Patents

Literature

121results about How to "High discharge platform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

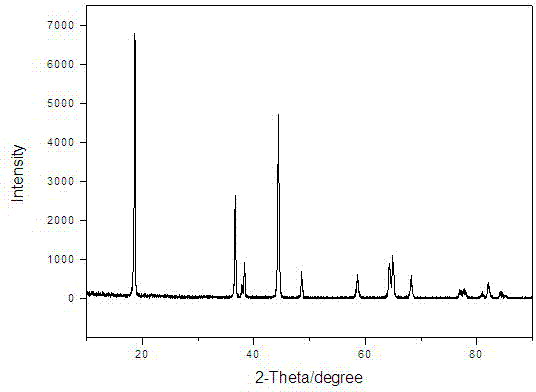

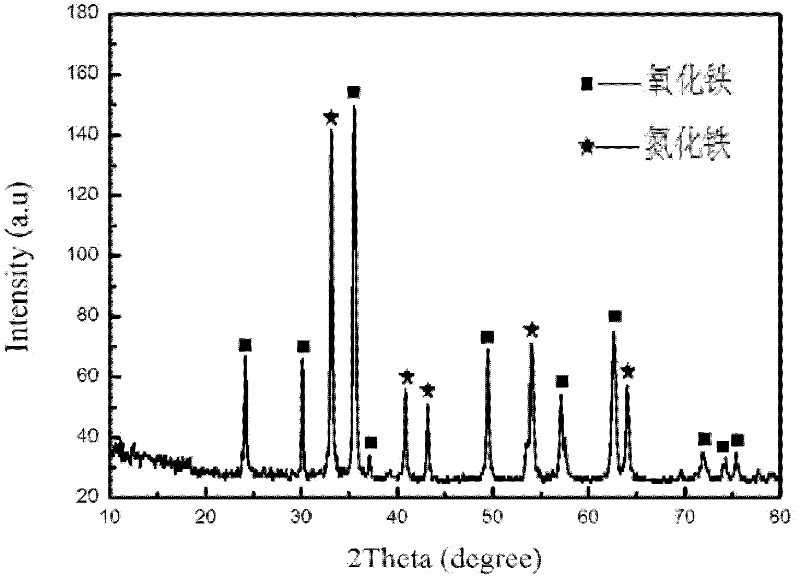

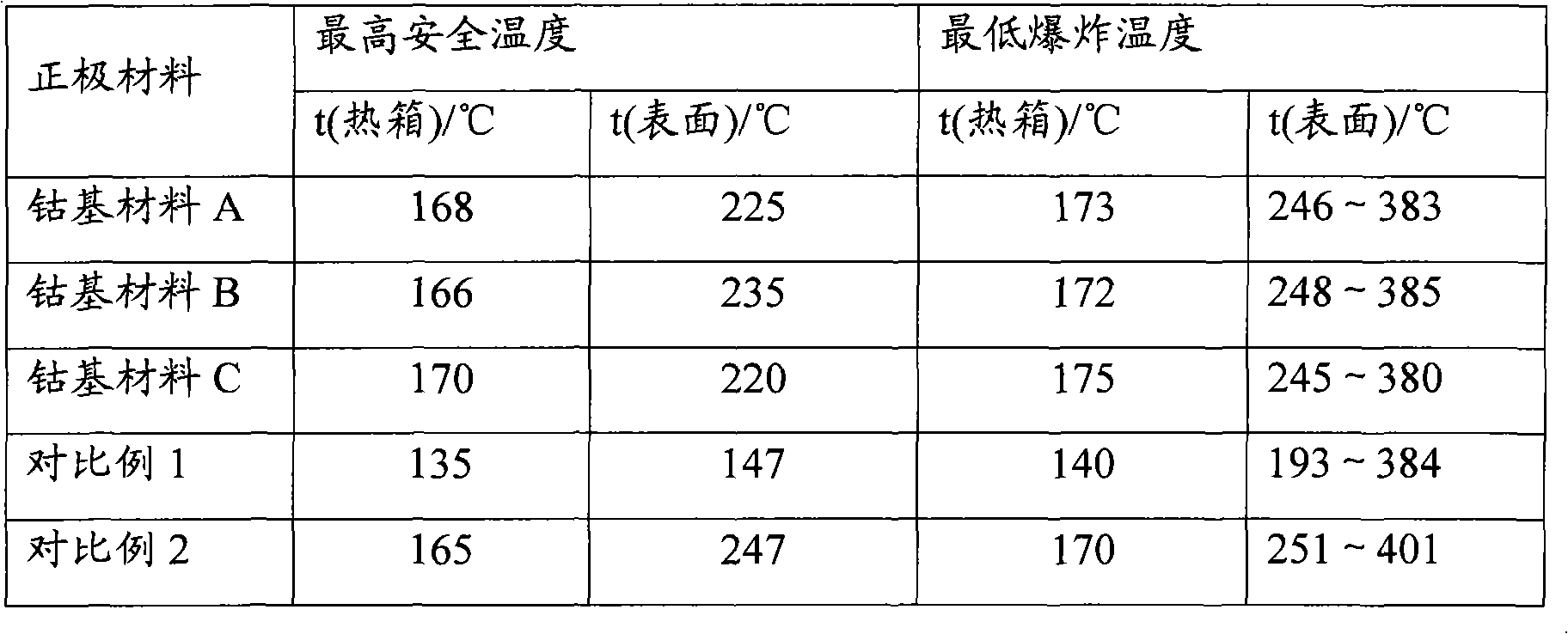

Method for preparing high-performance spherical lithium ion secondary battery cathode material

ActiveCN102110808AHigh densityHigh activityCell electrodesNickel compoundsHigh densityElectrical battery

The invention provides a method for preparing a high-performance spherical lithium ion secondary battery cathode material. The method comprises the steps of synthesizing a NiaCobMn1-a-b(OH)2 precursor through adopting a coprecipitation-crystallization method, coating NicCodMn1-c-d(OH)2NieCofMn1-e-f(oh)2 composite layer on the surface of the precursor through adopting a chemical method, and then fully mixing with lithium salt to prepare a high-performance spherical lithium ion secondary battery cathode material LiNiaCobMn1-a-bO2(LiNicCobMn1)-c-dO2LiNieCofMn1-e-fO2) through stepwise sintering. The cathode material prepared by adopting the method has high density, good activity, and accurate stoichiometric proportion. Malignant interaction between the cathode material and an electrolyte is avoided, capacity decrease caused by non- electrochemical active substances is prevented, and the circulating life of materials is prolonged. The method is easy to control, has a low manufacturing cost, and is convenient for mass production, so as to create conditions for the development of high-capacity lithium ion batteries.

Owner:HENAN KELONG NEW ENERGY CO LTD

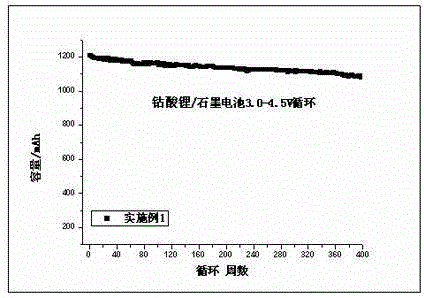

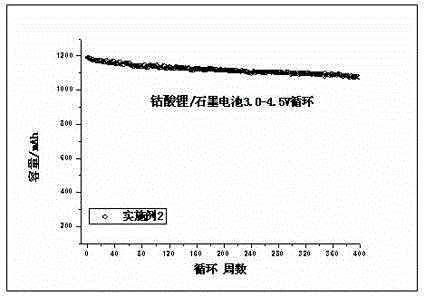

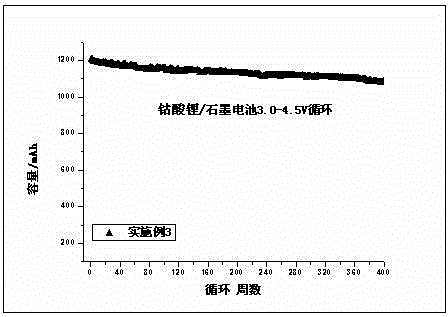

High-voltage high-energy-density lithium ion battery

InactiveCN103311539AIncrease energy densityHigh discharge platformFinal product manufactureElectrode carriers/collectorsElectrical batteryHigh energy

The invention discloses a high-voltage high-energy-density lithium ion battery which comprises a positive pole piece, a negative pole piece, a diaphragm, electrolyte and a shell, wherein the positive pole piece comprises a positive active material, a conducting agent, an adhesive and a current collector, and the weight percents of the positive active material, the conducting agent and the adhesion are 92 to 97%: 2 to 3.5%: 1 to 6%; the negative pole piece comprises a negative material, a conducting agent, an adhesive and a current collector, and the weight percents of the negative material, the conducting agent and the adhesive are respectively 90 to 96%, 1 to 5% and 4 to 10%; the lithium ion battery is prepared by adopting modified lithium cobalt oxides (LiCoO2) as the positive active material and the artificial graphite or natural graphite as the negative material and matching the corresponding ceramic diaphragm, high-voltage electrolyte, adhesive and conducting agent. The lithium ion battery not only has high energy density and high discharging platform, but also is good in chemical performance and safety performance and is applicable to the commercialized mass production.

Owner:SHENZHEN WISEWOD TECH +1

Lithium iron phosphate anode material and its preparing method

InactiveCN1767238AImprove conductivityHigh tap densityElectrode manufacturing processesCalcium/strontium/barium compoundsBorideAlcohol

The invention relates to ferric phosphate lithium anode material and its preparing method, which relates to a cell anode material, especially to a ferric phosphate lithium anode material used in lithium ion cell second time. It provides a cell anode material and ití»s preparing method which can elevate the LiFePO4 conductivity and tap density at the same time. It is formed by ferric phosphate lithium and calcium boride (by weight rate): ferric phosphate lithium: calcium boride=100í† (1.01- 5.26). It first syntheses pure ferric phosphate lithium: it balls the ferrous salt, microcosmic salt and lithium salt by alcohol grease, heats the mixed material and uses inactive gas as preserving gas. It balls the synthesis ferric phosphate lithium anode and calcium boride, burns the mixed material and adds inactive gas as preserving gas to obtain the object product.

Owner:河南天科科技有限公司

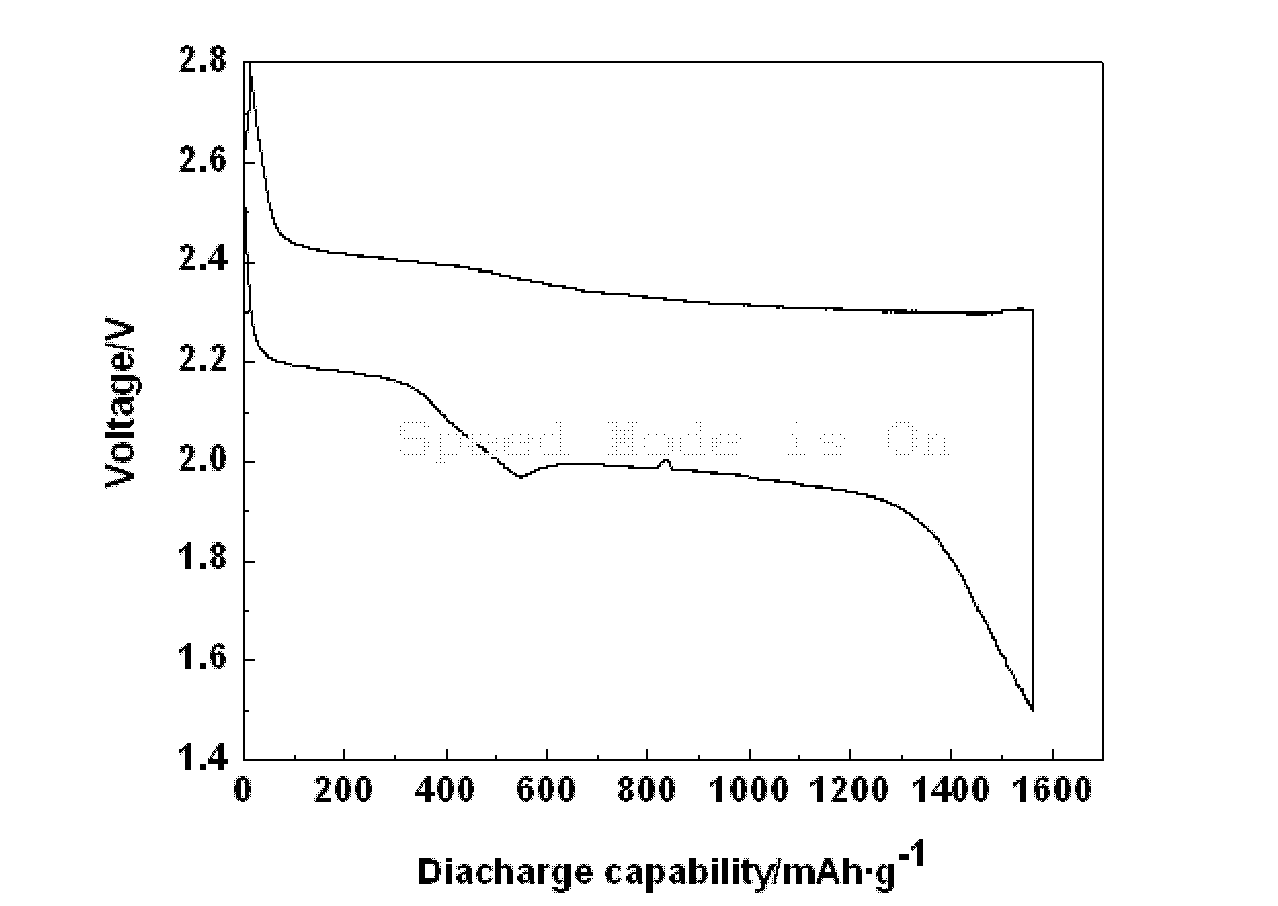

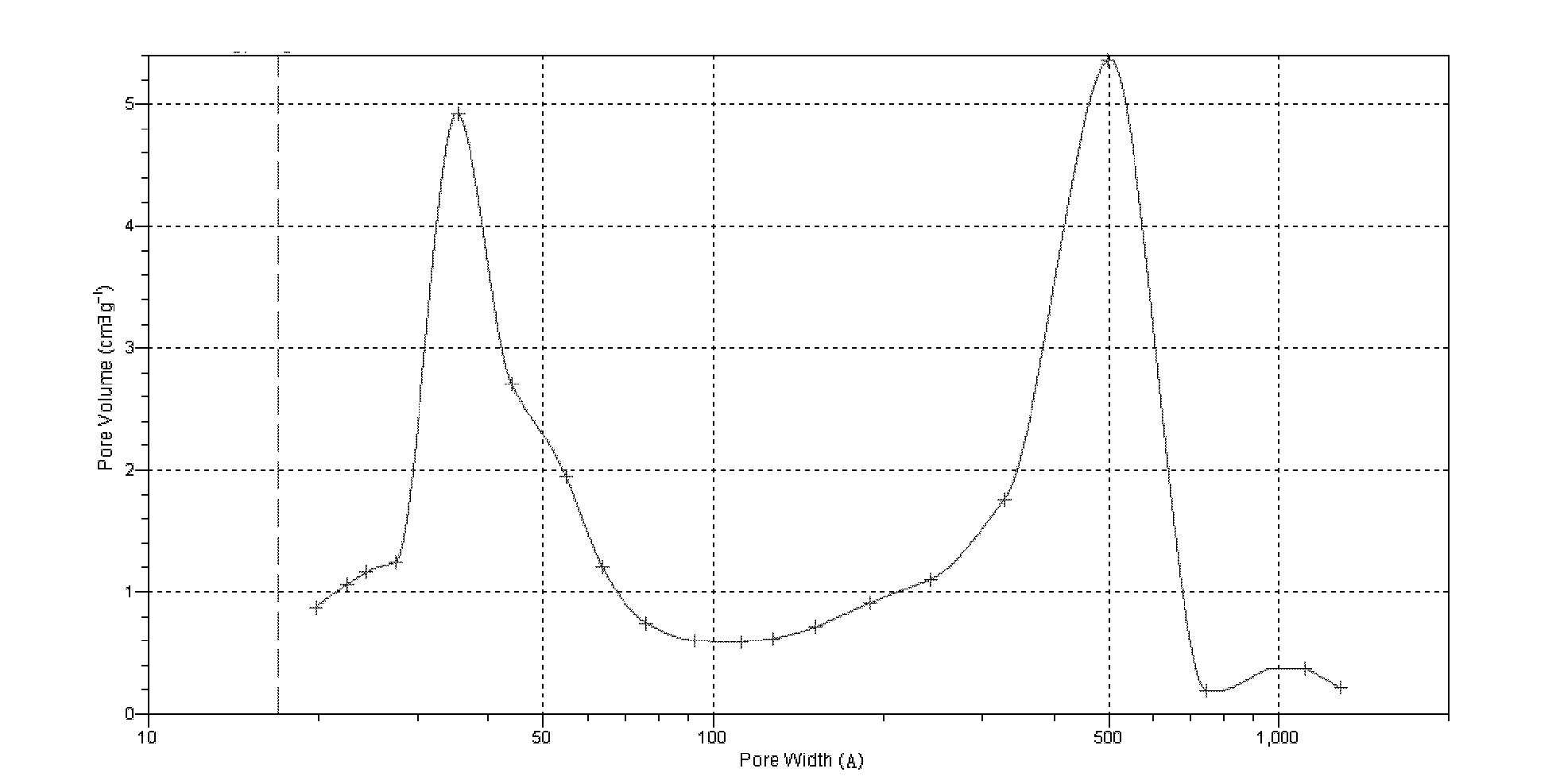

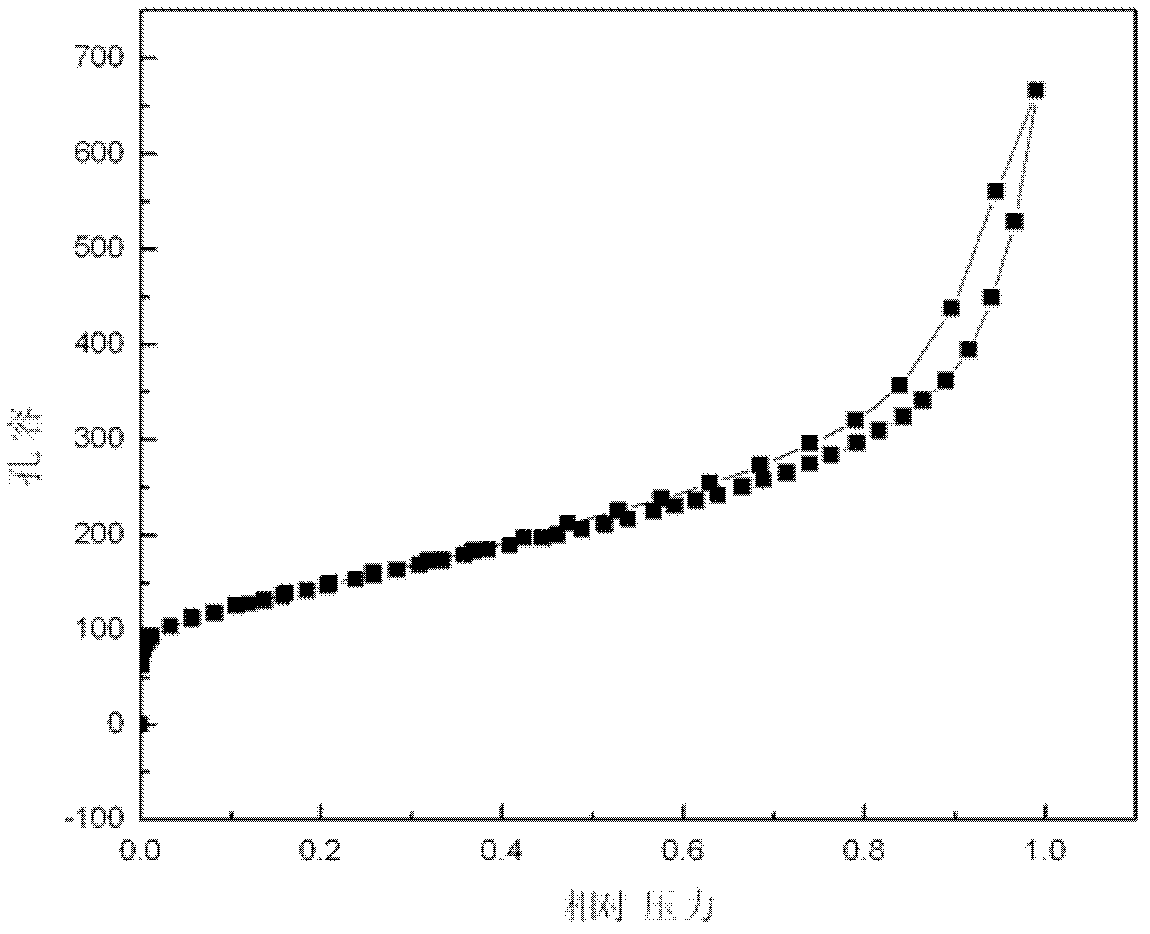

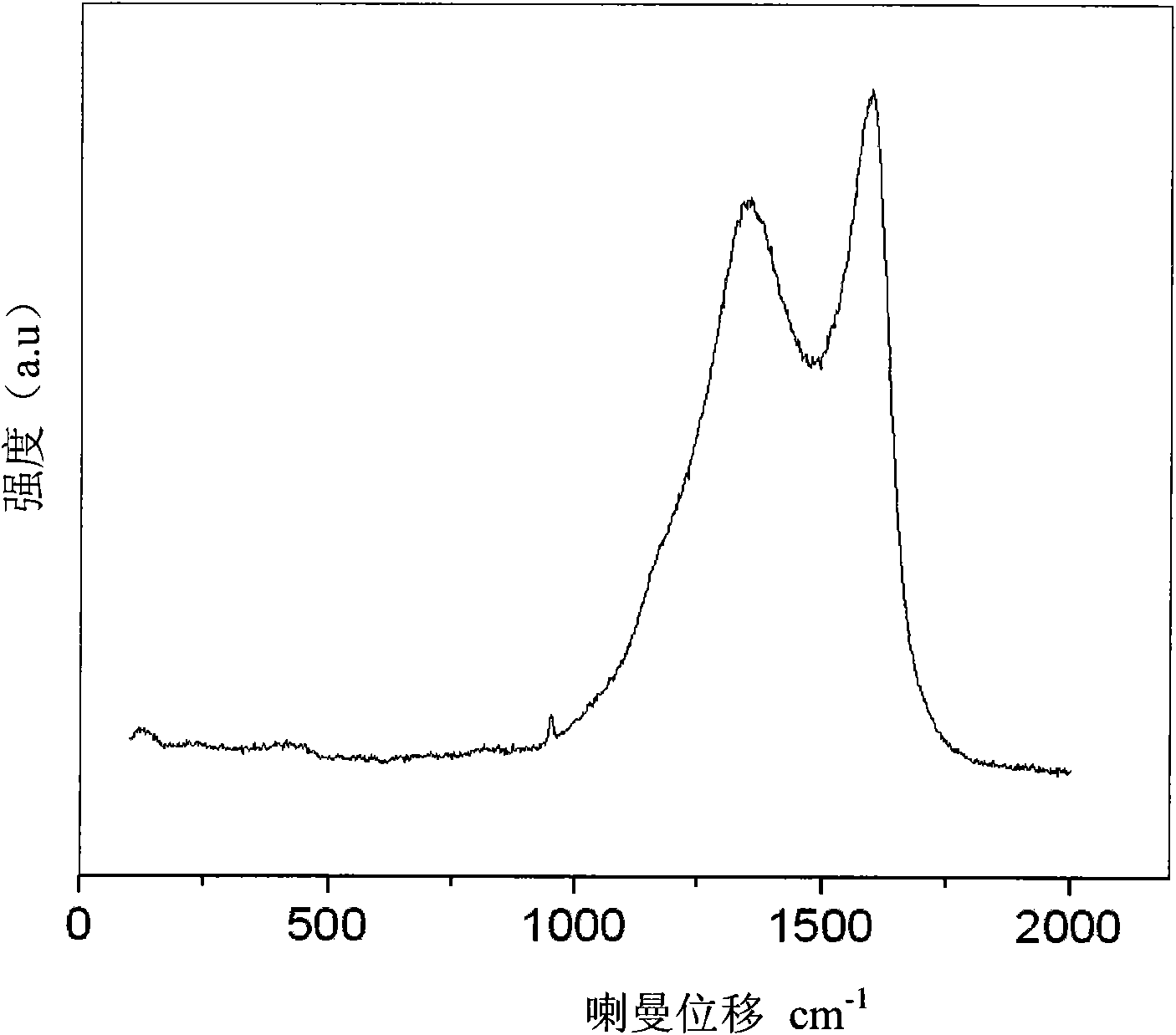

Carbon-sulphur composite used for cathode material of lithium sulphur battery as well as preparation method and application thereof

