Graphite-based composite material and preparation method thereof and lithium ion battery comprising the composite material

A technology for lithium-ion batteries and composite materials, applied in the fields of their preparation, lithium-ion batteries, and graphite-based composite materials, can solve the problems of short cycle life, large electrode expansion rate, large irreversible capacity loss, etc., to improve liquid absorption performance, Good cycle performance, high first effect and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

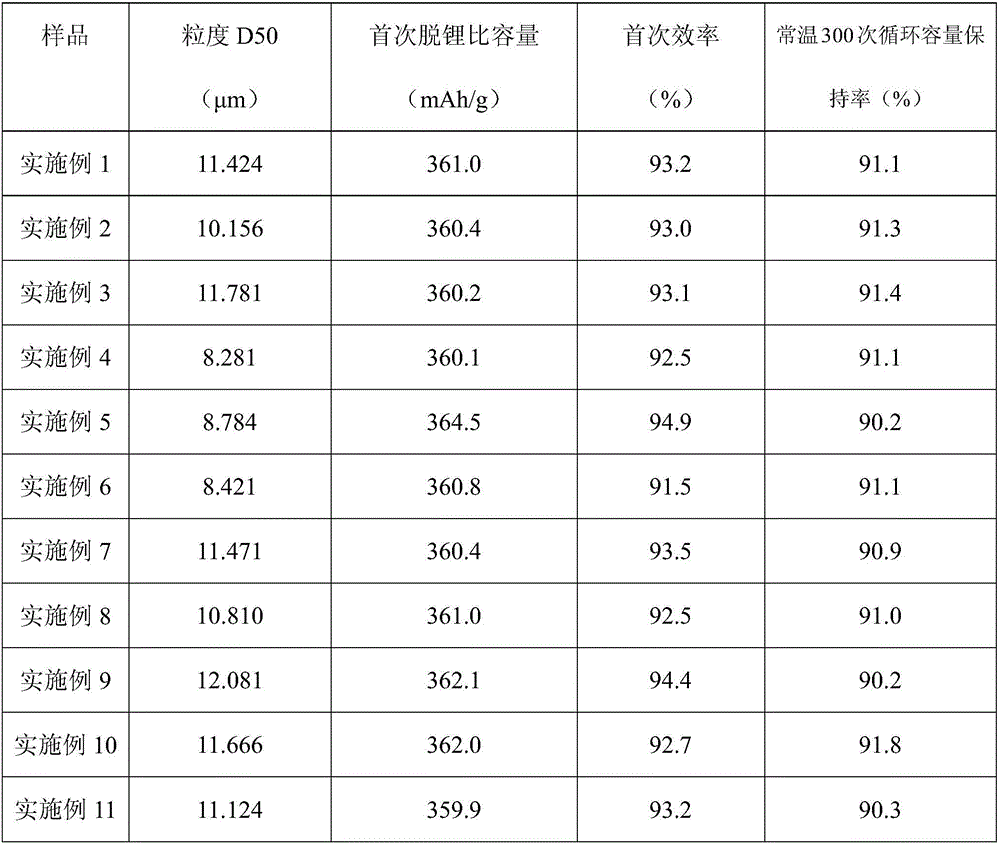

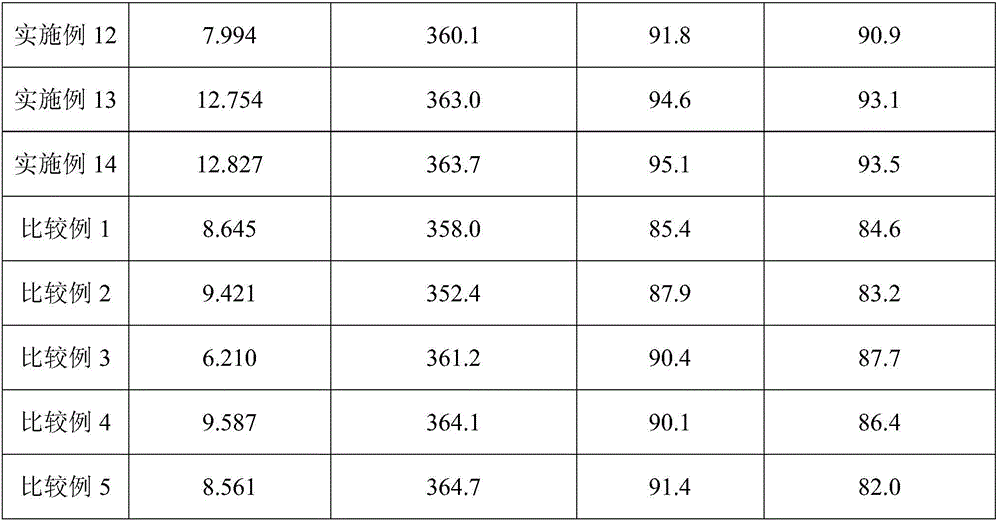

Examples

Embodiment 1

[0062] Natural spherical graphite (D50=6μm~8μm, S50=0.80~0.95) is placed in a rotary kiln, and oxygen is introduced, oxidized at 600°C for 2h, and the oxygen flow rate is 10L / h.kg to obtain oxidized natural graphite ( oxidized graphite). According to the mass ratio of 90:10, the oxidized graphite and petroleum pitch are mixed, and then 2 Under the atmosphere, place it in a fusion machine at 600°C for mechanical granulation. After 5 hours of mechanical granulation, cool the reaction product to room temperature, and then carbonize it at 1200°C to obtain a graphite-based composite material.

