Nonaqueous electrolyte battery and battery pack

A non-aqueous electrolyte and battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high temperature cycle life and safety reduction, and achieve the effect of excellent high temperature cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0015] According to the first embodiment, there is provided a non-aqueous electrolyte battery including a positive electrode, a negative electrode, and a non-aqueous electrolyte. Positive electrode includes LiNi x M 1-x O 2 Represents a lithium metal oxide in which M is a metal element including Mn, and x is in the range of 0.5≦x≦1. The negative electrode includes graphitized material particles and layers. The interplanar spacing derived from (002) reflection of the graphitized material particles is 0.337 nm or less according to the X-ray diffraction method. The layer includes titanium-containing oxide. The layer covers at least part of the surface of the graphitized material particles (hereinafter referred to as the covering layer).

[0016] LiNi x M 1-x O 2 The represented lithium metal oxide has high capacity (high energy density) and excellent thermal stability, where M is a metal element including Mn, and x is in the range of 0.5≦x≦1. In addition, the interplanar spacing ...

no. 2 approach

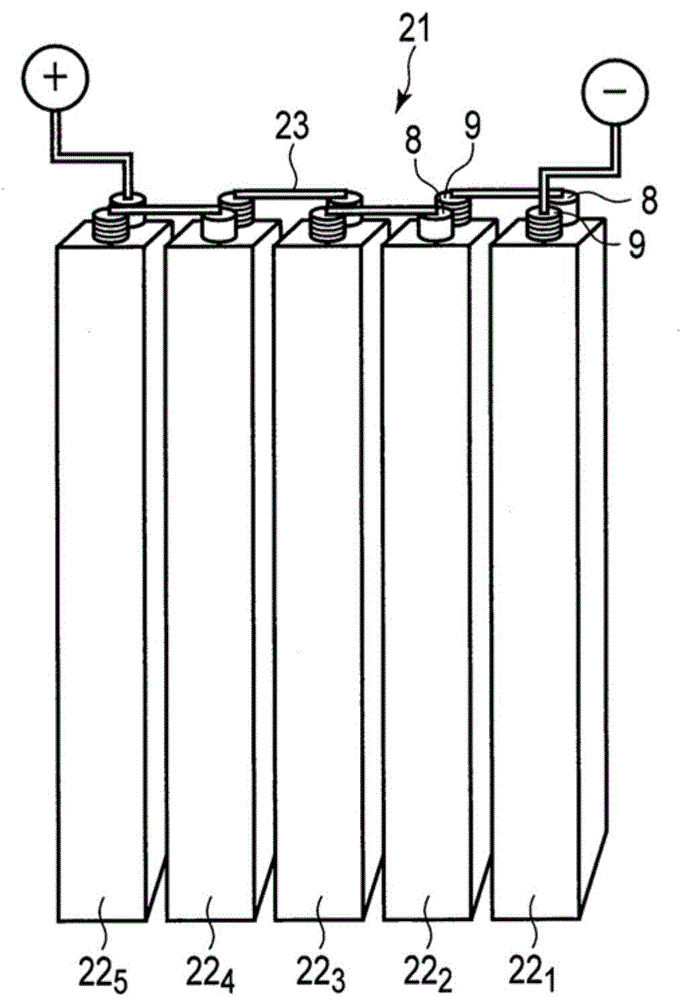

[0092] The battery pack according to the second embodiment includes one or more non-aqueous electrolyte batteries according to the first embodiment. The battery pack may further include a battery module composed of a plurality of batteries. The batteries may be connected in series or in parallel with each other, but are preferably connected in series and n times (n is an integer greater than or equal to 1) of 6 batteries in series.

