Cathode material of lithium ion battery, and preparation method thereof and lithium ion battery

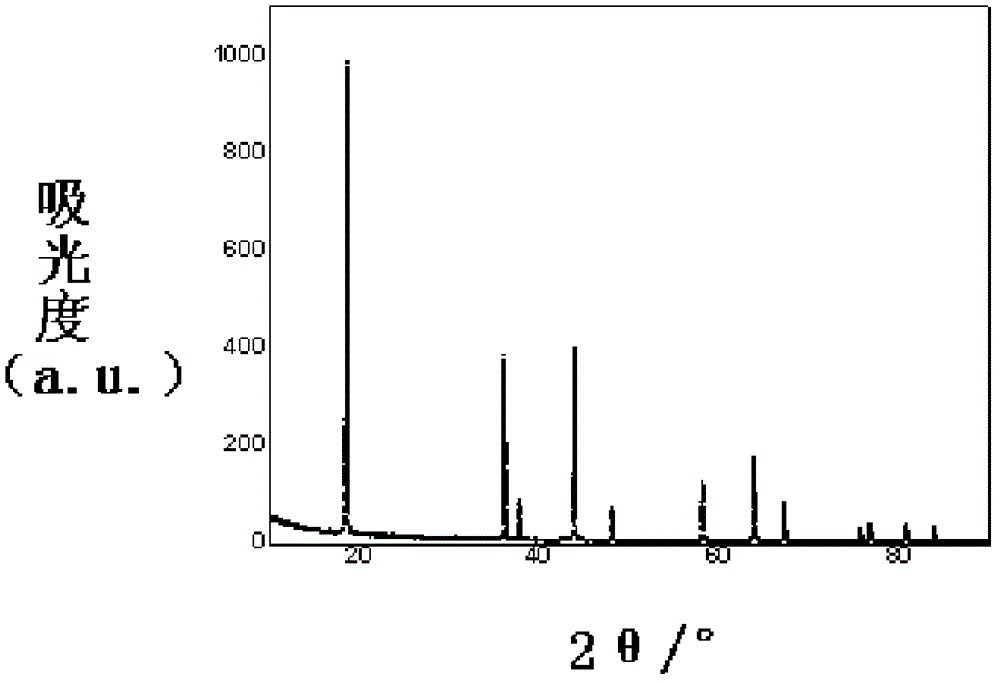

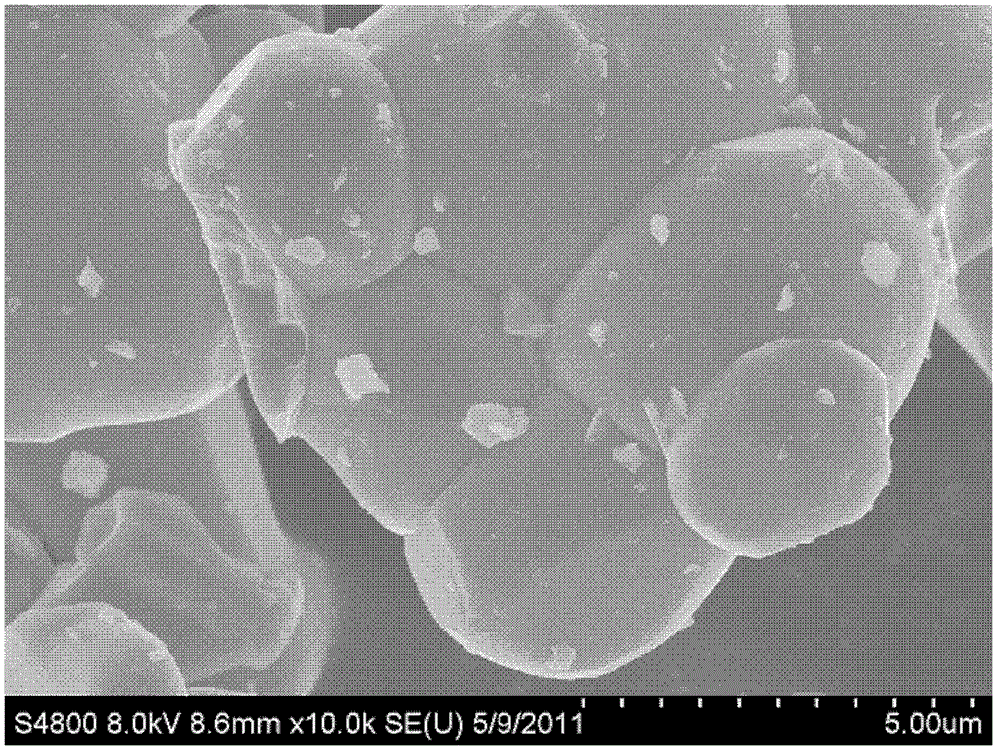

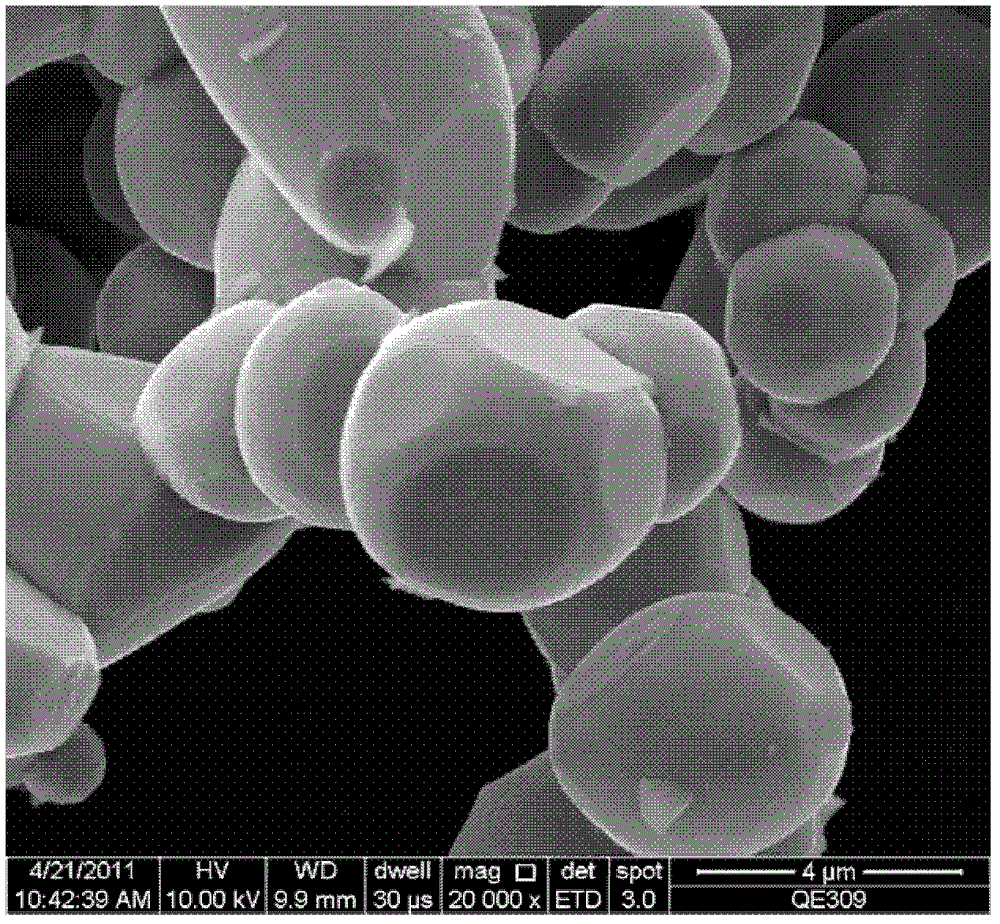

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of small specific surface area and poor filling performance of lithium manganese oxide materials, and achieve good high temperature cycle performance and filling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The present invention also provides a kind of preparation method of lithium-ion battery cathode material, comprises the following steps:

[0065] a) mixing the manganese-containing compound with a solvent to obtain a manganese-containing compound solution;

[0066] b) adding a precipitating agent to the manganese-containing compound solution obtained in step a) to obtain a precipitate, the precipitating agent being an alkali metal hydroxide solution, an alkali metal carbonate solution or an alkali metal bicarbonate solution;

[0067] c) roasting the precipitate obtained in step b) to obtain a positive electrode material precursor;

[0068] d) mixing the positive electrode material precursor, MnS and lithium-containing compound obtained in step c), roasting, and grinding to obtain a solid powder;

[0069] e) performing annealing treatment on the solid powder obtained in the step d) to obtain a positive electrode material for a lithium ion battery.

[0070] The inventi...

Embodiment 1~10

[0104] According to the raw materials, dosage and conditions shown in Table 1, the lithium manganese oxide material precursor was prepared according to the following steps:

