +1

Ternary cathode material lithium ion battery electrolyte

PendingCN111769326AImprove discharge performanceGood high temperature cycle performanceSecondary cellsNon-aqueous electrolytesElectrical batteryOrganosolv

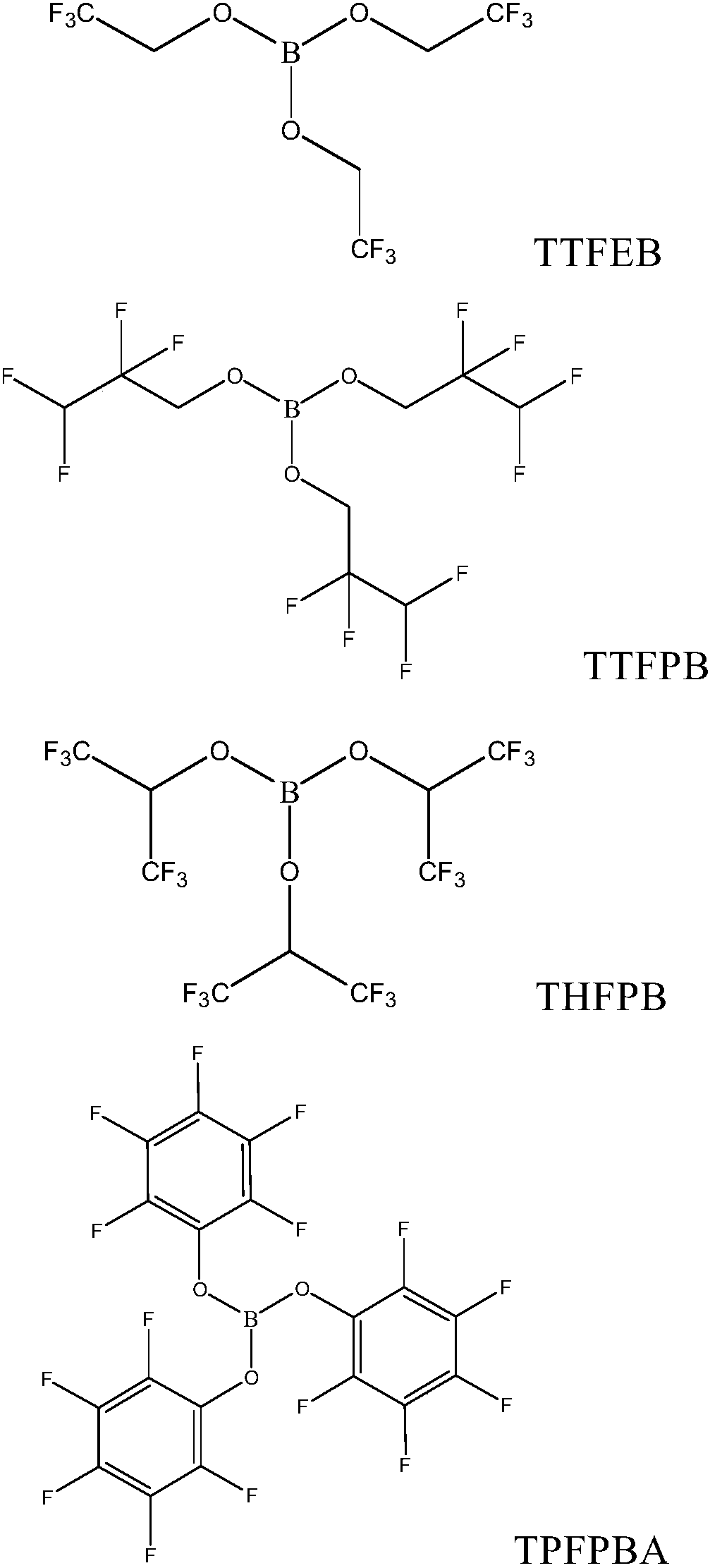

The invention discloses a ternary cathode material lithium ion battery electrolyte which comprises the following raw materials: an organic solvent, a lithium salt, a film-forming additive and a functional additive, and the functional additive comprises a low-impedance lithium salt, a sulfonate organic matter and a borate compound. Through the synergistic effect generated by using the three additives of the low-impedance lithium salt, the sulfonate organic matter and the borate compound, the ternary positive electrode material battery has excellent discharge performance in a low-temperature environment, and when the working voltage is 4.4 V or above, the high-temperature cycle performance is excellent, so that the electrolyte has a wide application prospect in a ternary battery system.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Electrolyte of lithium ion battery