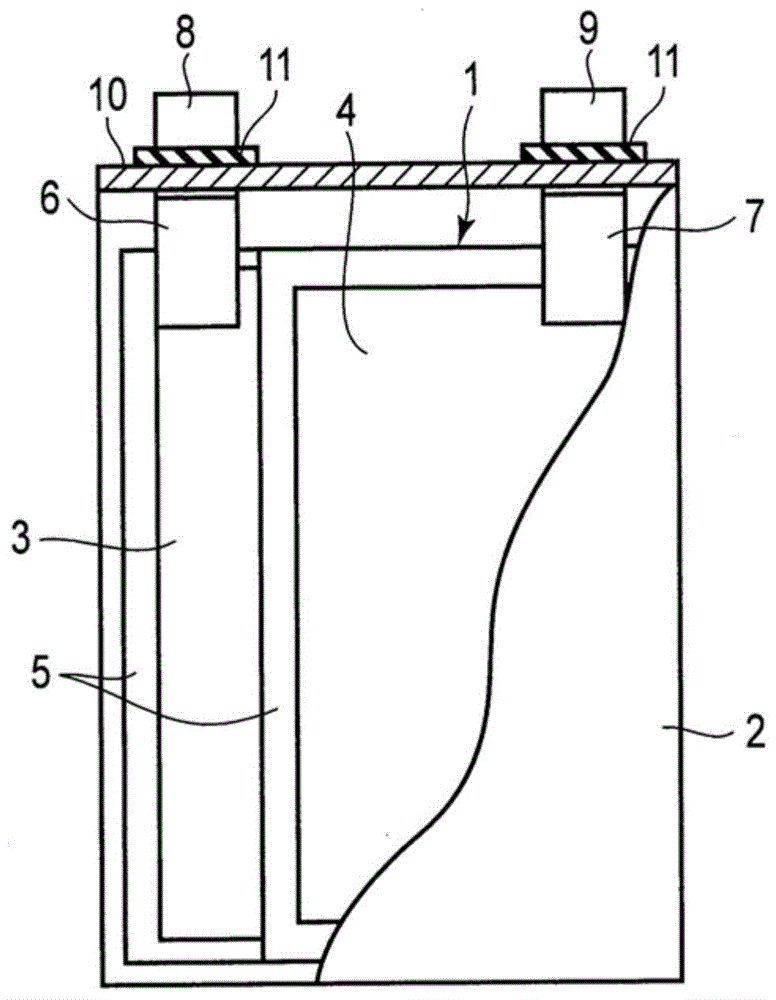

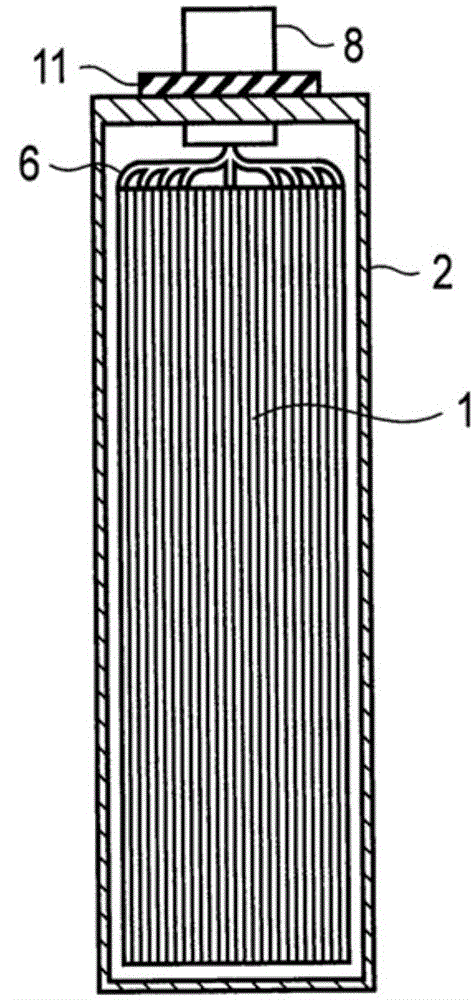

[0093] image 3 Shown is an embodiment of a battery module for a battery pack. According to the second embodiment, image 3 The battery module 21 shown includes a plurality of rectangular secondary batteries 22 1 -twenty two 5 . Secondary battery 22 1 The positive electrode lead lug 8 is electrically connected to the secondary battery 22 through the lead 23 1 Adjacent secondary battery 22 2 的 negative lead electrode lug 9. In addition, the secondary battery 22 2 The positive electrode lead lug 8 is connected to the secondary battery 22 through the ...

Embodiment 1

[0100] The positive electrode active material uses a layered structure of lithium nickel cobalt manganese oxide (LiNi 0.8 Co 0.1 Mn 0.1 O 2 ), the average particle size of the primary particles in the layered structure is 1 μm. With respect to the entire positive electrode, 5% by weight of the conductive agent acetylene black and 5% by weight of the binder PVdF are added to the mixture. The obtained mixture was dispersed in N-methylpyrrolidone (NMP) solvent to prepare a slurry. Then, the slurry was coated on both sides of a 15μm thick aluminum alloy foil (purity of 99%), and then dried to form a positive electrode material layer with an electrode density of 3.3g / cm by pressing 3 The thickness of each positive electrode material layer is 38μm.

[0101] As the negative electrode active material, according to X-ray diffraction method, (002) crystal plane spacing d 002 Is 0.3358nm, and (I r / I h ) Is 0.1 of artificial graphite powder added to the dissolved Ti(OC 3 H 7 ) 4 In the etha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice spacing | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com