Electrolyte, preparation method thereof, high-energy-density lithium ion battery containing electrolyte and preparation method thereof

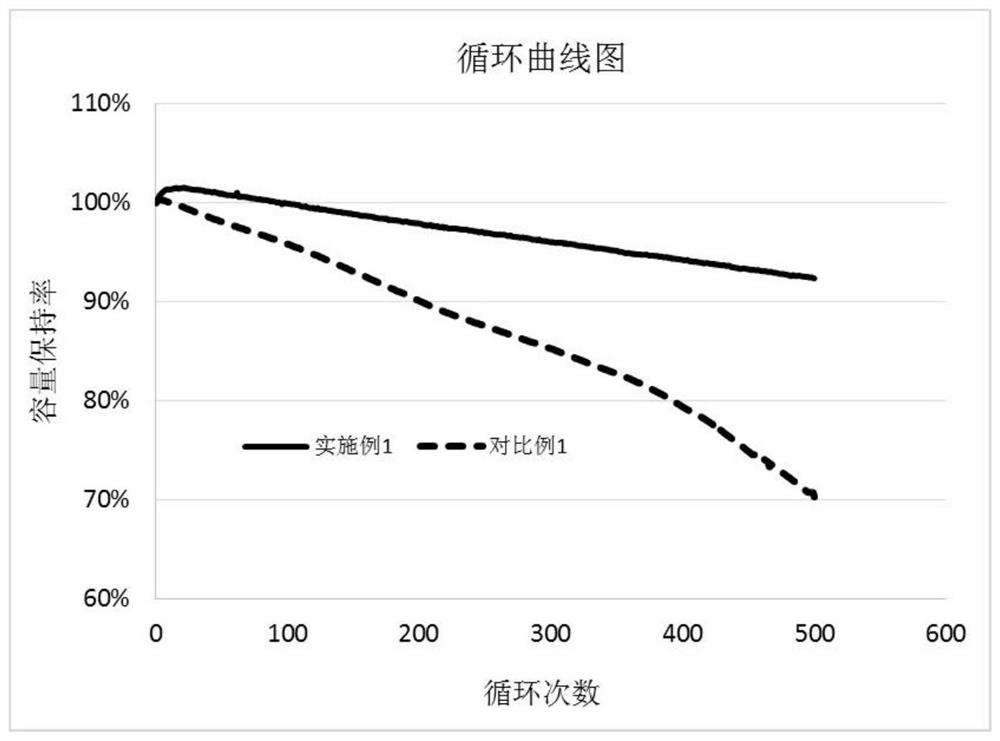

A lithium-ion battery, high energy density technology, applied in the field of lithium-ion batteries, can solve the problems of lithium battery capacity attenuation, etc., to achieve the effect of alleviating capacity attenuation, enhancing interaction, increasing solubility and electrolyte ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of electrolyte: in a glove box filled with argon (moisture ≤ 5ppm, oxygen ≤ 1ppm), mix ethylene carbonate and diethyl carbonate at a ratio of 2:3 to make a non-aqueous organic solvent, and take 80 %, add 6% fluoroethylene carbonate and 2% potassium carbonate by mass fraction, fully stir, slowly add 12% lithium hexafluorophosphate into the mixed solution, stir until completely dissolved, and obtain an electrolyte.

[0043] Prepare the positive electrode sheet: mix the positive electrode active material nickel cobalt lithium manganate NCM811, the conductive agent conductive carbon black, and the binder polyvinylidene fluoride with NMP solvent at a mass ratio of 98:1:1 to make a positive electrode slurry; then the positive electrode material The slurry is coated on the surface of the aluminum foil, dried, rolled and then cut to obtain the positive electrode sheet of the required size;

[0044] Prepare negative electrode sheet: mix silicon carbon material, singl...

Embodiment 2

[0048] Preparation of electrolyte: in a glove box filled with argon (moisture ≤ 5ppm, oxygen ≤ 1ppm), take 85% propylene carbonate, add 1,2-difluoroethylene carbonate with a mass fraction of 2%, 2% sodium carbonate, fully stirred, and slowly added 11% lithium bisfluorosulfonyl imide into the mixed solution, and stirred until completely dissolved to obtain an electrolyte solution.

[0049] Prepare the positive electrode sheet: mix lithium cobaltate, graphene and perfluorosulfonic acid resin with NMP solvent at a mass ratio of 85:7:8 to make a positive electrode slurry; then coat the positive electrode material slurry on the surface of the aluminum foil and dry it. Cut the sheet after rolling to obtain the positive electrode sheet of the required size;

[0050] Prepare the negative electrode sheet: mix artificial graphite, conductive carbon black, carbon fiber, perfluorosulfonic acid resin, polymethyl acrylate with water at a mass ratio of 88:5.2:2:3.5:1.3 to make negative elect...

Embodiment 3

[0054] Preparation of electrolyte: In a glove box filled with argon (moisture ≤ 5ppm, oxygen ≤ 1ppm), mix dimethyl carbonate and ethyl acetate with a mass of 1:1 to make a non-aqueous organic solvent, and take 86 %, add 2% chloroethylene carbonate and 2% lithium carbonate in a mass fraction, fully stir, slowly add 10% lithium bisfluorosulfonyl imide into the mixed solution, stir until completely dissolved, and obtain an electrolyte.

[0055] Preparation of positive electrode sheet: mix lithium iron phosphate, conductive graphite and polymethyl acrylate with NMP solvent at a mass ratio of 92:3:5 to make positive electrode slurry; then coat the positive electrode material slurry on the surface of aluminum foil, dry, and roll Cut the sheet after pressing to get the positive electrode sheet of the required size;

[0056] Preparation of negative electrode sheet: mix hard carbon, conductive carbon black, carbon fiber, polyvinylidene fluoride with water at a mass ratio of 82:7:3:8 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com