Multi-enzyme complex preparation containing microcapsule and preparation method and application thereof

A technology of microcapsules and complexes, applied in the application and treatment of tobacco, tobacco, etc., can solve the problems of reduced treatment effect and poor effect, and achieve the effects of increased sweetness, improved smoking quality, and coordinated ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

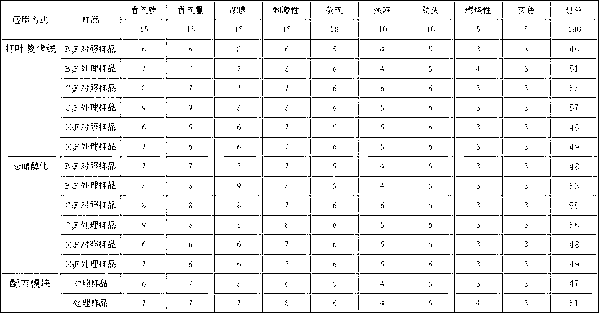

Examples

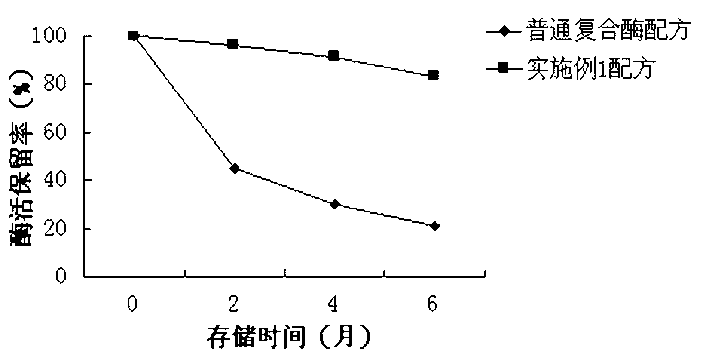

Embodiment 1

[0019] Prepare the following raw materials by weight percentage: amylase 20.7%, glucoamylase 10.3%, cellulase 8.6%, pectinase 10.9%, catalase 11.4%, laccase 6.4%, microencapsulated protease 9.3%, propylene glycol 7.5% %, 1% citric acid, 0.1% potassium sorbate, and the rest is water. Put amylase, glucoamylase, cellulase, pectinase, catalase, laccase, propylene glycol, citric acid, and potassium sorbate in water, stir to dissolve fully, and form an aqueous solution; then disperse the microencapsulated protease in In the above aqueous solution, a multi-enzyme complex preparation containing microcapsules is obtained.

[0020] The preparation process of microencapsulated protease is as follows: add maltodextrin wall material of 17% of the weight of the protease solution to the flavored protease solution, stir and mix evenly at 100r / min to obtain the wall material film-forming solution; then add the wall material film-forming solution 0.3% by weight of emulsifier distills monoglyce...

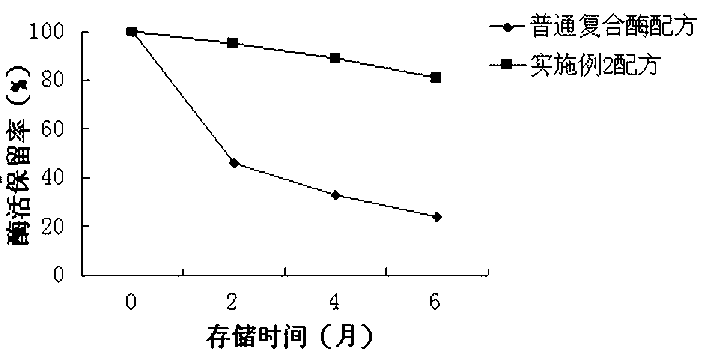

Embodiment 2

[0022] Prepare the following raw materials by weight percentage: amylase 22.9%, glucoamylase 11.3%, cellulase 9.8%, pectinase 12.5%, catalase 11.4%, laccase 6.4%, microencapsulated protease 12.5%, polyethylene Glycol 8%, sodium benzoate 0.2%, and the rest is water. Put amylase, glucoamylase, cellulase, pectinase, catalase, laccase, polyethylene glycol, sodium benzoate in water, stir to dissolve fully to form an aqueous solution; then disperse the microencapsulated protease in the above In the aqueous solution, the multi-enzyme complex preparation containing microcapsules can be obtained.

[0023] The preparation process of microencapsulated protease is as follows: add maltodextrin wall material of 23% of the weight of the protease solution to the neutral protease solution, stir and mix at a speed of 500r / min to obtain the wall material film-forming solution; then add the wall material film-forming solution 0.5% by weight of emulsifier distills monoglyceride, stirs and mixes e...

Embodiment 3

[0025] Prepare the following raw materials by weight percentage: amylase 21.5%, glucoamylase 8.4%, cellulase 9.8%, pectinase 11%, catalase 12.5%, laccase 8.1%, microencapsulated protease 8.6%, ethanol 0.2% %, ethyl hydroxybenzoate 0.5%, and the rest is water. Put amylase, glucoamylase, cellulase, pectinase, catalase, laccase, ethanol, and ethyl hydroxybenzoate in water, stir to dissolve fully to form an aqueous solution; then disperse microencapsulated protease in the above In the aqueous solution, the multi-enzyme complex preparation containing microcapsules can be obtained.

[0026] The preparation process of microencapsulated protease is as follows: add maltodextrin wall material of 20% of the weight of the protease solution to the flavored protease solution, stir and mix at a speed of 300r / min to obtain a wall material film-forming solution; then add the wall material film-forming solution 0.3% by weight of emulsifier distills monoglyceride, stirs and mixes evenly at 6000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com