ActiveCN103050669AImprove discharge capacityLarger than surfaceNon-aqueous electrolyte accumulator electrodesLithium–sulfur batterySulfur electrode

The invention relates to a carbon-sulphur composite used for a cathode material of a lithium sulphur battery as well as a preparation method and application thereof. The carbon-sulphur composite comprises a carbon material and elemental sulphur, wherein the carbon material is formed by doping mesoporous carbon with the aperture of 2-5nm and electroconductive carbon with the aperture of 30-70nm, and the electroconductive carbon with the aperture of 30-70nm contains micropores with the aperture of 0.5-1.7nm; and the elemental sulphur accounts for 10-90wt% of the total quantity of the composite. Abundant micropores guarantee that the carbon material has larger specific surface, adsorption capacity to polysulphide is stronger, and dissolution of the polysulphide can be effectively limited, so that stability of a sulphur electrode is improved. Meso pores in porous distribution can load more sulphur active substances, electrochemical capacity of a composite material is improved, and diffusion and transmission of lithium ions and electrolyte solution can be facilitated, so that reduction polarization of the elemental sulphur is reduced and discharge plateau of the elemental sulphur is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-voltage lithium-ion battery electrolyte

InactiveCN104466250AImprove electrochemical reactivityPromote circulationSecondary cellsOrganic electrolytesElectrolytic agentPhysical chemistry

The invention relates to the technical field of lithium-ion battery electrolytes, in particular to a high-voltage lithium-ion battery electrolyte. The high-voltage lithium-ion battery electrolyte comprises non-aqueous solvent, lithium salt and an additive. The additive comprises the mixture of phosphonitrile, annular sulphate and hydrogen fluoroether. The high-voltage lithium-ion battery electrolyte can form a film on the surface of an electrode through the synergistic effect of the phosphonitrile, the annular sulphate and the hydrogen fluoroether, oxygenolysis of the electrolyte is restrained, and the cycle performance of 4.5 V and 5.0 V high-voltage lithium-ion batteries is obviously improved.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

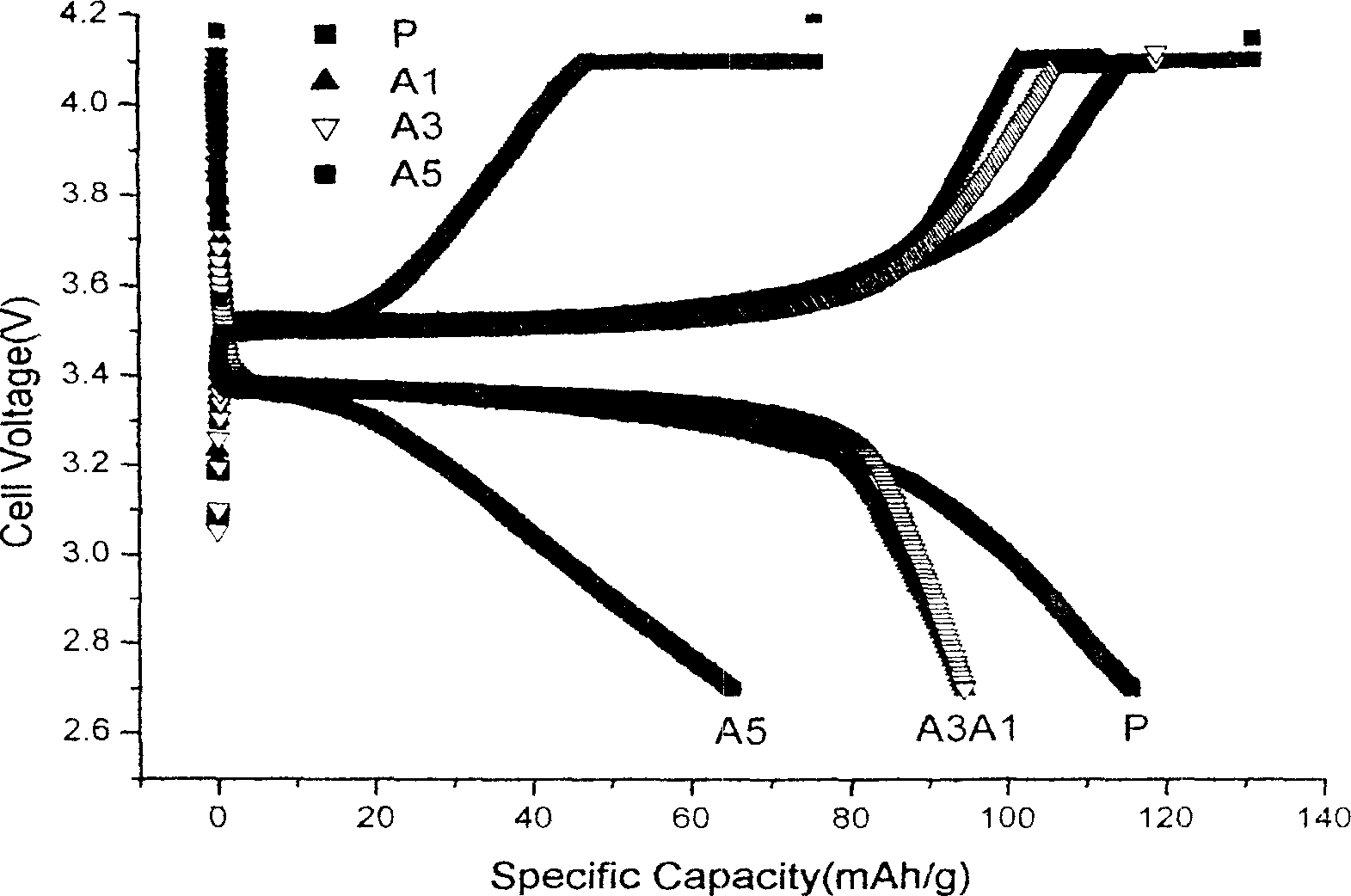

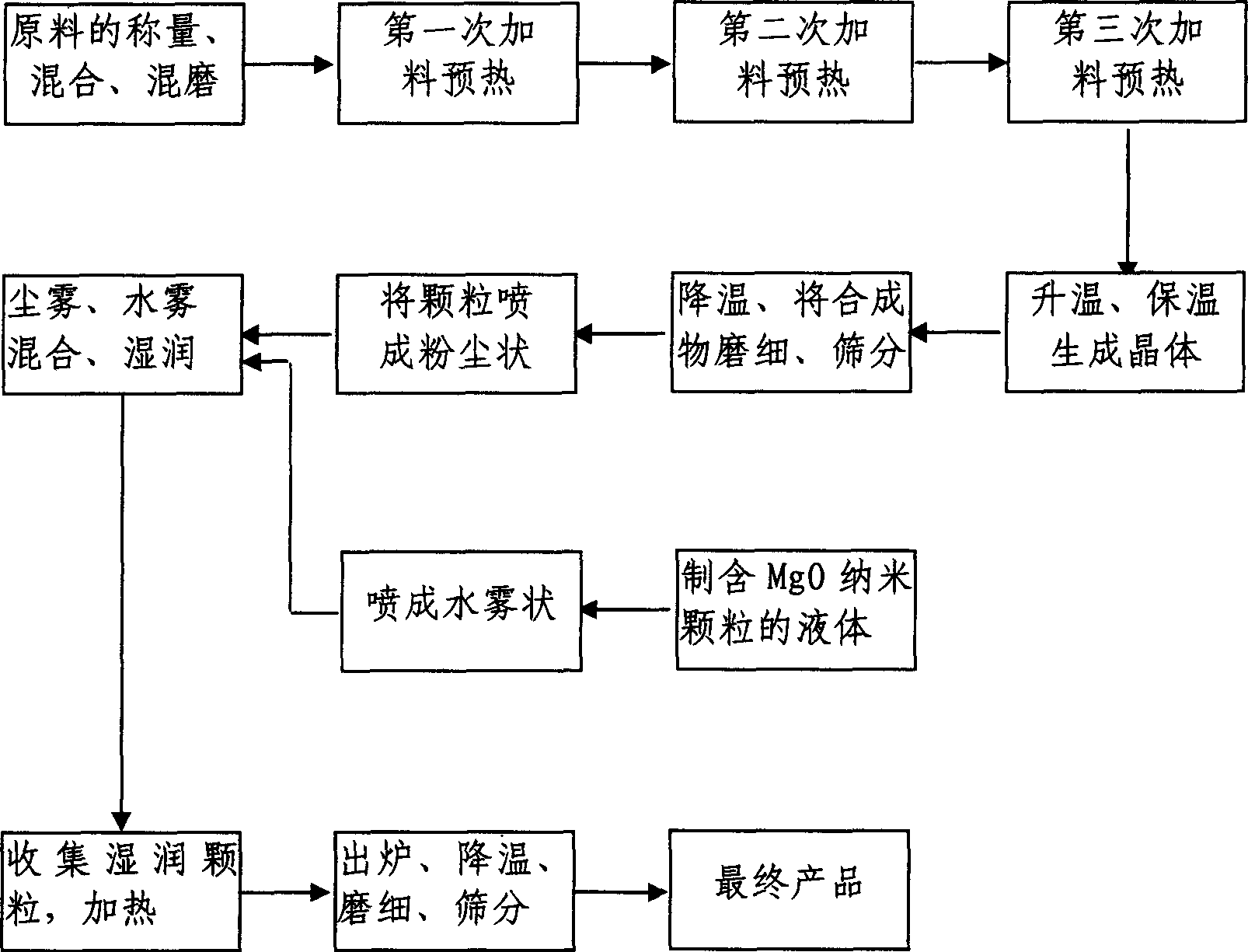

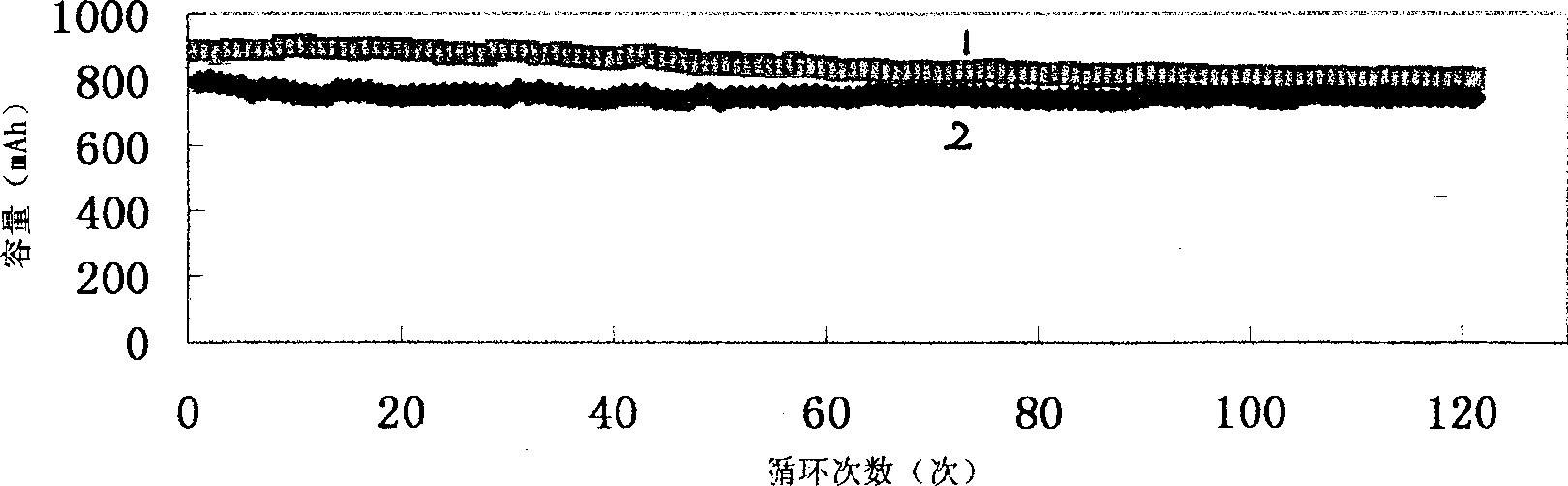

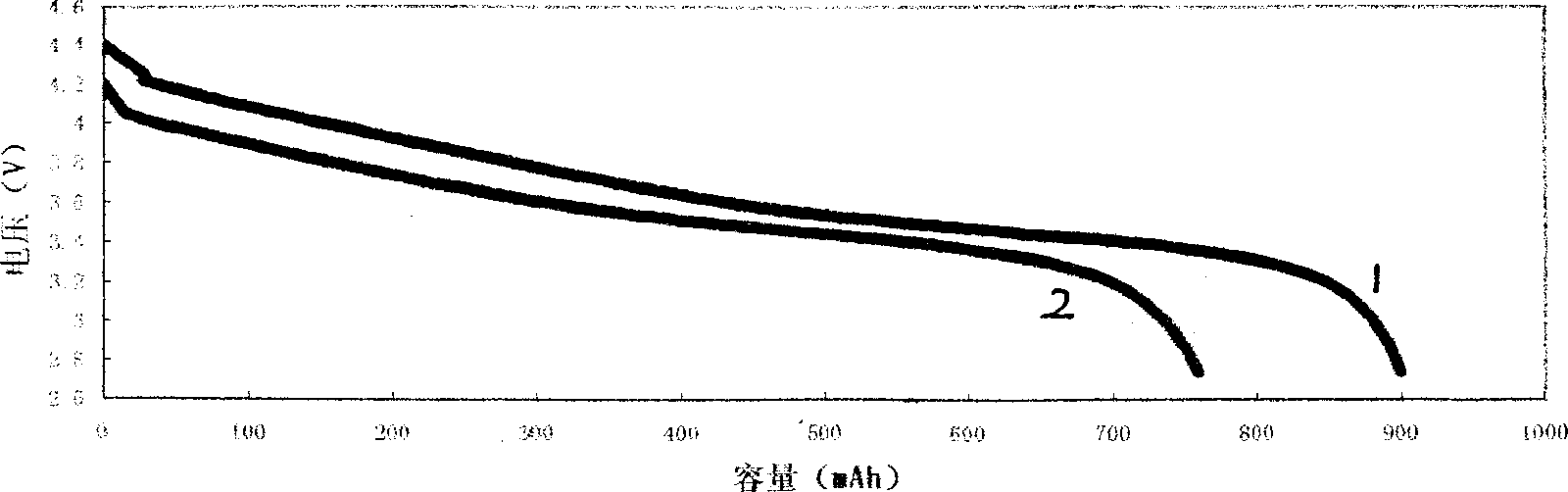

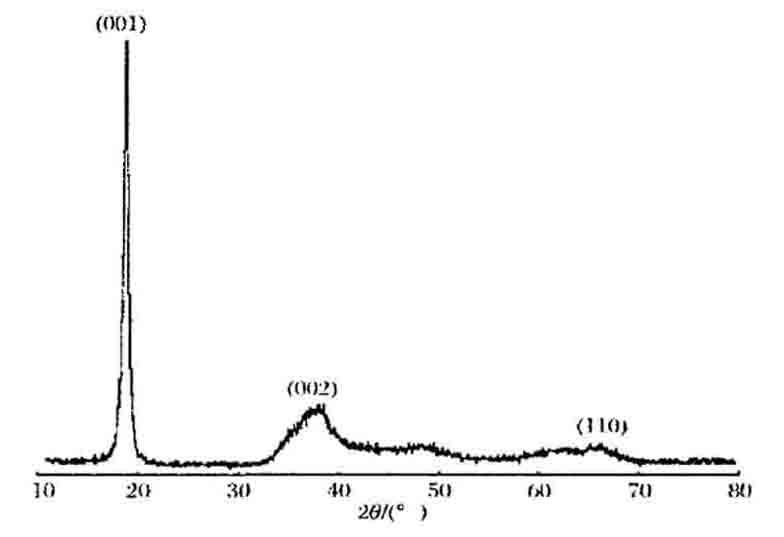

Doping and surface coating lithium nickel cobalt dioxide and its preparing method

This invention relates to lithium ion battery positive electrode mixture and surface nickel-to-cobalt acid lithium and its process method, which is characterized by the following: materials particle inner crystal core is LiNixCoyMgzO2 or LiNixCoyMnzO2; mixing Mg, Mn, or rare earth; outside surface layer is of nanometer MgO. The process method adopts three times adding and heating under 800 degrees temperature. The advantages of this invention embodies in crystal, structure, particle shape, large intensity and good flow and large capacity.

Owner:黎彦希

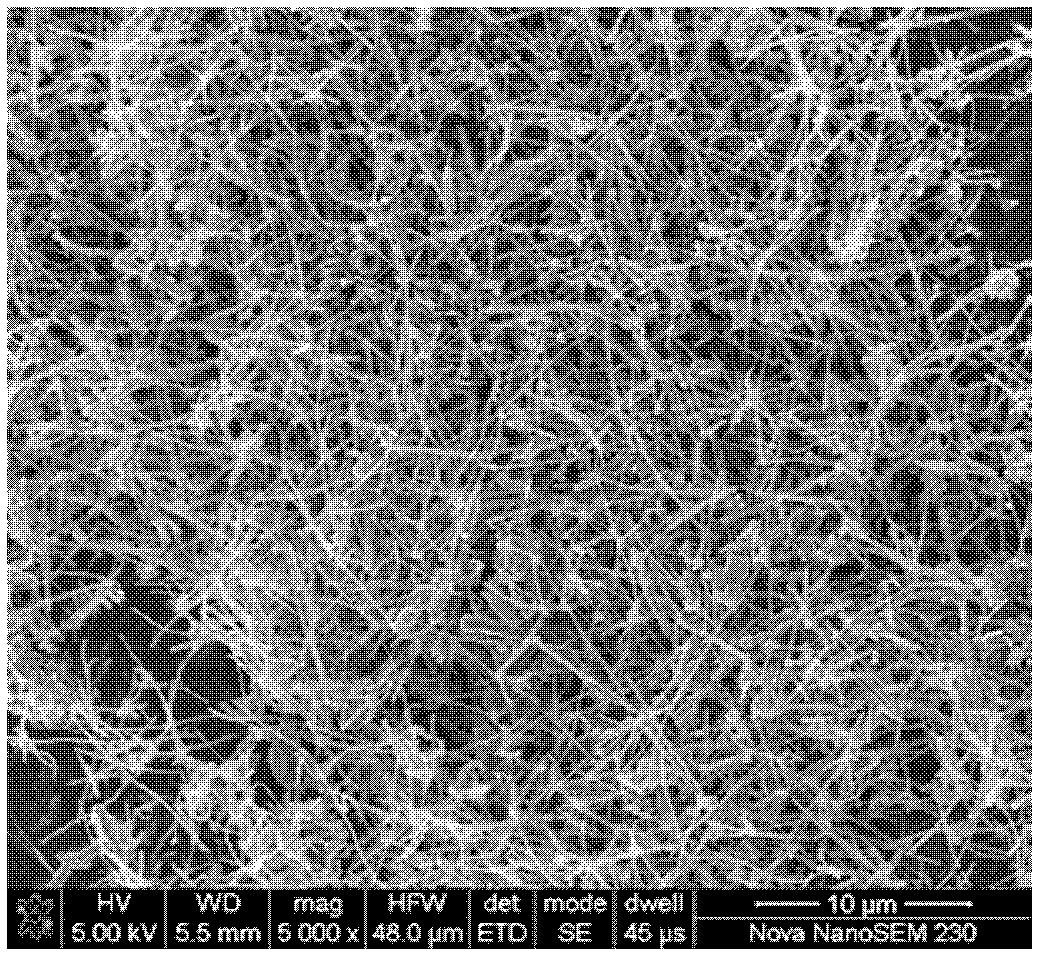

Micro-nano-structure anode material for Li-air battery and preparation method of micro-nano-structure anode material

The invention relates to a micro-nano-structure anode material for a Li-air battery and a preparation method of the micro-nano-structure anode material. The preparation method comprises the following steps of: preparation of hollow composite precursor fibers through electrostatic spinning by blending a metal nitride catalyst precursor with a high-carbon polymer in an organic solvent, preprocessing of the precursor fiber material, nitridation of complex fibers, and pore-forming and pore-expansion through activation. The preparation method is simple in technique and convenient to operate and is easy to realize the uniform distribution of nanoscale catalyst particles in hollow carbon fibers. A prepared anode material tube is hollow internally, a plurality of holes are formed on the wall of the tube, and metal nitride catalysts are uniformly distributed in the three-dimensional holes of the wall of the tube, so that high specific surface area provides a sufficient place for the reaction of the battery, and the hollow pore passage in the tube can ensure an oxygen diffusion channel to be smooth and has good ion transport capacity and electrical conductivity. According to the invention, the charge-discharge capacity of the Li-air battery can be improved effectively, the power multiplying performance and the power density of the Li-air battery can be improved, the internal resistance of the battery can be reduced, and the charge-discharge polarization can be lessened through the uniform distribution of the nanoscale metal nitride, therefore, the micro-nano-structure anode material has good industrialization prospect.

