High-voltage high-energy-density lithium ion battery

A lithium-ion battery, high energy density technology, applied in the field of lithium-ion batteries, can solve the problems of poor high temperature performance, shortened battery life, and the electrolyte has not been mass-produced, and achieves good chemical performance and safety performance. The effect of simplicity, high energy density and high discharge plateau

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

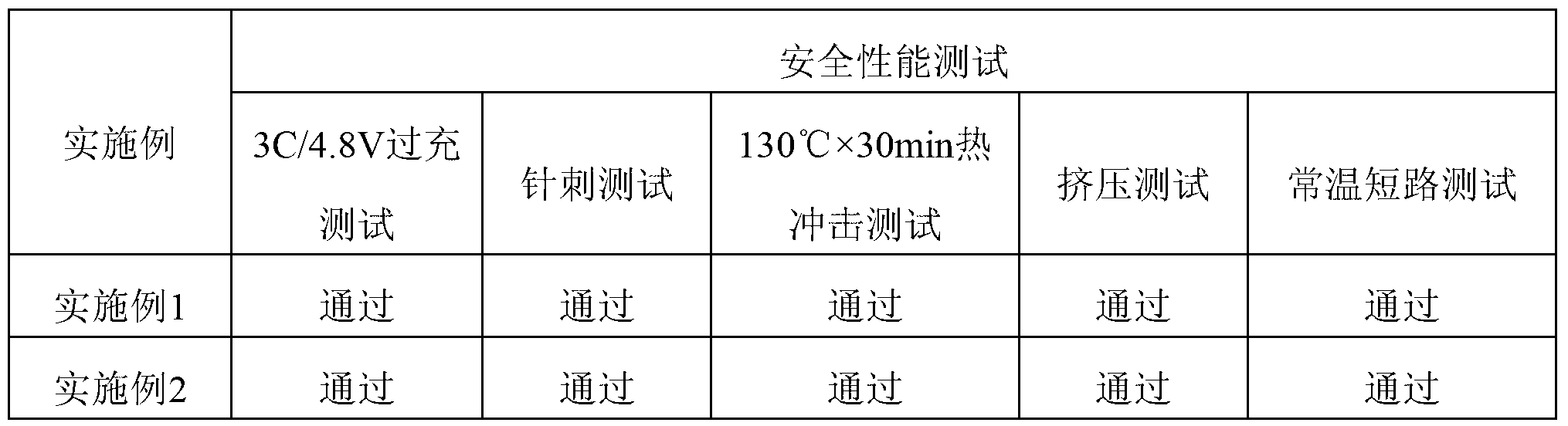

Embodiment 1

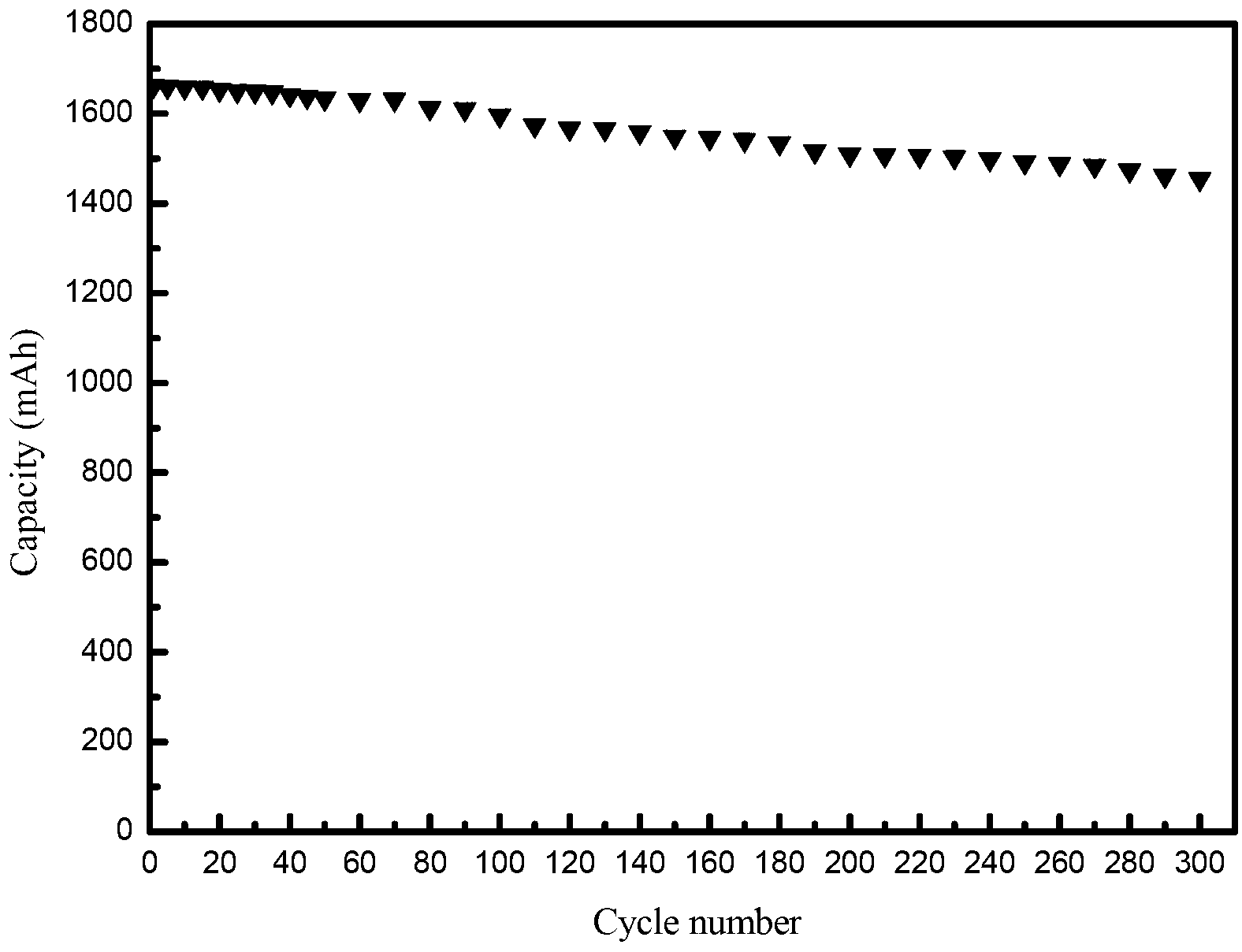

[0048] Take the production process of a 1630mAh soft-pack lithium-ion battery model 495148AR as an example to illustrate. The production method of the battery is as follows:

[0049] 1. Preparation of positive electrode active materials

[0050] Will NH 4 h 2 PO 4 with LiNO 3 Mix and stir evenly according to the molar ratio of 1:3, add lithium cobaltate particles, and continuously stir to make Li 3 PO 4 Evenly coated on the surface of lithium cobalt oxide. The mass percentage of coating and lithium cobaltate is 1.0wt.%. After being dried, it is sintered at 400-700° C. for 1-5 hours to obtain a positive electrode active material of the modified lithium cobaltate. The particle size D50 of the modified lithium cobaltate is 10-14μm, and the specific surface area is 0.2-0.4㎡ / g.

[0051] 2. Preparation of positive electrode sheet

[0052] First, PVDF was fully dissolved in N-dimethylpyrrolidone (NMP) solvent to make a 4wt.% solution, and then modified lithium cobaltate and ...

Embodiment 2

[0060] Taking the manufacturing process of a 3100mAh aluminum case lithium-ion battery with a model number of 535672AR as an example to illustrate, the manufacturing method of the battery is implemented as follows:

[0061] 1. Preparation of positive electrode sheet

[0062] Wherein, the preparation of the positive electrode active material is the same as that of Example 1, and will not be repeated here.

[0063] First, PVDF was fully dissolved in N-dimethylpyrrolidone (NMP) solvent to make a 4wt.% solution, and then modified lithium cobaltate and super conductive carbon black (SUP-P) were added to it several times. The ratio is LiCoO 2 : SUP-P: PVDF=96:1.5:2.5, after 4-6 hours, stir at a high speed, then vacuum defoam for 0.5 hours, control the viscosity of the pulp at 3000-10000cP, and the solid content at 65%-75%. Finally, use aluminum foil with a thickness of 16 μm as the current collector, and evenly coat the prepared slurry on the front and back of the aluminum foil, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com