ActiveCN103107358AImprove performanceLow and high temperature cycle performanceSecondary cellsPhysical chemistryPropylene carbonate

The invention discloses an electrolyte of a lithium ion battery. The electrolyte comprises lithium hexafluorophosphate LiPF6, a mixed solvent and an additive, wherein the mixed solvent comprises three to four out of diethyl carbonate (DEC), ethyl methyl carbonate (EMC), dimethyl carbonate (DMC), ethylene carbonate (EC) and propylene carbonate (PC); and the additive is a mixture of vinylene carbonate (VC), gamma-butyrolactone (GBL) and hexamethyl disilazane (HDMS). The lithium ion battery produced by adopting the electrolyte provided by the invention is excellent in high temperature and low temperature performances, and is remarkably improved in performances. The electrolyte of the lithium ion battery, provided by the invention, can simultaneously meet the requirements on use in a high temperature environment and a low temperature environment of -40-70 DEG C, and can not influence the service life of the battery.

Owner:DO FLUORIDE CHEM CO LTD

Preparation method of lithium manganate cathode material

ActiveCN103715415BComplete structureReduce solubilityCell electrodesSecondary cellsLiquid productPhysical chemistry

The invention discloses a preparation method of a lithium manganate anode material. The preparation method comprises the following steps: (1) preparing a salt-mixture solution; (2) preparing a precipitant solution; (3) slowly pumping the salt-mixture solution and the precipitant solution into a reaction kettle at a pH value of 7-13; (4) weighing manganese dioxide in proportion, adding the manganese dioxide to a mixed solution obtained in the step (3), continuously stirring, ageing for 5-20 hours, then separating solid-liquid products, and washing an obtained precursor with deionized water to alkalescence; (5) adding a lithium source and the washed precursor to a ball-milling tank, carrying out ball-milling for 2-5 hours, and then drying at the temperature of 80-120 DEG C, thus obtaining a precursor material; and (6) respectively roasting the obtained precursor material two times, breaking the material obtained by sintering, and sieving, thus obtaining the lithium manganate anode material. The preparation method is simple; the prepared lithium manganate anode material has high capacity and excellent high-temperature cycle performance.

