Long-cycle natural graphite-based modified composite material as well as preparation method and application thereof

A composite material and natural graphite technology, which is applied in the field of long-cycle natural graphite-based modified composite materials and their preparation, can solve problems such as complicated procedures, and achieve the effects of cost reduction and excellent high-temperature cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

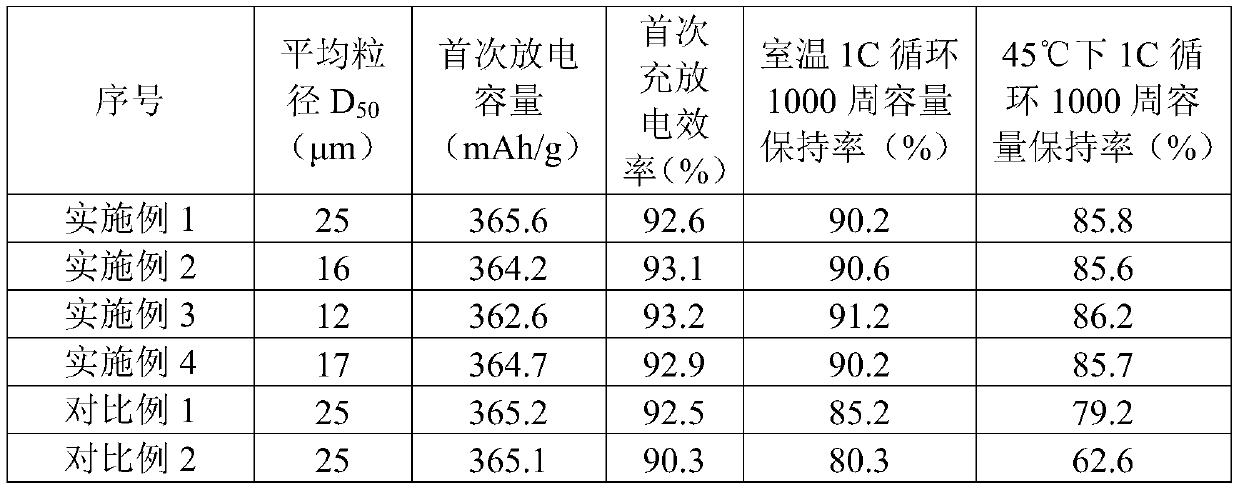

Examples

Embodiment 1

[0045] Weigh 12kg of petroleum pitch, whose physical and chemical indicators are 60% residual carbon value and 180°C softening point, heat the pitch to 220°C, weigh 100kg of natural flake graphite (150 μm) with a carbon mass content of 92.5%, and add it to the molten petroleum pitch , after stirring for 30 minutes, cooled to room temperature, then the cooled product was pulverized in a jet mill to D 50 was 27 μm, and material A was obtained.

[0046] Pass hot air at 160°C into the cavity of the shaping machine, put material A into the shaping machine for shaping, and obtain D 50 25 μm spherical graphite, then graphitized at 2800°C for 3 hours, cooled to room temperature, dispersed and sieved to obtain material B.

[0047] The isotropic pitch with a softening point of 240°C (coking value 60%) was crushed to 3 μm in an impact mill, and mixed with the above-mentioned material B at a mass ratio of 1.5:100. 2 Treat at 1200°C under protection for 4 hours, cool to room temperature,...

Embodiment 2

[0049] Take by weighing coal tar pitch 10kg, its physical and chemical index is residual carbon value 50%, 150 ℃ of softening points, pitch is heated to 180 ℃, weighs 100 kg of natural flake graphite (180 μ m) of carbon mass content 85.0% and joins in the coal pitch of melting, After stirring for 40 minutes, cool to room temperature, and then pulverize the cooled product in a jet mill until D 50 was 17 μm, and material A was obtained.

[0050] Pass hot air at 130°C into the cavity of the shaping machine, put material A into the shaping machine for shaping, and obtain D 50 Spherical graphite of 16 μm, then graphitized at 3000°C for 6 hours, cooled to room temperature, dispersed and sieved to obtain material B.

[0051] Isotropic asphalt (coking value 64%) with a softening point of 220°C was crushed to 3 μm in an impact mill, and mixed with the above-mentioned material B at a mass ratio of 1.0:100. 2 Treat at 1100°C under protection for 6 hours, cool to room temperature, dispe...

Embodiment 3

[0053] Take by weighing petroleum pitch 15kg, its physical and chemical index is residual carbon value 70%, 200 ℃ of softening points, pitch is heated to 220 ℃, weighs 90.0% natural flake graphite (180 μ m) of carbon mass content 100kg and joins in the petroleum pitch of melting, After stirring for 60 minutes, cool to room temperature, and then pulverize the cooled product in a jet mill until D 50 was 13 μm, and material A was obtained.

[0054] Pass hot air at 180°C into the cavity of the shaping machine, put material A into the shaping machine for shaping, and obtain D 50 12 μm spherical graphite, then graphitized at 3000°C for 3 hours, cooled to room temperature, dispersed and sieved to obtain material B.

[0055] Isotropic asphalt (coking value 72%) with a softening point of 200°C was crushed to 3 μm in an impact mill, mixed with the above-mentioned material B at a mass ratio of 0.8:100, and the 2 Treat at 1200°C under protection for 4 hours, cool to room temperature, di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com