Owner:CENT SOUTH UNIV

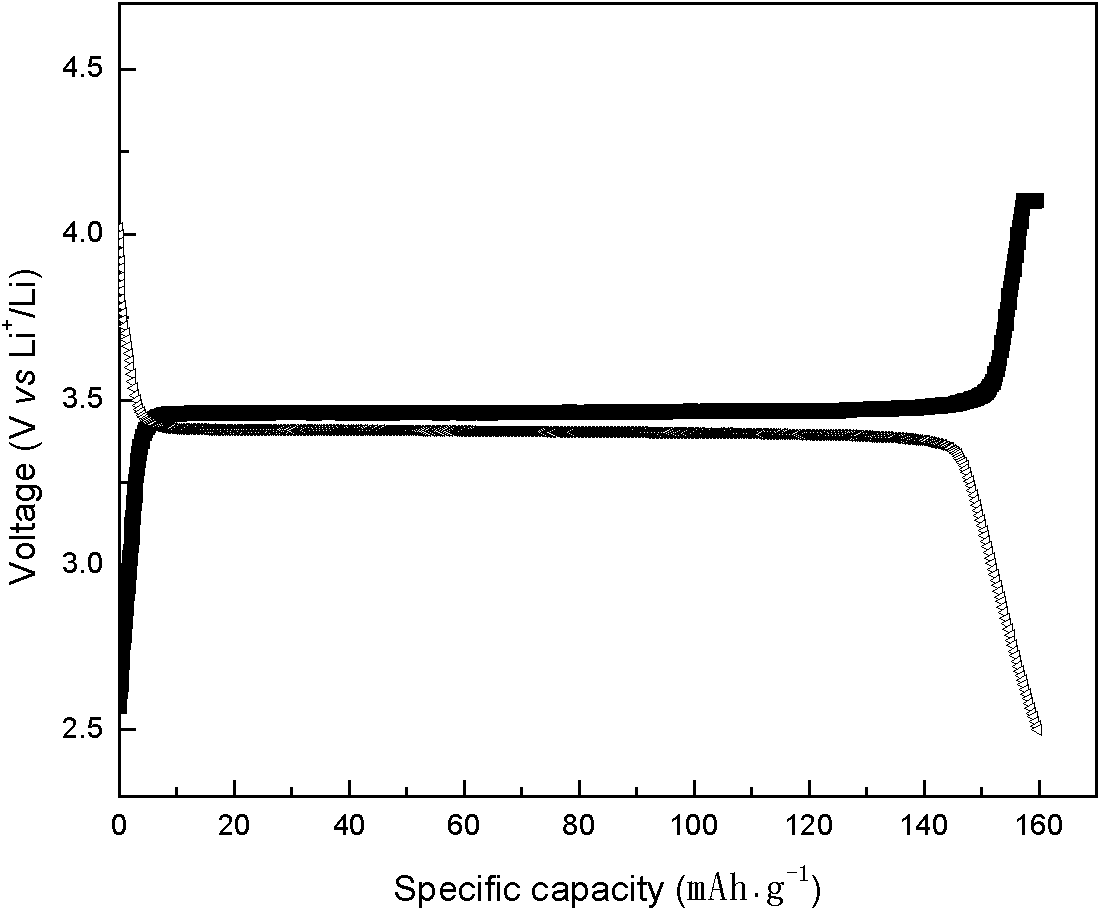

Method for preparing ternary anode material of long-service-life and high-capacity lithium ion battery

ActiveCN103682316AIncrease capacityImprove cycle performanceCell electrodesCapacity lossMaterial synthesis

A method for preparing a ternary anode material of a long-service-life and high-capacity lithium ion battery and belongs to the technical field of material synthesis. The method comprises the following steps: weighing a lithium source and NixCoyMnz(OH)2, uniformly mixing, pre-burning at a temperature of 400-600 DEG C for 2-6 h, and forging at a temperature of 700-1000 DEG C for 6-16 h; uniformly mixing the ternary anode material, the lithium source and nanometer TiO2; forging at a temperature of 700-950 DEG C for 3-8 h to obtain the ternary anode material which is prepared by twice lithium adding and twice forging. The ternary anode material is prepared through twice lithium adding and twice forging, and the extra lithium source which is introduced through twice lithium adding and twice forging is electrochemically pre-embedded in an anode. Meanwhile, the Li+ diffusion rate can be effectively increased through the doping of Ti4+, and the irreversible capacity loss is reduced. In an interval of 2.3-4.6 V, a discharging platform is prolonged, and the first discharging capacity, the cyclic performance and the rate performance of the material are obviously improved. The method is simple, effective, economical and practical and has a remarkable industrial application effect.

Owner:HARBIN INST OF TECH

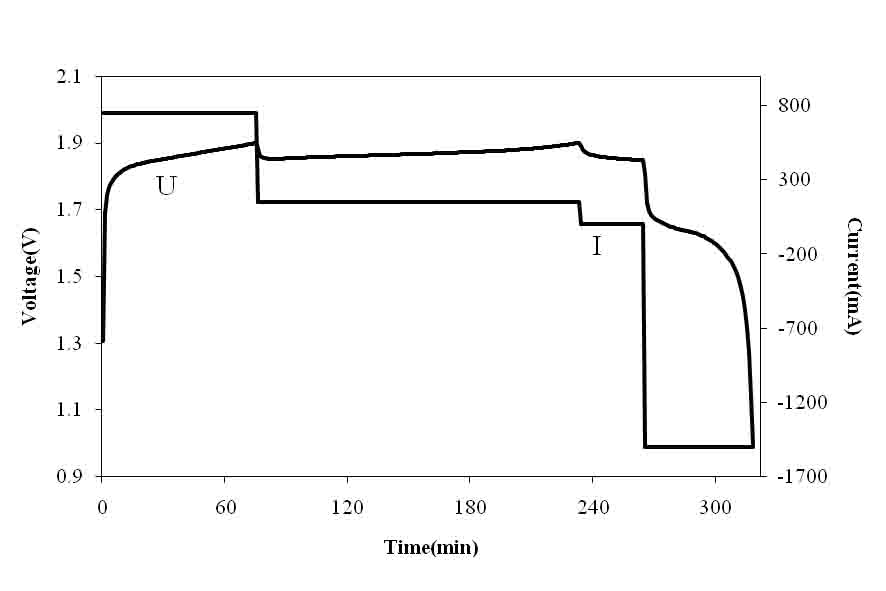

Nickel-zinc secondary battery and preparation method thereof

ActiveCN102024994AHigh discharge platformImprove performanceFinal product manufactureElectrode carriers/collectorsElectrolytic agentBattery cell

The invention relates to a nickel-zinc secondary battery and a preparation method thereof. The technical scheme is that: the preparation method comprises the following steps of: mixing 85 to 99 weight percent of anode active substance, 0.5 to 10 weight percent of anode additive and 0.5 to 5 weight percent of anode bonding agent uniformly; adding water into the mixture to prepare paste; coating the paste on an anode conductive matrix; drying, performing roll forming and slicing to obtain an anode plate; mixing 75 to 99 weight percent of cathode active substance, 0.5 to 20 weight percent of cathode additive and 0.5 to 5 weight percent of cathode bonding agent uniformly; adding water into the mixture to prepare paste; coating the paste on a cathode conductive matrix; drying, performing roll forming and slicing to obtain a cathode plate; separating the anode plate from the cathode plate by using diaphragm paper; winding the separated anode plate and cathode plate to be a cylindrical shape; sleeving the cylindrical object into a battery case; injecting electrolyte, wherein the anode plate is connected with an anode cap by a lug and the cathode plate contacts with the battery case; and sealing the battery to form the nickel-zinc secondary battery. The nickel-zinc secondary battery prepared by the method has a long cycle life, a high discharging platform and high specific energy.

Owner:LIAONING JIUYI ENERGY TECH

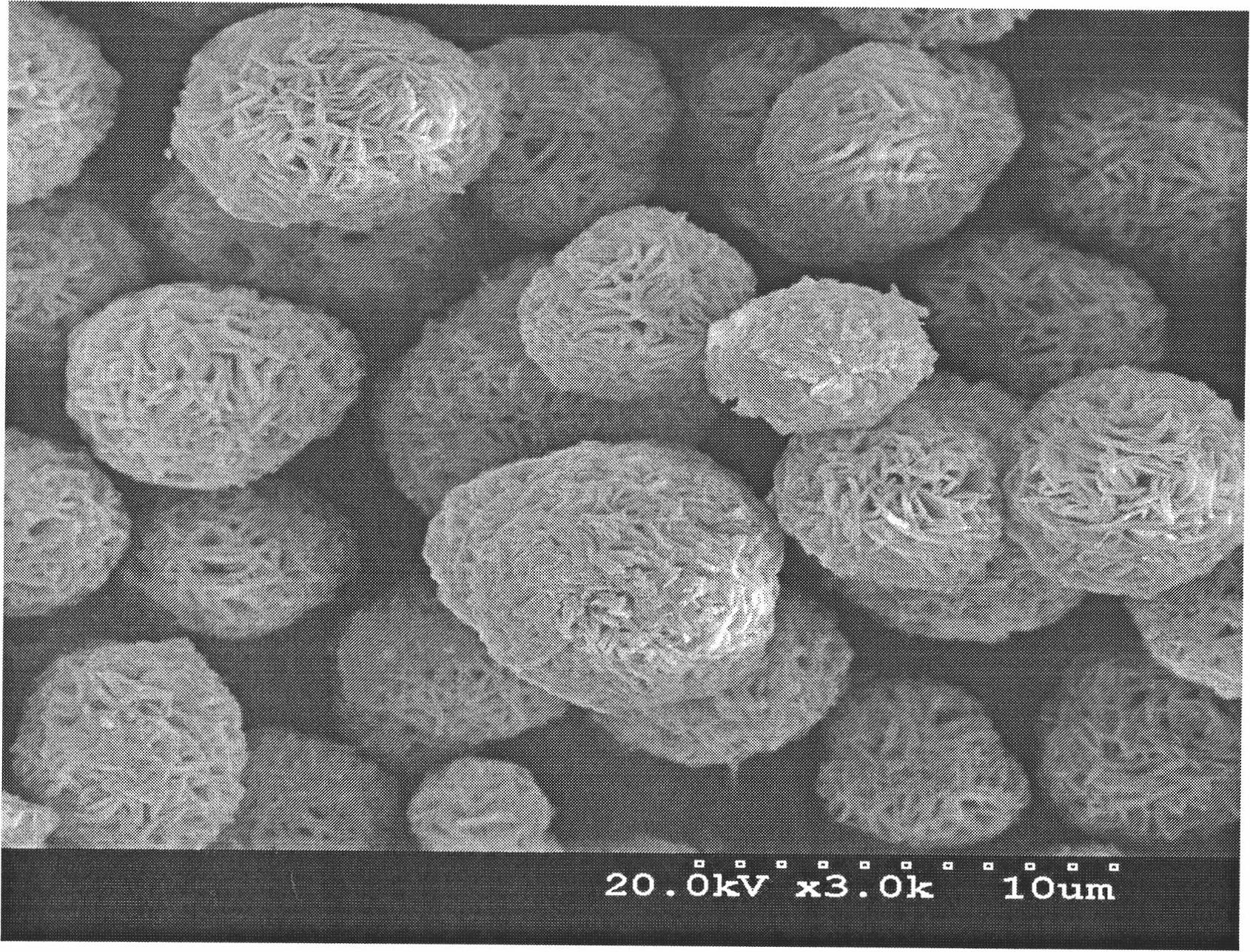

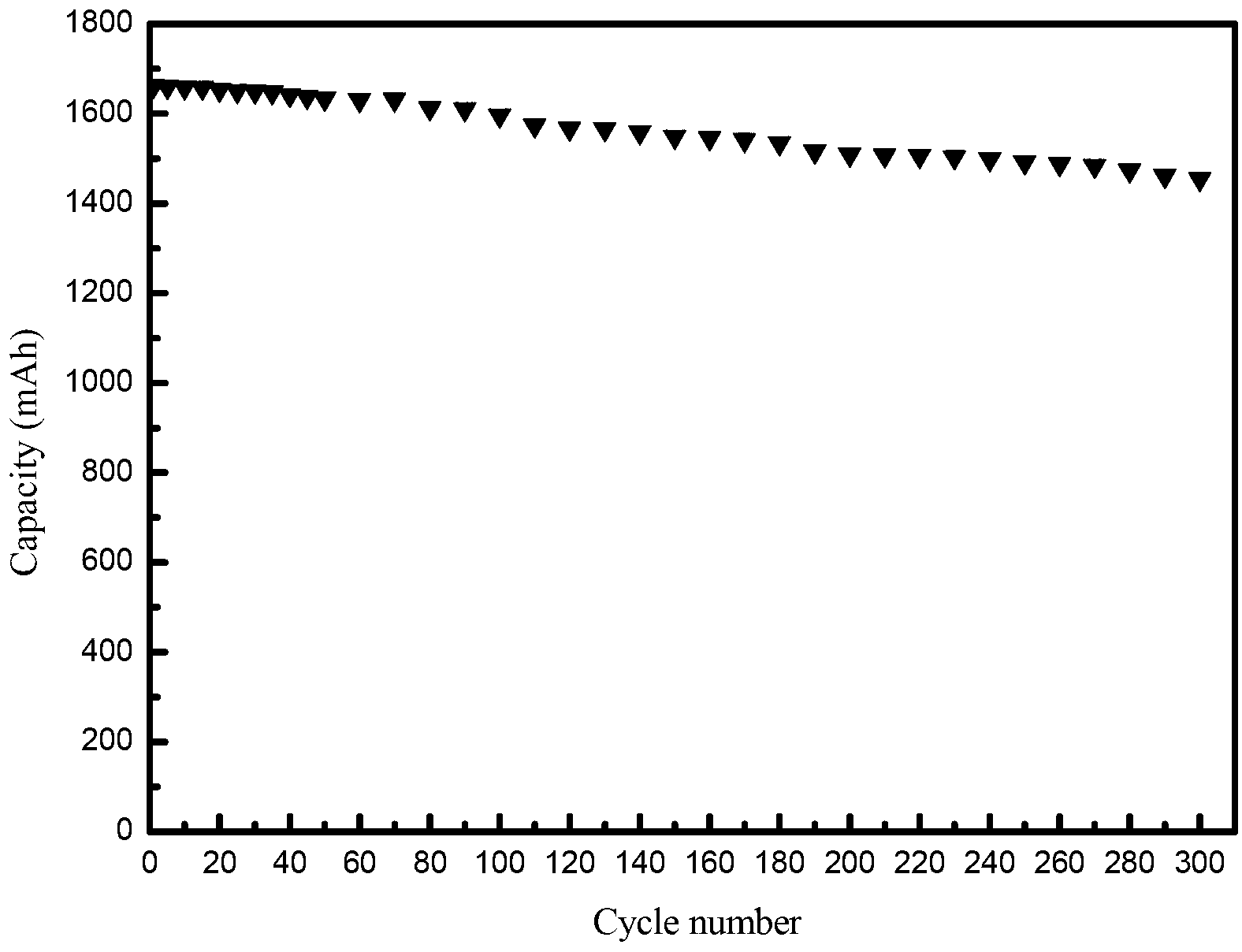

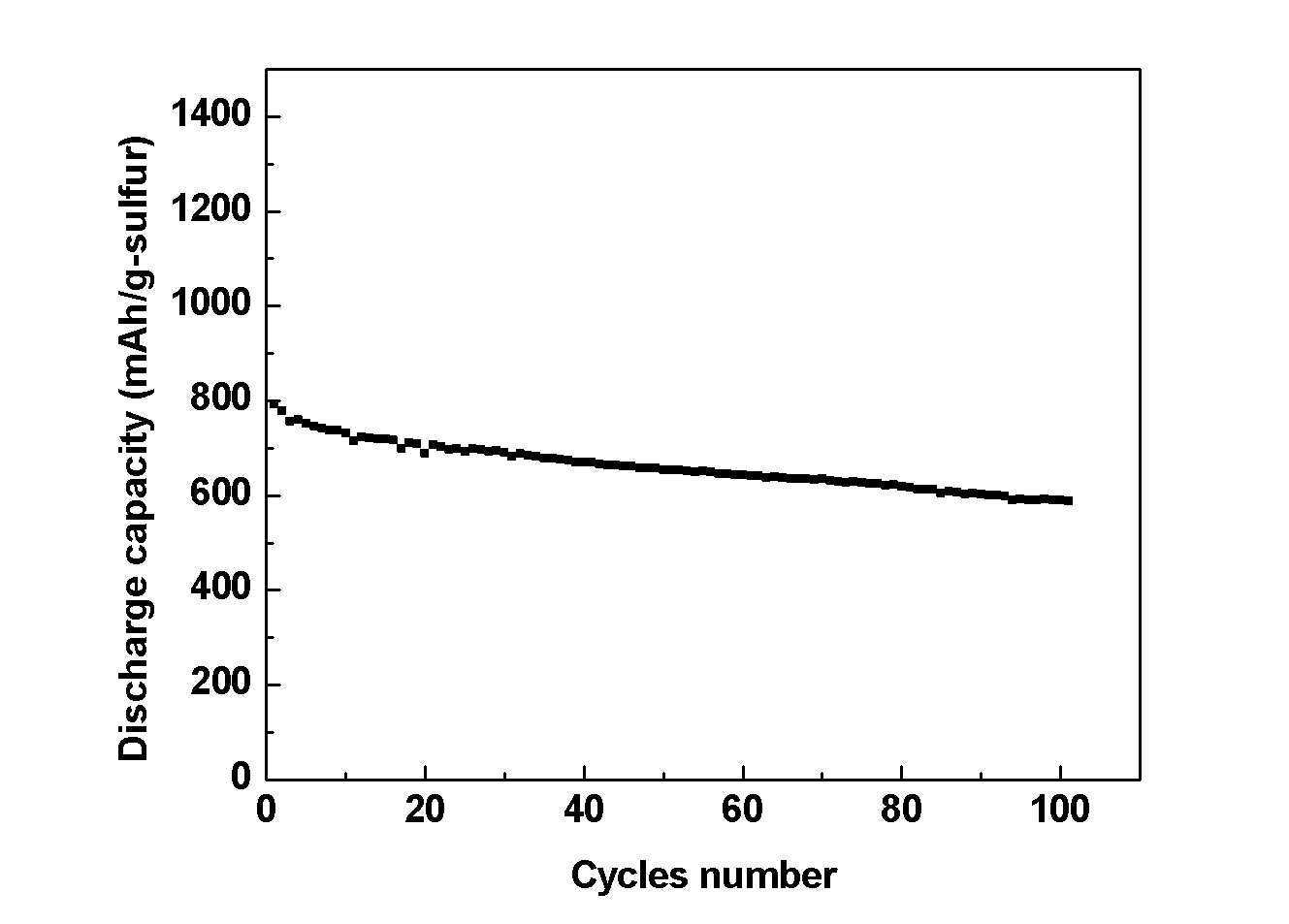

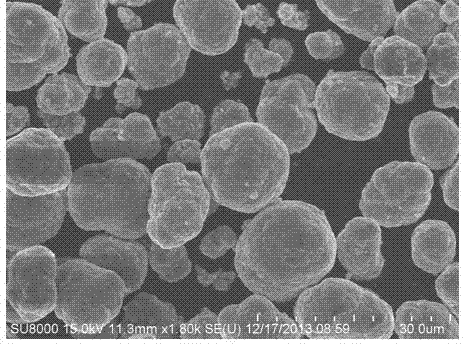

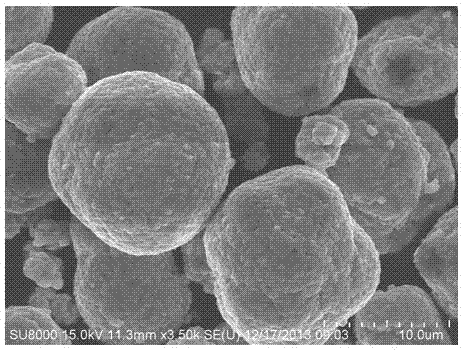

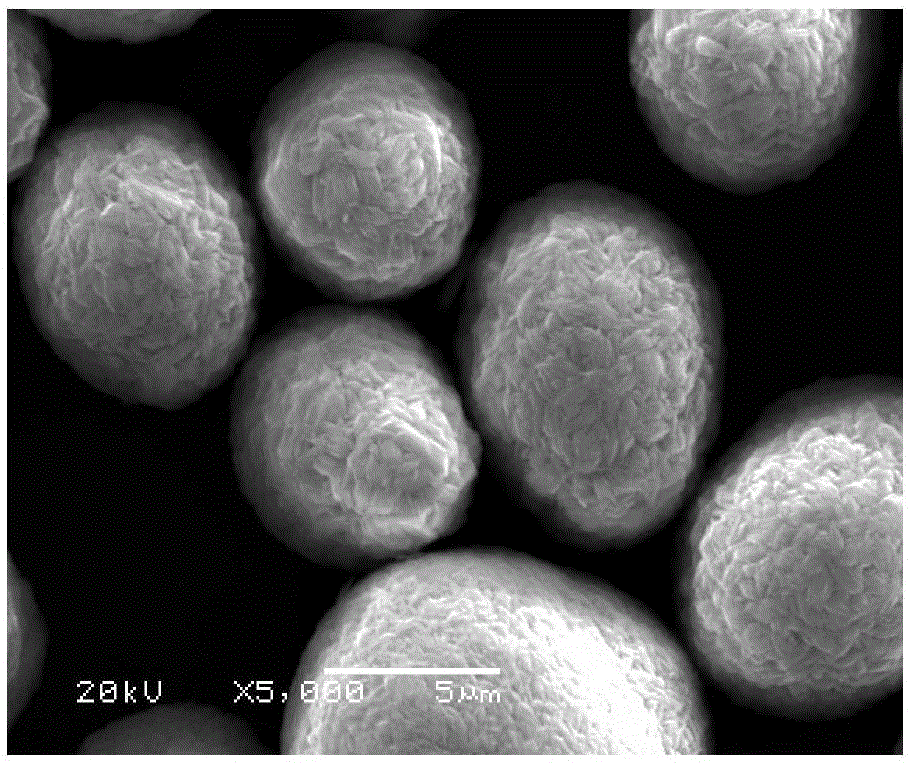

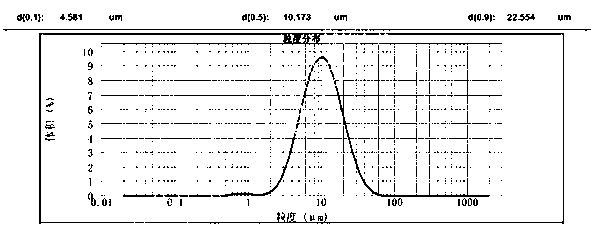

High-capacity nickel-cobalt-lithium manganate precursor and preparation method thereof

