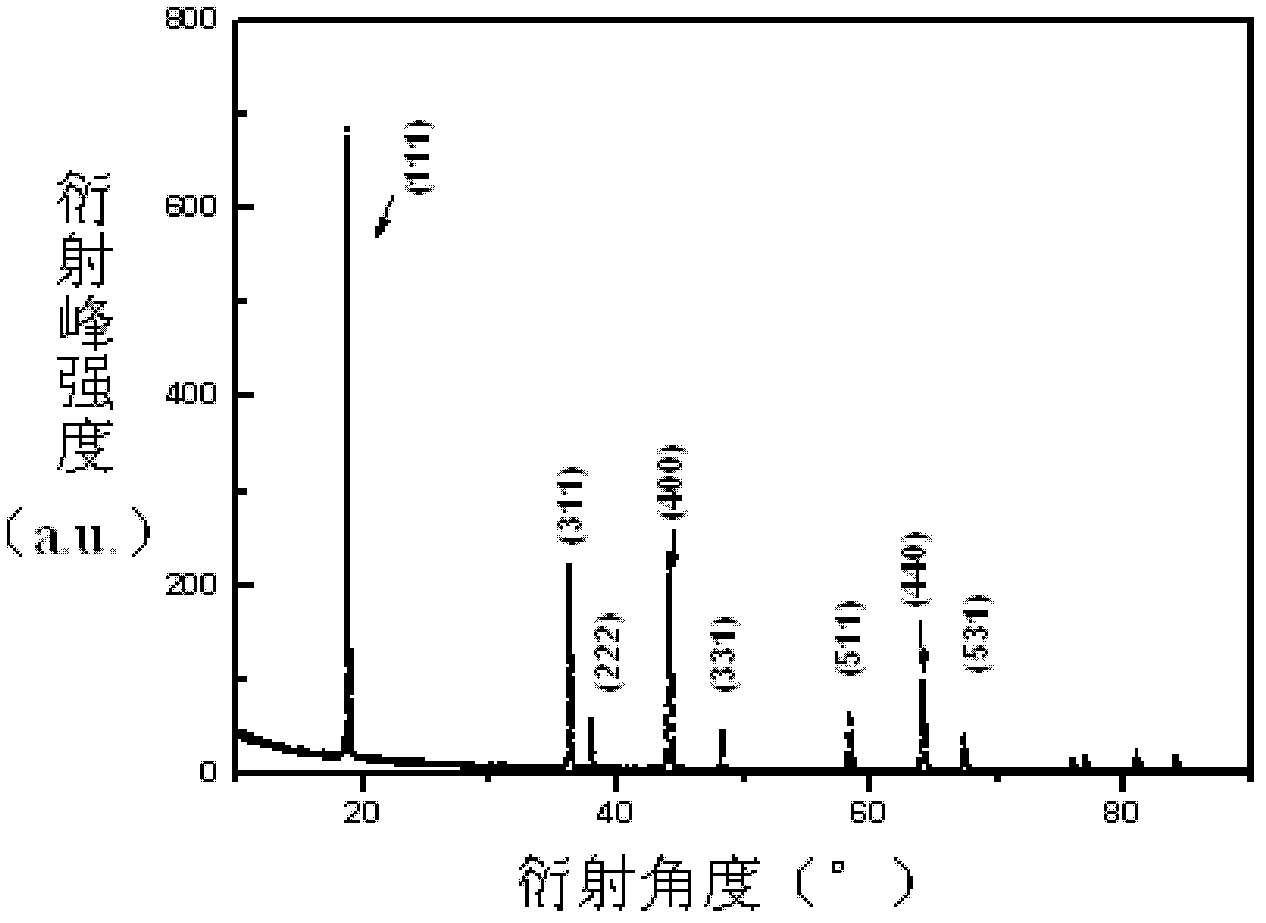

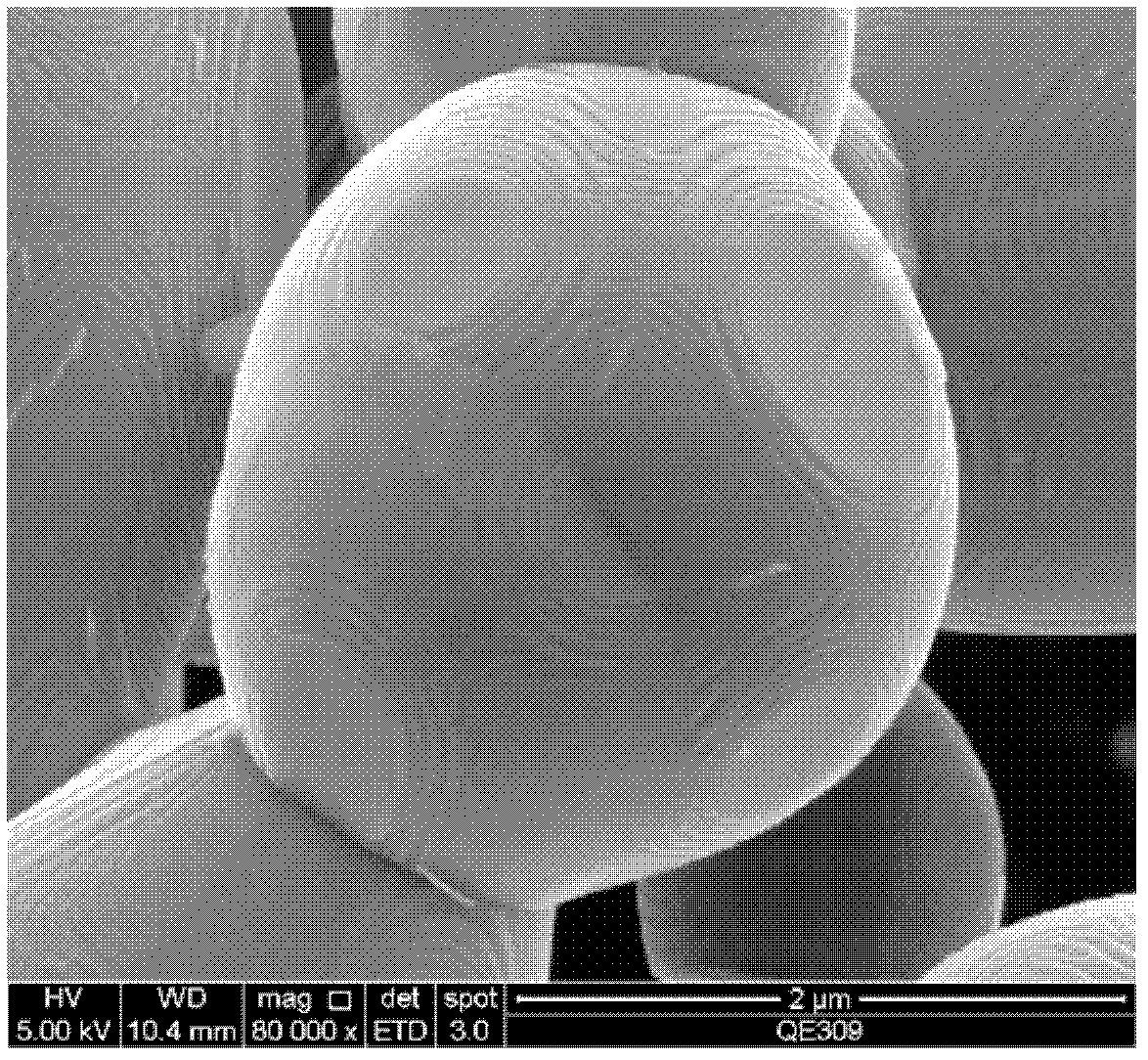

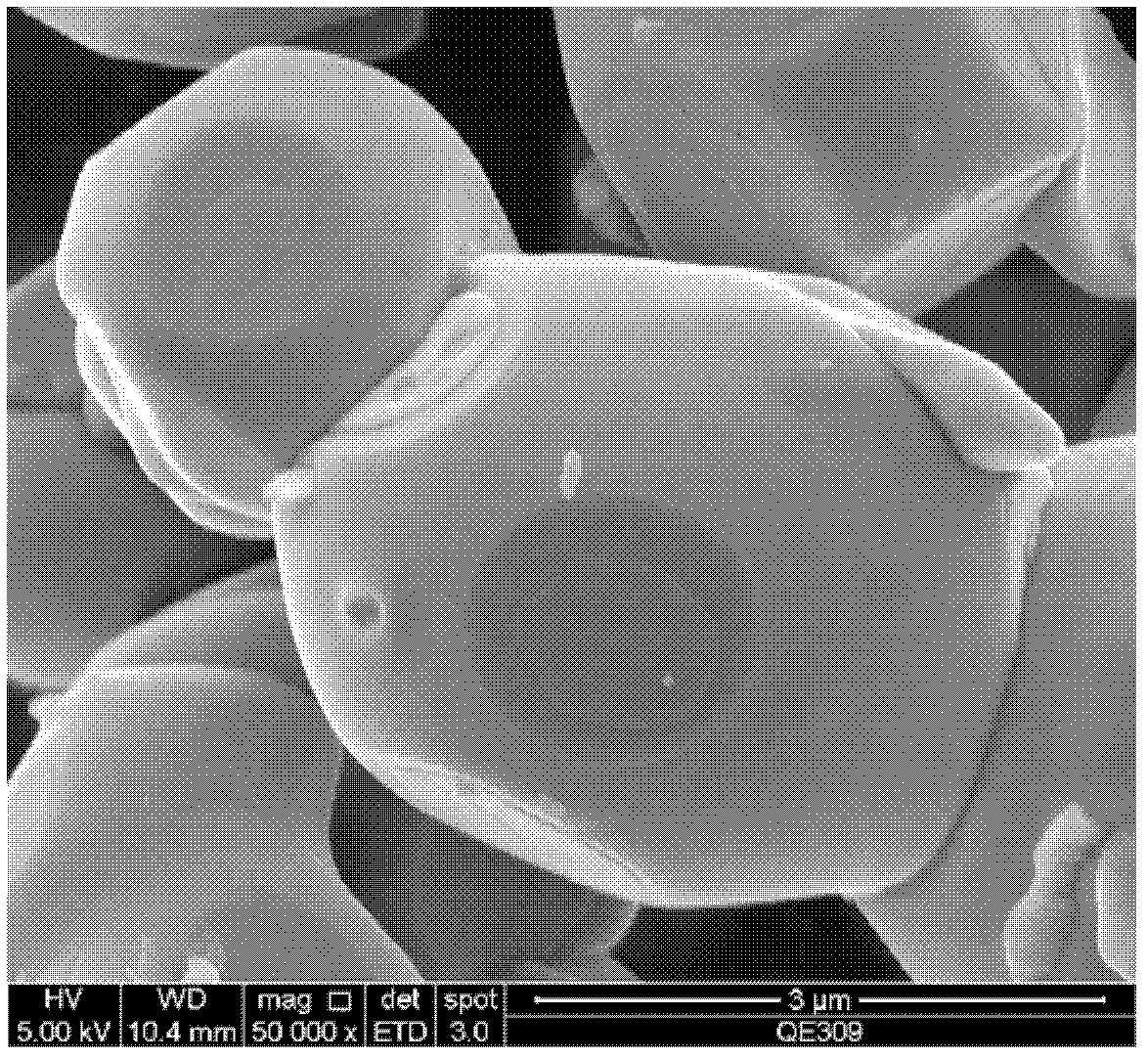

Cathode material of lithium ion battery and preparation method of cathode material

A technology for lithium-ion batteries and cathode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of high-temperature cycle performance and rate performance that need to be further improved, and achieve good high-temperature cycle performance, improve rate performance, and increase the number of products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Correspondingly, the present invention also provides a kind of preparation method of lithium-ion battery cathode material, comprises the following steps:

[0049] Manganese source compound, lithium source compound, M source compound and Z source compound are mixed uniformly and then pretreated, cooled