Spinel nickel manganese-based oxide cathode material and preparation process thereof

A cathode material, a nickel-manganese-based technology, applied in the field of spinel nickel-manganese-based oxide cathode materials and their preparation, can solve the problems of being unsuitable for industrial production, increasing production costs, harsh reaction conditions, etc., and achieving a good high-temperature cycle performance, reduce surface energy, and improve the effect of high temperature cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing a spinel nickel-manganese-based oxide cathode material, comprising the following steps:

[0046] a) Pretreatment after mixing the manganese-containing compound, nickel-containing compound, lithium-containing compound and M-containing compound uniformly, and cooling and grinding to obtain a lithium nickel manganese oxide precursor; the M-containing compound is a Mg-containing compound, an Al-containing compound, a Ti compound, V-containing compound, Cr-containing compound, Mn-containing compound, Fe-containing compound, Co-containing compound, Ni-containing compound, Cu-containing compound, Zr-containing compound, Nb-containing compound, Ag-containing compound, Sn-containing compound, Ce-containing compound , one or more of Nd-containing compounds, Ta-containing compounds, W-containing compounds, Pt-containing compounds and Au-containing compounds;

[0047] b) roasting the lithium nickel manganese oxide precursor...

Embodiment 1~10

[0064] According to the raw materials and dosage shown in Table 1, according to the treatment conditions shown in Table 2, the spinel nickel-manganese-based oxide positive electrode material was prepared according to the following steps:

[0065] Mix the manganese-containing compound, the nickel-containing compound, the lithium-containing compound and the M-containing compound uniformly before pretreatment, cool and grind to obtain a lithium nickel manganese oxide precursor; then roast the obtained lithium nickel manganese oxide precursor, cool and grind to obtain a solid powder; and annealing the obtained solid powder, cooling and grinding to obtain the spinel nickel-manganese-based oxide positive electrode material.

Embodiment 1

[0068] Table 2 The processing conditions for the preparation of spinel nickel-manganese-based oxide positive electrode materials in Examples 1-10 of the present invention

[0069]

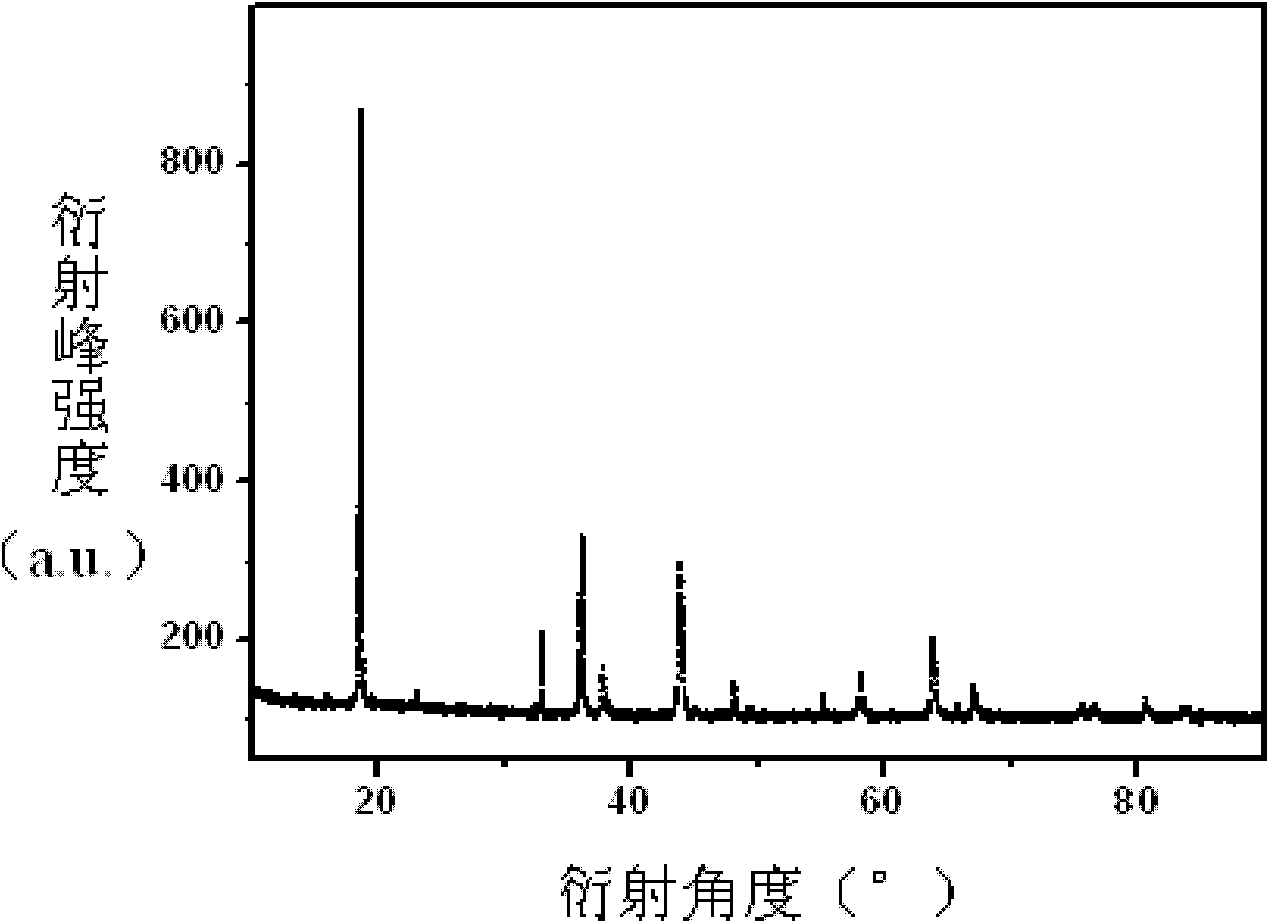

[0070] The spinel nickel-manganese-based oxide positive electrode material prepared in each embodiment was analyzed by X-ray diffraction using a polycrystalline diffractometer from Bruker, Germany. The CuKα line was used as the light source, and the diffraction angle 2θ was from 10° to 90°. For the results, see figure 1 , figure 1 The X-ray diffraction pattern of the spinel nickel-manganese-based oxide positive electrode material provided by Example 1 of the present invention is obtained by figure 1 It can be seen that the spinel nickel-manganese-based oxide positive electrode material prepared in Example 1 of the present invention has a standard positive spinel (FD-3M) cubic structure and no impurity phase. The spinel nickel-manganese-based oxide cathode materials prepared in Examples 2-10 all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com