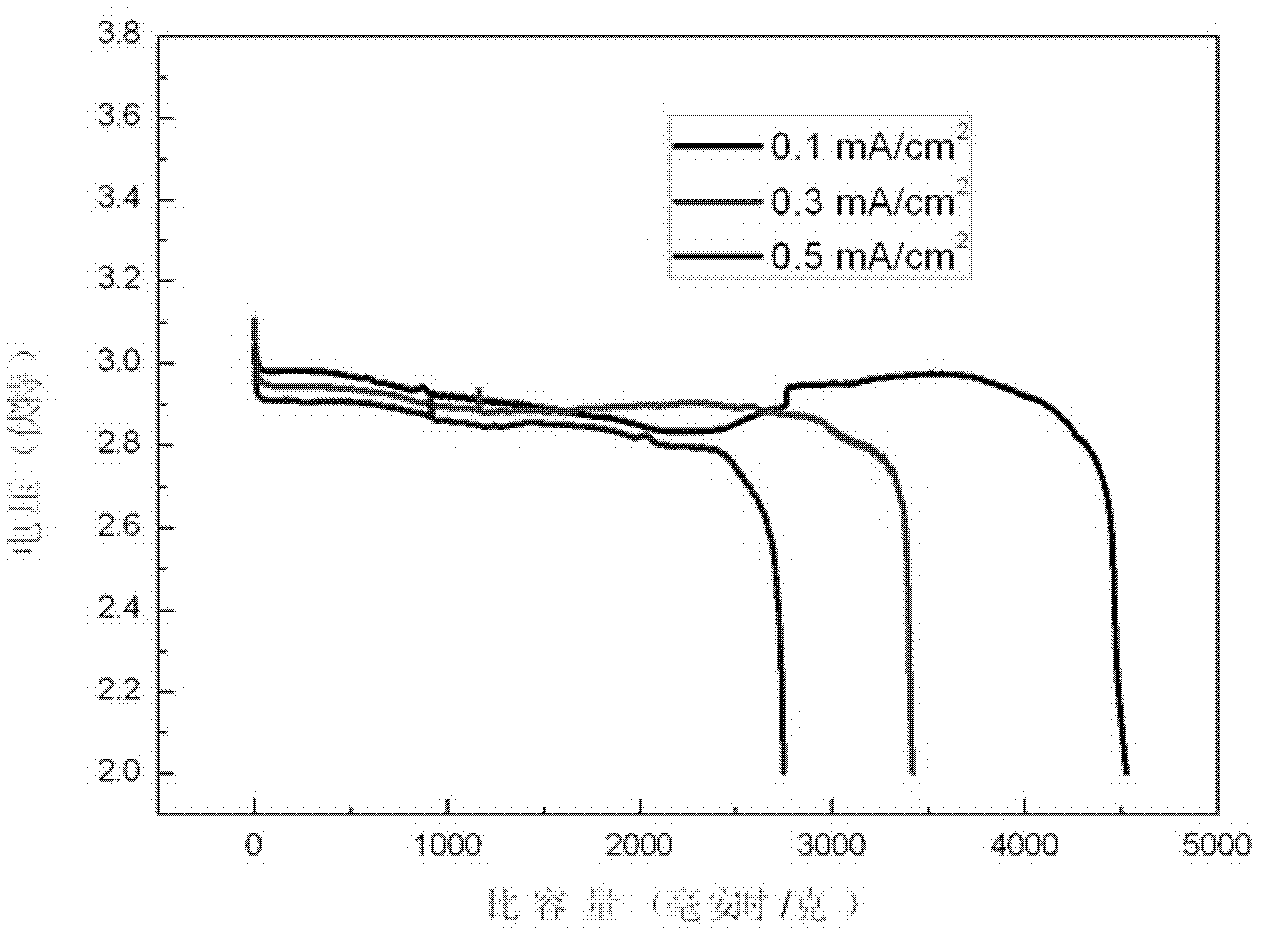

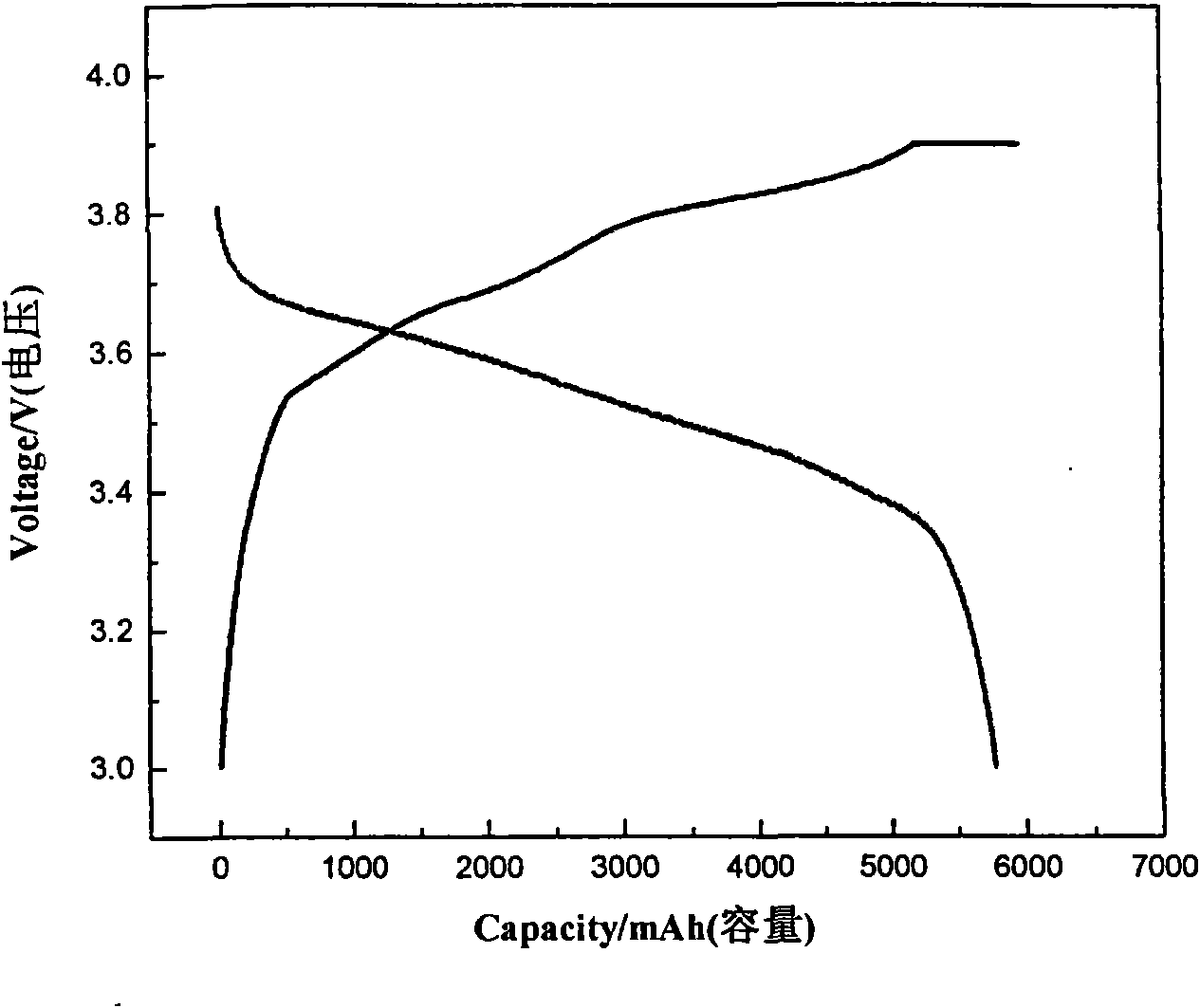

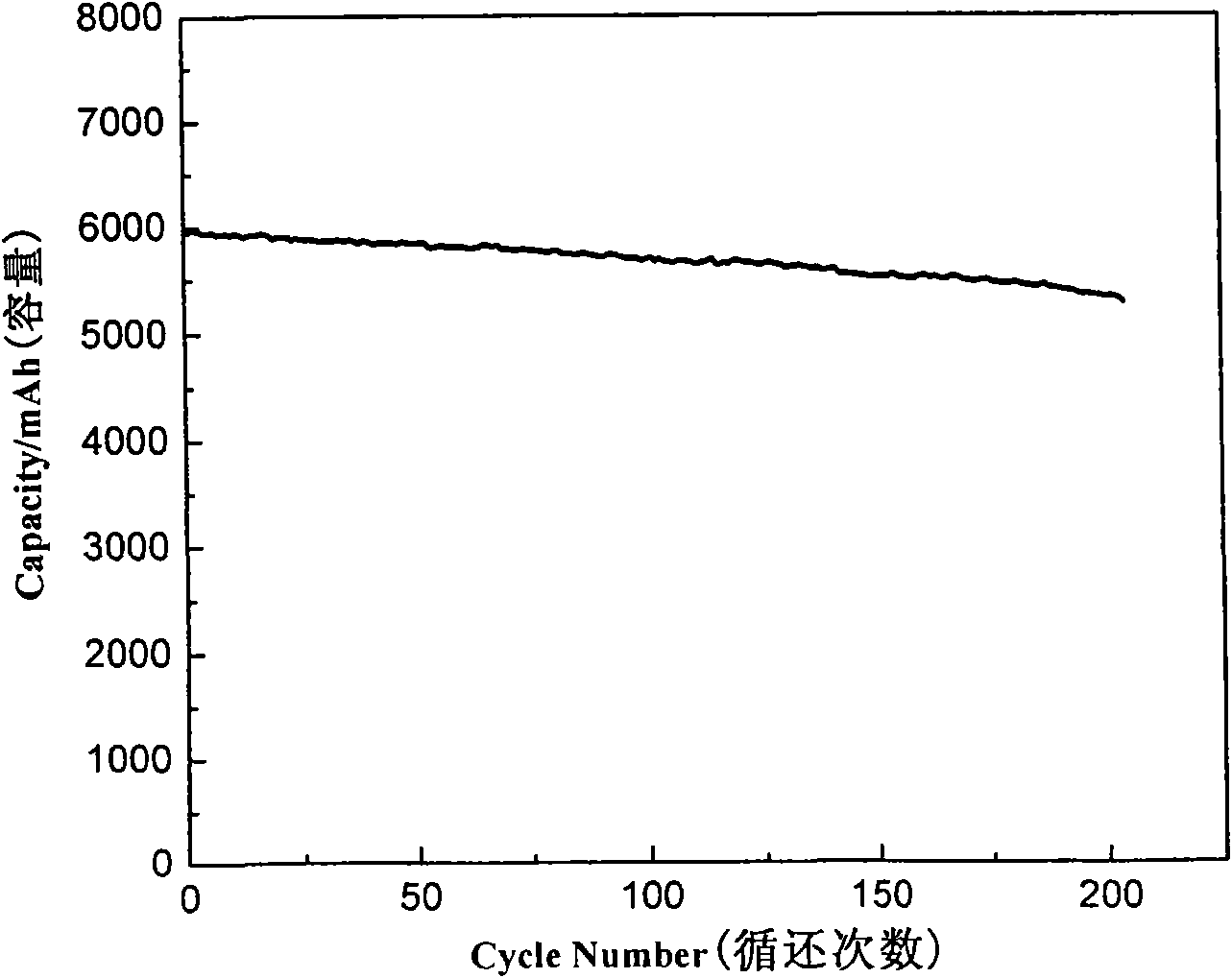

InactiveCN105118981AHigh tap densityConcentrated particle size distributionCell electrodesSecondary cellsManganateCharge discharge

The invention relates to a positive electrode material of a lithium ion battery, especially to a high-capacity nickel-cobalt-lithium manganate precursor and a preparation method thereof. The high-capacity nickel-cobalt-lithium manganate precursor is characterized by having a chemical formula of NixCoyMnz(OH)2, wherein x is no less than 0.5 and no more than 0.9, y is no less than 0.05 and no more than 0.2, z is no less than 0.05 and no more than 0.3, and x+y+z is equal to 1. The invention provides the high-capacity nickel-cobalt-lithium manganate precursor prepared through coprecipitation and the preparation method thereof; and the prepared precursor has concentratedly distributed particle size, high tap density, good sphericility, high specific capacity, low cost, long service life, higher discharge plateau and energy density, primary 1C charge-discharge specific capacity of 195 mA.h / g and 186.5 mA.h / g, and capacity retention ratio of 95.6% after 50 cycles.

Owner:NINGXIA ORIENT TANTALUM IND

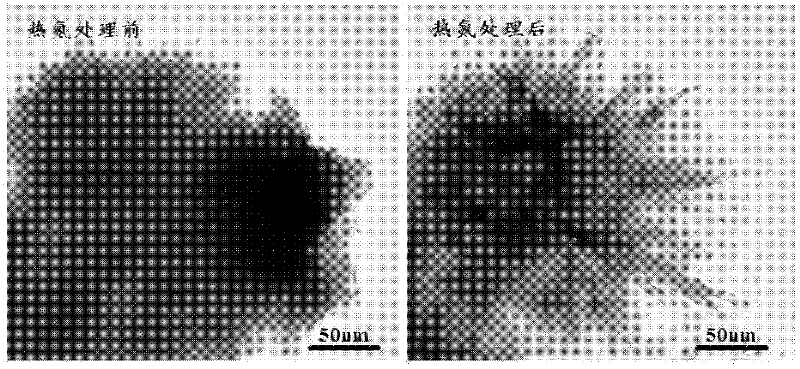

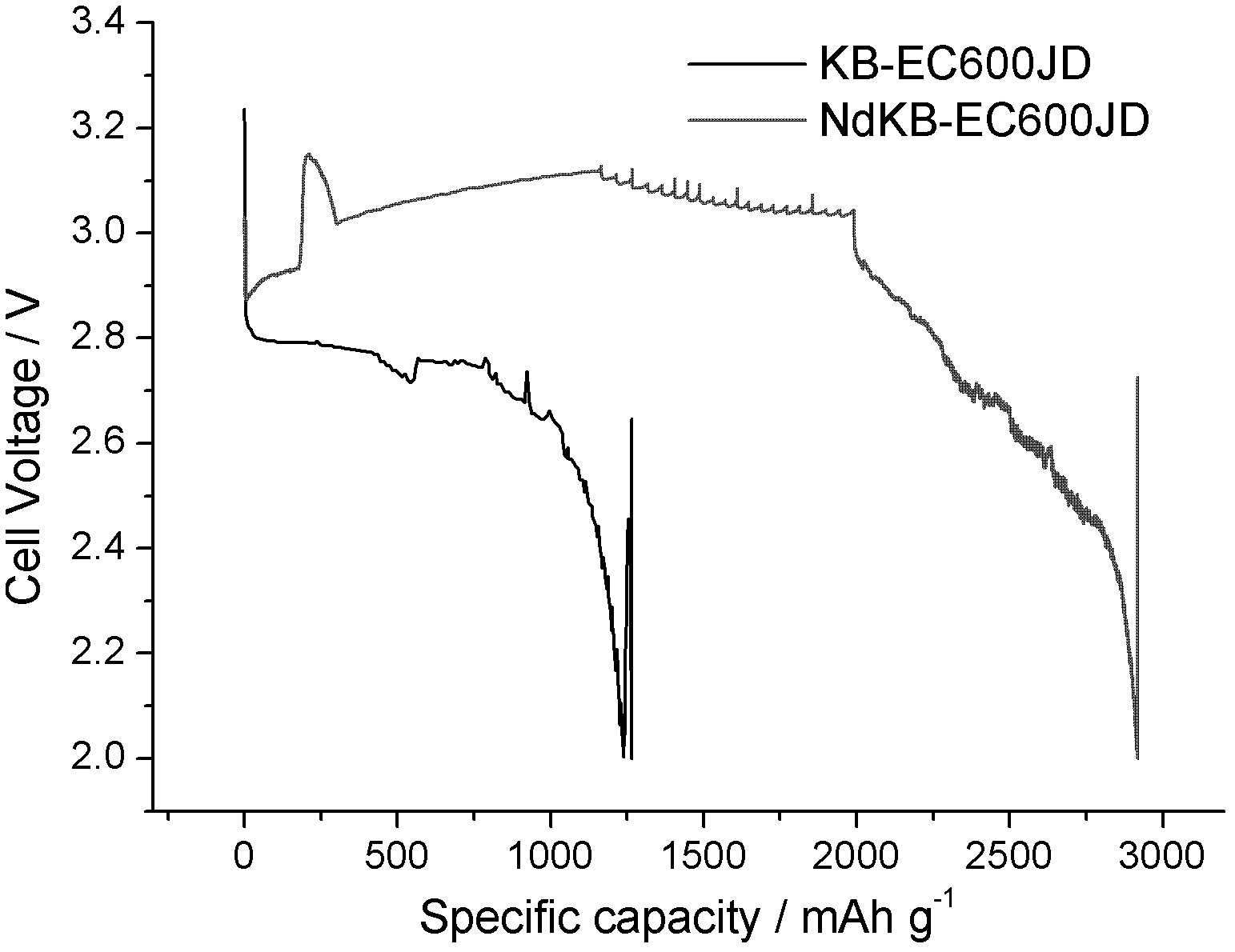

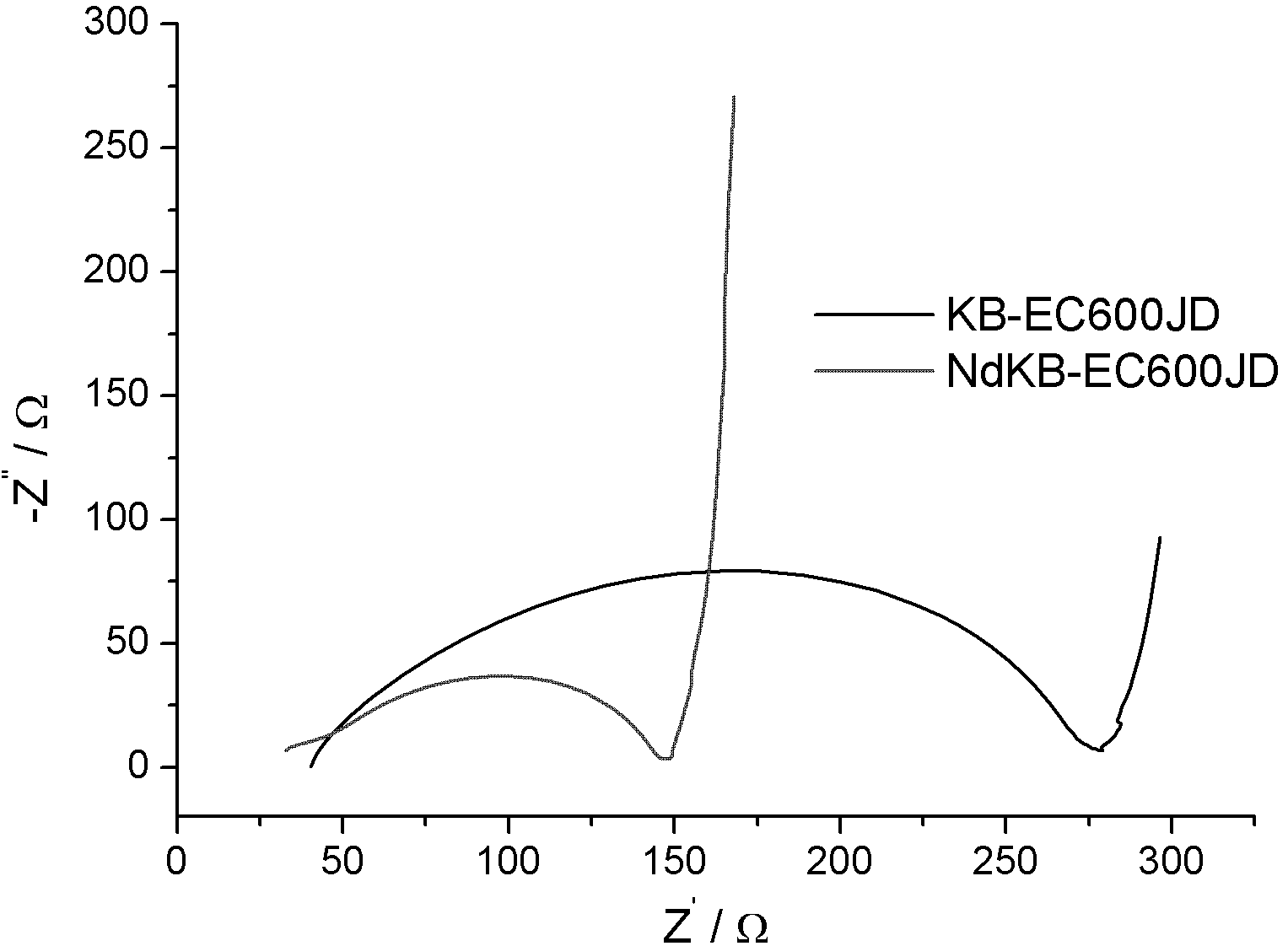

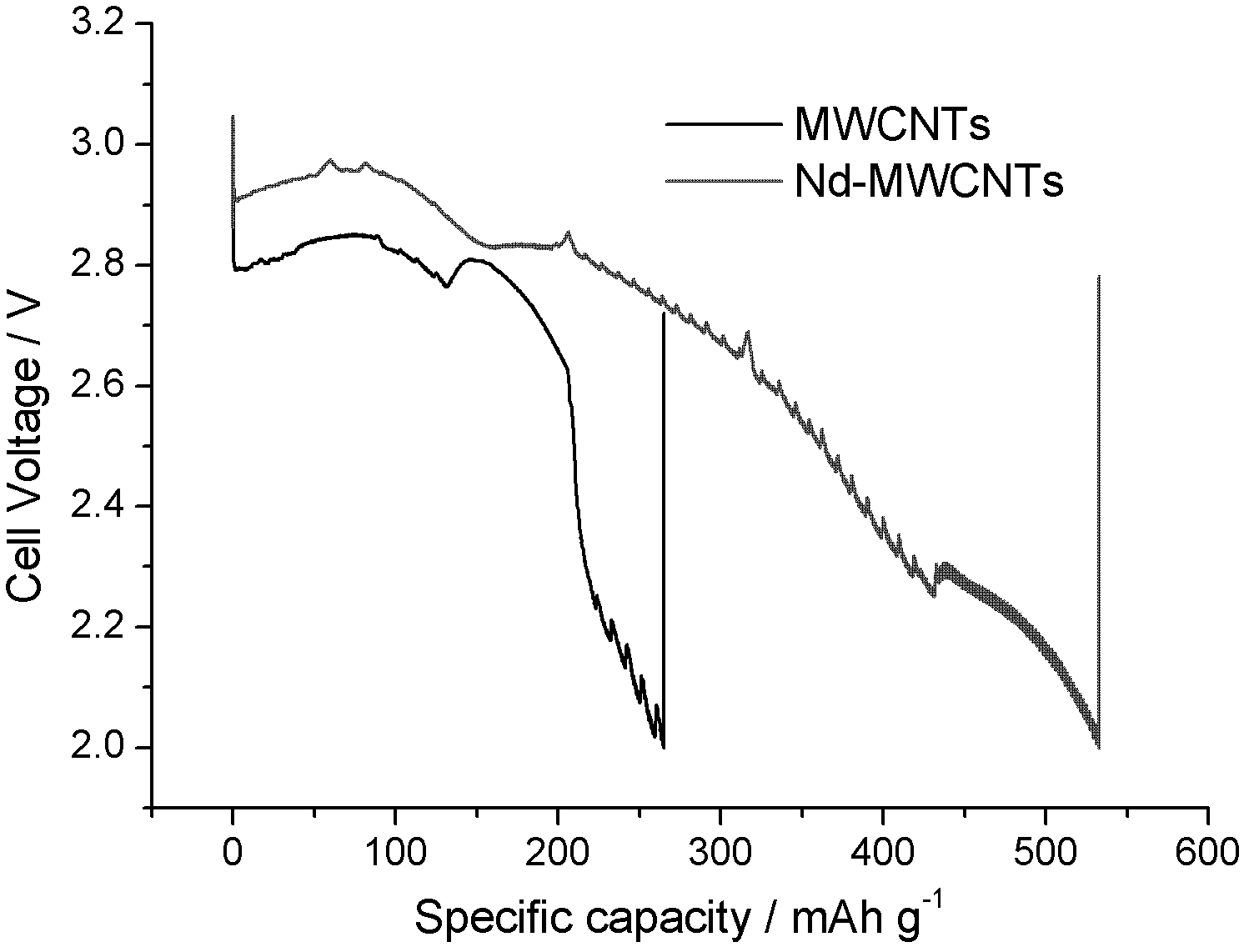

Composite electrocatalyst material used for Li-air batteries and preparation method thereof

InactiveCN102694185AImprove stabilityImprove conductivityPhysical/chemical process catalystsCell electrodesArgon atmosphereLithium–air battery

A composite electrocatalyst material used for Li-air batteries and a preparation method thereof. The transition metal oxide composite electrocatalyst modified by surface conductive transition metal nitride is obtained by conducting thermal nitrogen treatment, in an ammonia atmosphere or an ammonia and argon atmosphere, for transition metal oxide powder or transition metal oxide powder pretreated by nitrogen overlying, wherein the technology of the thermal nitrogen treatment is heating up the powder at a rate of 2-10 DEG C / min to reach the thermal nitrogen treatment temperature of 300-800 DEG C, preserving heat for 10min to 2h and then cooling in furnace. By controlling the content and flow rate of ammonia and the temperature and time of sintering, the thickness of the surface transition metal nitride can be controlled selectively. The method of the invention is simple in technology, convenient for operation, low in cost and strong in controllability. In addition, the obtained composite electrical catalyst has good conductivity and stability and can reduce the charging and discharging polarization of Li-air batteries effectively. The catalyst decreases the inner resistance of batteries and has good discharge capacity. The industrialization prospect of the catalyst is good.

