High-capacity lithium ion battery positive material with core-shell heterostructure and preparation method of material

A cathode material and core-shell structure technology, applied in the field of lithium-ion battery cathode materials, can solve the problems of lithium-rich materials such as large irreversible capacity, small working voltage range, and structural collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a lithium-ion battery positive electrode material with a heterogeneous core-shell structure. The lithium-ion battery positive electrode material is composed of a lithium-rich phase material as a shell material and a spinel phase material as a core material with a core-shell structure. Layered composite material, its chemical formula is 0.5[Li 1.5 Ni 0.25 mn 0.75 o 2.5 ]-0.5 [Li 0.5 Ni 0.25 mn 0.75 o 2 ],Proceed as follows:

[0026] 1) NiSO 4 ·6H 2 O and MnSO 4 ·H 2 O is dissolved in deionized water after mixing, the molar ratio of Ni and Mn is 0.25:0.75, and the obtained concentration is a mixed salt solution of 2mol / L;

[0027] 2) Add 0.2M ammonia water and 2M sodium carbonate solution to the above mixed salt solution under stirring conditions to carry out co-precipitation reaction, and control the flow rate of sodium carbonate solution and ammonia water to make the pH value of the mixed solution 8, and the stirring speed is 600rpm ,...

Embodiment 2

[0035] A preparation method of a lithium-ion battery cathode material with a heterogeneous core-shell structure, the chemical formula of the lithium-ion battery cathode material is 0.5[Li1.5 Ni 0.25 mn 0.75 o 2.5 ]-0.5 [Li 0.5 Ni 0.25 mn 0.75 o 2 ], the preparation steps are substantially the same as in Example 1, difference:

[0036] Combine the nuclear material prepared in step 3) with Li 2 CO 3 After mixing evenly at a molar ratio of 1:0.25, place it in a muffle furnace for calcination at a calcination temperature of 800°C and a calcination time of 15 hours to obtain a high-capacity lithium-ion battery cathode material.

Embodiment 3

[0038] A preparation method of a lithium-ion battery cathode material with a heterogeneous core-shell structure, the chemical formula of the lithium-ion battery cathode material is 0.5[Li 1.5 Ni 0.25 mn 0.75 o 2.5 ]-0.5 [Li 0.5 Ni 0.25 mn 0.75 o 2 ], the preparation steps are substantially the same as in Example 1, difference:

[0039] Combine the nuclear material prepared in step 3) with Li 2 CO 3 After mixing evenly at a molar ratio of 1:0.25, place it in a muffle furnace for calcination at a temperature of 900°C and a calcination time of 15 hours to obtain a high-capacity lithium-ion battery cathode material.

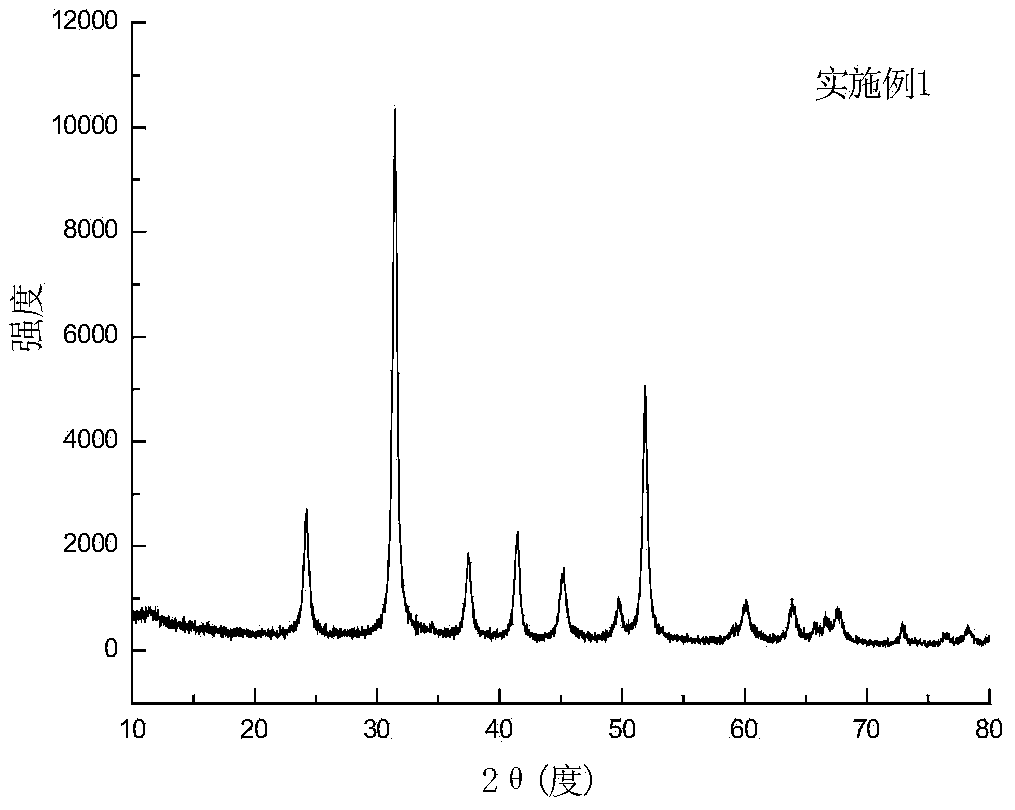

[0040] Figure 5 The XRD pattern of the heterogeneous core-shell structure lithium ion battery cathode material prepared for embodiment 1, 2 and 3 shows in the figure: the structure of the material in embodiment 1, embodiment 2 and embodiment 3 is a spinel phase ( Fd-3m) and the layered phase material (R-3m) structure, when the temperature rises, the (006) / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com