Method for preparing monodispersed silver powder with high tap density and low agglomeration

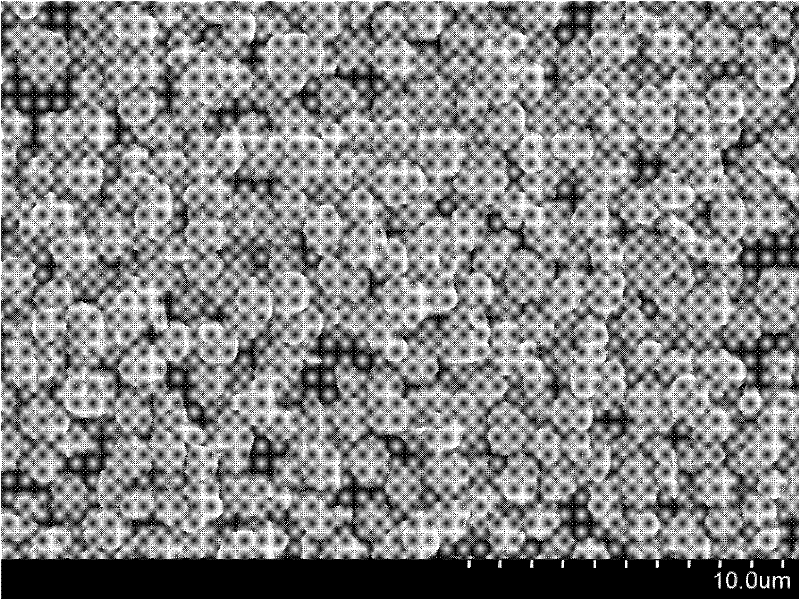

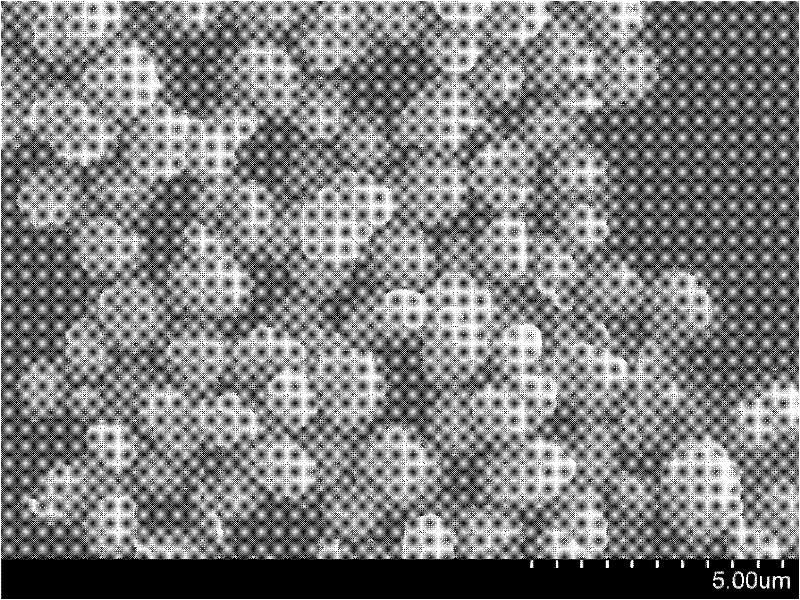

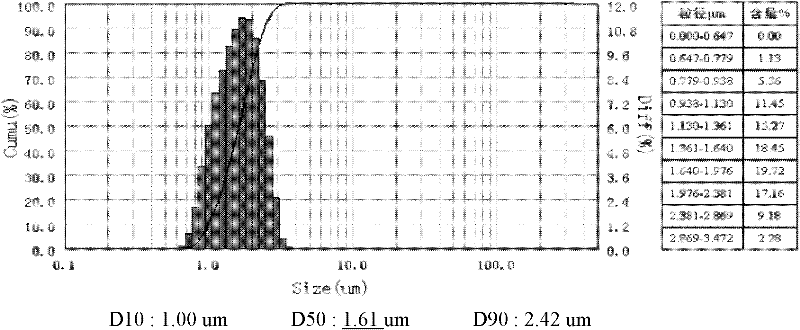

A monodisperse, silver powder technology is applied in the field of preparation of monodisperse high-tapping and low-agglomeration silver powder, which can solve the problems of complex process and difficulty in industrial production, and achieve the effects of high particle sphericity, narrow particle size dispersion range and high tap density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] For the reaction vessels, stirring paddles, etc. used, at 85°C, Na 3 PO 4 80g / L, Na 2 CO 3 120g / L, NaOH 120g / L, H 2 o 2 30ml / L solution for 15min, then rinse with deionized water.

[0021] Prepare an acidic silver salt solution, in which silver nitrate is 0.25mol / L. Prepare mixed reducing solution. L-ascorbic acid 0.13mol / L, polyethylene glycol (2000) 2.5×10 -4 mol / L and potassium nitrate 0.03g / L were prepared with deionized water to prepare a mixed reducing solution. Finally, adjust the pH of the mixed reducing solution to 1. While stirring the mixed reducing solution at a low speed, quickly mix the acidic silver salt solution and the mixed reducing solution uniformly for reaction, control the reaction temperature at 20° C., and the reaction time is 5 minutes. Post-treatment is performed on the reacted silver powder. After settling for 3 hours, the supernatant reaction solution was poured out, and then the precipitated silver powder was washed with deioniz...

Embodiment 2

[0024] For the reaction vessels, stirring paddles, etc. used, at 90°C, Na 3 PO 4 90g / L, Na 2 CO 3 100g / L, NaOH 130g / L, H 2 o 2 40ml / L solution for 20min, then rinse with deionized water.

[0025] Prepare an acidic silver salt solution, in which silver nitrate is 0.30mol / L. Prepare mixed reducing solution. L-ascorbic acid 0.18mol / L, gelatin 3.0×10 -3 mol / L and potassium carbonate 0.05g / L were prepared with deionized water to prepare a mixed reducing solution. Finally, adjust the pH of the mixed reducing solution to 0.5. While stirring the mixed reducing solution at a low speed, quickly mix the acidic silver salt solution and the mixed reducing solution evenly for reaction, control the reaction temperature at 25° C., and the reaction time is 6 minutes. Post-treatment is performed on the reacted silver powder. After 4 hours of sedimentation, the supernatant reaction solution was poured out, and then the precipitated silver powder was washed with deionized water until...

Embodiment 3

[0028] For the reaction vessels, stirring blades, etc. used, at 80°C, Na 3 PO 4 100g / L, Na 2 CO 3 130g / L, NaOH 150g / L, H 2 o 2 35ml / L solution for 25min, then rinse with deionized water.

[0029] Prepare an acidic silver salt solution, in which silver nitrate is 0.40mol / L. Prepare mixed reducing solution. 0.22 mol / L of L-ascorbic acid, 0.052 mol / L of ammonium stearate, and 0.7 g / L of potassium sulfate were prepared with deionized water to prepare a mixed reducing solution. Finally, adjust the pH of the mixed reducing solution to 0.3. While stirring the mixed reducing solution at a low speed, quickly mix the acidic silver salt solution and the mixed reducing solution uniformly for reaction, control the reaction temperature at 30° C., and the reaction time is 8 minutes. Post-treatment is performed on the reacted silver powder. After 4 hours of sedimentation, the supernatant reaction solution was poured out, and then the precipitated silver powder was washed with deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com