Owner:TIANJIN B&M SCI & TECH

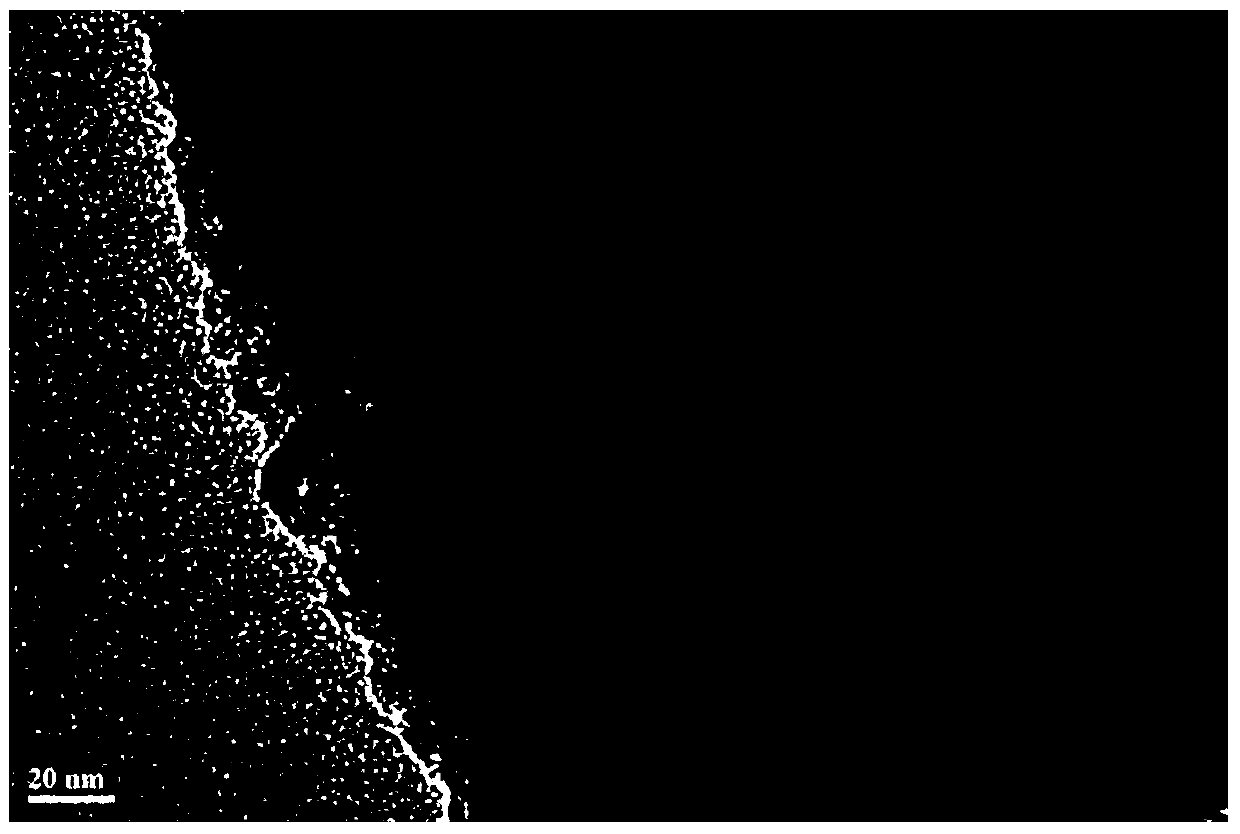

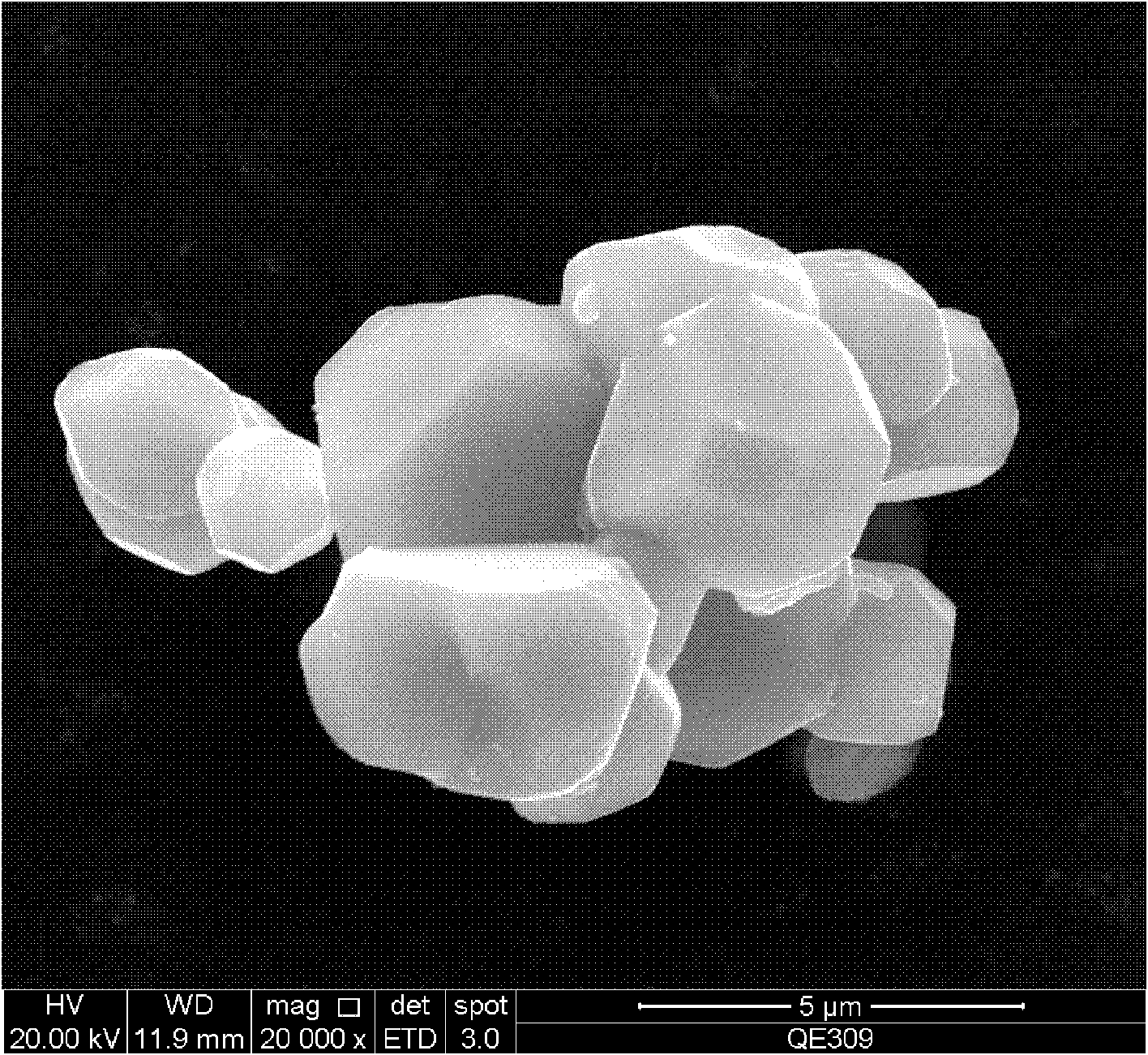

Coated-modified lithium manganese positive electrode material and preparation method thereof

The invention discloses a coated-modified lithium manganese positive electrode material and the preparation method thereof. A manganese source compound, an M source compound and a lithium source compound are taken as raw material for preparing LiaMn2 -bMbO4 particles, and then are mixed with molten solvent and A-source compound, so as to obtain coated-modified lithium manganese positive electrode material. Compared with the prior art, the LiaMn2-bMbO4 particles are similar to spheres in shape and are in crystal face connection through curved surfaces which have no clear edges; on one hand, the LiaMn2 -bMbO4 particles have very small specific surface area, so that molten solvent and coating material are more evenly dispersed on the surfaces of the particles, and the control to average thickness of a coating is facilitated; on the other hand, the features have very small surface energy, the coating material is enabled to be more easily to be combined with the LiaMn2 -bMbO4 particles to form the coating. Therefore, the coated-modified lithium manganese positive electrode material has an excellent high temperature cycling performance.

