Negative electrode with high compaction, excellent high-temperature performance and high energy density and preparation method thereof

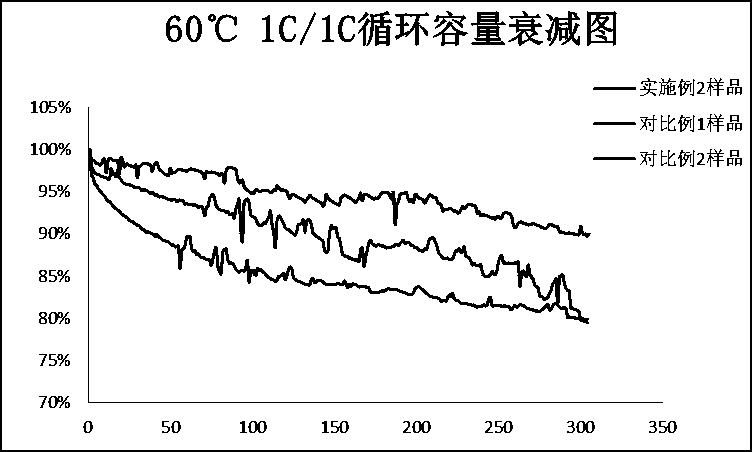

A high energy density, negative electrode material technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as poor solid performance, inability to repair internal defects of natural graphite, cycle performance attenuation, etc., to achieve high temperature cycle performance Poor, excellent high temperature cycle performance, the effect of high temperature cycle performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

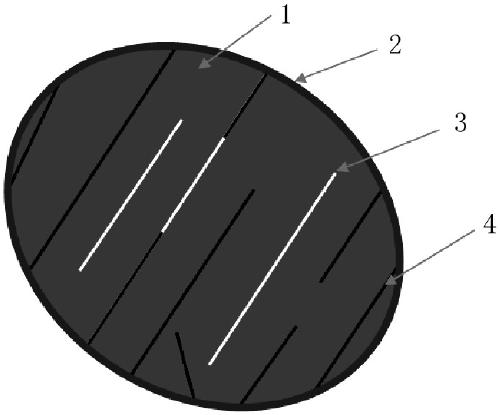

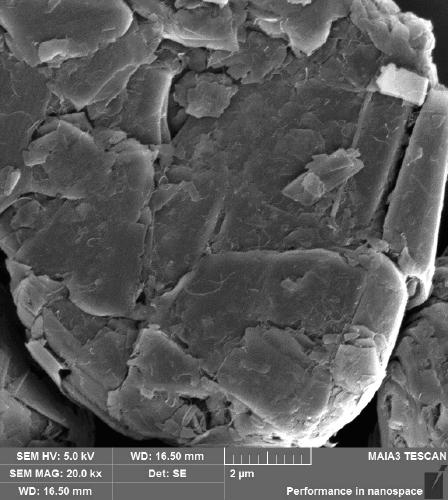

[0030] (1) Put the spherical natural graphite with an average particle size of 10 μm in the rotary furnace, adjust the rotating speed of the rotary furnace to 5r / min, fill it with nitrogen protective gas, raise the temperature to 900°C at 5.0°C / min, and then fill it with n-hexane and nitrogen The mixed gas, the volume of n-hexane accounts for 20% of the total gas volume, the gas flow rate is 2L / min, heat preservation for 2.0h, and natural cooling to room temperature to obtain the intermediate product of internal defect repair and surface deposition of pyrolytic carbon;

[0031] (2) The asphalt particles with a softening point of 120°C are pulverized by a jet mill until the average particle size is about 2 μm, and then the intermediate product and the asphalt particles are mixed at a mass ratio of 95:5, dispersed at high speed by VC, and then placed in a box Fill the furnace with nitrogen, raise the temperature to 1000.0°C at a heating rate of 5.0°C / min, keep the temperature for...

Embodiment 2

[0034] (1) Put the spherical natural graphite with an average particle size of 15 μm in the rotary furnace, adjust the rotating speed of the rotary furnace to 10r / min, fill it with argon protective gas, raise the temperature to 950 °C at 8.0 °C / min, and then fill it with cyclohexane The mixed gas with argon, cyclohexane accounts for 15% of the total gas volume, the flow rate is 2L / min, heat preservation for 3.0h, and naturally cooled to room temperature to obtain the intermediate product of internal defect repair and surface deposition of pyrolytic carbon;

[0035] (2) The intermediate product is crushed with a jet mill until the 150°C asphalt particles with an average particle size of about 3 μm are mixed at a mass ratio of 90:10, dispersed at high speed by VC, then placed in a box furnace, filled with nitrogen, and heated at 7.0 ℃ / min heating rate to 1200.0 ℃, heat preservation 8.0h, natural cooling to room temperature;

[0036] (3) Screening and demagnetization to obtain a ...

Embodiment 3

[0038] (1) Put the spherical natural graphite with an average particle size of 20 μm in the rotary furnace, adjust the rotating speed of the rotary furnace to 20r / min, fill in the nitrogen protection gas and raise the temperature to 1100°C at 10.0°C / min, and then fill in the mixture of methane and nitrogen Gas, methane accounts for 5% of the total gas volume, the flow rate is 5L / min, heat preservation for 5.0h, and naturally cool to room temperature to obtain the intermediate product of internal defect repair and surface deposition of pyrolytic carbon;

[0039] (2) Mix the intermediate product with the jet mill until the asphalt particles with an average particle size of about 5 μm and a softening point of 200°C are mixed at a mass ratio of 85:15, then dispersed at a high speed by VC, and then placed in a box furnace, fully charged Inject nitrogen, heat up to 1300.0°C at a heating rate of 10.0°C / min, keep warm for 10.0h, and cool down to room temperature naturally;

[0040] (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com