Owner:CENT SOUTH UNIV

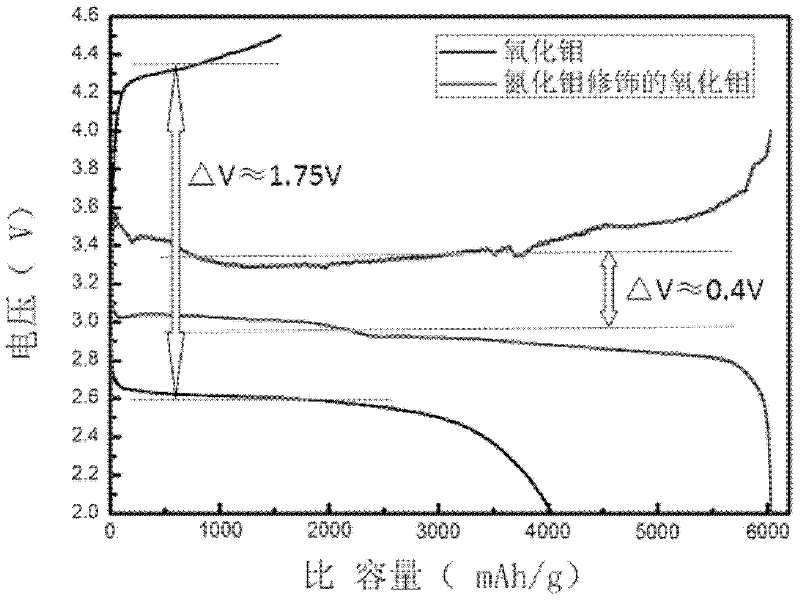

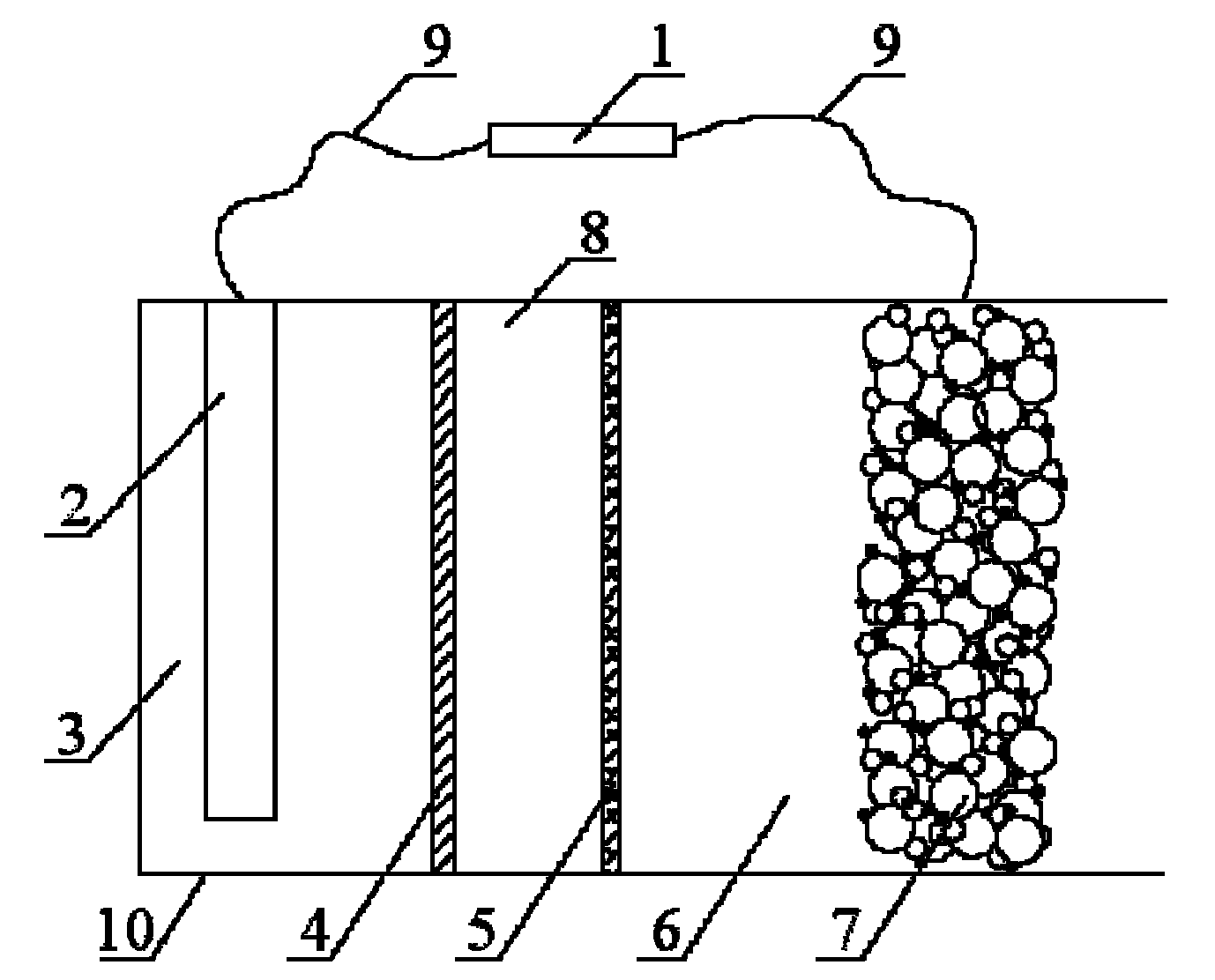

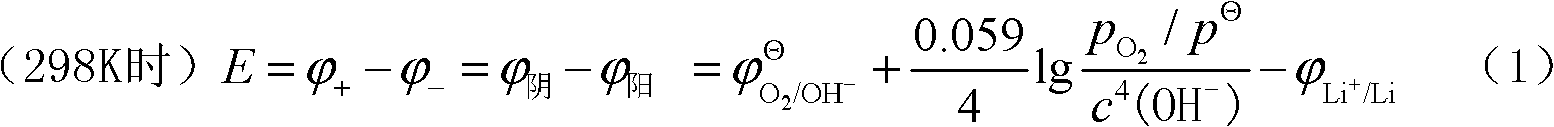

Lithium/air battery

InactiveCN102157763AProtection from erosionReduce corrosionFuel and primary cellsCell electrodesMetallic lithiumElectrochemical window

The invention discloses a lithium / air battery which belongs to the chemical power source field and is designed for solving the technical problem anode metallic lithium corrosion, high possibility of power failure and bad cycle performance of the existing lithium air battery. A shell is divided into an anode room, a buffer room and a cathode room by a solid inorganic electrolyte membrane and a diaphragm. The lithium / air battery uses a hydrophobic ionic liquid as an anode electrolyte, which has the advantages of non-volatile, high conductivity, wide electrochemical window, low melting point and moderate viscosity, and can prevent the metallic lithium from being corroded by water and oxygen. The cathode uses a water base-weak acid-buffer solution with the Ph of not less than 4 and not more than 5 as the electrolyte; compared with a neutral or alkaline electrolyte, the water base-weak acid-buffer solution ensures that the average discharge voltage (0.1-0.2V) can be improved, a discharge plateau can be prolonged, and the corrosion of the strongly alkaline electrolyte to the solid inorganic electrolyte membrane is reduced; and a cathode discharge product is a water-soluble LiOH which cannot deposit on the surface or in the duct of the cathode to cause power failure, and is good in cycle performance.

Owner:HARBIN INST OF TECH

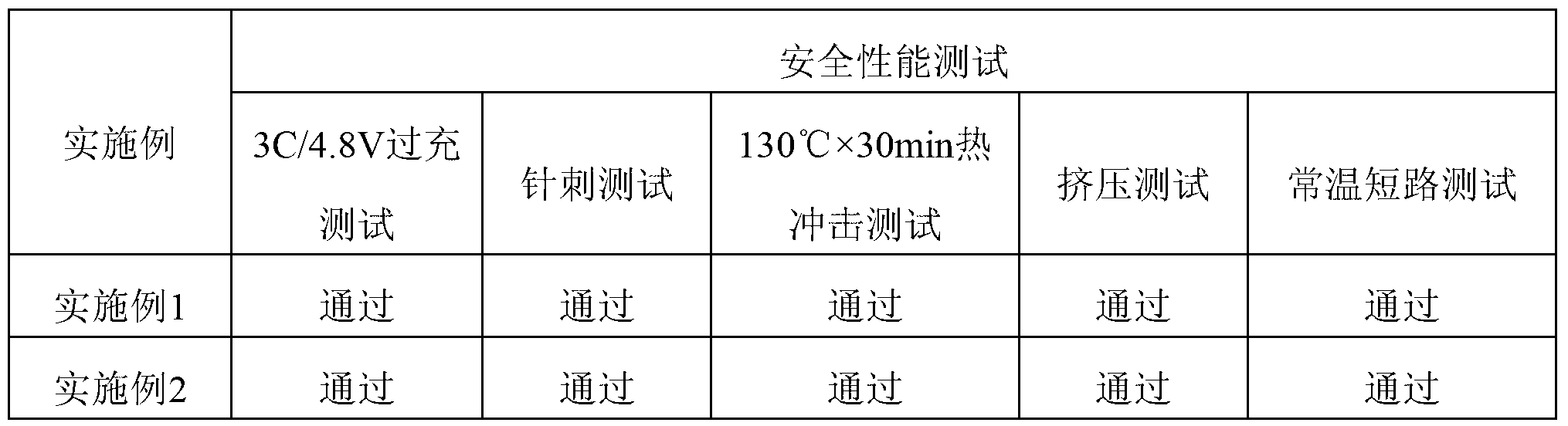

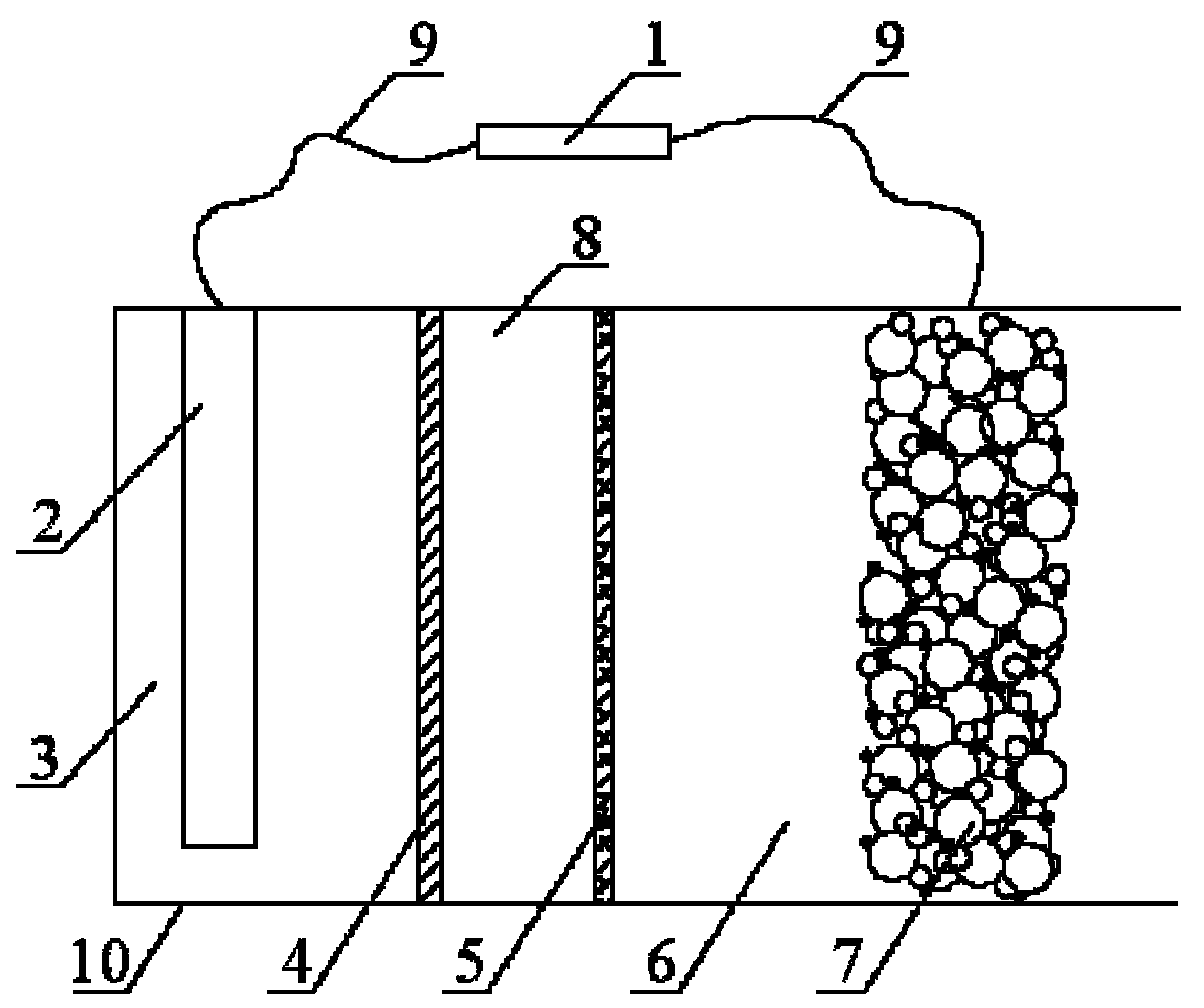

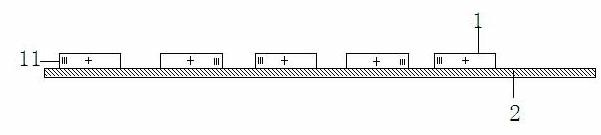

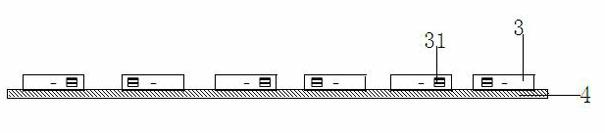

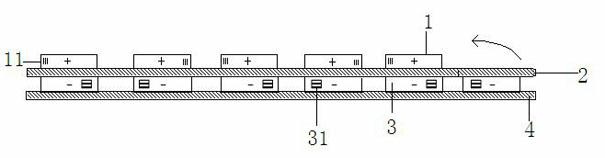

Lithium ion battery cell and preparation method thereof

InactiveCN102683742ALower internal impedanceReduce polarizationFinal product manufactureSecondary cellsInternal resistanceLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and in particular relates to a lithium ion battery cell which comprises at least two positive electrode plates, at least two negative electrode plates, a first wound membrane and a second wound membrane, wherein the positive electrode plates and the negative electrode plates are mutually overlapped, and the difference of the number of the positive electrode plates and the number of the negative electrode plates is one; the positive electrode plates are arranged at the same side of the first membrane; the negative electrode plates are arranged at the same side of the second membrane; and at the direction from the innermost circle to the outermost circle of the battery cell, the first membrane and the second membrane are alternatively arranged between the adjacent positive electrode plates and the negative electrode plates at intervals. Compared with the prior art, the lithium ion battery cell has the advantages that the parallel connection multiple layers of electrode plates provided by the invention can be used for reducing the internal resistance of the battery cell, thus the polarization is reduced, and the discharging platform is improved; the parallel connection of the electrode plates can be used for improving the high-multiplying-power charging and discharging capability of the battery cell; and because the electrode plates of the battery cell provided by the invention are stacked together, the internal structure is unified, the stress is distributed uniformly, the possibility of deformation is small. In addition, the invention also discloses a preparation method of the battery cell.

Owner:DONGGUAN AMPEREX TECH +1

Method for preparing positive electrode material of anion-cation multi-component compound lithium battery

The invention discloses a method for preparing a positive electrode material of an anion-cation multi-component compound lithium battery, which comprises the following steps of: performing ball-milling mixing on a substitute and a substrate raw material, adding at least one of water, ethanol and acetone serving as a ball-milling solvent into the mixture; performing spray drying to obtain a precursor; and sintering the spray-drying precursor under the protection of an inert atmosphere to finally obtain LiFe1-m(NixCoyMnz)mP1-nDnO4 positive electrode material of the lithium battery. The molecular formula of the material is LiFe1-m(NixCoyMnz)mP1-n-DnO4, wherein the Fe position is partially substituted by a ternary precursor (NixCoyMnz)(OH)2, and simultaneously the D at the P position uses a compound or a simple substance of boron, sulfur, silicon, chlorine, selenium, tellurium and tungsten and adopts a multi-component composite radical as a substitute to achieve the synergistic action of anions and cations or ion radicals so as to synchronously improve the ion diffusion and the electron conductivity of the material. The material prepared by the method has high charge and discharge capacities, good multiplying factor performance and good circle performance.

