Preparation method of coated lithium manganate

A technology of coating lithium manganese oxide and coating lithium manganate, which is applied in the field of materials, can solve the problems of high local current, uneven coating, and failure to reduce the contact between active material and electrolyte, and achieve good high-temperature cycle performance , Improve the stability and life of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

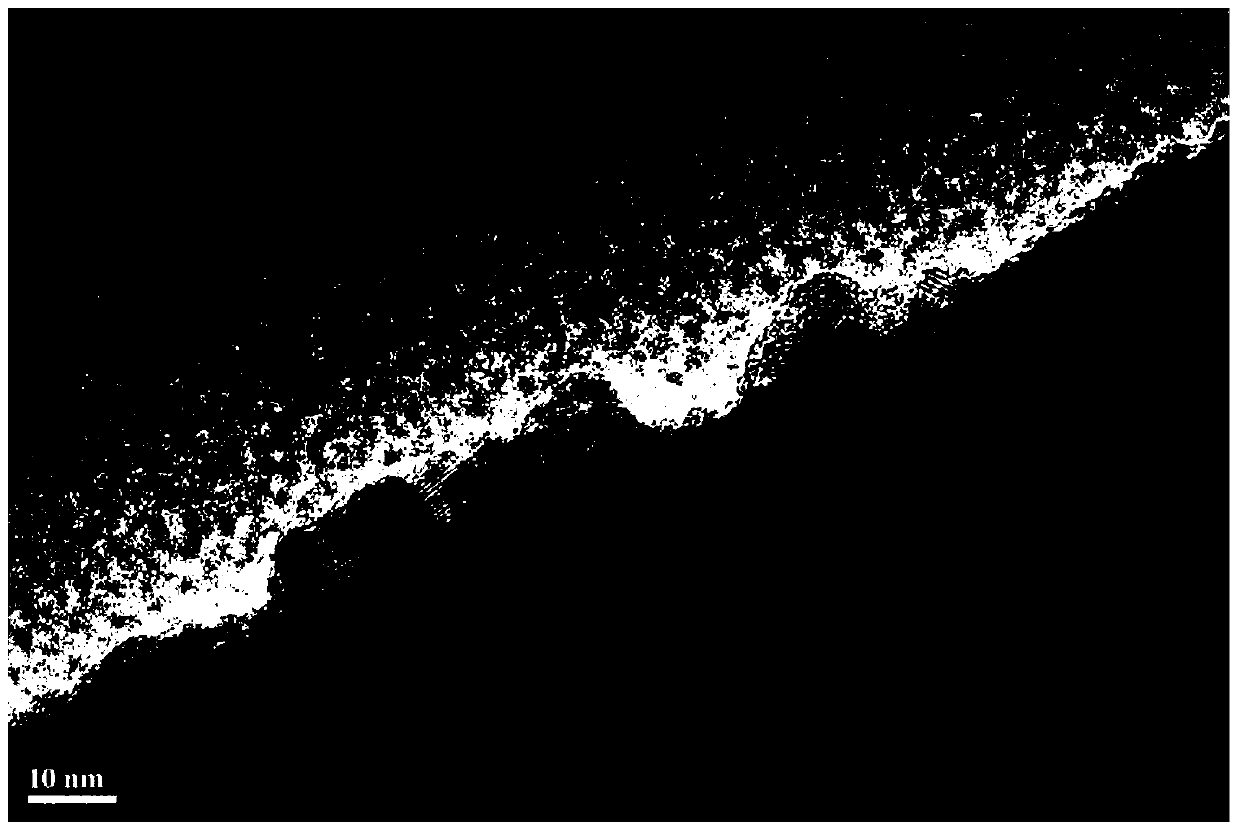

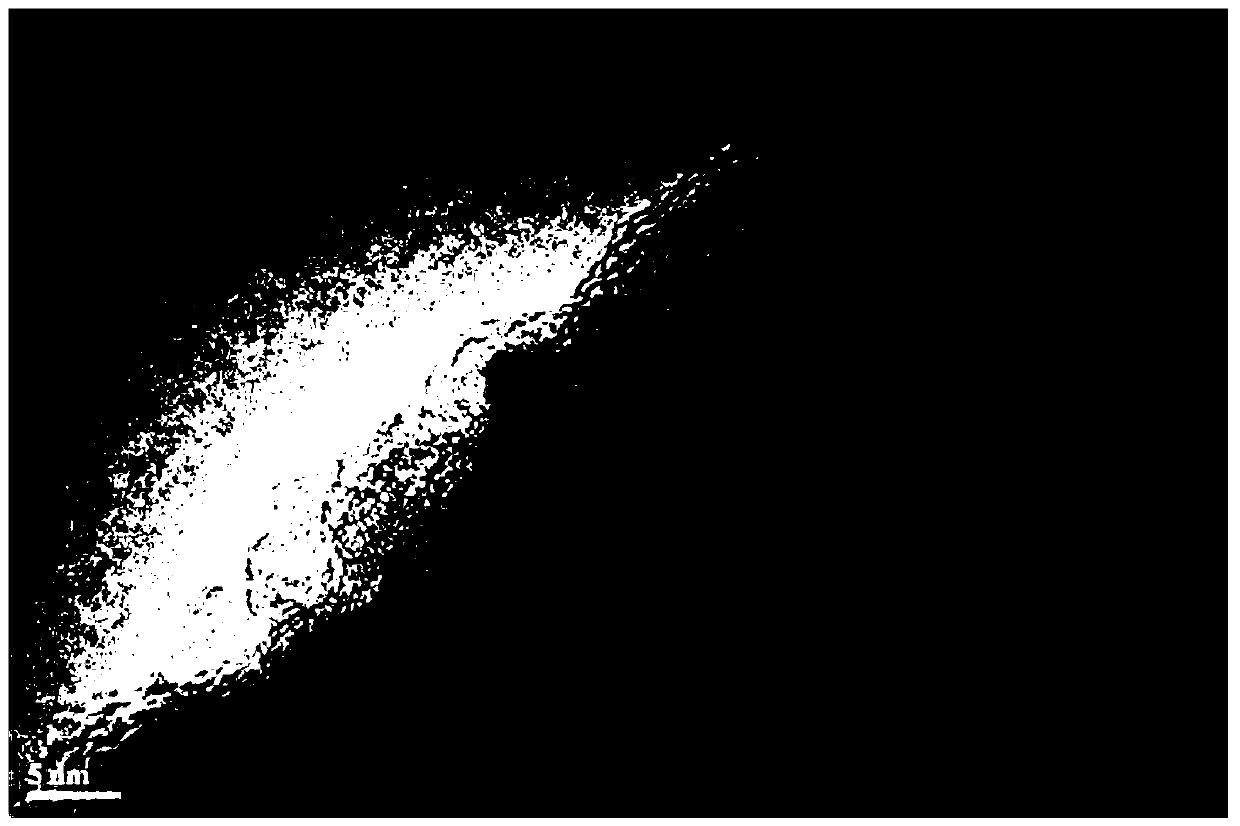

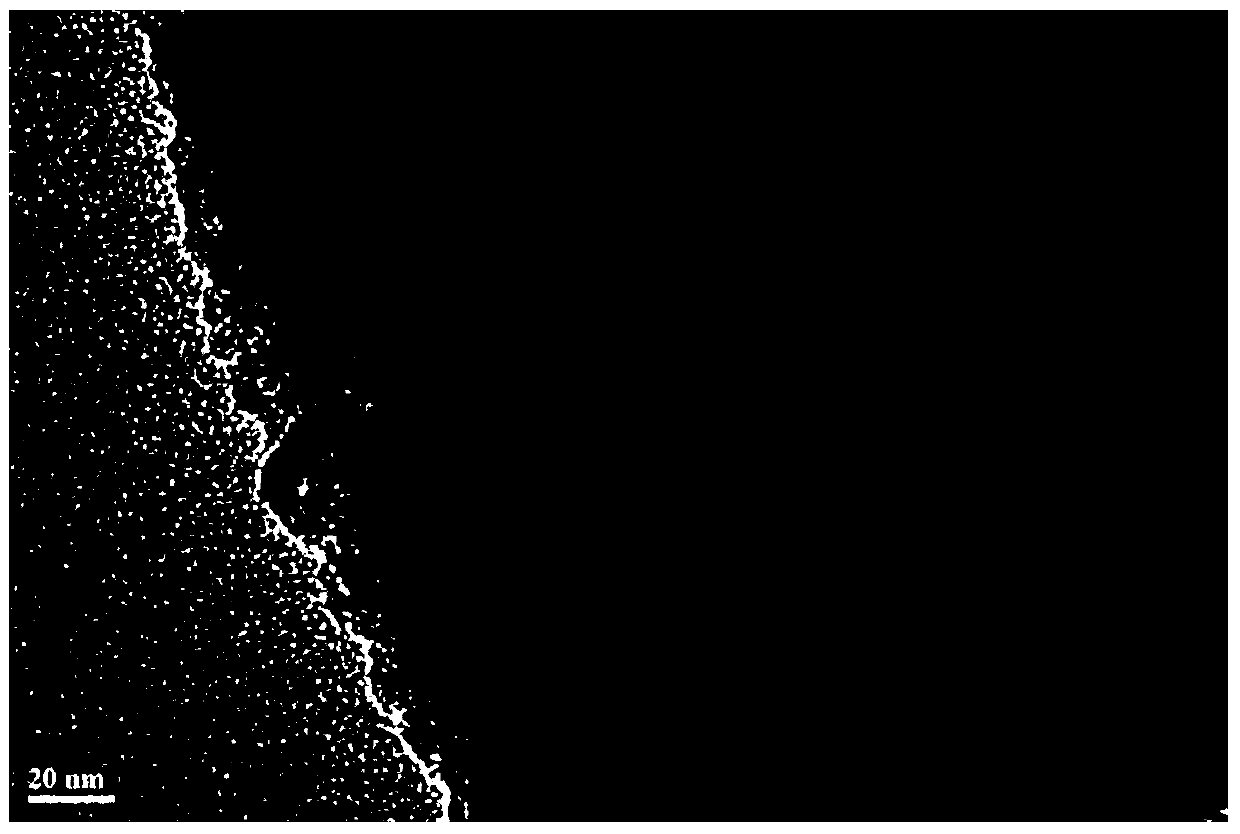

[0029] A method for preparing coated lithium manganate according to an embodiment of the present invention, comprising: preparing a metal oxide; adding lithium manganate to water, stirring and dispersing to form a suspension, and adjusting the pH of the suspension to 6-8; Add the prepared metal oxide into the suspension, stir for 0.8 to 1.5 hours to make it adsorb on lithium manganate LiMn 2 o 4 Surface: the product in step 3 is centrifugally washed and dried, and calcined to obtain metal oxide-coated lithium manganate.

