Silicon monoxide-graphite composite anode material for lithium ion battery and preparation method thereof

A technology of silicon oxide and negative electrode materials, applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of limited expansion of silicon oxide particles, shedding of the coating layer, and poor cycle performance of materials, so as to improve the first-time efficiency , shorten the transmission distance, overcome the effect of low first effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a silicon oxide-graphite composite negative electrode material, comprising the following steps:

[0042]1) Mix 120g of silicon oxide raw material with 1kg of absolute ethanol evenly and perform ball milling until the median particle size is 0.5um to obtain silicon oxide slurry 1;

[0043] 2) Mix 1 kg of natural graphite raw material with 2 kg of absolute ethanol evenly and perform ball milling until the median particle size is 1.5 μm to obtain graphite slurry 2;

[0044] 3) Mix silicon oxide slurry 1, graphite slurry 2, 100g medium-temperature coal tar pitch, 20g polyvinylpyrrolidone, and 1g aluminum isopropoxide in a ball mill tank for 4 hours;

[0045] 4) Spray-dry the slurry with an inlet temperature of 150° C. to obtain powder 1;

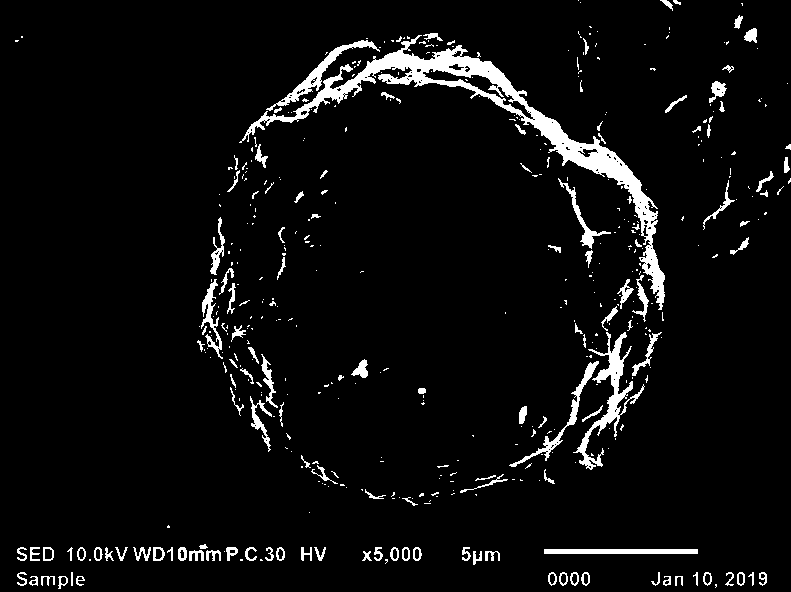

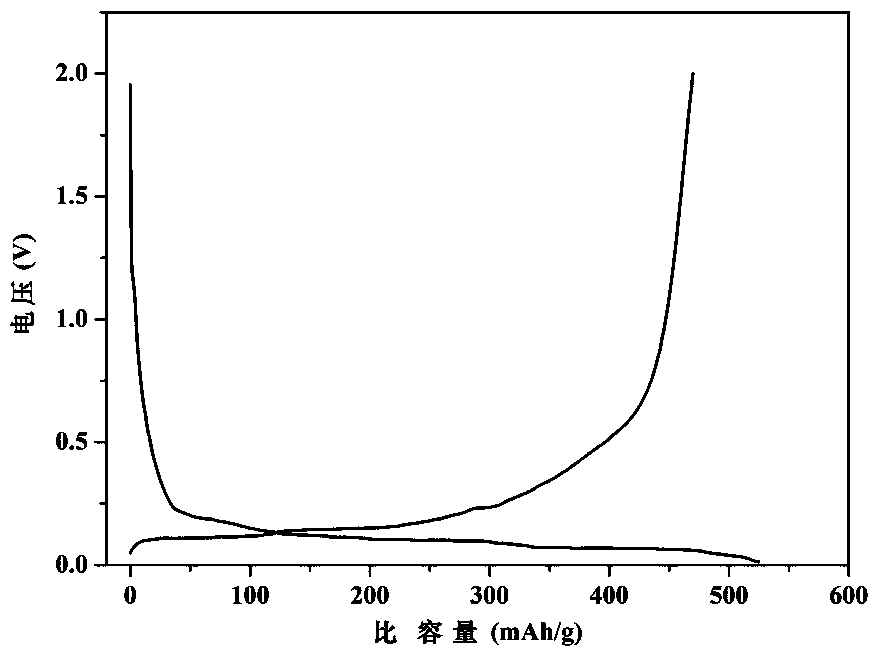

[0046] 5) The powder 1 was raised to 980° C. at a heating rate of 2° C. / min under a nitrogen atmosphere, and subjected to a constant temperature heat treatment for 2 hours to obtain the spherical silicon oxide-grap...

Embodiment 2

[0066] A method for preparing a spherical silicon oxide-graphite composite negative electrode material, comprising the following steps:

[0067] 1) Mix 90g of silicon oxide raw material with 1kg of absolute ethanol evenly and perform ball milling until the median particle size is 0.5um to obtain silicon oxide slurry 1;

[0068] 2) Mix 1 kg of natural graphite raw material with 2 kg of absolute ethanol evenly and perform ball milling until the median particle size is 1.5 μm to obtain graphite slurry 2;

[0069] 3) Mix silicon oxide slurry 1, graphite slurry 2, 95g medium-temperature coal tar pitch, 20g polyvinylpyrrolidone, and 0.9g aluminum isopropoxide in a ball mill tank for 4 hours;

[0070] 4) Spray-dry the slurry with an inlet temperature of 150° C. to obtain powder 1;

[0071] 5) Put the powder 1 into an appropriate amount of absolute ethanol solution for washing, then pour out the ethanol solution, and then replace it with a new absolute ethanol solution for washing ag...

Embodiment 3

[0074] A method for preparing a spherical silicon oxide-graphite composite negative electrode material, comprising the following steps:

[0075] 1) Mix 120g of silicon oxide raw material with 1kg of absolute ethanol evenly and perform ball milling until the median particle size is 0.5um to obtain silicon oxide slurry 1;

[0076] 2) Mix 1 kg of natural graphite raw material with 2 kg of absolute ethanol evenly and perform ball milling until the median particle size is 1.5 μm to obtain graphite slurry 2;

[0077] 3) Mix silicon oxide slurry 1, graphite slurry 2, 100g medium-temperature coal tar pitch, 20g polyethylene glycol 2000, and 1g aluminum isopropoxide in a ball mill tank for 4 hours;

[0078] 4) Spray-dry the slurry with an inlet temperature of 150° C. to obtain powder 1;

[0079] 5) Put the powder 1 into an appropriate amount of absolute ethanol solution for washing, then pour out the ethanol solution, and then replace it with a new absolute ethanol solution for washin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com