Owner:重庆特瑞新能源材料有限公司

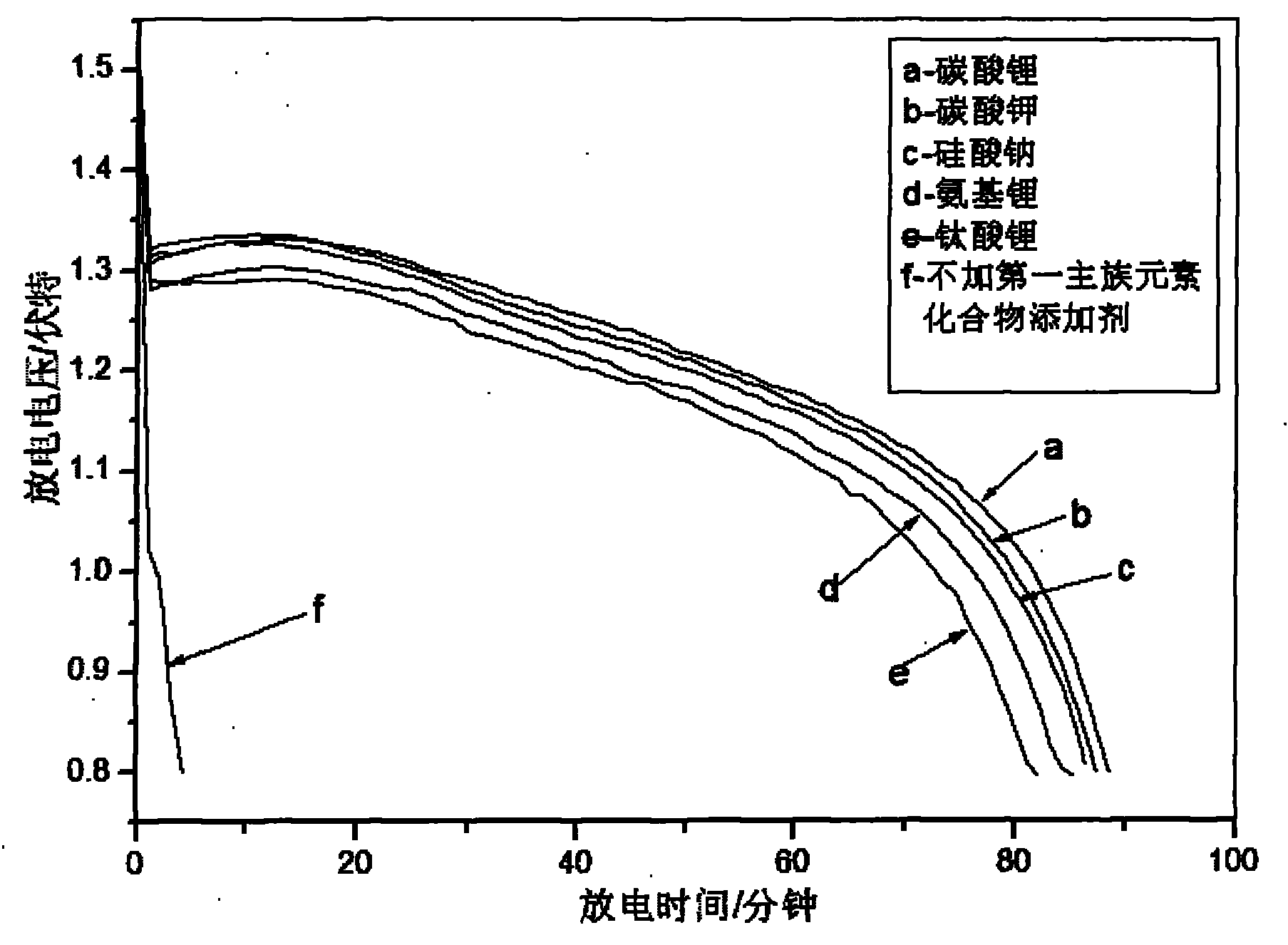

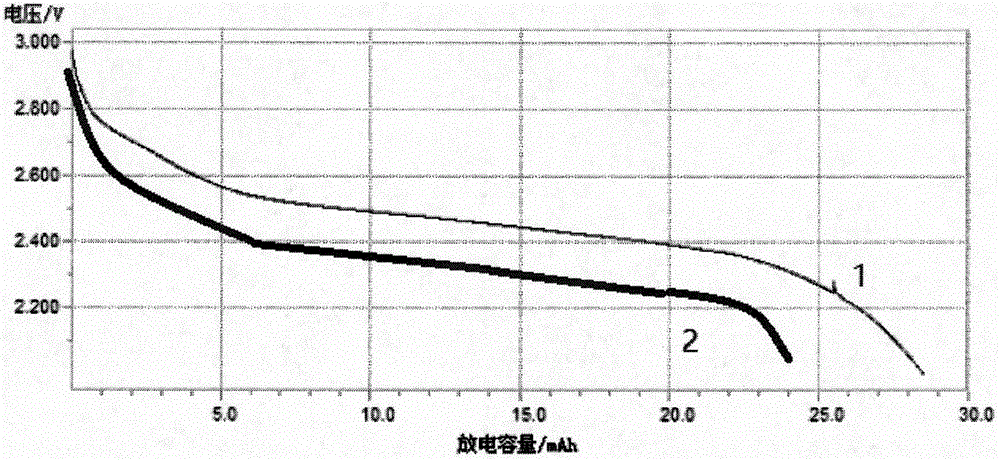

Anode material of Li-ferrous disulfide battery and battery

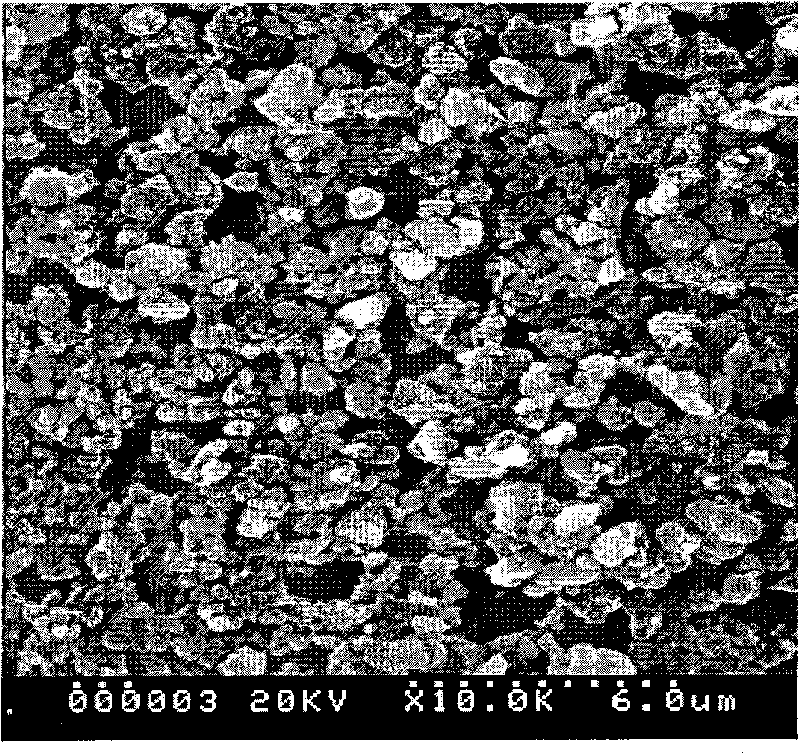

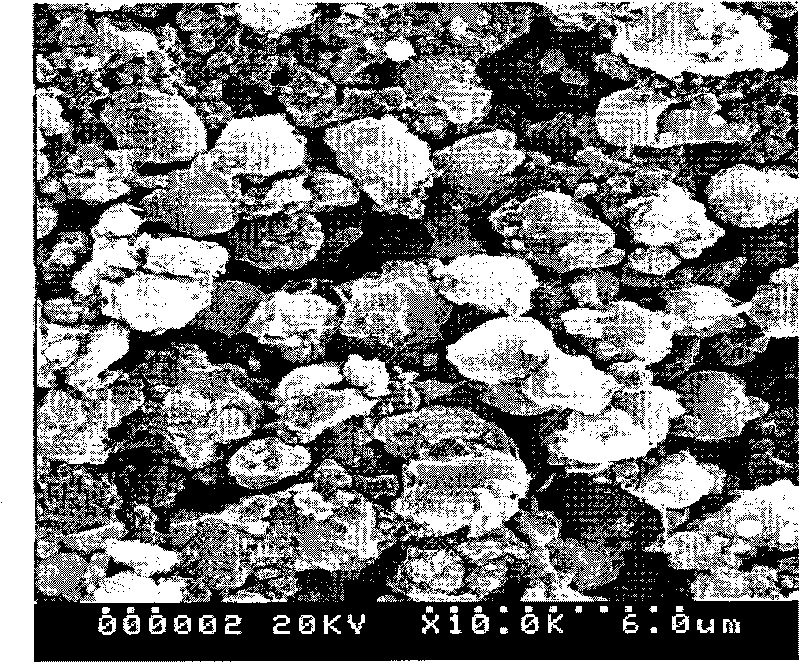

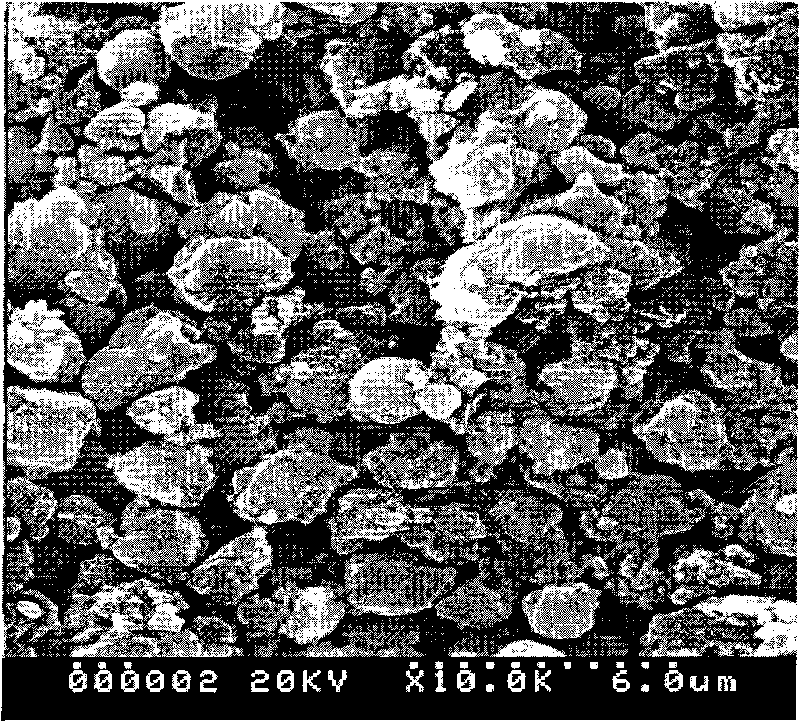

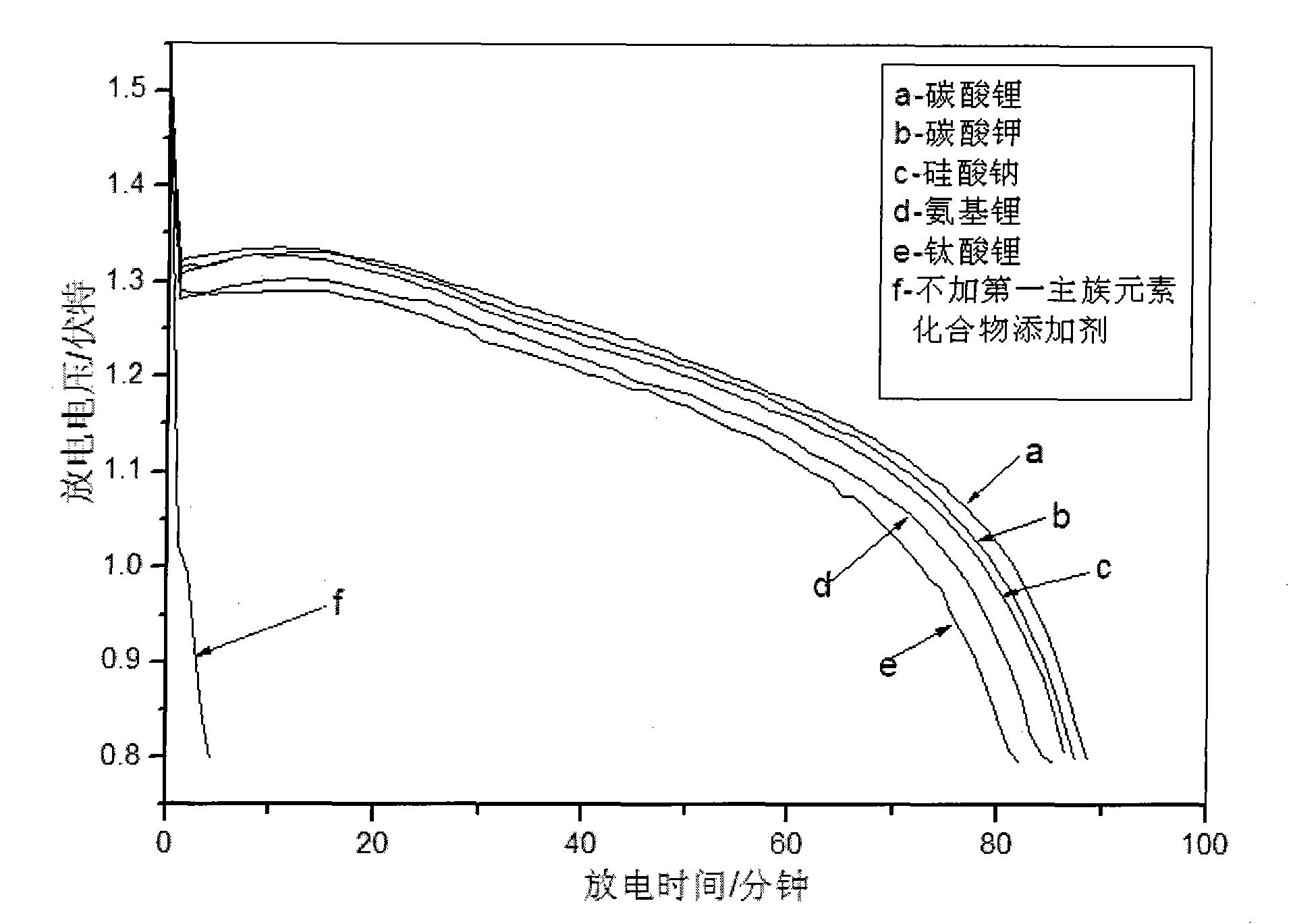

InactiveCN102024953AExtend discharge timeImprove discharge capacityFinal product manufactureCell electrodesAluminateMain group element

The invention relates to an anode material of a Li-ferrous disulfide battery and the Li-ferrous disulfide battery, belonging to the battery field. The anode material of the Li-ferrous disulfide battery comprises the following ingredients by weight percentage: 50-99.5 percent of ferrous disulfide powder, 0.25-25 percent of bonder, 0.25-25 percent of conductive agent and the balance first main group element compounds accounting for 0.4-10 percent of the quality of the ferrous disulfide powder; the first main group element compounds comprise one ore more o carbonate, bicarbonate, silicate, germanate, acetate, phosphate, aluminate, titanate and amino salts. In the invention, the added first main group element compounds greatly improve the discharging platform and discharging performance of the battery, the discharging platform of the battery is high, the discharging time is long, the discharge capacity is large, the heavy-current discharging property is good and the storage life is long.

Owner:GUANGZHOU GREAT POWER ENERGY & TECH CO LTD

Lithium air or oxygen battery

ActiveCN102593556AHigh specific capacityHigh discharge platformFuel and secondary cellsCell electrodesElectrochemistryOxygen

The invention discloses a lithium air or oxygen battery, comprising an air or oxygen electrode, a cathode, a diaphragm and electrolyte, wherein materials of the air or oxygen electrode comprise a nitrogen-doped carbon material and further comprise one or more than two of a transition metal oxide, a transition metal nitride, a transition metal carbonitride, a transition metal carbide and other catalysts. According to the invention, the nitrogen-doped carbon material is used to a traditional carbon material, meanwhile, the cheap catalyst which constitutes an active substance of the air or oxygen electrode can be used in an auxiliary way or is not used, and compared with the traditional lithium air or oxygen battery, the lithium air or oxygen battery which is finally obtained according to the invention has higher specific capacity, higher discharge plateau, favorable integral electrochemical performance and better industrial practical values. In addition, the lithium air or oxygen battery disclosed by the invention is extremely suitable for being used as a backup battery for substituting a lithium ion battery.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of ferrous silicate lithium doped anode material

InactiveCN101734674ALow costWide variety of sourcesCell electrodesAlkali metal silicatesPhosphorous acidWater baths

The invention discloses a preparation method of a ferrous silicate lithium doped anode material. The preparation method comprises the following steps of: weighing lithium salt, ferrous silicate salt, a silicon compound and phosphate according to the mole ratio being (0.95-1.10):(0.95-1.10):(0.80-0.999):(0.001-0.286) of lithium ions to ferrous silicate ions to silicon atoms to phosphorous acid radical ions in an initial reactant and mixing the compounds to obtain an initial reaction mixture; adding a carbon-containing compound which is 1-30 percent of the weight of an anhydrous state compound of the initial reaction mixture and a wet milling medium which is 0.10-10 times of the volume of the anhydrous state compound; ball milling and mixing and heating in a water bath; ball mixing and mixing gain; finally drying; placing the dried powder in an inert atmosphere or a weakly reducing atmosphere; and preparing doped ferrous silicate lithium by adopting a two-stage sintering method or a two stage program temperature-rising sintering method. The electrode material has better discharge performance; the discharge capacity of the prepared sample in a 3.0V zone is remarkably increased; and the prepared sample has excellent circulating performance under the current of 0.3C multiplying power, which lays a sound foundation for the industry.

Owner:FUJIAN NORMAL UNIV

Method for manufacturing novel lithium iron battery

InactiveCN101901936ALarge design spaceImprove high-current discharge performanceElectrode manufacturing processesFinal product manufactureHigh energyLithium-ion battery

The invention relates to a method for manufacturing a novel lithium iron battery. The novel lithium iron lithium ion battery is manufactured by combining an anode active substance made of a FeF3 / V2O5 composite material and LiMn2O4 with a carbon cathode, wherein the anode active substance is prepared by ballmilling 5 to 85 mass percent of LiMn2O4 and 95 to 15 mass percent of FeF3 / V2O5 composite material for 1 and 8 hours; before the anode active substance is prepared, the FeF3 / V2O5 composite material is prepared first, namely V2O5 accounting for 1 to 50 percent of the total mass of the composite material and FeF3 accounting for 99 to 50 percent of the total mass of the composite material are subjected to high-energy ball mill for 1 to 8 hours and the ground V2O5 and FeF3 are annealed at the temperature of between 100 and 600 DEG C for 1 to 12 hours to form the FeF3 / V2O5 composite material. The method has the advantages of improving the conductivity of the material, prolonging the service life of the battery, improving a discharging platform substantially and enhancing the large-current discharging capacity of the battery, along with high safety performance of the battery.

Owner:HUNAN HAIXING HIGH TECH POWER BATTERY

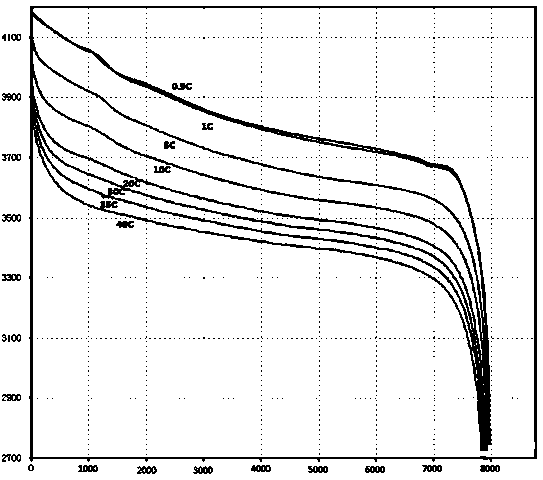

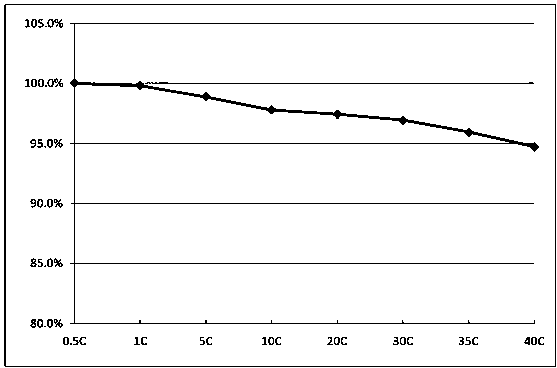

High-power lithium ion battery pole piece and preparation process thereof

InactiveCN103928657AImprove rate discharge performanceHigh discharge platformSecondary cellsNon-aqueous electrolyte accumulator electrodesPower batteryOrganic solvent

The invention relates to a high-power lithium ion battery pole piece and a preparation process thereof. The battery pole piece is provided with a current collector, wherein the positive and reverse sides of the current collector are coated with conductive base layers; the conductive base layers are coated with active substance coatings; each conductive base layer consists of a conductive agent and an adhesive according to a mass ratio of 75-95 percent to 7-25 percent. The preparation process comprises the following steps: mixing the adhesive with an organic solvent, thus obtaining an adhesive solution; stirring the conductive agent and the adhesive solution, thus obtaining slurry; grinding the slurry by using a colloid grinder, regulating the viscosity to be 300-1,000mpa.s, screening to obtain conductive slurry, coating the positive and reverse sides of the current collector with the conductive slurry, drying and compacting to obtain the conductive base layer; and coating the conductive base layer with the active substances, drying and compacting to obtain a high-power lithium ion power battery piece. The electric conductivity of the battery piece can be improved; for the battery piece under the same surface density condition, the rate discharge performance of the battery and a discharge platform are high, and over 94 percent of capacity can be preserved under the 40C-rate current discharge condition.

Owner:QUANZHOU JINTION ELECTRONICS

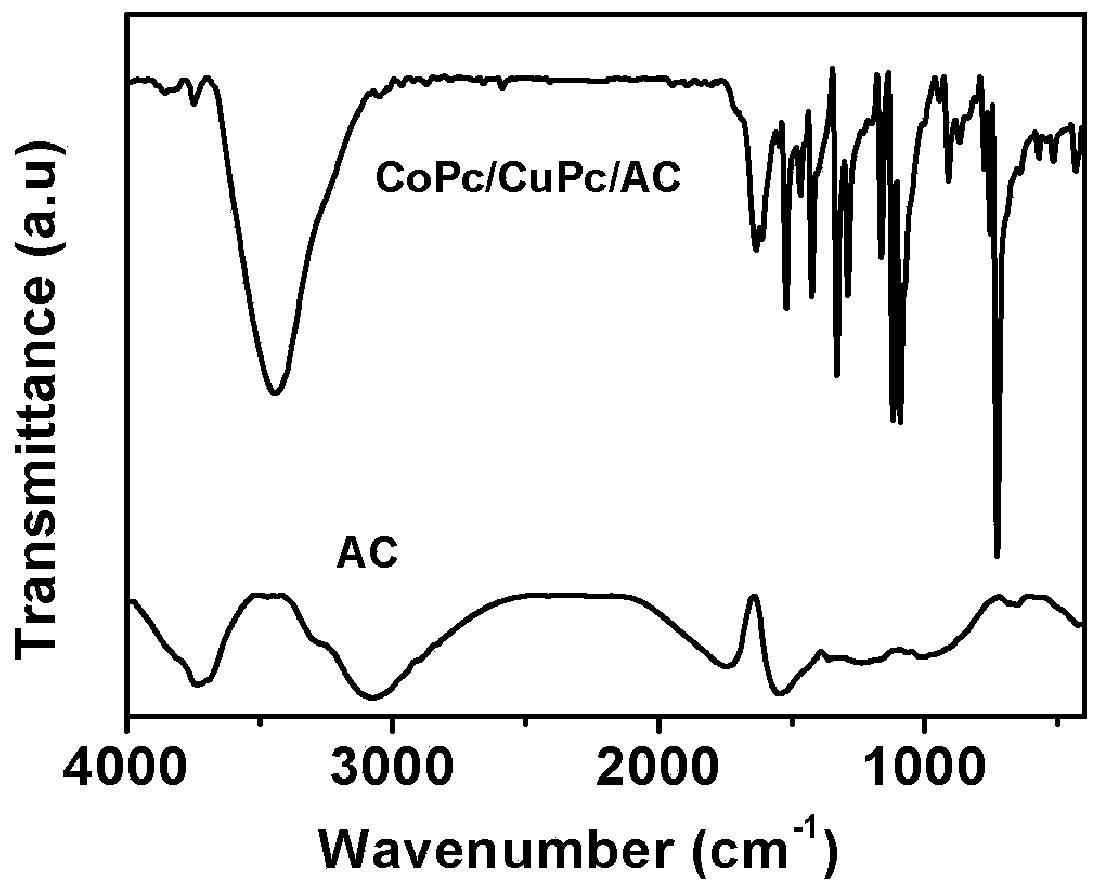

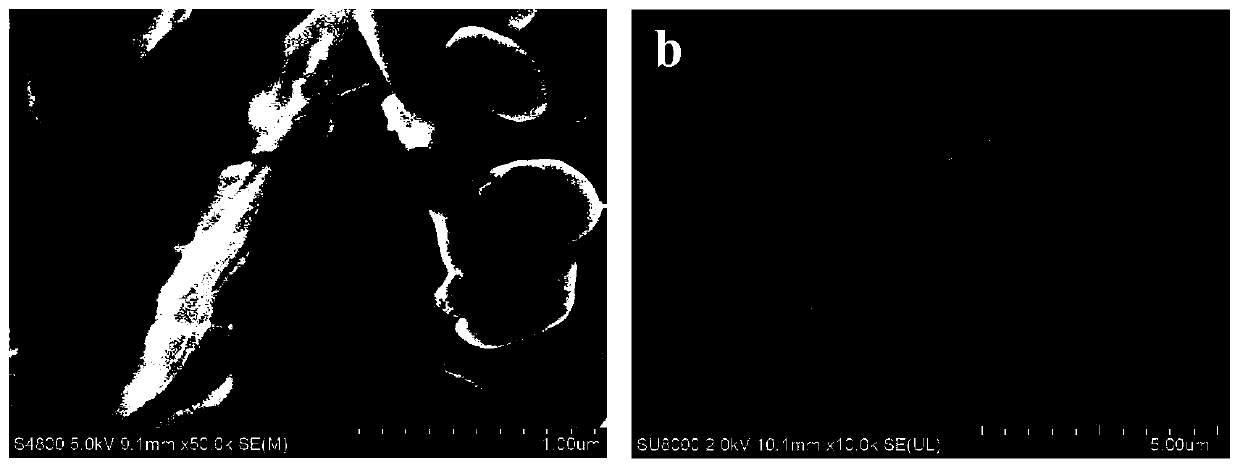

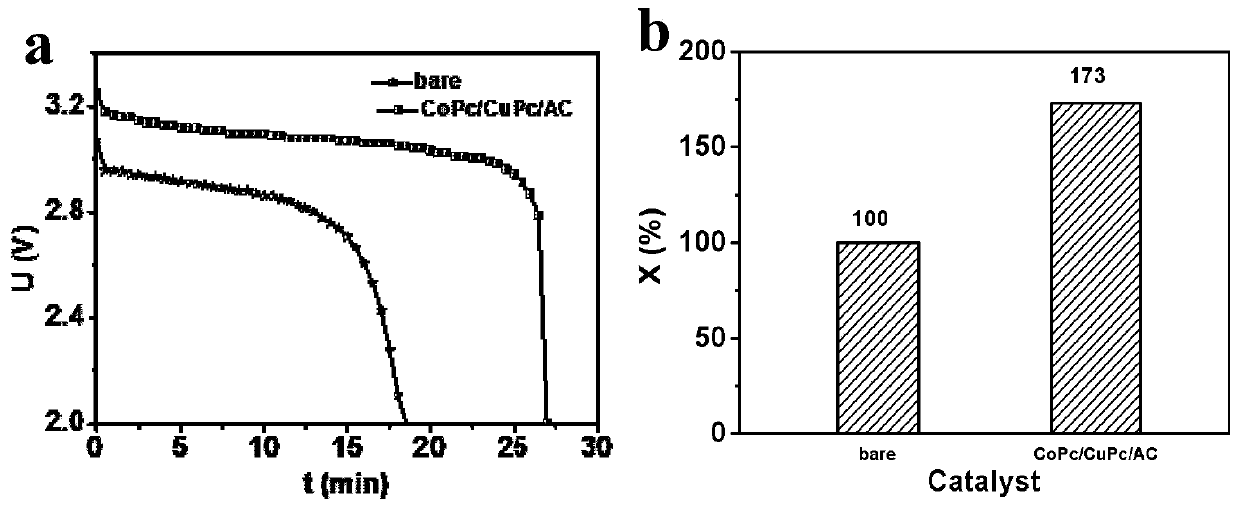

Cobalt phthalocyanine/copper phthalocyanine/pitch coke activated carbon catalytic material and method for preparing lithium thionyl chloride battery positive plate by using catalytic material

InactiveCN110233267AImprove conductivityAvoid reunionNon-aqueous electrolyte cellsPrimary cell electrodesSolid phasesActivated carbon

The invention relates to a cobalt phthalocyanine / copper phthalocyanine / pitch coke activated carbon catalytic material and method for preparing a lithium thionyl chloride battery positive plate by using the catalytic material. The method comprises the following steps of: taking pitch coke activated carbon with a large specific surface area (800m2 / g) and high activity as a template, and growing cobalt phthalocyanine and copper phthalocyanine on the surface in situ, wherein a pitch coke activated carbon framework plays a role in structural support, and is linked through hydrogen bonds and covalent bonds, so that agglomeration of phthalocyanine complexes is avoided, and the structural stability of the material is improved; in addition, the preparation process is simple and easy to control through a solid-phase in-situ one-step sintering method, the period is short, the energy consumption is low, the repeatability of the product is high, the yield is high, and the large-scale production isfacilitated. The catalytic material prepared by the method is used for the lithium thionyl chloride battery, the initial discharge voltage is increased by 0.18V and the energy density is increased by73% compared with the initial discharge voltage of the anode material without the catalytic material. The application prospect is wide.