Owner:宁波富理电池材料科技有限公司

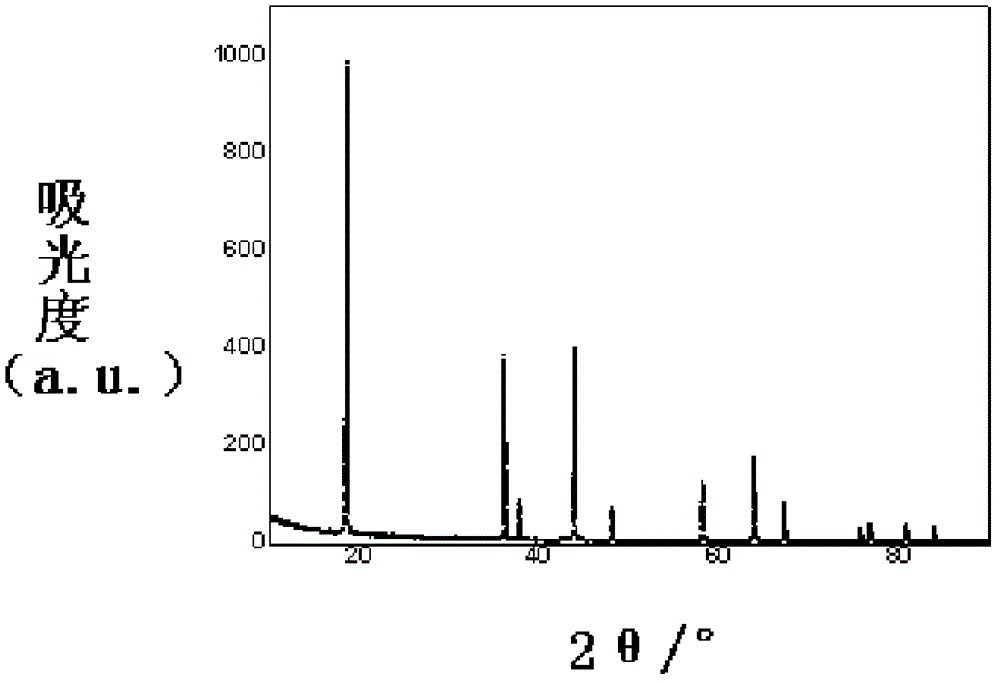

Nonaqueous electrolyte battery and battery pack

ActiveCN104466179AGood high temperature cycle performanceImprove securityCell electrodesSecondary cellsX-rayTitanium

According to one embodiment, a nonaqueous electrolyte battery including a positive electrode and a negative electrode is provided. The positive electrode includes LiNixM1-xO2, wherein M is a metal element including Mn, and x is within a range of 0.5<=x<=1. The negative electrode includes graphitized material particles and a layer. The graphitized material particles have an interplanar spacing (002), according to an X-ray diffraction method, of 0.337 nm or less. The layer includes a titanium-containing oxide. The layer covers at least a part of a surface of the graphitized material particles.