[0030] The metal oxides used in the embodiments of the present invention are titanium dioxide, silicon dioxide, aluminum oxide, lanthanum oxide, or iron oxide. Titanium dioxide is preferred, including anatase titanium dioxide or rutile titanium dioxide of type A or type B.

[0031] Lithium manganate LiMn 2 o 4 Preferred is spinel lithium manganese oxide LiMn 2 o 4 , can also be doped with one or more other metal elements to form a doped compound LiMxMn2...

Embodiment 1

[0034] First, prepare a mixed solution of hydrogen peroxide and ammonia with a volume ratio of 2:1, add 200-300 mesh titanium powder to the above aqueous solution, and stir for one hour. Glycolic acid was then added to the solution, and stirred at 80° C. for two hours. Next, the above solution was transferred to a hydrothermal kettle and reacted at 160° C. for two hours. The prepared B-type titanium dioxide is centrifugally washed and dried for use.

[0035] The LiMn prepared by the traditional solid-phase method 2 o 4 Add to a certain amount of water, stir to disperse, and adjust the pH value of the solution to 6-8 with dilute sulfuric acid.

[0036] A certain amount of B-type titanium dioxide was added to the above suspension, and stirred for one hour. The prepared product was centrifugally washed and dried, and finally calcined at a low temperature (≤500°C) to prepare B-type titanium dioxide-coated spinel-type lithium manganate LiMn 2 o 4 .

Embodiment 2

[0038] First, prepare 50ml of 1mmol / L aluminum acetate aqueous solution, slowly drop 0.5-2mL of ammonia water into the solution, stir for one hour, then centrifugally wash and dry. Next, the solid powder is calcined in the air and kept at 160° C. for one hour.

[0039] LiMn prepared by traditional solid-phase method 2 o 4 Add to a certain amount of water, stir to disperse, and adjust the pH value of the solution to 6-8 with dilute sulfuric acid.

[0040] Add a certain amount of Al2O3 powder into the above suspension and stir for one hour. The prepared product is centrifugally washed and dried, and finally calcined at a low temperature (≤500°C) to prepare alumina-coated spinel-type lithium manganate LiMn 2 o 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com