Owner:SHAANXI UNIV OF SCI & TECH

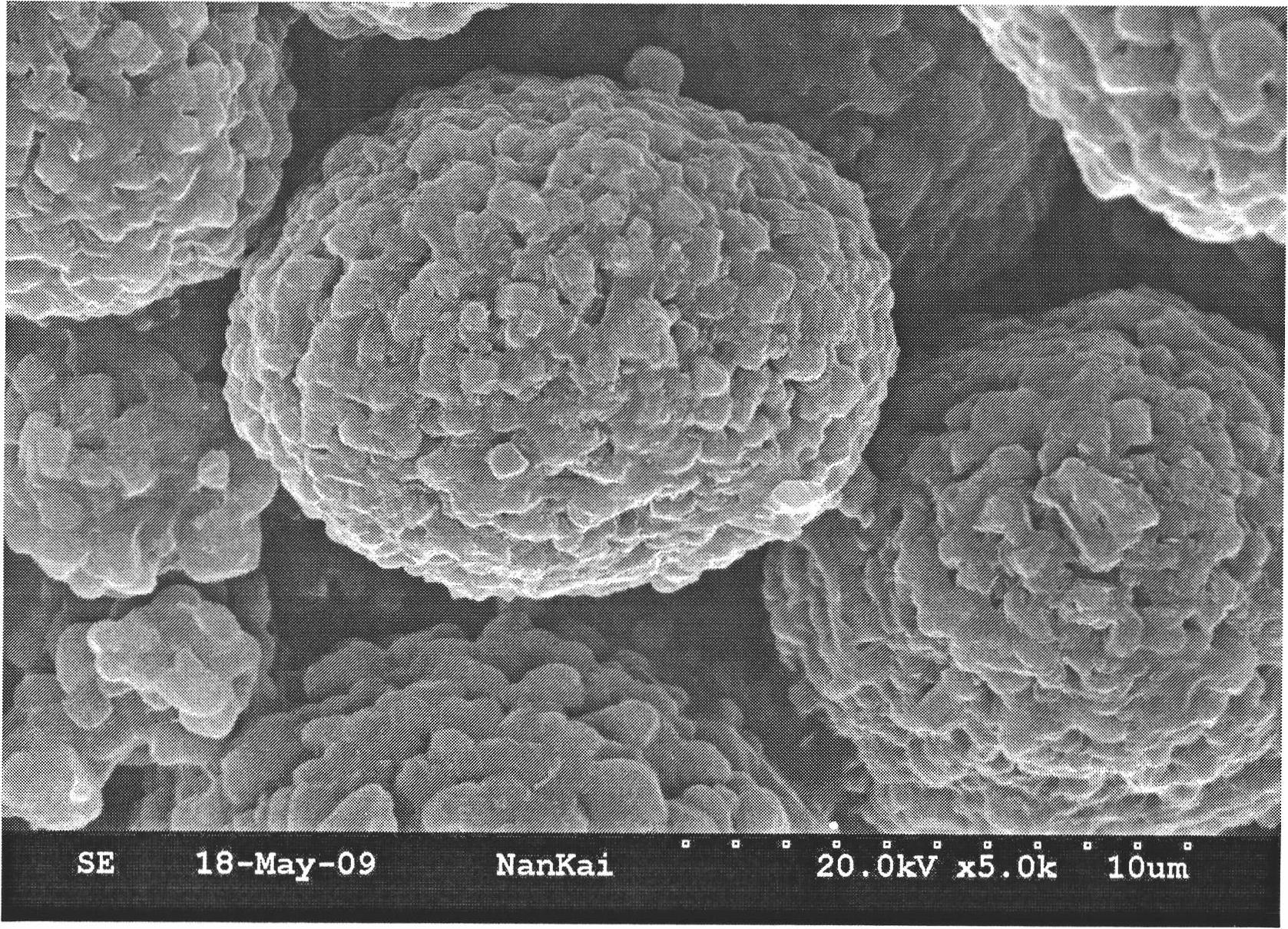

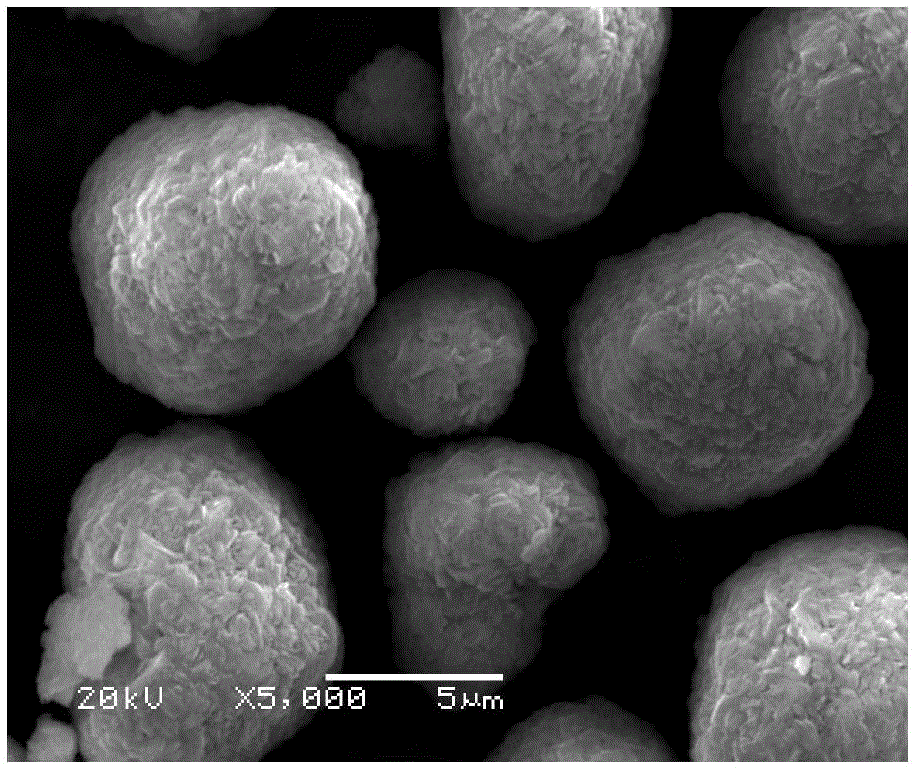

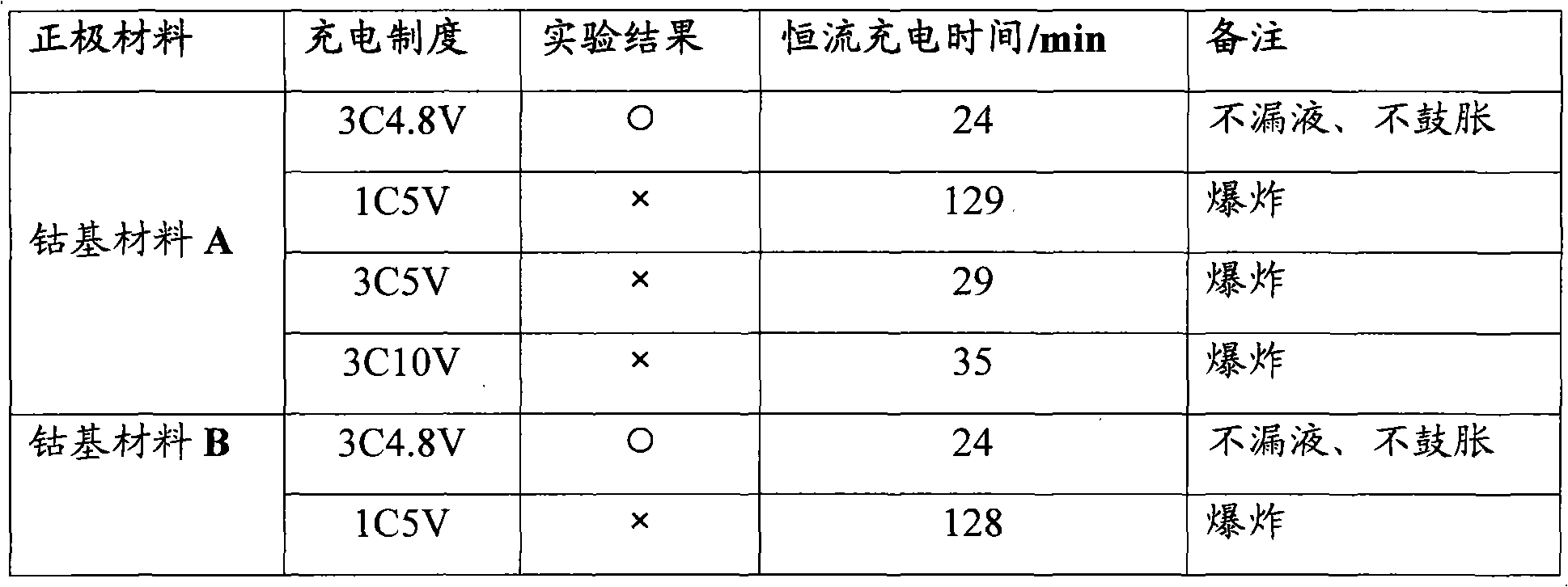

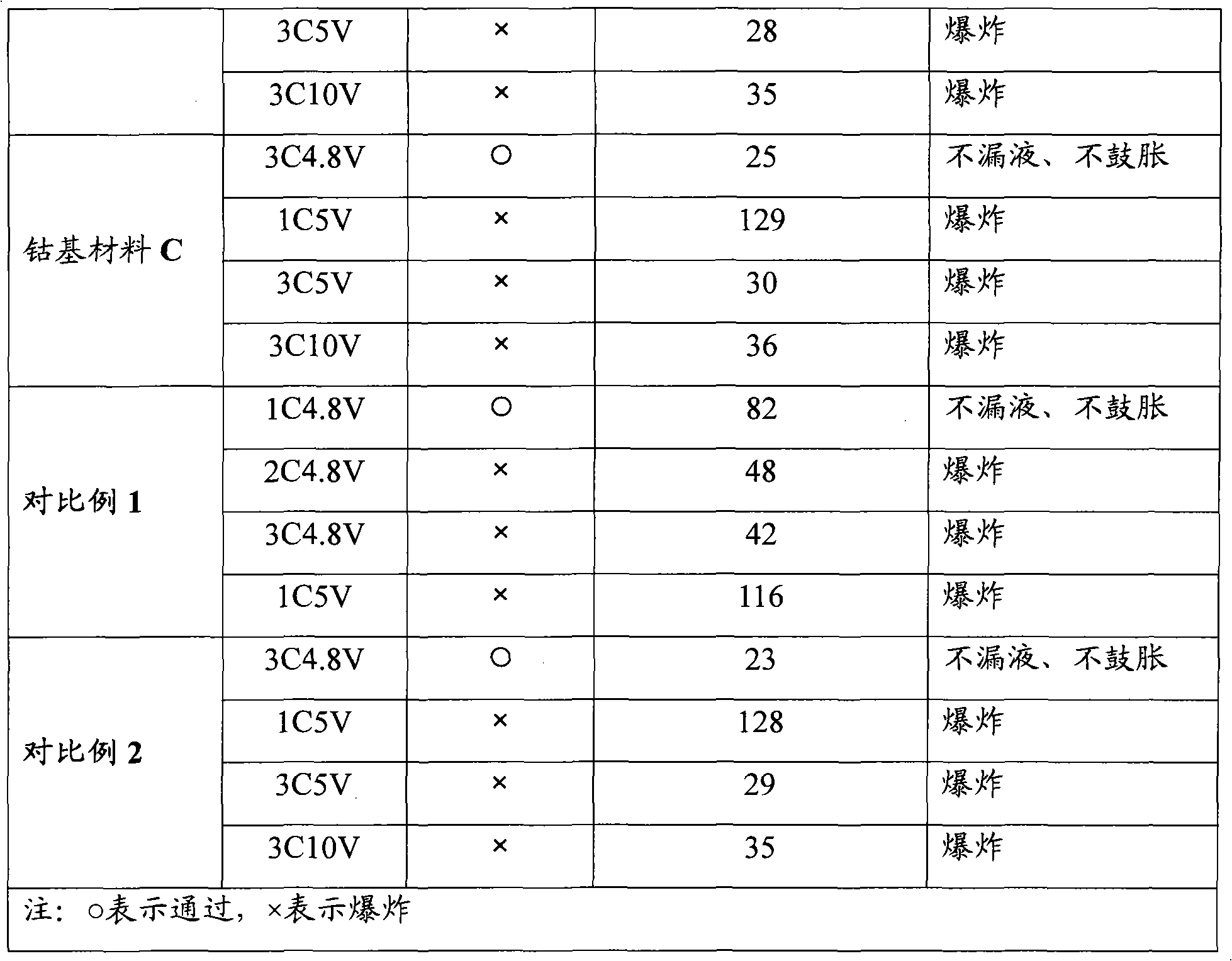

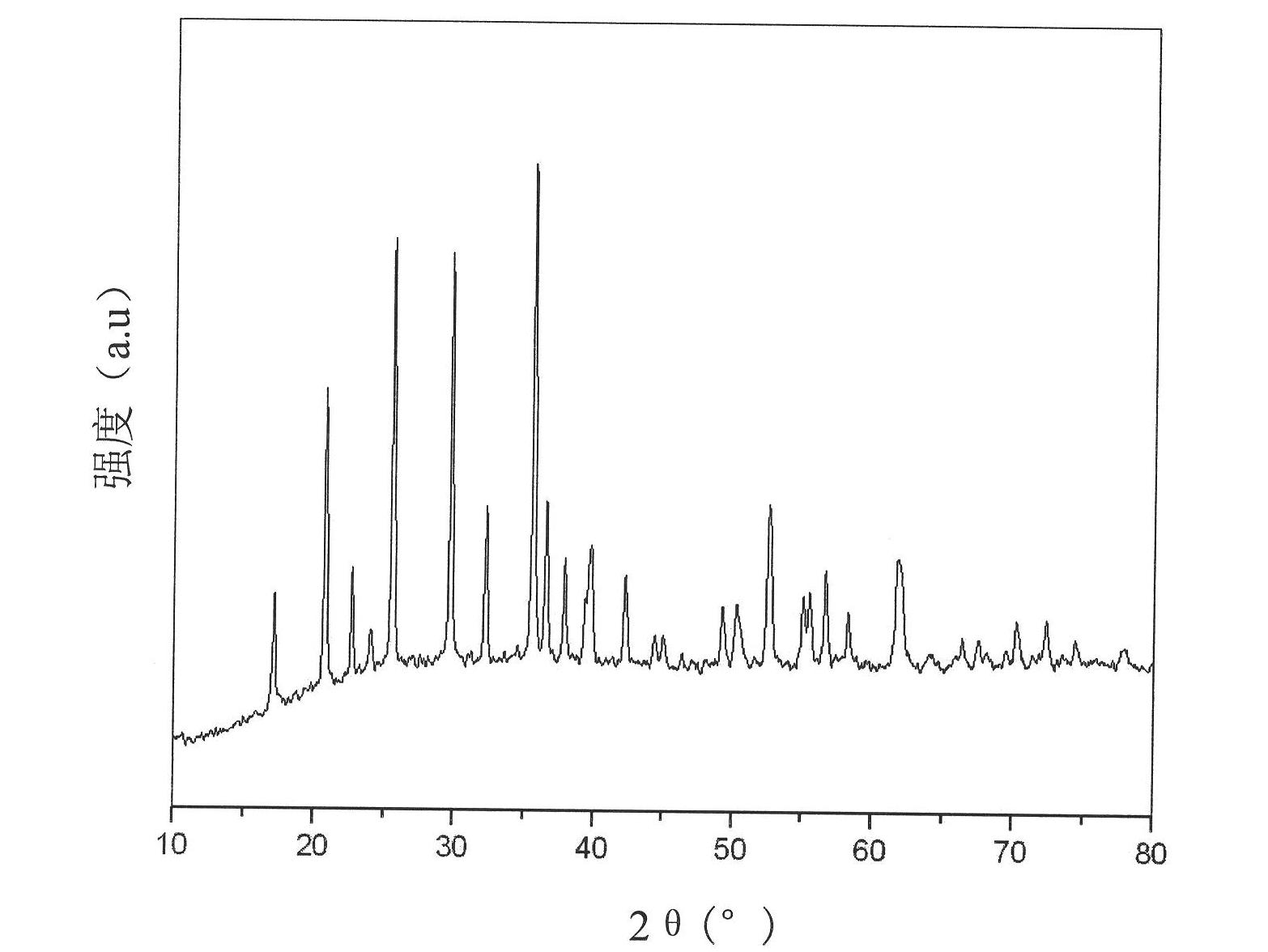

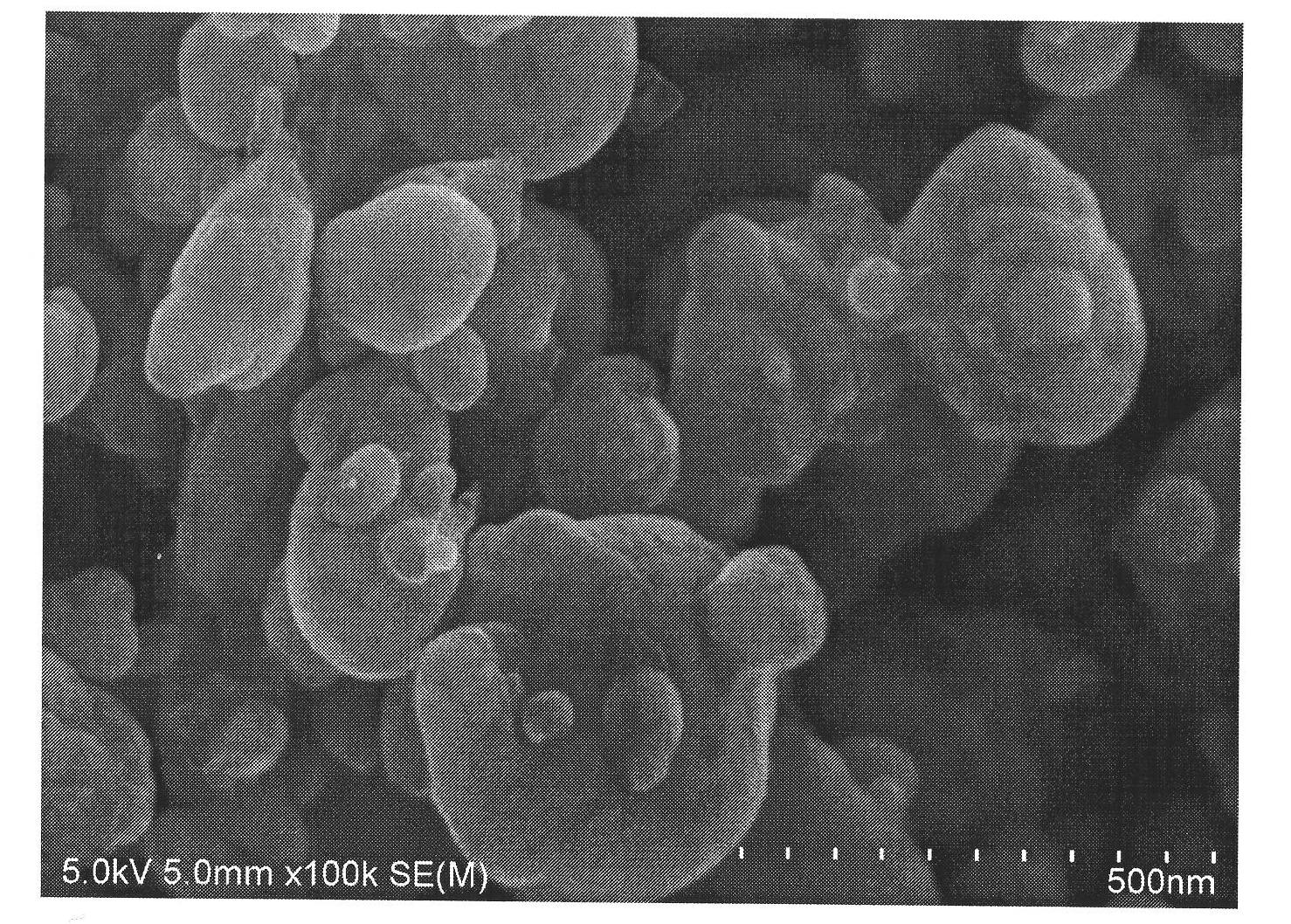

Preparation method of cobalt-based material

ActiveCN101944599AImprove discharge capacityGood high temperature performanceCell electrodesCobalt(II,III) oxideHeat stability

The invention discloses a preparation method of a cobalt-based material for the positive poles of lithium batteries, which comprises the following steps of: coating a nickel-cobalt-manganese hydroxide on the outer surface of spherical cobaltosic oxide and sintering to form the cobalt-based material of LiCo0.6Mn0.2Ni0.2O2. The cobalt-based material prepared by using the preparation method only not maintains the characteristics of lithium cobaltate materials of high volumetric specific energy and high discharge platform, but also has higher heat stability compared with lithium cobaltate, also reduces the cost of the lithium cobaltate materials and is the substitute of the next generation lithium cobaltate positive pole materials.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

Preparation method of high-rate capacity lithium iron phosphate material

The invention discloses a preparation method of a high-rate capacity lithium iron phosphate material, which comprises the steps of: weighing FePO4.xH2O and a lithium source compound as raw materials according to the mol ratio of Li to Fe of (1-1.05) :1, adding a carbon source compound and a catalyst (nitrate or acetate of Fe, Co, Ni and the like), ball-grinding for 0.5-24h by using deionized water, absolute ethyl alcohol or acetone as a ball grinding medium to obtain slurry, spraying and drying the slurry and then thermally treating under the protection of an inert gas, and in the process, with the thermal cracking of the carbon source compound, promoting the carbon source compound to form a carbon cladding cover with higher graphitization crystallinity under a lower temperature through mutual action of the catalyst and the carbon source compound. The lithium iron phosphate cathode material prepared by adopting the preparation method has higher electronic conductivity and higher specific capacity under the condition of lower carbon content, greatly improved high-rate performance especially, and better application value in the field of power batteries.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Method for preparing lithium-silicon alloy cathodes

The invention provides a method for preparing lithium-silicon alloy cathodes. The method includes mixing analytically pure silicon powder and lithium powder with each other according to a molar ratio of (8-5):(2-5) to obtain mixtures; carrying out ball-milling on the mixtures in inert atmosphere environments for 4 hours to obtain sandy substances; filling foamed nickel with the sandy substances according to certain filling density; compressing tablets; heating the tablets until the temperatures of the tablets reach 160-170 DEG C and keeping the temperatures of the tablets unchanged for 1 hour; cooling the tablets until the temperatures of the tablets reach the room temperature and taking out the tablets to obtain the lithium-silicon alloy cathodes. The method has the advantages that the lithium-silicon alloy cathodes are low in polarization, high in capacity and long in cycle life; processes for manufacturing the lithium-silicon alloy cathodes are simple and are easy to implement and control and low in energy consumption.

Owner:天津赫维科技有限公司

Method for preparing phosphate series lithium ion battery anode material

The invention relates to a method for preparing a phosphate series lithium ion battery anode material, comprising the following steps: preparing one or more of divalent manganese source compound, ferrum source compound, nickel source compound or cobalt source compound into a mixed solution; adding oxalic acid or oxalate, acid and urea, and slowly hydrolyzing the urea by controlling the reaction temperature and time; causing the pH value of the system to rise to reach the condition of homogeneous precipitation; after the reaction, filtering, washing and drying to obtain a precursor; evenly mixing and carrying out ball milling on the precursor, a lithium source and a phosphorous source; and calcining the mixture under the non-oxidability atmosphere to prepare the unitary or multielement phosphate series lithium ion battery anode material. The precursor prepared with the method has the advantages of stable ingredient proportion, even granularity distribution, good consistency and simple synthetic technology, does not need to consider the influence of flow rate and agitation and is suitable for industrial production. The synthesized battery anode material is the phosphate compound with an olivine structure, the average grain size of the primary particle is 100-500nm, and the battery anode material has good electrochemistry property.

Owner:襄阳泽东新能源发展有限公司

Surface treating method for hydrogen occluding alloy

InactiveCN101338417AImprove corrosion resistanceHigh catalytic activityLiquid/solution decomposition chemical coatingChemical platingHigh rate

The invention relates to a surface processing method of metal hydride. The surface processing method comprises fluoridation, hydroborate processing and chemical plating. A close coating is formed on the surface of metal hydride powder after being processed by the surface processing method and the close coating has high catalytic activity, good plastic property and strong corrosion resistance so as to improve the charge discharge efficiency of the metal hydride, reduce a charging platform, raise a discharging platform and increase the discharge capacity of the metal hydride. As a result, the high-rate discharge property of the metal hydride is greatly improved and the cycle life of the metal hydride is prolonged.