Owner:KK TOSHIBA

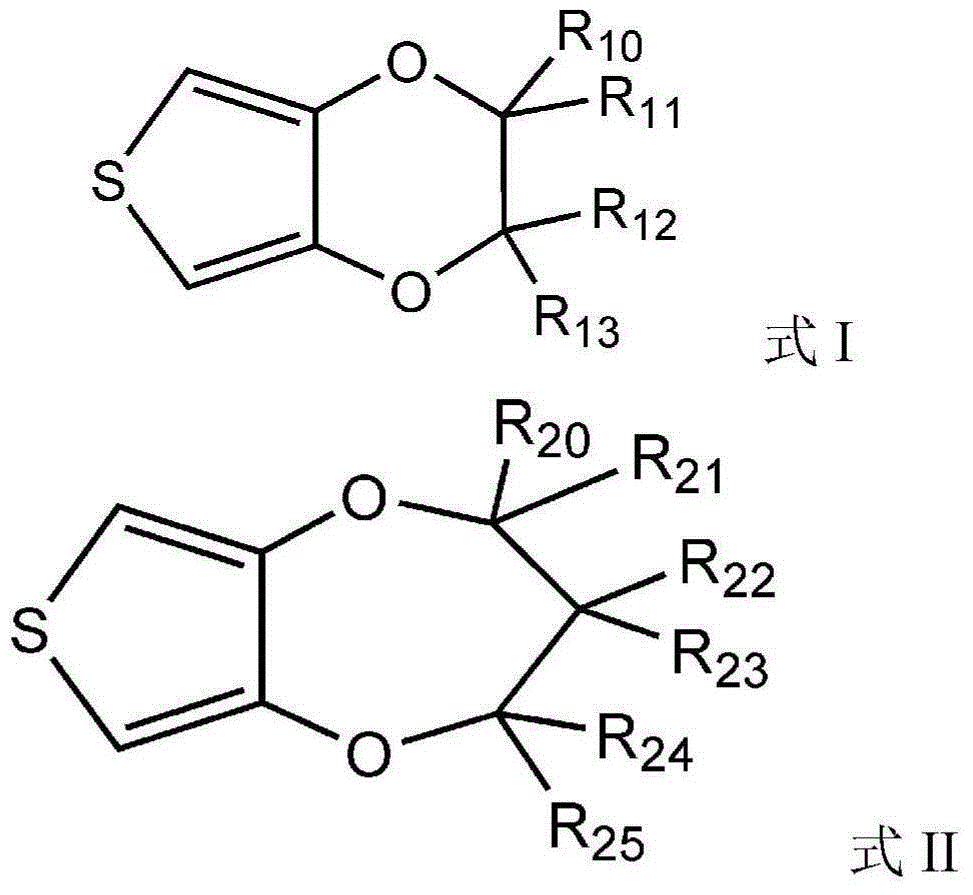

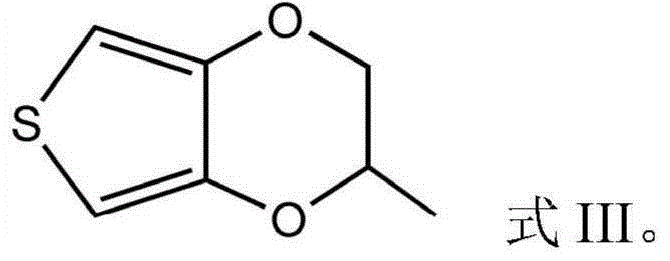

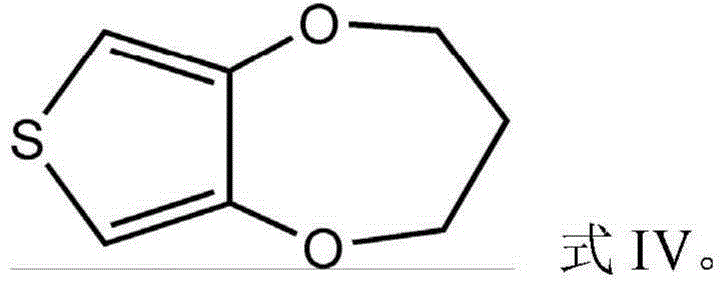

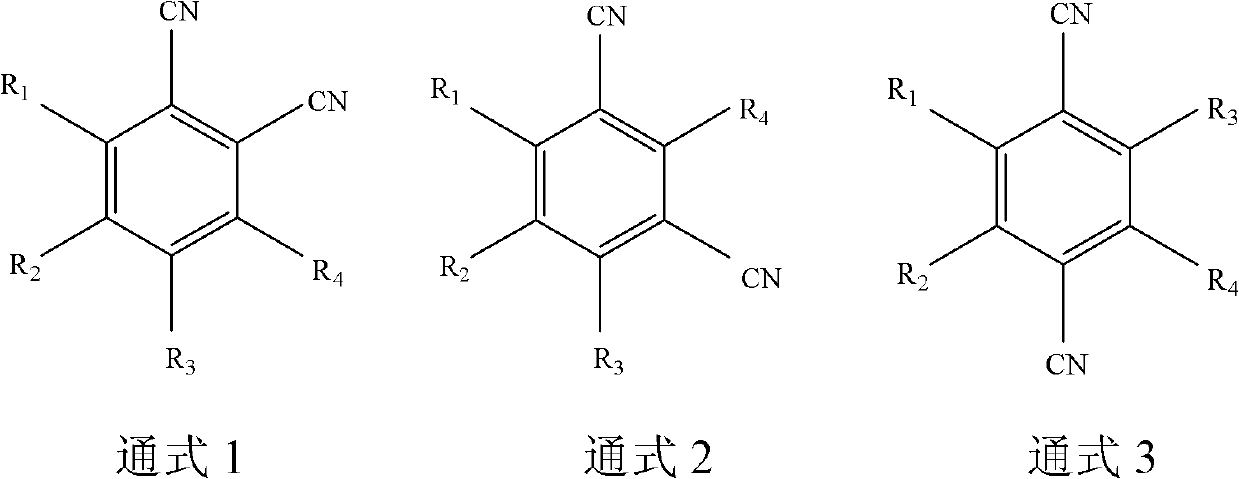

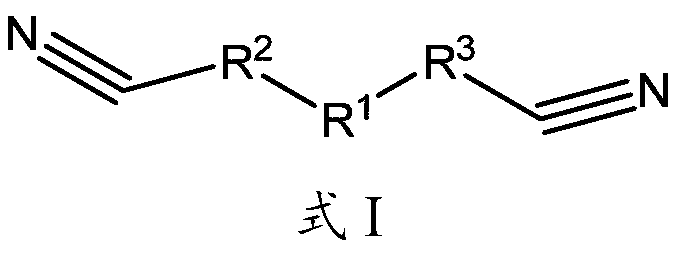

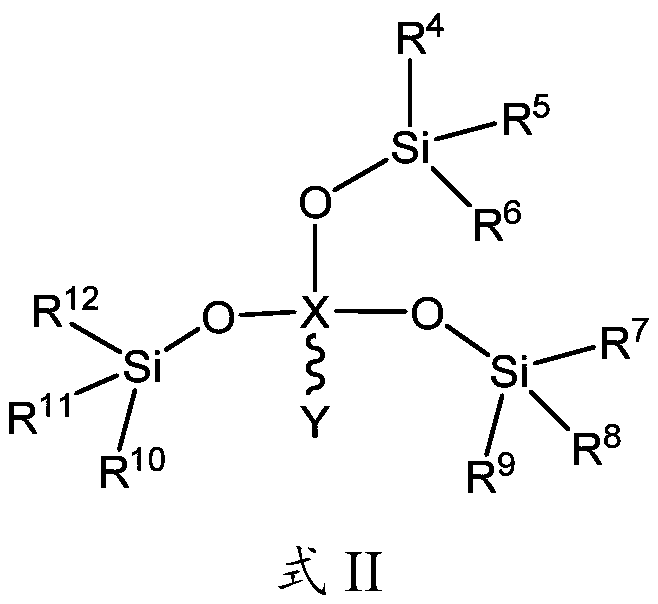

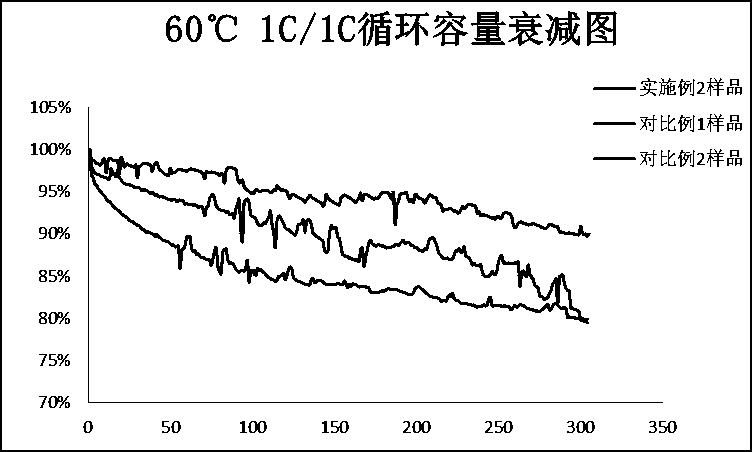

Electrolyte and lithium ion battery containing same

ActiveCN110611121AGood high temperature cycle performanceLow temperature storage performanceSecondary cells servicing/maintenanceOrganic electrolytesLithium electrodeOrganic solvent

The invention provides an electrolyte and a lithium ion battery containing the same. The electrolyte comprises an organic solvent, an electrolyte lithium salt dissolved in the organic solvent and additives. The additives comprise a first additive and a second additive. The first additive is selected from one or more of compounds shown in a formula I, and the second additive is selected from one ormore of compounds shown in a formula II. After the electrolyte disclosed by the invention is applied to the lithium ion battery, the lithium ion battery has relatively good cycle performance and storage performance at high temperature and relatively low direct-current impedance at low temperature, and thus, the lithium ion battery has relatively good high-temperature performance and low-temperature performance.

Owner:CONTEMPORARY AMPEREX TECH CO

Negative electrode with high compaction, excellent high-temperature performance and high energy density and preparation method thereof

InactiveCN109768247AImprove compactionIncrease energy densityGraphiteCell electrodesAlkaneHigh energy

The invention provides a preparation method of a negative electrode with high compaction, excellent high-temperature performance and high energy density. Carbon is deposited in holes and a surface ofnatural spherical graphite by pyrolysis of organic alkane, the defects in the natural spherical graphite and on the surface of the natural spherical graphite are recovered, high-speed stirring and uniform dispersing are performed after mixing with asphalt, and the negative electrode material with high compaction and high energy density is obtained by carbonization. The negative electrode materialprepared by the method has excellent high-temperature cycle performance, and the problem of poor high-temperature cycle property in the prior art is solved.

