High-nickel ternary positive electrode material with single crystal morphology and preparation method of high-nickel ternary positive electrode material

A positive electrode material, high-nickel technology, applied in the field of high-nickel ternary positive electrode materials and its preparation, can solve the problems of doping or complex sintering process, low secondary particle structure strength, material charge and discharge performance deterioration, etc., to ensure Doping and coating effects, which are conducive to large-scale industrial production and the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

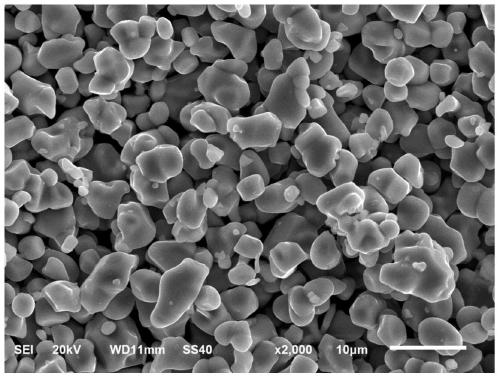

[0088] 1mol small particle nickel cobalt manganese precursor Ni 0.83 co 0.12 mn 0.05 (OH) 2 , D50: 3.5 μm, mixed with 1.06mol lithium hydroxide, added 0.004mol magnesium oxide and 0.002mol titanium dioxide, and mixed for 15 minutes using a high-speed mixer to obtain a mixture;

[0089] The above mixture was sintered at 850°C for 8 hours in an atmosphere with an oxygen concentration of 97%, mechanically pulverized, sieved and iron removed after cooling, and the sample after iron removal was washed with water for 5 minutes (solid-to-liquid ratio was 1:1) and placed in Dry at 180°C for 10 hours;

[0090] Get 100g of dried product and mix evenly with 0.2g of alumina;

[0091] Secondary sintering at 800°C for 8 hours in an atmosphere with an oxygen concentration of 97%, mechanically crushing after cooling, to obtain a high-nickel ternary positive electrode material with a single crystal morphology, the high-nickel ternary positive electrode material is expressed as Li 1.06 Ni ...

Embodiment 2

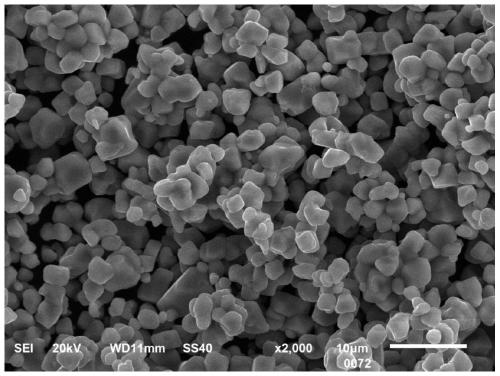

[0094] 1mol small particle nickel cobalt manganese precursor Ni 0.88 co 0.08 mn 0.04 (OH) 2 , where D50: 3.8 μm, mixed with 1.05mol lithium hydroxide, added 0.004mol magnesium oxide and 0.002mol boron oxide and mixed for 15 minutes using a high-speed mixer;

[0095] The above mixture was sintered at 800°C for 10 hours in an atmosphere with an oxygen concentration of 97%, mechanically pulverized, sieved and iron removed after cooling, and the sample after iron removal was washed with water for 10 minutes (solid-to-liquid ratio was 1:1) and placed in Dry at 180°C for 12 hours;

[0096] Take the dried product 100g and mix evenly with 0.2g alumina;

[0097] The above mixture was sintered for the second time at 800° C. for 8 hours in an atmosphere with an oxygen concentration of 97%, and mechanically pulverized after cooling to obtain a high-nickel ternary positive electrode material with a single crystal morphology, and the obtained high-nickel ternary positive electrode mater...

Embodiment 3

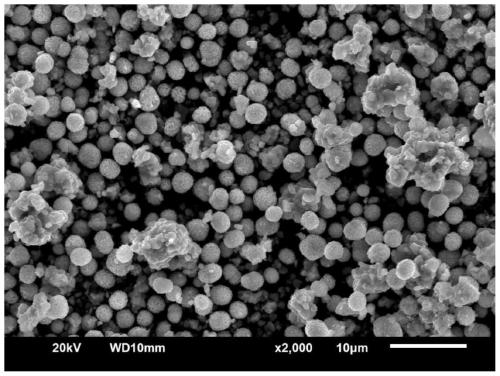

[0100] 1mol small particle nickel cobalt manganese precursor Ni 0.95 co 0.02 mn 0.03 (OH) 2 , wherein D50: 4.2 μm, mixed with 1.03mol lithium hydroxide, added 0.003mol magnesium oxide and 0.002mol alumina, and mixed for 15 minutes using a high-speed mixer to obtain a mixture;

[0101] The above mixture was sintered at 950° C. for 6 hours in an atmosphere of 97% oxygen concentration, mechanically pulverized, sieved and iron removed after cooling, and the sample after iron removal was washed with water for 10 minutes (solid-to-liquid ratio was 1:1) and placed in Dry at 190°C for 10 hours;

[0102] Get 100g of dried product and mix evenly with 0.3g of titanium oxide;

[0103] Secondary sintering at 900° C. for 8 hours in an atmosphere with an oxygen concentration of 97%, mechanically crushing after cooling, to obtain a high-nickel ternary positive electrode material with a single crystal morphology, and the average particle size of the particles is 4.6 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com