Owner:NANJING UNIV OF TECH

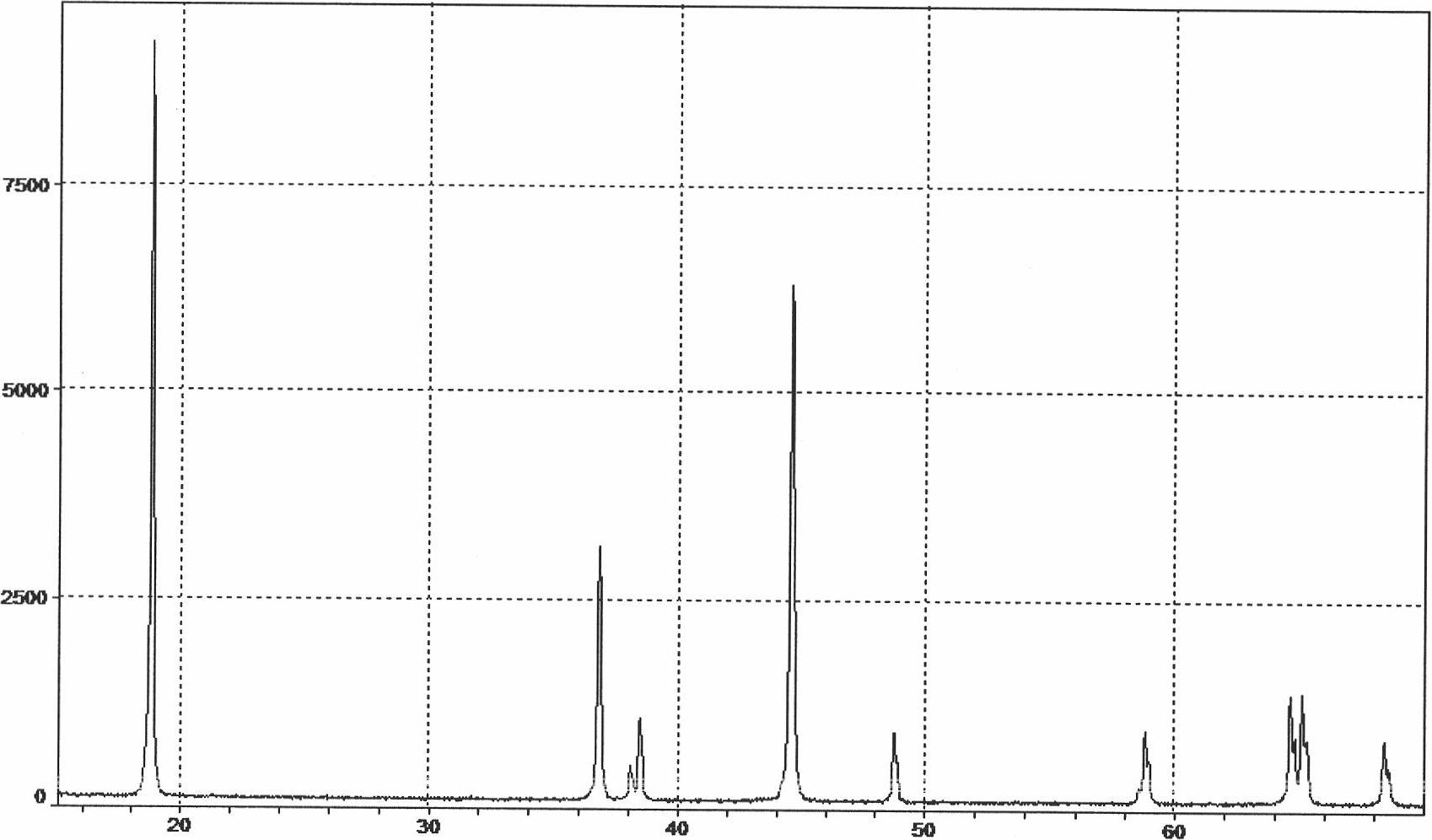

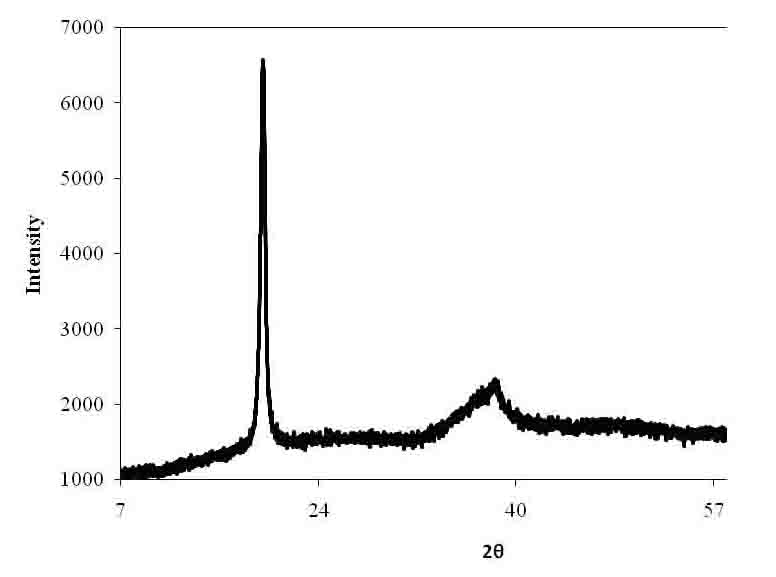

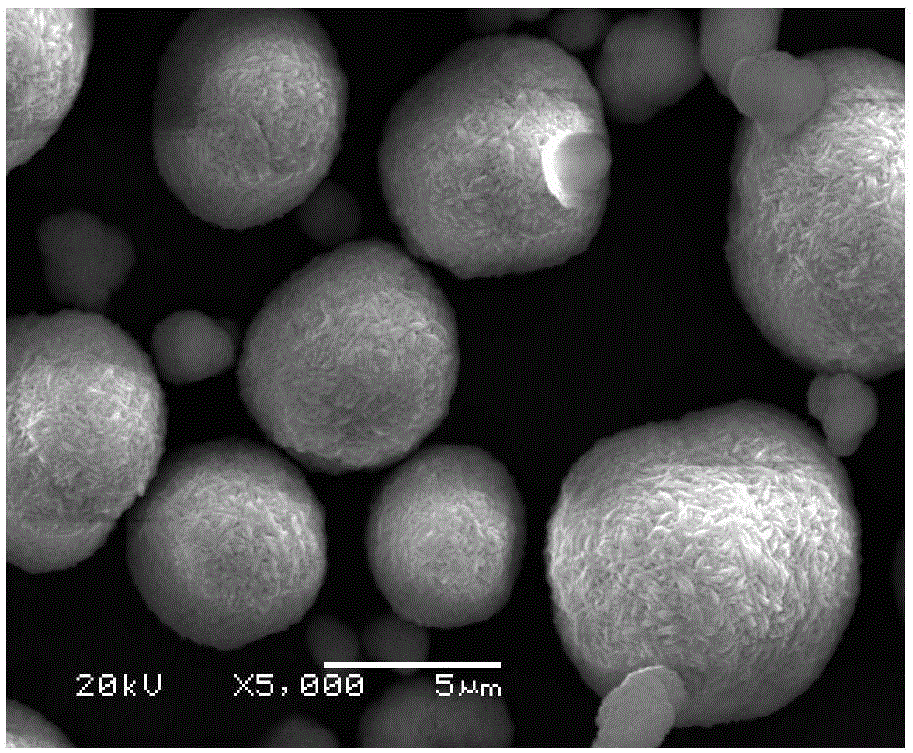

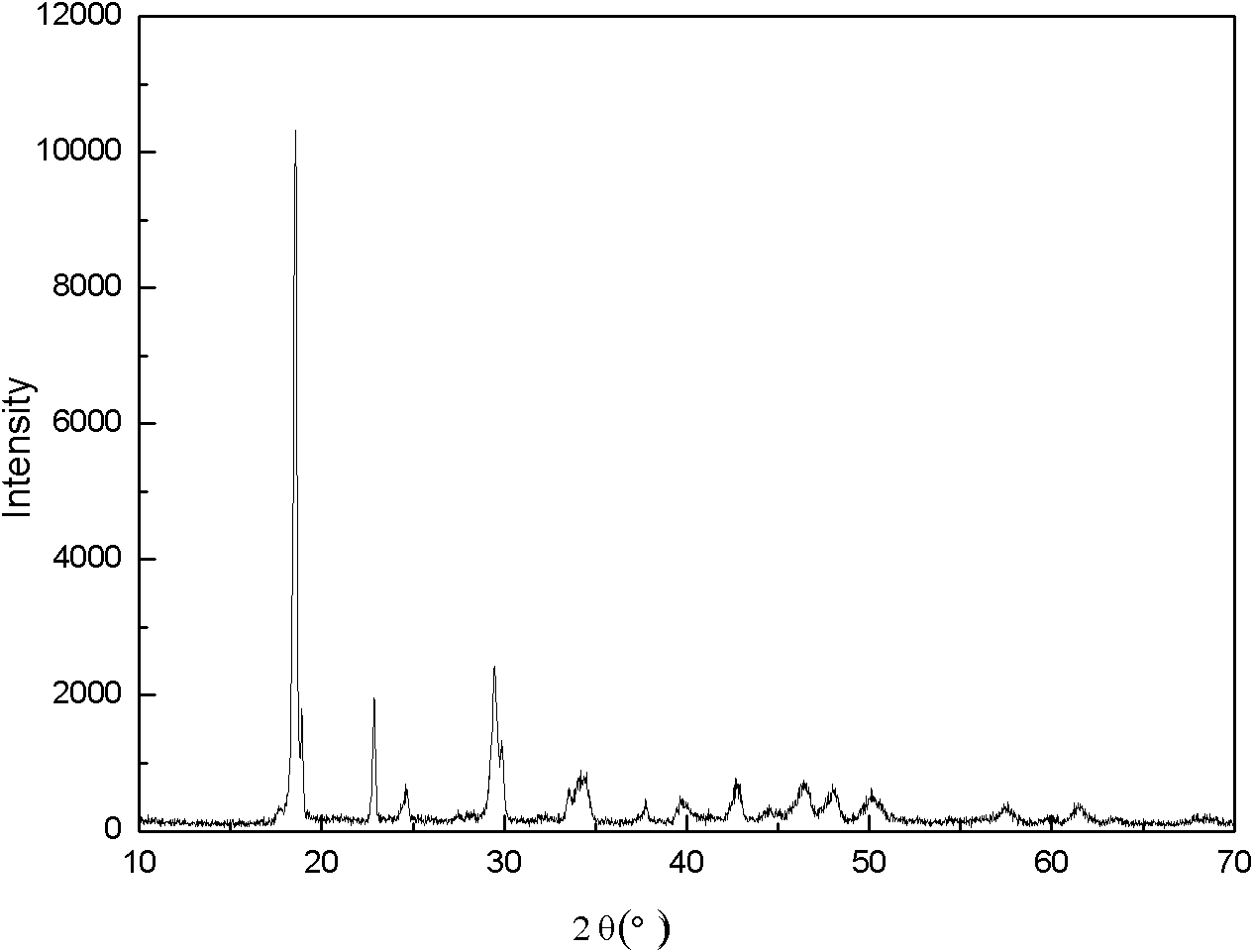

Preparation methods of spherical lithium manganate for lithium-ion power battery and precursor of spherical lithium manganate

ActiveCN103326012ALow impurity contentHigh discharge platformCell electrodesManganates/permanganatesWater bathsPower battery

The invention discloses preparation methods of a spherical lithium manganate for a lithium-ion power battery and a precursor of the spherical lithium manganate. The preparation method for the precursor is carried out as the following steps: (1) preparing a manganese salt water solution; (2) preparing a precipitant water solution; (3) injecting the prepared solutions in the step (1) and the step (2) to a reaction kettle with a stirrer and a constant-temperature water bath; (4) mixing the obtained MnCO3 and a compound containing an element M based on a mol ratio of M to Mn described in the invention, sintering and obtaining the precursor. The preparation method of the spherical lithium manganate is carried out as the following steps: mixing the precursor and Li2CO3, sintering and obtaining an M-doped spherical spinel lithium manganate. Compared with the prior art, the method of the invention has the advantages that: (1) impurity content is low, discharge plateau is high, specific capacity is high, cycle performance is good, high-temperature performance is good and tap density is high; and (2) raw material price and production cost are low, powder particle size can be controlled, microscale additive disperses uniformly, particle size distribution is concentrate, and microscopic morphology is spherical or spheroidic.

Owner:QINGDAO HUAGUAN HENGYUAN LI TECH

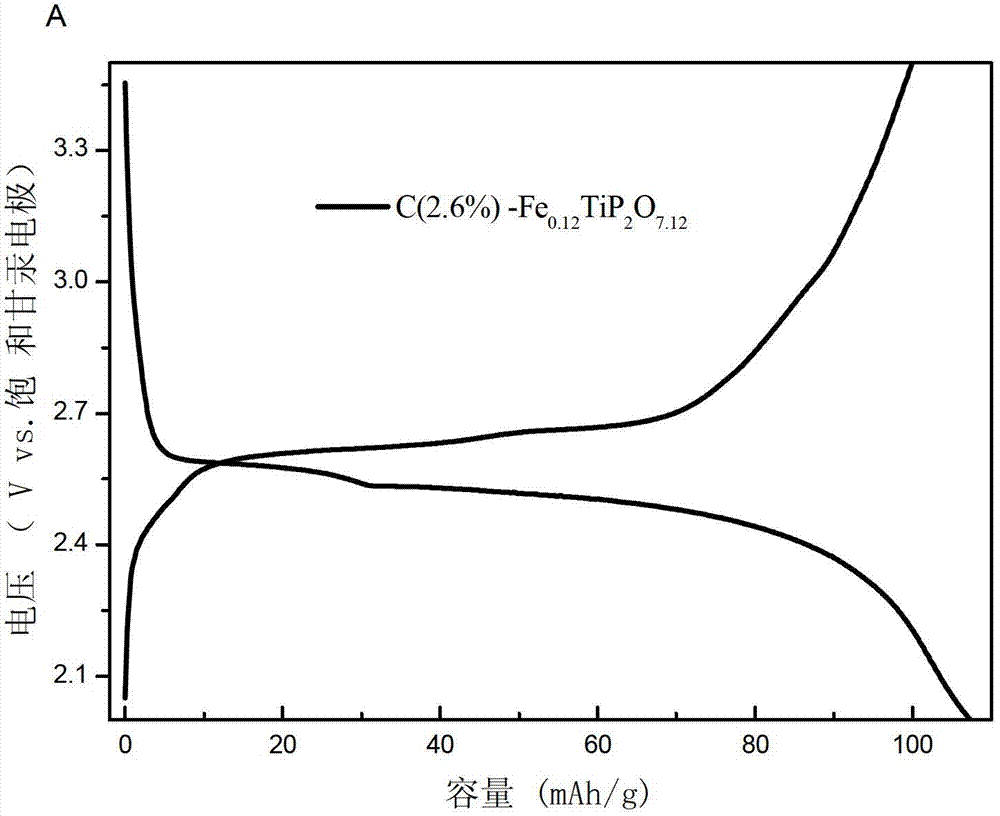

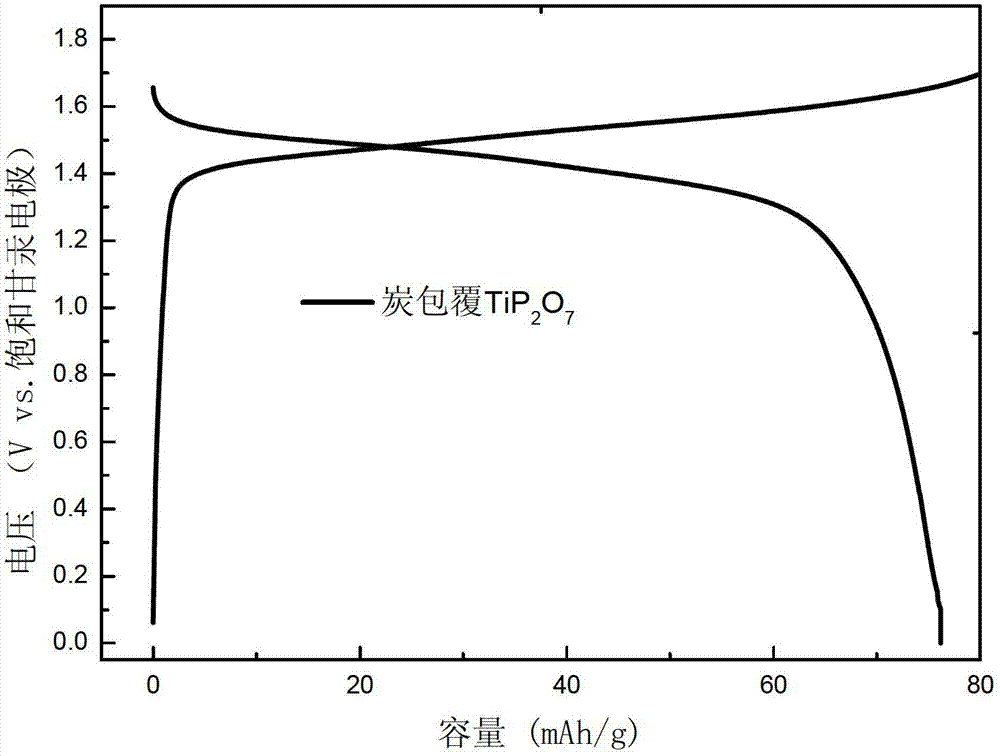

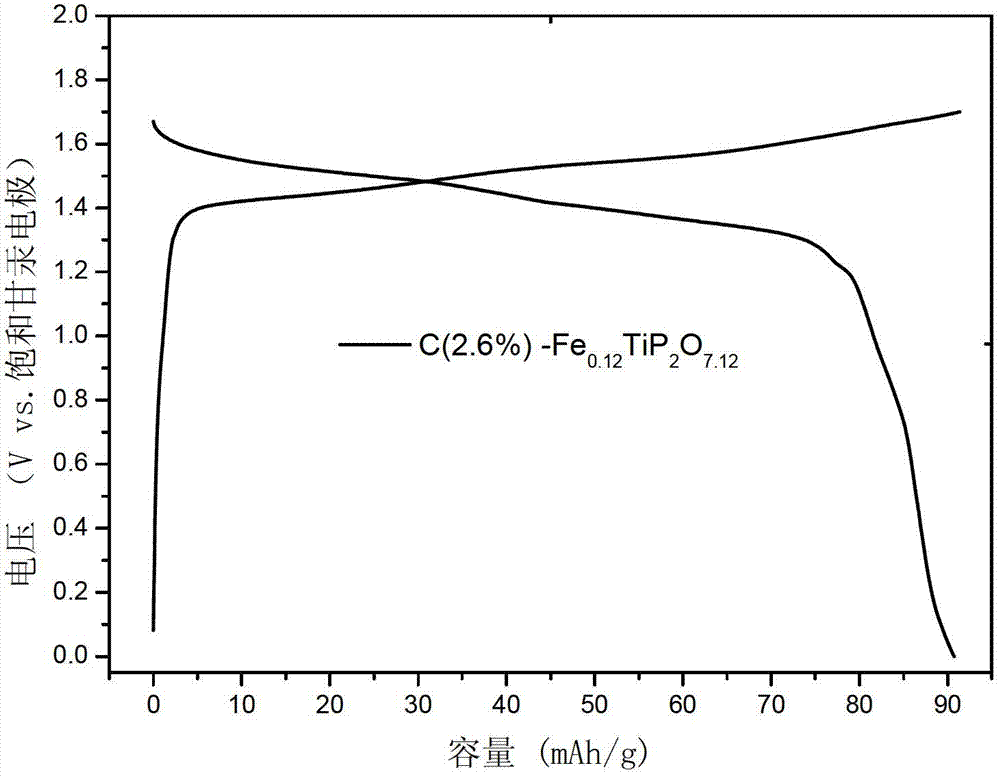

High-performance lithium ion battery electrode material and preparation method

ActiveCN103199245AIncreased rate capacityImproved magnification performanceCell electrodesElectrical conductorPhosphoric acid

The object of the present invention is to provide a novel titanium phosphate electrode material having good lithium ion battery characteristics, and is to solve the problem that the cycle life of a titanium pyrophosphate electrode material is poor in the prior art. The electrode material is intercalation compound carbon-coated C-Fe[x]TiP[2]O[7+x], and is a fast ion conductor electrode material of a three-dimensional structure. A preparation method comprises: (1) mixing and grinding TiO2 and NH4H2PO4, adding distilled water, stirring until the mixture is dried, finally placing the mixture in air for calcination to obtain TiP2O7; and (2) taking TiP2O7 obtained in Step (1) as a raw material, weighing TiP2O7 and an iron source material, mixing evenly, then adding a carbon source aqueous solution, stirring continuously at 40 DEG C until the mixture is dried, and finally calcining the mixture in a nitrogen atmosphere to obtain carbon-coated C-Fe[x]TiP[2]O[7+x].

Owner:常州孚达新能源科技有限公司

Lead-acid battery grid, polar plate and manufacturing method of grid

ActiveCN101740781AReduce the amount of lead usedImprove charge acceptanceElectrode carriers/collectorsLead-acid accumulator electrodesPunchingEngineering

The invention provides a lead-acid battery grid, comprising a grid main body, bulges which are arranged in arrays are formed on one side of the grid main body, and side-open type through holes are formed between the bulges and the grid main body. The invention also provides a lead-acid battery polar plate which comprises a grid and lead plaster coated on the surface of the grid. The invention also provides a method for preparing the above polar plate grid, comprising the steps of manufacturing a lead belt, rolling belt on the lead belt, punching and deep drawing. The invention can greatly save the use amount of lead, improve the charging receptivity, discharging platform, specific energy and specific power of the polar plate; the method provided in the invention is simple, and the manufactured polar plate grid has high quality, thus being capable of realizing continuous and high-yield production of the polar plate grid, reducing bit material remelting consumption of lead, and loweringproduction energy consumption and material oxidation.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

Method for coating surface of nano-alpha-phase nickel hydroxide with CoOOH

InactiveCN103094575AImprove conductivityImprove electrode performanceCell electrodesNickel oxide hydroxideOver potential

The invention discloses a method for coating the surface of nano-alpha-phase nickel hydroxide with CoOOH. The method is mainly characterized in that a precipitation conversion process is adopted to coat the surface of alpha-phase nickel hydroxide with a layer of CoOOH. The method obviously improves the conductive performance of the alpha-phase nickel hydroxide, and improves the electrode performance of nickel hydroxide, so the cell performances are obviously improved, for example, the specific capacity and the output power are improved, the large-rate discharge capability and the charge and discharge cycle performance are improved, and the oxygen evolution over-potential and the discharge plateau are improved. The discharge capacity of the cobalt coated nickel hydroxide prepared in the invention is high to 386mAh / g.

Owner:CHINA NAT ACAD NANOTECH & ENG

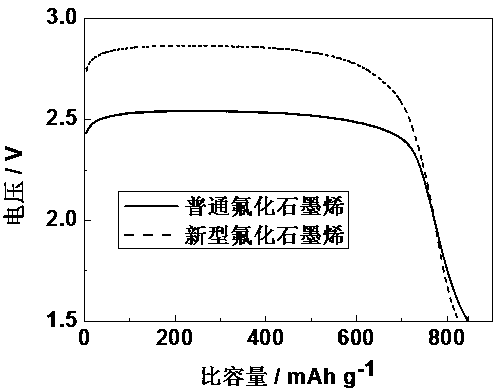

Preparation method of high-specific-energy fluorinated graphene lithium battery

InactiveCN109817978AFacilitated DiffusionPromotes in situ fluorinationCell electrodesDiffusion resistanceInternal resistance

The invention belongs to the technical field of lithium fluorocarbon batteries, and particularly relates to a preparation method of a high-specific-energy fluorinated graphene lithium battery. The lithium fluorocarbon battery takes novel fluorinated graphene as a positive electrode active material and takes a lithium alloy as a negative electrode material, wherein the novel fluorinated graphene isobtained by taking thermally reduced graphene as a raw material, reacting with a fluorinating agent, treating with an alkali solution, washing and drying, granulating and the like. The novel fluorinated graphene is adopted as the positive electrode active material, and the extremely high specific surface area and excellent conductivity of the fluorinated graphene are utilized, so that the ion diffusion resistance is reduced, the internal resistance is further reduced, and the fluorinated graphene lithium battery has the characteristics of high and stable discharge platform, high specific energy, excellent rate capability and the like.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com