[0063] Electrochemical performance test:

[0064] The graphite-based composite material obtained in Example 1 was used as the negative electrode active material, mixed uniformly according to the mass ratio of negative electrode active material: CMC:SBR=96.5:1.5:2, and then placed on the copper foil current collector, dried and punched for later use.

[0065] Assembly of the button cell:

...

Embodiment 2

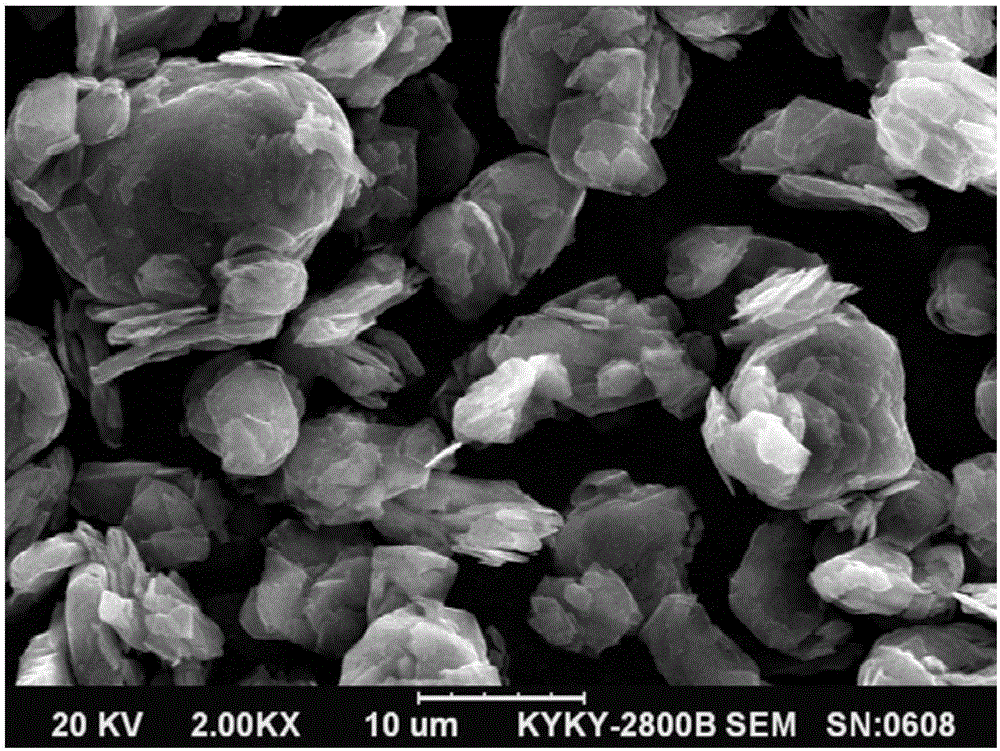

[0075] Natural spherical graphite (D50=6μm~8μm, S50=0.80~0.95) is placed in a rotary kiln, and oxygen is fed into it, and oxidized at 500°C for 2h, and the oxygen flow rate is 15L / h.kg, to obtain oxidized natural graphite ( oxidized graphite). According to the mass ratio of 88:12, the oxidized graphite and petroleum pitch are mixed, and then 2 Under the atmosphere, put it in a fusion machine at 650°C for mechanical granulation. After mechanical granulation for 5 hours, the reaction product was cooled to room temperature, and then carbonized at 1200°C to obtain a graphite-based composite material. The SEM of the obtained composite graphite material pictures such as figure 1 shown.

[0076] The same method as in Example 1 was used to prepare the negative electrode, assemble it into a button battery, and perform performance tests.

Embodiment 3

[0078] Natural spherical graphite (D50=6μm~8μm, S50=0.80~0.95) is placed in a rotary kiln, fed with oxygen, oxidized at 500°C for 4h, and the oxygen flow rate is 15L / h.kg to obtain oxidized natural graphite ( oxidized graphite). Mix the oxidized graphite and petroleum pitch according to the mass ratio of 85:15, and then 2 Under the atmosphere, place it in a fusion machine at 650°C for mechanical granulation. After 5 hours of mechanical granulation, cool the reaction product to room temperature, and then carbonize it at 1200°C to obtain a graphite-based composite material.

[0079]The same method as in Example 1 was used to prepare the negative electrode, assemble it into a button battery, and perform performance tests.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com