Owner:HUNAN SHINZOOM TECH

Lithium ion battery electrolyte and preparation method thereof, lithium ion battery and electric vehicle

PendingCN112909341AImproved magnification performanceImprove cycle performancePropulsion by batteries/cellsSecondary cells servicing/maintenanceElectrolytic agentElectric cars

The invention relates to the technical field of energy storage, and provides a lithium ion battery electrolyte and preparation thereof. A composite lithium salt is dissolved in an organic solvent, the composite lithium salt comprises a lithium salt additive and lithium hexafluorophosphate, and the molar concentration of final lithium ions is 0.8-2.5 mol / L when the composite lithium salt is dissolved in an electrolyte solvent. The bis (trifluoromethylsulfonyl) lithium imide obviously improves the low-temperature performance and the high-temperature performance of the battery, and the bis (trifluoromethylsulfonyl) lithium imide is used as a main lithium salt additive and is matched with lithium hexafluorophosphate, so that the ionic conductivity of the electrolyte can be further improved, the component proportion of an SEI film can be improved, the conduction of Li<+> is facilitated. The positive electrode structure is stabilized, and the dissolution of transition metal ions is inhibited, so that the rate capability and the cycle performance of the lithium ion battery are improved. The invention also provides an electric vehicle with the lithium ion battery.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

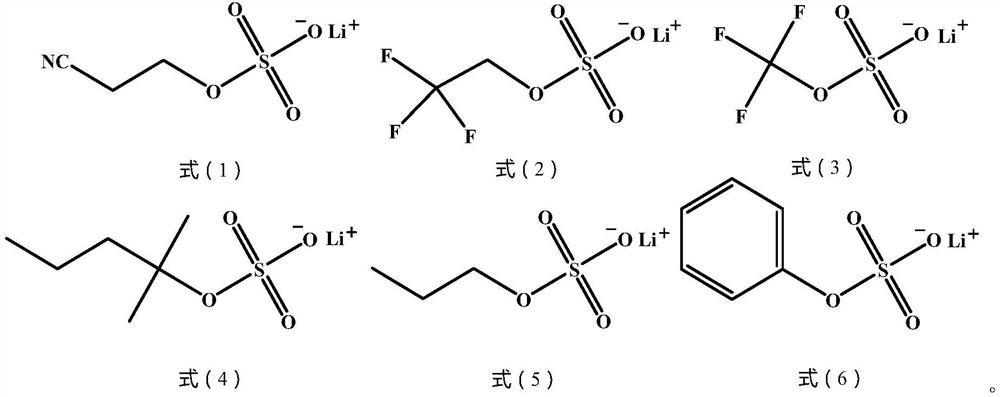

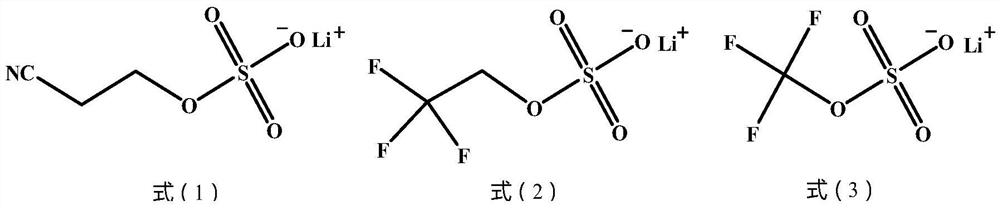

High-voltage electrolyte containing sulfate lithium salt additive and lithium ion battery containing electrolyte

InactiveCN112768765AImprove conductivityGood high temperature cycle performanceFinal product manufactureSecondary cells servicing/maintenanceElectrolytic agentOrganic solvent

The invention belongs to the technical field of lithium ion batteries, and discloses a high-voltage electrolyte containing a sulfate lithium salt additive and a lithium ion battery containing the electrolyte. The high-voltage electrolyte containing the sulfate lithium salt additive comprises lithium hexafluorophosphate, an organic solvent and an additive, the organic solvent comprises one or more of chain carbonic esters, cyclic carbonic esters and carboxylic esters, and the additive comprises a sulfate lithium salt compound. The sulfate lithium salt compound has good high temperature resistance, can form a smooth and uniform film on the surface of an electrode, prevents further oxygenolysis of the electrode and an electrolyte, and reduces gas generation expansion of the battery after high temperature placement; meanwhile, the membrane has good permeability to lithium ions, impedance increase caused by membrane formation can be reduced, the conductivity of electrolyte in the lithium ion battery is effectively improved, and the cycle performance of the lithium ion battery is improved.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com