Positive active material and preparation method and application thereof

A positive electrode active material and positive electrode material technology, applied in the field of positive electrode active materials, to achieve the effect of simple operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

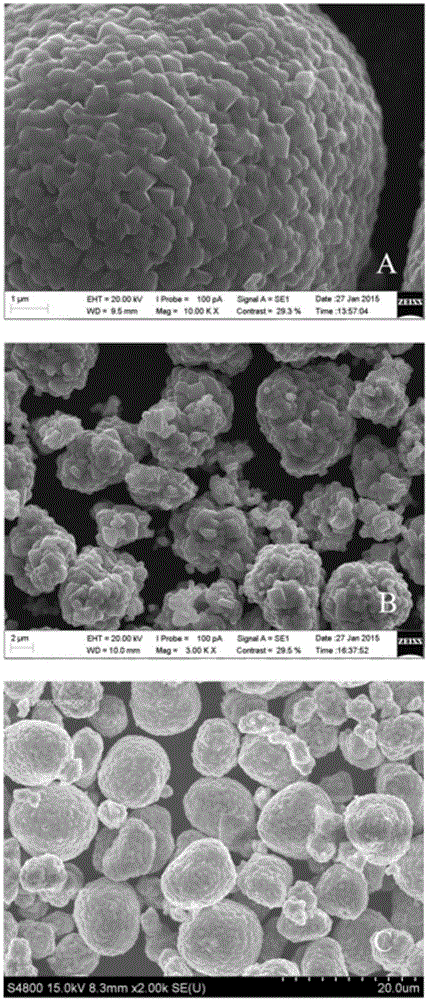

[0031] Positive electrode active material, made of nickel cobalt lithium aluminate LiNi 0.82 co 0.15 al 0.03 o 2 and lithium nickel cobalt manganese oxide LiNi 0.34 co 0.32 mn 0.34 o 2 Composition, in terms of mass percentage, is 78% of nickel-cobalt lithium aluminate and 22% of nickel-cobalt lithium manganese oxide. The grains of nickel-cobalt-lithium-aluminate are spherical, with a D50 of 13 μm, and the grains of nickel-cobalt-lithium manganate are spherical, with a D50 of 4 μm.

[0032] The preparation steps of the positive electrode active material are as follows: Accurately take nickel-cobalt lithium aluminate and nickel-cobalt lithium manganate according to the mass percentage, mix them, put them into a ball mill jar, and ball mill them at a speed of 100 rpm for 1.5 hours.

[0033] The positive electrode material is composed of the above-mentioned positive electrode active material, carbon black (conductive agent) and polyvinylidene fluoride (binder). In terms of ...

Embodiment 2

[0036] Positive electrode active material, made of nickel cobalt lithium aluminate LiNi 0.82 co 0.15 al 0.03 o 2 and lithium nickel cobalt manganese oxide LiNi 0.34 co 0.32 mn 0.34 o 2 Composition, in terms of mass percentage, is 70% of nickel-cobalt lithium aluminate and 30% of nickel-cobalt lithium manganese oxide. The grains of nickel-cobalt-lithium-aluminate are spherical, and the D50 is 10 μm, and the grains of nickel-cobalt-lithium manganate are spherical, and the D50 is 1 μm.

[0037] The preparation steps of the positive electrode active material are as follows: Accurately take nickel-cobalt lithium aluminate and nickel-cobalt lithium manganate according to the mass percentage, mix them, put them into a ball mill jar, and ball mill them at a speed of 120 rpm for 1 hour to obtain the product.

[0038] The positive electrode material is composed of the above-mentioned positive electrode active material, acetylene black and polyvinylidene fluoride. In terms of mass...

Embodiment 3

[0041] Positive electrode active material, made of nickel cobalt lithium aluminate LiNi 0.82 co 0.15 al 0.03 o 2 and lithium nickel cobalt manganese oxide LiNi 0.34 co 0.32 mn 0.34o 2 Composition, in terms of mass percentage, is 85% nickel-cobalt lithium aluminate and 15% nickel-cobalt lithium manganese oxide. The grains of nickel-cobalt-lithium-aluminate are spherical, with a D50 of 15 μm, and the grains of nickel-cobalt-lithium manganate are spherical, with a D50 of 6 μm.

[0042] The preparation steps of the positive electrode active material are as follows: Accurately take nickel-cobalt lithium aluminate and nickel-cobalt lithium manganate according to the mass percentage, mix them, put them into a ball mill jar, and ball mill them at a speed of 80 rpm for 2 hours to obtain the product.

[0043] The positive electrode material is composed of the above positive electrode active material, carbon black and polyvinylidene fluoride, in terms of mass percentage, the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com