[0105] Add a displacing agent to the manganese compound-containing solution, slowly add a precipitating agent dropwise under stirring conditions, adjust the pH value of the resulting mixed solution, and obtain a mixed precipitate after filtering; dry the mixed precipitate in a vacuum at 80°C 8h, the dried mixed precipitate was calcined in a tube furnace with an oxygen flow rate of 2mL / min to obtain a precursor of lithium manganese oxide material.

[0106] Table 1 The formula and conditions for preparing the precursor of lithium manganese oxide material in Examples 1-10 of the present invention

[0107]

[0108] According to the raw materials, dosage and conditions shown in Table 2, the lithium manganese oxide material was prepared according to the following steps:

[0109] Put the precursor of the lit...

Embodiment 11

[0133] 8g of the lithium manganese oxide material prepared in Example 1, 1g of acetylene black, 1g of polyvinylidene fluoride and 30g of N-methylpyrrolidone were mixed at normal temperature and pressure to form a slurry, which was uniformly coated on the surface of aluminum foil to obtain a pole piece; The pole pieces were dried at 80°C and pressed tightly, and cut into an area of 1.32cm 2 The circular sheet is used as the positive electrode, the pure lithium sheet is used as the negative electrode, and 1mol / L LiPF 6 A solution of ethylene carbonate (EC) and dimethyl carbonate (DMC) was used as the electrolyte, wherein the volume ratio of EC and DMC was 1:1, and a lithium-ion battery was assembled in an argon-filled glove box.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com