and ground to obtain a lithium manganate precursor, M is Li, Mg, Al, Ca, Sc, Ti, V, Cr, One of Mn, Fe, Co, Ni, Cu, Zn, Ga, Ge, Zr, Nb, Mo, Ag, Sn, La, Ce, Nd, Hf, Ta, W, Pt, Au, Ru and Pb or Several kinds; Z is one or more of F, Cl, Br, I and Se;

[0050] The lithium manganate precursor is subjected to roasting treatment, and solid powder is obtained after cooling and grinding, and the way of the roasting treatment is to change the roasting temperature several times during the roasting process;

[0051] The solid powder is annealed, cooled and ground to obtain the positive electrode material of the lithium ion battery.

[0052] In the present invention, the manganese sou...

Embodiment 1~10

[0066] According to the raw materials, dosage and conditions shown in Table 1, the lithium manganate precursor was prepared according to the following steps:

[0067] The manganese source compound, the lithium source compound, the M source compound, the M source compound and the Z source compound are uniformly mixed, pretreated, cooled and ground to obtain a lithium manganate precursor.

[0068] Table 1 Preparation of lithium manganate precursor formula and conditions in Examples 1-10 of the present invention

[0069]

[0070]

[0071] Continuation of Table 1 Preparation of lithium manganate precursor formula and conditions in Examples 1 to 10 of the present invention

[0072]

[0073]

[0074] According to the raw materials, consumption and conditions shown in Table 2, the lithium manganate material was prepared according to the following steps:

[0075] The lithium manganate precursor is roasted several times, cooled and ground to obtain a solid powder; then the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com